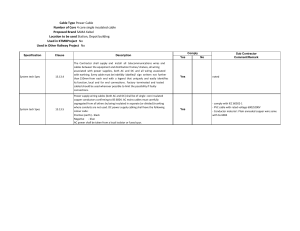

MATERIAL SUBMITTAL PROJECT NAME : JH0017 MADINAT JUMEIRAH LIVING - PHASE 3A CLIENT CLIENT REP CONCEPT CONSULTANT D & B CONSULTANT D & B MAIN CONTRACTOR MJL NORTH 25 DSA ARCHITECTS INTERNATIONAL NEXT ENGINEERING AL SAHEL CONTRACTING CO LLC. DATE 28/10/2022 Material Submittal Reference Specifications REF NO J260-SFCO-MEP-MAT-EL-034-03 Attachments B.O.Q Material As per Index N/A ICT NETWORK & ACTIVE SYSTEM Use For purpose At place Alternative proposal Reason Material Subcontractor x x Saifco Electromechanical Works Consultant's receipt date & sign Approved Approved Subject to comments Approval requested by ( date ) For consultant's use Revised & Resubmit Supplier / Brand IBAM SYSTEMS / OPTERNA, HUAWEI, EATON Contractor's stamp & sign Rejected Engr. Comments SECURITY CONSULTANT COMMENTS: 1. CLOSED. 2.1 CLOSED. CONTRACTOR SHALL BE RESPONSIBLE TO PROVIDE AUXILIARY COMPONENTS REQUIRED TO DELIVER A FULLY FUNCTIONAL SOLUTION AS PER PROJECT SPECIFICATION. 2.2 CLOSED. 2.3 CLOSED. CONTRACTOR SHALL ENSURE PDU OUTLET TYPE MATCHES THE EQUIPMENT PLUG/TERMINAL TYPE. 3. CLOSED. 4.1 CLOSED. CONTRACTOR SHALL ENSURE QTY OF NETWORK SWITCHES AND RELATED COMPONENTS ARE SUFFICIENT TO MEET SPARES REQUIREMENT. 4.2 CLOSED. MORE DETAILS REGARDING PORT SCHEDULING AND EQUIPMENT ARRANGEMENT SHALL BE PROVIDED DURING SHOP DRAWING SUBMISSION BY THE CONTRACTOR. 5. CLOSED. CALCULATION SHALL BE FURTHER DEVELOPED DURING SHOP DRAWING SUBMISSION. 6. CLOSED. CONTRACTOR TO ENSURE THAT ALL DATA POINTS REQUIREMENTS ARE COVERED. 7. CLOSED. 8. CLOSED. 9. CLOSED. 10. CLOSED. ENSURE DETAILS TO BE PROVIDED DURING SHOP DRAWING. COORDINATE WITH CLIENT/OPERATOR ON THE APPROVED LABELLING SCHEME AND PROVIDE RECORD. 11. CLOSED. 12. CLOSED. CONTRACTOR SHALL INCLUDE PATCH CABLES DETAILS IN SHOP DRAWINGS. ENSURE COLOUR CODES ARE ASSIGNED PER SYSTEM'S DATA POINT. 13. CLOSED. Refer Next comments in Compliance Statement ( Page No : 10 ) 14 Way PDU to be provided for all Intercom Rack. Include this in the Equipment Schedule & provide associated Catalogue. Ensure this PDU can be accomodated in 27u Rack . (10 Way C13 & 4 Way C19) as per Specification (Refer Attached Data Communication specification) Also note that : Refer CCTV & UPS Material Submittal 24 Way PDU is already exist in the Approved Equipment Schedule for Main ICT Rack Sign & date (Consultant / Client Representative Saleel / John 08-11-2022 MATERIAL SUBMITTAL PROJECT NAME : JH0017 MADINAT JUMEIRAH LIVING - PHASE 3A CLIENT CLIENT REP CONCEPT CONSULTANT D & B CONSULTANT D & B MAIN CONTRACTOR MJL NORTH 25 DSA ARCHITECTS INTERNATIONAL NEXT ENGINEERING AL SAHEL CONTRACTING CO LLC. DATE 27/09/2022 Material Submittal Reference Specifications REF NO J260-SFCO-MEP-MAT-EL-034-02 Attachments B.O.Q Material As per Index N/A ICT NETWORK & ACTIVE SYSTEM Use For purpose At place Alternative proposal Reason Material Subcontractor x x Saifco Electromechanical Works Consultant's receipt date & sign Approved Approved Subject to comments Approval requested by ( date ) For consultant's use Revised & Resubmit Supplier / Brand IBAM SYSTEMS / OPTERNA, HUAWEI, EATON Contractor's stamp & sign Rejected Engr. Comments SECURITY CONSULTANT COMMENTS: 1. CLOSED. 2.1 FIREWALL IS NOT INCLUDED IN THE LIST OF MATERIALS AND CONNECTIVITY IS NOT SHOWN IN THE SCHEMATIC DIAGRAM. CONFIRM IF REDUNDANT FIREWALLS ARE PROPOSED. ENSURE COMPLETE DETAILS REGARDING THE COMPONENT ARE PROVIDED IN THE SUBMITTAL. 2.2 CLOSED. 2.3 CLOSED. CONTRACTOR SHALL ENSURE PDU OUTLET TYPE MATCHES THE EQUIPMENT PLUG/TERMINAL TYPE. 3. CLOSED. 4.1 CLOSED. CONTRACTOR SHALL ENSURE QTY OF NETWORK SWITCHES AND RELATED COMPONENTS ARE SUFFICIENT TO MEET SPARES REQUIREMENT. 4.2 CLOSED. MORE DETAILS REGARDING PORT SCHEDULING AND EQUIPMENT ARRANGEMENT SHALL BE PROVIDED DURING SHOP DRAWING SUBMISSION BY THE CONTRACTOR. 5. CLOSED. CALCULATION SHALL BE FURTHER DEVELOPED DURING SHOP DRAWING SUBMISSION. 6. CONTRACTOR TO ENSURE THAT ALL DATA POINTS REQUIREMENTS ARE COVERED. 7. CLOSED. 8. CLOSED. 9. CLOSED. 10. CLOSED. ENSURE DETAILS TO BE PROVIDED DURING SHOP DRAWING. COORDINATE WITH CLIENT/OPERATOR ON THE APPROVED LABELLING SCHEME AND PROVIDE RECORD. 11. CLOSED. 12. CLOSED. CONTRACTOR SHALL INCLUDE PATCH CABLES DETAILS IN SHOP DRAWINGS. ENSURE COLOUR CODES ARE ASSIGNED PER SYSTEM'S DATA POINT. 13. ADDITIONAL NOTE: CONTRACTOR TO ENSURE THAT ALL UPS UNITS ARE EQUIPPED WITH SNMP MODULES. NEC Comments 1. 14 Way PDU to be provided for all Intercom Rack. Include this in the Equipment Schedule & provide associated Catalogue. Ensure this can be accomodated in 27u Rack . (10 Way C13 & 4 Way C19) as per Specification ( Attached) 2. Contractor has not provided Compliance Statement for Data Communication Specification by DSA. This has been already commented in Rev01. Sign & date (Consultant / Client Representative Saleel PS / John 13-10-2022 MATERIAL SUBMITTAL ICT NETWORK & ACTIVE SYSTEM PROJECT MADINAT JUMEIRAH LIVING PHASE - 3A, JUMERIAH UMM SUQIEM Client Consultant Main Contractor Ibam Systems LLC .م.م.ذ.اﯾﺒﺎم ﻟﻼﻧﻈﻤﺔ ش MEP Contractor PROJECT DETAILS PROJECT MADINAT JUMEIRAH LIVING PHASE - 3A, JUMERIAH UMM SUQIEM CLIENT MADINAT JUMEIRAH LIVING CONSULTANT DSA ARCHITECTS INTERNATIONAL MAIN CONTRACTOR AL SAHEL CONTRACTING COMPANY LLC MEP CONTRACTOR SAIFCO ELECTROMECHANICAL WORKS LLC SYSTEM INTEGRATOR IBAM SYSTEMS LLC CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 INDEX S.No. Contents Index No. 1 Consultant Comments 1 2 Reply To Comments 2 3 List of Manufacturer 3 4 Technical Specification 4 5 Technical Compliance of the Specification 5 6 List of Proposed material with model number 6 7 Valid Trade License 7 8 Local Authorities approval for the proposed material 8 9 Country of Origin Certificate 9 10 Quality Assurance and Third-Party Certification 10 11 Original Product Catalogue 11 12 System Architect/Schematic Diagram 12 13 List of Project Executed 13 14 Company Profile 14 15 Valid Civil Defense/SIRA card/Local Authority (certificate) 15 16 Method Statement/Fixing detail for installation 16 17 Storing/Handling the Material 17 18 Scope Of Work 18 19 Load Calculation 19 20 Rack Details & Patch Panel Schedule 20 21 Annexure 21 CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 1. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 Consultant Comments MATERIAL SUBMITTAL PROJECT NAME : JH0017 MADINAT JUMEIRAH LIVING - PHASE 3A CLIENT CLIENT REP CONCEPT CONSULTANT D & B CONSULTANT D & B MAIN CONTRACTOR MJL NORTH 25 DSA ARCHITECTS INTERNATIONAL NEXT ENGINEERING AL SAHEL CONTRACTING CO LLC. DATE 27/09/2022 Material Submittal Reference Specifications REF NO J260-SFCO-MEP-MAT-EL-034-02 Attachments B.O.Q Material As per Index N/A ICT NETWORK & ACTIVE SYSTEM Use For purpose At place Alternative proposal Reason Material Subcontractor x x Saifco Electromechanical Works Consultant's receipt date & sign Approved Approved Subject to comments Approval requested by ( date ) For consultant's use Revised & Resubmit Supplier / Brand IBAM SYSTEMS / OPTERNA, HUAWEI, EATON Contractor's stamp & sign Rejected Engr. Comments SECURITY CONSULTANT COMMENTS: 1. CLOSED. 2.1 FIREWALL IS NOT INCLUDED IN THE LIST OF MATERIALS AND CONNECTIVITY IS NOT SHOWN IN THE SCHEMATIC DIAGRAM. CONFIRM IF REDUNDANT FIREWALLS ARE PROPOSED. ENSURE COMPLETE DETAILS REGARDING THE COMPONENT ARE PROVIDED IN THE SUBMITTAL. 2.2 CLOSED. 2.3 CLOSED. CONTRACTOR SHALL ENSURE PDU OUTLET TYPE MATCHES THE EQUIPMENT PLUG/TERMINAL TYPE. 3. CLOSED. 4.1 CLOSED. CONTRACTOR SHALL ENSURE QTY OF NETWORK SWITCHES AND RELATED COMPONENTS ARE SUFFICIENT TO MEET SPARES REQUIREMENT. 4.2 CLOSED. MORE DETAILS REGARDING PORT SCHEDULING AND EQUIPMENT ARRANGEMENT SHALL BE PROVIDED DURING SHOP DRAWING SUBMISSION BY THE CONTRACTOR. 5. CLOSED. CALCULATION SHALL BE FURTHER DEVELOPED DURING SHOP DRAWING SUBMISSION. 6. CONTRACTOR TO ENSURE THAT ALL DATA POINTS REQUIREMENTS ARE COVERED. 7. CLOSED. 8. CLOSED. 9. CLOSED. 10. CLOSED. ENSURE DETAILS TO BE PROVIDED DURING SHOP DRAWING. COORDINATE WITH CLIENT/OPERATOR ON THE APPROVED LABELLING SCHEME AND PROVIDE RECORD. 11. CLOSED. 12. CLOSED. CONTRACTOR SHALL INCLUDE PATCH CABLES DETAILS IN SHOP DRAWINGS. ENSURE COLOUR CODES ARE ASSIGNED PER SYSTEM'S DATA POINT. 13. ADDITIONAL NOTE: CONTRACTOR TO ENSURE THAT ALL UPS UNITS ARE EQUIPPED WITH SNMP MODULES. NEC Comments 1. 14 Way PDU to be provided for all Intercom Rack. Include this in the Equipment Schedule & provide associated Catalogue. Ensure this can be accomodated in 27u Rack . (10 Way C13 & 4 Way C19) as per Specification ( Attached) 2. Contractor has not provided Compliance Statement for Data Communication Specification by DSA. This has been already commented in Rev01. Sign & date (Consultant / Client Representative Saleel PS / John 13-10-2022 A R C H I T E C TS Madinat Jumeirah Living — Phase 3A Design Compliance Performance Criteria Data Communication System Specification INTERNATIONAL Rack shall have a roof panel with 2 apertures of not less than 300mm x 50mm finished with brush strip (to prevent air leakage) to allow entry of high-level data cabling. Rack shall be with 50mm, minimum, wiring space on any side where terminations are made, the wiring space shall be adjusted (increased] to suit the quantities ond types of cables entering and leaving the equipment rack. Rack shall be provided with four roofs mounted fans and have no loss of installation height. Rack shall be provided with suitable means of securing the complete assembly to floors and / or walls. The rack shall be able to support a maximum equipment load of 1000kg. 7) Racks shall be provided with self-levelling feet/castors and shall sit directly on to the access floor or concrete slab. The feet/castors sholl be able to support the maximum load capacity of the rack. 8) The surfaces of the rack shall be protected by good quality paintwork. The paint shall be smooth, continuous and free from blemishes and scratches. The colour of the paintwork shall be agreed with the Employer before installation. 9) The front and rear doors shall be provided mechanical barrel type locks and with two sets of mechanical keys. The front and rear doors shall be the same lock on each rack. A full height and width side infill panel complete with vertical wire ways finished with brush strip for inter-rack and frame cabling shall be provided by the Contractor. 1 1) Three (x3) slotted component shelves per 42U rack shall be provided. 12) All racks shall be provided with removal panels, escutcheon plates (Doors Locks), and covers. 13) The Rack shall have suitable clearance to ensure that the closure of the rack door shall not interfere with ony device within the enclosure. 10. Power Strip for Equipment Rock o. The power strips for the equipment racks shall be designed to comply with the following standards: • BS 7671 (IEE Wiring Regulation) • BS 5733 (General requirements for electrical accessories) b. The main housing of the power strips shall be made of anodized aluminium extrusion and mouldings shall be made of high impact, flame retardant grade of polycarbonate. c. The internal wiring shall be single cables insulated in low smoke, low fume grade of material to BS 711. The power leads shall be multi-core flexible cables complying with BS 6500, and shall be low smoke and fume. d. The sockets are designed and tested to BS 1363 Part 2 (Specification for 13A switched and unswitched socket-outlets). They shall be individually fused as 5A. e. The tape-off lead shall be at least 3 metre and the terminating plug shall be fused as 13A. f. Power requirements for racks: Locofion ICT Rack Power Rotin 16 Amps PDU Quont X02 Min. no. of Outlets 10 way: C13 04 way: C19 Remarks Vertically mounted CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 2. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 Reply to Comments REPLY TO COMMENTS S.NO CONSULTANT COMMENTS REPLY TO COMMENTS SECURITY CONSULTANT COMMENTS: 1. Firewall is not included in the list of materials and connectivity is not shown in the schematic diagram. Confirm if redundant firewalls are proposed. Ensure complete details regarding the component are provided in the submittal. Comply. Firewall considered. Refer section 06 point 37. There is no redundancy mentioned for firewall in the specification. 2. Contractor shall ensure pdu outlet type matches the equipment plug/terminal type. Noted & Comply. 3. Contractor shall ensure qty of network switches and related components are sufficient to meet spares requirement. More details regarding port scheduling and equipment arrangement shall be provided during shop drawing submission by the contractor. Comply. 5. Calculation shall be further developed during shop drawing submission. Comply. 6. Contractor to ensure that all data points requirements are covered. Comply. 7. Ensure details to be provided during shop drawing. Coordinate with client/operator on the approved labelling scheme and provide record. Comply. 8. Contractor shall include patch cables details in shop drawings. Ensure colour codes are assigned per system's data point. Contractor to ensure that all ups units are equipped with snmp modules. Comply. 4. 9. Comply. Comply. NEC COMMENTS 1. 14 Way PDU to be provided for all Intercom Rack. Include this in the Equipment Schedule & provide associated Catalogue. Ensure this can be accomodated in 27u Rack . (10 Way C13 & 4 Way C19) as per Specification ( Attached) Noted.14way PDU provided in main ICT rack & 6 way PDU provided in the IDF racks(ICT racks at different level) as per DSA specification ( refer page 19 of DSA specification). Response not acceptable. 14 Way PDU to be provided for all Intercom Rack. Include this in the Equipment Schedule & provide associated Catalogue. Ensure this PDU can be accomodated in 27u Rack . (10 Way C13 & 4 Way C19) as per Specification (Refer Attached Data Communication specification) Also note that : Refer CCTV & UPS Material Submittal 24 Way PDU is already exist in the Approved Equipment Schedule for Main ICT Rack 2. Contractor has not provided Compliance Statement for Data Communication Specification by DSA. This has been already Commented in Rev01. Comply. Refer section 05. CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 3. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 List of Manufacturer Opterna branded equipments have been proposed for structured cabling system CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 4. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 Technical Specification TABLE OF CONTENTS PART 1: GENERAL .............................................................................................................................. 3 A. OVERVIEW ............................................................................................................................. 3 B. SCOPE OF WORKS .................................................................................................................. 4 C. RELATED WORKS ................................................................................................................... 4 D. CODES, REGULATIONS AND STANDARDS .............................................................................. 5 E. SUBMITTALS .......................................................................................................................... 6 F. DELIVERY, STORAGE AND HANDLING .................................................................................... 8 G. WARRANTY AND CERTIFICATION .......................................................................................... 8 PART 2: PRODUCTS ........................................................................................................................... 8 A. GENERAL STRUCTURED CABLING COMPONENTS .................................................................. 8 B. ROOF TOP ROOM AND MOBILE SERVICE ROOM (GSM) ........................................................ 9 C. EQUIPMENT/SERVER CABINET ............................................................................................ 10 D. GENERAL IDF/FLOOR TELEPHONE ROOM (FTR) CABINET .................................................... 11 E. IDF/FTR STANDING CABINET ............................................................................................... 11 F. IDF/FTR WALL-MOUNTED CABINET ..................................................................................... 13 G. HORIZONTAL CABLING- CAT6A UTP .................................................................................... 13 H. CAT6A COPPER PATCH CORDS ............................................................................................. 14 I. CAT6A COPPER PATCH PANELS ........................................................................................... 15 J. DATA OUTLETS .................................................................................................................... 16 K. MULTIMODE FIBER OPTIC CABLES ....................................................................................... 16 L. SINGLE MODE FIBER OPTIC CABLES ..................................................................................... 17 M. FIBER OPTIC PATCH PANELS ............................................................................................ 18 N. FIBER CONNECTORS ............................................................................................................ 19 O. ACTIVE NETWORK SYSTEM BRIEF ........................................................................................ 21 P. CORE SWITCHES .................................................................................................................. 23 Q. CORE SWITCHES MODULES ................................................................................................. 24 R. ACCESS/EDGE SWITCHES ..................................................................................................... 24 S. UNINTERRUPTIBLE POWER SUPPLY (UPS) ........................................................................... 25 PART 3: EXECUTION ........................................................................................................................ 26 A. GENERAL ............................................................................................................................. 26 B. INSTALLATION ..................................................................................................................... 26 SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 1 C. INSPECTION ......................................................................................................................... 27 D. TEST EQUIPMENT ................................................................................................................ 27 E. DOCUMENT SUBMITTALS .................................................................................................... 27 F. WARRANTY ......................................................................................................................... 29 G. MAINTENANCE .................................................................................................................... 29 H. TRAINING ............................................................................................................................ 30 SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 2 ICT/TELECOMMUNCATION PART 1: GENERAL A. OVERVIEW 1. It is the Design Intent to provide an intra-building structured cabling system which will support 10 Gb/s switched, multi-protocol, ethernet-based networks. 2. The networks shall be compliant with ANSI/TIA/EIA, ISO standards and Building Industry Consulting Service International (BICSI) Telecommunications Design Methods to the facility. 3. The Structured Cabling shall support the following dedicated networks: a. Converge ICT network- for the residential intercom and Background Music System (BGM) which shall utilize common network and network switches for management and connectivity b. Security Network- dedicated for the security systems for the connectivity of cameras, access control devices, etc. 4. Incoming services infrastructure should be provided from the Service Providers network to the Main Telecom Room which is dedicated for both the service provider of the facility. The Client shall determine the chosen lead services provider (Etisalat/Du) for the project. 5. Fibre and copper connectivity shall be by the contactor between MTR, IDF rooms, Landlord Server Room and Tenant space as required providing adequate connectivity for data, telephone and TV services. 6. All the active core equipment for the multiple networks (as detailed above) shall be located in the Server Room. The Server Room shall be sub-divided for each of the above networks providing physical separation and security. 