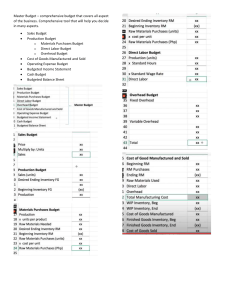

CHAPTER 6 MASTER BUDGET AND RESPONSIBILITY ACCOUNTING 6-1 What are the four elements of the budgeting cycle? The budgeting cycle includes the following elements: a. Planning the performance of the company as a whole as well as planning the performance of its subunits. Management agrees on what is expected. b. Providing a frame of reference, a set of specific expectations against which actual results can be compared. c. Investigating variations from plans. If necessary, corrective action follows investigation. d. Planning again, in light of feedback and changed conditions. 6-2 Define master budget. The master budget expresses management’s operating and financial plans for a specified period (usually a fiscal year) and includes a set of budgeted financial statements. It is the initial plan of what the company intends to accomplish in the period. List five the key questions which must be considered by managers for developing successful strategies. What are our main objectives? How can we create value for our customers and differentiate ourselves from our competitors? Where is our market and who are our customers? What is the best organizational and financial structure for us? What are the alternative strategies and opportunities and their relevant risks? 6-3 “Budgets provide a framework for evaluating performance and improving learning.” Do you agree? Explain. Yes, budgets can help a company’s managers to measure and evaluate actual performance against predicted performance. When actual outcomes differ from budgeted or planned results, it prompts managers to investigate and find out the reason(s) for the variance(s). This exercise leads to an improved learning for future budgeting. 6-4 6-5 “Budgets can promote coordination and communication among subunits within the company.” Do you agree? Explain. Yes, budgets can promote coordination and communication among all aspects of production or service and all departments in a company. Budgets can provide a communication mechanism that seamlessly links all subunits and their employees, helping them understand their individual goals or objectives of the company. This understanding can facilitate coordination among individual departments within the company. “Budgets motivate managers and other employees to the company’s goals.” Do you agree? Explain. Yes, budgets create goals as well as challenges for managers and employees, and motivate them to improve their performances and to achieve their goals. Managers and employees regard not meeting their budgets as a failure and, therefore, they are motivated to work harder in order to avoid such situations. 6-6 6-7 Define rolling budget. Give an example. 6-1 A rolling budget, also called a continuous budget, is a budget or plan that is always available for a specified future period, by continually adding a period (month, quarter, or year) to the period that just ended. A four-quarter rolling budget for 2017 is superseded by a four-quarter rolling budget for April 2017 to March 2018, and so on. 6-8 Outline the steps in preparing an operating budget. The steps in preparing an operating budget are as follows: 1. Prepare the revenues budget. 2. Prepare the production budget (in units). 3. Prepare the direct material usage budget and direct material purchases budget. 4. Prepare the direct manufacturing labor budget. 5. Prepare the manufacturing overhead budget. 6. Prepare the ending inventories budget. 7. Prepare the cost of goods sold budget. 8. Prepare the nonmanufacturing costs budget. 9. Prepare the budgeted income statement. 6-9 What is the usual starting point for the operating budget? Usually, a revenues budget is the starting point for the operating budget because the forecasted level of unit sales or revenues has a major impact on the production capacity, the inventory levels planned, and determines all of the costs required to support the budgeted revenues. 6-10 How can sensitivity analysis be used to increase the benefits of budgeting? How can sensitivity analysis be used to increase the benefits of budgeting? Sensitivity analysis adds an extra dimension to budgeting. It enables managers to examine how budgeted amounts change with changes in the underlying assumptions. This assists managers in monitoring those assumptions that are most critical to a company in attaining its budget and allows them to make timely adjustments to plans when appropriate. 6-11 What is the key emphasis in Kaizen budgeting? The key emphasis in Kaizen budgeting is continuous improvement, resulting in cost reductions, during the budget period. 6-12 Describe how nonoutput-based cost drivers can be incorporated into budgeting. Nonoutput-based cost drivers can be incorporated into budgeting by the use of activity-based budgeting (ABB). ABB focuses on the budgeted cost of activities necessary to produce and sell products and services. Nonoutput-based cost drivers, such as the number of parts, number of batches, and number of new products can be used with ABB. Explain how the choice of the type of responsibility center (cost, revenue, profit, or investment) affects behavior. The choice of the type of responsibility center determines what the manager is accountable for and thereby affects the manager’s behavior. For example, if a revenue center is chosen, the manager will focus on revenues, not on costs or investments. The choice of a responsibility center type guides the variables to be included in the budgeting exercise. 6-13 6-14 What are some additional considerations that arise when budgeting in multinational companies? 6-2 Budgeting in multinational companies may involve budgeting in several different foreign currencies. Further, management accountants must translate operating performance into a single currency for reporting to shareholders by budgeting for exchange rates. Managers and accountants must understand the factors that impact exchange rates and, where possible, plan financial strategies to limit the downside of unexpected unfavorable moves in currency valuations. In developing budgets for operations in different countries, they must also have good understanding of political, legal, and economic issues in those countries. 6-15 Explain why cash budgets are important. Cash budgets are significantly important for cash planning and control, especially to avoid having idle cash and unexpected cash deficiencies. The cash budget can help managers to not only identify the periods of idle cash and periods of cash shortage but also to determine necessary cash balances in line with their needs in any given period during the budget year. It allows managers to make appropriate decisions in terms of either using excess cash or financing from outside to achieve the company’s goals. 6-16 Master budget. Which of the following statements is correct regarding the components of the master budget? a. The cash budget is used to create the capital budget. b. Operating budgets are used to create cash budgets. c. The manufacturing overhead budget is used to create the production budget. d. The cost of goods sold budget is used to create the selling and administrative expense budget. SOLUTION Master budget. Choice "b" is correct. All of the operating budgets (like the sales budget, production budget, selling and administrative expense budget, etc.) are used to create financial budgets like the cash budget and the proforma financial statements. Of course, after cash budgets have been formulated, companies use this information to also adjust the operating budget. Choice "a" is incorrect. The capital budget is used to create the cash budget. Choice "c" is incorrect. The factory overhead budget is derived from the production budget. Choice "d" is incorrect. The cost of goods sold budget and the selling and administrative expense budget are completely independent of one another and both are usually determined based on the revenues budget. 6-17 Operating and financial budgets. Which of the following statements is correct regarding the drivers of operating and financial budgets? a. The sales budget will drive the cost of goods sold budget. b. The cost of goods sold budget will drive the units of production budget. c. The production budget will drive the selling and administrative expense budget. d. The cash budget will drive the production and selling and administrative expense budgets. 6-3 SOLUTION Operating and financial budgets. Choice "a" is correct. The sales (or revenues) budget is the primary driver of most components of the master budget, which includes both operating and financial budgets. The sales budget will drive the production budget, which in turn drives budgets for direct materials, direct labor, and factory overhead. All three of these budgets combine to form the cost of goods sold budget. Choice "b" is incorrect. The units of production budget drives the budgets for direct materials, direct labor, and manufacturing overhead. These three budgets combine to form the cost of goods sold budget. Choice "c" is incorrect. The selling and administrative expense budget is separate from the production budget, although both are driven by the sales budget. Choice "d" is incorrect. The cash budget is driven by the production and selling and administrative expense budgets. Of course, cash needs might affect the final production and selling budget. 6-18 Production budget. Superior Industries sales budget shows quarterly sales for the next year as follows: Quarter 1–10,000; Quarter 2–8,000; Quarter 3–12,000; Quarter 4–14,000. Company policy is to have a target finished-goods inventory at the end of each quarter equal to 20% of the next quarter’s sales. Budgeted production for the second quarter of next year would be: 1. 7,200 units; 2. 8,800 units; 3. 12,000 units; 4. 10,400 units SOLUTION Production budget. Choice "2" is correct. 8,800 units are the budgeted production for the second quarter. The calculation proceeds with first determining the beginning inventory for the second quarter (20% × second quarter sales, 8,000 units = 1,600 units) and the ending inventory for the second quarter (20% × third quarter sales, 12,000 units = 2,400 units). We then use the following equation to calculate production for the second quarter: Beginning inventory + Production = Sales + Ending inventory Production = Sales + Ending inventory – Beginning inventory = 8,000 + 2,400 – 1,600 = 8,800 units Check: Second Quarter Beginning inventory (20% × 8,000) 1,600 units Add Production (plug) 8,800 units 10,400 units Deduct Sales 8,000 units Ending inventory (20% × 12,000) 2,400 units 6-19 Responsibility centers. Elmhurst Corporation is considering changes to its responsibility accounting system. Which of the following statements is/are correct for a responsibility accounting system. 6-4 I. In a cost center, managers are responsible for controlling costs but not revenue. II. The idea behind responsibility accounting is that a manager should be held responsible for those items that the manager can control to a significant extent. III. To be effective, a good responsibility accounting system must help managers to plan and to control. IV.Costs that are allocated to a responsibility center are normally controllable by the responsibility center manager. 1. I and II only are correct. 2. II and III only are correct. 3. I, II, and III are correct. 4. I, II and IV are correct. SOLUTION Responsibility centers. Choice "3" is correct. The question asks which of a series of statements is/are correct for a responsibility accounting system. "None of the above" is not an available option, and neither is "All of the above." Statement I says that, in a cost center, managers are responsible for controlling costs but not revenue. Statement I is correct. Statement II says that the idea behind responsibility accounting is that a manager should be held responsible for those items that the manager can control to a significant extent. Statement II is correct. Statement III says that, to be effective, a good responsibility accounting system must help managers to plan and control. Planning without control and control without planning is not effective. Statement III is correct. Statement IV says that costs that are allocated to a responsibility center are normally controllable by the responsibility center manager. Costs that are allocated are normally not controllable by the responsibility center manager. Statement IV is incorrect. 6-20 Cash budget. Mary Jacobs, the controller of the Jenks Company is working on Jenks’ cash budget for year 2. She has information on each of the following items: I. Wages due to workers accrued as of December 31, year 1. II. Limits on a line of credit that may be used to fund Jenks’ operations in year 2. III. The balance in accounts payable as of December 31, year 1, from credit purchases made in year 1. Which of the items above should Jacobs take into account when building the cash budget for year 2? a. I, II b. I, III c. II, III d. I, II, III SOLUTION Cash budget Choice "d" is correct. All of the elements listed should be considered when building the cash budget. Accrued wages will be factored into the determination of cash disbursements in year 2, which is part of the cash budget. Financing budgets, a component of the cash budget, cover how a company will fund its current operations. One of the methods the company may use is a line of 6-5 credit, which will have limits as to how much cash a company can access at a given time. The accounts payable balance is important as well, as eventually vendors must be paid in cash in year 2 for credit purchases made by the company in year 1. Choice "a" is incorrect. This choice leaves out accounts payable, which eventually must be paid with cash in year 2. Choice "b" is incorrect. This choice leaves out the analysis of limits on a line of credit that the company may need to fund its operations in year 2. Choice "c" is incorrect. This choice leaves out accrued wages, which will ultimately have to be paid by the company in year 2. 6-21 Sales budget, service setting. In 2017, Rouse & Sons, a small environmental-testing firm, performed 12,200 radon tests for $290 each and 16,400 lead tests for $240 each. Because newer homes are being built with lead-free pipes, lead-testing volume is expected to decrease by 10% next year. However, awareness of radon-related health hazards is expected to result in a 6% increase in radon-test volume each year in the near future. Jim Rouse feels that if he lowers his price for lead testing to $230 per test, he will have to face only a 7% decline in lead-test sales in 2018. Required: 1. Prepare a 2018 sales budget for Rouse & Sons assuming that Rouse holds prices at 2017 levels. 2. Prepare a 2018 sales budget for Rouse & Sons assuming that Rouse lowers the price of a lead test to $230. Should Rouse lower the price of a lead test in 2018 if the company’s goal is to maximize sales revenue? SOLUTION (15 min.) Sales budget, service setting. 1. Rouse & Sons Radon Tests Lead Tests 2017 At 2017 Volume Selling Prices 12,200 $290 16,400 $240 Expected 2018 Change in Volume + 6% –10% Expected 2018 Volume 12,932 14,760 Rouse & Sons Sales Budget For the Year Ended December 31, 2018 Radon Tests Lead Tests Selling Price $290 $240 Units Sold 12,932 14,760 Total Revenues $3,750,280 3,542,400 $7,292,680 2. Rouse & Sons Radon Tests Lead Tests 2017 Planned 2018 Expected 2018 Volume Selling Prices Change in Volume 12,200 $290 +6% 16,400 $230 –7% 6-6 Expected 2018 Volume 12,932 15,252 Rouse & Sons Sales Budget For the Year Ended December 31, 2018 Radon Tests Lead Tests Selling Price Units Sold $290 12,932 $230 15,252 Total Revenues $3,750,280 3,507,960 $7,258,240 Expected revenues at the new 2018 prices are $7,258,240, which is lower than the expected 2018 revenues of $7,292,680 if the prices are unchanged. So, if the goal is to maximize sales revenue and if Jim Rouse’s forecasts are reliable, the company should not lower its price for a lead test in 2018. 