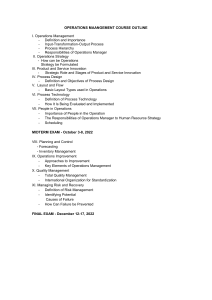

12/27/2022 Operations management Chapter 1 - Goods, Services, and Operations Management 1 TS.Đặng Hữu Phúc Learning outcome 1-1 Explain the concept and importance of operations management. 1-2 Describe what operations managers do. 1-3 Explain the differences between goods and services. 1-4 Describe a customer benefit package. 1-5 Explain the role of processes in OM and identify three general types of processes. 1-6 Summarize the historical development of OM. 1-7 Describe current challenges facing OM. TS. Đặng Hữu Phúc 1 12/27/2022 Basic functions of business organizations 3 TS. Đặng Hữu Phúc Definition Operations management (OM) is the science and art of ensuring that goods and services are created and delivered successfully to customers. Planning Controlling OM Organizing Leading 4 TS. Đặng Hữu Phúc 2 12/27/2022 Definition The role of operations management is to transform a company’s inputs into the finished goods or services 5 TS. Đặng Hữu Phúc Definition 6 TS. Đặng Hữu Phúc 3 12/27/2022 OPERATION MANAGEMENT Marketing Option Current Sales Cost of Goods Sold Gross Margin Finance Costs Net Margin Taxes @ 25% Contribution $100,000 Sales Revenue : +50% $150,000 -80,000 Finance & OM Option Accounting Option Finance Production Costs: -50% Costs: -20% $100,000 $100,000 -120,000 -80,000 -64,000 20,000 30,000 20,000 36,000 -6,000 -6,000 -3,000 -6,000 14,000 24,000 17,000 30,000 -3,500 -6,000 -4,250 -7,500 10,500 18,000 12,750 22,500 7 TS. Đặng Hữu Phúc What Do Operations Managers Do? https://www.youtube.com/watch?v=FbbGlVle3oU&t=25s ✓ Forecasting ✓ Supply chain management ✓ Facility layout and design ✓ Technology selection ✓ Quality management ✓ Purchasing ✓ Resource and capacity management ✓ Process design ✓ Job design ✓ Service encounter design ✓ Scheduling 8 TS. Đặng Hữu Phúc 4 12/27/2022 OM in the Workplace Shelly Decker, an accounting and information systems major in college, and her sister created an entrepreneurial venture to manufacture and sell natural soaps and body products. Shelly uses OM skills every day: • Process design – When a new product is to be introduced, the best way to produce it must be determined. This involves charting the detailed steps needed to make the product. • Inventory management – Inventory is tightly controlled to keep cost down and to avoid production that isn't needed. Inventory is taken every four weeks and adjusted in the inventory management system accordingly. 9 TS. Đặng Hữu Phúc OM in the Workplace Shelly uses OM skills every day: • • Scheduling – Production schedules are created to ensure that enough product is available for both retail and wholesale customers, taking into account such factors as current inventory and soap production capacity. Quality management – Each product is inspected and must conform to the highest quality standards. If a product does not conform to standard (for example, wrong color, improper packaging, improper labeling, improper weight, size, or shape), then it is removed from inventory to determine where the process broke down and to initiate corrective action. 10 TS. Đặng Hữu Phúc 5 12/27/2022 OM in the Workplace Ryan is Process Manager of Credit Card Division in Bank of America What are his responsibilities: • Planning and budgeting: ??? • Inventory management: ??? • Scheduling and capacity: ??? • Quality: ??? 11 TS. Đặng Hữu Phúc Understanding Goods and Services • A good is a physical product that you can see, touch, or possibly consume, including durable good (is a product that typically lasts at least three years) and non-durable good (is perishable and generally lasts for less than three years) • A service is any primary or complementary activity that does not directly produce a physical product. 12 TS. Đặng Hữu Phúc 6 12/27/2022 Service characteristics 13 TS. Đặng Hữu Phúc Service characteristics: Intangibility • Services can not be seen, tasted, felt, heard, or smelled. • Rely on references, reputation and facilities to judge a service • Intangibility increases the level of uncertainty 14 TS. Đặng Hữu Phúc 7 12/27/2022 Service characteristics: Inseparability • Services are produced and consumed simultaneously. • Producer and consumer must normally interact in order for the benefits of the service to be realized 15 TS. Đặng Hữu Phúc Service characteristics: Perishability • Services cannot be stored for later sale or use • Particular service irreversibly vanishes as it has been consumed by the consumer 16 TS. Đặng Hữu Phúc 8 12/27/2022 Service characteristics: Variability • The quality of the service may vary depending on who provides it, as well as when and how it is provided. • Reducing variability involves determining the causes. • • • Personality traits Poor training and supervision Lack of regular support 17 TS. Đặng Hữu Phúc - Goods and services provide value and satisfaction to customers who purchase and use them. - They both can be standardized or customized to individual wants and needs. - A process creates and delivers each good or service, and therefore, OM is a critical skill. - Goods are tangible while services are intangible. - Customers participate in many service processes, activities, and transactions. - The demand for services is more difficult to predict than the demand for goods. - Services cannot be stored as physical inventory. - Service management skills are essential to a successful service encounter. - Service facilities typically need to be in close proximity to the customer. - Patents do not protect services. Differences Between Goods and Services Similarities Between Goods and Services Understanding Goods and Services 18 TS. Đặng Hữu Phúc 9 12/27/2022 How Goods and Services Affect Operations Management Activities 19 TS. Đặng Hữu Phúc Customer Benefit Packages (CBP) • A customer benefit package (CBP) is a clearly defined set of tangible (goods-content) and intangible (service-content) features that the customer recognizes, pays for, uses, or experiences. • In simple terms, a CBP is some combination of goods and services configured in a certain way to provide value to customers. • A CBP consists of a primary good or service, coupled with peripheral goods and/or services. 