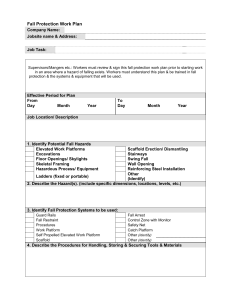

Fall Protection Systems ANSI/ASSE A10.32-2004 AMERICAN NATIONAL STANDARD ANSI/ASSE A10.32-2004 ANSI/ASSE A10.32-2004 Fall Protection Systems— American National Standard for Construction and Demolition Operations A S S E AMERICAN SOCIETY OF SAFETY ENGINEERS The information and materials contained in this publication have been developed from sources believed to be reliable. However, the American Society of Safety Engineers (ASSE) as secretariat of the ANSI accredited A10 Committee or individual committee members accept no legal responsibility for the correctness or completeness of this material or its application to specific factual situations. By publication of this standard, ASSE or the A10 Committee does not ensure that adherence to these recommendations will protect the safety or health of any persons, or preserve property. ANSI® A10.32-2004 American National Standard for Construction and Demolition Operations Fall Protection Systems Secretariat American Society of Safety Engineers 1800 East Oakton Street Des Plaines, Illinois 60018-2187 (847) 699-2929 • www.asse.org Approved May 3, 2004 American National Standards Institute, Inc. American National Standard Approval of an American National Standard requires verification by ANSI that the requirements for due process, consensus, and other criteria for approval have been met by the standards developer. Consensus is established when, in the judgment of the ANSI Board of Standards Review, substantial agreement has been reached by directly and materially affected interests. Substantial agreement means much more than a simple majority, but not necessarily unanimity. Consensus requires that all views and objections be considered, and that a concerted effort be made toward their resolution. The use of American National Standards is completely voluntary; their existence does not in any respect preclude anyone, whether he/she has approved the standards or not, from manufacturing, marketing, purchasing, or using products, processes, or procedures not conforming to the standards. The American National Standards Institute does not develop standards and will in no circumstance give an interpretation of any American National Standard. Moreover, no person shall have the right or authority to issue an interpretation of an American National Standard in the name of the American National Standards Institute. Requests for interpretation should be addressed to the secretariat or sponsor whose name appears on the title page of this standard. Caution Notice: This American National Standard may be revised or withdrawn at any time. The procedures of the American National Standards Institute requires that action be taken periodically to reaffirm, revise, or withdraw this standard. Purchasers of American National Standards may receive current information on all standards by calling or writing the American National Standards Institute. Published Jul y 2004 by American Society of Safety Engineers 1800 East Oakton Street Des Plaines, Illinois 60018-2187 (847) 699-2929 • www.asse.org Copyright © 2004 by the American Society of Safety Engineers All rights reserved No part of this publication my be reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission of the publisher. Printed in the United States of America Foreword (This Foreword is not a part of American National Standard A10.32-2004.) This standard is one of a series of safety standards that have been formulated by the Accredited Standards Committee on Safety in Construction and Demolition Operations, A10. It is expected that the standards in the A10 series will find a major application in industry, serving as a guide to contractors, labor, and equipment manufacturers. For the convenience of users, a list of existing and proposed standards in the A10 series for Safety Requirements in Construction and Demolition Operations follows. A10.2 A10.3 A10.4 A10.5 A10.6 A10.7 A10.8 A10.9 A10.10 A10.11 A10.12 A10.13 A10.15 A10.16 A10.17 A10.18 A10.19 A10.20 A10.21 A10.22 A10.23 A10.24 A10.25 A10.26 A10.27 A10.28 A10.29 A10.30 A10.31 A10.32 A10.33 A10.34 A10.35 A10.36 A10.37 A10.38 A10.39 A10.40 A10.41 A10.42 A10.43 A10.44 A10.45 A10.46 A10.47 A10.48 Safety, Health, and Environmental Training (under development) Powder-Actuated Fastening Systems Personnel Hoists and Employee Elevators Material Hoists (under development) Demolition Operations Transportation, Storage, Handling, and Use of Commercial Explosives and Blasting Agents Scaffolding Concrete and Masonry Construction Temporary and Portable Space Heating Devices Personnel and Debris Nets Excavation Steel Erection Dredging Tunnels, Shafts, and Caissons Safe Operating Practices for Hot Mix Asphalt (HMA) Construction Temporary Floor Holes, Wall Openings, Stairways, and Other Unprotected Edges Pile Installation and Extraction Operations (under development) Ceramic Tile, Terrazzo, and Marble Work Proper Cleaning and Disposal of Contaminated Work Clothing Rope-Guided and Nonguided Workers’ Hoists Back Injury Prevention Programs (under development) Roofing (under development) Sanitation in Construction (under development) Emergency Procedures for Construction Sites (under development) Hot Mix Asphalt Facilities Work Platforms Suspended from Cranes or Derricks Aerial Lifts in Construction (under development) Workplace Security Digger-Derricks Fall Protection Systems for Construction Industry Users Safety and Health Program Requirements for Multi-Employer Projects Public Protection High Pressure Hydro Blasting (under development) Railroad Construction Safety (under development) Debris Nets Basic Elements of a Program to Provide a Safe and Healthful Work Environment Construction Safety and Health Audit Program Ergonomics in Construction (under development) Equipment Operator and Supervisor Qualifications and Responsibilities (under development) Rigging Qualifications and Responsibilities in the Construction Industry Confined Spaces in Construction (under development) LockOut TagOut in Construction (under development) Disaster Response Preparedness for Construction Workers (under development) Hearing Loss Prevention (under development) Highway Construction Safety (under development) Communications Tower Erection (under development) One purpose of these standards is to serve as guides to governmental authorities having jurisdiction over subjects within the scope of the A10 Committee standards. If these standards are adopted for governmental use, the reference of other national codes or standards in individual volumes may be changed to refer to the corresponding regulations. Revisions: The A10 Committee welcomes proposals for revisions to this standard. Revisions are made to the standard periodically (usually five years from the date of the standard) to incorporate changes that appear necessary or desirable, as demonstrated by experience gained from the application of the standard. Proposals should be as specific as possible, citing the relevant paragraph number(s), the proposed wording, and the reason for the proposal. Pertinent documentation would enable the A10 Committee to process the changes in a more timely manner. Interpretations: Upon a request in writing to the Secretariat, the A10 Committee will render an interpretation of any requirement of the standard. The request for interpretation should be clear, citing the relevant paragraph number(s) and phrased as a request for a clarification of a specific requirement. Oral interpretations are not provided. No one but the A10 Committee (through the A10 Secretariat) is authorized to provide any interpretation of this standard. Approval: Neither the A10 Committee nor American National Standards Institute (ANSI) "approves," "certifies," "rates," or "endorses" any item, construction, proprietary device, or activity. Appendixes: Appendixes are included in most standards to provide the user with additional information related to the subject of the standard. Appendices are not part of the approved standard. Committee Meetings: The A10 Committee meets twice a year. Persons wishing to attend a meeting should contact the Secretariat for information. Standard Approval: This standard was processed and approved for submittal to ANSI by the American National Standards Committee on Safety in Construction and Demolition Operations, A10. Approval of the standard does not necessarily imply (nor is it required) that all Committee members voted for its approval. At the time this standard was published, the A10 Committee had the following members: Richard King, Chairman James Tomaseski, Vice Chairman Timothy R. Fisher, Secretary CSP, ARM, CPEA