6-22 Sales and production budget. The Albright Company manufactures ball pens and expects sales of 452,000 units in 2018. Albright estimates that its ending inventory for 2018 will be 65,400 pens. The beginning inventory is 46,500 pens. Compute the number of pens budgeted for production in 2018. (5 min.) Sales and production budget. Budgeted sales in units Add target ending finished goods inventory Total requirements Deduct beginning finished goods inventory Units to be produced 452,000 65,400 517,400 46,500 470,900 6-23 Direct material budget. Polyhidron Corporation produces 5-gallon plastic buckets. The company expects to produce 430,000 buckets in 2018. Polyhidron purchases high quality plastic granules for the production of buckets. Each pound of plastic granules produces two 5-gallon buckets. Target ending inventory of the company is 35,200 pounds of plastic granules; its beginning inventory is 22,500. Compute how many pounds of plastic granules need to be purchased in 2018. (5 min.) Direct materials purchases budget. Direct materials to be used in production (pounds): (430,000÷2) Add target ending direct materials inventory (pounds) Total requirements (pounds) Deduct beginning direct materials inventory (pounds) Direct materials to be purchased (pounds) 215,000 35,200 250,200 22,500 227,700 6-24 Material purchases budget. The Ceremicon Company produces teapots from stoneware clay. The company has prepared a sales budget of 150,000 units of teapots for a 3-month period. It has an inventory of 34,000 units of teapots on hand at December 31 and has estimated an inventory of 38,000 units of teapots at the end of the succeeding quarter. One unit of teapot needs 2 pounds of stoneware clay. The company has an inventory of 6-7 82,000 pounds of stoneware clay at December 31 and has a target ending inventory of 95,000 pounds of stoneware clay at the end of the succeeding quarter. How many pounds of direct materials (stoneware clay) should Ceremicon purchase during the 3 months ending March 31? (10 min.) Budgeting material purchases. Production Budget: Finished Goods (units) 150,000 38,000 188,000 34,000 154,000 Budgeted sales Add target ending teapots inventory Total requirements Deduct beginning teapots inventory Units to be produced Direct Materials (stoneware clay) Purchases Budget: Direct materials needed for production (154,000 2) Add target ending direct materials inventory Total requirements Deduct beginning direct materials inventory Direct materials to be purchased Direct Materials (in pounds) 308,000 95,000 403,000 82,000 321,000 6-25 Revenues, production, and purchases budgets. The Deluxe Motorcar in northern California manufactures motor cars of all categories. Its budgeted sales for the most popular sedan model XE8 in 2018 is 4,000 units. Deluxe Motorcar has a beginning finished inventory of 600 units. Its ending inventory is 450 units. The present selling price of model XE8 to the distributors and dealers is $35,200. The company does not want to increase its selling price in 2018. Deluxe Motorcar does not produce tyres. It buys the tyres from an outside supplier. One complete car requires five tyres including the tyre for the extra wheel. The company’s target ending inventory is 400 tyres, and its beginning inventory is 350 tyres. The budgeted purchase price is $45 per tyre. Required: 1. 2. 3. 4. Compute the budgeted revenues in dollars. Compute the number of cars that Deluxe Motorcar should produce. Compute the budgeted purchases of tyres in units and in dollars. What actions can Deluxe Motorcar’s managers take to reduce budgeted purchasing costs of tyres assuming the same budgeted sales for Model XE8? SOLUTION (15–20 min.) 1. Revenues, production, and purchases budget. 4,000 cars $35,200 = $140,800,000 6-8 2. Budgeted sales (Model XE8 cars) Add target ending finished goods inventory Total requirements (units) Deduct beginning finished goods inventory Units to be produced 3. Direct materials (tyres) to be used in production, 3,850× 5 (tyres) Add target ending direct materials inventory Total requirements Deduct beginning direct materials inventory Direct materials to be purchased (tyres) Cost per tyre in dollars Direct materials purchase cost 4,000 450 4,450 600 3,850 19,250 400 19,650 350 19,300 × $45 $ 868,500 4. Deluxe Motorcar does not maintain a high inventory of tyres. Note the relatively small inventory of wheels. The company appears to be using something close to a just-in-time inventory system, which is already saving the company the cost of holding materials inventory. Nevertheless, Deluxe Motorcar’s managers would want to check why the target ending inventory of tyres (400) is greater than the beginning inventory of 350. Could the production time lag between the order of tyres placed and the ordered tyres received to reduce the need to hold more inventories? Furthermore, Deluxe Motorcar could help and advice its tyre supplier to improve the quality of its tyres by taking more quality control measures and to improve efficiency and productivity of the employees by conducting effective training programmes which may result in reduction of the cost of manufacturing tyres with a less number of defective tyres. It would certainly reduce the price the supplier charges Deluxe Motorcar. Toyota routinely aids its suppliers in this way and also reduces costs through better coordination between suppliers and the company. 6-26 Revenues and production budget. Price, Inc., bottles and distributes mineral water from the company’s natural springs in northern Oregon. Price markets two products: 12-ounce disposable plastic bottles and 1-gallon reusable plastic containers. Required: 1. For 2015, Price marketing managers project monthly sales of 420,000 12-ounce bottles and 170,000 1-gallon containers. Average selling prices are estimated at $0.20 per 12-ounce bottle and $1.50 per 1-gallon container. Prepare a revenues budget for Price, Inc., for the year ending December 31, 2015. 2. Price begins 2015 with 890,000 12-ounce bottles in inventory. The vice president of operations requests that 12-ounce bottles ending inventory on December 31, 2015, be no less than 680,000 bottles. Based on sales projections as budgeted previously, what is the minimum number of 12-ounce bottles Price must produce during 2015? 3. The VP of operations requests that ending inventory of 1-gallon containers on December 31, 2015, be 240,000 units. If the production budget calls for Price to produce 1,900,000 1-gallon 6-9 containers during 2015, what is the beginning inventory of 1-gallon containers on January 1, 2015? SOLUTION (30 min.) Revenues and production budget. 1. 12-ounce bottles 1-gallon units a b Selling Price $0.20 1.50 Units Sold 5,040,000a 2,040,000b Total Revenues $1,008,000 3,060,000 $4,068,000 420,000 × 12 months = 5,040,000 170,000 × 12 months = 2,040,000 2. Budgeted unit sales (12-ounce bottles) 5,040,000 Add target ending finished goods inventory 680,000 Total requirements 5,720,000 Deduct beginning finished goods inventory 890,000 Units to be produced 4,830,000 3. Beginning Inventory = Budgeted sales + Target ending inventory – Budgeted production = 2,040,000 + 240,000 1,900,000 = 380,000 1-gallon units 6-27 Budgeting; direct material usage, manufacturing cost, and gross margin. Xander Manufacturing Company manufactures blue rugs, using wool and dye as direct materials. One rug is budgeted to use 36 skeins of wool at a cost of $2 per skein and 0.8 gallons of dye at a cost of $6 per gallon. All other materials are indirect. At the beginning of the year Xander has an inventory of 458,000 skeins of wool at a cost of $961,800 and 4,000 gallons of dye at a cost of $23,680. Target ending inventory of wool and dye is zero. Xander uses the FIFO inventory costflow method. Xander blue rugs are very popular and demand is high, but because of capacity constraints the firm will produce only 200,000 blue rugs per year. The budgeted selling price is $2,000 each. There are no rugs in beginning inventory. Target ending inventory of rugs is also zero. Xander makes rugs by hand, but uses a machine to dye the wool. Thus, overhead costs are accumulated in two cost pools—one for weaving and the other for dyeing. Weaving overhead is allocated to products based on direct manufacturing labor-hours (DMLH). Dyeing overhead is allocated to products based on machine-hours (MH). There is no direct manufacturing labor cost for dyeing. Xander budgets 62 direct manufacturing labor-hours to weave a rug at a budgeted rate of $13 per hour. It budgets 0.2 machine-hours to dye each skein in the dyeing process. The following table presents the budgeted overhead costs for the dyeing and weaving cost pools: 6-10 Required: 1. 2. 3. 4. 5. 6. 7. 8. Prepare a direct materials usage budget in both units and dollars. Calculate the budgeted overhead allocation rates for weaving and dyeing. Calculate the budgeted unit cost of a blue rug for the year. Prepare a revenues budget for blue rugs for the year, assuming Xander sells (a) 200,000 or (b) 185,000 blue rugs (that is, at two different sales levels). Calculate the budgeted cost of goods sold for blue rugs under each sales assumption. Find the budgeted gross margin for blue rugs under each sales assumption. What actions might you take as a manager to improve profitability if sales drop to 185,000 blue rugs? How might top management at Xander use the budget developed in requirements 1–6 to better manage the company? SOLUTION (30 min.) Budgeting: direct material usage, manufacturing cost, and gross margin. 1. Direct Material Usage Budget in Quantity and Dollars Material Wool Physical Units Budget Direct materials required for Blue Rugs (200,000 rugs × 36 skeins and 0.8 gal.) Cost Budget Available from beginning direct materials inventory: (a) Wool: 458,000 skeins Dye: 4,000 gallons To be purchased this period: (b) Wool: (7,200,000 – 458,000) skeins × $2 per skein Dye: (160,000 – 4,000) gal. × $6 per gal. Direct materials to be used this period: (a) + (b) 6-11 7,200,000 skeins $ Dye Total 160,000 gal. 961,800 $ 23,680 13,484,000 $14,445,800 936,000 $ 959,680 $15,405,480 2. $31,620,000 Weaving budgeted = = $2.55 per DMLH overhead rate 12,400,000 DMLH $17, 280, 000 Dyeing budgeted = = $12 per MH overhead rate 1, 440,000 MH 3. Budgeted Unit Cost of Blue Rug Wool Dye Direct manufacturing labor Dyeing overhead Weaving overhead Total 1 Input per Unit of Output 36 skeins 0.8 gal. 62 hrs. 7.21 mach-hrs. 62 DMLH Cost per Unit of Input $ 2 6 13 12 2.55 Total 72.00 4.80 806.00 86.40 158.10 $1,127.30 $ 0.2 machine hour per skein 36 skeins per rug = 7.2 machine-hrs. per rug. 4. Revenue Budget Blue Rugs Blue Rugs Selling Units Price Total Revenues 200,000 $2,000 $400,000,000 185,000 $2,000 $370,000,000 5a. Sales = 200,000 rugs Cost of Goods Sold Budget From Schedule Beginning finished goods inventory Direct materials used Direct manufacturing labor ($806 × 200,000) Dyeing overhead ($86.40 × 200,000) Weaving overhead ($158.10 × 200,000) Cost of goods available for sale Deduct ending finished goods inventory Cost of goods sold 5b. Sales = 185,000 rugs Production = 200,000 rugs 6-12 Total $ $ 15,405,480 161,200,000 17,280,000 31,620,000 0 225,505,480 225,505,480 0 $225,505,480 Cost of Goods Sold Budget From Schedule Beginning finished goods inventory Direct materials used Direct manufacturing labor ($806 × 200,000) Dyeing overhead ($86.40 × 200,000) Weaving overhead ($158.10 × 200,000) Cost of goods available for sale Deduct ending finished goods inventory ($1,127.30 × 15,000) Cost of goods sold Total $ $ 15,405,480 161,200,000 17,280,000 31,620,000 0 225,505,480 225,505,480 16,909,500 $208,595,980 Some students assume that Xander will produce only 185,000 rugs to match 185,000 rugs that ar expected to be sold and carry no finished good inventory of the rugs. In this case the Cost of goods sold budget will be as follows. The Cost of Goods Sold budget is higher because the fixed overhead costs in the dyeing and weaving cost pools do not get “inventoried” in the closing inventory of rugs but are instead expensed in the current period. Sales = 185,000 rugs Cost of Goods Sold Budget for Producing 185,000 rugs From Schedule Beginning finished goods inventory Direct materials useda Direct manufacturing labor ($806 × 185,000) Variable dyeing overhead ($70.55b × 185,000) Fixed dyeing overheadc Variable weaving overhead ($119.15d × 185,000) Fixed weaving overheade Cost of goods available for sale Deduct ending finished goods inventory Cost of goods sold Total $ $ 14,253,480 149,110,000 13,051,750 3,170,000 22,042750 7,790,000 0 209,417,980 209,417,980 0 $209,417,980 a [$961,800 + (185,000 rugs×36 skeins−458,000)×$2] + [$23,680 + (185,000 rugs×0.8 gallons−4,000)×$6] Variable dyeing overhead cost per rug = ($6,560,000 + $7,550,000) ÷ 200,000 rugs = $70.55 per rug c Fixed dyeing overhead costs = $347,000 + $2,100,000 + $723,000 = $3,170,000 d Variable weaving overhead cost per rug = ($15,400,000 + $5,540,000 + $2,890,000) ÷ 200,000 rugs = $119.15 per rug e Fixed weaving overhead costs = $1,700,000 + $274,000 + $5,816,000 = $7,790,000 b 6. Revenue Less: Cost of goods sold Gross margin 200,000 rugs sold $400,000,000 225,505,480 $174,494,520 185,000 rugs sold 200,000 rugs produced $370,000,000 208,595,980 $161,404,020 185,000 rugs sold 185,000 rugs produced $370,000,000 209,417,980 $160,582,020 7. If sales drop to 185,000 blue rugs, Xander should look to reduce fixed costs and produce less to reduce variable costs and inventory costs. 6-13 8. Top management can look for ways to increase (stretch) sales and improve quality, efficiency, and input prices to reduce costs in each cost category such as direct materials, direct manufacturing labor, and overhead costs. Top management can also use the budget to coordinate and communicate across different parts of the organization, create a framework for judging performance and facilitating learning, and motivate managers and employees to achieve “stretch” targets of higher revenues and lower costs. 6-28 Budgeting, service company. Ever Clean Company provides gutter cleaning services to residential clients. The company has enjoyed considerable growth in recent years due to a successful marketing campaign and favorable reviews on service-rating Web sites. Ever Clean owner Joanne Clark makes sales calls herself and quotes on jobs based on length of gutter surface. Ever Clean hires college students to drive the company vans to jobs and clean the gutters. A part-time bookkeeper takes care of billing customers and other office tasks. Overhead is allocated based on direct labor-hours (DLH). Joanne Clark estimates that her gutter cleaners will work a total of 1,000 jobs during the year. Each job averages 600 feet of gutter surface and requires 12 direct labor-hours. Clark pays her gutter cleaners $15 per hour, inclusive of taxes and benefits. The following table presents the budgeted overhead costs for 2018: Required: 1. Prepare a direct labor budget in both hours and dollars. 2. Calculate the budgeted overhead allocation rate based on the budgeted quantity of the cost drivers. 3. Calculate the budgeted total cost of all jobs for the year and the budgeted cost of an average 600-foot gutter-cleaning job. 4. Prepare a revenues budget for the year, assuming that Ever Clean charges customers $0.60 per square foot. 5. Calculate the budgeted operating income. 6. What actions can Clark take if sales should decline to 900 jobs annually? SOLUTION (20 min.) Budgeting: service company. 1. Direct Labor Budget in Hours and Dollars Total Hours Budget Direct labor hours required (1,000 jobs × 12 hours per job) 12,000 hours 6-14 Cost Budget Wages (12,000 hours × $15 per hour) Cost per direct-labor hour ($180,000 ÷ 12,000 DLH) $180,000 $15.00/DLH 2. Budgeted overhead rate = $144,000 = $12 per DLH 12,000 DLH 3. Budgeted Total Cost and Average Cost of 600-Foot Gutter-Cleaning Job Direct labor costs $180,000 Overhead costs 144,000 Total costs of 1,000 jobs $324,000 Budgeted cost of average 600-foot gutter-cleaning job = $324,000 ÷ 1,000 = $324 per job. 4. Revenue Budget Feet of Gutter Surface 1,000 jobs 600 ft./job = 600,000 ft. 5. Price per Foot Total Revenues $0.60 $360,000 Operating Income Budget 1,000 jobs Revenue $360,000 Expenses 324,000 Operating Income $ 36,000 6. The following table shows Ever Clean’s profitability if sales decline to 900 jobs. Revenue (900 jobs 600 sq. ft. 0.60/sq. ft. Wages (900 jobs 12 hours per job × $15 per hour) Supplies (900 jobs 12 hours per job × $6.50 per hour) Fixed indirect labor costs Fixed depreciation costs Other fixed costs $324,000 $162,000 70,200 25,000 17,000 24,000 298,200 $ 25,800 If revenue should fall to 900 jobs, Clark should examine the company’s fixed overhead costs to determine if any cuts are possible. Variable product costs will naturally decline with a decline in jobs, but Clark should evaluate if variable supplies cost of $6.50 per direct labor hour could be reduced. Fixed costs will not decline without management taking action. While depreciation cost is not likely something that management can reduce, the fixed indirect costs and “other” fixed overhead costs are significant and should be examined. 