20 TS. Đặng Hữu Phúc 10 12/27/2022 Customer Benefit Packages (CBP) • A primary good or service is the “core” offering that attracts customers and responds to their basic needs. For example, the primary service of a personal checking account is the capability to do convenient financial transactions. • Peripheral goods or services are those that are not essential to the primary good or service, but enhance it. Examples for a personal checking account: online access and bill payment, debit card, designer checks , paper or electronic account statement 21 TS. Đặng Hữu Phúc Customer Benefit Packages (CBP) Exhibit 1.2 Example for Purchasing a Vehicle 22 TS. Đặng Hữu Phúc 11 12/27/2022 Working in Group Draw the customer benefit package (CBP) for three of the items in the following list and explain how your CBP provides value to the customer. • A new personal computer • A trip to Disney World • A credit card • A fast-food restaurant • A new smartphone • A hotel • …… You can either create them by yourself or collect them from internet 23 TS. Đặng Hữu Phúc Six Eras of Operations Management 24 TS. Đặng Hữu Phúc 12 12/27/2022 Sustainability • Sustainability refers to service and production processes that use resources in ways that do not harm ecological systems that support both current and future human existence 25 TS. Đặng Hữu Phúc Sustainability + Waste management + Energy optimization + Transportation optimization + Technology upgrades + Air quality + Sustainable product design +Performance excellence + Financial management + Resource management + Emergency preparedness - Product safety -Workforce health and safety -Ethics and governance - Community 26 TS. Đặng Hữu Phúc 13 12/27/2022 Group discussion Prepare for Case study: Hazel (30 minutes) Answer: Question 1 27 TS. Đặng Hữu Phúc www.website.com 28 TS.Đặng Hữu Phúc 14 12/27/2022 OPERATIONMANAGEMENT VALUE CHAINS 29 TS.Đặng Hữu Phúc Learning outcome 2-1 Explain the concept of value and how it can be increased. 2-2 Describe a value chain and the two major perspectives that characterize it. 2-3 Explain outsourcing and vertical integration in value chains. 2-4 Explain offshoring and issues that managers must consider in offshoring decisions. 2-5 Identify important issues associated with value chains in a global business environment. 2-6 Describe how sustainability plays an important role in value chains. 30 TS. Đặng Hữu Phúc 15 12/27/2022 Value and Supply Chains • The value chain is a process in which a company adds value to its raw materials to produce products eventually sold to consumers. • The supply chain represents all the steps required to get the product to the customer. 31 TS. Đặng Hữu Phúc VALUE AND SUPPLY CHAINS 32 TS. Đặng Hữu Phúc 16 12/27/2022 The Concept of Value Value is the perception of the benefits associated with a good, service, or bundle of goods and services (i.e., the customer benefit package) in relation to what buyers are willing to pay for them. 33 TS. Đặng Hữu Phúc The Concept of Value If the value ratio is high, the good or service is perceived favorably by customers, and the organization providing it is more likely to be successful. To increase value, an organization must: Perceived benefits Value = Price (cost) to the customer (a) increase perceived benefits while holding price or cost constant, (b) increase perceived benefits while reducing price or cost, or (c) decrease price or cost while holding perceived benefits constant. 34 TS. Đặng Hữu Phúc 17 12/27/2022 Value Chain Paradigms and Perspectives • Input-Output Model: A value chain begins with suppliers who provide inputs that are transformed into value-added goods and services through processes that are supported by resources such as equipment and facilities, labor, money, and information. These goods and services are delivered or provided to customers and targeted market segments. ❖ Value-creation processes ❖ Support processes ❖ General management processes 35 TS. Đặng Hữu Phúc • Input-Output Model 36 TS. Đặng Hữu Phúc 18 12/27/2022 Value Chain Paradigms and Perspectives 37 TS. Đặng Hữu Phúc Integration • • Vertical integration refers to the process of acquiring and consolidating elements of a value chain to achieve more control. • Backward integration refers to acquiring capabilities toward suppliers • Forward integration refers to acquiring capabilities toward distribution or even customers. Horizontal integration is the acquisition of a business operating at the same level of the value chain in a similar or different industry. 38 TS. Đặng Hữu Phúc 19 12/27/2022 39 TS. Đặng Hữu Phúc Outsourcing • Outsourcing is the process of having suppliers provide goods and services that were previously provided internally. TS. Đặng Hữu Phúc 20 12/27/2022 Potential advantages and disadvantages of Outsourcing • Group working Discuss the advantages and disadvantages of outsourcing ------------------When do we decide to outsource? 41 TS. Đặng Hữu Phúc The Economics of Outsourcing • • • • • • • VC1 = Variable cost/unit if produced VC2 = Variable cost/unit if outsourced FC = Fixed costs associated with producing the part Q = Quantity produced (volume) Total cost of production = (VC1)Q + FC Total cost of outsourcing = (VC2)Q Find the breakeven point: (VC2)Q = (VC1)Q + FC 𝑭𝑪 Q* = 𝐕𝐂𝟐 −𝑽𝑪𝟏 42 TS. Đặng Hữu Phúc 21 12/27/2022 The Economics of Outsourcing Solved Problem—In-House versus Outsource • Suppose that a manufacturer needs to produce a custom aluminum housing for a special customer order. Because it currently does not have the equipment necessary to make the housing, it would have to acquire machines and tooling at a fixed cost (net of salvage value after the project is completed) of $250,000. The variable cost of production is estimated to be $20 per unit. The company can outsource the housing to a metal fabricator at a cost of $35 per unit. The customer order is for 12,000 units. • What should they do? 43 TS. Đặng Hữu Phúc Problem A university currently has a recycling program for paper waste. The fixed cost of running this program is $8,000 per year. The variable cost for picking up and disposing of each ton of recyclable paper is $40. If the work is outsourced to a recycling company, the cost would be $70 per ton. • Find Q*. • If the university recycles 200 tons each year, what should it do? 44 TS. Đặng Hữu Phúc 22 12/27/2022 Break-even point analysis • Break Even Analysis in economics, business, and cost accounting refers to the point in which total cost and total revenue are equal. 