Patrick J. Arkins, Assistant Secretary Organization Represented Name of Representative Accident Prevention Corp. Frank Burg Michael Serpe Matthew J. Burkart, PE Judith Burkhart David Szuch Richard Sanner Robert Renney Ted P. Sharp Aegis Corporation Allegheny Power System Alstrom Power, Integrated Services American Federation of Labor and Congress of Industrial Organizations American Insurance Services Group American Society of Safety Engineers American Subcontractors Association Asbestos Workers International Union Associated Builders and Contractors Associated General Contractors of America, The Barton-Malow Company Black & Veatch Center to Protect Workers’ Rights, The Chicago Bridge & Iron Company Clark Construction Group Cole-Miller Safety Consulting, Inc. Philip L. Colleran Construction Users Roundtable, The ECI Safety Services Co. Edison Electric Institute E. I. duPont de Nemours & Company Elevator Industry Preservation Fund Gilbane Building Co. Richard D. Hislop Institute of Makers of Explosives International Association of Bridge, Structural, Ornamental and Reinforcing Iron Workers International Brotherhood of Boilermakers Jim E. Lapping, MS, P.E., CSP Edward Campbell James G. Borchardt, CSP, CPE Allen Macenski, CSP, J.D. A. David Brayton Luke McFadden Dante Pulignani, ASP Terry Lynch Jim E. Lapping, MS, P.E., CSP Michael W. Hayslip, P.E. Anita Drummond James Brown Ron Prichard, Ph.D., P.E. John Gleichman Richard F. King, CSP Paul Weida, CSP Mike McCann Pete Stafford James Rhudy Wallace K. Melvin Jack Duley Barry Cole Steve Miller Philip L. Colleran, CSP Ron G. Prichard, Ph.D., P.E. Anthony Merisola Patrick Brennan R. Lee Reed, Jr. Charles Kelly Jane Schindewolf Robert Krzywicki John Quackenbush John P. O’Donovan Carol Murkland Richard Hislop Lon D. Santis J. Christopher Ronay Frank Migliaccio, Jr. David Haggerty Bridget Conner International Brotherhood of Electrical Workers International Safety Equipment Association International Union of Operating Engineers International Union of Painters & Allied Trades Jack L. Mickle & Associates Laborers International Union of North America Maryland Occupational Safety & Health Mechanical Contractors Association of America National Association of Home Builders National Association of Railroad Safety Consultants & Investigators National Roofing Contractors Association National Society of Professional Engineers NEA – The Association of Union Constructors Operative Plasterers and Cement Masons, International Association Daniel M. Paine Power Consultants, Incorporated Professional Safety Consultants, Inc. Property Casualty Insurers Association of America Ryland Group, Inc., The Safety and Quality Plus Scaffolding, Shoring & Forming Institute Sheet Metal Workers International Association Sigma Associates, Ltd. SINCO / SALA SPA, Incorporated TIC-The Industrial Company Turner Construction Company United Association of Plumbers and Pipefitters United Brotherhood of Carpenters and Joiners of America United Union of Roofers, Waterproofers and Allied Workers U.S. Department of the Army – Corps of Engineers U.S. Department of Energy James Tomaseski Jerry Westerholm Janice Bradley, CSP Cristine Fargo Emmett Russell Steve Brown Jim Williams Jack Mickle, Ph.D. Scott Schneider George Macaluso Roy E. Blades Mischelle Vanreusel Peter Chaney Dennis Langley Robert Matuga George Middleton Lewis Barbe, P.E., CSP, CRSP Tom Shanahan Harry Dietz C.E. Jackson, Jr., P.E. E. Ross Curtis, P.E., NSPE William Treharne, P.E. Wayne Rice Gerald Ryan Daniel M. Paine Barbara Paine David Goldsmith S. Jecker Timothy Palmer, Ph.D., P.E. John Neil Bob Masterson, CSP Ron Lattanzio Chris Johnson Jerry Meadors Gary Batykefer Charles Austin A. J. Scardino, Jr. Daniel Paine David Denny Brian Clarke Stanley D. Pulz Jessica Pulz Stephen Gale Brett Richardson Dennis Falvey William Rhoten Vacant Robert J. Krul John Barnhard Samuel Testerman Brian Becker Patrick Finn Leslie Bermudez U.S. Department of Labor – OSHA West Virginia University - Extension Service Z Con Safety Consultants ZBD Constructors (Zurn Industries) Subgroup A10.32 had the following members: John O’Donovan (Chairman) Damiel Paine (Liaison) Harry Anuskiewicz H. Andrew Batty, Jr. Michael Bell Barbara Bielaski Janice Bradley Matthew Burkart Philip Clemmons J. Nigel Ellis C.E. Jackson, Jr. Charles Maresca Richard Morelle Craig Neustater Ron Prichard, Ph.D., P.E. Tom Shanahan Camille Villanova H. Berrien Zettler Mark Fullen Brandon Takacs Ingo Zeise Greg Thompson Jeffrey D. Meddin, CSP, CHCM Contents SECTION .................................................................................................... PAGE 1. General.......................................................................................................9 1.1 Scope .................................................................................................9 1.2 Purpose...............................................................................................9 1.3 Application..........................................................................................9 1.4 Resolutions .........................................................................................9 2. Definitions................................................................................................. 10 3. General Requirements .................................................................................. 15 4. Performance Requirements ............................................................................ 16 4.1 Anchorage .......................................................................................... 16 4.2 Fall Arrest.......................................................................................... 17 4.3 Self-Retracting Lanyards (SRL) .............................................................. 17 4.4 Rope Grab.......................................................................................... 17 4.5 Snaphooks and Carabiners ..................................................................... 18 4.6 Lanyards ............................................................................................19 5. Marking Requirements................................................................................. 20 5.1 General Marking Requirements............................................................... 20 5.2 Special Marking Requirements for Individual Components.......................... 20 6. Employer Requirements ............................................................................... 22 6.1 Training............................................................................................. 22 6.2 Rescue ............................................................................................... 22 6.3 Inspection........................................................................................... 23 6.4 Compatibility.....................................................................................24 6.5 C ompetent Person............................................................................. 24 6.6 Hazard Protection.............................................................................. 24 6.7 Job Task ........................................................................................... 24 6.8 Fall Restraint Systems.......................................................................... 24 7. Test Requirements ...................................................................................... 24 7.1 Harness, Belt and Lanyard Performance Test Procedures.............................. 24 7.2 Lifeline Performance Test Procedures.......................................................29 7.3 Rope Grab Performance Test Procedures................................................... 30 7.4 Hardware Test Procedures...................................................................... 31 8. Appendix A..............................................................................................33 Appendix B ..............................................................................................34 Appendix C..............................................................................................35 ANSI A10.32-2004 AMERICAN NATIONAL STANDARD ANSI A10.32 STANDARD FOR PERSONAL FALL PROTECTION USED IN CONSTRUCTION AND DEMOLITION OPERATIONS 1. GENERAL 1.1 Scope. This standard establishes performance criteria for personal fall protection equipment and systems in construction and demolition and provides guidelines, recommendations for their use and inspection. It includes, but is not limited to; fall arrest, restraint, positioning, climbing, descending, rescue, escape and training activities. Exceptions: This standard does not include lineman’s body belts, pole straps, window washers belts, chest/waist harnesses, and sports equipment. E1.1 The personal fall protection equipment selected should match the particular work situation. A qualified or Competent Person should select the appropriate personal fall arrest, restraint or positioning equipment based on this person’s professional evaluation of the work site, considering work conditions and the nature of the work performed. Ladder climbing protection devices are covered in ANSI A14.3. 