ICT Computer Servicing 9: Assess Quality of Materials

advertisement

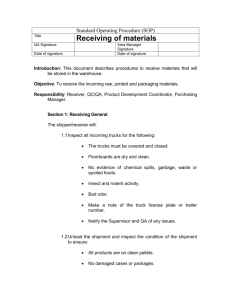

9 ICT – Computer System Servicing 9 Quarter 1 – Module 1: Lesson 1 :Applying Quality Standards (AQS)- Assess Quality of Received Materials Empowerment Technologies– Grade 11/12 Self-Learning Module (SLM) Quarter 1 – Module 1: Assess Quality of Received Materials First Edition, 2020 Republic Act 8293, section 176 states that: No copyright shall subsist in any work of the Government of the Philippines. However, prior approval of the government agency or office wherein the work is created shall be necessary for exploitation of such work for profit. Such agency or office may, among other things, impose as a condition the payment of royalties. Borrowed materials (i.e., songs, stories, poems, pictures, photos, brand names, trademarks, etc.) included in this module are owned by their respective copyright holders. Every effort has been exerted to locate and seek permission to use these materials from their respective copyright owners. The publisher and authors do not represent nor claim ownership over them. Development Team of the Module Writers: Arnold A. Edroso Editors: Mary Joy M. Velasco, Dawn Hope S. Almuena Reviewers: Evelyn C. Frusa, Ph.d, Grace J. Miravalles, Rolex I. Lotilla and Arvin Tejada Illustrator: Name Layout Artist: Name Cover Art Designer: Ian Caesar E. Frondoza Management Team: Allan G. Farnazo, CESO IV – Regional Director Fiel Y. Almendra, CESO V – Assistant Regional Director Name of Schools Division Superintendent Name of Assistant Schools Division Superintendent Gilbert B. Barrera – Chief, CLMD Arturo D. Tingson Jr. – REPS, LRMS Peter Van C. Ang-ug – REPS, ADM Name of REPS – Subject Area Supervisor Name of CID Chief Name of Division EPS In Charge of LRMS Name of Division ADM Coordinator Name of EPS – Subject Area Supervisor Printed in the Philippines byDepartment of Education –SOCCSKSARGENRegion Office Address: Telefax: E-mail Address: Regional Center, Brgy. Carpenter Hill, City of Koronadal (083) 2288825/ (083) 2281893 region12@deped.gov.ph Introductory Message This Self-learning Module (SLM) is prepared so that you, our dear learners, can continue your studies and learn while at home. Activities, questions, directions, exercises, and discussions are carefully stated for you to understand each lesson. Each SLM is composed of different parts. Each part shall guide you stepby-step as you discover and understand the lesson prepared for you. Pre-test are provided to measure your prior knowledge on lessons in each SLM. This will tell you if you need to proceed on completing this module, or if you need to ask your facilitator or your teacher’s assistance for better understanding of the lesson. At the end of each module, you need to answer the post-test to check self- check your learning. Answer keys are provided for each activity and test. We trust that you will be honest in using these. In addition to the material in the main text, Notes to the teachers are also provided to the facilitators and parents for strategies and reminders on how they can best help you on your home-based learning. Please use this module with care. Do not put unnecessary marks on any part of this SLM. Use a separate sheet of paper in answering the exercises and tests. Read the instructions carefully before performing each task. If you have any questions in using this SLM or any difficulty in answering the task in this module, do not hesitate to consult your teacher or facilitator. Thank you. What I Need to Know This module was designed and written with you in mind. It is here to help you master the Input data into computer. The scope of this module permits it to be used in many different learning situations. The language used recognizes the diverse vocabulary level of students. The lessons are arranged to follow the standard sequence of the course. But the order in which you read them can be changed to correspond with the textbook you are now using. The module has one lesson, namely: ● Lesson 1– Apply Quality Standards [AQS]- Assess Quality of Received Materials. After going through this module, you are expected to: 1. Understand that work instruction is obtained and carried out in accordance with standard operating procedures. 2. Determine that received materials are checked against workplace standards and specifications. 3. Identify faulty materials related to work are isolated and recorded/ or reported to supervisor concerned in accordance with workplace procedures. 3 Lesson 1 Applying Quality Standards (AQS) Assess Quality of Received Materials. What’s In Solve the crossword below. Write your answers on the separate sheet of paper. What’s New 4 What’s New Activity 1 Read and answer each question concisely 1. Define a Standard Operation Procedure (SOP) ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ 2. Discuss the things to do when receiving materials under the Standard Operation Procedure (SOP). ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ 3. Enumerate the things to do when making the Inventory Report of Materials. ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ ____________________________________________________________________________ 3 What is It The Factors in Selecting the Materials: 1. Selection of material – it is the ability to choose the materials using the following considerations: • Cost of the material – is the amount of purchasing the materials, it may differ from one supplier to another even if the specifications are the same. • Environmental consideration – anything that leads to the pollution of soil, water and air, especially its energy consumption impact. At the end of ICT hardware use, recycling, disposal like e-waste this would be used in landfills and would provide impact and effect to the environment. • Chemical properties – is a material property evident during the time of its use will show chemical reaction. • Physical properties – the identifiable and unique aspect of a material most particularly its basic capabilities. • Mechanical attributes – the physical properties that any material exhibits when applied with forces, such as elasticity, tensile strength, elongation, hardness and fatigue limit. • Company producing the material – the business name provides identity to the business and the product it produces, especially when the enterprise produces unique and amazing products. 2. Testing of material – this will help analyze the quality and standards of materials using the following techniques: • Hardness tester – any device that checks the hardness of a material by measuring the durability of such material. • Comprehensive strength test – it is more of mechanical test that measures the maximum amount of compressive load a material can bear before such material breaks. • Impact test – is used to observe the mechanics how the material exhibit when it experiences shock and such material immediately deform. • Fluoroscope – is an imaging machine which uses X-rays to determine the interior characteristics of an object. • Testing machine – a universal tester for materials for testing tensile strength and compressive strength of materials. • Creep test – is subjecting the material to high temperature progressive deformation at constant stress test or ability to alter its form after such test has been taken. 4 3. Cost of material – the amount when buying or selecting the materials for specific project. Though this is economical in the selection process, the amount must consider also the quality and reliability of materials. The ICT Materials, Components, Assemblies and Its Specifications In relation to the factors in selecting the materials, as a learner, you need to be familiar with the ICT materials, components and assemblies’ specifications. Not just the name of these items, you must be particular also on how to describe details about such item. Mouse Flash disk Compact disc USB 2.0 / 3.0 8GB / 16GB Memory/RAM DDR 3/DDR 4 2GB/ 4GB/ 8GB CD 700MB DVD 4.7GB Microprocessor Intel Core i7 Processor 8M Cache, 4.8 GHz 4 Cores U-Ultra low power 10th Generation Head set with microphone Camera/webcam HxWxD:29mm x 94mm x 24mm Full HD 1080p 90° field of view Logitech stereo headset Full stereo sound Noise-cancellingMicrophone In-line audio control 5 Logitech corded mouse USB connectivity 800 dpi resolution 5 feet cord AVR 3 outlet with 220V Max 500VA / 500watts Solid State Electronics Scanner Type: Flatbed color Photoelectric device Color CCD line sensor 3200dpi Keyboard UTP cable and RJ45 Cable tester USB keyboard Touch sensitive Slim keyboard Spill resistant Slow & Fast test switch RJ45 10Base T RJ11/12 Cables Power supply 9Vbattery UTP Gigabit Ethernet 100 Base-T Standard 4 pair UTP 24 AWG RJ45 8P8C 8-pin Standard Operating Procedure (SOP) Title QA Signature Date of signature Receiving of materials Area Manager Signature Date of signature Introduction: This document describes procedures to receive materials that will be stored in the warehouse. Objective: To receive the incoming raw, printed and packaging materials. Responsibility: Receiver, QC/QA, Product Development Coordinator, Purchasing Manager. Section 1: Receiving General The shipper/receiver will: 1.1 Inspect all incoming trucks for the following: ● The trucks must be covered and closed. ● Floorboards are dry and clean ● No evidence of chemical spills, garbage, waste or spoiled foods. ● ● ● ● Insect and rodent activity. Bad odor. Make a note of the truck license plate or trailer number. Notify the Supervisor and QA of any issues. 1.2 Unload the shipment and inspect the condition of the shipment to ensure: ● All products are on clean pallets. ● No damaged cases or packages. ● No evidence of any non-food items or items that could contaminate the products being received. 6 ● On receipt of damaged goods follow section 5. 1.3 Check the drivers slip to ensure the company states ‘our company’ 1.4 Tag each skid with the product name and BV code and notify the Supervisor and QA of any issues. 1.5 Count the goods and compare the quantity, name, and lot numbers to the information stated on the shipping documents and company purchase order (PO). Investigate any discrepancies. 