45 TS. Đặng Hữu Phúc Break-even point analysis A book publisher has fixed costs of $300,000 and variable costs per book of $8.00. The book sells for $23.00 per copy. a) How many books must be sold to break even? b) If the fixed cost increased, would the new break-even point be higher or lower? c) If the variable cost per unit decreased, would the new break-even point be higher or lower? 46 TS. Đặng Hữu Phúc 23 12/27/2022 Assignment A language center organizes a training course lasting within 18 weeks with the following information • The course take place on Saturday and Sunday, weekly • The total tuition fee the course is 29,000,000 VND • The operation cost are listed in the following slide. 47 TS. Đặng Hữu Phúc Assignement Expenditure Cost Educator expense $4,000,000 / day Transportation allowance $500,000 / day Teaching facilities $1,500,000 / day Tax 6% revenue Fee for recruiting one new student 10% revenue Fee for issuing one certificate $100,000 / 1 certificate Management expense 10% revenue Other expense 6% revenue TS. Đặng Hữu Phúcare needed to break even? → How many students 48 24 12/27/2022 OFFSHORE • • Offshoring is the building, acquiring, or moving of process capabilities from a domestic location to another country location while maintaining ownership and control. Offshoring is the relocation of a business process from one country to another—typically an operational process, such as manufacturing, or supporting processes, such as accounting. 49 TS. Đặng Hữu Phúc OFFSHORE Things to Consider When Making Offshore Decisions ------------------- 50 TS. Đặng Hữu Phúc 25 12/27/2022 OFFSHORE – TAX HAVEN Normal Offshore A buy Rolex at $100 B buy Rolex at $100 Example A buy Rolex from B at $1000 A sell Rolex at $1000 A sell Rolex at $1000 A get a profit for $900 A get a profit for $00 B get a profit for $900 A pay for tax about 20% = $180 A pay for tax about 20% = 0 B do not pay for tax Totally, pay for tax $180 Totally, pay for tax $0 51 TS. Đặng Hữu Phúc Value Chains in a Global Business Environment • A multinational enterprise is an organization that sources, markets, and produces its goods and services in several countries to minimize costs, and to maximize profit, customer satisfaction, and social welfare. 52 TS. Đặng Hữu Phúc 26 12/27/2022 Value Chains in a Global Business Environment Group working Research the potential issues related to Value Chains in a Global Business Environment? • --------• --------• --------- 53 TS. Đặng Hữu Phúc www.website.com 54 TS.Đặng Hữu Phúc 27 12/27/2022 Group assignment • Find out the international corporation and analyze its value chain based on Porter model. It does not matter if that company is successful or failed. • Each group is going to prepare PPT file and deliver presentation on last 2 days of this course. • The content includes: • • • Brief introduction about the company Detail analysis about its value chain based on Porter model Some lessons from its success or failure. • Choose the company for analysis. Ensure that each group analyzes different company. Register your choice in our Zalo group. TS. Đặng Hữu Phúc Operation Management Forecasting and Demand Planning TS.Đặng Hữu Phúc 56 28 12/27/2022 Learning Outcomes • Describe the importance of forecasting to the value chain. • Explain basic concepts of forecasting and time series. • Explain how to apply single moving average and exponential smoothing models. • Describe how to apply regression as a forecasting approach. • Explain the role of judgment in forecasting. • Describe how statistical and judgmental forecasting techniques are applied in practice. 57 TS. Đặng Hữu Phúc Basic Concepts in Forecasting A time series is a set of observations measured at successive points in time or over successive periods of time. A time series pattern may have one or more of the following five characteristics: • • • • • Trend Seasonal patterns Cyclical patterns Random variation (or noise) Irregular (one time) variation 58 TS. Đặng Hữu Phúc 29 12/27/2022 Basic Concepts in Forecasting ❖ A trend is the underlying pattern of growth or decline in a time series. ❖ Seasonal patterns are characterized by repeatable periods of ups and downs over short periods of time. ❖ Cyclical patterns are regular patterns in a data series that take place over longer periods of time. ❖ Random variation (sometimes called noise) is the unexplained deviation of a time series from a predictable pattern, such as a trend, seasonal, or cyclical pattern. ❖ Irregular variation is a one-time variation that is explainable. 59 TS. Đặng Hữu Phúc Seasonal Pattern of Home Natural Gas Usage 60 TS. Đặng Hữu Phúc 30 12/27/2022 Trend and Business Cycle Characteristics (each data point is 1 year apart) 61 TS. Đặng Hữu Phúc Statistical Forecasting Models • Statistical forecasting is based on the assumption that the future will be an extrapolation of the past. • Judgmental forecasting relies upon opinions and expertise of people in developing forecasts. 