1.2 Purpose. To provide minimum guidelines to users and manufacturers of personal fall protection equipment. 1.3 Application. This standard applies to E1.3 This standard applies to all users of fall manufacturers and users of personal fall protection protection equipment ranging in size from equipment; to those personnel responsible for the individuals to multiple employee companies. selection, procurement, inspection, use, care and maintenance of the equipment; and to those responsible for training and supervision of the users. 1.4 Resolutions. In order to provide for superior protection to the user, this standard permits: 1.4.1 Only full body harnesses shall be used for fall arrest. The fall arrest attachment point of the body harness shall be at the center of the user’s back near shoulder level. 1.4.2 Maximum arresting force imposed on the user’s body shall not exceed 1,000 lb. E1.4.2 The maximum arresting force can be reduced by limiting the free fall distance, or using a deceleration device (self-retracting lanyard, shock absorber, or similar component of energyabsorbing equipment as an integral part of the fall protection system). 1.4.3 All equipment used in a fall protection system shall be compatible to limit force levels, maintain system strength, and prevent accidental disengagement. E1.4.3 Compatible devices are suitably sized and configured to properly operate together as a component part of a fall protection system. 9 ANSI A10.32-2004 1.4.4 The service life of fall protection equipment manufactured of synthetic fiber shall be 5 years unless otherwise specified by the manufacturer. E1.4.4 There is no guarantee that 5 years is the actual service life as it is dependent on diverse factors which must be accounted for. 1.4.5 Equipment serviced by the Manufacturer or their authorized representative shall be capable of meeting all performance requirements of this standard. 2. DEFINITIONS 2.1 Accidental Disengagement. A process whereby a connector unintentionally comes free from the component to which it is attached. E2.1 Various incidents are known as “roll out”, in the case of non-locking snap-hooks, and “burst out”, in the case of locking snap-hooks. 2.2 Anchorage. A secure point of attachment for lifeline, lanyards or deceleration devices. E2.2 This includes the term ‘Anchor point’ and may be used with restraint systems as well as fall arrest systems. 2.3 Anchorage Connector. A device used for attaching to a fall arrest anchorage where it is not possible to make a direct connection with a snap hook or carabineer. E2.3 Examples of an anchorage connector are a web sling and a boom strap. A lanyard connected back onto itself is NOT a correct anchorage connector. 2.4 Arresting Force. The force produced by the fall arrest system on the human body when arresting a fall. 2.5 Body Belt (Safety Belt or Waist Belt). A support which is used for positioning, restraint or ladder climbing only. E2.5 Studies have concluded that prolonged suspension in a body belt could complicate injuries or cause death. Regulation by standards groups and equipment design have reduced the possible fall distance in climbing and positioning activities to minimize forces on the user permitting use of body belts. (Refer to ANSI A10.14-1991 for background information. Note: This standard was administratively withdrawn by ANSI.) 2.6 Body Harness, Full. A design of straps which contains the torso and is secured about the user in a manner to distribute the arresting forces over the torso and thighs with a means for attaching it to other components of a personal fall arrest system. Attachments for positioning, restraint, retrieval, or rappelling may be included. 2.7 Buckle. A connector for holding the body belt or body harness closed around the user. 2.8 Capacity. The combined weight for which the component is designed to be used. 10 E2.8 The combined weight includes the body weight, clothing, tools and other objects carried by the user. ANSI A10.32-2004 2.9 Carabiner. A connector generally comprised of a trapezoidal or oval-shaped body with a normally closed gate or similar arrangement which may be opened to receive an object and, when released, automatically closes to retain the object. The three types of carabiners are: Carabiner locking-type (Required by this standard); Carabiner non-locking type. (Not permitted as an integral part of the lanyard assembly); Carabiner manual locking type. (Not permitted by this standard). E2.9 Carabiners usually do not include a captive eye, such as a snap hook, and are primarily used to connect two separate objects where a snap hook will not suffice. 2.10 Clearance Distance. The measured distance by which one object is separated from another. 2.11 Climbing System. A combination of equipment that permits the user to use both hands freely while being tied off to a deceleration device while climbing fixed structures. 2.12 Competent Person. One who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them. 2.13 Component. A part of a personal fall protection system. 2.14 Connector. A device which is used to couple (connect) parts of a fall protection system together. E2.14 It may be an independent component of the system (such as a carabiner), or an integral component or part of the system (such as buckle or D-ring sewn into a body belt or body harness, or a snap-hook spliced or sewn to a lanyard or self-retracting lanyard). 2.15 Deceleration Device. Any mechanism which serves to dissipate energy during a fall. E2.15 Examples of deceleration devices are: ripstitch, friction, rope-grab, tearing and deforming lanyards. 2.16 Deceleration Distance. The vertical distance a falling person travels, excluding lifeline elongation, before stopping, from the point at which the deceleration device engages. E2.16 This is measured as the distance between the location of a user’s body harness attachment point just prior to activation of the deceleration device during a fall, and the location of that attachment point after the user comes to a full stop. 2.17 Descent Control Device. An automatic or manually controlled lowering device for escape or rescue. May be used as part of a single point suspended scaffold in conjunction with an independent lifeline fall arrest system. E2.17 Definition included for clarity – not a part of the standard at this time. 11 ANSI A10.32-2004 2.18 Fall Arrest. The act of stopping a free fall of more than 2 feet by the use of Personal Fall Protection Equipment. 2.19 Fall Factor. The distance (measured in feet or meters) of a free fall divided by the lanyard (measured in feet or meters) length from the harness connection to the anchorage tie off. E2.19 Fall Factor is important in determining strength of materials used in fall arrest equipment as well as the forces generated by a user. 2.20 Fall Protection. Equipment and methods to guard against the injurious consequences of a fall. E2.20 Equipment and methods to both guard against the injurious consequences of a fall and to prevent a fall where possible. 2.21 Force Factor. The ratio of the peak arresting force recorded using a rigid weight in laboratory testing to that on a human body having the same weight, both falling under identical conditions. For the purposes of this standard, a registered peak force shall be divided by 1.4 to allow for body compression. E2.21 This factor is necessary to properly relate test forces experienced by humans during fall arrest. 2.22 Free Fall. The act of falling vertically before the personal arrest system activates to stop the fall. 2.23 Free-Fall Distance. The vertical distance a user falls before the fall arresting system begins to stop the fall. This includes any rope grab slide or self-retracting lifeline/lanyard extension before they activate. This excludes elongation of lifelines, lanyards and activation distance of shock absorbers. 2.24 Hardware. Rigid connectors used to attach components of a fall protection system. 2.25 Formal Inspection. The examination by a Competent or Qualified Person. 