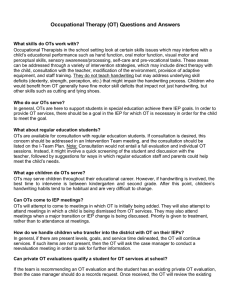

Risk Identification Checklist Structural unit ______ Workplace (profession) ____engraving and milling machine operator, plotter cutting machine operator __ Date of registration _________ Evaluation options and evaluation criteria «+» «++» «+++» «–» "N/a" Minimal risk level High level of risk Very high level of risk No risk It is not possible to assess qualitative and quantitative indicators. At the same time, explanations are made in the column "Note" (for example, there are no measurements of the parameters of sanitary and hygienic factors of the production environment at the workplace, etc.) Equipment used Лазерный гравировальный станок BODOR BCL1309X (1) Engraving and Milling Machine MULTICAM1000 (2) Гравировально-фрезерный станок CAMTECH Z7 (3) BODOR Solid State Laser Machine (4) TPS8000 Brace Bending Machine (5) Лазерный сварочный станок AOHUA-Laser (6) DUCAN UV Machine (7) Danger Risk level Basis for a positive assessment Basis for a negative assessment Risk mitigation measures The floors are flat, the passages are not cluttered, wet cleaning is carried out in the absence of staff There is cluttering of the passage between the machines (2) and (3) with production waste Comply with the existing procedure for the maintenance of the premises. There are no conditions for this risk Ots. (a) Mechanical hazards: - the risk of falling due to loss of balance, including when stumbling or slipping, when moving on slippery surfaces or wet floors; «+» - the danger of falling from a height, «-» Develop measures to organize the storage of production waste in the process of work for subsequent disposal, minimization (grinding) of waste. Ensure daily disposal of waste from the work area. Notes - the danger of falling due to the sudden appearance of a large height difference on the route; «-» There are no conditions for this risk Ots. - the danger impact; of «-» There are no conditions for this risk Ots. - the danger of being pricked or pierced as a result of exposure to moving stabbing parts of mechanisms, machines; «+» - the danger of bumping into a fixed piercing surface (tip); «-» There are no conditions for this risk Ots. - the danger of cutting parts of the body, including the edge of «+» There is a complete firstaid kit with the appropriate safety sign Ots. The risk of damage to the hand in case of careless contact with the working area of the machine (8). Strictly follow the instruction manual of the TPS8000 (8) bending machine. Installation of additional fencing is not possible Strictly comply requirements: with the 04-IOT "Andthe instruction on labor a sheet of paper, a stationery knife, scissors, (EC 01) within walking distance -danger from the impact of cutting tools (circular knives, circular saws); «-» There are no conditions for this risk - The risk of rupture; «-» There are no conditions for this risk - the risk of injury, including as a result of the ejection of a movable workpiece, falling or discarded objects, moving parts of equipment, snow and (or) ice falling from the roofs of buildings and structures; «-» There are no conditions for this risk protection for the provision of first aid to victims in case of accidents at work"; 33IOT "Andthe instruction no o ochreis not difficult forthe operator of the plotter cutting machine" b) electrical hazards: - the risk of electric shock due to direct contact with the current-carrying parts due to the contact of the unprotected parts of the body of the parts under voltage; «+» Electronic connection units of machines (1) – (6) are closed with standard casings that exclude accidental access The UV machine (7) has an open electrical connection unit on the upper side panel - the risk of electric shock due to contact with current-carrying parts that are under voltage due to a faulty state (indirect contact); «-» All machines are in good condition, maintenance is carried out in accordance with the operating instructions Ots. - the danger of electrostatic charge damage; «-» Ots. - the danger of electric shock from induced stress in the workplace; «-» Ots. Aboutthe open electrical connection unit Stanka UV (7) close with a casing that excludes accidental access - the risk of damage due to the occurrence of an electric arc; «-» Ots. - the danger of being struck by direct lightning; «-» Ots. - the danger of indirect lightning strike; «-» Ots. c) thermal hazards: «-» Ots. d) hazards associated with the impact of microclimate