62 TS. Đặng Hữu Phúc 31 12/27/2022 Naïve Method The naïve method is one of the simplest forecasting models. It assumes that the next period’s forecast is equal to the current period’s actual. Ft+1 : Forecast of demand for next period, t+1 At : Actual value for current period t t : Current time period 63 TS. Đặng Hữu Phúc Single Moving Average A moving average (MA) forecast is an average of the most recent “n” observations in a time series. Ft+1 : Forecast of demand for next period, t+1 At : Actual demand observed in period t n : number of periods or data points to be averaged MA methods work best for short planning horizons when there is no major trend, seasonal, or business cycle pattern. • As the value of “n” increases, the forecast reacts slowly to recent changes in the time series data. 64 TS. Đặng Hữu Phúc 32 12/27/2022 Solved Problem Develop three-period moving-average forecasts Period Demand Period Demand 1 86 7 91 2 93 8 93 3 88 9 96 4 89 10 97 5 92 11 93 6 94 12 95 65 TS. Đặng Hữu Phúc Weighted Moving Average (WMA) • Weighted moving averages assign a heavier weighting to more current data points since they are more relevant than data points in the distant past • The sum of the weighting should add up to 1 (or 100 percent). In the case of the simple moving average, the weightings are equally distributed Ft+1 = wtAt + wt-1At–1 + ... + wt-nAt-n Ft+1 : Forecast of demand for next period, t+1 At : Actual demand observed in period t wt : the weighting in period t n : number of periods or data points to be averaged 66 TS. Đặng Hữu Phúc 33 12/27/2022 Weighted Moving Average (WMA) Date Closing Price of AAPL Weighting June 26 $90.90 5/15 June 25 $90.36 4/15 June 24 $90.28 3/15 June 23 $90.83 2/15 June 20 $90.91 1/15 67 TS. Đặng Hữu Phúc Single Exponential Smoothing • Single Exponential Smoothing (SES) is a forecasting technique that uses a weighted average of past time-series values to forecast the value of the time series in the next period. Ft+1 = At + (1 – )Ft = Ft + (At – Ft) where α is called the smoothing constant (0 ≤ α ≤ 1). 68 TS. Đặng Hữu Phúc 34 12/27/2022 Trend-Adjusted Exponential Smoothing • Step 1: Calculate the forecast using Single Exponential Smoothing (Ft); Ft= Ft-1 + (At-1 – Ft-1) • Step 2: Adjust the trend Tt = x (Ft − Ft -1) + (1− )Tt-1 where is called the trending constant (0 ≤ ≤ 1). where T is called the trending adjustment. • Step 3: Calculate Forecast Including Trend (FITt): FITt= Ft + Tt 69 TS. Đặng Hữu Phúc Exponential Smoothing with Trend The last demands related to a product are listed in the following table: Month Demand 1 2000 2 2100 3 1500 4 1400 5 1300 6 1600 Let’s assume that α = 0.8, = 0.5, F1 = 2200 và T1 = 0 Forecast the next month using the exponential smoothing with trend. 70 TS. Đặng Hữu Phúc 35 12/27/2022 Exponential Smoothing with Trend Month α = 0.8 Ai Ft = Ft-1 + (At-1 – Ft-1) = 0.5 Tt = x (Ft − Ft -1) +(1−)Tt-1 FIT 1 2000 2200 0 2200 2 2100 2040 -80 1960 3 1500 4 1400 5 1300 6 1600 7 - ??? 71 TS. Đặng Hữu Phúc Problem • Sunrise company deliveries its own Donuts through a food chain. The demand for Donuts within the last 4 weeks are in the following table. 4 weeks ago 3 weeks ago 2 weeks ago 1 weeks ago Monday 2200 2400 2300 2400 Tuesday 2000 2100 2200 2200 Wednesday 2300 2400 2300 2500 Thursday 1800 1900 1800 2000 Friday 1900 1800 2100 2000 Saturday 2010 2020 2000 2300 Sunday 2800 2700 3000 2900 72 TS. Đặng Hữu Phúc 36 12/27/2022 4 weeks ago 3 weeks ago 2 weeks ago 1 weeks ago Monday 2200 Tuesday 2000 2400 2300 2400 2100 2200 2200 Wednesday 2300 2400 2300 2500 Thursday 1800 1900 1800 2000 Friday 1900 1800 2100 2000 Saturday 2010 2020 2000 2300 Sunday 2800 2700 3000 2900 Forecast the demand for this week with: a. Forecast the daily demand using single moving average (4 weeks). b. Forecast the daily demand using weighted moving average, the weights are 0,4; 0,3; 0,2; 0,1. c. This firms is planning to purchase the material for Donuts. Assume that the forecast for last week was 22000 units, while the actual need was 21000 units. Forecast for this week using the Exponential Smoothing With Trend with = 0,10, β = 0.5, and last T = 150 d. With the result from question C, the actual demand for this week is 22500 units, make the forecast for next week? 73 TS. Đặng Hữu Phúc Regression as a Forecasting Approach • Regression analysis is a method for building a statistical model that defines a relationship between a single dependent variable and one or more independent variables, all of which are numerical. • • • • • • Y : dependent variable x : independent variable (time) a : intercept of the regression line b : slope of the regression line CusSatis = 2.85 - 0.34*Price Ice-cream Revenue = 34 + 0.75*Temperature 74 TS. Đặng Hữu Phúc 37 12/27/2022 Causal Forecasting with Multiple Regression A linear regression model with more than one independent variable is called a multiple linear regression model. 75 TS. Đặng Hữu Phúc Basic Concepts in Forecasting • Forecast error is the difference between the observed value of the time series and the forecast, or At – Ft Mean Square Error (MSE) MSE = Σ(At – Ft )2 n Mean Absolute Deviation Error (MAD) MAD = Σ׀At – Ft ׀ n Mean Absolute Percentage Error (MAPE) MAPE = Σ(׀At – Ft )/At ׀X 100 n TS. Đặng Hữu Phúc 38 12/27/2022 Example • Standard Parts Corporation is comparing the accuracy of two methods that it has used to forecast sales of its popular valve. Forecasts using method A and method B are shown against the actual values for January through May. Which method provided better forecast accuracy? Month Actual Sales Forecast Method A Method B January 30 28 30 February 26 25 28 March 32 32 36 April 29 30 30 May 31 TS. Đặng Hữu Phúc 30 28 77 Judgmental Forecasting • Judgmental forecasting relies upon opinions and expertise of people in developing forecasts. − − Grass Roots forecasting is simply asking those who are close to the end consumer, such as salespeople, about the customers’ purchasing plans. The Delphi method consists of forecasting by expert opinion by gathering judgments and opinions of key personnel based on their experience and knowledge of the situation. TS. Đặng Hữu Phúc 39 12/27/2022 www.website.com TS.Đặng Hữu Phúc 79 Individual Assignment • The below table shows the real demand of a product within last 7 months. Using MSE to compare the forecasting methods between 2-period SMA and Exponential Smoothing with Trend (α = 0.8, β = 0.4, F1= 2100, T1=0) Month Demand 1 2000 2 2100 3 1500 4 1400 5 1300 6 1600 80 7 TS. Đặng Hữu Phúc 1550 40 12/27/2022 Operation Management Managing Inventories TS.