2.26 Integral. Not removable from the component, system or sub-system without mutilating any element or without use of a special tool. 2.27 Lanyard. A flexible line which connects at one end to a full body harness, and at the other end to an anchorage, deceleration device or lifeline for fall arrest, positioning or restraint purposes. 2.28 Lifeline. A flexible line that has a connector at one end, if used in a vertical position, and each end if used in a horizontal position. 12 E2.24 Examples: snap-hooks, D rings, buckles, carabiners, adjusters, O rings, etc. ANSI A10.32-2004 2.29 Manufacturer. Any entity that manufactures or assembles a fall arrest system, bearing its identification. E2.29 Manufacturers typically buy components such as hardware and webbing, and assemble them according to their design. 2.30 Pendulum (Swing) Fall. A body suspended from a fixed point so as to swing freely to and from under the action of gravity. 2.31 Personal Fall Arrest System. Any combination of an anchorage, connectors, body harness, lanyard, deceleration device or lifeline used to arrest a fall from any working level. 2.32 Positioning Device System. A combination of equipment that permits the user to use both hands freely while being supported on an elevated vertical surface. E2.32 Fully body harnesses with built-in or modular positioning belts are acceptable as well as body belts constructed for this purpose. When using the body belt for positioning, the free fall distance must be limited to 2 feet or less. Note: Waist belts do not comply with this standard for fall arrest. 2.33 Qualified Person. One who, by possession of a recognized degree, certificate, or professional standing, or who be extensive knowledge, training, and experience, has successfully demonstrated his ability to solve or resolve problems relating to the subject matter, the work or the project. 2.34 Restraint (Tether) System. A combination of equipment to prevent a user from reaching a point where a fall could occur from an elevated work surface. E2.34 Restraint systems should be used only where there is no possibility of falling at any angle of restraint (i.e., lifelines that are used on roofs to prevent a user from falling over the edge. This is for a free fall distance of zero feet.) 2.35 Rope Grab. A device which travels on a lifeline, engages the lifeline and locks to arrest the fall of a user. E2.35 A Rope Grab that is used on a horizontal lifeline is subject to damage. Contact the manufacturer for specific guidelines for use 2.36 Safety Factor. A ratio of the design load and the ultimate strength of the material. 2.37 Self-Retracting Lifeline/Lanyard (SRL). A device which contains a drum-wound line which may be slowly extracted from or retracted onto the drum under slight tension during normal user movement, and which after onset of a fall, automatically locks the drum and arrests the fall. E2.37 May include a raising/lowering function. 2.38 Service Life. The life of the product beginning from the date of first use. E2.38 In the absence of documentation of date of first use, the date of manufacturer will be considered the start of service life. 13 ANSI A10.32-2004 2.39 Shall. The word “shall” is to be understood as mandatory. 2.40 Shock Absorber. A component of a fall arrest system that is used to dissipate and limit the arrest forces on a human body during free fall. 2.41 Should. The word “should” is to be understood as advisory. 2.42 Snap-Hook. A connector consisting of a hook-shaped body with a normally closed gate or similar arrangement which may be opened to permit the hook to receive an object and, when released, automatically closes to retain the object. 2.42.1 Snap-Hook, Self-Locking. The locking type (required by this standard) with a selfclosing, self-locking gate which remains closed and locked until intentionally opened by the user for connection or disconnection. E2.42.1 This definition reflects what is commonly called a self-locking or double-locking snap-hook. A captive eye is an integral part of a snap hook, but is independent of the hook and gate portion. 2.42.2 Snap-Hook, Manual-Locking. The manual-locking type (not permitted by this standard) with a self-closing gate which remains closed but not locked (unless purposely locked by the user) until intentionally opened by the user for connection or disconnection. 2.43 System. Any combination of fall arrest equipment that prevents personal injury. E2.43 Examples are: A full body harness, anchorage and lanyard comprise a system as does a full body harness, lanyard, rope grab and lifeline and anchorage. 2.44 Tie Off. When a user wearing personal fall protection equipment connects directly or indirectly to an anchorage. The term also means the condition of a user being connected to an anchorage. E2.44 Tie Off is slang for connection to a secure anchorage. 2.45 Total Fall Distance. The maximum vertical distance between a user’s full body harness attachment point before and after the fall is arrested, including free fall distance and deceleration distance plus any elongation of the system or anchorage. E2.45 Elongation is a function of the materials used (i.e., nylon webbing). Request further information from the manufacturer of your equipment. 2.46 Travel Restricting. Restricting a user in a way to limit access to, or contact with, a free fall hazard. 14 ANSI A10.32-2004 2.47 User. The individual wearing or utilizing the fall protection equipment and/or system. E2.47 Includes employers. 3. GENERAL REQUIREMENTS 3.1 Selection of fall protection equipment shall be made by a Competent Person. E3.1 Where components of different manufacturers are combined into a system, a Qualified Person should approve the system. 3.2 All fall protection equipment should be purchased new and unused. E3.2 Used equipment may have been subjected to degradation or force factors that exceed permissible limits which could lead to unexpected failure. 3.4 Fall protection equipment shall be removed from service upon evidence of defects, damage or deterioration; once it has been subjected to impact loading; or upon expiration of the manufacturer’s specified service limits, whichever comes first. 3.5 When vertical lifelines are used, they shall be limited to one user per lifeline. 3.6 Horizontal lifelines shall be designed, installed, and used, under the supervision of a Qualified Person, as part of a complete personal fall arrest system, which maintains a safety factor of at least two. 3.7 Lanyards and lifelines shall be used in a manner to minimize cuts, abrasion and deterioration. E3.7 The line should be sleeved or otherwise protected to minimize cuts, abrasion, deterioration or burning. Anchorage connectors should be used to avoid damage from sharp bends in the line or abrasive wear. 3.7.1 Lanyards shall not be connected back upon themselves unless authorized by the equipment manufacturer. E3.7.1 An anchorage connector is to be used. Improper use can cause failure of the snap-hook gate or other failure. 3.7.2 Lanyards shall not be connected to selfretracting lanyards E3.7.2 Manufacturers may specify a D-ring extension to the harness to ease connection to the D-ring. 3.7.3 Knots are not allowed in lifelines, lanyards or other direct-impact components. E3.7.3 Except as a “stop” to prevent a device from accidentally running off the end of a lifeline, or to secure the free end of a lifeline at ground level. 3.8 Harnesses, lanyards, belts, lifelines and other load-bearing devices shall not be made of natural fibers (including, but not limited to, cotton, manila and leather.) 15 ANSI A10.32-2004 3.9 Connectors shall be corrosion resistant, and all surfaces and edges shall be smooth to prevent damage to interfacing parts of the system. 3.10 Snap-hooks and carabiners shall be selfclosing and self-locking and shall be capable of being opened to release the load only by at least two consecutive deliberate actions. 3.10.1 Other design of snap-hooks and carabiners shall be tested to follow the intent of the requirements of this standard. E3.10.1 Future developments may cause change to be made to the method of opening. 3.11 The component parts of a restraint system including anchorages shall be designed and manufactured to meet the strength requirements of fall arrest equipment as specified in this standard. 3.11.1 Restraint systems shall be designed by a Qualified Person. 3.11.2 Restraint systems shall be installed and used under the supervision of a Competent Person. 3.11.3 The restraint system shall eliminate possibility of a free fall. 3.12 Where equipment or fittings may come in contact with energized electrical power sources, either the equipment or fitting shall have sufficient dielectric resistance or be shielded from contact with the electrical power source or the electrical power source shall be rendered inoperative. 