6-29 Budgets for production and direct manufacturing labor. (CMA, adapted) Roletter Company makes and sells artistic frames for pictures of weddings, graduations, and other special events. Bob Anderson, the controller, is responsible for preparing Roletter’s master budget and has 6-15 accumulated the following information for 2018: In addition to wages, direct manufacturing labor-related costs include pension contributions of $0.50 per hour, worker’s compensation insurance of $0.20 per hour, employee medical insurance of $0.30 per hour, and Social Security taxes. Assume that as of January 1, 2018, the Social Security tax rates are 7.5% for employers and 7.5% for employees. The cost of employee benefits paid by Roletter on its employees is treated as a direct manufacturing labor cost. Roletter has a labor contract that calls for a wage increase to $13 per hour on April 1, 2018. New laborsaving machinery has been installed and will be fully operational by March 1, 2018. Roletter expects to have 17,500 frames on hand at December 31, 2018, and it has a policy of carrying an end-of-month inventory of 100% of the following month’s sales plus 50% of the second following month’s sales. Required: 1. Prepare a production budget and a direct manufacturing labor budget for Roletter Company by month and for the first quarter of 2018. You may combine both budgets in one schedule. The direct manufacturing labor budget should include labor-hours and show the details for each labor cost category. 2. What actions has the budget process prompted Roletter’s management to take? 3. How might Roletter’s managers use the budget developed in requirement 1 to better manage the company? SOLUTION (15-25 min.) Budgets for production and direct manufacturing labor. Budgeted sales (units) Add target ending finished goods inventorya (units) Total requirements (units) Deduct beginning finished goods inventory (units) Units to be produced Direct manufacturing labor-hours (DMLH) per unit Roletter Company Budget for Production and Direct Manufacturing Labor for the Quarter Ended March 31, 2018 January February March Quarter 10,000 14,000 7,000 31,000 17,500 27,500 11,000 25,000 12,000 19,000 12,000 43,000 17,500 10,000 17,500 7,500 11,000 8,000 17,500 25,500 2.0 2.0 1.5 6-16 Total hours of direct manufacturing labor time needed Direct manufacturing labor costs: Wages ($12.00 per DMLH) Pension contributions ($0.50 per DMLH) Workers’ compensation insurance ($0.20 per DMLH) Employee medical insurance ($0.30 per DMLH) Social Security tax (employer’s share) ($12.00 0.075 = $0.90 per DMLH) Total direct manufacturing labor costs 20,000 15,000 12,000 47,000 $240,000 10,000 $180,000 7,500 $144,000 6,000 $564,000 23,500 4,000 3,000 2,400 9,400 6,000 4,500 3,600 14,100 18,000 $278,000 13,500 $208,500 10,800 $166,800 42,300 $653,300 a 100% of the first following month’s sales plus 50% of the second following month’s sales. Note that the employee Social Security tax of 7.5% is irrelevant. Such taxes are withheld from employees’ wages and paid to the government by the employer on behalf of the employees; therefore, the 7.5% amounts are not additional costs to the employer. 2. The budget process would prompt Roletter’s management to look for ways to reduce finished goods inventories, the manufacturing labor hours needed to produce each unit both before and after installing new labor-saving machinery; some of the other costs such as Social Security tax and workers’ compensation insurance may be fixed by law, while pension contributions and medical insurance might be features that make Roletter an attractive employer. 3 .Wea l r e a dys e eonee x ampl eofade c i s i ont ha tRol e t t e r ’ sma na ge me ntt ookba s e don t he budge t e de x pe ns e s —i ns t a l l i ng l a bor s a vi ng ma c hi ne sa he a d ofwa ge i nc r e a s e s . Rol e t t e r ’ sma na ge me nts houl da l s oc ont i nuet owor kwi t he mpl oye e st oi nc r e a s el a bor pr oduc t i vi t y . 6-30 Activity-based budgeting. The Jerico store of Jiffy Mart, a chain of small neighborhood convenience stores, is preparing its activity-based budget for January 2018. Jiffy Mart has three product categories: soft drinks (35% of cost of goods sold [COGS]), fresh produce (25% of COGS), and packaged food (40% of COGS). The following table shows the four activities that consume indirect resources at the Jerico store, the cost drivers and their rates, and the cost-driver amount budgeted to be consumed by each activity in January 2018. Required: 6-17 1. What is the total budgeted indirect cost at the Jerico store in January 2018? What is the total budgeted cost of each activity at the Jerico store for January 2018? What is the budgeted indirect cost of each product category for January 2018? 2. Which product category has the largest fraction of total budgeted indirect costs? 3. Given your answer in requirement 2, what advantage does Jiffy Mart gain by using an activity-based approach to budgeting over, say, allocating indirect costs to products based on cost of goods sold? SOLUTION (20–30 min.) Activity-based budgeting. 1. Cost Hierarchy Activity Ordering $45 14; 24; 14 Delivery $41 12; 62; 19 Shelf-stocking $10.50 16; 172; 94 Customer support $0.09 4,600; 34,200; 10,750 Total budgeted indirect costs Batch-level Batch-level Output-unitlevel Output-unitlevel Percentage of total indirect costs Total indirect costs allocated according to COGS (35%; 25%; 40% 13,574) Soft Drinks Fresh Snacks Packaged Food $ 630 $1,080 $ 630 $ 2,340 492 2,542 779 3,813 168 1,806 987 2,961 414 $1,704 3,078 $8,506 968 $3,364 4,460 $13,574 12.5% 62.7% 24.8% $4,751 $3,393 Total $5,430 2. Refer to the last row of the table in requirement 1. Fresh snacks, which represents the smallest portion of COGS (25%), is the product category that consumes the largest share (62.7%) of the indirect resources. Fresh snacks demand the highest level of ordering, delivery, shelfstocking, and customer support resources of all three product categories—it has to be ordered, delivered, and stocked in small, perishable batches, and convenience store customers often require more assistance when purchasing. 3. An ABB approach recognizes how different products require different mixes of support activities. The relative percentage of how each product area uses the cost driver at each activity area is: Activity Ordering Delivery Shelf-stocking Customer support Cost Hierarchy Batch-level Batch-level Output-unit-level Output-unit-level Soft Drinks 27% 13 6 9 Fresh Snacks 46% 67 61 69 Packaged Food 27% 20 33 22 Total 100% 100 100 100 By recognizing these differences, Jiffy Mart’s managers are better able to budget for different unit sales levels and different mixes of individual product-line items sold. Using a single cost driver (such as COGS) assumes homogeneity in the use of indirect costs (support activities) 6-18 across product lines which does not occur at Jiffy Mart. If Jiffy Mart had used COGS to allocate costs, Fresh Snacks would have been allocated 25% of the indirect costs, much lower than the 62.7% of the indirect costs based on an analysis of the activities it actually uses. Soft Drinks would have been allocated 35% and Packaged Food 40% of the indirect costs, much higher than the 12.5% and 24.8% respectively based on the cost of activities they actually use. Other benefits cited by managers include: (1) better identification of resource needs, (2) clearer linking of costs with staff responsibilities, and (3) identification of budgetary slack. 6-31 Kaizen approach to activity-based budgeting (continuation of 6-30). Jiffy Mart has a Kaizen (continuous improvement) approach to budgeting monthly activity costs for each month of 2018. Each successive month, the budgeted cost-driver rate decreases by 0.4% relative to the preceding month. So, for example, February’s budgeted cost-driver rate is 0.996 times January’s budgeted cost-driver rate, and March’s budgeted cost-driver rate is 0.996 times the budgeted February rate. Jiffy Mart assumes that the budgeted amount of cost-driver usage remains the same each month. Required: 1. What are the total budgeted cost for each activity and the total budgeted indirect cost for March 2018? 2. What are the benefits of using a Kaizen approach to budgeting? What are the limitations of this approach, and how might Jiffy Mart management overcome them? SOLUTION (20–30 min.) Kaizen approach to activity-based budgeting (continuation of 6-30). 1. Activity Ordering Delivery Shelf-stocking Customer support Cost Hierarchy Batch-level Batch-level Output-unit-level Output-unit-level Budgeted Cost-Driver Rates January February March $45.00 $44.82000a $44.64072b 40.67266 40.83600 41.00 10.41617 10.45800 10.50 0.08928 0.08964 0.09 a $45 × 0.996 = $44.82000; b$44.82000 × 0.996 = $44.64072 The March 2018 rates can be used to compute the total budgeted cost for each activity area in March 2018: Activity Ordering $44.64072 14; 24; 14 Delivery $40.67266 12; 62; 19 Shelf-stocking $10.41617 16; 172; 94 Customer support $0.08928 4,600; 34,200; 10,750 Total Cost Hierarchy Soft Drinks Fresh Produce Packaged Food Batch-level $ 625 $1,071 $ 625 $ 2,321 Batch-level 488 2,522 773 3,783 Output-unit-level 167 1,792 979 2,938 Output-unit-level 411 $1,691 3,053 $8,438 960 $3,337 4,424 $13,466 6-19 Total 2. A Kaizen budgeting approach signals management’s commitment to systematic cost reduction. Compare the budgeted costs from Question 6-30 and 6-31. ShelfCustomer Ordering Delivery Stocking Support Exercise 6-30 $2,340 $3,813 $2,961 $4,460 Exercise 6-31 (Kaizen) 2,321 3,783 2,938 4,424 The Kaizen budget number will show unfavorable variances for managers whose activities do not meet the required monthly cost reductions. This likely will put more pressure on managers to creatively seek out cost reductions by working “smarter” within Jiffy Mart or by having “better” interactions with suppliers or customers. One limitation of Kaizen budgeting, as illustrated in this question, is that it assumes small incremental improvements each month. It is possible that some cost improvements arise from large discontinuous changes in operating processes, supplier networks, or customer interactions. Companies need to highlight the importance of seeking these large discontinuous improvements as well as the small incremental improvements. A second limitation is the difficulty and challenge of determining the rate of improvement (0.4% in this example) and whether a constant percentage improvement can be sustained over a period of time. Jiffy’s managers might determine this rate of improvement by benchmarking against other companies or evaluating Jiffy’s performance over time. It might decrease the rate of improvement if it concludes that the rate of improvement is difficult to sustain and needs to be lowered. 6-32 Responsibility and controllability. Consider each of the following independent situations for Prestige Fountains. Prestige manufactures and sells decorative fountains for commercial properties. The company also contracts to service both its own and other brands of fountains. Prestige has a manufacturing plant, a supply warehouse that supplies both the manufacturing plant and the service technicians (who often need parts to repair fountains), and 12 service vans. The service technicians drive to customer sites to service the fountains. Prestige owns the vans, pays for the gas, and supplies fountain parts, but the technicians own their own tools. 1. In the manufacturing plant, the production manager is not happy with the motors that the purchasing manager has been purchasing. In May, the production manager stops requesting motors from the supply warehouse and starts purchasing them directly from a different motor manufacturer. Actual materials costs in May are higher than budgeted. 2. Overhead costs in the manufacturing plant for June are much higher than budgeted. Investigation reveals a utility rate hike in effect that was not figured into the budget. 3. Gasoline costs for each van are budgeted based on the service area of the van and the amount of driving expected for the month. The driver of van 3 routinely has monthly gasoline costs exceeding the budget for van 3. After investigating, the service manager finds that the driver has been driving the van for personal use. 4. Regency Mall, one of Prestige’s fountain service customers, calls the service people only for emergencies and not for routine maintenance. Thus, the materials and labor costs for these service calls exceeds the monthly budgeted costs for a contract customer. 5. Prestige’s service technicians are paid an hourly wage of $22, regardless of experience or time with the company. As a result of an analysis performed last month, the service manager determined that service technicians in their first year of employment worked on average 20% more slowly than other employees. Prestige bills customers per service call, not per hour. 6. The cost of health insurance for service technicians has increased by 40% this year, which 6-20 caused the actual health insurance costs to greatly exceed the budgeted health insurance costs for the service technicians. Required: For each situation described, determine where (that is, with whom) (a) responsibility and (b) controllability lie. Suggest ways to solve the problem or to improve the situation. SOLUTION (15 min.) Responsibility and controllability. 1. (a) Production manager (b) Purchasing Manager The purchasing manager has control of the cost to the extent that he/she is doing the purchasing and can seek or contract for the best price. The production manager should work with the purchasing manager. They can, together, possibly find a combination of better motor and better price for the motor than the production manager has found. 2. (a) Production Manager (b) External Forces In the case of the utility rate hike, the production manager would be responsible for the costs, but they are hard to control. The rates are fixed by the utility company, and there is usually no choice of which utility company to use. The production manager can try to reduce waste (turn off lights when not in use, turn of machines when not running, don’t leave water running, etc.) but other than conservation measures, the manager has no say in the utility rates. The production manager might consider purchasing more energy-efficient machines. 3. (a) Van 3 driver (b) Service manager The driver of each van has the responsibility to stay within budget for the costs of the service vehicle. The service manager should set policies to which the drivers must adhere, including not using the van for personal use. The service manager could install GPS in the vans to make sure they are where they are supposed to be, and can also fire the driver of Van 3 for misusing company property. (Using the van for personal driving affects the tax deductibility of the van for the firm as well). 4. (a) Prestige’s service manager (b) Regency manager Because Regency has a maintenance contract with Prestige, both the mall manager and Prestige’s service manager should work together to make sure routine maintenance is scheduled for the mall’s fountains. This will decrease the number and cost of the repair emergencies. The manager should also consider the average cost of service calls over the months where there were no calls. 5. (a) Service manager (b) Service manager 6-21 It is not surprising that service technicians who are new to the job may work more slowly than those with more experience. Unless the service manager feels that it is necessary to pay new employees the full $22 per hour in order to attract qualified applicants, he or she may consider paying a 20% lower hourly wage to employees in the first year, with an increase at the beginning of the second year. He or she may also consider additional training for new employees to help them get up to speed more quickly. It is probably not a good idea for Prestige to convert to an hourly charge for service calls, as it would punish customers for whom the new technicians were assigned. 6. (a) Service manager (b) External forces Like the cost of utilities, the cost of employee health insurance is determined externally. However, unlike the case of utilities, it is possible that the service manager can seek out bids from other providers or negotiate another rate with the existing company. The service manager may also choose to require employees to pay a greater share of the cost of the health insurance premium to at least partially offset the increase. 6-33 Responsibility, controllability, and stretch targets. Consider each of the following independent situations for Sunrise Tours, a company owned by David Bartlett that sells motor coach tours to schools and other groups. Sunshine Tours owns a fleet of 10 motor coaches and employs 12 drivers, maintenance technician, 3 sales representatives, and an office manager. Sunshine Tours pays for all fuel and maintenance on the coaches. Drivers are paid $0.50 per mile while in transit, plus $15 per hour while idle (time spent waiting while tour groups are visiting their destinations). The maintenance technician and office manager are both full-time salaried employees. The sales representatives work on straight commission. 