Đặng Hữu Phúc 81 Learning outcomes • • • • • • Explain the importance of inventory, types of inventories, and key decisions and costs. Describe the major characteristics that impact inventory decisions. Describe how to conduct an ABC inventory analysis. Explain how a fixed order quantity inventory system operates, and how to use the EOQ and safety stock models. Explain how a fixed period inventory system operates. Describe how to apply the single-period inventory model. 82 TS. Đặng Hữu Phúc 41 12/27/2022 Concept • Inventory is any asset held for future use or sale. Objectives: • − − Maintain sufficient inventory Incur lowest possible cost Inventory management involves planning, coordinating, and controlling the acquisition, storage, handling, movement, distribution, and possible sale of raw materials, component parts and subassemblies, supplies and tools, replacement parts, and other assets that are needed to meet customer wants and needs. Stock Management V.s Inventory Management 83 TS. Đặng Hữu Phúc Understanding Inventory • • • • • • Raw materials Component parts Work-in-process (WIP) inventory Finished goods inventory Distribution inventory Maintenance, repair, and operational (MRO) inventory 84 TS. Đặng Hữu Phúc 42 12/27/2022 Role of Inventory in the Value Chain 85 TS. Đặng Hữu Phúc Group Activities Thinking about your local food supermarket • • What are the main risks of running out of stock? How can they manage the inventory? Taking 30 minutes for research and then report the above issues - Upload your group report to LMS Present your group report (randomly choose) 86 TS. Đặng Hữu Phúc 43 12/27/2022 Inventory Management Decisions and Costs Inventory managers deal with two fundamental decisions: 1. When to order items from a supplier or when to initiate production runs if the firm makes its own items. 2. How much to order or produce each time a supplier or production order is placed. 87 TS. Đặng Hữu Phúc Inventory Management Decisions and Costs Four categories of inventory costs: • Shortage costs • Unit cost of the stock-keeping units (SKUs) • Ordering or setup costs • Inventory-holding costs 88 TS. Đặng Hữu Phúc 44 12/27/2022 Inventory Management Decisions & Costs • Shortage costs or stockout costs are the costs associated with a SKU being unavailable when needed to meet demand, including • • • Back-order cost Lost sale Unit cost is the price paid for purchased goods or the internal cost of producing them. 89 TS. Đặng Hữu Phúc Inventory Management Decisions & Costs • Ordering costs or setup costs are incurred as a result of the work involved in placing purchase orders with suppliers or configuring tools, equipment, and machines within a factory to produce an item. It normally include • • • • Clerical costs of preparing purchase orders Cost of finding suppliers and expediting orders Transportation costs Receiving costs 90 TS. Đặng Hữu Phúc 45 12/27/2022 Inventory Management Decisions & Costs • Inventory-holding costs or inventory-carrying costs are the expenses associated with carrying inventory. Holding costs are typically defined as a percentage of the dollar value of inventory per unit of time (generally one year). ➢Storage cost ➢Capital cost ➢Risk cost 91 TS. Đặng Hữu Phúc Inventory Management Decisions & Costs Holding Costs Category Housing costs (including rent or depreciation, operating costs, taxes, insurance) Material handling costs (equipment lease or depreciation, power, operating cost) Labor cost Cost (and Range) as a Percent of Inventory Value 6% (3 - 10%) 3% (1 - 3.5%) 3% (3 - 5%) Investment costs (borrowing costs, taxes, and insurance on inventory) Pilferage, space, and obsolescence 11% (6 - 24%) Overall carrying cost 26% 3% (2 - 5%) TS. Đặng Hữu Phúc 46 12/27/2022 Inventory Characteristics • Stockout − A stockout is the inability to satisfy demand for an item. − A backorder occurs when a customer is willing to wait for an item. − A lost sale occurs when the customer is unwilling to wait and purchases the item elsewhere. 93 TS. Đặng Hữu Phúc ABC Inventory Analysis 94 TS. Đặng Hữu Phúc 47 12/27/2022 ABC Inventory Analysis 95 TS. Đặng Hữu Phúc Procedure for an ABC Inventory Analysis 1. Calculate the annual dollar usage for each item. 2. List the items in descending order based on annual dollar usage. 3. Calculate the cumulative annual dollar volume. 4. Classify the items into groups 96 TS. Đặng Hữu Phúc 48 12/27/2022 ABC Inventory Analysis • The data shows projected annual dollar usage for 20 items. 97 TS. Đặng Hữu Phúc ABC Inventory Analysis • • Excel ABC Template After Sorting, 98 TS. Đặng Hữu Phúc 49 12/27/2022 ABC Inventory Analysis • ABC Histogram for the Results 99 TS. Đặng Hữu Phúc Cycle Counting Example 5,000 items in inventory, 500 A items, 1,750 B items, 2,750 C items Policy is to count A items every month (20 working days), B items every quarter (60 days), and C items every six months (120 days) → How can we assign a person to check such items following the regulation? TS. Đặng Hữu Phúc 50 12/27/2022 The economic order quantity (EOQ) • • The Economic Order Quantity (EOQ) model is a classic economic model developed in the early 1900s that minimizes total cost, which is the sum of the inventory-holding cost and the ordering cost. Assumptions: ✓ ✓ ✓ ✓ ✓ ✓ Demand for the product is known and constant Lead time is constant Quantity discounts are not considered Ordering and setup costs are fixed and constant Does not permit back orders The quantity ordered arrives at once 101 TS. Đặng Hữu Phúc Managing Fixed Quantity Inventory Systems • Fixed Quantity System (FQS) under Stable Demand 102 TS. Đặng Hữu Phúc 51 12/27/2022 The EOQ Model Average cycle inventory = (Maximum inventory + Minimum inventory) / 2 = Q/2 103 TS. Đặng Hữu Phúc The EOQ Model Inventory Holding Cost • The cost of storing one unit in inventory for the year, H, is: H = (I) (C) Where: • • I = Annual inventory-holding charge expressed as a percent of unit cost. C = Unit cost of the inventory item or SKU. Annual inventory-holding cost