4. PERFORMANCE REQUIREMENTS 4.1 Anchorage. Anchorage shall be capable of supporting at least 5,000 lbs. per user attached, or shall be designed, installed and used under the supervision of a Qualified Person as part of a complete system which maintains a safety factor of at least two. 4.1.1 An anchor connector shall be used if an anchorage does not have a connection point compatible with a carabiner or snap hook. 16 E3.11.3 Restraint systems may be subject to poor design, improper installation or misuse and create a free fall hazard which must be eliminated. ANSI A10.32-2004 4.2 Fall Arrest. 4.2.1 Personal fall arrest systems, when stopping a fall, shall be rigged such that an employee can neither free fall more than 6 feet (1.8m), nor contact any lower level or obstruction. 4.2.2 Maximum deceleration distance shall be 3.5 feet. E4.2.2 This only is applicable to a maximum six (6) foot free fall from a fixed anchorage and does not apply to a free fall when attached to a horizontal lifeline or when the personal fall arrest system has been designed by a Qualified Person. 4.2.3 The angle of rest for a user after a fall shall not be greater than 30 degrees to the vertical. E4.2.3 Please see Appendix A, which is Figure 20 from the Z359.1-1992 (R1999) American National Standard, “Safety Requirement for Personal Fall Arrest Systems, Subsystems and Components.” 4.3 Self-Retracting Lanyards (SRL). 4.3.1 Self-Retracting lanyards shall automatically limit free fall distance to two (2) feet (0.61m) or less and shall be capable of sustaining a minimum tensile load of 3,000 pounds (13.3kn) applied to the device with the lanyard in the fully extended position. 4.4 Rope Grab. 4.4.1 For the purpose of this standard, Rope Grabs are classified as follows: Type 1.: designed to be used on a vertical lifeline. Type 2.: designed to be used on a horizontal lifeline. Type 3.: designed to be used on a lifeline of any orientation. 4.4.2 Connectors used with Rope Grabs (whether integral, separate components or elements of separate components) shall meet the requirements of this standard. Integral rings or similar openings designed to accept connectors shall be designed to minimize potential rollout of mating connector. E4.4.2 An effort should be made to encourage compatible connector couplings 4.4.3 Rope Grabs shall be automatic in their locking (fall stopping) function. The possibility of overriding the self-locking feature of the SRL shall be guarded against. Rope Grabs which are designed to work on vertical lifelines and which rely solely on the lever principle for locking, shall be designed such that locking will become effective before the lever becomes perpendicular E4.4.3 The intent of guarding against overriding of the self-locking feature of the Rope Grab during use is to reduce the possibility that the device may be deactivated if reflexively grabbed or held during onset of a fall. Knots are not predictable or testable over the given lifetime of a lifeline. 17 ANSI A10.32-2004 to the lifeline. Systems incorporating “knot” type fall arresters are excluded from this standard. 4.4.4 Type 1 Rope Grabs that are not bidirectional (could arrest a fall or lock in both directions of travel) and which could be installed upside down on the lifeline shall be clearly marked showing proper orientation of use. E4.4.4 A bi-directional rope grab is one which will lock in both directions of travel on a lifeline. 4.4.5 Type 1 Rope Grabs shall be incapable of creeping down the lifeline during work operations at a given elevation. 4.4.6 Corrosion protection shall be afforded to all elements (parts) of the Rope Grab to a degree deemed necessary by a Qualified Person(s) directly responsible for the design of the device. Protection shall at a minimum allow the device to operate as intended and show no sign of corrosion which if left unchecked could result in corrosion-related failure of the device after being salt spray (fog) tested for 48 hours in accordance with ASTM B117-90. Working parts critical to the operation of the device shall be fully exposed during salt spray even if disassembly of the device is required to do so. 4.4.7 Rope Grabs shall have an ultimate strength of not less than 3,600 pounds (16kN) 4.5 Snaphooks and Carabiners. 4.5.1 Corrosion. All hardware shall be corrosion resistant, prohibiting any loss of functionality or presence of red rust when tested in accordance with Section 7.4.1. The presence of white scale is acceptable. 4.5.2 Test Loads. 4.5.2.1 Rings. (D rings, O rings and oval rings) shall be capable of withstanding a 5,000 pound tensile load without breaking when tested in accordance with Section 7.4.2.1. 4.5.2.2 Snaphooks and carabiners shall be capable of withstanding a 5,000 pound tensile load without breaking or distortion sufficient to release the gate when tested in accordance with Section 7.4.2.2. 18 E4.4.6 Devices intended for use in specific environments may require special attention to corrosion protection. Care must be used when combining dissimilar metals to avoid adverse galvanic couples. ANSI A10.32-2004 4.5.3 Gate Load for Snaphooks and Carabiners. The snaphook or carabiner shall be capable of withstanding a minimum load of 220 pounds without the gate separating from the nose of the snaphook or carabiner body by more than 0.125 inch when tested in accordance with Section 7.4.3.1. The gate of the snaphook or carabiner shall be capable of withstanding a minimum side load of 350 pounds when tested in accordance with Section 7.4.3.2. Failure shall be defined as permanent deformation of the gate more than 0.125 inch, or separation of the gate from the body of the snaphook or carabiner body by more than 0.125 inch. 4.5.4 Adjusters and Buckles. Buckles, oval rings used as adjusters and other adjusters shall be capable of withstanding a minimum tensile load of 4,000 pounds without breaking when tested in accordance with Section 7.4.4. 4.5.5 Proof Loading Test Requirements. All snaphooks, carabiners and D rings shall be 100% proof tested to a 3,600 pound (16kN) tensile load without cracking, breaking or taking permanent deformation when tested in accordance with Section 7.4.5 4.6 Lanyards. 4.6.1 Lanyard Construction. 4.6.1.1 The lanyard shall be made from suitable materials capable of meeting the performance requirements of Section 7.1.1.3.1. The lanyard may be permanently attached to a shockabsorbing component that complies with this standard. 4.6.1.2 Rope and webbing used in the construction of lanyards shall be made of virgin synthetic material having strength, aging, abrasion resistance and heat resistance characteristics equivalent or superior to polyamides. 4.6.1.3 Wire rope used in the construction of lanyards shall be constructed in accordance with Federal Specification RR-W-410D. 4.6.1.4 Chain used in the construction of E4.6.1.4 Chain is generally used for work lanyards shall be manufactured in accordance with positioning, i.e., re-bar and concrete form work. the requirements for grade 80 set forth in ASTM E8-89b. 19 ANSI A10.32-2004 5. MARKING REQUIREMENTS 5.1 General Marking Requirements. 5.1.1 Markings shall be permanent, legible and written in English. E5.1.1 Other languages may be included at manufacturer’s option. Labels may be fabric, leather, paper, metallic, or any other material that is suitable. Imprints and stamps are also acceptable. 5.1.2 Except for connectors, all equipment shall be marked with the following information: E5.1.2 Examples: Full body harnesses, lanyards, rope grabs, retractable lifelines, anchor connectors, etc. UL 969 should be referred to for reference. 5.1.2.1 “DO NOT REMOVE THIS LABEL”. 5.1.2.2 Part Number and/or model designation. 5.1.2.3 Month and year of manufacture. 5.1.2.4 Manufacturer’s name or identifying logo or mark. 5.1.2.5 Maximum user weight including tools as determined in Section 7. 5.1.2.6 Standard number (A10.32) - (year). 5.1.2.7 Primary web and rope fiber material(s). E5.1.2.7 Example: web or rope - nylon or polyester. 5.1.2.8 Warning to remove from service if subject to a fall arrest. 5.1.2.9 Warning to read instructions before using. 5.1.2.10 Expiration Date. 5.1.3 Provision shall be made to record formal inspection dates and inspector’s initials. 5.1.3.1 Ten (10) spaces shall be provided for dates and initials of inspector, signifying two (2) formal inspections per year over five (5) years E5.1.3.1 An additional paper record should be maintained as backup records. 5.2 Special Marking Requirements for Individual Components. 