1. When the office manager receives calls from potential customers, she is instructed to handle the contracts herself. Recently, however, the number of contracts written up by the office manager has declined. At the same time, one of the sales representatives has experienced a significant increase in contracts. The other two representatives believe that the office manager has been colluding with the third representative to send him the prospective customers. 2. One of the motor coach drivers seems to be reaching his destinations more quickly than any of the other drivers and is reporting longer idle time. 3. Regular preventive maintenance of the motor coaches has been proven to improve fuel efficiency and reduce overall operating costs by averting costly repairs. During busy months, however, it is difficult for the maintenance technician to complete all of the maintenance tasks within his 40-hour workweek. 4. David Bartlett has read about stretch targets, and he believes that a change in the compensation structure of the sales representatives may improve sales. Rather than a straight commission of 10% of sales, he is considering a system where each representative is given a monthly goal of 50 contracts. If the goal is met, the representative is paid a 12% commission. If the goal is not met, the commission falls to 8%. Currently, each sales representative averages 45 contracts per month. 5. Fuel consumption has increased significantly in recent months. David Bartlett is considering ways to promote improved fuel efficiency and reduce harmful emissions using stretch environmental targets, where drivers and the maintenance mechanic would receive a bonus if fuel consumption falls below 90% of budgeted fuel usage per mile driven. 6-22 Required: For situations 1–3, discuss which employee has responsibility for the related costs and the extent to which costs are controllable and by whom. What are the risks or costs to the company? What can be done to solve the problem or improve the situation? For situations 4 and 5, describe the potential benefits and costs of establishing stretch targets. SOLUTION (15 min.) Responsibility, controllability, and stretch targets. 1. The office manager has the responsibility to follow company guidelines and write contracts herself for customers who call her directly. She can also control these costs. Diverting potential customers to the sales representative costs the company a sales commission that would not have otherwise been paid. If satisfaction surveys are sent to customers asking about their first contact with the company, this may be enough to prevent the office manager from breaking the rules. 2. Each driver is responsible for controlling and keeping an accurate accounting of his or her time. Because the drivers are paid for mileage while driving and an hourly rate while in idle, there is an incentive to report less travel time and more idle time. The cost could be controlled by using global positioning systems (GPS) to track the movement and location of the motor coaches. 3. The maintenance technician is clearly responsible for completing all of the preventative maintenance. Requiring the technician to work significant overtime will likely decrease his efficiency. Ignoring routine maintenance will end up costing the company more money in fuel and repair costs. If the technician cannot complete the tasks during busy months, the company should consider outsourcing some of the more routine maintenance jobs or hiring additional help during those months. 4. The maintenance technician is clearly responsible for completing all of the preventative maintenance. If he cannot complete the tasks during busy months, the company should consider outsourcing some of the more routine maintenance jobs. Requiring the technician to work significant overtime will likely decrease his efficiency. Ignoring routine maintenance will end up costing the company more money in fuel and repair costs. 5. Bartlett has designed the stretch target system correctly. Taking advantage of loss aversion, Bartlett has set a stretch target of 50 contracts rewarding the representative with a 12 percent commission (assuming paying this amount of commission is profitable). If the target is not met, the commission decreases to 8 percent. This will motivate the representatives to achieve 50 contracts. In establishing “stretch targets,” Bartlett should be sure that there are sufficient potential contracts to allow all three sales representatives to achieve the higher target. Otherwise, the stretch target may cause friction among the sales representatives. One or more of the sales representatives may decide that the 8 percent commission is not sufficient incentive to stay with the company, and may leave to work for a competitor, resulting in overall reduced sales. 5. The drivers are responsible for driving the motor coaches at fuel-efficient speeds on the highway. The maintenance technician is responsible for maintaining the vehicles to improve 6-23 efficiency. An increase in fuel consumption would be difficult to pin on either employee because either could be responsible. However, the bonus offered to drivers would have to exceed the loss of pay due to driving slower, as they are paid by the mile, and the loss in personal comfort from sitting in a hot or cold bus may outweigh the bonus from fuel savings while the bus is idle. “Stretch targets” such as these are more challenging when employees from different departments must both work in order to achieve them but this may be necessary to get better fuel efficiency. For the reduced emissions target, Bartlett could consider rewarding just the technicians, as the maintenance they perform has a direct impact on emissions. 6-34 Cash flow analysis, sensitivity analysis. HealthMart is a retail store selling home medical supplies. HealthMart also services home oxygen equipment, for which the company bills customers monthly. HealthMart has budgeted for increases in service revenue of $500 each month due to a recent advertising campaign. The forecast of sales and service revenue for the March–June 2018 is as follows: Almost all of the retail sales are credit card sales; cash sales are negligible. The credit card company deposits 92% of the revenue recorded each day into HealthMart’s account overnight. 70% of oxygen service billed each month is collected in the month of the service, and 30% is collected in the month after the service. Required: 1. Calculate the cash that HealthMart expects to collect in April, May, and June 2018. Show calculations for each month. 2. HealthMart has budgeted expenditures for May of $14,100. a. Given your answer to requirement 1, and assuming a beginning cash balance for May of $650, will HealthMart be able to cover its payments for May? b. Assume (independently for each situation) that May revenues might also be 10% lower or that costs might be 5% higher. Under each of those two scenarios, show the total net cash for May and the amount HealthMart would have to borrow if cash receipts are less than cash payments. The company requires a minimum cash balance of $600. (Again, assume a balance of $650 on May 1.) 3. Why do HealthMart’s managers prepare a cash budget in addition to the revenue, expenses, and operating income budget? Has preparing the cash budget been helpful? Explain briefly. SOLUTION (30 min.) Cash flow analysis, sensitivity analysis. 6-24 1. The cash that HealthMart can expect to collect during April, May, and June is calculated below. Cash collection in From sales revenue (credit cards) April ($8,400 × 0.92) May ($9,100 × 0.92) April ($10,500 × 0.92) From service revenue March ($5,000 × 0.30) April ($5,000 × 0.70; 0.30) May ($5,000 × 0.70; 0.30) June ($5,000 × 0.70; 0.30) Total collections 2. April May June $7,728 $8,372 $9,660 $1,500 $3,850 $1,650 $4,200 $13,078 $14,222 $1,800 $4,550 $16,010 (a) Beginning balance $650 + Collections $14,222 – Expenditures $14,100 = $772. Yes, HealthMart will be able to cover the budgeted expenditures and maintain a minimum ending balance of more than $600. (b) Beginning cash Collections Expenditures Total Original Numbers $650.00 14,222.00 14,100.00 $772.00 May Revenues Decrease 10% $650.00 12,799.80 14,100.00 ($650.20) May Costs Increase 5% $650.00 14,222.00 14,805.00 $67.00 If May costs increase by as much as 5%, it would not be necessary to borrow money. If May revenues decrease 10%, HealthMart would have to borrow $1,250.20 ($650.20 + $600) in order to maintain an ending balance of $600. 3. HealthMart’s managers prepare a cash budget in addition to the operating income budget to plan cash flows to ensure that the company has adequate cash to make expenditures as they come due. HealthMart’s managers may need to initiate a plan to borrow money to finance any shortfall. Building a profitable operating plan does not guarantee that adequate cash will be available, so HealthMart’s managers need to prepare a cash budget in addition to an operating income budget. 6-35 Budget schedules for a manufacturer. Lame Specialties manufactures, among other things, woollen blankets for the athletic teams of the two local high schools. The company sews the blankets from fabric and sews on a logo patch purchased from the licensed logo store site. The teams are as follows: 6-25 ■ Knights, with red blankets and the Knights logo ■ Raiders, with black blankets and the Raider logo Also, the black blankets are slightly larger than the red blankets. The budgeted direct-cost inputs for each product in 2017are as follows: Unit data pertaining to the direct materials for March 2017 are as follows: Unit cost data for direct-cost inputs pertaining to February 2017and March 2017 are as follows: Manufacturing overhead (both variable and fixed) is allocated to each blanket on the basis of budgeted direct manufacturing labor-hours per blanket. The budgeted variable manufacturing overhead rate for March 2017 is $16 per direct manufacturing labor-hour. The budgeted fixed manufacturing overhead for March 2017 is $14,640. Both variable and fixed manufacturing overhead costs are allocated to each unit of finished goods. Data relating to finished goods inventory for March 2017are as follows: 6-26 Budgeted sales for March 2017 are 130 units of the Knights blankets and 190 units of the Raiders blankets. The budgeted selling prices per unit in March 2017 are $229 for the Knights blankets and $296 for the Raiders blankets. Assume the following in your answer: Work-in-process inventories are negligible and ignored. Direct materials inventory and finished goods inventory are costed using the FIFO method. Unit costs of direct materials purchased and finished goods are constant in March2017. Required: 1. Prepare the following budgets for March2017: a. Revenues budget b. Production budget in units c. Direct material usage budget and direct material purchases budget d. Direct manufacturing labor budget e. Manufacturing overhead budget f. Ending inventories budget (direct materials and finished goods) g. Cost of goods sold budget 2. Suppose Lame Specialties decides to incorporate continuous improvement into its budgeting process. Describe two areas where it could incorporate continuous improvement into the budget schedules in requirement 1. SOLUTION (40 min.) Budget schedules for a manufacturer. 1a. Revenues Budget Units sold Selling price Budgeted revenues b. Knights Blankets 130 $ 229 $29,770 Raiders Blankets 190 $ 296 $56,240 $86,010 Production Budget in Units Budgeted unit sales Add budgeted ending fin. goods inventory Total requirements Deduct beginning fin. goods inventory Budgeted production c. Total Direct Materials Usage Budget (units) 6-27 Knights Blankets 130 22 152 12 140 Raiders Blankets 190 27 217 17 200 Red wool Black wool Knights Raiders logo patches logo patches – – – 1 140 140 – – – – – – 5 200 1,000 – – – 1 200 200 560 1,000 140 200 35 $ 9 15 $ 12 45 $ 7 60 $ 6 $ 315 $ 180 $315 $ 360 525 $ 10 985 $ 11 95 $ 7 140 $ 8 $5,250 $10,835 $665 $1,120 $17,870 $5,565 $11,015 $980 $1,480 $19,040 Knights blankets: 1. Budgeted input per f.g. unit 4 2. Budgeted production 140 3. Budgeted usage (1 × 2) 560 Raiders blankets: 4. Budgeted input per f.g. unit 5. Budgeted production 6. Budgeted usage (4 × 5) 7. Total direct materials usage (3 + 6) Direct Materials Cost Budget 8. Beginning inventory 9. Unit price (FIFO) 10. Cost of DM used from beginning inventory (8 × 9) 11. Materials to be used from purchases (7 – 8) 12. Cost of DM in March 13. Cost of DM purchased and used in March (11 × 12) 14. Direct materials to be used (10 + 13) Direct Materials Purchases Budget Budgeted usage (from line 7) Add target ending inventory Total requirements Deduct beginning inventory Total DM purchases Purchase price (March) Total purchases d. Red wool Black wool Knight Raiders s logos logos 560 1,000 140 200 25 585 25 1,025 25 165 25 225 35 550 $ 10 $5,500 15 1,010 $ 11 $11,110 45 120 $ 7 $840 60 165 $ 8 $1,320 Direct Manufacturing Labor Budget Direct Budgete Manuf. Labord Units Hours per Total 6-28 Hourly Total $18,770 Total $ 1,170 Knights blankets Raiders blankets e. Produce d Output Unit Hours Rate Total 140 3 420 $27 $11,340 200 4 800 1,220 $27 21,600 $32,940 Manufacturing Overhead Budget Variable manufacturing overhead costs (1,220 × $16) Fixed manufacturing overhead costs Total manufacturing overhead costs $19,520 14,640 $34,160 Total manuf. overhead cost per hour = $34,160 ÷ 1,220 = $28 per direct manufacturing laborhour Fixed manuf. overhead cost per hour = $ 14,640 ÷ 1,220 = $12 per direct manufacturing laborhour f. Computation of unit costs of ending inventory of finished goods Knights Raiders Blankets Blankets Direct materials Red wool ($10 × 4, 0) $ 40 $ 0 Black wool ($11 × 0, 5) 0 55 Knights logos ($7 × 1, 0) 7 0 Raiders logos ($8 × 0, 1) 0 8 Direct manufacturing labor ($27 × 3, 4) 81 108 Manufacturing overhead Variable ($16 × 3, 4) 48 64 Fixed ($12 × 3, 4) 36 48 Total manufacturing cost $212 $283 Ending Inventories Budget Direct Materials Red wool Black wool Knights logo patches Raiders logo patches Finished Goods Knights blankets Raiders blankets Cost per Unit Units Total $ 10 11 7 8 25 25 25 25 $ 250 275 175 200 900 212 283 22 27 4,664 7,641 12,305 $13,205 Total g. Cost of goods sold budget Beginning fin. goods inventory, March 1, 2014 ($1,440 + $2,550) 6-29 $ 3,990 Direct materials used (from Dir. materials cost budget) $19,040 Direct manufacturing labor (Dir. manuf. labor budget) 32,940 Manufacturing overhead (Manuf. overhead budget) 34,160 Cost of goods manufactured 86,140 Cost of goods available for sale 90,130 Deduct ending fin. goods inventory, March 31, 2014 (Inventories budget) 12,305 Cost of goods sold $77,825 2. Areas where continuous improvement might be incorporated into the budgeting process: a. Direct materials. Either an improvement in usage or price could be budgeted. For example, the budgeted usage amounts for the fabric could be related to the maximum improvement (current usage – minimum possible usage) of yards of fabric for either blanket. It may also be feasible to decrease the price paid, particularly with quantity discounts on things like the logo patches. b. Direct manufacturing labor. The budgeted usage of 3 hours/4 hours could be continuously revised on a monthly basis. Similarly, the manufacturing labor cost per hour of $27 could be continuously revised down. The former appears more feasible than the latter. c. Variable manufacturing overhead. By budgeting more efficient use of the allocation base, a signal is given for continuous improvement. A second approach is to budget continuous improvement in the budgeted variable overhead cost per unit of the allocation base. d. Fixed manufacturing overhead. The approach here is to budget for reductions in the year-to-year amounts of fixed overhead. If these costs are appropriately classified as fixed, then they are more difficult to adjust down on a monthly basis. 6-36 Budgeted costs, Kaizen improvements environmental costs. US Apparel (USA) manufactures plain white and solid-colored T-shirts. Budgeted inputs include the following: Budgeted sales and selling price per unit are as follows: USA has the opportunity to switch from using the dye it currently uses to using an environmentally friendly dye that costs $1.25 per ounce. The company would still need 4 ounces of dye per shirt. USA is reluctant to change because of the increase in costs (and decrease in profit), but the Environmental Protection Agency has threatened to fine the company $130,000 if it continues to use the harmful but less expensive dye. Required: 6-30 1. Given the preceding information, would USA be better off financially by switching to the environmentally friendly dye? (Assume all other costs would remain the same.) 2. Assume USA chooses to be environmentally responsible regardless of cost, and it switches to the new dye. The production manager suggests trying Kaizen costing. If USA can reduce fabric and labor costs each by 1% per month on all the shirts it manufactures, by how much will overall costs decrease at the end of 12 months? (Round to the nearest dollar for calculating cost reductions.) 