is computed as: Annual inventory = holding cost ( )( average inventory ) annual holding cost per unit = 1 QH 2 104 TS. Đặng Hữu Phúc 52 12/27/2022 The EOQ Model Ordering Cost If D = Annual demand and we order Q units each time, then we place D/Q orders/year. Annual ordering cost is computed as: annual = ordering cost ( number of orders per year )( cost per order ) () = D Q S Where S is the cost of placing one order/ setting up. 105 TS. Đặng Hữu Phúc The EOQ Model Total Annual Cost • Total annual cost is the sum of the inventory holding cost plus the order or setup cost plus annual purchase cost TC = 1 D S + DC QH + Q 2 Where TC is total annual cost S is setting up/ordering cost H is holding cost C is unit cost D is annual quantity demand Q is Volume per Order 106 TS. Đặng Hữu Phúc 53 12/27/2022 The EOQ Model 107 TS. Đặng Hữu Phúc The EOQ Model Economic Order Quantity • The EOQ is the order quantity that minimizes the total annual cost: Q* = √ 2DS H 108 TS. Đặng Hữu Phúc 54 12/27/2022 The EOQ Model • Number of orders per year * • Time between orders (TBO) Where N is number of orders 109 TS. Đặng Hữu Phúc The EOQ Model Calculating the Reorder Point • The reorder point, r, depends on the lead time and demand rate. r = Lead r = (Average demand) x (lead time) = (d) x (L) Where: d = Average daily demand (constant) L = Lead time in days (constant) 110 TS. Đặng Hữu Phúc 55 12/27/2022 The EOQ Model Given the following information, find the economic order quantity, the reorder point, and total cost. Comparing to Q = 2000, how much company can save? D = 24,000 cases per year. S = $38.00 per order. I = 18% C = $12.00 per case. L = 3 days Working days per year = 250 111 TS. Đặng Hữu Phúc Question • A company faces an annual demand of 2,000 units. It costs the company $1,000 for every order placed and $250 per unit of the product. It faces a carrying cost of 10% of a unit cost. Lead time is 2 weeks. What is the economic order quantity? Time between orders? Reorder point? • Assuming the working days: 360 112 TS. Đặng Hữu Phúc 56 12/27/2022 Managing Fixed Quantity Inventory Systems • Fixed Quantity System (FQS) with highly variable Demand 113 TS. Đặng Hữu Phúc Safety Stock and Uncertain Demand in a Fixed Order Quantity System When demand is uncertain, using EOQ based on the average demand will result in a high probability of a stockout. ✓Safety stock is additional planned on-hand inventory that acts as a buffer to reduce the risk of a stockout. ✓A service level is the desired probability of not having a stockout during a lead-time period. 114 TS. Đặng Hữu Phúc 57 12/27/2022 Safety Stock and Uncertain Demand in a Fixed Order Quantity System Re-order point after including safety stocks: R = mL + zsL = (d x L) + zsL Where • • • mL : Average demand during the lead time. sL: Standard deviation of demand during the lead time. z : The number of standard deviations necessary to achieve the acceptable service level. • “zsL” : represents the amount of safety stock. 115 TS. Đặng Hữu Phúc Safety Stock and Uncertain Demand in a Fixed Order Quantity System • We may not know the mean and standard deviation • of demand during the lead time, but we may know mean and standard deviation of daily demand Suppose that md and sd are the mean and standard deviation of daily demand. mL = md L sL = sd √L = √ L x s2d 116 TS. Đặng Hữu Phúc 58 12/27/2022 Example • d = 60 • sd = 7 • S = $10 • H = $0.50 • L=6 • Working days = 365 → Calculate Q* and re-order point with confident level at 95% (z=1.64) 117 TS. Đặng Hữu Phúc Question 1 Southern Office Supplies, Inc. distributes laser printer paper. • • • • • • Ordering costs are $45.00 per order. One ream of paper costs $3.80. Annual inventory-holding cost rate is 20%. The average annual demand is 15,000 reams, or about 15,000/52 = 288.5 per week. The standard deviation of weekly demand is about 71. The lead time from the manufacturer is two weeks. - Find out EOQ. Desired service level of 95% (z=1.64), find out reorder point, the cost of the additional safety stock. 118 TS. Đặng Hữu Phúc 59 12/27/2022 Break 119 2. POQ – Production Order Quantity 120 TS. Đặng Hữu Phúc 60 12/27/2022 2. POQ model POQ model have the same assumptions with EOQ, except: • The entire order quantity (Q) arrive in the inventory at more than one time and finish after t. Used when units are produced and sold simultaneously p : Daily production rate d : Daily demand/usage rate Inventory 121 TS. Đặng Hữu Phúc 2. POQ model • Example The requirement: 100 units (Q) Daily production rate: 50 units (p) Daily usage rate: 10 units (d) 122 TS. Đặng Hữu Phúc 61 12/27/2022 2. POQ model • Example On the first day: Assume that there is no inventory: + 50 units are produced (p) + 10 units are consumed (d) At the end of first day: inventory → 40 units (p-d) On the second day: + 50 units are produced + 10 units are consumed At the end of second day: inventory → 40 units (1st) + 40 units (2nd) = 80 units 123 TS. Đặng Hữu Phúc 2. POQ model • Example On the third day: + 0 units are produced (since 100 units already be produced) + 10 units are consumed At the end of third day: inventory → 80 units – 10 units = 70 units Similarity At the end of fourth day: inventory → 60 units …. At the end of tenth day: inventory → 0 unit → Conclusion: maximum inventory (80 units), minimum inventory (0 unit) 124 TS. Đặng Hữu Phúc 62 12/27/2022 2. POQ model Inventory level Q = Number of pieces per order p = Daily production rate H = Holding cost per unit per year d = Daily demand/usage rate t = Length of the production run (in days) Part of inventory cycle during which production (and usage) is taking place Demand part of cycle with no production Maximum inventory t Time 125 TS. Đặng Hữu Phúc 2. POQ model • t = Q/ p; • Imax = (p – d)t = (p – d).Q/p = Q (1 – d/p) • Imin = 0 ➔Iaveg = Q (1 – d/p)/2 TCHH = 1 2 Q(1 – d/p) H + D S + DC Q Average annual inventory 126 TS. Đặng Hữu Phúc 63 12/27/2022 2. POQ model Q = Number of pieces per order H = Holding cost per unit per year D = Annual demand p = Daily production rate d = Daily demand/usage rate 127 TS. Đặng Hữu Phúc 2. POQ example D = 1,000 units S = $10 H = $0.50 per unit per year p = 8 units per day d = 4 units per day TS. Đặng Hữu Phúc 64 12/27/2022 Question • The average monthly demand for a material is 125 units. According to the agreement, the price is $10/unit and the order will be executed many times with an average supply of 40 units / week. The average ordering cost is $15; holding cost equals to 20% of the purchase price. Number of working days is 250 days/year, a 5-day working week. • Determine the optimal order quantity? 