and climatic hazards: «-» In the set of equipment used there is exhaust ventilation, air conditioners are installed in the production facilities. The Company has the Order of the Head No. 29-OD dated 17.07.2019 "On Hygienic Requirements for the Ots. Microclimate of Production Facilities" e) dangers due to lack of oxygen in the air: «+» - the danger of lack of oxygen due to its displacement by other gases or liquids; «++» 40-IOT "Andthe instruction on labor protection forworking with liquid nitrogen and Dewar vessels" When working on the machine (4) liquid nitrogen is used The PPE kit provides for the useof "with the help Liquid acrylic is used in Strictly comply with the requirements of the relevant HSE instructions. Prohibit the storage of a cylinder of liquid nitrogen directly in the room where the machine is located when the machine is stopped for more than three days. (e) Hazards associated with exposure to a chemical factor: - the danger fromthe respiration of vapors of harmful liquids; «++» of personal respiratory protection filtering" the operation of the UV Machine (7). It is necessary to install an autonomous ventilation system in the room where the UV machine is located (7). In the set of equipment used there is exhaust ventilation, air conditioners are installed in the production facilities. The Company has the Order of the Head No. 29-OD dated 17.07.2019 "On Hygienic Requirements for the Microclimate of Production Facilities" Containers with liquid To reduce the consumption acrylic are placed in the of acrylic and, accordingly, production room. reduce the time of release of harmful vapors during production - to ensure the air supply to the working area of the machine not lower than t + 24° C. To store a stock of containers with liquid acrylic and prepare (stir) chemical material, allocate a separate ventilated room. Store in the production hall a stock of liquid acrylic for no more than 1 shift. A safety sign "Caution. Harmful to health allergic (irritating substances)" (W18) - danger of exposure to the skinof fattening and «+» The premises have a centralized water supply Ensure the continued use of respiratory protection masks in the operator's work. Ots. Ensure the availability of detergents. degreasing substances within walking distance from the workplaces. The PPE kit includes the use of gloves. g) hazards associated with exposure to aerosols of predominantly fibrogenic action: «-» Ots. h) hazards associated with exposure to a biological factor: «-» Ots. i) hazards associated with the impact of the severity and intensity of the labor process: - the danger associated with the movement of the goods manually; All goods transported on the territory of the workshop have an allowable weight. Ots. - the danger of lifting weights exceeding the permissible weight; Loads exceeding the permissible weight shall be moved by at least two workers and over a limited distance or by the use of a crane-beam. Ots. 12-IOT Instruction on labor protection andwork with a cranebeam j) hazards associated with exposure to noise: - the risk of damage to the membrane membrane of the ear associated with exposure to highintensity noise; - the danger associated with the possibility of not hearing the sound signal of danger; «++» The set of PPE of employees provides for the use of "Headphones anti-noise". «+» Machines (2) and (3) produce high-intensity noise during operation Ensure strict compliance with the requirements for use during operation of antinoise headphones. Install an additional siren and strobolamp to give an alarm k) hazards associated with exposure to vibration: - the danger from exposure to local vibration when using manual mechanisms; «-» Ots. - the hazard associated with the effects of general vibration; «-» Ots. - the danger of insufficient illumination in the working area; «+» Insufficiently lit working area of machines (2) and (3) - the danger of increased brightness of light; «-» Ots. - the danger of reduced contrast; «-» Ots. l) hazards associated with exposure to the light environment: Install additional lighting fixtures in the working area of the machines (2) and (3) (m) Hazards associated with nonionizing radiation: - the danger associated with exposure to laser radiation; «+» Place a safety sign in the room "Caution! Laser radiation!" (W 10) . - dangers associated with exposure to ultraviolet radiation; «+» (o) Hazards associated with insect exposure: «-» Ots. n) hazards associated with plant