7. Multi-mode OM4, Single-mode OS2 Optical Fiber and Cat 6A Copper cables shall be provided for the backbone system in a hierarchical star arrangement which will terminate on fibre and copper patch panels at each IDF (Intermediate Distribution Frame). 8. The Backbone shall consist of Multi-mode, Single-mode Fiber and/or Cat6A UTP copper cables and shall be routed as per the IT single line diagrams through the main IT riser and IDFs. 9. Horizontal cabling shall be ANSI/TIA/EIA Category 6A UTP (or equivalent), deployed in a “home- run” arrangement from the IDF to the Telecommunications Outlet (TO), floor boxes and consolidation points. 10. Horizontal cabling shall be terminated within the IDF rooms using ANSI/TIA/EIA Category 6A Patch panels. Dedicated patch panels and lockable equipment cabinets shall be provided for the 2 networks. Each cable shall be terminated in the equipment cabinet and associated patch panel corresponding to the use of the end device. 11. Patching within Server Room and IDF rooms shall be provided for 100% of outlets and active edge switch ports. 12. The entire installation shall be fully certified by the manufacturer. A guaranteed Channel Performance with Product and Application Certification shall be provided for the entire cabling system installation (copper and fibre). SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 3 13. Main Earthing & Bonding system clean earth shall be provided to each equipment rooms (Security Control room, IDF’s) by the Contractor. Connection from clean earth to Structured Cabling System by ELV / IT Contractor. 14. Training shall be provided from the manufacturer or an authorized training centre as described further herein. 15. The Contractor shall be responsible for providing the requirements for Telecom room and verifying space, selection of rack (dimension and door type), power and cooling requirements associated with this Section and coordinate with the relevant trades. 16. Use the same manufacturer throughout the SCS installation. 17. Rack mountable UPS with backup of 30 minutes and SNMP card shall be considered with additional of 25% spare load. 18. Communication link between lift and BMS room or between lift and security room shall be provided. B. SCOPE OF WORKS 1. The scope consists of all passive data network components for the building associated with all IP Network and telecom spaces (MMR, MTR, Server Room, IDFs etc.) throughout the facility, Telecommunication Outlets (TO) and all interconnecting copper and fibre cabling. 2. The scope also consists of all active data network components for the building associated with all IP network throughout the facility and IP Data transmission for all networkconnected systems. 3. Building connectivity to MTR should through nearest existing Telecom manhole. 4. This scope does not cover design for operational servers or data storage for operational systems such as Building Management, billing, etc. 5. This scope does not cover design for systems provided by Third Parties such as the HighSpeed Internet Access (HSIA), IPTV, Wireless Internet Billing etc. 6. All connections from core to access layers to be are 2 x 10GB providing a total of 20GB per access layer switch. 7. All Access Layer switches will 10/100/1000 Mbps. 8. Access switches enabled with PoE+ shall be provided to the Apartment Intercom and BGM system devices (as necessary). Access switches requirement for the security systems is detailed in the security systems specification. C. RELATED WORKS 1. Raceway, cable tray, ladder runway, sleeves, channels, conduits and pull boxes specified under electrical specifications 2. Standard-compliant telecommunications grounding system to be provided under earthing/grounding (electrical) specifications 3. Raised access flooring (specified under architectural design), if ever applicable 4. Cutting, patching and painting (generally civil works) 5. Conduit stubs below floors and above the finished ceilings at designated locations specified under electrical specifications 6. Double gang, deep back boxes at each wall mounted outlet location specified under electrical specifications 7. Shared power/telecom and shared power/telecom /AV raised access floor flush-mounted boxes specified under electrical specifications SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 4 8. Security, audio-visual and BMS systems proprietary cabling and equipment designed and specified in each respective section 9. Installation of and cross-connection to hardware and cabling assemblies supplied by telephone system, data or data hardware vendors 10. Provision of inter-machine cabling and ancillary communications cabling within the equipment rooms, except as indicated on the drawings 11. Uninterruptible Power Supply (UPS) specified under electrical specifications D. CODES, REGULATIONS AND STANDARDS 1. Comply with the most recently issued requirements, standards, recommendations, rules, and regulations of: a. Telecommunications Regulatory Authority, UAE b. TRA/Common Du and Etisalat guidelines c. The National Electrical Code (NEC) d. National Fire Protection Act (NFPA) e. Occupational Safety and Health Administration (OSHA) f. Building Industry Consulting Services International (BICSI) g. Underwriter’s Laboratories (UL) h. Institute of Electrical and Electronic Engineers (IEEE) 2. Follow the most restrictive code or recommendations. Undistinguishable details shall be consulted to the responsible engineer for interpretation. 3. All equipment shall be equal to or shall exceed the minimum requirements of NEC, IEEE, ASME, ANSI and UL. 4. The requirements and recommendations of the following are included herein and made a part of these contract documents: a. Electrical Specifications Sections b. UAE laws and Telecommunications Regulations Authority (TRA) codes c. TRA/DU & Etisalat Design and Installation Guidelines d. ICT requirements for Residential Towers. e. ANSI/TIA-568-C: Generic Telecommunications Cabling for Customer Premises, published 2009 f. ANSI/TIA-568-C.1: Commercial Building Telecommunications Cabling Standard, 2009. g. ANSI/TIA-568-C.2: Balanced Twisted-Pair Telecommunication Cabling and Components Standard, 2009. h. ANSI/TIA-568-C.3: Optical Fiber Cabling Components Standard, 2008. i. ANSI/TIA-758-A: Customer-owned Outside Plant Telecommunications Infrastructure Standard, 2005. j. NSI/TIA-942-2: Telecommunications Infrastructure Standard for Data Centres Addendum 2- Additional Media and Guidelines for Data Centres – 2010. k. ANSI/TIA -492 Series: Single and Multimode series of specifications up to OS2 and OM4 Fibers. l. International Standards Organization/International Electro Technical Commission ISO/IEC 11801, Amendment 1, 2009: Generic Cabling for Customer Premises, Class EA. m. Underwriters Laboratories (UL®) Cable Certification and Follow up Program. n. BICSI Telecommunications Distribution Methods Manual 12th Edition SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 5 o. L 910, Test for Flame-Propagation and Smoke Density Values for Electrical and Optical Fiber Cables in Spaces Transporting Environmental Air, 1997 p. UL 1685, Vertical-Tray Fire Protection and Smoke Release Test for Electrical and Optical Fiber Cables. q. IEEE 1100-2005, Powering and Grounding of Electronic Equipment. 5. All equipment shall be as per latest TRA requirements. E. SUBMITTALS 1. Bid Submittal a. The contractor shall submit to the Consultant – four (4) copies of Descriptive Literature which also includes list of equipment, Technical Data, Catalogues, Installation Instructions and Maintenance recommendation of all the Products used. b. Provide a Schedule of values and quantities for the equipment where each piece of equipment shall be priced individually. c. Include on the above schedule non-equipment and service cost schedule. This will include: i. Engineering Design. ii. Pre-installation works. iii. Installation including wiring and site supervision. iv. Software programming (if applicable) v. Documentation vi. Training vii. Project management viii. Warranties d. Submit proposal for Alternates and associated equipment costs. e. Shop drawings – detailed schematic, layout, installation & rack details. f. Organization profile, chart and career & qualification records of Project manager / technical staff. g. The submittal must include all the electronic copies of the required documentations and the sample product. h. In addition to hard copy submittals, submit all files necessary to produce the above submittals as follows: i. Transportation media shall be on CD ROM format. ii. A Master File List in text format shall be placed on each CD ROM with a short description of files in the submittal. iii. The shop drawings shall be in AutoCAD R2015 or later drawing (.DWG) format. All XREFs, fonts, and other drawing parts necessary shall be included. iv. Manufacturers’ data sheets, equipment manuals, and other documentation provided by the Manufacturers to the Contractor or documents that are similarly not otherwise available to the Contractor in electronic format shall be excluded from this requirement. 2. Product Datasheet a. Submit catalogue data sheets, space for submittal stamps. List all proposed equipment. Indicate all accepted substitutions. b. Submit a schedule of finishes indicating proposed materials and color selections for all exposed items subject to Architect selection. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 6 c. Submit a list showing coordination of selected frequencies for all wireless transmitters. 3. Construction Schedule a. The Contractor shall provide a Construction Schedule indicating general project deadlines with specific dates relating to the installation of the system. At a minimum, this construction schedule shall include the following milestones: i. Cabling Procurement Date ii. Equipment Procurement Date iii. Cabling Installation Start Date iv. Cabling Installation Completion Date v. Equipment Installation Start Date vi. Equipment Installation Completion Date vii. Equipment Testing Start Date viii. Equipment Testing Completion Date ix. Completion of Documentation 4. Shop Drawings a. Shop drawings must include, but not limited to: b. All drawings must be the same size as the project drawings. c. All drawings must follow the Project’s drafting standards. d. All plans drawn to project standard scales for floor plans, ceiling plans, sections, enlarged details, etc., and must be drawn in Landscape, not Portrait rotation. e. Submit as-installed point-to-point wiring diagrams and typed wire lists identifying every connection for information. Include electronic devices f. Submit system layouts showing all as-installed device locations, ceiling layouts. g. Submit conduit riser diagrams showing as-installed connection of all devices. h. Submit rack layouts indicating the as-installed arrangement of mounted equipment. i. Submit as-installed fully dimensioned construction details of all panels, plates. 5. Submit wiring diagrams identifying every connection for information including: a. All equipment such as distribution hub, power supply etc., complete with make and model numbers. b. Electronic devices such as distribution switches, transformers, and terminal blocks. c. Calculated voltage loss in each circuit and cable distance should be followed as per manufacture’s guidelines. d. Indicate locations of all components by room number. e. Identify cables by types, models, colors, and wire numbers. f. Identify all connector types including make and model along with cable termination details including connector pin-outs, conductor color codes and cable dressing details for each type of connector used in the system. g. Submit system plans showing all device locations, containment riser diagrams showing connection of all devices, required containment type and sizes along with types and quantities of cables to be used and cable identification tags. h. Submit Power and cooling requirements for each equipment rack / room. i. Submit fully dimensioned construction details of all panels. Include complete parts lists and, as required, schematic diagrams. j. Submit electronic copies of any custom programming including source codes. Include printed copies of all control screens, wiring pages, etc. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 7 6. Samples a. Label samples to indicate product, characteristics, and locations in the Work. Samples will be reviewed for color and appearance and workmanship. Compliance with all other requirements is the exclusive responsibility of the Contractor. Furnish samples of the following: b. All exposed plates and panels for approval of color, engraving, text size and material. c. Terminated cable samples. 7. Upon completion of the installation, Contractor shall prepare as built documentation of the entire installation. And should also include the electronic copies. F. DELIVERY, STORAGE AND HANDLING 1. Deliver, store and handling of the equipment will be at designated areas as defined by the Client. 2. Deliver and store materials in manufacturer’s original packaging labelled to show name, brand, type, and grade. Store materials in protected environment in accordance with manufacturer’s instructions, any loss or damage to the equipment will be fully responsible by the contractor. 3. Equipment damaged prior to system acceptance shall be replaced at no cost to the Employer. G. WARRANTY AND CERTIFICATION 1. The Contractor shall provide a letter from the Manufacturer confirming certifications and trained engineers under the employ of the company. The Contractor shall provide the Manufacturer’s Warranty, including the Manufacturers Performance Guarantee & Test Data and all applications supported under the warranty. The period of the warranty shall not be less than twenty five (25) years in accordance with the manufacturer’s extended warranty program. 2. Warrant all other portions of the work against faulty and improper material and workmanship for a minimum period of five (5) years from the date of acceptance as defined herein. Where warranties for longer terms are offered through manufacturer/installer programs, such longer terms shall apply. PART 2: PRODUCTS A. GENERAL STRUCTURED CABLING COMPONENTS 1. All materials and products, excepting Owner Furnished Equipment (OFE), and materials, shall be appropriate for the intended use and shall meet all applicable UL, EN, BS, ISO and IEC Regulations. 2. All system components shall be manufactured by ISO 9001:2008 certified companies and all packaging shall carry clear product identification (catalogue number, quality control number, etc.) 3. All products shall be new of the latest version at time of Installation, and brought to the job site in original manufacturer's packaging. Electrical components shall bear the Underwriter's Laboratories label. This listing requirement applies to the entire assembly. Only systems and equipment that meet or exceed the level of quality and capabilities stated within this document will be considered for acceptance. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 8 4. Materials shall be listed and approved for the particular application and permitted by the authority having jurisdiction for the application. 5. All system components of the entire cabling system (copper and fibre) shall be from a single manufacturer which will ensure that a single performance warranty covers all applications on vertical and horizontal links. This includes but is not limited to: a. Horizontal distribution b. Fiber optics distribution c. Copper distribution d. Patch Panels 6. All components and devices will be provided with labelling to the standards set out in ANSI/TIA/EIA 606-B. Prior written authorization must be obtained from the Client or Supervising Engineer for any deviation from this standard. 7. All components are to be accepted by the Engineer and afford the most aesthetic value possible while maintaining specified functionality. Hardware will adhere to the following guidelines: a. Fit and finish to the existing surrounding structure. b. Unobtrusiveness c. Functionality 8. All workstation termination hardware shall match the existing wall surface colour as closely as possible, to include mounting boxes, faceplates, and outlets. 9. Used equipment or damaged material will be rejected. B. ROOF TOP ROOM AND MOBILE SERVICE ROOM (GSM) 1. Roof top room and Service Room shall be provided based on the TRA requirement for a multi-tenant building which are up to G+10 floors or less at a minimum dedicated 3m x 3m x 3m (WLH). 2. GSM Room shall also be provided in the ground floor adjacent to the Main Telecom Room. This will be a dedicated room for GSM equipment. A cable tray 300mmx 150mm is required from GSM room to Main Telecom Room and will extend until the Roof top GSM Room. 3. The main requirements for the Roof Top Room for the residential building are below but not limited to: a. The roof-top room shall be connected to building riser through 300mm x 50mm vertical cable tray. b. The doors of this room shall open outwards and have a minimum opening of 1000mm x 2100mm (WxH). c. The following electromechanical must be provided while designing roof-top room. d. 4 x13A twin sockets fed from the essential power supply with dedicated 20A circuit breaker. e. 2 number of AC & DC earth bars connected to the dedicated earth pits with resistance less than 1ohm. f. Add 2 x 63A TP isolator fed with dedicated feeder from essential power supply (EDB); g. Dedicated A/C system (ducted split FCU) with duty & standby units with proper interlocking, to maintain the room temp. at 21°C ± 1°C; h. Heat dissipation can be considered at 36kW for roof-top Room; i. 2 nos. handheld CO2 cylinder extinguishers to be provided inside the room; SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 9 j. 4. 5. 6. 7. 8. Room should be provided with adequate lighting with minimum of 200 Lux at table level; k. Room shall be compliant with the fire and safety requirements like smoke detector, fire alarm, emergency light etc. as per local authority standards. Any water sprinklers must be avoided. The floors of the roof-top rooms must have a minimum distributed load rating of 10kN/m2. Openings must be provided to the room to allow for cables to connect to external antennas. These openings must be 600mm x 400mm (W x H), 500mm below the room ceiling in walls facing the building’s roof-top area. Space must be reserved on the roof-top of the building for the installation of mobile-service antennas. This setup may vary from building to building scenario, but this will be typically at the corners of the building or on any raised structure on the roof-top. The requirements as stated above shall be coordinated by the contractor to the respective provider/contractor to ensure full compliance. C. EQUIPMENT/SERVER CABINET 1. The contractor shall provide Server racks in the main server room in the configuration shown on the design drawings. 2. The outside dimensions of the server cabinets shall be 800mm (W) x 1000mm (D). 3. Server Cabinets shall be constructed of rust free alloy, with a flange base, capable of minimum 42U of useable interior height. 4. Server Cabinets shall be fully enclosed, lockable, ventilated modular type steel construction and treated to resist corrosion. 5. Finish: Black/Grey, Powder coat pain with fingerprint and scratch resistant finish. 6. Server cabinets shall be provided with EIA 19” rack mounting frames with rack spaces (units) stamped every unit. 7. Cabinets shall be provided with modular cooling trays/panels to provide mechanical air circulation and heat extract from the active equipment. The cooling trays/panels are to be selected for the appropriate hot air flow directions from the active equipment, taking into account cold and hot aisle configurations and locations of computer room air conditioning distribution. 8. Server racks shall be provided with stabilizer feet attached to the front and sides of each enclosure for increased stability. 9. Accessories: Horizontal stabilization hardware, appropriate fasteners for mechanical attachment to structural floor. 10. Server racks shall be provided with a minimum of 2 (two) Power Distribution Units (PDU) for primary and secondary supplies to the equipment. Each PDU shall be sized to present a dedicated outlet for each piece of active equipment with an additional 20% for future installations. Each outlet must be rated to support the full load of each attached piece of equipment. 11. Integral vertical cable management: SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 10 12. 13. 14. 15. 16. 