129 TS. Đặng Hữu Phúc 3. FIXED PERIOD SYSTEM – FPS (P-model) 130 TS. Đặng Hữu Phúc 65 12/27/2022 3. FPS model • Inventory counted only at end of period • Orders placed at the end of a fixed period • Order brings inventory up to target level • May be scheduled at convenient times • Appropriate in routine situations 131 TS. Đặng Hữu Phúc Inventory Level in a Fixed Period System Various amounts (Qi) are ordered at regular time intervals (p) based on the quantity necessary to bring inventory up to target maximum Target maximum Q1 Q4 Q2 d Inventory Q3 p p p Time TS. Đặng Hữu Phúc 66 12/27/2022 3. FPS model Average demand Order amount + Safety stock - Inventory = in the review position period q = d(T+L) z s(T+L) + - IP q = order quantity T = the number of days between reviews L = Lead time d = daily/weekly forecast demand Z = the number of standard deviations for a specified service probability s(T+L) = Standard deviation of demand over the review and lead time 133 TS. Đặng Hữu Phúc 3. FPS model Average demand Order amount + Safety stock - Inventory = in the review position period q = d(T+L) + z s(T+L) - IP IP = (Inventory position) • Inventory position (IP) is the on-hand quantity (OH) plus any orders placed but which have not arrived (scheduled receipts, or SR), minus any backorders (BO). IP = OH + SR – BO 134 TS. Đặng Hữu Phúc 67 12/27/2022 3. FPS model • Question: Daily demand for a product is 10 units, with a standard deviation of 3 units. The review period is 30 days, and the lead time is 14 days. Management has set a policy of satisfying 98 percent (z = 2.05) of demand from items in stock. At the beginning of this review period, there are 150 units in inventory. How many units should be ordered? 135 TS. Đặng Hữu Phúc 3. FPS model 136 TS. Đặng Hữu Phúc 68 12/27/2022 4. QUANTITY DISCOUNT MODEL – QDM 137 TS. Đặng Hữu Phúc 4. QDM Model • Reduced prices are often available when larger quantities are purchased • Trade-off is between reduced product cost and increased holding cost TS. Đặng Hữu Phúc 69 12/27/2022 4. QDM Model A typical quantity discount schedule Discount Number Discount Quantity Discount (%) Discount Price (P) 1 0 to 999 no discount $5.00 2 1,000 to 1,999 4 $4.80 3 2,000 and over 5 $4.75 TS. Đặng Hữu Phúc 4. QDM Model Steps in analyzing a quantity discount 1. For each discount, calculate Q* Q* = √ 2DS H 2. If Q* for a discount doesn’t qualify, choose the nearest possible order size to get the discount (Q**) TS. Đặng Hữu Phúc 70 12/27/2022 4. QDM Model Steps in analyzing a quantity discount 3. Compute the total cost for each adjusted value Q** from Step 2 ** ** 4. Select the Q** that gives the lowest total cost TS. Đặng Hữu Phúc Example Suppose that Annual demand = 5,200 Ordering cost = $200, Annual holding cost = 28% price. → Calculate the optimal order quantity 142 TS. Đặng Hữu Phúc 71 12/27/2022 4. QDM model • Step 1: Q*1 = 273 units ; Q*2 = 276 units ; Q*3 = 279 units • Step 2: Adjust Q* into Q** ▪ Q*1 = 273 units → Q**1 = 119 units ▪ Q*2 = 276 units → Q**2 = 276 units ▪ Q*3 = 279 units → Q**3 = 1,500 units 143 TS. Đặng Hữu Phúc Q**1= 119 Q*1= 273 Q**3 = 1500 Q*2 = Q**2 = 276 Q*3 = 279 144 TS. Đặng Hữu Phúc 72 12/27/2022 4. QDM model • Step 3: compute total cost ** ** • • • TC1 = $530.405 TC2 = $517.155 TC3 = $520.053 • Step 4 Since TC2 is smallest, the optimal order quantity is 276 units, and the total cost is $517.155. 145 TS. Đặng Hữu Phúc www.website.com 146 TS.Đặng Hữu Phúc 73 12/27/2022 Operation management Operations Scheduling and Sequencing TS.Đặng Hữu Phúc 150 Learning Outcomes • Explain the concepts of scheduling and sequencing. • Describe staff scheduling and appointment system decisions. • Explain sequencing performance criteria and rules. • Describe how to solve single- and two-resource sequencing problems. • Explain the need for monitoring schedules using Gantt charts. 151 TS. Đặng Hữu Phúc 74 12/27/2022 Scheduling • • Scheduling refers to the assignment of start and completion times to particular jobs, people, or equipment. Examples: Scheduling restaurant employees, airline crews and planes, sports teams, factory jobs. QUẢN TRỊ ĐIỀU HÀNH 152 TS. Đặng Hữu Phúc Scheduling Applications and Approaches • Tools ❖ Spreadsheets ❖ Software packages ❖ Web-based tools 153 TS. Đặng Hữu Phúc 75 12/27/2022 Scheduling Applications and Approaches Staff scheduling attempts to match available personnel with the needs of the organization by: 1. Accurately forecasting demand and translating it into the quantity and timing of work to be done. 2. Determining the staffing required to perform the work by time period. 3. Determining the personnel available and the full- and part-time mix. 4. Matching capacity to demand requirements and developing a work schedule that maximizes service and minimizes costs. 154 TS. Đặng Hữu Phúc Staff scheduling problem Given minimum worker requirements for each day of the week, schedule employees so that each has number of consecutive days off and all demand requirements are met. Method: 1. Locate the set of number of consecutive days with the smallest requirements 2. Circle the requirements for these days, and assign a worker to all days not circled. 3. Subtract 1 from the requirement of each day not circled, removing existing circles, and repeat this process until all requirements are satisfied. 