5.2.1 Connectors. Manufacturer’s identification. 20 E5.2.1 Name or logo with year of manufacture and traceability designation. ANSI A10.32-2004 5.2.1.1 Snap-hooks and carabiners shall be marked PT to indicate they have been successfully proof tested as described in Section 4.5.5. The year of manufacture shall also be marked on the snap-hook and carabiner and other markings sufficient to provide traceability. 5.2.2 Shock absorbers. 5.2.2.1 Customized absorbers for increased weight (over 310 lb.), fall distance (over 6 feet), or horizontal lifeline applications shall be labeled accordingly. 5.2.3 Lanyards. 5.2.3.1 Maximum distance of free fall. 5.2.3.2 Warnings, if not suitable for fall arrest. 5.2.4 Rope grabs. 5.2.4.1 Arrow indicating the direction of travel on a lifeline. 5.2.4.2 Proper size and type of lifeline to use. 5.2.4.3 Maximum length of lanyard. 5.2.5 Self-retracting lanyards. 5.2.5.1 Diameter of rope or wire rope and width and thickness of webbing used in the lanyard. 5.2.5.2 The fiber of other materials used in the lanyard construction. 5.2.5.3 The lanyard length. 5.2.5.4 Maximum arrest force. 5.2.5.5 Proper installation means. 5.2.5.6 The need for inspection at periodic intervals and at least monthly. 5.2.5.7 Testing of the device for locking before each use. 5.2.5.8 Arrest distance. 5.2.6 Waist belts (body belts). Shall not be used for fall arrest. E5.2.6 May be used for positioning and climbing only. 21 ANSI A10.32-2004 6. EMPLOYER REQUIREMENTS 6.1 Training. E6.1.1 For more information about the general 6.1.1 The employer shall provide a training program for each employee who might be issues of training, reference ANSI/ASSE Z490.1-2001 Criteria for Accepted Practices in Safety, Health, exposed to fall hazards. The program shall enable each employee to recognize the hazards of and Environmental Training. falling and shall train each employee in the procedures to be followed in order to minimize these hazards. Relevant Federal, State and local regulatory requirements, procedures and standards shall also be included. 6.1.2 The employer shall assure that each employee has been trained, as necessary, by a Competent or Qualified Person in the following areas: The nature of fall hazards in the work area; the correct procedures for erecting, maintaining, disassembling and inspecting the fall protection systems to be used; the use and operation of personal fall arrest systems, safety net systems and other protection to be used. E6.1.2 Training is the most important component of any fall protection program. The individuals actually wearing and using the equipment must be thoroughly trained in all aspects of the equipment. 6.1.2.1 Employees shall demonstrate an understanding on at least the following: How the individual components function together as a system to restrain or arrest a fall; proper donning and adjustment; proper tie-off procedure; inspection and maintenance procedure; rescue procedure; learning how equipment is to be used on the specific project; and unique hazards. 6.1.2.2 Employee training shall include lectures, demonstrations and hands-on experience performing tasks described in section 6.1.2. 6.2 Rescue. 6.2.1 Employees shall be trained in self-rescue or E6.2.1 Alternate means include retrieval and medical care. alternate means shall be provided for prompt rescue in the event of a fall. 6.2.2 A project-specific rescue plan shall be developed which will provide for a form of rescue for employees. 6.2.3 All rescuers shall be provided with adequate training, equipment and personal protective equipment where needed. 22 ANSI A10.32-2004 6.3 Inspection. 6.3.1 A regular inspection and maintenance program in accordance with the manufacturer’s instructions shall be established. E6.3.1 Even though a maximum life of fall arrest equipment has been established by this standard or a manufacturer, this does not mean it will last for this period. Therefore, inspection prior to use is critical. 6.3.1.1 The manufacturer’s instructions shall be readily available for reference. 6.3.1.2 The date of the first use shall be recorded by the employer. 6.3.2 Formal inspections shall be made by either a Competent or Qualified Person on at least a semi-annual basis. E6.3.2 Suggested examination periods are 3/1 to 3/31 and 9/1 to 9/30 for each employer. 6.3.2.1 Inspect the snap-hook or carabiner by examining the gate and hook body to see if the hook is fully closed after manually opening and allowing the snap-hook or carabiner to self-close slowly. Any separation by more than 0.125 in. in a jammed condition shall be reason for rejecting the snap-hook or carabiner from further use by removal and tagging until it has received maintenance or determined to be unfit for further use and destroyed. 6.3.3 Prior to each use, fall protection equipment shall be inspected by the user for defects, damage or deterioration. Any suspected defective equipment shall be removed from service. E6.3.3 The user should be instructed to observe the equipment for the appearance of specific defects which could affect reliability and their personal safety. 6.3.3.1 Harnesses, lanyards and lifelines that show evidence of wear beyond that deemed acceptable by the manufacturer’s recommendations, shall be removed from service. 6.3.3.2 Self-retracting lanyards, rope grabs, tripods and other mechanical equipment that show evidence of wear beyond that deemed acceptable by the manufacturer’s recommendations, may be recertified by the manufacturer following test and evaluation for re-use. 6.3.4 If the manufacturer’s label is not legible or is missing, the equipment shall be removed from service. 23 ANSI A10.32-2004 6.4 Compatibility. When fall arrest components made by different manufacturers are used in a system, a Competent Person shall determine that they shall meet the requirements of this standard, and are compatible to one another. 6.5 Competent Person. A Competent Person shall ensure that Self-retracting lanyard’s be installed so that the maximum free fall distance is limited to two feet. 6.6 Hazard Protection. Fall Protection Equipment shall be protected from abrasion, cutting, welding, electrical and chemical hazards and shall be selected to resist these hazards. 6.7 Job Task. Every job task shall be surveyed to identify potential fall hazards and appropriate protection provided. 6.7.1 Equipment Selection. If the hazard cannot be eliminated, then appropriate fall arrest equipment must be selected to restrict the individual or arrest a fall, should it occur. E6.7.1 A competent or Qualified Person must select the equipment to make certain that it will provide the desired protection as well as be suitable for the specific work being performed. 6.8 Fall Restraint Systems. 6.8.1 The work site shall be surveyed by a Qualified Person to determine if the fall restraint system will provide protection from a free fall. 7. TEST REQUIREMENTS 7.1 Harness, Belt, and Lanyard Performance Test Procedures. Fall protection products which are designed and packaged to operate as a system shall be tested according to Procedure A. Fall protection products which are meant to operate interchangeably with other fall protection products, or systems which are easily broken down to otherwise useable components shall be tested according to Procedure B. 7.1.1 Strength Tests. Procedure A The fall arrest test system shall contain an anchorage which shall not have a deflection greater than .04 inch (1 mm) when a force of 2,250 lb.. (10 kN) is applied. 24 E7.1.1 A fall factor of 1.0 is when the drop height is equal to the lanyard length on a conventional system. A fall factor of 2.0 is when the drop height is equal to twice the lanyard length, the maximum fall physically possible. Fall factors can range from 0. 