17. a. 150mm, 254mm, 300mm and 406.4mm wide vertical management cages, with individual 1-rack unit fingers, including spools and bend limiting clips. The cages will be covered by double hinged aluminum doors. Clip-on panels are not acceptable. b. Integral bend radius control to eliminate strain on cables. c. In the case where racks are assembled side by side, they shall be separated by minimum 200mm wide cable management cages. The bottom flange shall turn inwards, allowing it to fit on a floor tile. Provide adjustable (sliding type) equipment support bracket to ensure that all active equipment are adequately supported from the rear as well as the front. Equipment not adequately supported (front and rear) will not be accepted. Server cabinets shall be provided with Honeycomb style side rails and baffles which shall be combined to manage intake and exhaust air from side vented equipment to creating cold aisle / hot aisle air distribution. The Contractor shall provide blank panels for all unoccupied spaces within enclosure(s) to maintain correct air flow. All enclosures shall be provided with cable organizers. All enclosures shall be provided with Grounding (Earthing) kit and shall be connected to the nearest clean earth bar with suitable earth wire as detailed in the electrical section of this specification. D. GENERAL IDF/FLOOR TELEPHONE ROOM (FTR) CABINET 1. IDFs shall be provided with dedicated cabinets for each of the networks installed in the development. Refer to the structured cabling schematic and voice data layout for details of the cabinets to be installed in each of the IDFs. 2. IDF equipment cabinets shall be sized accordingly to accommodate all active and passive equipment required to support the full functionality of the associated network design intent + 20% spare capacity for future use. 3. All cabinets shall be fully enclosed, lockable, ventilated modular type steel construction and treated to resist corrosion. 4. Wall mounted cabinets may be used where network requirements do not warrant full height floor standing cabinets. 5. Where multiple wall mounted cabinets are located on the same wall, they shall not be installed vertically aligned. The contractor shall offset the cabinets to ensure unobstructed vertical routes for containment to high level horizontal distribution. 6. The contractor shall ensure that wall mounted cabinets are installed at a height where installation and maintenance works can be undertaken without the use of a ladder or alternative elevating equipment. 7. Each cabinet shall be provided with dedicated power and connections to the local clean earth. E. IDF/FTR STANDING CABINET 1. The contractor shall provide Equipment racks in the IDF rooms in the configuration shown on the design drawings. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 11 2. The outside dimensions of the server cabinets shall be 800mm (W) x 800mm (D). 3. Equipment Cabinets shall be constructed of rust free alloy, with a flange base, capable of minimum 42U of useable interior height. 4. Equipment Cabinets shall be fully enclosed, lockable, ventilated modular type steel construction and treated to resist corrosion. 5. Finish: Black/Grey, Powder coat pain with fingerprint and scratch resistant finish. 6. Equipment cabinets shall be provided with EIA 19” rack mounting frames with rack spaces (units) stamped every unit. 7. Cabinets shall be provided with modular cooling trays/panels to provide mechanical air circulation and heat extract from the active equipment. The cooling trays/panels are to be selected for the appropriate hot air flow directions from the active equipment, taking into account cold and hot aisle configurations and locations of computer room air conditioning distribution. 8. Equipment racks shall be provided with stabilizer feet attached to the front and sides of each enclosure for increased stability. 9. Accessories: Horizontal stabilization hardware, appropriate fasteners for mechanical attachment to structural floor. 10. Equipment racks shall be provided with a minimum of 2 (two) Power Distribution Units (PDU) for primary and secondary supplies to the equipment. Each PDU shall be sized to present a dedicated outlet for each piece of active equipment with an additional 20% for future installations. Each outlet must be rated to support the full load of each attached piece of equipment. 11. Integral vertical cable management: a. 150mm, 254mm, 300mm and 406.4mm wide vertical management cages, with individual 1-rack unit fingers, including spools and bend limiting clips. The cages will be covered by double hinged aluminium doors. Clip-on panels are not acceptable. b. Integral bend radius control to eliminate strain on cables. c. In the case where racks are assembled side by side, they shall be separated by minimum 200mm wide cable management cages. 12. Provide adjustable (sliding type) equipment support bracket to ensure that all active equipment are adequately supported from the rear as well as the front. Equipment not adequately supported (front and rear) will not be accepted. 13. Equipment cabinets shall be provided with Honeycomb style side rails and baffles which shall be combined to manage intake and exhaust air from side vented equipment to creating cold aisle / hot aisle air distribution. 14. The Contractor shall provide blank panels for all unoccupied spaces within enclosure(s) to maintain correct air flow. 15. All enclosures shall be provided with cable organizers. 16. All enclosures shall be provided with Grounding (Earthing) kit and shall be connected to the nearest clean earth bar with suitable earth wire as detailed in the electrical section of this specification. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 12 F. IDF/FTR WALL-MOUNTED CABINET 1. The contractor shall provide wall mounted equipment racks in the IDF rooms in the configuration shown on the design drawings. 2. Wall mounted cabinet shall be sized accordingly to accommodate the associated active and passive requirements of the network supported. Cabinets shall have minimum dimensions of 15 U (Rack Units) (H) x 600mm (W) x 600mm (D). 3. Wall mounted cabinets shall be constructed of rust free alloy, welded construction. 4. Equipment Cabinets shall be fully enclosed, lockable, ventilated modular type steel construction and treated to resist corrosion. 5. Finish: Black/Grey, Powder coat pain with fingerprint and scratch resistant finish. 6. Equipment cabinets shall be provided with EIA 19” rack mounting frames with rack spaces (units) stamped every unit. 7. Cabinets shall be provided with modular cooling trays/panels to provide mechanical air circulation and heat extract from the active equipment. The cooling trays/panels are to be selected for the appropriate hot air flow directions from the active equipment, taking into account cold and hot aisle configurations and locations of computer room air conditioning distribution. 8. Cabinets shall be provided with Lockable glass front door with 180° opening, quick release pins and cable entry points at the top and rear with gland plates. 9. Cabinets shall be provided with hinged rear and front section providing easy access to the rear of installed equipment. The contractor shall ensure that all cabling is installed with enough "slack" to allow for full opening of front section of the cabinet without damage to cables. Installations not providing full opening and swing of front section will be rejected. 10. Cabinets shall be provided with removable, lockable vented sides. 11. Cabinets shall be provided with 4 x 19" adjustable mounting frames. 12. Equipment racks shall be provided with a minimum of 2 (two) Power Distribution Units (PDU) for primary and secondary supplies to the equipment. Each PDU shall be sized to present a dedicated outlet for each piece of active equipment with an additional 20% for future installations. Each outlet must be rated to support the full load of each attached piece of equipment. 13. The Contractor shall provide blank panels for all unoccupied spaces within enclosure(s) to maintain correct air flow. 14. All enclosures shall be provided with cable organizers. 15. All enclosures shall be provided with Grounding (Earthing) kit and shall be connected to the nearest clean earth bar with suitable earth wire as detailed in the electrical section of this specification. 16. The size and exact details of the cabinets may vary due to the location and installation conditions. Where proposed cabinets are proposed that deviate from the above details, the contractor is provide the appropriate material submittals and shop drawings for approval by the client’s representative. G. HORIZONTAL CABLING- CAT6A UTP 1. Be augmented category 6A component compliant out to 500MHz with operational bandwidth to 500 MHz. 2. Have a round LSOH cable jacket available with a nominal cable O.D. of less than or equal to 7.4mm SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 13 3. Have a construction comprised of 4-pairs of 0.57mm (0.02 in) (22AWG) solid bare copper conductors utilizing a centre isolation member to maintain pair geometry for optimal NEXT performance 4. Have a Foil tape surrounding the cable pairs with a drain wire with an aluminium foil tape surrounding the drain wire. 5. Have a rip cord installed under the jacket for jacket removal. Be available in both 305m, 500m and 1000m reels. 6. Be available in jacket colours of Blue – CMR, Gray – CMX and Violet - LSOH 7. Provide the following 100m, 4-connector topology performance (white cells – std ref. values in grey cells): 8. Meet the following electrical characteristics: Max DC Resistance (@ 20°C) <8.5Ω /100m Characteristic Impedance (no impedance averaging allowed) 1-100 MHz: 100 ohms ± 15% 100 - 750MHz: 100 ohms ± 22% Nominal Velocity of Propagation (NVP) LSOH – 67% H. CAT6A COPPER PATCH CORDS 1. Category 6A RJ45, third party component verified to Cat 6A ANSI/TIA/EIA 568 B 2.1. and ISO/IEC 11801 Cat 6 channel compliant. 2. Support T568A and T568B wiring. 3. Support applications up to 500 MHz 4. Durable black powder coat finish with flame retardant UL 94V-0. 5. Connection of the cable will be carried out through rear IDC contacts with use of a standard 110 impact tool. 6. Shall consist of 24 ports on 1 RU of rack space. In the case of rack space shortages, 48 ports with 1RU space shall be available. 7. Angled Patch Panels shall be used for all patch panels. Patch panels shall be recessed from the 19” rails. 8. Rear-side cable support bracket far enough from the panel to accommodate the cable bend radius limitations. 9. Metal structure enabling it to be durably fixed to the uprights of the 19”chassis assuring ground SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 14 10. continuity with metal frames. 11. Modular contacts shall be plated with minimum 50 micro-inches of gold. Manufacturer will be the same as that selected for work area outlet jacks. 12. Allow for re-terminations without signal degradation below standards compliance limit. 13. Augmented category 6A component compliant out to 250MHz with operational bandwidth to 500MHz. 14. Factory assembled and 100% transmission tested with laboratory grade network analyzers for proper performance up to 250MHz. 15. Backwards compatible with lower performing categories. 16. Equipped with identical screened modular 8-position plugs on both ends, wired straight through with standards compliant wiring. 17. Utilize patented metallic isolator shields pairs inside plug for optimum NEXT performance and a 360 degree crimp for providing strain relief without causing pair deformation. 18. Use bend relief compliant boots (with optional color-coded icons) to ensure proper category 6 performance and feature a latch guard to protect against snagging. 19. Resistant to corrosion from humidity, extreme temperatures, and airborne contaminants. 20. Available in standard lengths of 1, 2, 3 and 5 meters with custom lengths available upon request 21. Made by an ISO 9001 Certified Manufacturer. 22. Certified by Underwriters Laboratories to United States Standards and C22.2 Canadian Telecommunications Standards. I. CAT6A COPPER PATCH PANELS 1. Patch panels shall be used in the cross-connect facilities to connect the four-twisted pair cables and their related outlet, to the active devices via patch cords. 2. Category 6A RJ45, third party component verified to Cat 6 ANSI/TIA/EIA 568 B 2.1. and ISO/IEC 11801 Cat 6 channel compliant. 3. Support T568A and T568B wiring. 4. Support applications of 1Gb/s at 500 MHz. 5. Compliant to FCC part 68500, section F and UL1863, dealing with the interface's physical 6. dimensions, including the 1.27μm gilding on the contacts, the traction force to be borne by the RJ45 socket, the plug (100 grams) and the maximum force authorized for connecting the plug in the jack (2.2 kg). 7. Durable black powder coat finish with flame retardant UL 94V-0. 8. Connection of the cable will be carried out through rear IDC contacts with use of a standard 110 impact tool. 9. Shall consist of 24 ports on 1 RU of rack space. In the case of rack space shortages, 48 ports with 2RU space shall be available. 10. Rear-side cable support bracket far enough from the panel to accommodate the cable bend radius limitations. 11. Slots in the front face for the insertion of designation tabs (icons for Voice- Data-Video) for ports and a label designation system in the front and in the back to provide identification marking that meets the requirements of standard ANSI/TIA/EIA –606-A. 12. Metal structure enabling it to be durably fixed to the uprights of the 19”chassis assuring ground continuity with metal frames. 13. Modular contacts shall be plated with minimum 50 micro-inches of gold. Manufacturer will be the same as that selected for work area outlet jacks. 14. Allow for re-terminations without signal degradation below standards compliance limit. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 15 15. made by an ISO 9001 Certified Manufacturer. J. DATA OUTLETS 1. All 500MHz category 6 information outlets designed for termination of 4-pair balanced twisted- pair category 6A copper cables must possess the following characteristics at the minimum: a. Exceed category 6A component compliance through the frequency range of 1 to 500MHz with usable bandwidth to 500MHz. b. Be available in black, white, red, grey, yellow, blue, green, orange, ivory, bright white, light ivory and alpine white. c. Universal design allows the same outlet to be mounted in flat or angled orientation. d. Be backwards compatible to allow lower performing categories of cables or connecting hardware to operate to their full capacity. e. Support industry standards for T568A or T568B wiring options on each individual outlet. f. Provide color-coded, snap-in icons available for circuit identification. g. Allow for a minimum of 5 terminations without signal degradation below standards compliance limits. h. Be constructed of high impact, glass reinforced nylon. i. Faceplates shall be a single or double gang as identified on drawings, Jacks shall be of the same manufacturer. j. Must be certified by Underwriters Laboratories to United States Standards and C22.2 Canadian Telecommunications Standards. K. MULTIMODE FIBER OPTIC CABLES 1. Backbone Fibre Cables shall be provided as per the structured cabling schematic. 2. The fibres shall meet ITU-T: G652 for multi-mode specifications. 3. Laser Optimized 50/125um multimode fiber optical fiber cables shall be in compliance with the following standards: a. ISO/IEC 11801:2002 Amendment 2 OM4 b. ANSI/TIA/EIA-568-C.3 c. ANSI/TIA-598-C d. ANSI/TIA-492 AAAD e. IEC 60793-2-10 Fiber type A1a.3 f. Telcordia GR-409-CORE g. IEC 60332-1-2(Single strand) h. IEC 60754-1(Non Halogens) i. IEC 60754-2(Acid gas) j. IEC 61034-2(Smoke Density) 4. All optical fiber cable shall be appropriate for the environment in which it is installed. 5. In addition to meeting the applicable performance specifications, all optical fiber cable shall be appropriate for the environment in which it is installed. 6. Have a round lead free cable jacket available in OFNR, OFNP and LSOH constructions. 7. Shall contain a Rip Cord applied longitudinally under the cable jacket for easy cable jacket removal 8. Shall contain a light weight central strength member located in the middle of the fibre bundles. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 16 9. 10. 11. 12. Shall contain both colour-coded buffered fibres as well as colour-coded buffer tubes. Cables shall have length markings in 2 ft. increments. Fibre will be available in strand counts of 4, 6, 12, 24, 48, 72 and 96. Shall meet these minimum performance parameters: Minimum Performance Parameters for Qualified Cables Maximum Attenuation Minimum Bandwidth (MHz-km) Group Index of Refraction (dB/km) 850 nm 1300 nm 850 nm 1300 nm 850 nm 1300 nm Laser - 2000 OFL 1500 OFL - 500 3.5 1.0 1.483 1.479 13. Ethernet applications supported: Application Distance (m) 10GBASE-SX (850 nm) 10GBASE-LX4 (1300 nm) 1000BASE-SX (850 nm) 1000BASE-LX (1300 nm) Fibre Channel 266 (1300 nm) ATM 622 (1300 nm) ATM 155 (1300 nm) ATM 52 (1300 nm) FDDI (Original 1300 nm) 100BASE-FX (1300 nm) 300 300 900 600 1,500 500 2,000 3,000 2,000 2,000 14. Physical Characteristics 50/125um: L. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Core Size (Microns) Cladding Size (Microns) Coating Size (Microns) Buffer Size (Microns) Core Cladding Concentricity (Microns) 50 ± 3 125 ± 2 245 ± 10 900 ± 50 ≤3.0 SINGLE MODE FIBER OPTIC CABLES Backbone Fibre Cables shall be provided as per the structured cabling schematic. The fibres shall meet ITU-T: G652 for single mode specifications. Single mode optical fiber cable shall be used for Backbone and ISP applications only. Optical fiber backbone cable shall be plenum rated and meet the following fire performance standards: IEC 60332-1, IEC60332-3C, IEC 1034-1/2, IEC 754-1/2. Have a Yellow coloured round lead free cable jacket available in OFNR, OFNP and LSOH constructions. Shall contain a Rip Cord applied longitudinally under the cable jacket for easy cable jacket removal. Shall contain a lightweight Central Strength member located in the middle of the fibre bundles. Shall contain both colour-coded buffered fibres as well as colour-coded buffer tubes. Cables shall have length markings in 2 ft. increments. Fibre will be available in strand counts of 4, 6, 12, 24, 48, 72, and 96. Shall meet these minimum performance parameters: SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 17 Minimum Performance Parameters for Qualified Cables Maximum Attenuation (dB/km) Cable Type Indoor 1310 nm 1550 nm 0.60 0.60 Zero dispersion Slope Wavelength (nm) (nm²-km) 1300-1324 <0.093 Index of Refraction 1310 nm 1550 nm 1.467 1.468 12. Ethernet Applications Supported: Application 10GBASE-L (1310 nm) 10GBASE-E (1550 nm) 10G Fibre Channel (Serial-1310 nm) 10G Fibre Channel (WDM-1310 nm) 1000BASE-LX (1300 nm) Fibre Channel 266/1062 (1300 nm) ATM 52/155/622 (1300 nm) Distance (m) 8,000 30,000 10,000 10,000 5,000 10,000 15,000 13. Physical Characteristics: Mode and Fiber Type Core Size (Microns) Cladding Size (Microns) Single mode 8.3 ± 1.0 125 ± 1.0 Coating Size Buffer Size (Microns) (Microns) 245 ± 10 900 ± 50 Core Cladding Concentricity (Microns) ≤ 0.8 M. FIBER OPTIC PATCH PANELS 1. All fiber patch panels, enclosures, and coupler inserts shall be of the same manufacturer and colour. 2. Shall be used in the cross-connect facilities to connect optical fiber cables to active devices via fiber jumpers. They shall be dimensioned to enable the connection of all fiber cores of the installed cables. 3. Shall be a black metallic box type modular structure, with front section comprising of standardized 19" chassis, and able to accommodate all standard optical connector such as: LC, SC, ST. They shall include all the appropriate cabling accessories (bend limiting clips for the cables and fiber jumper, cable-ties, label-holders, etc.), to ensure correct positioning of fiber cores and to maintain the minimum bend radius for all changes in direction. 4. Shall have removable doors/panels front and rear. They will be designed for cable entry from the rear of the enclosure and be equipped with appropriate means for physically securing the cable(s) in place. 5. All enclosure housings are required to be equipped with an integral bonding lug or stud for securing the fiber strength member. 6. Each 2U enclosure shall provide space for a minimum of 4 coupler panels and 4 splice trays. 7. Each 4U enclosure shall provide space for 12 coupler panels and 12 splice trays. 8. For connectors that employ a plastic housing, coupler panels will provide color-coding in accordance with industry standards (i.e. beige adapters for graded-index optical fiber, blue for single-mode optical fiber). 