3. Refer to requirement 2. How could the reduction in material and labor costs be accomplished? Are there any problems with this plan? SOLUTION (45 min.) Budgeted costs, Kaizen improvements. 1. Increase in Costs for the Year Assume US Apparel uses New Dye Units to dye 50,000 Cost differential ($1.25 – $0.50) per ounce × 4 ounces × $3.00 Increase in costs $150,000 Because the fine is only $130,000, US Apparel would be financially better off by not switching. 3. If US Apparel switches to the new dye, costs will increase by $150,000. If US Apparel implements Kaizen costing, costs will be reduced as follows: Original monthly costs Input Fabric Labor Total * Unit cost $6.00 $4.00 Number of units 5,000* 5,000* Total cost $30,000 20,000 $50,000 (10,000 + 50,000)/12 months = 5,000 units Monthly decrease in costs (calculated at 99% of previous month’s cost) Fabric Labor cost Month 1 $ 30,000 Month 1 Month 2 29,700 Month 2 Month 3 29,403 Month 3 Month 4 29,109 Month 4 Month 5 28,818 Month 5 Month 6 28,530 Month 6 Month 7 28,245 Month 7 Month 8 27,963 Month 8 Month 9 27,683 Month 9 Month 10 27,406 Month 10 6-31 $ 20,000 19,800 19,602 19,406 19,212 19,020 18,830 18,642 18,456 18,271 Annual cost $360,000 240,000 $600,000 Month 11 Month 12 TOTAL 27,132 26,861 $340,850 Month 11 Month 12 18,088 17,907 $227,234 Difference between costs with and without Kaizen improvements ($600,000 – $568,064) $568,064 $ 31,916 This means costs increase a net amount of $150,000 – 31,916 = $118,084. With Kaizen, the cost of using the higher cost dye is less than the $130,000 fine for using the harmful dye. US Apparel would be better off by switching to the new dye. 3. Reduction in materials can be accomplished by reducing waste and scrap. Reduction in direct labor can be accomplished by improving the efficiency of operations and decreasing down time. Employees who make and dye the T-shirts may have suggestions for ways to do their jobs more efficiently. For instance, employees may recommend process changes that reduce idle time, setup time, and scrap. To motivate workers to improve efficiency, many companies have set up programs that share productivity gains with the workers. US Apparel must be careful that productivity improvements and cost reductions do not in any way compromise product quality. 6-37 Revenue and production budgets. (CPA, adapted) The Sabat Corporation manufactures and sells two products: Thingone and Thingtwo. In July 2016, Sabat’s budget department gathered the following data to prepare budgets for 2017: 2017 Projected Sales 2017 Inventories in Units The following direct materials are used in the two products: Projected data for 2017 for direct materials are: 6-32 Projected direct manufacturing labor requirements and rates for 2017 are: Manufacturing overhead is allocated at the rate of $24 per direct manufacturing labor-hour. Required: Based on the preceding projections and budget requirements for Thingone and Thingtwo, prepare the following budgets for 2017: 1. Revenues budget (in dollars) 2. What questions might the CEO ask the marketing manager when reviewing the revenues budget? Explain briefly. 3. Production budget (in units) 4. Direct material purchases budget (in quantities) 5. Direct material purchases budget (in dollars) 6. Direct manufacturing labor budget (in dollars) 7. Budgeted finished-goods inventory at December 31, 2017 (in dollars) 8. What questions might the CEO ask the production manager when reviewing the production, direct materials, and direct manufacturing labor budgets? 9. How does preparing a budget help Sabat Corporation’s top management better manage the company? SOLUTION (30–40 min.) Revenue and production budgets. This is a routine budgeting problem. The key to its solution is to compute the correct quantities of finished goods and direct materials. Use the following general formula: production ending Budgeted sales or Beginning Budgeted = Target or purchases inventory materials used inventory + – 1. Sabat Corporation Revenues Budget for 2017 Units Thingone Thingtwo Budgeted revenues Price Total 62,000 $172 $10,664,000 46,000 264 12,144,000 $22,808,000 6-33 2. The CEO would want to probe if the revenue budget is sufficiently stretched. Is the revenue growing faster than the market? Should the company increase marketing and advertising spending to grow sales? Would increasing the sales force or giving salespersons stronger incentives result in higher sales? 3. Sabat Corporation Production Budget (in units) for 2017 Budgeted sales in units Add target finished goods inventories, December 31, 2017 Total requirements Deduct finished goods inventories, January 1, 2017 Units to be produced 4. Thingone 62,000 Thingtwo 46,000 26,000 88,000 14,000 60,000 21,000 67,000 13,000 47,000 Sabat Corporation Direct Materials Purchases Budget (in quantities) for 2017 Direct materials to be used in production • Thingone (budgeted production of 67,000 units times 5 lbs. of A, 3 lbs. of B) • Thingtwo (budgeted production of 47,000 units times 6 lbs. of A, 4 lbs. of B, 2 lb. of C) Total Add target ending inventories, December 31, 2017 Total requirements in units Deduct beginning inventories, January 1, 2017 Direct materials to be purchased (units) 5. C 335,000 201,000 -- 282,000 617,000 40,000 188,000 389,000 35,000 94,000 94,000 12,000 657,000 37,000 620,000 424,000 32,000 392,000 106,000 10,000 96,000 Sabat Corporation Direct Materials Purchases Budget (in dollars) for 2017 Direct material A Direct material B Direct material C Budgeted purchases 6. Direct Materials A B Budgeted Purchases (Units) 620,000 392,000 96,000 Expected Purchase Price per unit $11 6 5 Sabat Corporation Direct Manufacturing Labor Budget (in dollars) for 2017 Direct 6-34 Total $6,820,000 2,352,000 480,000 $9,652,000 Thingone Thingtwo Total 7. Budgeted Production (Units) 67,000 47,000 Manufacturing Labor-Hours per Unit 3 4 Total Hours 201,000 188,000 Rate per Hour $11 14 Total $2,211,000 2,632,000 $4,843,000 Sabat Corporation Budgeted Finished Goods Inventory at December 31, 2017 Thingone: Direct materials costs: A, 5 pounds × $11 $55 B, 3 pounds × $6 18 $ 73 Direct manufacturing labor costs, 3 hours × $11 33 Manufacturing overhead costs at $19 per direct manufacturing labor-hour (3 hours × $19) 57 Budgeted manufacturing costs per unit $163 Finished goods inventory of Thingone $163 × 26,000 units $4,238,000 Thingtwo: Direct materials costs: A, 6 pounds × $11 $66 B, 4 pounds × $6 24 C, 2 each × $5 10 $100 Direct manufacturing labor costs, 4 hours × $14 56 Manufacturing overhead costs at $19 per direct manufacturing labor-hour (4 hours × $19) 76 Budgeted manufacturing costs per unit $232 Finished goods inventory of Thingtwo $232 × 14,000 units 3,248,000 Budgeted finished goods inventory, December 31,2017 $7,486,000 8. The CEO would want to ask the production manager why the target ending inventories have increased. Could production be more closely tailored to demand? Could the efficiency and productivity of direct materials and direct manufacturing labor be increased? Could direct materials inventory be reduced? 9. Preparing a budget helps Saadi Corporation manage costs based on revenues and production needs, look for opportunities to increase efficiencies, reduce costs, particularly in areas where costs are high, coordinate and communicate across different parts of the organization, create a framework for judging performance and facilitating learning, and motivate managers and employees to achieve “stretch” targets of higher revenues and lower costs. 6-38 Budgeted income statement. (CMA, adapted) Smart Video Company is a manufacturer of videoconferencing products. Maintaining the videoconferencing equipment is an important 6-35 area of customer satisfaction. A recent downturn in the computer industry has caused the videoconferencing equipment segment to suffer, leading to a decline in Smart Video’s financial performance. The following income statement shows results for 2017: Smart Video Company Income Statement for the Year Ended December 31, 2017 (in thousands) Smart Video’s management team is preparing the 2018 budget and is studying the following information: 1. Selling prices of equipment are expected to increase by 10% as the economic recovery begins. The selling price of each maintenance contract is expected to remain unchanged from 2017. 2. Equipment sales in units are expected to increase by 6%, with a corresponding 6% growth in units of maintenance contracts. 3. Cost of each unit sold is expected to increase by 5% to pay for the necessary technology and quality improvements. 4. Marketing costs are expected to increase by $290,000, but administration costs are expected to remain at 2017 levels. 5. Distribution costs vary in proportion to the number of units of equipment sold. 6. Two maintenance technicians are to be hired at a total cost of $160,000, which covers wages and related travel costs. The objective is to improve customer service and shorten response time. 7. There is no beginning or ending inventory of equipment. Required: 1. Prepare a budgeted income statement for the year ending December 31, 2018. 2. How well does the budget align with Smart Video’s strategy? 3. How does preparing the budget help Smart Video’s management team better manage the company? SOLUTION 6-36 (30 min.) Budgeted income statement. 1. Smart Video Company Budgeted Income Statement for 2017 (in thousands) Revenues Equipment ($8,000 × 1.06 × 1.10) Maintenance contracts ($1,900 × 1.06) Total revenues Cost of goods sold ($4,000 × 1.06 × 1.05) Gross margin Operating costs: Marketing costs ($630 + $290) Distribution costs ($100 × 1.06) Customer maintenance costs ($1,100 + $160) Administrative costs Total operating costs Operating income $9,328 2,014 $11,342 4,452 6,890 920 106 1,260 920 3,206 $3,684 2. The budget aligns with Videocom’s key strategy of customer satisfaction through maintaining videoconferencing equipment by hiring maintenance technicians and increasing costs of customer maintenance by 14.55% ($160,000 ÷ $1,100,000) more than the 6% forecasted increase in sales. 3. Preparing a budget helps Videocom manage costs based on revenues and production needs, look for opportunities to increase efficiencies, reduce costs, particularly in areas where costs are high, coordinate and communicate across different parts of the organization, create a framework for judging performance and facilitating learning, and motivate managers and employees to achieve “stretch” targets of higher revenues and lower costs. 6-39 Responsibility in a restaurant. Christa Schuller owns an outlet of a popular chain of restaurants in the southern part of Germany. One of the chain’s popular lunch items is the cheeseburger. It is a hamburger topped with cheese. On demand, purchasing agents from each outlet orders the cheese and meat patties from the Central Warehouse. In January 2018, one of the freezers in Central Warehouse broke down and the production of meat patty and storing of cheese were reduced by 20-30% for 4 days. During these 4 days, Christa’s franchise runs out of meat patties and cheese slices while facing a high demand for cheeseburgers. Christa’s chef, Kelly Lyn, decides to prepare cheeseburgers using ingredients from a local market, sending one of the kitchen helpers to the market to buy the ingredients. Although the customers’ are satisfied, Christa’s restaurant has to pay twice the cost of the Central Warehouse’s products to procure meat and cheese from the local market, and the restaurant loses money on this item for those 4 days. Christa is angry with the purchasing agent for not ordering enough meat patty and cheese to avoid running out of stock, and with Kelly for spending too much money on the procurement of meat and cheese. Required: 6-37 Who is responsible for the cost of the meat patty and cheese as ingredients of a cheeseburger? At what level is the cost controllable? Do you agree that Christa should be angry with the purchasing agent? With Kelly? Why or why not? SOLUTION (15 min.) Responsibility of purchasing agent. The procurement of meat patties and cheese slices is usually the responsibility of the purchasing agent, though the costs of these items are not under his control. It is usually controllable by the Central Warehouse. However, in this scenario, Kelly, the cook, has taken the responsibility for the cost of the meat to be used in meat patties and cheese slices from the local market by making a purchasing decision. As Christa holds the purchasing agent responsible for the costs of meat and cheese, and presuming that Kelly knew this, Kelly should have discussed her decision with the purchasing agent before sending the kitchen helper to the local market. In any case, Christa should not be angry because her employees acted to satisfy the customers on a short-term emergency basis. Assuming that the Central Warehouse does not consistently have problems with their freezer, there is no way the purchasing agent could foresee the incident beforehand and plan accordingly. The problem only lasted four days, which, in the course of the year (or even the month) will not seriously harm the profits of a restaurant that sells a variety of foods along with the cheeseburger. However, if they had not cooked the cheeseburger with local ingredients when they went out of meat patties and cheese slices for four days, there could have been a long-term implications on customer satisfaction and customer loyalty, and in the long run this could harm profits as customers could have found other restaurants to frequent for lunch. 6-40 Comprehensive problem with ABC costing. Animal Gear Company makes two pet carriers, the Cat-allac and the Dog-eriffic. They are both made of plastic with metal doors, but the Cat-allac is smaller. Information for the two products for the month of April is given in the following tables: 6-38 Animal Gear accounts for direct materials using a FIFO cost-flow assumption. Animal Gear uses a FIFO cost-flow assumption for finished-goods inventory. Animal Gear uses an activity-based costing system and classifies overhead into three activity pools: Setup, Processing, and Inspection. Activity rates for these activities are $105 per setuphour, $10 per machine-hour, and $15 per inspection-hour, respectively. Other information follows: If necessary, round up to calculate number of batches. Nonmanufacturing fixed costs for March equal $32,000, half of which are salaries. Salaries are expected to increase 5% in April. Other nonmanufacturing fixed costs will remain the same. The only variable nonmanufacturing cost is sales commission, equal to 1% of sales revenue. Prepare the following for April: Required: 1. 2. 3. 4. 5. 