1, a minimum fall, to 2.0, a maximum fall. The actual physical distance of the fall is dependent on the lanyard length. ANSI A10.32-2004 In the case of a fall arrest product, the harness shall be affixed to a rigid test dummy weighing 220 lb. + 3 lb. (100 kg +1.4 kg). The fall factor shall be 2.0. In the case of a positioning or retrieval or similar product, the belt or harness shall be affixed to a rigid test dummy (or a belt may be attached to a rigid test weight) weighing 220 lb. +/- 3 lb. (100 kg + 1.4 kg). The fall factor shall be 1.0. Rig the product to subject the test dummy to the above specified fall factor. Release the dummy quickly and cleanly, allowing it to fall free to its hanging location without interference, obstruction or hitting the floor during the test. Failure of the strength test shall consist of any breakage or slippage sufficient to permit the test dummy to fall free. 7.1.1.1 Integral System and Integral Subsystem Testing. Put the harness on the test torso, fasten all buckles and adjust it snugly as though the torso were a person. Attach the free end of the lanyard to the load cell connected to the test structure. Attach the quick release mechanism to the test torso (neck ring for “feet first” drop and crotch ring for “head first” drop). Raise the test torso to a level which will allow a 6 foot (1.829 mm) free fall or the maximum permitted by the lanyard, whichever is less, upon release of the test torso. The torso shall be released from a point no more than 12 inches (305 mm) measured horizontally from the point of the lanyard connection to the load cell. Release the torso using the quick release mechanism. Measure and record the maximum arrest force and deceleration distance. After the drop the torso is to remain suspended by the harness for a period of 5 minutes. During the post-fall suspension period, measure and record the angle at rest. Perform the test once each for a “feet-first” and a “head-first” drop. A new test specimen may be used for each test. Compare the test results to the requirements in this standard. Procedure B 7.1.1.1 Fall Arrest Body Harness. The body harness to be tested shall be affixed snugly to a rigid test dummy weighing 220 lb. + 3 lb. (100 kg + 1.4 kg) and subjected to a fall factor of 2.0 in the following manner: E7.1.1.1 Minimum safety factors can be determined by testing at increased heights, increased weights, or a combination of both (the latter has been done in the past). The "typical" worker is assumed to weigh 220 pounds (100 25 ANSI A10.32-2004 The harness and test dummy shall be attached to an anchorage which shall not have a deflection greater than 0.4 inch (1 mm) when a force of 2,250 lb. (10 kN) is applied. The lanyard used to attach the harness to the rigid anchorage shall be a 6 foot +/- 1 inch (1.8 m +/- 2.5 cm) web-lanyard with a minimum tensile strength of 5,000 pounds. The length shall be measured under a tension of 10 lb. (4.5 kg). One end of the lanyard shall be attached to the rear D-ring on the harness, and the other end to the anchorage. Hoist the test dummy to a point 6 feet ± .7 inch (1.8 m + 2.5 cm) above the anchorage point. Release the dummy quickly and cleanly, allowing it to fall free to its hanging location without interference, obstruction or hitting the floor during the test. Failure of the strength test shall consist of any breakage or slippage sufficient to permit the test dummy to fall free or elongation of the web lanyard to a total length of 80 inches (2 m) at rest. 7.1.1.2 Positioning Harnesses, Retrieval Harnesses, Body Belts. The harness or belt to be tested shall be affixed to a rigid test dummy (or it may be attached to a rigid test weight weighing 220 lb. + 3 lb. (100 kg + 1.4 kg) and subjected to a fall factor of 1.0 in the following manner,: The harness and test weight shall be attached to an anchorage which shall not have a deflection greater than .04 inch (1 mm) when a force of 2,250 lb. (10 kN) is applied. The lanyard used to attach the belt or harness to the rigid anchorage shall be a 6 foot ± 1 inch (1.8 m +/- 2.5 cm) web-lanyard with a minimum tensile strength of 5000 lb.. The length should be measured under a tension of 10 lb. (4.5 kilograms). Hoist the test dummy to a point where the drop height equals the lanyard length (6 foot + 2 inches (1.8 m + 5 cm) drop). Release the weight quickly and cleanly, allowing it to fall free to its hanging location without interference, obstruction, or hitting the floor during the test. Failure of the strength test shall consist of any breakage or slippage sufficient to permit the test weight to fall free or elongation of the web lanyard to a total length of 80 inches (2 m) at rest. 26 kilograms) and to be rigged to experience a fall factor of 1.0 on a 6 foot lanyard. The safety factors are designed to account for variations from this "typical" condition. The ANSI A10.32 committee has concluded that the most likely variance from this is a misuse situation where the worker is rigged to experience a fall factor of 2.0. Although the committee most emphatically does not condone this misuse, it has chosen to duplicate this condition to perform the Strength Tests. ANSI A10.32-2004 7.1.1.3 Shock Absorbing Lanyards, or Rope, Web, Lanyards Intended for Fall Arrest. 7.1.1.3.1 Lanyard Material. Lanyard material shall be tested for tensile strength according to ASTM D4268 and shall not break below 5,000 lb.. The lanyard or shock absorber/lanyard to be tested shall be affixed to a rigid test weight weighing 220 lb. + 3 lb. (100 kg + 1.4 kg) and subjected to a fall factor of 2.0 in the following manner: The lanyard and test weight shall be attached to an anchorage which shall not have deflection greater than .04 inch (1 mm) when a force of 2,250 lb. (10 kN) is applied. Hoist the test weight to a point where the drop height equals twice the lanyard length, then release the weight quickly and cleanly. The weight shall fall free to its hanging location without interference, obstruction, or hitting the floor during the test. Failure of the strength test shall consist of any damage sufficient to permit the test weight to hit the floor or ground. 7.1.1.3.1 A lanyard or shock absorber/lanyard shall normally be tested independently of other devices. However, in the case of a lanyard permanently fastened to a rope grab, test the combination according to 7.3.1. 7.1.1.4 Positioning, Retrieval, or Similar Lanyards Not Intended for Fall Arrest. A lanyard shall be affixed to a rigid test weight weighing 220 lb. + 3 lb. (100 kg + 1.4 kg) and subjected to a fall factor of 1.0 in the following manner,: The lanyard shall be attached to an anchorage which shall not have a deflection greater than .04 inch (1 mm) when a force of 2,250 lb. (10 kN) is applied. Hoist the test dummy to a point where the drop height equals the lanyard length. Release the weight quickly and cleanly. The test weight shall fall free to its hanging location without interference, obstruction, or hitting the floor or ground during the test. Failure of the strength test shall consist of any damage sufficient to permit the test weight to hit the floor or ground. 27 ANSI A10.32-2004 7.1.2 Force Test. This standard tests only lanyards for fall arrest forces. Alternative fall protection designs which do not use a lanyard shall use a modification of this procedure, approved by a Qualified Person, to be sure that the end user is subjected to no greater than 1,000 lb. (4.5 kN) in a fall. Procedure A The fall arrest test system shall contain an anchorage which shall not have a deflection greater than .04 inch (1 mm) when a force of 2,250 lb. (10 kN) is applied. The product to be tested shall be affixed to a rigid test weight weighing 220 lb. + 3 lb. (100 kg + 1.4 kg). The product shall be attached to a force measuring device having the characteristics in Section 7.1.2.1 below. Attach a recorder to obtain the peak force and, if desired, the time trace of the resulting force, either at the actual time or at a later time, after storage of the information. The force measuring device shall be attached to the rigid anchorage. The initial length shall be determined under the 220 lb. load. Rig the product to subject the test weight to a fall factor of 1.0. Release the weight quickly and cleanly. The weight shall fall free to its hanging location without interference, obstruction or hitting the floor or ground during the test. Failure of the force test shall be a recorded maximum arrest force of greater than 1,400 lb. (6.2 kN). Procedure B 7.1.2.1 Shock Absorbing Lanyards, or Rope, Web, Lanyards Intended for Fall Arrest. Measuring Range - 0-3,000 lb. minimum Accuracy - ±2.5% Full Scale Resolution (0-1,000 lb.) - 10 lb. maximum Rigidity - 0.001 inch maximum at full load Resonant Frequency - 200 Hz minimum Frequency Response - 100 Hz Electronics must be in compliance with the National institute of Standards and Technology (NIST). 