9. All optical fiber cables shall be fusion spliced to LC pigtails of 2m length. They shall meet the following performance: a. Ultra-Physical Contact (UPC) finish for single-mode: Insertion loss: 0.40dB maximum, 0.20 dB typical; Return loss: minimum 55db. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 18 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. b. Physical Contact (PC) finish for Multimode 50 micron: Insertion loss: 0.50dB maximum, 0.30 dB typical; Return loss: minimum 20db. All connectors and adaptors shall be provided with dust caps. Not be bigger than one rack mount space and accommodate up to 36 ports for SC, MT-RJ, LC or ST adapter plates. Have preloaded adapter plates with ST and SC fiber adapters in 6 and 8-port version, as well as a 12 port version for the SC, MT-RJ and LC adapters. Have blank adapter plates for future growth of the fiber infrastructure. Be modular in design with internal fiber managers that provide slack storage to comply with fiber bend radius and the recommended slack storage length. Have a snap-on front shield to be used as a labeling surface and to protect jumpers. This shield can also relocate to another position during termination to maintain circuit identification. All connectors and adaptors shall be provided with dust caps. Accommodates a splice tray for mechanical or fusion splices. Be available with a drawer mechanism, which allows the panel to slide forward or to the rear. The following solutions are not acceptable: a. Field polishing. b. Composite / Polymer ferrules. c. Mechanically splicing pigtails. Must be certified by Underwriters Laboratories to United States Standards and C22.2 Canadian Telecommunications Standards. N. FIBER CONNECTORS 1. LC Connectors- Multimode a. Meet the Fiber Optic Connector Intermateability Standards (FOCIS) specifications of TIA/EIA-604-10. b. Be available in simplex and duplex versions. c. Utilize same termination kit available for ST and SC versions with the addition of an LC upgrade kit. d. Terminate both 50/125um and 62.5/125um optical fiber. e. Have a quick field termination process, which does not require power. f. Have a termination process, which incorporates use of a reliable anaerobic adhesive, which has a high resistance to environmental extremes. g. Have jacketed and buffered versions. h. Meet the following performance specifications: Parameter Performance(dB) Insertion Loss (typ) 0.1 Insertion Loss (max) < 0.2 Durability (500 cycles) < 0.1 Return Loss (min) 20 2. LC Connectors- Single Mode a. Meet the Fiber Optic Connector Intermateability Standards (FOCIS) specifications of TIA/EIA-604-10A. b. Be available in simplex and duplex versions. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 19 c. Utilize same termination kit available for ST and SC versions with the addition of an LC upgrade kit. d. Have a quick field termination process, which does not require power. e. Have a termination process, which incorporates use of a reliable anaerobic adhesive, which has a high resistance to environmental extremes. f. Have jacketed and buffered versions. g. An outer housing color-coded (blue) in accordance with TIA and ISO cabling standards. h. Meet the following performance specifications: Insertion Loss (typ) Performance (dB) 0.1 Insertion Loss (max) < 0.2 Durability (500 cycles) < 0.1 Parameter Return Loss (min) 55 3. LC Multimode Fiber Jumpers a. Be available in standard lengths of 1, 2, 3 and 5 meters with custom lengths available upon request. b. Utilize 50/125um duplex multimode fiber cable that is OFNR riser grade and meets the requirements of NEC/NFPA 70 Section 770-51(B) c. Meet IEEE 802.3ae 10 Gigabit Ethernet requirements as well as IEC 60793-2-10 and TIA 492AAAC specifications for laser bandwidth Differential Modal Delay (DMD) specifications. d. Meet Telcordia and ISO/IEC specifications for end-face geometry (including radius of curvature, apex offset, and spherical undercut). e. Use cable and connectors that are complaint with color coding specifications as listed in ANSI/TIA/EIA-568-B.3 and ANSI/TIA/EIA-598-B. f. Have LC-SC hybrid versions available. g. Include dust caps on all assemblies. h. Be 100% optically tested to meet the following performance specifications: Parameter Min. Cable Bandwidth (MHzkm) Max. Insertion Loss (dB) Min. Return Loss (dB) 850nm 50/125m 1300nm 850nm* 1500 500 2000 0.50 (0.10 Typical) 30 (35 Typical) *laser bandwidth 4. LC Single Mode Fiber Jumpers a. Be available in standard lengths of 1, 2, 3 and 5 meters with custom lengths available upon request b. Utilize duplex single-mode fiber cable that is OFNR riser grade and meets the requirements of NEC/NFPA 70 Section 770-51(B). c. Offer a superior connector polish that meets Telcordia and ISO/IEC specifications for end- face geometry (including radius of curvature, apex offset, and spherical undercut) d. Use cable and connectors that are complaint with colour coding specifications as listed in ANSI/TIA/EIA-568-B.3 and ANSI/TIA/EIA-598-B e. Have SC-LC hybrid versions available SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 20 f. Include dust caps on all assemblies g. Be 100% optically tested to meet the following performance specifications: Parameter Single Mode Max. Insertion Loss (dB) 0.40 (0.1 Typical) Min. Return Loss (dB) 55 (60 Typical) 5. LC Multimode Fiber Pigtails a. Be available in standard lengths of 1 meter with custom lengths available upon request b. requirements as well as IEC 60793-2-10 and TIA 492AAAC specifications for laser bandwidth Differential Modal Delay (DMD) specifications. c. Offer a superior connector polish that meets Telcordia and ISO/IEC specifications for end- face geometry (including radius of curvature, apex offset, and spherical undercut) d. Use connectors that are complaint with color coding specifications as listed in ANSI/TIA/EIA-568-B.3 and ANSI/TIA/EIA-598-B. e. Include dust caps on all connectors f. Be 100% optically tested to meet the following performance specifications: Parameter Min. Cable Bandwidth (MHzkm) Max. Insertion Loss (dB) Min. Return Loss (dB) 850nm 50/125m 1300nm 1500 500 850nm* 2000 0.50 (0.10 Typical) 30 (35 Typical) *laser bandwidth 6. LC Single Mode Fiber Pigtails a. Be available in standard lengths of 1 meter with custom lengths available upon request b. Offer a superior connector polish that meets Telcordia and ISO/IEC specifications for end- face geometry (including radius of curvature, apex offset, and spherical undercut) c. Use connectors that are complaint with colour coding specifications as listed in ANSI/TIA/EIA-568-B.3 and ANSI/TIA/EIA-598-B d. Include dust caps on all assemblies. e. Be 100% optically tested to meet the following performance specifications: Parameter Singlemode Max. Insertion Loss (dB) 0.40 (0.1 Typical) Min. Return Loss (dB) 55 (60 Typical) O. ACTIVE NETWORK SYSTEM BRIEF 1. Converged ICT & Security Networks – The development shall be provided with multiple independent networks. These networks shall provide dedicated services. These networks SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 21 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. shall run on independent infrastructure and utilize dedicated switching hardware. The current defined independent networks are : a. Converged ICT Network b. Security Network Various building systems will use the networks as their transport method. It is the requirement of this Section to provide fully redundant network to meet these requirements. The various building systems will be separated onto the networks as follows: a. Converged ICT Network i. BGM and Apartment Intercom System ii. Building Management Applications such as email, building management software, billing software, time attendance etc. (as required) iii. Back of House Office computers and printers (as required) iv. Building Management System (BMS) b. Security Network i. Video Surveillance System ii. Access Control System and other related security systems iii. Security Headend Equipment and Control Room Devices/Equipment All networks shall be configured to a fully dual-redundant star topology with the network cores in the server room and the edge switches in the IDFs. The Contractor shall provide logical separation between different Networks. Each network shall be provided with a dedicated server room space, dedicated backbone cabling dedicated racks in the IDF's. The contractor shall provide firewall, router, dedicated core and edge switches for each network as shown on the design drawings. A dedicated MTR room has been provided on the B2 level to house all the IT equipment for the chosen Internet Service Providers (ISPs) incoming infrastructure from the site boundary and the service distribution to building networks. GSM rooms are provided to house the active GSM equipment for the 2 GSM service providers. The contractor is to provide dedicated UPS units for all IT related rooms to support the installed equipment for a minimum of 30 minutes unless otherwise specified or agreed. The Contractor shall be responsible for providing the requirements for and verifying space, selection of rack (size and door type) power and cooling requirements associated with this Section and coordinate with the relevant trades. It is the Design Intent to provide multiple intra-building infrastructures which shall support fully redundant, high-speed, standards-based, switched 10/100/1000 Mbps, multi-protocol, Ethernet network, providing IP services based on ANSI/TIA/EIA and ISO standards, and Building Industry Consulting Service Inter- national (BICSI) Telecommunications Design Methods Manual (TDMM). All network end-points and outlets shall support 10/100/1000 Mbps operation and Power over Ethernet for optimum performance of all users and applications. The system LAN configurations shall be a two-tier hierarchical star. All services for the development will originate at the redundant Core Switches located in the Server room. Core Switches will be interconnected to the optical fiber backbone by means of rackmounted fibre interconnect patch cords as detailed in the structured cabling section of this document. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 22 15. The backbone will deliver data to and terminate at the Edge Switches located in the IDF’s located throughout the building. 16. Firewalls shall be used for added network protection as detailed in the network topology drawings. 17. The network is an IP network, therefore it is required that all Active components such as CCTV surveillance must support IP over the provided network. The data network extends to the structured cabling system, which must be capable of accommodating a variety of IP enabled devices as well as the above listed items. Systems for Security Cameras and Access control are not to be included in this network. 18. Access layer devices must support Power over Ethernet plus (PoE+) in order to provide electrical power to access layer devices capable of utilising the PoE+ standard. 19. Access Switch stacks shall have Layer 3 capability and dual uplinks over multimode fibre, with a minimum bandwidth of 10G per uplink, connecting to the distribution / core layer. 20. All materials and products, excepting Owner Furnished Equipment (OFE), and materials, shall be appropriate for the intended use and shall meet all applicable UL, EN, BS, ISO and IEC Regulations 21. All products shall be new, of the latest version at time of Installation, and brought to the job Site in original manufacturer's packaging. 22. The Contractor is to provide a written statement from all manufacturers that all installed hardware and software are the latest models at the time of Taking-Over. 23. All software supplied for the Project shall be manufacturer furnished and supported applications. The Contractor “custom” software, written in-house, will not be accepted except in cases where a suitable application does not exist and only with prior written acceptance by the Engineer. 24. Materials shall be listed and approved for the particular application and permitted by the authority having jurisdiction for the application. 25. All workstation termination hardware shall match the existing wall surface color as closely as possible, to include mounting boxes, faceplates, and outlets. 26. Used equipment or damaged material will be rejected. P. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. CORE SWITCHES Fully redundant Core Switches shall be provided for all of the active networks on the project. Switches shall be provided with the premium build software and all required licenses. Each core switch is required to have redundant power supply and redundant supervisor module. Scalability and performance and port density across several chassis configuration and LAN, WAN and metropolitan-area network (MAN) interfaces. Redundant power supply and redundant supervisor module in each core switch. Enabled Hardware accelerated IPv6m MPLS, GRE and NAT. Integrating high performance forwarding capacity upto 150Mpps. with the new routing and forwarding engine including third generation policy features card (PFC3). Simplified network operations. Resilient and load-sharing Switching Fabrics in the core switches with a maximum stateful failover time at Layer 2 and Layer 3 of <1second. Synchronization of dynamic and static information shall be replicated on both processors modules In a multi-switch network scenario, either of primary or secondary core switches shall failover to the other in <1second by means of layer 2 resiliency techniques (having uplinks SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 23 11. 12. 13. 14. 15. 16. from edge switches split among the two core switches. All links between any given edge switch and all core switches shall be actively load-sharing traffic.) Hot Swappable Switch Fabric, Power Supplies and fan trays and Switching modules. Dual switch software and configuration file images on processors. Active Alternate locations for switch software and configuration file images (Flash, PCMCIA, Network Drive). Real-time operating system (RTOS) for mission critical applications which is Stable and reliable with no vulnerabilities in Software / configurations. The switch’s operating system or application-specific software(s) shall not, at any time, affect the operation by causing a system to: crash, reboot, enter a state of Denial of Service (DoS), fail to respond to any type of user/network traffic, fail to respond to any type of management traffic, use built-in user name/passwords to gain illegal access to the switch. Ability to Cluster both backbone switches to provide a single virtual Switch facing the Servers and the Edge switches. Thus all links between the (backbone switches – edge switches), (Backbone switches – Servers) shall be active and Load-Sharing using Standard 802.3ad. Q. CORE SWITCHES MODULES 1. Supervisor modules. 2 no supervisor modules shall be provided per core switch. 2. Supervisor modules must be configured to include network system virtualization technologies to cluster the core switches as a single virtual switch. 3. 10/100/1000-MBPS Ethernet Interface Modules for IP (over copper) connectivity to local devices within 100m from the core switch. 4. 10Gb fibre Ethernet modules for backbone uplinks to edge and server switches requiring higher bandwidth (greater than 1Gbps) availability. 10Gb modules should not be subject to oversubscription unless approved otherwise. 5. SFP modules as per the design requirements. R. ACCESS/EDGE SWITCHES 1. The contractor must maintain a single model of server/edge switch throughout the project to ensure the consistency of the design, reliability of the performance, efficacy of manageability and maintain lower overhead of the maintenance. 2. The contractor shall provide switches with capability of 10GB uplinks from the core switches for all 24 and 48 port switches. External switches (if any) must be provided with a minimum of 10GB uplink capability. 3. The number of ports on the active components design is based on the number of cable terminations to the IDF location. Effective schedule of area document will facilitate calculating the ports required per IDF location. 20% of active ports spare to be calculated for each IDF location. 4. All edge switches must connect directly to the redundant equivalent switch and directly to the core switch using the fiber uplink ports with primary uplink to first core switch and secondary uplink to the second core switch, cascading in any form is not permitted in the network. 5. 20% Spare uplink ports and associated cores must be available with the fiber infrastructure to accommodate future expansion. 6. Two servers farm switch type will be required to be installed in the CCTV Network servers‘ racks each with 48 Gigabit ports and two fiber uplinks to the core switches. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 24 7. The individual switches shall be ASIC based and have an internal switch fabric which operates at speed greater than or equal to 24 Gbps for the Giga Ethernet interfaces. Each shall have expansion slot, which has access to the internal switch fabric. The operating code in each switch shall be stored in Flash memory and to be upgraded by downloading new code to the switch. 8. Layer 2 requirements – Full 10/100/1000 UTP auto-negotiation. No Single Point of Failure. 9. All switches must be POE (Power over Ethernet) Enabled. 10. Support port monitoring. The edge switches shall support the port monitoring for at least once source/destination pair at a time. The source and the destination ports can be selected from any Ethernet port in any switch in the switching stacks. 11. Load-Balancing load uplink capabilities using link aggregation group (LAG) allows multiple links to be grouped. 12. The LAG shall load share the traffic between two switches allowing the bandwidth to be multiplied and the traffic to be averaged. The use of LAG in addition to boosting the performance of an uplink, also inherently increase the resilience of the solution since the links behaves as hot standby links to one another. 13. If the traffic is shared over multiple links, and one of the links is lost the traffic shall be automatically redistributed over the other links and communications shall continue without interruption. 14. Inter-module-Redundancy Provides link redundancy functionality in the event of module failure. 15. The switchover time between the ports in event of failure of the primary port shall be less than 1 second. 16. The traffic prioritization according to IEEE 802.1p tagged frames. 17. Leaky LAN: the switches shall support leaky LAN and support block broadcast traffic between VLANs but allows unicast traffic to be forwarded to VLANs. 18. Ability to download S/W images shall be in safe mode, check CRC, copy, compare, then to be active. 19. Backup code always to be present. Security on MAC address. 20. Ability to enable and disable port security as required. 21. Ability to implement port security by locking the addresses in the switch MAC tables, only allowing access to those devices whose MAC addresses are known. 22. Each switch shall have an integral network management agent. IP multicast filtering via IGMP snooping. 23. All switches shall comply with NEBS level 3 requirements and to be certified. 24. All switches shall meet the requirements of IR-NWT-000063 NEBS for shock criteria, vibration criteria, shock and vibration test methods and Layer 4 load balancing. 25. Support SSH and CRYPTO and central logging commands 26. For External devices such as the CCTV points, externally rated with operating temperatures of - 40 °C to 85°C. 27. All external switches must be externally rated as detailed above and must be mounted in an IP 65 enclosure as a minimum. All enclosures and mounting details must be submitted for approval by the clients’ representative prior to procurement and installation. S. UNINTERRUPTIBLE POWER SUPPLY (UPS) 1. Refer to the electrical specifications for the UPS requirement. 2. Minimum of 15 mins backup, generator-powered power supply shall be considered for ICT equipment. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 25 3. Security equipment shall comply with SIRA requirements of minimum 30mins UPS backup and 120mins backup for the security control room. PART 3: EXECUTION A. GENERAL 1. All materials and products, excepting Owner Furnished Equipment (OFE), and materials, shall be appropriate for the intended use and shall meet all applicable UL, EN, BS, ISO and IEC Regulations 2. All system components shall be manufactured by ISO 9001:2008 certified companies and all packaging shall carry clear product identification (catalogue number, quality control number, etc) 3. All products shall be new, of the latest version at time of Installation, and brought to the job Site in original manufacturer's packaging. Electrical components shall bear the Underwriter's Laboratories label. This listing requirement applies to the entire assembly. Only systems and equipment that meet or exceed the level of quality and capabilities stated within this document will be considered for acceptance. 4. Materials shall be listed and approved for the particular application and permitted by the authority having jurisdiction for the application. 5. All system components of the entire cabling system (copper and fibre) shall be from a single manufacturer which will ensure that a single performance warranty covers all applications on vertical and horizontal links. This includes but is not limited to: a. Horizontal Distribution b. Fiber Optic Distribution c. Copper Distribution d. Patch Panels e. Copper and Fibre Outlet Modules B. INSTALLATION 1. Install components in accordance with Contract Drawings, manufacturer’s instructions and approved submittal data. 2. System installation and construction methods shall conform to the requirements of the applicable International Standards. 3. The Contractor shall install all system components including Employer Furnished Equipment, and appurtenances in accordance with the manufacturer's instructions, and adjustments required to deliver a complete and operable system. 4. Earthing and Bonding shall be installed as necessary to preclude ground loops, noise, and surges from adversely affecting system operation. 5. The Contractor shall adhere to the installation schedule of the Engineer and should attend all construction meetings scheduled by the Engineer. 6. Final configuration of the network equipment shall be performed to the satisfaction of the Employer’s IT Staff. This includes, but is not limited to; VLAN configuration, IP addressing schemas, final port assignments, and trunking/bonding configurations. The Contractor shall ensure that the proper documentation is provided to assist in the final system configuration. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 26 7. Mount all equipment to be installed over public areas in a manner adequate to support the equipment loads with a minimum safety factor of five. Do not use formed eyebolts or lag screws for support of suspended equipment. 8. Firmly and permanently, attach electrical boxes, enclosures, and permanent equipment to the building. Rigidly mounted equipment and devices shall be plumb and square. 9. Choose color and finishes of all exposed and custom fabricated items and labels to blend in with the surroundings as accepted by the Engineer. C. INSPECTION 1. The Contractor shall undertake testing and commissioning for all elements and aspects of the installation. Witnessing of testing and commissioning of the installation shall be offered to the Engineer for acceptance and sign-off. 2. Prior to an inspection, the Contractor shall issue, for acceptance, an Installation, Testing and Commissioning Plan detailing each test that will be conducted and the expected results required to pass the inspection. 3. Provide a statement of completion certifying that the system is installed and is ready for acceptance testing and equalization to The Engineer. 4. Schedule a time for The Engineer to perform system acceptance testing and equalization with at least 14 days advance notice. 5. Furnish a technician who is familiar with the system to assist The Engineer during the acceptance testing and equalization for the duration of time it takes to complete the adjustments (regular time or overtime as required). A minimum of 24 hours, as required to complete the adjustments. 6. Each cable shall be inspected for proper termination. 7. Record final settings on all equipment and submit with contract closeout documents. 8. Upon completion of initial tests and adjustments, submit written report of tests to the Employer along with all documents, diagrams, and record drawings required herein. 9. If the system does not meet criteria or if additional trips to the Site for testing or equalization are required, The Contractor shall reimburse the Employer for all expenses and professional time encountered by The Engineer. D. TEST EQUIPMENT 1. Furnish all test equipment necessary for the complete testing and commissioning of the system, to be available for the entire test period through final system testing and TakingOver. 2. Test equipment shall be calibrated no more than 1 month prior to the start of testing. All test equipment must be accompanied with a certificate from the equipment manufacturer showing date of last calibration. E. DOCUMENT SUBMITTALS 1. Upon project completion and acceptance, submit the following to the property management: a. Technical Manuals: Provide documentation as follows: b. Block Diagrams: Detailed functional block diagrams that illustrate as-built conditions. i. Identify each equipment item by manufacturer and model number, label alpha numerically contractor furnished controls, relays, patch panel jacks, and similar devices. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 27 c. d. e. f. g. h. i. j. k. l. m. n. ii. Reference the designations on fabrication drawings, patch panel details and related instruments. Fabrications: Detailed as-built drawings of contractor fabrications. Illustrate the mechanical and electrical construction, with manufacturer’s part numbers and values for components. Rack Elevations: Final rack elevation drawings. Manufacturer’s Literature: Descriptive literature and performance specifications, operating manuals, and servicing information. Control Settings: Schedule of nominal control settings for proper system operation. Test & Measurements: Documented data gathered during systems tests and commissioning. Systems Operating Instructions: Describe the functions, operation and maintenance for each installed system. Write the instructions in full detail in language sufficiently clear for comprehension by non-technical persons. Troubleshooting Guide: System operator’s procedures to follow in the event of an apparent equipment failure, written in logical outline format. Terms & Conditions: Restatement of the systems warranty terms and conditions and schedule of manufacturer’s warranties covering parts and labor for the provided equipment. Programming: Submit to the property management, a legal copy of the authoring software and unrestricted license and an archival electronic copy of the uncompiled operating code when submitting the record (as-built) documents for system programs. Upon completion of the installation, Contractor shall prepare as built documentation of the entire installation. This documentation should include the electronic copies. i. User Manuals 1. Systems Operating Instructions: Describe each provided system, specifically the functions, operation, and maintenance. Write the instructions in full detail and in language sufficiently clear for comprehension by non-technical persons. 2. Control Settings: Schedule of nominal control settings for proper system operation. 3. Troubleshooting Guide: Operator’s procedures to follow in the event of an apparent equipment failure, written in logical outline form. 4. Block Diagrams: Simplified as-built block diagrams with alpha numeric references to controls, relays, patch panel jacks and other similar devices. 5. Terms & Conditions: A restatement of the system warranty terms and conditions. Describe the terms of manufacturers’ warranties that extend beyond the two year provisions of the system warranty. 6. Document Revisions: Submit within four weeks official system acceptance, four complete sets of corrected and revised pages and drawings to update the operating and maintenance manuals described above to reflect adjustments and changes to the system during the final testing and acceptance. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 28 ii. Operation Manual 1. Table of Contents 2. Typed description of each system including key features 3. Setup diagrams as directed by the Consultant 4. Single-line detailed schematics and layout showing all major system components 5. Manufacturer's operation manuals for equipment intended for operation by system users 6. All software shall be fully documented, and that documentation included. 7. Any and all user definable software configurations and/or programming shall become the sole property of the employer. This includes all source code, source code copyrights, and related documentation. iii. Maintenance Manual 1. Bind each with tabbed dividers between sections and include a title page with space for submittal stamps. 2. Table of Contents 3. Company name, address, telephone number and contact name for system service or maintenance 4. Listing of all equipment and materials manufacturer's names, addresses, and telephone numbers, model or part numbers and catalogue data sheets 5. Product manufacturers' warranties and a typed system warranty explicitly covering all materials and labor 6. Manufacturers' service manuals for all major equipment items. 7. Test documentation showing results of source quality control tests, field quality control tests, acceptance testing, and equalization 8. List of spare equipment F. WARRANTY 1. The contractor will provide a written warranty valid for minimum 20 years from date of structured cabling acceptance or practical completion, whichever is the later. Advanced replacements should be available during this period. 2. For Active Equipment, the contractor will provide a written warranty valid for minimum 3 Years from date of system acceptance or practical completion, whichever is the later. Advanced replacements should be available during this period. 3. Acting as a franchised dealer, the contractor is required to provide agreed service of equipment including warranty claims and repairs; 4. Support costs required for 3 years (or show qty 3 x 1 year support cost) and should include new equipment / software and extend any existing contract to end approximately the same time as any new contract. G. MAINTENANCE 1. Annual Maintenance Contract SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 29 2. Include along with pricing of AMC any services schedule, preventative maintenance scheduling and actual contract wording. 3. 24x7x4 terms are mandatory for all critical components 4. 8x5xnbd terms are acceptable for non-critical components such as telephone handsets. 5. Direct vendor support contracts are mandatory although the contractor can submit an alternative to direct vendor support if the contractor has extensive supplies of equipment in UAE and can match or exceed the service and expertise of the vendor. H. TRAINING 1. The manufacturers authorized and factory trained personnel must provide 5 Days of training sessions. Duration of each training session shall be at-least four hours long. Contractor to video record each session and provide six soft copies of the recording as part of the CloseOut Submittals. 2. The training must include at a minimum: a. Preventive maintenance service techniques and schedules. b. Overall system concepts, capabilities and functions. c. Explanation of all control functions. 3. Methods and means of troubleshooting and replacement of all distribution and drop wiring and devices. 4. Manuals, drawings and technical documentation must be used in training and shall be left with the Employer, or its designated representative at the completion of training for Employer use in the future. 5. The use of proprietary equipment does not justify failure to provide technical documentation, such as programming information, electronic schematic drawings and technical description, as part of training and documentation. It shall be the responsibility of the Contractor to ensure this documentation can be obtained prior to acceptance, as listed in this document. END OF SECTION SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 30 MADINAT JUMEIRAH LIVING PHASE 3A DATA COMUNICATION SYSTEM SPECIFICATION (ICT, AV, INTERCOM) REV. A DESIGN COMPLIANCE PERFORMANCE CRITERIA 27TH JUNE 2019 Revision A Date 2019 06 27 By SN Description DESIGN COMPLIANCE PERFORMANCE CRITERIA Resp. Consult BW NOTE: THIS DOCUMENT TO BE READ IN CONJUNCTION WITH THE CONCEPT REPORT SCALE: NTS SHEET SIZE: A4 DATE STARTED: 2019 06 13 CHECKED: RT DWG № 18164E-TE-GEN-0-050-01 STAGE: CPT Rev: A Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Table of Contents PART 1 - GENERAL ................................................................................................................................ 3 1.01 PROJECT INTRODUCTION ...................................................................................................... 3 1.02 SCOPE OF SPECIFICATION ..................................................................................................... 3 1.03 TENDER SUBMITTAL .................................................................................................................. 4 1.04 TENDER DRAWINGS ................................................................................................................ 4 1.05 COORDINATION ..................................................................................................................... 4 1.06 QUALITY ASSURANCE ............................................................................................................. 5 PART 2 – DATA COMMUNICATIONS SYSTEMS ................................................................................... 6 2.01 – ICT (INFORMATION AND COMMUNICATIONS TECHNOLOGY) ............................................................. 6 2.02 AUDIO-VISUAL SYSTEM (BACKGROUND MUSIC SYSTEM) ................................................................ 25 2.03 AUDIO INTERCOM SYSTEM ........................................................................................................... 28 2 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification SECTION 27 0000 DATA COMMUNICATIONS SYSTEM (ICT, AV, INTERCOM) PART 1 - GENERAL Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. 1.01 PROJECT INTRODUCTION A. B. C. Madinat Jumeirah Living (MJL) Project, Dubai. Madinat Living will share the same DNA as the Madinat Jumeirah. The site is accessible from the surrounding wellestablished road network (Sheikh Zayed Road, Umm Suqeim Road, Al Wasl Road and Jumeirah Beach Road). This specification focuses in the Building 6, 7 and 8 of the Madinat Jumeirah living development contained within Phase 3A of the Project and focuses on the Data Communication System (ICT, AV, Intercom) to be installed in MJL buildings 6, 7 and 8. The underlying concepts behind the design of the Data Communication systems for this project are as follows: 1. The MJL development wish to provide Data Communication systems in specific areas of the development. This forms the basis of this specification. 2. Provision of features and services that will help differentiate the development from its competitors 3. Provision of systems that meet the guidelines of the MJL requirements and international best practices. In responding to this tender, the contractor shall consider the requirements and needs of the operator with specific regard to the following criteria:1. The nature of the development 2. The Intrinsic business nature of the residences. 3. The criteria provided by the client. 4. Current industry trends 1.02 SCOPE OF SPECIFICATION A. B. C. D. E. This specification covers Data Communications systems (ICT, AV, Intercom) as described below for the MJL Development The objective is to provide professional systems, installed, acceptance tested, and ready for use. Drawings pertaining to this specification shall be considered as a part of the specification and shall be a part of the Contract documents. System features that are mentioned in one part may not be shown in the others. In case of conflict between the written specifications and the drawings, Contractor must seek clarification from the Engineer. In the event that the Contractor fails to obtain such clarification, the interpretation of the Engineer will prevail. The General Conditions, Particular Conditions, Electrical General Provisions, and the applicable requirements of the Main Contract apply to each and every contract, contractor, subcontractor or other persons supplying materials and/or labor for this project. The security contractor must ensure that the developed detailed design provides a robust resilient system with considerable expansion capability throughout all 3 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification F. G. H. I. J. K. L. M. N. security equipment with the purpose and functionality of all security subsystem components, combined to provide a fully functional and integral system. In all cases guidance should be requested from the Client and Consultant. Comprehensive method statement shall be submitted for approval and this statement must clearly include all aspects of installation. The contractor shall comply with the project safety standards. Liaise with and coordinate all works with the client and consultant. This specification document outlines the design criteria, distribution routes and considerations which form the basis for the development of Security Services. Contractor shall perform all work, coordination, aid to system integration, engineering design and testing, and shall install and provide all products in approved manner to ensure a fully operative system. Acceptance Test plan would be executed to verify the installation and operation of the system. All material / installation shall be approved by the ID/Engineers/Client representative. The contractor must ensure that the developed detailed design provides a robust resilient system with considerable expansion capability throughout all security equipment with the purpose and functionality of all security subsystem components, combined to provide a fully functional and integral system Detailed specifications are provided within section 2.0 of this document. 1.03 TENDER SUBMITTAL A. The following items are to be submitted with the tender return. 1. Provide a detailed Bill of Quantity with brands and model number. 2. Provide a schedule of equipment showing manufacturer and model 3. Provide a compliance statement stating if fully compliant, partially compliant or non-complaint with reasons if not fully complying. 4. Provide system description and schematic. 5. Provide all data sheets of the system being provided 6. Provide compliance with authorities 7. Provide company profile and highlight the projects done that are similar to this project 8. Provide project implementation plan 9. Provide Project team plan with resumes of probable team members 10. Provide training details. 1.04 TENDER DRAWINGS A. The specification should be read with reference made to the tender drawings and reference to the contract electrical and architectural drawings. B. It should be noted that tender drawings are detailed only to the extent necessary to show design intent and signal flow. It is understood and agreed by the contractor that the work herein described shall be complete in every detail so as to provide a complete and fully functional system even though every item necessarily involved is not specifically mentioned. 1.05 COORDINATION A. Coordinate all work with the Architect, Interior Designer and Engineer. B. Coordinate the location of all active equipment with the location of all electrical mains power outlets. 4 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 1.06 QUALITY ASSURANCE A. Contractor Status: The Security Contractor shall be a registered, certified business partner and authorized installer for the proposed ACS manufacturer. B. The contractor Have previously installed at least 5 projects of the same scale with the brands being proposed and has completed within the last five years. They must be currently certified by the manufacturers. Provide at least on such completed job for inspection by the Engineer. Proof of the same must be submitted at the presentation of bid proposal. C. The Contractor shall have ten years’ experience with equipment and systems of the types specified, shall maintain a fully in house staffed and equipped service facility, and shall be an authorized service provider for the major brands specified for the project D. The Contractor resumes of engineers and installers shall be provided as being planned for the project. This shall be presented during the Prequalification at the tender submission stage. E. The Contractor shall have local presence within Dubai and provide 24/7 service support. F. The integrator must have a good standing within Dubai on all current /previous projects. Proof to be provided of successful handing over of such projects. This is subject to be verified by client. G. The contractor must submit proof for each of the below mentioned items in the prequalification list at time of tender submission. H. Proof of all above items must be submitted during pre-qualifications at the time of tender submission. 