155 TS. Đặng Hữu Phúc 76 12/27/2022 Example • T.R. Accounting Service is developing a workforce schedule for three weeks from now, and has forecast demand and translated it into the following minimum personnel requirements for the week. Day Mon Min Personnel • Tue 8 Wed Thu 6 6 6 Fri Sat 9 Sun 5 3 The staff requirements are for fulltime accountants. Company wants to schedule the employees so that each employee has two consecutive days off and all demand requirements are met. 156 TS. Đặng Hữu Phúc Day Min Personnel Mon 8 Tue 6 Wed 6 Thur 6 Fri 9 Sat 5 Sun 3 Employee 1: New requirements: Employee 2: New requirements: Employee 3: New requirements: TS. Đặng Hữu Phúc 77 12/27/2022 Ex: Remaining assignments 158 TS. Đặng Hữu Phúc Ex: Final Accountant Schedule Minimum requirements 8 6 6 6 9 5 3 159 TS. Đặng Hữu Phúc 78 12/27/2022 Assignment •A swimming pool needs lifeguards seven days a week. Develop the schedules so that each lifeguard has two consecutive days off during the week. • Monday as the first day of the week. Thus an employee cannot be off on Sunday and Monday. 160 TS. Đặng Hữu Phúc Understanding Scheduling and Sequencing • • Sequencing refers to determining the order in which jobs or tasks are processed. Examples: Emergency room patients, automobile models on an assembly line, outgoing flights on runways. 161 TS. Đặng Hữu Phúc 79 12/27/2022 Sequencing • • Sequencing is required when several activities must be processed using a common resource. Commonly Used Priority Rules 1. First come, first served (FCFS): 2. Earliest due date (EDD) 3. Shortest processing time (SPT) 162 TS. Đặng Hữu Phúc Sequencing: Measuring performance Flow time is the amount of time a job spent in the shop or factory. Fi = ∑pij + ∑wij = Ci - Ri Fi = Flow time of job i ∑pij = Sum of all processing times of job i at workstation or area j (run + setup times) ∑wij = Sum of all waiting times of job i at workstation or area j Ci = Completion time of job i Ri = Ready time for job i where all materials, specifications, and so on are available 163 TS. Đặng Hữu Phúc 80 12/27/2022 Sequencing Makespan: is the time needed to process a given set of jobs. M=C-S M = Makespan of a group of jobs C = Completion time of last job in the group S = Start time of first job in the group 164 TS. Đặng Hữu Phúc Sequencing • Lateness is the difference between the completion time and the due date (either positive or negative). • Tardiness is the amount of time by which the completion time exceeds the due date. (Tardiness is defined as zero if the job is completed before the due date.) Li = Ci - Di Ti = Max (0, Li) Where Li Ti Di Ci = Lateness of job i = Tardiness of job i = Due date of job i = Completion time of job i 165 TS. Đặng Hữu Phúc 81 12/27/2022 Sequencing Sequencing rules for a fixed set of jobs: • Shortest Processing Time (SPT) ✓ SPT sequencing maximizes resource utilization and minimizes average flow time and work-in-process inventory. • Earliest Due Date (EDD) ✓ EDD minimizes the maximum job tardiness and lateness. 166 TS. Đặng Hữu Phúc Example • Consider a work station that has one maintenance mechanic to repair failed machines. We can think of the mechanic as the processor (scarce resource) and the machines awaiting repair as the jobs. Let us assume that six machines are down, with estimated repair times given here, and that no new jobs arrive. 167 TS. Đặng Hữu Phúc 82 12/27/2022 Example: SPT Rule Job Sequence Flow Time Sum Job Sequence Flow Time Sum Job Sequence Flow Time Sum #1 10 10 #4 2 2 #6 6 6 #2 3 13 #2 3 5 #2 3 9 #3 7 20 #6 6 11 #4 2 11 #4 2 22 #3 7 18 #3 7 18 #5 9 31 #5 9 27 #5 9 27 #6 6 37 #1 10 37 #1 10 37 Sum 133 Sum 100 Sum 108 Average 22.16667 Average 16.66667 Average 18 168 TS. Đặng Hữu Phúc Suppose an insurance underwriting work area (that is, the single processor) has five commercial insurance jobs to quote that have these processing times and due dates: FCFS Rule Job 1 2 3 4 5 Processing Time (days) 4 7 2 6 3 Due Date 15 16 8 21 9 169 TS. Đặng Hữu Phúc 83 12/27/2022 Examples of Sequencing Rules SPT Rule Job 1 2 3 4 5 Processing Time (days) 4 7 2 6 3 Due Date 15 16 8 21 9 170 TS. Đặng Hữu Phúc Examples of Sequencing Rules EDD Rule Job 1 2 3 4 5 Processing Time (days) 4 7 2 6 3 Due Date 15 16 8 21 9 171 TS. Đặng Hữu Phúc 84 12/27/2022 Examples of Sequencing Rules Comparison of Three Ways (By-the Numbers, SPT, and EDD) to Sequence the Five Jobs 172 TS. Đặng Hữu Phúc Solved Problem Five tax analysis jobs are waiting to be processed by Martha at T.R. Accounting Service. Use the shortest-processing-time (SPT) and earliest-due-date (EDD) sequencing rules to sequence the jobs. Compute the flow time, tardiness, and lateness for each job, and the average flow time, average tardiness, and average lateness for all jobs. Which rule do you recommend? Why? TS. Đặng Hữu Phúc 85 12/27/2022 Applications of Sequencing Rules Two-Resource Sequencing Problem (Johnson’s Rule) 1. List the jobs and their processing times on Resources #1 and #2. 2. Find the job with the shortest processing time (on either resource). 3. If this time corresponds to Resource #1, sequence the job first; if it corresponds to Resource #2, sequence the job last. 4. Repeat steps 2 and 3, using the next-shortest processing time and working inward from both ends of the sequence until all jobs have been scheduled. 174 TS. Đặng Hữu Phúc Applications of Sequencing Rules Example: Two-Resource Sequencing Problem (Johnson’s Rule) Each job requires first a shearing operation (Resource #1) and then a punch-press operation (Resource #2). Next, both job 1 on the shear and job 3 on the punch press have the next shortest time. Choose job 1: Continuing, choose job 3 and finally job 4: 175 TS. Đặng Hữu Phúc 86 12/27/2022 Applications of Sequencing Rules 176 TS. Đặng Hữu Phúc Schedule Monitoring and Control • • Schedule progress must be monitored on a continuing basis. Reschedules are a normal part of scheduling. Gantt charts are useful tools for monitoring schedules. This helps to track jobs that are behind, on, or ahead of schedule. 177 TS. Đặng Hữu Phúc 87 12/27/2022 Schedule Monitoring and Control Gantt Chart Example for Monitoring Schedule Progress 178 TS. Đặng Hữu Phúc www.website.com TS.Đặng Hữu Phúc 179 88