exposure: «-» Ots. (p) Risk of drowning: «-» Ots. In the set of PPE employees there are special glasses to protect the eyes from ultraviolet radiation. Ots. Place a safety sign in the room "Caution! Ultraviolet radiation!" (W 73) . (c) The hazard of the location of the workplace: Ots. «-» t) hazards associated with organizational shortcomings: - the danger associated with the absence at the workplace of instructions containing the procedure for the safe performance of work and information on the existing hazards associated with the performance of work operations; «+» - the danger associated with the absence of the described measures (the content of «+» The shop manager has a complete package of HSE instructions. Staff workshop equipped with UFA on OT and TB. Logs of HSE briefings in the workplace are maintained The head of the printing shop has instructions and passports for technological equipment. Staff Place the relevant instructions directly on the side surfaces of the equipment in the process pockets. actions) in the event of malfunctions (dangerous situations) during the maintenance of devices, equipment, devices; familiarized. Periodic knowledge testing is carried out. - the danger associated with the absence of a list of possible accidents at the workplace; «+» The head of the workshop has instructions and passports for technological equipment. Staff familiarized. Periodic knowledge testing is carried out. - the danger associated with the absence of a first-aid kit at the workplace, instructions for providing first aid to the victim at work and means of communication; «-» The first aid kit is within walking distance from the workplaces. Designated with the appropriate safety sign in accordance with GOST 12.4.026-2015. Completed in accordance with the requirements of the Place a list of possible accidents in the OT corner Order of the Ministry of Health and Social Development of the Russian Federation dated March 5, 2011 N 169n "On approval of the requirements for the completion of first-aid kits for first aid to employees with medical products" - the danger associated with the lack of information (scheme, signs, markings) on the direction of evacuation in the event of an accident; «-» Evacuation signs are installed in accordance with GOST 12.4.0262015 - the danger associated with the admission of employees who have not undergone «+» An introductory briefing, a primary briefing at the workplace was carried out with all employees. Periodic repeated training in labor protection; briefings are held at the workplace 1 time / 6 months. In the danger of fire: - danger from inhalation of smoke, vapors of harmful gases and dust in case of fire; «+» All employees are familiar with the Rules of Conduct in Case of Fire. - the risk of ignition; «-» Ots. - the risk of exposure to open flames; «-» Ots. - the danger of exposure to elevated ambient temperature; «-» Ots. - the danger of exposure to a reduced concentration of oxygen in the air; «+» 40-IOT Andsafety instruction when working with liquid nitrogen and Dewar vessels When working on the Machine (4) liquid nitrogen is used Provide supply and exhaust ventilation in the room - the risk of exposure to extinguishing agents; «-» Ots. - the danger of exposure to fragments of parts of destroyed buildings, structures, structures; «-» Ots. (f) The risk of collapse: «-» Ots. (x) Transport hazards: «-» Ots. (c) The risk of violence: «-» Ots. b) explosion hazards: «-» Ots. h) hazards associated with the use of personal protective equipment: «-» Ots. Objects Production process 1. Use of personal protective equipment (PPE) Contents 2. Desktops and equipment 3. Shelves and racks 4. Surfaces 5. Containers for garbage and waste 6. Gender Basis for a positive assessment Evaluati on The company has developed a REGULATION "On the procedure for the acquisition, issuance of free special clothing, special shoes and other personal protective equipment, use, storage and care". Cards on the norms and issuance of PPE to employees have been drawn up and maintained. PPE is purchased at the expense of the employer in accordance with the anatomical features of employees (by size). «-» Desktops and equipment are in good condition, periodic inspections and maintenance of equipment are carried out. Existing shelves and racks are in good condition. Fixed properly. The norms of loading of goods and materials on racks are observed. Periodic inspections of existing racks and shelves are