1.07 WARRANTY A. Contractor to provide Owner with exact beginning and ending dates of the warranty period. Include the name of the person to call for service and telephone number. This information to be part of Project Record Drawings and handover. B. Manufacturer shall provide a limited 3-year warranty for Manufacturer supplied hardware to be free of defects in material and workmanship. C. Manufacturer shall provide software support and updates for a period of 12 months. Extended support options shall be available. D. Client software shall not require a license and have no limitations on number of client users. This excludes third-party plug-ins. 1.08 TRAINING A. Provide on-site training for Owner's representatives as appointed. All manufacturers’ equipment manuals for each system described in these specifications will be on-site during training. Unless training is provided, this Contract will not be considered complete. B. Provide required training sessions for all the supplied and installed system. 5 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification PART 2 – DATA COMMUNICATIONS SYSTEMS 2.01 – ICT (Information and Communications Technology) A. SCOPE OF WORK 1. Supply, delivery, supervision, coordination, and installation, of equipment specified herein and shown on the Tender and Contract Drawings. 2. Supervision, coordination and installation of Structured Cabling System (SCS) as required by Etisalat and Du. 3. Incorporation of Client Furnished Equipment as required, providing a complete installation. 4. Termination, testing, documentation and instruction of equipment specified herein and shown on the Tender and Contract Drawings. 5. The Contractor shall verify space, power and cooling requirements associated with the Structured Cabling System as described within this and related documents. 6. Provide all equipment, materials, labour, and services, not specifically mentioned or shown, which may be necessary to complete or perfect all aspects of the installation. Ensure that they comply with requirements stated or reasonably inferred by the specifications. 7. Provide calculations and analysis to support design and engineering decisions as specified in submittals. 8. Comply with codes, ordinances, regulations, and other legal requirements of public authorities which bear on performance of work. 9. The Contractor shall provide system performance warranty for the SCS from the cabling system manufacturer to ensure all end-to-end connectivity channels can support up to 1 Gigabits per second. 10. The Contractor shall provide proper earthing of all components in the SCS including but not be limited to equipment cabinets / racks. The Contractor shall coordinate with the Client / MEP Contractor for the locations of the nearest earth nodes from where the Contractor shall install the equipotential bonding to the SCS equipment. 11. The Contractor shall ensure that all of their works are coordinated both in terms of design and on-site integration with the works of other contractors, including but not be limited to the contractors for other systems installations, any sub-contractors employed by the Contractor and other relevant parties including the Employer and / or the Consultant and / or its representatives. 12. The Contractor shall liaise and co-ordinate with appropriate statutory authorities as required. 13. The Contractor shall designate qualified person(s), other than the Project Manager, to be responsible for the on-site quality control and attendance of regular design with Employer implementation progress meetings. The Contractor shall furnish adequate information and drawings in a timely manner to the Employer and / or the Consultant in ensuring smooth SCS implementations. 14. The Contractor shall provide SCS documentation including system schematics, design topology, wiring schemes, labelling conventions, rack layout plans, SCS outlet layout plans, and also other information relevant to utilizing this infrastructure 15. The Contractor shall provide a complete SCS that includes components including but not be limited to all cables and wirings, drop cables and patch cords for connecting outlets to equipment, under-floor outlet back-boxes, outlets, jacks, faceplates, cable terminations, cable ties, cable labelling and outlet labelling, patch panels, patch cords, equipment racks, plywood and frames, termination boxes (back-box and junction boxes), cable containment (including trunking, cable trays, cable ladders, riser trunking, conduits, etc.) within the Main Telecom Room, IDF Rooms, Electrical Rooms, 6 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. • and equipment racks, and all necessary printed warning notices, signage and labels and the like as specified in this Technical Specification. The contractor shall be responsible to have anti-static paint in all technical room floors including main telecom room, floor telecom rooms, GSM rooms, AV rooms…etc. The Contractor shall be responsible in developing requirements into a fully functional and complete system to produce a detailed SCS design that is fully co-ordinated with other building services, the building structure and architectural features and all furniture, fittings, and equipment. The Contractor shall also provide fire stopping materials to fill the holes after the trunking / tray has been installed. The fire stopping materials shall meet the original fire rating of the floors and walls that the holes are on. It shall be the Contractor's responsibility to coordinate and liaise with the Employer and or the Main Contractor to ensure the final cable containment sizing shall meet the Employer's requirements. The Contractor shall coordinate with other contractors for the termination of cables required by other systems. The Contractor shall supply and install all equipment cabinets and racks for the System. The Contractor shall coordinate with others for cabinet / rack standards and quantities required for the Project. These shall include but not be limited to the cabinets / racks in the Main Telecom Room, IDF rooms and other locations specified by the Consultant / the Employer. The Contractor shall refer to the Tender Drawings for the arrangement of cabinets / racks. The Contractor shall provide all patch cords and drop cables (equipment leads) for all systems on Day One. All patch cables and drop cables shall be patched to the cabling patch panels and punch down frames and neatly dressed within cabinets, racks and wall frames. Final connection to active equipment shall be undertaken by other respective contractors, unless otherwise stated or requested. The Contractor shall provide weather proof termination boxes for outlets installed at outdoor locations. The Contractor shall perform full (100%) testing and commissioning of all installed cables, including drop cables at two ends and connectors, and submit test reports accordingly. The Contractor shall provide patching records (in the format agreed by the Employer and / or the Consultant), prepare and submit Operation & Maintenance Manuals to document the SCS installation and include the test reports into the manuals. The Contractor shall provide full documentation with labelling of the entire SCS, including cables and connectors, cabling cabinets / racks, equipment cabinets / racks, patch cords, patch panels, etc. for the Project. The Contractor shall conduct on-site user training on the System to the Employer's operation team and relevant representatives. The Contractor shall be responsible for running the fibre cable from the Telecom Equipment Cabinet to the equipment rack and respective termination need to be carried out. The Contractor shall ensure that all of their works are co-ordinated both in terms of design and on-site integration with the works of other contractors, including but not be limited to the contractors for other systems installations, any sub-contractors employed by the Contractor and other relevant parties including the Client and / or the Consultant and / or its representatives. Related work specified elsewhere: The work described in this document includes hardware, installation, training, and support activities related to providing complete systems as described within this, and related sections. 7 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Where specifications require exact match or conformance to an established sample or quality standard or objective, the Consultant’s decision will be final on whether a proposed product or installation practices matches satisfactorily. • Requirements for inconspicuous or concealed installation, as one example, establish such a standard and objective. If required, fabricate custom-made enclosures and or chassis with careful consideration being given to aesthetic, technical, and functional aspects of the components and their installation. 29. Coordination will be required between the Contractor and the following entities to ensure a complete working system, including, but not limited to: • Du • Etisalat • Other Trades • B. SYSTEM & PRODUCT 1. System Description a. The intra-building infrastructure shall support a high-speed1Gb switched, multiprotocol, Ethernet based network providing converged IP-based services based on ANSI/TIA/ETA, ISO standards and BICSI TDMM (Telecommunications Design Methods Manual). b. The backbone connectivity shall be subdivided into the following: • ISP (Combined DU and Etisalat - TRA guidelines) - Backbone for Apartments • Building ICT Backbone (Building CNS Backbone) c. Madinah Jumeirah Living will have latest ISP design guidelines called TRA guidelines, and the same need to be implemented in this project. d. As per TRA design guidelines combined (Du & Etisalat) MTR room should be provided in the building. e. Single infrastructure to be provided inside building for ISP connectivity to every residential apartment. f. Madinah Jumeirah Living buildings having one Main Telecommunication Room (combined DU and Etisalat) at Ground Level provided as per latest TRA design guidelines. g. Four-core single mode fibre cable shall be linked between Mini ODF and every residential apartment HCC (Home consolidation Cabinet) as per latest ISP (TRA) design guidelines. h. Multicore Fibre should be pulled between Mini ODFs at different levels of telecom room and ISP - MTR room at Ground level, refer Schematic layouts. i. Horizontal cabling inside each apartment shall be ANSI/TIA/EIA Category 6 UTP, deployed in a "home-run" arrangement. Cat.6a horizontal cable permanent link shall not exceed 90 meters. j. Horizontal cables inside each apartment shall be terminated on 1U patch panels in HCC (Home Consolidation Cabinet). k. Each residential apartment will have 12U HCC panel (600mm H x 600mm W x 150mm D) as per TRA guidelines. l. All pairs of all horizontal cables will terminate to a modular 8-Position, 8-Conductor outlet at the telecommunications outlet. m. MDF Rack for ICT Backbone shall be located in ground floor MTR room. n. GSM services should be provided as per TRA design guidelines. o. GSM containment should be provided between MTR room and GSM room p. Main GSM room in GF and Roof be considered as shown in the schematic layouts. 8 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification q. Multi core (24 core as per TRA Guidelines) single mode fibre cable shall be pulled between MTR room and GSM rooms as per latest design guidelines. r. Space shall be provided to allow for the development of a Tetra system. s. Tenderer to assure that no fibre and copper cables is manufactured in China, shipped, assembled or repackaged in other country. t. Tenderer to provide confirmation on manufacturer letterhead on Country of Origin and country of manufacture, details/locations of their own manufacturing facilities, including ISO certificates u. Tenderer to provide letter from manufacturer to confirm Country of Origin / Country of manufacture, details/locations of their own manufacturing facilities, including ISO certificates. 2. Design Topology a. The Contractor shall refer schematics and Drawings for the detail such as locations and quantities of IT related equipment rooms and the quantities of cables required between the rooms. b. The Contractor shall undertake site surveys to familiarize themselves with the site conditions. C. ISP (DU and Etisalat) Backbone for Apartments 1. Madinah Jumeirah Living-buildings 6, 7 and 8 will have single telecom (ISP) infrastructure for Du & Etisalat service as per latest design guidelines (TRA) inside building. 2. Entry ducts should be provided from ISP (Internet Service Provider) OSP manhole to combined MTR room inside building. 3. Four Core indoor rated Single-mode Optical Fibre Cables shall be considering for ISP connectivity to apartments as per latest ISP (TRA) Standards. 4. Four core single mode fibre cable shall be provided between Home Consolidation cabinet (HCC) located in each apartment and Mini ODF located in Floor Telecommunication rooms at different levels in the tower. 5. fibre cable shall be of continuous lengths free from joints, branches or patching. 6. Four core fibre cable should be ITU-T standard compliant with G.652D as per ISP guidelines. 7. Jacket of the cable shall be Low Smoke Zero Halogen(LSZH) or Flame-retardant polythene sheath(FRP). 8. Multicore Single mode fibre cable shall be connected between Mini ODF at different levels and Main Telecommunication Room(MTR). 9. Contractor must follow latest ISP design guidelines for the calculation of multicore single mode fibre core count and fibre termination details. 10. The contractor shall terminate the fibre cable in MTR, Mini ODFs as well as a dedicated, secure HCC (Home Consolidation Cabinet) in each Apartment as per latest TRA design guidelines. 11. Contractor shall be responsible for the installation of cable containments / conduits within the MTR’s, Mini ODFs or other designated rooms. 12. The fibre cables should be labelled at both ends with a unique reference for the consolidation point served, Mini ODFs and the MTR. 13. Contractor shall make sure that all the installation should be in accordance with ISP (TRA) latest standards. 14. The Contractor shall undertake site surveys to familiarize themselves with the site conditions. 9 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification D. Building ICT backbone 1. ICT communication network will establish communication between: • IP based devices for Background Music System. Building intercom system – Outdoor unit in Reception and all units will have intercom handset. MDF Rack for ICT Backbone shall be located in ground floor FTR (Floor Telecom Room) Fiber Backbone (2 x 2 core multi-mode fibre cable) shall be connected between GF Floor Telecom Room and Floor Communication Network Racks (IDF’s) at different levels. OM4 multi-mode indoor LSZH (Low Smoke Zero Halogen) Tight Buffered fibre shall be provided for Building ICT Backbone. OM4 Multimode fibre shall be completed with graded index optical fibre waveguide with mode field diameter of 50µm ±0.5µm and cladding diameter of 125µm ±2 µm. Optical fibre shall conform to the OM4 standard defined in ISO-11801 2" Edition, to support 10 GB Ethernet over increased distances. All fibres shall operate in both 850nm and 1300nm optical windows with maximum attenuation of 3.5dB/km and 1.5dB/km respectively. All fibre shall have its minimum information transmission capacity for 850nm and 1300nm optical windows as 200 MHz-km and 500 MHz-km respectively. All fibre cables shall be of a dry and dielectric construction. No gel or metallic content shall be allowed. The sheath of the cable shall be of LSZH construction. The sheath of the cable shall be extruded free from pin holes, joints, mended places and other defects. It shall be reasonably circular and the curvature of the external surface shall not be concave at any point. The minimum allowable bending radius of the cable shall be 10D and 20D during and after installation respectively where D stands for the overall cable diameter. The cable shall have water sellable yarn located with the fibres to prevent the migration of water should the sheath material become punctured. The cable shall operate within the stated specifications for temperatures ranging from -10°C to +65 °C • 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. ICT and ISP (Telecom) will share the Riser space, however 50mm gap should be provisioned between each trucking as mentioned in the floor layouts. 14. Communication network riser shall be established between Control room and mechanical floors & designated floors and should have dedicated wall mount cabinet. 15. Wall mount cabinet shall have 13Amps Dual Power socket and rack-mounted 2 kVA UPS. 16. Wall mount rack will accommodate Network Access Switch. 17. Main ICT rack in Ground floor FTR room - should have a dedicated 42U rack (800 mm x 1000mm) allocated, this rack includes: • Riser fiber patch panels • Core switch – connecting to all mechanical floors and designated floors as per building ICT requirements such as Intercom Systems etc. • IP based connections such as server, workstation or other devices via access switch. • 3kva UPS 10 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 18. Communication network will be used for services/devices which supports IP based communications such as Intercom and BGM …etc. as per client requirements. E. Apartment ICT Requirements 1. Each apartment will have 12U Home Consolidation Cabinet (HCC) (600mm H x 600mm W X 150mm D) with dual 13Amps power sockets. 2. Home Consolidation Cabinet(HCC) will accommodate the service provider’s ONUs. 3. CAT 6a, UTP cable should be used inside apartment for horizontal cabling. 4. All Cat.6a Cable inside apartment should be terminated in 1U Cat.6a patch panel 5. Cable organizer should be provided for proper management of patch cords inside HCC panel 6. ISP 4 core fibre cable should be terminated inside HCC panel as per ISP design guidelines. 7. Proper Labelling should be provided for Cat.6a patch panels, Cat.6a Cables, Face plates and patch cords inside apartment, and the labelling scheme should be approved by client/ consultant. F. GSM Services 1. GSM services should be provided as per latest TRA design guidelines 2. Every GSM room should be connected to MTR room with multicore single mode fiber optic cables, refer TRA guidelines. 3. GSM room should have 4 x 13 Amps twin power sockets fed from essential power supply with dedicated 20A circuit breaker. 4. 2 numbers of ac & dc earth bars connected to the dedicated earth pits with resistance less than 1 ohm. 5. 2 x 63 Amps TP isolator fed from dedicated feeder from essential power supply should be provided inside GSM rooms 6. Cross connect cabinet with fiber cable termination devices should be provided in GSM rooms as per design guidelines 7. Firefighting & fire safety requirements should be provided inside GSM room based on design guidelines. 8. GSM antenna locations and equipment details will be designed by GSM service provider. 9. Scope of Installation and termination should be done as per TRA guidelines, by service provider. G. Horizontal Cabling (CAT 6a) Topology 1. Category 6a(UTP) Standard, structured cabling shall be considered for horizontal cabling. 2. The physical topology of the horizontal cabling should be configured as a star with each outlet connected directly to a Home Consolidation Cabinet(HCC) inside Apartment. 3. The Contractor shall ensure that the end-to-end length of each individual run of any fixed horizontal cable from the Distribution Box / Equipment rack to the SCS outlets shall not exceed 90 meters. 4. All Horizontal Cables inside each Apartments shall be terminated on 1U patch panel provided in 12U Home Consolidation cabinets (600mm h x 600mm W x 150 mm D), flush mount Cabinet. 11 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 5. The maximum combined length of any work area equipment patch cable /cord and equipment patch cable / cord shall not exceed 10 meters. 6. The Contractor shall leave an extra length of 3m of cable on either end for terminations. The cable must be suitably labelled. 7. The Contractor shall leave an extra length of 5m of cable, for Wireless Access Point. The cable must be suitably labelled. 