28 E7.1.2 Drop impact testing with a rigid test weight will yield a higher fall arrest force than would be experienced by a person falling under identical conditions. This is due to physiological factors such as flailing limbs, internal energy absorption, etc. A rule of thumb used by both the industry and OSHA is that this ratio is 1.4 / 1. For example, if the force recorded in a test on a rigid weight is 1,400 lb., the force on a person using that same system would be 1,000 lb.. ANSI A10.32-2004 Attach a recorder to obtain the peak force and, if desired, the time trace of the resulting force, either at the actual time or at a later time, after storage of the information. The force measuring device shall be attached to a rigid anchorage, which shall not have a deflection greater than .04 inch (1 mm) when a force of 2,250 lb. (10 kN) is applied. Carefully suspend the test weight (do not allow any free fall) from the anchorage supported only by the lanyard. Determine the length of the lanyard under the 220 lb. (100 k-g) load. The test weight shall be hoisted to a point that the drop height equals the lanyard length, which is equivalent to a fall factor of 1.0. Release the weight quickly and cleanly. The weight shall fall free to its hanging location without interference, obstruction or hitting the floor or ground during the test. Failure of the force test shall be a recorded maximum arrest force of greater than 1,400 lb. (6.2 kN) and for a final measured length (while still under the 220 lb. load) greater than 42 inches (1.1 m) longer than the initial measured length. 7.1.2.1.1 In the case of a shock absorber/ lanyard permanently attached to a rope grab, the 1,400 lb. (6.1 kN) maximum arresting force applies to the combination, not to the shock absorber or the rope grab tested separately. 7.2 Lifeline Performance Test Procedures. 7.2.1 Strength Test. 7.2.1.1 Wire rope shall be tested for tensile strength according to the procedure in Federal Spec. RRW410-Rev. D and shall not break below 5,000 lb.. 7.2.1.2 Wire rope tensile strength shall be determined at a pull rate of 1 inch (2.5 cm) per minute. 7.2.1.3 Synthetic rope tensile strength shall be determined at a pull rate of 2 inches (5.0 cm) per minute. 29 ANSI A10.32-2004 7.2.2 Retained Strength-After Testing. 7.2.2.1 Lifelines used to test rope grab devices shall retain at least 5000 lb. tensile strength in the area where the rope grab was activated. Tests shall be run according to the requirements of 7.2.1. 7.3 Rope Grab Performance Test Procedures. 7.3.1 Strength Test. The rope grab to be tested shall be attached to a vertical lifeline which meets all of the requirements of the rope specified in the labels or literature packaged with the rope grab. Rope grabs without information on acceptable lifelines shall be considered incomplete and shall not be tested. The vertical lifeline shall be attached to an anchorage which shall not have a deflection greater than .04 inch (1 mm) when a force of 2,250 lb. (10 kN) is applied. There must be a minimum of 4 ft. (1.2 m) of lifeline beneath the rope grab connection point. The rope grab shall be attached to a rigid test weight weighing 220 lb. + 3 lb. (100 kg + 1.4 kg) with a lanyard (See 7.3.1 below). Carefully suspend the test weight (do not allow any free fall) from the anchorage supported only by the lifeline, rope grab and lanyard. The distance between the anchorage point and the rope grab connection point shall be 2 ft. (.6 m) + 1 inch (25 mm). Permanently mark the location of the rope grab on the lifeline. Determine the distance from the marked location on the lifeline to the suspended 220 lb. (100 kg) weight. 7.3.1.1 If the rope grab comes with a permanently attached lanyard, the test weight shall be hoisted to a point that results in a fall factor of 2.0. Release the weight quickly and cleanly, allowing it to fall free to its hanging location without interference, obstruction, or hitting the floor during the test. Failure shall consist of any breakage which allows the test weight to fall free, or slippage which allows the weight to travel greater than 42 inches (1.1 30 E7.2.2.1 In order to ensure consistency in testing, tensile tests are run on a tensile testing machine using a straight piece of brand new material. In actual use, tied knots, abrasive wear, and bending over sharp edges can significantly lower these values. Care should be taken to eliminate knots, minimize wear, and use a proper anchorage connector so that the lifeline or lanyard does not come into contact with sharp edges. In addition, frequent inspections must be performed to remove questionable or unsafe products from service. ANSI A10.32-2004 meter) below its original hanging location as measured from the mark on the lifeline. Lifeline damage shall be evaluated according to 7.2.2. 7.3.1.2 If the rope grab does not come with a permanently attached lanyard, use a 3 ft. ± 1 inch (0.9 m ± 2.5 cm) web-lanyard with a minimum tensile of 5,000 lb.. The length should be measured under a tension of 10 lb. (4.5 kg). Hoist the test weight to a point 3 ft. + 2 inches (0.9 m + 5 cm) above the rope grab. Release the weight quickly and cleanly, allowing it to fall free to its hanging location without interference, obstruction, or hitting the floor during the test. Failure shall consist of any breakage which allows the test weight to fall free, or slippage which allows the weight to travel greater than 42 inches (1.1 meter) below its original hanging location as measured from the mark on the lifeline. Lifeline damage shall be evaluated according to 7.2.2. 7.4 Hardware Test Procedures. 7.4.1 Corrosion. All hardware shall be tested in accordance with ASTM B117-90 for corrosion resistance for a period of 48 hours. 7.4.2 Tensile Strength Testing of Rings, Snaphooks and Carabiners. 7.4.2.1 Rings. A 5,000 pound test load shall be applied to the D ring, oval ring or other connector over 1 minute to reach load and avoid any dynamic effects; mandrels (test fixture pins) shall be rigid and of round or rectangular crosssection. Maintain the test load for a minimum period of 1 minute and evaluate in accordance with Section 4.5.2.1. 7.4.2.2 Snaphooks and Caribiners. A 5,000 pound test load shall be applied to the snaphook or carabiner over 1 minute to reach load and avoid any dynamic effects; mandrels (test fixture pins) shall be rigid and of round or rectangular cross-section maximum size shall be no greater than the throat opening of the snaphook or carabiner. Maintain the test load for a minimum period of 1 minute and evaluate in accordance with Section 4.5.2.2. 31 ANSI A10.32-2004 7.4.3 Gate Load Test Procedure. 7.4.3.1 Gate Face Testing. Position the snaphook or carabiner in the clamping fixture such that the outside face of the gate is generally parallel to the test bed and the gate’s motion is perpendicular to the test bed and the gate’s motion is perpendicular to the test bed. Using a rigid bar shown in Appendix B, apply a load perpendicular to the face of the gate at point as close to the nose of the hook body as possible. The load shall be applied increasingly until the required test load of 220 pounds is reached. The rigid bar travel rate shall not exceed 3 inches/ minute. Maintain the test load for minimum period of 1 minute. While the load is applied, measure the distance of the gate separation from the hook or carabiner nose at the point of minimum clearance. E7.4.3.1 Please see Appendix B, which is Figure 22 from the Z359.1-1992 (R1999) American National Standard, “Safety Requirement for Personal Fall Arrest Systems, Subsystems and Components” 7.4.3.2 Side Load Testing. Position the snaphook or carabiner in the clamping fixture such that the opening motion of the gate is generally parallel to the test bed and the snaphook or carabiner is supported above the test bed from each end. Measure the height from the test bed as shown in Appendix C. Apply the test load at an increasing rate (speed of 3 inches/minute) until the required test load of 350 pounds is reached. Maintain the test load for minimum period of 1 minute. While the load is applied, measure the distance of gate separation from the hook or carabiner nose at the point of minimum clearance. Remove the load and measure the gate height from the test bed. Calculate the permanent deformation of the gate. E7.4.3.2 Please see Appendix C, which is Figure 23 from the Z359.1-1992 (R1999) American National Standard, “Safety Requirement for Personal Fall Arrest Systems, Subsystems and Components” 7.4.4 Tensile Strength of Adjusters and Buckles. Subject the buckles, oval ring used as adjuster or other adjuster to an internally applied test load of 4,000 pounds (17.8 kN) over 1 minute to reach load and avoid any dynamic effects. Evaluate the buckle or adjuster in accordance with Section 4.5.4. 7.4.5 Proof Load Testing Procedure. D rings, Oval rings, O rings, Carabiners and Snaphooks shall be subjected to a 100% proof load verification. Time to reach the 3,600 pound (16 kN) shall be greater than 1 second. Maintain that proof load for a period of not less than 2 seconds. Inspect the connector in accordance with Section 4.5.5. 32 APPENDIX A ANSI A10.32-2004 33 ANSI A10.32-2004 34 APPENDIX B APPENDIX C ANSI A10.32-2004 35 A S S E Printed in U.S.A.