1.6 Complete the “Receiving Log” with the following information: Product Information: ● Received date ● PO number ● RA-Code ● Description ● Weight in kg (if applicable) ● Lot number ● Quantity received ● Shipment Supplier ● Shipment Carrier Vehicle Inspection: ● Visual inspection ● Odor inspection ● Pest / Rodent activity ● Truck/trailer number Receiver’s initial 1.7 Once QC has applied the QC approved green stickers store product in the designated area. 1.8 For raw materials follow section 2. 1.9 For printed materials follow section 3. 1.10 For packaging components follow section 4. Section 2: Receiving Raw Materials The shipper/receiver will: 2.1 Follow section 1. 2.2 Place on hold labels on the skid/boxes 2.3 Pass the PO with all relevant information to the QC department. 2.4 QC will take sample as per sampling procedure SOP New Raw Material Approval. 2.5 Once the goods are acceptable, QC will: ● Place a “QC Approved sticker” on the product. ● Tag the product with lot number, date received, product name, RA-code, purchase order number and quantity. 7 ● Complete the “Receiving Log” with the following information: QC Check ● Certificate of Analysis ● QC Approval ● Expiration Date ● Date of Rejection ● Date sample taken QC inspector initial 2.6 Material deemed unacceptable (out of specification) will be tagged by QC as “on hold” and should be moved to the QC hold area. 2.7 Further testing would be done by QC/R&D supervisor and if the material is still out of specifications, it will be tagged with “QC Rejected” tags and noted as rejected in the receiving log. 2.8 Purchasing Manager will contact the supplier as to the action required for the rejected material i.e. to be returned, replaced, destroyed, etc. 2.9 Purchasing Manager will inform the Receiver and QC with the status of rejected material. QC will record the status of raw materials on original PO and return the original PO back to Purchasing Manager 2.10 QC will file the copy of PO in QC Rejected Material binder. Section 3: Receiving Printed Materials Printed materials include labels, printed bags, sleeves, printed boxes (not shippers), etc. The shipper/receiver will: 3.1 Follow section 1. 3.2 Place on hold labels on each side of the skid/each box. 3.3 Place labels out side the label room and all other printed materials in the printed materials area. 3.4 Place the PO and associated documentation in the label room door holder for sampling and QC checking. Label control will: 3.5 Remove 5 samples from each batch of labels/sleeves/bags/boxes/etc, write the new count on the roll/box/etc, attach the samples to the PO and receiving paperwork then pass to QC for inspection. 3.6 QC and the Product Development Coordinator will review the printed materials as per SOP: Label Control. 3.7 On receipt of the “approved green stickers” from the Product Development Coordinator, apply the ‘approved’ stickers over the ‘on hold’ stickers and store product in the designated area (i.e. label room or printed materials area). ● For printed materials stored on skids in the warehouse (outside of the label room) the Product Development Coordinator will also supply box tags containing the product name and code. These should be applied 8 to the boxes (after the “approved green stickers”) and the quantity in each box should be written on the tag. 3.8 Material deemed unacceptable (out of specification) will be tagged by Product Development Coordinator as “rejected” and moved to the WHS 99 or returned to the printer for replacement. Section 4: Receiving Packaging components The shipper/receiver will: 4.1 Follow section 1. 4.2 Pass the PO to the Purchasing Manager. 4.3 Store the materials in the designated area. Section 5: Receipt of Damaged Goods On receipt of a damaged shipment the shipper/receiver will: 5.1Take a photo of the damaged product (camera in supervisors office) and ensure the truck driver signs the receiving document as evidence. 5.2 Notify QC. On being notified of a damaged shipment QC will: 5.3 Inspect the damaged product and note the damage on the PO. 5.4 Place the damaged product in sterile plastic bag (if required) in QC Detention Area, until notification is received from the Purchasing Manager to return or destroy. 5.5 Label damaged product with all information: name, lot#, quantity, report #, purchase order # and date. 5.6 Attach the picture to the signed Purchase Order and pass to the Purchasing Manager (or e-mail photo to the Purchasing Manager). On receipt of a PO with damaged product the Purchasing Manager will: 5.7 Instruct QC to save for supplier’s inspection or for disposal. 5.8 Contact the supplier for a claim. 5.9 If product is to be disposed, follow SOP Product Disposal. Documentation Receiving Log G:\Production\Receiving Log QC Rejected tags QC On Hold tags. Act as quality checker – record the date of receipt, name of materials purchased, quantity, official receipt number, signature of the person who bought the materials. 