carried out. The surfaces of the workplaces are flat, without chips and burrs. In accordance with the IOT, regular cleaning of surfaces is carried out. Tools, appliances and other equipment that is not subject to use in the technological process on the surfaces of workplaces is not located. Containers for garbage and waste are available in sufficient quantities. They are released daily from garbage and waste at the end of the working day. The floors are flat, the aisles are not cluttered, wet cleaning is carried out in the absence of staff. «-» «+» Occupational safety when working on production equipment 7. Construction and The design and technical condition of the technological equipment is technical condition good. All equipment is serviceable and safe during operation. «-» «-» «+» «+» Note (hazard description; explanation of "N/a" assessment) 8. Emergency stop controls 9. Means of protection 10. Fixed service areas and stairs Emergency stopping controls for machines and equipment are standard, in accordance with the documentation of the developer's company. Means of sewing machines and equipment are standard, in accordance with the documentation of the developer's company. «+» Not used «-» Environmental factors in the workplace 11. Noise Within the normal range (CONCLUSION of the SAWT) «+» «+» 12. Lighting Within the normal range (CONCLUSION of the SAWT) «+» 13. Air of the working area Within the normal range (CONCLUSION of the SAWT) «+» 14. Temperature, humidity and air exchange Within the normal range (CONCLUSION of the SAWT) «+» 15. Chemicals Within the normal range (CONCLUSION of the SAWT) «+» Within the normal range (CONCLUSION of the SAWT) «+» Within the normal range (CONCLUSION of the SAWT) «+» Ergonomic factors 16. Parameters of the workplace and the position of the body when working 17. Moving and lifting loads manually 18. Repetitive work operations Within the normal range (CONCLUSION of the SAWT) «+» 19. Change of body position during operation Within the normal range (CONCLUSION of the SAWT) «+» Passages and driveways (for 10 meters) 20. Device, designation, The passages are not cluttered, sufficient for the movement of safety gates personnel and the transfer of goods, appropriate fences and safety signs are installed to prevent unauthorized persons in accordance with GOST 12.4.026-2015 "INTERSTATE STANDARD. System of occupational safety standards. SIGNAL COLOURS, SAFETY SIGNS AND SIGNAL MARKINGS» 21. Order and Condition Order is observed constantly, the condition is good. 22. Visibility and lighting Sufficient (SAWT Conclusion) Rescue and first aid options (at the points closest to the workplace) 23. De-energizing switch There is «-» «-» «-» «+» 24. Rescue and first aid equipment A first-aid kit is available and equipped. Periodic replenishment is made. «+» 25. Fire extinguishing equipment The premises are equipped with fire extinguishers OU-3 in accordance with the PPB. Marked with appropriate safety signs in accordance with GOST 12.4.026-2015. Periodic inspection and recharging are carried out in accordance with the PPB. Marked with appropriate safety signs in accordance with GOST 12.4.026-2015. «+» 26. Escape routes «-» 27. Actions of personnel in the event of an emergency Staff are trained in the use of fire extinguishers. There is a person responsible for compliance with the PPB, trained in the PTM program in the training center. «+» Leader of the Evaluation Team __ Members of the evaluation team: Head of Production Department_____ ____ Head of Printing Department__ Machine Shop Manager___ ___ Welding Section Master___ energetic____ specialist FROM_______________________ _______________________ _________ «_____» _______ 20____ salon manager____ specialist OK_____ I am familiar with the risk factors in the workplace. __ (position) (Signed) (Acting Surname) _____ (position) (Signed) (position) (Signed) (position) (Signed) (Acting Surname) _____ (Acting Surname) _____ (Acting Surname) _____ (position) _____ (Signed) (Acting Surname) (position) (Signed) (Acting Surname) (position) (Signed) (Acting Surname) (position) (Signed) (Acting Surname) _____ _____ __ (position) (Signed) (Acting Surname) _____ (position) (Signed) (position) (Signed) (position) (Signed) (Acting Surname) _____ (Acting Surname) _____ (Acting Surname) _____ (position) (Signed) (Acting Surname) _____ (position) (Signed) (Acting Surname) (position) (Signed) (Acting Surname) (position) (Signed) (Acting Surname) _____ _____