8. The Contractor shall provide horizontal cabling connectivity to the RJ45 outlets to support the following services / applications: • Data • Voice (VoIP) • Other services / applications as requested by the Client 9. Refer to schematics & Drawings to develop schedule for the location and quantity of outlets required. 10. The Contractor shall coordinate regularly with other parties such as the Client, architect, other contractors for the final quantities and locations of SCS outlets. H. Components 1. General a. Between any two termination points, all installed cables shall be continuous and without any joints or splices. b. All indoor cables shall not be laid on areas exposed to external weather conditions. Cables shall not be laid on wet or damp concrete surfaces. c. The SCS shall be designed and installed to make the best use of the installed containment in terms of diversity, system resilience, utilization and room for expansion. d. All cable bundles shall not run over hard or sharp edges. e. All cable bends shall not be tighter than the manufacturer's minimum bending radius requirements. f. All the installed cables shall be terminated at both ends and labelled neatly on patch panels inside racks and faceplates on slab-mounted boxes or outer termination boxes where appropriate. g. The Contractor shall provide the manufacturer's original certificates for cables or related components of the Work for review by the Employer and / or the Consultant. h. All cable types shall be proposed by the Contractor and quoted in the Tender Returns. Generally, all wiring shall be run in conduit and trunking systems. i. Tenderer to assure that no fiber and copper cables is manufactured in China, shipped, assembled or repackaged in other country j. Tenderer to provide confirmation on manufacturer letterhead on Country of Origin and country of manufacture, details/locations of their own manufacturing facilities, including ISO certificates 2. Horizontal Cabling (Cat.6a UTP) a. All Category 6a UTP cables shall be of Low Smoke Zero Halogen (LSZH) type. b. All cables shall be accompanied with traceable serial numbers from the manufacturer indicated on the packaging to assist in quality validation of the installed cables. c. All cables shall have cable markings – “Category 6a UTP" imprinted on the cable sheath in a color that contrasts with the sheath color. d. The length of each individual run of fixed horizontal cable from the ACP/equipment rack to the SCS outlet shall not exceed 90 meters and within 4 connections. 12 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification e. All cables shall be 4-pair (Unshielded twisted pair UTP) cables meeting or exceeding the quality and performance requirements for Category 6a UTP cables stipulated in Class 'E' ANSI/TIA/EIA 568B-2.1:2001 and ISO/IEC 11801:2002. f. The UTP copper cabling system shall be properly ground and bond. The grounding and bonding requirements specified in the current TIA J-STD-607-A Commercial Building Grounding (Earthing) and Bonding Requirements for Telecommunications shall be applied to the copper cabling systems. 3. Patch Panels a. Copper Patch Panels 1) The Category 6a patch panels shall meet or exceed the quality and performance requirements for Category 6a cross-connect panel stipulated in EIA/TIA-568-B.2. 2) The patch panels shall incorporate enough space to accommodate a label for each port to indicate its function / termination / application. 3) The patch panels shall pass the reliability test of no more than 1 failure in 500 insertions for each modular jack port. b. 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) Optical Fiber Patch Panels Fiber patch panels shall be used to terminate all optical fiber cables with LC type connections, using fusion splicing technology. Patch panels shall be modular in design, equipped with patch-cord routing troughs and suitable for mounting in the frames/racks supplied. The patch panels shall provide protection from mechanical stresses, and macro bending losses on the cables. The patch panels shall provide means to locate and clamp the incoming cables without causing damage to the cable or affecting the quality and performance of the link. Patch panels shall provide patch guides, with a closed front to protect the patch cords. Patch panels shall be designed to allow termination and maintenance work, that can be carried out without having to remove the entire panel. Patch panels shall provide enough space to accommodate the bending radius for the patch cords, once connected to the panel. Patch panels shall provide enough management space and tools to store the fiber after breaking the fibers out from the cable. Patch panels shall be provided with either a screw-in or lockable dustcover to protect unused connector adapters. Patch panels shall have enough space in its front, to accommodate a minimum of one label. The label shall indicate its function/termination/application for each connection. 4. Patch Cords & Connectors a. Copper Patch Cords 1) The patch cords and work area cords shall be pre-terminated rather than fieldterminated. 2) All patch cords shall exceed or be an equivalent of TIA/EIA and ISO/IEC Category 6a 3) The patch cords shall provide air-tight connections and shall comply with ISO 11801 and EIA/TIA-568-B.2 Category 6a requirement. 4) The Contractor shall provide different colors of patch cords to distinguish between different services / applications. 13 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 5) The color and length of patch cords to be used for each service shall be agreed with the Employer and / or the Consultant. Normally patch cords shall come in 1m, 2m and 5m in length, excluding modular plugs at both ends. 6) Patch cords shall have built-in exclusion features to prevent accidental polarity reversals and split pairs. They shall have a latching mechanism to prevent accidental dislodging of the plug from the termination module or modular jack panel. 7) All cordage shall be round, and shall consist of 22-24 AWG copper, stranded conductors, tightly twisted into individual pairs. 8) The Contractor shall provide and include adequate quantities of copper and fiber patch cords. b. Horizontal Cable Connectors 1) All horizontal cables shall be terminated with RJ-45 modular jacks at the user outlet end and IDC-type patch modules at the equipment rack/HCC end. 2) Cable connectors shall be wired to the T568B wiring pattern. 3) Cable connectors shall be constructed with a housing of polycarbonate of rating 94V-0. 4) Cable connectors shall be mechanically and electrically compatible with the Category 6a UTP cables supplied under this Contract. 5) Communications outlets shall be Underwriter's Laboratories (UL) listed. 6) Communications outlets shall be of RJ-45 type, with Insulation Displacement Connectors (IDC) used to terminate the cable. 7) Horizontal cables shall terminate on RJ-45 sockets, 4-pair terminated, housed in closures agreed with the Employer as acceptable. 8) The installed connectors shall meet or exceed the quality and performance characteristics for Category 6a connector stipulated in EIA/TIA-568-B.2. c. Single-mode Optical Fiber Patch Cords 1) 2) 3) 4) 5) 6) 7) The single-mode fiber patch cords shall be single fiber cords, flexible in nature with factory terminated fiber connectors at both ends. The color and length of patch cords to be used for each service shall be agreed with the Employer and / or the Consultant. Normally the length of each single-mode fiber patch cord shall come in various lengths of 1 m, 2 m, and 5 m, excluding the mechanical structure of the connectors. The single-mode fiber patch cords shall have core diameter of 8.7pm ±0.5µm and cladding diameter of 125µm ± 2µm. The outer jacket of the single-mode fiber patch cord shall be made of LSZH. The cable marking shall include traceable part numbers from the manufacturer packaging to assist in quality validation of the installed cable. The outer jacket shall be color coded and imprinted with cable markings "Singlemode" in a contrasting color. The outer diameter of the single-mode fiber cord shall not exceed 3mm. d. Fiber Connectors 1) LC type duplex fiber connector /adaptors shall be used for single mode and multimode fiber cables and have a locking feature on the duplex coupler. 2) Pigtail shall be field installable, compatible with other fibers supplied in this project. 14 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 3) Pigtail shall allow the use of PC polishing on the tip, to provide high yield during installation. 4) Fiber connectors shall be able to operate within specification in temperatures ranging from - 10 to +65°C. 5) The insertion loss of mated connectors shall have a mean value of 0.35dB and a standard deviation of 0.2dB. 6) The insertion loss change due to temperature variations within the operating temperature shall be less than 0.3dB. 7) Insertion loss change after 1,000 reconnections shall be less than 0.2dB. 8) The return loss of the connector for the connections shall be better than -20dB for multimode connections and -40dB for single mode connections. 9) The tip material of the fiber connector shall be made of ceramic. 10) Refer ISP Standards for DU and Etisalat cable termination and type of connectors. 5. Faceplates, Outlets, Trunking a. Faceplates 1) Flush mount (flush-fitted wall-mounted) outlets shall be used for wall mounted outlets and wherever else possible. 2) Where space does not permit mounting of a flush face plate, modular surface mounted boxes shall be used. 3) Modular faceplates for mounting either at 90 degrees (straight) or 45 degrees (angled) RJ-45 modular jacks shall be installed for the floor slab-mounted outlet boxes where a raised floor is provided. 4) All face plates shall be constructed of ABS mounding compound and be compatible with standard electrical outlet boxes used by the MEP contractor. 5) Shutter covers shall be provided for each RJ-45 modular jack. Insertion of an RJ-45 jack shall cause the shutter to open. When the plug is removed, the shutter shall close automatically to protect the jack from ingress of dust. 6) Dust cover / blanks shall be provided for unused jacks. 7) Flush plates shall be mounted on skirting wiring duct cover section, metal wall box for outlets in masonry walls or metal mounting brackets for outlets in plasterboard lined stud walls. 8) The Contractor shall coordinate with the Employer and / or the IT Consultant, and architect on the colour and finish of faceplates to be provided and the same should be match with electrical accessories. 6. Cable Laying a. Cable Laying Principles 1) Cables shall be fixed in straight parallel runs and shall be held in place by broad cable ties at not more than 900mm centers on horizontal trays and 900mm on vertical trays. 2) Cables shall not be held so tightly or by sufficiently narrow cable ties that permanent indentation (enough to measurably affect the transmission characteristics of the cable) or cutting of the outer sheath or conductor insulation occurs. 3) The manufacturer's minimum bending radius requirements shall be adhered during cable installation. 4) Cables running along horizontal and vertical cable ladder system shall be neatly dressed, tied and wrapped at regular intervals. Different types of cables shall be 15 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 5) 6) 7) 8) 9) grouped separately. Velcro type cable ties shall be used for all 4-pair twisted pair cabling; PVC cable ties shall be acceptable for larger multi-core cables. Sufficient protection shall be provided to all installed cables and terminations to prevent damages from other trades on the construction site. Any damaged cables shall be replaced at Contractor's own costs. Installed cable shall take the shortest route consistent with the defined routes, and shall not, unless specified, contain length in excess of the distance required. All cables which cross service pipes carrying hot or refrigerant fluids shall be protected from excessive high or low temperatures or condensation. This may require separation and / or thermal insulation. Cables shall be kept clear of fire suppression outlets, heat and smoke detectors and water detector strips. Installed cables shall not be subject to vibration or movement. Cables shall not be fixed with staples, Cables should be properly routed with velcro tapes. 7. Separation from power cables a. The communications cables shall not be tied to power cables or run along the same conduits/ducts or run through the same connection box. b. Any internal cables running in metal enclosed trunking or conduit shall be separated from external parallel runs of power cables by a minimum of 600mm. All other power and communications cables shall be separated according to the recommendations stated in CIBSE AM7. c. Where busbar inter-connecting power cables cross communications cable trays these cables shall cross at 90-degree angles. These power cables shall be shielded to minimize any interference with communications cabling data signals. 8. Cables in Trunking / Conduit a. Trunking compartments shall be no more than 60% full to allow for future installation of cables. b. Cables shall enter and exit trunking via bridges to ensure complete separation between communications and power compartments, if any. c. The number of cables in each conduit shall be controlled to allow for future cable installation and to stay within the manufacturers' maximum allowable cable pulling tension. d. All draw wires shall be replaced during each cable pull. e. After cabling in trunking that passes through a fire-resistant structural element that has been designated as fire barrier, such as floor and wall, approved type of fire resisting material with the appropriate degree of fire protection shall be provided to prevent the spread of fire or smoke through the trunking. Supply and installation of all firestopping materials at the openings to walls, ceiling and partitions shall be by the Contractor 16 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 9. Equipment Cabinets & Racks a. Preferable Dimensions of the racks shall be as follows: Location ICT Rack in MTR Room (MDF) ICT Racks in different levels (Telecommunication Rooms) HCC Cabinets in Apartments Rack Dimension 800mm (W) x 1000mm (D) x 42U (H) 600mm (W) x 600mm (D) x 15U (H) Wall Mount Enclosure 600mm (W) x 150mm (D) x 15U (H) Flush Mount b. Power Sockets Requirement for ICT MDF, ICT IDF, and HCC/RCC: Location ICT Rack in GF FTR Room (MDF) ICT Racks in different levels (Telecommunication Rooms) HCC Cabinets in Apartments/Shops. c. d. e. f. g. h. i. j. Socket Rating No. of Sockets Backup – UPS + Generator 16 Amps Industrial Type (Surface Mounted) X 02 2 kva mount Rack 13 Amps X 01 1 kva mount Rack 13 Amps X 01 Not Required For exact dimension and location of the racks, the Contractor shall verify at site and submit for Employer and Consultant's approval. The Contractor shall supply and install one 13Amps twin power sockets power inside the HCC for powering the network equipment. The Contractor shall supply and install 1 no 13 Amps rated non-switched 6- way power strip as a minimum for each 12U equipment rack at HCC and earth bonded to the rack frame. The Contractor shall supply and install one 13Amps twin power sockets power inside the ICT racks in telecommunication room’s for powering the network equipment The Contractor shall supply and install one 13 Amps rated non-switched 6- way power strip as a minimum for each 12U ICT equipment rack floor telecommunication rooms of Building 1 and Building 2 and earth bonded to the cabinet frame / rack frame. The Contractor shall supply and install 2Nos. 16 Amps twin power sockets power for the ICT MDF rack in Ground floor MTR room for powering the ICT network equipment The Contractor shall supply and install 2 Nos. 16 Amps rated non-switched 10- way C13 & 4-way C19 power strip as a minimum for 42U ICT MDF rack in Ground floor MTR room and earth bonded to the cabinet frame / rack frame. ICT MDF rack (800mm W x 1000mm D) characteristics as listed below: 1) Rack shall have a roof panel with 2 apertures of not less than 300mm x 50mm finished with brush strip (to prevent air leakage) to allow entry of high-level data cabling. 17 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 2) Rack shall have a roof panel with 2 apertures of not less than 300mm x 50mm finished with brush strip (to prevent air leakage) to allow entry of high-level data cabling. 3) Rack shall be with 50mm, minimum, wiring space on any side where terminations are made, the wiring space shall be adjusted (increased) to suit the quantities and types of cables entering and leaving the equipment rack. 4) Rack shall be provided with four roofs mounted fans and have no loss of installation height. 5) Rack shall be provided with suitable means of securing the complete assembly to floors and / or walls. 6) The rack shall be able to support a maximum equipment load of 1000kg. 7) Racks shall be provided with self-levelling feet/castors and shall sit directly on to the access floor or concrete slab. The feet/castors shall be able to support the maximum load capacity of the rack. 8) The surfaces of the rack shall be protected by good quality paintwork. The paint shall be smooth, continuous and free from blemishes and scratches. The colour of the paintwork shall be agreed with the Employer before installation. 9) The front and rear doors shall be provided mechanical barrel type locks and with two sets of mechanical keys. The front and rear doors shall be the same lock on each rack. 10) A full height and width side infill panel complete with vertical wire ways finished with brush strip for inter-rack and frame cabling shall be provided by the Contractor. 11) Three (x3) slotted component shelves per 42U rack shall be provided. 12) All racks shall be provided with removal panels, escutcheon plates (Doors Locks), and covers. 13) The Rack shall have suitable clearance to ensure that the closure of the rack door shall not interfere with any device within the enclosure. 10. Power Strip for Equipment Rack a. The power strips for the equipment racks shall be designed to comply with the following standards: • BS 7671 (IEE Wiring Regulation) • BS 5733 (General requirements for electrical accessories) b. The main housing of the power strips shall be made of anodized aluminium extrusion and mouldings shall be made of high impact, flame retardant grade of polycarbonate. c. The internal wiring shall be single cables insulated in low smoke, low fume grade of material to BS 711. The power leads shall be multi-core flexible cables complying with BS 6500, and shall be low smoke and fume. d. The sockets are designed and tested to BS 1363 Part 2 (Specification for 13A switched and unswitched socket-outlets). They shall be individually fused as 5A. e. The tape-off lead shall be at least 3 metre and the terminating plug shall be fused as 13A. f. Power requirements for racks: Location Power Rating Quantity ICT Rack 16 Amps PDU x02 Min. no. of Outlets 10 way : C13 04 way : C19 Remarks Vertically mounted 18 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification ICT Racks at different levels 13 Amps Power Strip x01 x06 : 3pin UK type HCC/RCP Cabinets in Apartments/Shops. 