9 = Log report to be accomplished by the quality checker Date Received OR # Item name Quantity Signature Quality Checker • Monitor and coordinate the checking requirements – identify the materials that are in good condition, damage or needing replacements. = Assessment form of materials received Quality Checker Item Name Date: Comments Total # in Good Total # of Errors Condition • Generate reports when receiving the materials – record data of the reports both record book and digital format (administrative software) 10 What’s More Crossword Puzzle: Using the crossword puzzle form below, use your understanding on names, specification of materials and components, locate at least 20 words horizontally, vertically, diagonally and combinations. C K A B C D E F G H I H E A D S E T J C H O E K L M N O P Q R S N T U C B W X O E M S Y A A A B I C T R V R T A B B A M M A A T B B F L A S H D I S K N C C B P I T B A B O B C J D Q D R D E N D D C A C E C B C C A D K E W C O R W E E E D C A R D C D D C R L F D F N T W R F F E T L I E D E H D R D G E H M C A Q G G F D A A F E F A E W M H T C E D D D H H G I B L G F G R F E N H D D N R A D J I H S C A H G H D G B O J F C T E S T I N G C M E C H A N I C A L G C U E T G K J I A D A I H I E H A P K C A M E R A M K J B E B C I J S I M Q Q M O U S E A L L K C F C A H K S J E R W E F E D N G N M L D G D B J I E K F S E M R I B G C O N M E H E L K L N L G T R O T J N T D P O N F I F E L M F E H U T R Y K D H E Q P O G J G T E S T E R V Y Y D L S B C R Q P H M I C R O P R O C E S S O R C U S R Q I 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. ____________________________ ____________________________ ____________________________ ____________________________ ____________________________ 11 ____________________________ ____________________________ ____________________________ ____________________________ ____________________________ What I Have Learned Read and answer each question concisely 1. Discuss the specification of materials and components. ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ 2. Discuss the work order and standard procedures. ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ___________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ 3. What are the reports needed related to work order and standard procedures. ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ___________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ 3 What I Can Do Make a log report of the received materials using the appropriate form below: 15 pcs Flash disk, 32 GB, OR #4405 100 pcs RJ 45, OR# 77325 8 pcs Optical mouse, OR# 66378 10 meters UTP cable Cat6, OR# 2243 20 pcs DVD compact discs, OR# 12354 6 pcs Headset with microphone, Sales Invoice# 23465 2 pcs LAN tester, good condition, Invoice# 114367 2 units Laptop computer, OR# 78934 10 pcs Computer monitor, 15” screen, Invoice# 2654 5 pcs Keyboard, OR# 8756 = Log report to be accomplished by the quality checker Date Received OR # Item Name Quantity 4 Signature Quality Checker Assessment Read and answer each question concisely 1. Give three factors to be considered when choosing the right material? ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ 2. Give three characteristic of materials to be used for specific project? ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ___________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ 3. What Good Quality means? ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ___________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ ____________________________________________________________________ 5 Additional Activities You are assigned to be the Quality checker for the Month of June. Make a Log Report, and Assessment Report using the following data below. Make sure you will record all the items listed and if they were in good condition or not. Write your answer on a sheet of paper 1. - June 9, 2008 - 5 Hard disk, 2 128MB SDRAM memory chips Received from Jun Salcedo (PC chain), OR #20256 Found out that 1 Hard disk has error need for replacement 2. - June 15, 2008 - Refill ink cartridge from STARINK Shop, OR# 5623 3. - June 20, 2008 - 10 PS/2 keyboard, 10 Optic mouse, 2 power supply - Received from Allan Rivera (Octagon), OR#12544 - 3 defective keyboard need replacement 4. - June 28, 2008 - 2 CD-Rom drive - Received from Jun Salcedo (PC Chain), OR#20400 6 Answer Key What I Know What’s more CHEMICAL 1. D. COMPACT DISC2. F. 3. G MOUSE STRENGTH 4. A COST ENVIRONMENT5. B 6. I WEBCAM MEMORY 7. C KEYBOARD 8. E TESTING MACHINE 9. J CAMERA 10. H MATERIAL MECHANICAL CABLE TESTER HEAD SET FLASH DISK HARDNESS MICROPROCESSO R SCANNER W hat It Is Cost Chemical Mechanical Hardness Comprehensive Fluoroscope Testing Creep Environmental References Checking Your Brand New Laptop https://www.youtube.com/watch?v=oqbyogMSs18 Product Inspection Guide Notes https://www.intouchquality.com/blog/product-inspection-lab-testing-verify-qualitymaterials TLE 2020 Learning Module – DepEd PC Hardware Servicing, The Strengthened Technical Vocational Education Program, pdf file pp. 17 https://kapitolyohs.files.wordpress.com/2011/06/applying-qualitystandard.pdf https://www.slideshare.net/BongBandola/applying-qualitystandard-css85792577?from_action=save 7 For inquiries or feedback, please write or call: Department of Education SOCCSKSARGEN Learning Resource Management System (LRMS) – Regional Center, Brgy. Carpenter Hill, City of Koronadal Telefax No.: (083) 2288825/ (083) 2281893 Email Address: region12@deped.gov.ph 8