6. Revenues budget Production budget in units Direct material usage budget and direct material purchases budget Direct manufacturing labor cost budget Manufacturing overhead cost budgets for each of the three activities Budgeted unit cost of ending finished-goods inventory and ending inventories budget 6-39 7 Cost of goods sold budget 8. Nonmanufacturing costs budget 9. Budgeted income statement (ignore income taxes) 10. How does preparing the budget help Animal Gear’s management team better manage the company? SOLUTION (60 min.) Comprehensive problem with ABC costing 1. Revenue Budget For the Month of April Cat-allac Dog-eriffic Total Units 530 225 Selling Price $205 310 Total Revenues $108,650 69,750 $178,400 2. Production Budget For the Month of April Budgeted unit sales Add target ending finished goods inventory Total required units Deduct beginning finished goods inventory Units of finished goods to be produced Product Cat-allac Dog-eriffic 530 225 30 10 560 235 10 19 550 216 3. Direct Material Usage Budget in Quantity and Dollars For the Month of April Material Plastic Metal Physical Units Budget Direct materials required for Cat-allac (550 units × 4 lbs. and 0.5 lb.) Dog-eriffic (216 units × 6 lbs. and 1 lb.) Total quantity of direct material to be used 2,200 lbs. 1,296 lbs. 3,496 lbs. Cost Budget Available from beginning direct materials inventory (under a FIFO cost-flow assumption) Plastic: 290 lbs. × $3.80 per lb. Metal: 70 lbs. × $3.10 per lb. 6-40 275 lbs. 216 lbs. 491 lbs. $ 1,102 $ 217 Total To be purchased this period Plastic: (3,496 – 290) lbs. $5 per lb. Metal: (485 – 70) lbs. $4 per lb. Direct materials to be used this period 16,030 _ $17,132 1,684 $1,901 $19,033 Direct Material Purchases Budget For the Month of April Material Plastic Physical Units Budget To be used in production (requirement 3) Add target ending inventory Total requirements Deduct beginning inventory Purchases to be made Cost Budget Plastic: 3,616 lbs. $5 Metal: 486 lbs. $4 Purchases 3,496 lbs. 410 lbs. 3,906 lbs. 290 lbs. 3,616 lbs. $18,080 _______ $18,080 Metal Total 491 lbs. 65 lbs. 556 lbs. 70 lbs. 486 lbs. $1,944 $1,944 $20,024 4. Direct Manufacturing Labor Costs Budget For the Month of April Cat-allac Dog-eriffic Total Output Units Produced (requirement 2) 550 216 DMLH per Unit 3 5 Total Hours 1,650 1,080 Hourly Wage Rate $10 10 Total $16,500 10,800 $27,300 5. Machine Setup Overhead Units to be produced Units per batch Number of batches (rounded up) Setup time per batch Total setup time Cat-allac 550 ÷ 25 22 ×1.50 hrs. 33 hrs. Dog-eriffic 216 ÷9 24 ×1.75 hrs. 42 hrs. Total 75 hrs. Budgeted machine setup costs = $105 per setup hour 75 hours = $7,875 Processing Overhead Budgeted machine-hours (MH) = (11 MH per unit × 550 units) + (19 MH per unit × 216 units) = 6,050 MH + 4,104 MH = 10,154 MH Budgeted processing costs = $10 per MH × 10,154 MH = $101,540 Inspection Overhead Budgeted inspection-hours = (0.5 22 batches) + (0.7 24 batches) 6-41 = 11 + 16.8 = 27.8 inspection hrs. Budgeted inspection costs = $15 per inspection hr. 27.8 inspection hours = $417 Manufacturing Overhead Budget For the Month of April Machine setup costs $ 7,875 Processing costs 101,540 Inspection costs 417 Total costs $109,832 6. Unit Costs of Ending Finished Goods Inventory April 30 Product Cat-allac Dog-eriffic Cost per Input per Input per Unit of Unit of Unit of Input Output Total Output Total Plastic $ 5 4 lbs. $ 20.00 6 lbs. $ 30.00 Metal 4 0.5 lbs. 2.00 1 lb. 4.00 Direct manufacturing labor 10 3 hrs. 30.00 5 hrs. 50.00 Machine setup 105 0.06 hrs.a 6.30 0.2 hra 21.00 Processing 10 11 MH 110.00 19 MH 190.00 Inspection 15 0.02 hrb 0.30 0.08 hr.b 1.20 Total $168.60 $296.20 a b 33 setup-hours ÷ 550 units = 0.06 hours per unit; 42 setup-hours ÷ 210 units = 0.2 hours per unit 11 inspection hours ÷ 550 units = 0.02 hours per unit; 16.8 inspection hours ÷ 210 units = 0.08 hours per unit Ending Inventories Budget April 30 Quantity Direct Materials Plastic Metals Finished goods Cat-allac Dog-eriffic Total ending inventory Cost per unit 410 65 $ 5 4 30 10 $168.60 296.20 Total $2,050 260 $5,058 2,962 $ 2,310 8,020 $10,330 7. Cost of Goods Sold Budget For the Month of April Beginning finished goods inventory, April, 1 ($1,000 + $4,650) Direct materials used (requirement 3) 6-42 $ $ 19,033 5,650 Direct manufacturing labor (requirement 4) Manufacturing overhead (requirement 5) Cost of goods manufactured Cost of goods available for sale Deduct: Ending finished goods inventory, April 30 (requirement 6) Cost of goods sold 27,300 109,832 156,165 161,815 8,020 $153,795 8. Nonmanufacturing Costs Budget For the Month of April Salaries ($32,000 ÷ 2 1.05) $16,800 Other fixed costs ($32,000 ÷ 2) 16,000 1,784 Sales commissions ($178,400 1%) Total nonmanufacturing costs $34,584 9. Budgeted Income Statement For the Month of April Revenues Cost of goods sold Gross margin Operating (nonmanufacturing) costs Operating income $178,400 153,795 24,605 34,584 $ (9,979) 10. Animal Gear is making a loss and will need to increase revenues and manage costs to turn around the business. Preparing a budget helps Animal Gear manage costs based on revenues and production needs, look for opportunities to increase efficiencies, reduce costs, particularly in areas where costs are high, coordinate and communicate across different parts of the organization, create a framework for judging performance and facilitating learning, and motivate management and employees to achieve “stretch” targets of higher revenues and lower costs. 6-41 Cash budget (continuation of 6-40). Refer to the information in Problem 6-40. Assume the following: Animal Gear (AG) does not make any sales on credit. AG sells only to the public and accepts cash and credit cards; 90% of its sales are to customers using credit cards, for which AG gets the cash right away, less a 2% transaction fee. Purchases of materials are on account. AG pays for half the purchases in the period of the purchase and the other half in the following period. At the end of March, AG owes suppliers $8,000. AG plans to replace a machine in April at a net cash cost of $13,000. Labor, other manufacturing costs, and nonmanufacturing costs are paid in cash in the month incurred except of course depreciation, which is not a cash flow. Depreciation is $25,000 of the manufacturing cost and $10,000 of the nonmanufacturing cost for April. AG currently has a $2,000 loan at an annual interest rate of 12%. The interest is paid at the 6-43 end of each month. If AG has more than $7,000 cash at the end of April it will pay back the loan. AG owes $5,000 in income taxes that need to be remitted in April. AG has cash of $5,900 on hand at the end of March. Required: 1. Prepare a cash budget for April for Animal Gear. 2. Why do Animal Gear’s managers prepare a cash budget in addition to the revenue, expenses, and operating income budget? SOLUTION (25 min.) Cash budget (Continuation of 6-40) (Appendix) Cash Budget April 30 Cash balance, April 1 Add receipts Cash sales ($178,400 × 10%) Credit card sales ($178,400 × 90% × 98%) Total cash available for needs (x) Deduct cash disbursements Direct materials ($8,000 + $20,024 × 50%) Direct manufacturing labor Manufacturing overhead ($109,832 ─ $25,000 depreciation) Nonmanufacturing salaries Sales commissions Other nonmanufacturing fixed costs ($16,000 ─ $10,000 depreciation) Machinery purchase Income taxes Total disbursements (y) Financing Repayment of loan 1 Interest at 12% ($2,000 12% ) 12 Total effects of financing (z) Ending cash balance, April 30 (x) ─ (y) ─ (z) $ 5,900 17,840 157,349 $181,089 $ 18,012 27,300 84,832 16,800 1,784 6,000 13,000 5,000 $172,728 $ 2,000 20 $ 2,020 $ 6,341 Note: The solution assumes that the loan is repaid. Some students may point out that the cash balance at the end of April after the loan is paid is anticipated to be $6,341, which is less than $7,000 and so Animal Gear would not repay the loan. Under this assumption, the $2,000 repayment would not be shown. Our assumption is that Animal Gear has $8,361 ($181,089 − $172,728) at the end of April before the loan is paid which is more than $7,000 and so the loan will be repaid. 2. Animal Gear’s managers prepare a cash budget in addition to the operating income budget to plan cash flows to ensure that the company has adequate cash to pay vendors, meet payroll, and pay operating expenses as these payments come due. Animal Gear could be very 6-44 profitable on an accrual accounting basis, but the pattern of cash receipts from revenues might be delayed and result in insufficient cash being available to make scheduled payments for its expenses. Animal Gear’s managers may then need to initiate a plan to borrow money to finance any shortfall. Building a profitable operating plan does not guarantee that adequate cash will be available, so Animal Gear’s managers need to prepare a cash budget in addition to an operating income budget. 6-42 Comprehensive operating budget. Skulas, Inc., manufactures and sells snowboards. Skulas manufactures a single model, the Pipex. In late 2017, Skulas’s management accountant gathered the following data to prepare budgets for January 2018: Skulas’s CEO expects to sell 2,900 snowboards during January 2018 at an estimated retail price of $650 per board. Further, the CEO expects 2018 beginning inventory of 500 snowboards and would like to end January 2018 with 200 snowboards in stock. Variable manufacturing overhead is $7 per direct manufacturing labor-hour. There are also $81,000 in fixed manufacturing overhead costs budgeted for January 2018. Skulas combines both variable and fixed manufacturing overhead into a single rate based on direct manufacturing labor-hours. Variable marketing costs are allocated at the rate of $250 per sales visit. The marketing plan calls for 38 sales visits during January 2018. Finally, there are $35,000 in fixed nonmanufacturing costs budgeted for January 2018. Other data include: The inventoriable unit cost for ending finished-goods inventory on December 31, 2017, is $374.80. Assume Skulas uses a FIFO inventory method for both direct materials and finished goods. Ignore work in process in your calculations. Required: 1. Prepare the January 2018 revenues budget (in dollars). 2. Prepare the January 2018 production budget (in units). 3. Prepare the direct material usage and purchases budgets for January 2018. 4. Prepare a direct manufacturing labor costs budget for January 2018. 6-45 Prepare a manufacturing overhead costs budget for January 2018. What is the budgeted manufacturing overhead rate for January 2018? What is the budgeted manufacturing overhead cost per output unit in January 2018? Calculate the cost of a snowboard manufactured in January 2018. Prepare an ending inventory budget for both direct materials and finished goods for January 2018. 10. Prepare a cost of goods sold budget for January 2018. 11. Prepare the budgeted income statement for Skulas, Inc., for January 2018. 12. What questions might the CEO ask the management team when reviewing the budget? Should the CEO set stretch targets? Explain briefly. 13. How does preparing the budget help Skulas’s management team better manage the company? 5. 6. 7. 8. 9. SOLUTION (60 min.) Comprehensive operating budget, budgeted balance sheet. 1. Schedule 1: Revenues Budget for January 2018 Units Selling Price Snowboards 2. 2,900 $650 $1,885,000 Schedule 2: Production Budget (in Units) for January 2018 Snowboards 2,900 200 3,100 500 2,600 Budgeted unit sales (Schedule 1) Add target ending finished goods inventory Total requirements Deduct beginning finished goods inventory Units to be produced 3. Total Revenues Schedule 3A: Direct Materials Usage Budget for January 2018 Wood Total Fiberglass Physical Units Budget Wood: 2,600 × 9 b.f. Fiberglass: 2,600 × 10 yards To be used in production Cost Budget Available from beginning inventory Wood: 2,040 b.f. × $32.00 Fiberglass: 1,040 b.f. × $8.00 To be used from purchases this period Wood: (23,400 – 2,040) × $34.00 Fiberglass: (26,000 – 1,040) × $9.00 Total cost of direct materials to be used 23,400 _______ 23,400 26,000 26,000 $ 65,280 $ 726,240 _______ $791,520 8,320 224,640 $232,960 $1,024,480 Schedule 3B: Direct Materials Purchases Budget for January 2018 Wood Physical Units Budget Production usage (from Schedule 3A) 23,400 6-46 Fiberglass 26,000 Total Add target ending inventory Total requirements Deduct beginning inventory Purchases Cost Budget Wood: 22,900 × $34.00 Fiberglass: 27,000 × $9.00 Purchases 1,540 24,940 2,040 22,900 2,040 28,040 1,040 27,000 $778,600 ________ $778,600 $243,000 $243,000 6-47 $1,021,600 4. Schedule 4: Direct Manufacturing Labor Budget for January 2018 Labor Category Manufacturing labor 5. Cost Driver Units 2,600 DML Hours per Driver Unit 5.00 Total Hours 13,000 Wage Rate $29.00 Total $377,000 Schedule 5: Manufacturing Overhead Budget for January 2018 At Budgeted Level of 13,000 Direct Manufacturing Labor-Hours Variable manufacturing overhead costs ($7.00 × 13,000) Fixed manufacturing overhead costs Total manufacturing overhead costs 6. 7. 8. $ 91,000 81,000 $172,000 $172,000 = $13.23 per hour 13,000 $172,000 Budgeted manufacturing overhead cost per output unit: = $66 per output unit 2,600 Schedule 6A: Computation of Unit Costs of Manufacturing Finished Goods in January 2018 Budgeted manufacturing overhead rate: Direct materials Wood Fiberglass Direct manufacturing labor Total manufacturing overhead Cost per Unit of Inputa Inputsb $34.00 9.00 29.00 9.00 10.00 5.00 Total $306.00 90.00 145.00 66.00 $607.00 a Cost is per board foot, yard, or per hour Inputs is the amount of each input per board b 9. Schedule 6B: Ending Inventories Budget, January 31, 2018 Direct materials Wood Fiberglass Finished goods Snowboards Total Ending Inventory Units Cost per Unit Total 1,540 2,040 $ 34.00 9.00 $ 52,360 18,360 200 607.00 121,400 $192,120 6-48 10. Schedule 7: Cost of Goods Sold Budget for January 2018 From Schedule Beginning finished goods inventory January 1, 2018, $374.80 × 500 Given Direct materials used 3A $1,024,480 Direct manufacturing labor 4 377,000 Manufacturing overhead 5 172,000 Cost of goods manufactured Cost of goods available for sale Deduct ending finished goods inventory, January 31, 2018 6B Cost of goods sold 11. Budgeted Income Statement for Skulas for January 2018 Revenues Schedule 1 Cost of goods sold Schedule 7 Gross margin Operating costs Variable marketing costs ($250 × 38) $ 9,500 Fixed nonmanufacturing costs 35,000 Operating income Total $ 187,400 1,573,480 1,760,880 121,400 $1,639,480 $1,885,000 1,639,480 245,520 44,500 $ 201,020 13. The CEO would want to probe if the revenue budget is sufficiently stretched. Is the revenue growing faster than the market? Should the company increase marketing and advertising spending to grow sales? Would increasing the sales force or giving salespersons stronger incentives result in higher sales? The CEO would want to ask the production manager if production could be more closely tailored to demand? Could the efficiency and productivity of direct materials and direct manufacturing labor be increased? Could direct materials inventory be reduced? The CEO should set stretch targets that are challenging but achievable because creating some performance anxiety motivates employees to exert extra effort and attain better performance. A major rationale for stretch targets is the psychological motivation that comes from loss aversion—people feel the pain of loss more than the joy of success. Setting challenging targets motivates employees to reach these targets because failing to achieve a target is seen as failing. At no point should the pressure for performance push employees to engage in illegal or unethical practices. So, while setting stretch targets, the CEO must place great emphasis on adhering to codes of conduct and following appropriate norms and values. The CEO should also not set targets that are very difficult or impossible to achieve. Such targets demotivate employees because they give up on trying to achieve them. 14. Preparing a budget helps Skulas manage costs based on revenues and production needs, look for opportunities to increase efficiencies, reduce costs, particularly in areas where costs are high, coordinate and communicate across different parts of the organization, create a framework for judging performance and facilitating learning, and motivate management and employees to achieve “stretch” targets of higher revenues and lower costs. 6-49 6-43 Cash budgeting, budgeted balance sheet. (Continuation of 6-42) (Appendix) Refer to the information in Problem 6-42. Budgeted balances at January 31, 2018 are as follows: Selected budget information for December 2017 follows: Customer invoices are payable within 30 days. From past experience, Skulas’s accountant projects 40% of invoices will be collected in the month invoiced, and 60% will be collected in the following month. Accounts payable relates only to the purchase of direct materials. Direct materials are purchased on credit with 50% of direct materials purchases paid during the month of the purchase, and 50% paid in the month following purchase. Fixed manufacturing overhead costs include $64,000 of depreciation costs and fixed nonmanufacturing overhead costs include $10,000 of depreciation costs. Direct manufacturing labor and the remaining manufacturing and nonmanufacturing overhead costs are paid monthly. All property, plant, and equipment acquired during January 2018 were purchased on credit and did not entail any outflow of cash. There were no borrowings or repayments with respect to long-term liabilities in January 2018. On December 15, 2017, Skulas’s board of directors voted to pay a $160,000 dividend to stockholders on January 31, 2018. Required: 1. Prepare a cash budget for January 2018. Show supporting schedules for the calculation of collection of receivables and payments of accounts payable, and for disbursements for fixed manufacturing and nonmanufacturing overhead. 2. Skulas is interested in maintaining a minimum cash balance of $120,000 at the end of each month. Will Skulas be in a position to pay the $160,000 dividend on January 31? 3. Why do Skulas’s managers prepare a cash budget in addition to the revenue, expenses, and operating income budget? 4. Prepare a budgeted balance sheet for January 31, 2018 by calculating the January 31, 2018 balances in (a) cash (b) accounts receivable (c) inventory (d) accounts payable and (e) plugging in the balance for stockholders’ equity. SOLUTION (30 min.) Cash budgeting, chapter appendix. 