Basic Biomechanics of the Musculoskeletal System, 5e Margareta Nordin, Victor Frankel

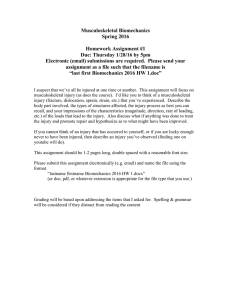

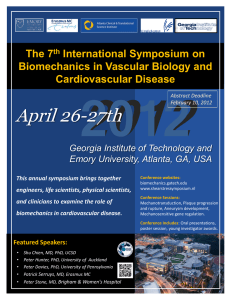

advertisement