6-50 1. Cash Collections from Receivables From sales in: December7 (60% $1,650,000) January (40% $1,885,000) Total $ 990,000 754,000 $1,744,000 Cash Disbursements for Material Purchases For purchases in: December (50% × $820,000) January (50% × $1,021,600a) Total $410,000 510,800 $920,800 a 6-37, Schedule 3B Cash Disbursements for Fixed Overhead Costs Fixed manufacturing overhead ($81,000b – $64,000) Fixed nonmanufacturing overhead ($35,000c – $10,000) Total $17,000 25,000 $42,000 b 6-42, Schedule 5 6-42, Budgeted Income Statement c Cash Budget for January 2018 Beginning cash balance $ 124,000 Add receipts: Collection of receivables Total cash available 1,744,000 $1,868,000 Deduct disbursements: Material purchases Direct manufacturing labor Variable manufacturing overhead Fixed manufacturing overhead Variable marketing costs Fixed nonmanufacturing costs Cash dividends Total disbursements Ending cash balance $ 920,800 377,000 91,000 17,000 9,500 25,000 160,000 1,600,300 $ 267,700 2. Yes. Skulas has a budgeted cash balance of $267,700 on January 31, 2018, after paying the dividend of $160,000 at the end of January. 6-51 3. Skulas’ managers prepare a cash budget in addition to the operating income budget to plan cash flows to ensure that the company has adequate cash to pay vendors, meet payroll, and pay operating expenses as these payments come due. Skulas could be very profitable on an accrual accounting basis, but the pattern of cash receipts from revenues might be delayed and result in insufficient cash being available to make scheduled payments for its expenses. Skulas’ managers may then need to initiate a plan to borrow money to finance any shortfall. Building a profitable operating plan does not guarantee that adequate cash will be available, so Skulas’ managers need to prepare a cash budget in addition to an operating income budget. 4. Budgeted Balance Sheet for Skulas as of January 31, 2018 Cash $ 267,700 Accounts receivable (60% × $1,885,000) 1,131,000 Inventory Schedule 6B 192,120 Property, plant, and equipment (net) 1,175,600 Total assets $2,766,420 Accounts Payable Long-term liabilities Stockholders’ equity Total liabilities and stockholders’ equity $ 510,800 182,000 2,073,620 $2,766,420 6-44 Comprehensive problem; ABC manufacturing, two products. Hazlett, Inc., operates at capacity and makes plastic combs and hairbrushes. Although the combs and brushes are a matching set, they are sold individually and so the sales mix is not 1:1. Hazlett’s management is planning its annual budget for fiscal year 2018. Here is information for 2018: Hazlett accounts for direct materials using a FIFO cost flow. 6-52 Hazlett uses a FIFO cost-flow assumption for finished-goods inventory. Combs are manufactured in batches of 200, and brushes are manufactured in batches of 100. It takes 20 minutes to set up for a batch of combs and 1 hour to set up for a batch of brushes. Hazlett uses activity-based costing and has classified all overhead costs as shown in the following table. Budgeted fixed overhead costs vary with capacity. Hazlett operates at capacity so budgeted fixed overhead cost per unit equals the budgeted fixed overhead costs divided by the budgeted quantities of the cost allocation base. Delivery trucks transport units sold in delivery sizes of 1,000 combs or 1,000 brushes. Do the following for the year 2018: Required: 1. Prepare the revenues budget. 2. Use the revenues budget to: a. Find the budgeted allocation rate for marketing costs. b. Find the budgeted number of deliveries and allocation rate for distribution costs. 3. Prepare the production budget in units. 4. Use the production budget to: a. Find the budgeted number of setups and setup-hours and the allocation rate for setup costs. b. Find the budgeted total machine-hours and the allocation rate for processing costs. c. Find the budgeted total units produced and the allocation rate for inspection costs. 5. Prepare the direct material usage budget and the direct material purchases budget in both units and dollars; round to whole dollars. 6. Use the direct material usage budget to find the budgeted allocation rate for materialshandling costs. 7. Prepare the direct manufacturing labor cost budget. 8. Prepare the manufacturing overhead cost budget for materials handling, setup, processing, and inspection costs. 9. Prepare the budgeted unit cost of ending finished-goods inventory and ending inventories budget. 10. Prepare the cost of goods sold budget. 11. Prepare the nonmanufacturing overhead costs budget for marketing and distribution. 6-53 12. Prepare a budgeted income statement (ignore income taxes). 13. How does preparing the budget help Hazlett’s management team better manage the company? SOLUTION (60 min.) Comprehensive problem; ABC manufacturing, two products. 1. Revenues Budget For the Year Ending December 31, 2018 Combs Brushes Total Units 12,000 14,000 Selling Price $ 9 $30 Total Revenues $108,000 420,000 $528,000 2a. Total budgeted marketing costs = Budgeted variable marketing costs + Budgeted fixed marketing costs = $21,150 + $90,000 = $111,150 Marketing allocation rate = $111,150 ÷ $528,000 = $0.2105 per sales dollar 2b. Total budgeted distribution costs = Budgeted variable distribn. costs + Budgeted fixed distribn. costs = $0 + $1,170 = $1,170 Combs: Brushes: Total 12,000 units ÷ 1,000 units per delivery 14,000 units ÷ 1,000 units per delivery 12 deliveries 14 deliveries 26 deliveries Delivery allocation rate = $1,170 ÷ 26 deliveries = $45 per delivery 3. Production Budget (in Units) For the Year Ending December 31, 2018 Product Combs Brushes Budgeted unit sales 12,000 14,000 Add target ending finished goods inventory 1,200 1,400 Total required units 13,200 15,400 Deduct beginning finished goods inventory 600 1,200 Units of finished goods to be produced 12,600 14,200 4a. Machine setup overhead Units to be produced Combs Brushes 12,600 14,200 6-54 Total Units per batch Number of setups Hours to setup per batch Total setup hours ÷200 63 ×1/3 21 ÷100 142 ×1 142 163 Total budgeted setup costs = Budgeted variable setup costs + Budgeted fixed setup costs = $10,245 + $16,650 = $26,895 Machine setup allocation rate = $26,895 ÷ 163 setup hours = $165 per setup hour b. Combs: Brushes: Total 12,600 units × 0.025 MH per unit 14,200 units × 0.1 MH per unit 315 MH 1,420 MH 1,735 MH Total budgeted processing costs = Budgeted variable processing costs + Budgeted fixed processing costs = $11,640 + $30,000 = $41,640 Processing allocation rate = $41,640 ÷ 1,735 MH = $24 per MH c. Total budgeted inspection costs = Budgeted variable inspection costs + Budgeted fixed inspection costs = $10,500 + $1,560 = $12,060 Inspection allocation rate = $12,060 ÷ 26,800 units = $0.45 per unit 6-55 5. Direct Material Usage Budget in Quantity and Dollars For the Year Ending December 31, 2018 Plastic Physical Units Budget Direct materials required for Combs (12,600 units × 5 oz and 0 bunches) Brushes (14,200 units × 8 oz and 16 bunches) Total quantity of direct materials to be used Material Bristles Total 63,000 oz. 113,600 oz. 227,200 bunches 176,600 oz. 227,200 bunches Cost Budget Available from beginning direct materials inventory (under a FIFO cost-flow assumption) $ 456 To be purchased this period Plastic: (176,600 oz. – 1,600 oz) × $0.30 per oz. 52,500 Bristles: (227,200 bunches – 1,820) × $0.75 per bunch _______ Direct materials to be used this period $52,956 $ 1,419 169,035 $170,454 $223,410 Direct Materials Purchases Budget For the Year Ending December 31, 2018 Plastic Material Bristles Physical Units Budget To be used in production (requirement 5) Add: Target ending direct material inventory Total requirements Deduct: Beginning direct material inventory Purchases to be made 176,600 oz. 227,200 bunches 1,766 oz. 2,272 bunches 178,366 oz. 229,472 bunches 1,600 oz. 1,820 bunches 176,766 oz. 227,652 bunches Cost Budget Plastic: 176,766 oz. $0.30 per oz Bristles : 227,652 bunches $0.75 per bunch Purchases $ 53,030 _______ $ 53,030 $170,739 $170,739 Total $223,769 6. Total budgeted matls. handlg. cost = Budgeted variable matls. handlg. cost + Budgeted fixed matls. handlg. cost = $17,235 + $22,500 = $39,735 Materials handling allocation rate = $39,735 ÷ 176,600 oz = $0.225 per oz. of plastic 6-56 7. Direct Manufacturing Labor Costs Budget For the Year Ending December 31, 2018 Output Units Produced 12,600 14,200 Combs Brushes Total Direct Manufacturing Labor-Hours per Unit 0.05 0.2 Total Hourly Wage Hours Rate 630 $18 2,840 18 Total $11,340 51,120 $62,460 8. Manufacturing Overhead Cost Budget For the Year Ending December 31, 2018 Materials handling Machine setup Processing Inspection Total Variable $17,235 10,245 11,640 10,500 $49,620 Fixed $22,500 16,650 30,000 1,560 $70,710 Total $ 39,735 26,895 41,640 12,060 $120,330 9. Unit Costs of Ending Finished Goods Inventory For the Year Ending December 31, 2018 Plastic Bristles Direct manufacturing labor Materials handling Machine setup Processing Inspection Totals Cost per Unit of Input $0.30 0.75 18.00 0.225 165.00 24.00 0.45 Combs Input per Unit of Output 5 oz. ─ 0.05 hrs. 5 oz. 0.001667 hrs.a 0.025 MH 1 unit Total $1.50 ─ 0.90 1.125 0.275 0.60 0.45 $4.85 Brushes Input per Unit of Output Total 8 oz $ 2.40 16 bunches 12.00 0.2 hour 3.60 8 oz 1.80 0.01 setup-hra 1.65 0.1 MH 2.40 1 unit 0.45 $24.30 a 21 setup-hours ÷ 12,600 units = 0.001667 hours per unit; 142 setup hours ÷ 14,200 units = 0.01 hours per unit Ending Inventories Budget December 31, 2018 Quantity Direct Materials Plastic Bristles Finished goods Combs Brushes Total ending inventory Cost per unit 1,766 oz 2,272 bunches 1,200 1,400 6-57 Total $0.30 0.75 $ 529.80 1,704.00 $4.85 24.30 $ 5,820.00 34,020.00 $ 2,233.80 39,840.00 $42,073.80 10. Cost of Goods Sold Budget For the Year Ending December 31, 2018 Beginning finished goods inventory, Jan. 1 ($2,700 + $27,180) Direct materials used (requirement 5) $223,410 Direct manufacturing labor (requirement 7) 62,460 Manufacturing overhead (requirement 8) 120,330 Cost of goods manufactured Cost of goods available for sale Deduct: Ending finished goods inventory, December 31 (reqmt. 9) Cost of goods sold $ 29,880 406,200 436,080 39,840 $396,240 11. Nonmanufacturing Costs Budget For the Year Ending December 31, 2018 Marketing Distribution Total Variable $21,150 0 $21,150 Fixed $90,000 1,170 $91,170 Total $111,150 1,170 $112,320 12. Budgeted Income Statement For the Year Ending December 31, 2018 Revenue $528,000 Cost of goods sold 396,240 Gross margin 131,760 Operating (nonmanufacturing) costs 112,320 Operating income $ 19,440 13. Preparing a budget helps Hazlett manage costs based on revenues and production needs, look for opportunities to increase efficiencies, reduce costs, particularly in areas where costs are high, coordinate and communicate across different parts of the organization, create a framework for judging performance and facilitating learning, and motivate management and employees to achieve “stretch” targets of higher revenues and lower costs. 6-45 Cash budget. (Continuation of 6-44) (Appendix) Refer to the information in Problem 6-44. All purchases made in a given month are paid for in the following month, and direct material purchases make up all of the accounts payable balance and are reflected in the accounts payable balances at the beginning and the end of the year. Sales are made to customers with terms net 45 days. Fifty percent of a month’s sales are collected in the month of the sale, 25% are collected in the month following the sale, and 25% are collected two months after the sale and are reflected in the accounts receivables balances at the beginning and the end of the year. 6-58 Direct manufacturing labor, variable manufacturing overhead and variable marketing costs are paid as they are incurred. Fifty percent of fixed manufacturing overhead costs, 60% of fixed marketing costs, and 100% of fixed distribution costs are depreciation expenses. The remaining fixed manufacturing overhead and marketing costs are paid as they are incurred. Selected balances for December 31, 2017, follow: Selected budget information for December 2018 follows: Hazlett has budgeted to purchase equipment costing $145,000 for cash during 2018. Hazlett desires a minimum cash balance of $25,000. The company has a line of credit from which it may borrow in increments of $1,000 at an interest rate of 12% per year. By special arrangement, with the bank, Hazlett pays interest when repaying the principal, which only needs to be repaid in 2019. Required: 1. Prepare a cash budget for 2018. If Hazlett must borrow cash to meet its desired ending cash balance, show the amount that must be borrowed. 2. Does the cash budget for 2018 give Hazlett’s managers all of the information necessary to manage cash in 2018? How might that be improved? 3. What insight does the cash budget give to Hazlett’s managers that the budgeted income statement does not? SOLUTION Cash budget (Continuation of 6-44) Cash Budget for 2018 Beginning cash balance Add receipts: Collections from customersa Total cash available 519,500 $ 548,700 Deduct disbursements: Material purchasesb Direct manufacturing labor Variable manufacturing overhead Fixed manufacturing overheadc Variable marketing costs Fixed marketing costsd Equipment purchase Total disbursements Excess or (deficiency) of cash $ 217,449 62,460 49,620 35,355 21,150 36,000 145,000 567,034 (18,334) 6-59 $ 29,200 Need to borrow Ending cash balance $ 44,000 25,666 a $40,000 beg. accounts receivable + $528,000 sales in 2018 - $48,500 ending accounts receivable = $519,500 disbursed b $21,450 beg. accounts payable + $223,769 direct material purchases - $27,770 ending accounts payable = $217,449 disbursed c $70,710 fixed manufacturing overhead – (50% × $70,710) depreciation = $35,355 disbursed d $90,000 fixed marketing overhead – (60% × $90,000) depreciation = $36,000 disbursed 2. The cash budget for 2018 does not show when during the year the equipment will be purchased. As a result, Hazlett’s managers do not know when to plan to borrow the $44,000 to achieve the minimum ending cash balance at the end of the year. It could be improved by preparing a cash budget for each month of the year. The problem did not present the data in such a way to make that possible here, but an actual company would have sufficient information. 3. Hazlett’s managers prepare a cash budget in addition to the operating income budget to plan cash flows to ensure that the company has adequate cash to pay vendors, meet payroll, and pay operating expenses as these payments come due. Hazlett could be very profitable on an accrual accounting basis, but the pattern of cash receipts from revenues might be delayed and result in insufficient cash being available to make scheduled payments for its expenses. Hazlett’s managers may then need to initiate a plan to borrow money to finance any shortfall. Building a profitable operating plan does not guarantee that adequate cash will be available, so Hazlett’s managers need to prepare a cash budget in addition to an operating income budget. 6-46 Budgeting and ethics. Jayzee Company manufactures a variety of products in a variety of departments and evaluates departments and departmental managers by comparing actual cost and output relative to the budget. Departmental managers help create the budgets and usually provide information about input quantities for materials, labor, and overhead costs. Kurt Jackson is the manager of the department that produces product Z. Kurt has estimated these inputs for product Z: The department produces about 100 units of product Z each day. Kurt’s department always gets excellent evaluations, sometimes exceeding budgeted production quantities. For each 100 units of product Z produced, the company uses, on average, about 48 hours of direct manufacturing labor (eight people working 6 hours each), 790 pounds of material, and 39.5 machine-hours. Top management of Jayzee Company has decided to implement budget standards that will challenge the workers in each department, and it has asked Kurt to design more challenging input standards for product Z. Kurt provides top management with the following input quantities: Required: 6-60 Discuss the following: 1. Are these budget standards challenging for the department that produces product Z? 2. Why do you suppose Kurt picked these particular standards? 3. What steps can Jayzee Company’s top management take to make sure Kurt’s standards really meet the goals of the firm? SOLUTION (15 min.) Budgeting and ethics. 1. The standards proposed by Kurt are not challenging. In fact, he set the target at the level his department currently achieves. Direct materials: 7.9 lbs. × 100 units = 790 lbs. Direct manufacturing labor: 29 min. × 100 units = 2,900 min ÷ 60 = 48.33 hrs. Machine time: 23.6 min. × 100 units = 2,360 min. ÷ 60 = 39.33 hrs. approx 2. Kurt probably chose these standards so that his department would be able to make the goal and receive any resulting reward. With a little effort, his department can likely beat these goals. 3. Top management should point out that the targets set by Kurt are targets that the department already achieves. Top management is seeking targets that are slightly difficult to achieve, a stretch target that would challenge workers. As discussed in the chapter, benchmarking might also be used to highlight the easy targets set by Kurt and to determine more challenging targets. Perhaps the organization has multiple plant locations that could be used as comparisons. Alternatively, management could use industry averages. Also, management should work with Kurt to better understand his department and encourage him to set more realistic targets. Finally, the reward structure should be designed to encourage increasing productivity, not beating the budget. Management could also set continuous improvement standards. 6-47 Kaizen budgeting for carbon emissions. Apex Chemical Company currently operates three manufacturing plants in Colorado, Utah, and Arizona. Annual carbon emissions for these plants in the first quarter of 2018 are 125,000 metric tons per quarter (or 500,000 metric tons in 2018). Apex management is investigating improved manufacturing techniques that will reduce annual carbon emissions to below 475,000 metric tons so that the company can meet Environmental Protection Agency guidelines by 2019. Costs and benefits are as follows: Total cost to reduce carbon emissions $10 per metric ton reduced in 2019 below 500,000 metric tons Fine in 2019 if EPA guidelines are not met $300,000 Apex Management has chosen to use Kaizen budgeting to achieve its goal for carbon emissions. Required: 1. If Apex reduces emissions by 1% each quarter, beginning with the second quarter of 2018, will the company reach its goal of 475,000 metric tons by the end of 2019? 6-61 2. What would be the net financial cost or benefit of their plan? Ignore the time value of money. 3. What factors other than cost might weigh into Apex’s decision to carry out this plan? SOLUTION (30 min.) Kaizen budgeting for carbon emissions. 1. Yes, the company would achieve its goal. Total carbon emissions for 2019 are calculated in the following table. Each quarter’s emissions are 99% of the previous quarter’s emissions since Apex reduces emissions by 1% each quarter. Total emissions in 2019 would be 120,075 + 118,874 + 117,685 + 116,508 = 473,142 metric tons, which is below the Environmental Protection Agency (EPA) guideline of 475,000 metric tons. Quarter 2018 Q1 2018 Q2 2018 Q3 2019 Q4 2019 Q1 2019 Q2 2019 Q3 2019 Q4 Quarterly Emissions 125,000 metric tons 123,750a metric tons 122,513b metric tons 121,287 metric tons 120,075 metric tons 118,874 metric tons 117,685 metric tons 116,508 metric tons a 123,750 = 125,000 × 0.99; b122,513 = 123,750 × 0.99 2. Apex’s emissions are below the EPA guideline of 475,000 metric tons. Consequently the EPA will not assess Apex a fine of $300,000. Current annual emissions Emissions in 2019 Reduction in emissions 500,000 metric tons 473,142 metric tons 26,858 metric tons Fine avoided Cost at $10 per metric ton reduction, 26,858 × $10 Net benefit of plan $300,000 268,580 $ 31,420 3. While this plan would benefit Apex marginally by $31,420, avoidance of the EPA fine should not be the company’s sole motivation in carrying out this plan. Reducing carbon emissions is good for the environment, and will contribute to a smaller impact on climate change. Research has shown that good environmental and sustainability practices has positive effects on investors, consumers, and employees. Apex may also be able to share this plan with the general population and gain favorable publicity. Apex may want to continue to reduce carbon emissions if they have the technology to do so. 6-62 6-48 Comprehensive budgeting problem; activity-based costing, operating and financial budgets. Tyva makes a very popular undyed cloth sandal in one style, but in Regular and Deluxe. The Regular sandals have cloth soles and the Deluxe sandals have cloth-covered wooden soles. Tyva is preparing its budget for June 2018 and has estimated sales based on past experience. Other information for the month of June follows: Tyva accounts for direct materials using a FIFO cost-flow assumption. Tyva uses a FIFO cost-flow assumption for finished-goods inventory. All the sandals are made in batches of 50 pairs of sandals. Tyva incurs manufacturing overhead costs, marketing and general administration, and shipping costs. Besides materials and labor, manufacturing costs include setup, processing, and inspection costs. Tyva ships 40 pairs of sandals per shipment. Tyva uses activity-based costing and has classified all overhead costs for the month of June as shown in the following chart: 6-63 Required: 1. Prepare each of the following for June: a. Revenues budget b. Production budget in units c. Direct material usage budget and direct material purchases budget in both units and dollars; round to dollars d. Direct manufacturing labor cost budget e. Manufacturing overhead cost budgets for setup, processing, and inspection activities f. Budgeted unit cost of ending finished-goods inventory and ending inventories budget g. Cost of goods sold budget h. Marketing and general administration and shipping costs budget 2. Tyva’s balance sheet for May 31 follows. Use the balance sheet and the following information to prepare a cash budget for Tyva for June. Round to dollars. • All sales are on account; 60% are collected in the month of the sale, 38% are collected the following month, and 2% are never collected and written off as bad debts. • All purchases of materials are on account. Tyva pays for 80% of purchases in the month of purchase and 20% in the following month. • All other costs are paid in the month incurred, including the declaration and payment of a $15,000 cash dividend in June. • Tyva is making monthly interest payments of 0.5% (6% per year) on a $150,000 long-term loan. • Tyva plans to pay the $10,800 of taxes owed as of May 31 in the month of June. Income tax expense for June is zero. • 30% of processing, setup, and inspection costs and 10% of marketing and general administration and shipping costs are depreciation. 6-64 3. Prepare a budgeted income statement for June and a budgeted balance sheet for Tyva as of June 30, 2018. SOLUTION (60 min.) Comprehensive budgeting problem; activity-based costing, operating and financial budgets. 1a. Revenues Budget For the Month of June, 2018 Regular Deluxe Total Units Selling Price Total Revenues 2,000 $120 $240,000 3,000 195 585,000 $825,000 b. Production Budget For the Month of June, 2018 Budgeted unit sales Add: target ending finished goods inventory Total required units Deduct: beginning finished goods inventory Units of finished goods to be produced Product Regular Deluxe 2,000 3,000 400 600 2,400 3,600 250 650 2,150 2,950 c. Direct Material Usage Budget in Quantity and Dollars For the Month of June, 2018 Material Cloth Wood Physical Units Budget Direct materials required for Regular (2,150 units × 1.3 yd.; 0 b.f.) Deluxe (2,950 units × 1.5 yds.; 2 b.f.) Total quantity of direct materials to be used Total 2,795 yds. 0 b.f. 4,425 yds. 5,900 b.f. 7,220 yds. 5,900 b.f. Cost Budget Available from beginning direct materials inventory (under a FIFO cost-flow assumption) To be purchased this period Cloth: (7,220 yd. – 610 yd.) × $5.25 per yd. Wood: (5,900 – 800) × $7.50 per b. f. Direct materials to be used this period 6-65 $ 3,219 $ 6,060 34,703 $37,922 38,250 $44,310 $82,232 Direct Materials Purchases Budget For the Month of June, 2018 Material Cloth Wood Physical Units Budget To be used in production Add: Target ending direct material inventory Total requirements Deduct: beginning direct material inventory Purchases to be made Cost Budget Cloth: (6,996 yds. × $5.25 per yd.) Wood: (5,395 ft × $7.50 per b.f.) Total 7,220 yds. 386 yds. 7,606 yds. 610 yds. 6,996 yds. $36,729 ______ $36,729 Total 5,900 ft 295 ft 6,195 ft 800 ft 5,395 ft $40,463 $40,463 $77,192 d. Direct Manufacturing Labor Costs Budget For the Month of June, 2018 Regular Deluxe Total Output Units Produced 2,150 2,950 Direct Manufacturing Labor-Hours per Unit 5 7 Total Hourly Wage Hours Rate 10,750 $15 20,650 15 31,400 Total $161,250 309,750 $471,000 e. Manufacturing Overhead Costs Budget For the Month of June 2018 Total Machine setup (Regular, 43 batchesa × 2 hrs./batch + Deluxe, 59 batchesb × 3 hrs./batch) $18/hour Processing (31,400 DMLH $1.80) Inspection [(2,150 + 2,950) pairs $1.35 per pair] Total a Regular: 2,150 pairs ÷ 50 pairs per batch = 43; bDeluxe: 2,950 pairs ÷ 50 pairs per batch = 59 6-66 $ 4,734 56,520 6,885 $68,139 f. Cloth Wood Direct manufacturing labor Machine setup Processing Inspection Total a b Unit Costs of Ending Finished Goods Inventory For the Month of June, 2018 Regular Deluxe Cost per Input per Input per Unit of Input Unit of Output Total Unit of Output Total $ 5.25 1.3 yd $ 6.83 1.5 yd $ 7.88 7.50 0 b.f. 0.00 2 b.f. 15.00 15.00 5 hr. 75.00 7 hrs. 105.00 18.00 0.04 hra 0.72 0.06 hrb 1.08 1.80 5 hrs 9.00 7 hrs 12.60 1.35 1 pair 1.35 1 pair 1.35 $92.90 $142.91 2 hours per setup ÷ 50 pairs per batch = 0.04 hr. per unit 3 hours per setup ÷ 50 pairs per batch = 0.06 hr. per unit Ending Inventories Budget June, 2018 Quantity Direct Materials Cloth Wood Cost per unit 386 yards 295 b.f. Finished goods Regular Deluxe Total ending inventory 400 600 Total $5.25 7.50 $2,026.50 2,212.50 $ 92.90 142.91 $37,160 85,746 $ 4,239 122,906 $127,145 g. Cost of Goods Sold Budget For the Month of June, 2018 Beginning finished goods inventory, June 1 ($23,250 + $92,625) Direct materials used (requirement c) Direct manufacturing labor (requirement d) Manufacturing overhead (requirement e) Cost of goods manufactured Cost of goods available for sale Deduct ending finished goods inventory, June 30 (requirement f) Cost of goods sold $115,875 $ 82,232 471,000 68,139 621,371 737,246 122,906 $614,340 h. Nonmanufacturing Costs Budget For the Month of June, 2018 Total Marketing and general administration 8% × $825,000 Shipping (5,000 pairs ÷ 40 pairs per shipment) × $15 Total 2. 6-67 $66,000 1,875 $67,875 Cash Budget June 30, 2018 Cash balance, June 1 (from Balance Sheet) Add receipts Collections from May accounts receivable Collections from June accounts receivable ($825,000 60%) $ 9,435 307,800 495,000 Total collection from customers Total cash available for needs (x) Deduct cash disbursements Direct material purchases in May Direct material purchases in June ($77,192 80%) Direct manufacturing labor Manufacturing overhead ($68,139 70% because 30% is depreciation) Nonmanufacturing costs ($67,875 90% because 10% is depreciation) Taxes Dividends Total disbursements (y) Financing Interest at 6% ($150,0006% 1 ÷ 12) (z) Ending cash balance, June 30 (x) – (y) – (z) 802,800 $812,235 $ 15,600 61,754 471,000 47,697 61,088 10,800 15,000 $682,939 $ 750 $128,546 3. Budgeted Income Statement For the Month of June, 2018 Revenues $825,000 16,500 Bad debt expense ($825,000 2%) Net revenues Cost of goods sold Gross margin Operating (nonmanufacturing) costs $67,875 Interest expense (for June) 750 Net income $808,500 614,340 194,160 68,625 $125,535 Budgeted Balance Sheet June 30, 2018 Assets Cash Accounts receivable ($825,000 × 40%) Less: allowance for doubtful accounts Inventories Direct materials Finished goods $ 128,546 $330,000 16,500 $ 6-68 4,239 122,906 313,500 127,145 Fixed assets Less: accumulated depreciation ($136,335 + $68,13930% + $67,875 × 10%)) Total assets Liabilities and Equity Accounts payable ($77,192 × 20%) Interest payable Long-term debt Common stock Retained earnings ($698,904 + $125,535 – $15,000)) Total liabilities and equity $870,000 163,564 706,436 $1,275,627 $ 15,438 750 150,000 300,000 809,439 $1,275,627 Try It 6-1 Solution Knox Ayer Total Schedule 1: Revenues Budget for the Year Ending December 31, 2017 Units Selling Price Total Revenues 21,000 $25 $525,000 10,000 40 400,000 $925,000 Schedule 2: Production Budget (in Units) for the Year Ending December 31, 2017 Product Knox Ayer Budgeted sales in units (Schedule 1) 21,000 10,000 Add target ending finished goods inventory 2,000 1,000 Total required units 23,000 11,000 Deduct beginning finished goods inventory 3,000 1,000 Units of finished goods to be produced 20,000 10,000 Try It 6-2 Solution Schedule 3A: Direct Material Usage Budget in Quantity and Dollars for the Year Ending December 31, 2017 Material Metal Fabric Physical Units Budget Direct materials required for Knox lamps 40,000 pounds 20,000 yards (20,000 units × 2 pounds and 1 yard) Direct materials required for Ayer lamps 30,000 pounds 15,000 yards (10,000 units × 3 pounds and 1.5 yards) Total quantity of direct materials to be used 70,000 pounds 35,000 yards Cost Budget Available from beginning direct materials inventory (under a FIFO cost-flow assumption) 6-69 Total Material (Given) Metal: 12,000 pounds × $3 per pound Fabric: 7,000 yards × $4 per yard To be purchased and used this period Metal: (70,000 – 12,000) pounds × $3 per pound Fabric:(35,000 – 7,000) yards × $4 per yard Direct materials to be used this period $ 36,000 $ 28,000 174,000 $210,000 112,000 $140,000 Schedule 3B: Direct Material Purchases Budget for the Year Ending December 31, 2017 Material Metal Fabric Physical Units Budget To be used in production (from Schedule 70,000 pounds 35,000 yards 3A) Add target ending inventory 10,000 pounds 5,000 yards Total requirements 80,000 pounds 40,000 yards Deduct beginning inventory 12,000 pounds 7,000 yards Purchases to be made 68,000 pounds 33,000 yards Cost Budget Metal: 68,000 pounds × $3 per pound $204,000 Fabric: 33,000 yards × $4 per yard $132,000 Direct materials to be purchased this period $204,000 $132,000 Knox Ayer Total Schedule 4: Direct Manufacturing Labor Costs Budget for the Year Ending December 31, 2017 Direct Manufacturing Output Units Labor-Hours Hourly Produced per Unit Total Hours Wage Rate (Schedule 2) 20,000 0.15 3,000 $20 10,000 0.2 2,000 20 5,000 $350,000 Total $336,000 Total $ 60,000 40,000 $100,000 Try It 6-3 Solution 1. Quantity of lamps to be produced 2. Number of lamps to be produced per batch 3. Number of batches (1) ÷ (2) 4. Setup time per batch 5. Total setup-hours (3) × (4) Knox 20,000 lamps 100 lamps/batch 200 batches 3 hours/batch 600 hours 6-70 Ayer 10,000 lamps 80 lamps/batch 125 batches 4 hours/batch 500 hours Schedule 5: Manufacturing Overhead Costs Budget for the Year Ending December 31, 2017 Machine Setup Overhead Costs Variable costs ($60 per setup-hour × 1,100 setup-hours) Fixed costs (to support capacity of 1,100 setup-hours) Total machine setup overhead costs Try It 6-4 Solution $66,000 77,000 $143,000 Schedule 6A: Budgeted Unit Costs of Ending Finished Goods Inventory December 31, 2017 Product Knox Ayer Input per Input per Unit of Unit of Cost per Unit Output Output Total of Input Metal $ 3 2 pounds. $ 6.00 3 pounds. Fabric 4 1 yard 4.00 1.5 yards Direct manufacturing labor 20 0.15 hrs. 3.00 0.2 hrs. Machine setup overhead 130 0.03 hrs. 3.90 0.05 hrs. Total $16.90 Total $ 9.00 6.00 4.00 6.50 $25.50 Under the FIFO method, managers use this unit cost to calculate the cost of target ending inventories of finished goods in Schedule 6B. Schedule 6B: Ending Inventories Budget December 31, 2017 Quantity Cost per Unit Direct materials Metal 10,000 $ 3.00 $30,000 Fabric 5,000 4.00 20,000 Finished goods Knox 2,000 $16.90 $33,800 Ayer 1,000 25.50 25,500 Total ending inventory Total $ 50,000 59,300 $109,300 Try It 6-5 Solution Schedule 7: Cost of Goods Sold Budget for the Year Ending December 31, 2017 From Schedule Beginning finished goods inventory, January 1, 2017 Given Direct materials used 3A Direct manufacturing labor 4 Manufacturing overhead 5 Cost of goods manufactured Cost of goods available for sale Deduct ending finished goods inventory, December 6B 31, 2017 6-71 Total $ 76,200 $350,000 100,000 143,000 593,000 669,200 59,300 From Schedule Total $609,900 Cost of goods sold Schedule 8: Nonmanufacturing Costs Budget for the Year Ending December 31, 2017 Business Function Variable Costs Fixed Costs Marketing (Variable cost: $925,000 0.04) $37,000 $ 43,000 45,000 40,000 Distribution (Variable cost: $1.5030,000 cu. ft.) Administration costs 0 75,000 $82,000 $158,000 Budgeted Income Statement for Jimenez Corporation for the Year Ending December 31, 2017 From Schedule Revenues Given* Cost of goods sold 7 Gross margin Operating costs Marketing costs 8 80,000 Distribution costs 8 85,000 Administration costs 8 75,000 Operating income Total Costs $ 80,000 85,000 75,000 $240,000 Total $925,000 609,900 315,100 240,000 $ 75,100 Try It 6-6 Solution Schedule of Cash Collections Quarters 1 Accounts receivable balance on 1-12017 (Fourth-quarter sales from 2016 collected in first quarter of 2017) From first-quarter 2017 sales ($230,000 0.80; $230,000 0.20) From second-quarter 2017 sales ($245,000 0.80; $245,000 0.20) From third-quarter 2017 sales ($210,000 0.80; $210,000 0.20) From fourth-quarter 2017 sales ($240,000 0.80) Total collections 2 3 4 $ 46,000 184,000 $ 46,000 196,000 $230,000 6-72 $242,000 $ 49,000 168,000 $ 42,000 $217,000 192,000 $234,000