13 Amps Power Strip x01 x06 : 3pin UK type 1U;600m m horizontal 1U;600m m horizontal 11. Uninterruptible Power Supply a. An Uninterruptible Power Supply (UPS) shall be provided for the ICT MDF Room, & ICT IDF to provide uninterruptible electrical supply to the IT and electronic equipment inside the rooms. b. For the input to ICT MDF rack , the UPS shall be supplied by 1-phase essential power in- feeds from the electrical rooms with full back up by emergency generators. c. In addition to supplying all the loads inside the ICT Racks, the UPS shall have sufficient spare capacity of 20% to ensure its service reliability to support any surge loads and also cater for future expansion of the IT and electronic equipment inside the rooms. d. The rated capacity of each UPS shall be expandable at least 30% for future expansion. e. The UPS capacity shall comply with the following rating requirements. f. UPS Rating • ICT MDF Rack : 02 kVA • ICT IDF Racks : 01 kVA g. The battery bank of each UPS shall have sufficient capacity for support the normal equipment operation under full loads for at least 15 minutes in case of city mains failure. h. The electrical provisions shall be equipped with the necessary by-pass mechanism to main the normal supply to all connected loads during the routine maintenance and / or enhancement of the UPS. i. In case of UPS breakdowns, the loads shall be automatically transferred to the city mains bypass via the system static bypass unit without any interruption. j. Each UPS shall be equipped with necessary interface and network card for connection to Local-Area-Network via SNMP protocol for remote monitoring of the UPS status including mains failure, output on battery, low battery, mains restored and return on UPS, etc. k. UPS management system shall be able to forward all type of alarm to an e-mail or SNMP trap. l. UPS management system shall have the ability to monitor and control UPS systems connected via network-based SNMP card. m. UPS management system shall be able to generate connected UPS health report. n. The UPS equipment shall comply with the following specifications as a minimum: 1 2 Description Type Configuration 3 Construction Specification On-line type N; with flexibility to upgrade to N+1, 2N configuration, if required in future High reliability rack-mounted modular UPS, with no limit of scalability and paralleling for IDF rooms (Service Floors) 19 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Standalone UPS for ICT MDF Room 200% of phase busbar (double neutral) Minimum 65% capacity within 10 times of discharge time (i.e. 300 minutes) 400V / 230V, +10% to -15% (read + confirm) <5% 4 Neutral Busbar 5 Recharge Time 6 Input Voltage 7 8 Total Harmonic Distortion Power Factor - at 100% load - at 50% load 9 Efficiency - at 100% load - at 50% load 10 11 12 Output Rating Output Voltage Adjustment Output Voltage (Transient) 13 14 Output Voltage Transient Response Overload Capability 15 16 17 18 19 20 21 Short Circuit Current Capability Audible Noise Operating Temperature Operating Humidity Mean Time Between Failure (MTBF) Automatic Battery Test Battery Care Voltage Compensation : >0.9 : >0.83 : 92% p.f. 0.8 lagging : 91.5% As mentioned in Section 2.3.7 220V, 50Hz 20% load step, ± 4% 30% load step, ± 5% 50% load step, ± 8% <50ms 110% 60 minutes 125% 10 minutes 150% 60 seconds 200% 200 ms 150% for 0.3 second <50dB (A) 0 – 40⁰C Up to 905 (90%) non-condensing Up to 200,000 hours Yes Yes o. The battery unit shall comply with the following specifications as a minimum: Description Specification 1. Type Sealed Lead Acid Inbuilt battery 2. Backup Time 15 minutes 3. Accommodation arrangement Inbuilt with UPS 12. Entry Duct 1. The contractor must provide lead-in ducts from the plot boundary to the main telecom room (MTR). The exact connection points at the plot boundary will depend on the DU/ Etisalat manhole location. 2. The contractor shall connect to the DU/ Etisalat ICT Infrastructure ducting system. 3. The ISP construction NOC will identify the location and quantity of their lead-in ducts. 4. Refer ISP guidelines (TRA) for lead-in duct specifications. 20 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification I. Performance Requirements 1. Contractor shall provide enough skilled labour to complete testing within the agreed upon test period. 2. Cabling system need to be tested with latest technology testing equipment as per the guidelines of TIA/EIA 568. C 3. Contractor shall have a minimum of 5 years’ experience installing and testing fibre optic, Unshielded Twisted Pair and coaxial cabling systems. All installers assigned by the Contractor to the installation shall have a minimum of 2 years’ experience in the installation of cabling systems. 4. Contractor is responsible for supplying all of the required test equipment used to conduct acceptances tests. 5. Installation, Termination and testing shall be done by manufacturer’s certified technicians. 6. Testing Equipment shall be calibrated as per the manufacturer’s instructions and specifications 7. Contractor shall produce testing equipment calibration certificate prior to the testing carried out at site. 8. NVP testing shall be carried out in room temperature as well as high ambient temperature as per the manufacture specifications. 9. Testing of all horizontal cabling shall be performed prior to system cutover. Voice and data horizontal wiring pairs shall be tested from the telecommunications outlet to the copper Patch Panel. The cable runs shall be tested for conformance to the specifications of EIA/TIA 568B Category 6a Testing 10. Horizontal cabling testing shall be done with a TIA/EIA TSB-67 UL Certified Level 3 test set. Test shall include length, mutual capacitance, characteristic impedance, attenuation, and near-end crosstalk. Near end crosstalk measurements shall be done at both the information outlet and the cross connect. 11. All fibre testing shall be performed on all fibres in the completed end-to-end system. Testing shall consist of a bidirectional end to end OTDR trace performed. The system loss measurements shall be provided at 850 and 1310 nanometres for multimode fibres and 1310 and 1550 for single mode fibres. Fibre Splicing and testing shall be performed in clean, neat and dust free atmosphere J. EXECUTION 1. Pre –Installation Site Survey a. Prior to start of systems installation, meet at the project site with the owner's representative and representatives of trades performing related work to coordinate efforts. Review areas of potential interference and resolve conflicts before proceeding with the work. Facilitation with the General Contractor will be necessary to plan the crucial scheduled completions of the equipment room and telecommunications closets. b. Examine areas and conditions under which the system is to be installed. Do not proceed with the work until satisfactory conditions have been achieved. 2. Installation a. Receive, check, unload, handle, store, and adequately protect equipment and materials to be installed as part of the contract. Store in areas as directed by the 21 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification b. c. owner's representative. Include delivery, unloading, setting in place, fastening to walls, floors, ceilings, or other structures where required, interconnecting wiring of system components, equipment alignment and adjustment, and other related work whether or not expressly defined herein. Install materials and equipment in accordance with applicable standards, and manufacturer requirements, recommendations and manufacturer's printed instructions. Adhere to manufacturer's published specifications for pulling tension, minimum bend radii, and sidewall pressure when installing cables 3. Grounding a. b. c. Grounding shall conform to ANSI/TIA/EIA 607 - Commercial Building Grounding and Bonding Requirements for Telecommunications, and manufacturer's grounding requirements as minimum Ground equipment racks, housings, messenger cables, and raceways. Connect cabinets, racks, and frames to single-point ground which is connected to building ground system via #6 AWG green insulated copper grounding conductor. 4. Labelling a. b. c. Labelling shall conform to ANSI/TIA/EIA-606(A) standards. Provide labelling at each outlet, both end of the cables, Patch Panel port, patch panel, rack...etc. Labelling scheme/schedule shall be approved by client/Consultant prior to implement at site Labelling scheme/Schedule shall be reflected in as built drawings 5. Submittals 1. Submit Four (4) Sets of electronic copies and (4) Sets of hard copies for all below Items 3 to 7. 2. Electronic copies shall have: • Transportation media shall be in IBM-type structure on DVD format. • A Master File List in text format shall be placed on each DVD with a short description of files in the submittal. • The shop drawings shall be in AutoCAD 2018 or later drawing (.DWG) format. Drawing Exchange File Format (.DXF) is not acceptable. All XREFs, fonts, and other drawing parts necessary shall be included. • Word processing files shall be in latest MS Word format. Graphs and charts shall be in MS Excel format. Any graphic images necessary for the reproduction of the submittals shall be included in the files, and shall be included in JPEG (.JPG) file format. • Manufacturers' data sheets, equipment manuals, and other documentation provided by the Manufacturers to the Contractor or documents that are similarly not otherwise available to the Contractor in electronic format shall be excluded from this requirement. • Detailed Network Map (High level and Low level designs) 22 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 3. The Contractor shall provide a detailed network map to be utilized as a road map during the implementation of the Structured Cabling System. This map shall show all segments, all interconnects between segments and all active network devices. This network map shall not include the individual nodes interconnected to each concentrator but shall have the modules, interfaces, protocols, addresses and other identifying features for each concentrator and other active device. 4. The Contractor shall provide a Cable Plant interconnectivity chart showing all fiber patch panels and individual identifiers for each fiber associated with the interconnectivity of each network device. 5. The Contractor shall also provide a time scaled Construction Schedule indicating general project deadlines with specific dates relating to the installation of the system. At a minimum, this Construction Schedule shall include the following milestones per floor: • Equipment Installation Start Date • Equipment Installation Completion Date • Equipment Testing Start Date • Equipment Testing Completion Date • Potential Slippage Periods • Contingent Tasks • Concurrent Tasks • Completion of Documentation 6. Product Data • Submit catalogue data sheets, neatly bound with title page, space for submittal stamps, and tabbed dividers between sections. List all proposed equipment with reference to corresponding specification paragraph numbers or equipment title. Indicate all accepted substitutions. • Submit a schedule of finishes indicating proposed materials and color selections for all exposed items subject to Consultant selection. • Submit a list showing coordination of selected frequencies for all wireless transmitters. 7. Shop Drawings • Submit point-to-point wiring diagrams and typed wire lists identifying every connection for information. Include electronic devices such as switches, transformers, and terminal blocks. Indicate locations of all components. Identify cables by types, colors, and wire numbers. • Submit system plans showing all device locations and ceiling distributed loudspeaker layouts with wattage tap settings. • Submit conduit riser diagrams showing connection of all devices, required conduit sizes along with types and quantities of cables to be used and cable identification tags. • Submit rack layouts indicating the proposed arrangement of mounted equipment including junction boxes and locations of conduit penetrations. • Submit fully dimensioned construction details of all panels, plates and other custom fabricated items or modifications (e.g. installation of audio/visual equipment in lecterns). Include complete parts lists and, as required, schematic diagrams. • Submit mounting and support details for distributed ceiling loudspeakers, and all other items mounted overhead complete with parts lists and dimensions. Include a full plan view, front elevation, and side elevation of each item with corresponding support structure and mounting hardware. Verify load ratings of all hanging components including attachment hardware. 23 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Submit electronic copies of any custom programming including source codes. Include printed copies of all control screens, wiring pages, etc. 8. Samples submit for Consultant's action. Label samples to indicate product, characteristics and locations in the work. Samples will be reviewed for color, appearance, and workmanship. Compliance with all other requirements is the exclusive responsibility of the Contractor. • Label samples to indicate product, characteristics, and locations in the Work. Samples will be reviewed for color and appearance and workmanship. Compliance with all other requirements is the exclusive responsibility of the Contractor. • Furnish samples of the following:o All exposed plates and panels for approval of color, engraving, text size and material. o All exposed equipment’s such as display trims, projector assembly panels etc. o Terminated cable samples. • 9. The Contractor shall provide the username and password for all levels (hardware, operating system, application) of each programmable device. 10. The Contractor shall provide complete TAFV project-related configuration files of programmable devices including final program /codes. 11. The Contractor shall provide the related license details and program software of systems. 12. The Contractor shall provide details of Warranty and prepare asset register with all details as per forms provided by consultant. 3.1 Product Warranty 1. Materials, workmanship and performance specifications hereinafter specified and furnished shall be fully guaranteed by the manufacturer for 20 years from transfer of title against any defects. Defects, which may occur as the result of faulty materials or workmanship within 20 years after installation and acceptance by The Customer, shall be corrected by The Vendor at no additional cost to The Customer. 2. This warranty shall in no manner cover equipment that has been damaged or rendered unserviceable due to negligence, misuse, acts of vandalism, or tampering by The Customer or anyone other than employees or agents of The Vendor. The Vendor’s obligation under its warranty is limited to the cost of repair of the warranted item or replacement thereof, at The Vendor’s option 3. Contractor has to provide 1-year free maintenance starting since hand over of the project. 24 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 2.02 Audio-Visual System (Background Music System) A. SCOPE OF WORK 1. Supply, delivery, supervision, coordination, installation of equipment items specified herein and shown on The Contract Drawings as well as incorporation of Employer Furnished Equipment (E.F.E), testing, documentation, and instruction related to complete Audio, Video, Racks, Consoles, Cables, and Control wiring for the Audiovisual System. 2. Complete Audio-Visual Systems for the Madinah Jumeirah Living- shall include including Public Spaces like Main Lobby and Gym. 3. Provide all equipment, materials, labour, and services, not specifically mentioned or shown, which may be necessary to complete or perfect all aspects of the installation. Ensure that they comply with requirements stated or reasonably inferred by the specifications. 4. Perform all work; provide all products, systems integration, engineering, design work, and testing required for the project in order to ensure fully operative systems and proper installation of equipment. Provide calculations and analysis to support design and engineering decisions as specified in submittals. 5. The Contractor shall ensure that all of their works are coordinated both in terms of design and on-site integration with the works of other contractors, including but not be limited to the contractors for other systems installations, any sub-contractors employed by the Contractor and other relevant parties including the Employer and / or the Consultant and / or its representatives. 6. The Contractor shall designate qualified person(s), other than the Project Manager, to be responsible for the on-site quality control and attendance of regular design with Employer implementation progress meetings. The Contractor shall furnish adequate information and drawings in a timely manner to the Employer and / or the Consultant in ensuring smooth AV systems implementations. 7. The Contractor shall provide AV system documentation including system schematics, design topology, wiring schemes, labelling conventions, rack layout plans, Equipment layout plans, and also other information relevant to utilizing this infrastructure. 8. Contractor shall ensure that all ducts and conduits till display screens are done as required and shall consider any type of drill work under his scope. 9. The Contractor shall be responsible in developing requirements into a fully functional and complete system to produce a detailed AV design that is fully coordinated with other building services, and architectural features. 10. The AV installations must be fully coordinated with the interior design and with other technologies such as voice/data and the fire alarm systems. AV control system must have an audio override by the fire alarm system. 11. The Contractor shall conduct on-site user training on the System to the Employer's operation team and relevant representatives under the supervision of the consultant. 12. The Contractor shall ensure that all of their works are coordinated both in terms of design and on-site integration with the works of other contractors, including but not be limited to the contractors for other systems installations, any sub-contractors employed by the Contractor and other relevant parties including the Client and / or the Consultant and / or its representatives. 25 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification B. CODES AND STANDARDS 1. Codes: Work should be performed in accordance with applicable requirements of governing codes, rules and regulations including the following minimum standards, whether statutory or not: • Local Building Code • National Electric Code (NEC) • National Fire Protection Association (NFPA) • Federal Communications Commission (FCC) • City, and other local codes and requirements 2. Standards: Equipment and materials specified should conform to the current edition of the following standards where applicable: • UL – Underwriters' Laboratories • ASTM – American Society for Testing Materials • NEMA – National Electrical Manufacturer's Association • ANSI – American National Standards Institute • ETL – Electrical Testing Laboratories • SMPTE – Society of Motion Picture and Television Engineers • EIA – Electronic Industries Association • ISO – International Standards Organization • SCTE – Society of Cable Television Engineers C. 1. SYSTEM & PRODUCT Design Topology The Madinah Jumeirah Living project expects good quality BGM. Background music should be provided the following areas: • Main Lobby • Gym area a. As a design principle, ensure that guests are not able to hear more than one music source at any time, in public spaces. b. BGM system should have scheduling feature, so client can prearrange music changes according to time of day. As per program changes occur automatically and do not require client intervention or action. c. Provide central matrix audio distribution system. The matrix system shall also provide digital signal processing capabilities, volume controls and similar functions should be available over Ethernet. d. Contractor should provide Separate Network system for AV and BGM system. BGM music should be provided to all AV racks through Network switch. e. BGM, Ceiling speakers shall be 5.5“, 6’’ or bigger size, depending on the ceiling height (Refer Drawings). f. Proposed System should be digital DSP and can be expanded easily. g. BGM Rack should have integration with Fire evacuation system. During Trigger from fire evacuation BGM music should be muted. h. 20% Spare capacity should be kept in each BGM & AV Amplifiers. 26 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Provide Facility panel/Audio Tie line to connect local source & provide Control panel to select source and control volume. Location should be as per client requirements. Below area should be consider for facility panel: • Gym • Main Lobby-Reception Area j. Provide a secured system to prevent unauthorized access to the audio system electronics, when an authorized operator is not present. k. Contractor should coordinate with ID & client for reflected ceiling plans. l. The MJL Personnel should have convenient access to the control panel to select source and volume. m. Sufficient Cabling (Fiber/AV/Cat6a) should be consider between BGM/Fire Evacuation/Voice Evacuation panel (located elsewhere in project) and AV Room for Integration functionalities. n. Contractor should co-ordinate with interior designer and architect for BGM/AV niche, jack locations and speaker types. o. Contractor should coordinate with the ID and architect for Finishes. i. 2. BGM System Requirement The following is a general outline of minimum requirements for the Background Music system: • Digital music Server with minimum 04 output channels • CD/MP3 player (6 CD changer) • Amplifiers, speakers and volume controls with channel selector • DSP supporting AVB/DANTE • Amplifier should have at least 01 spare channel. • Equipment rack with complete accessories. • UPS rack mounted • Monitor speaker rack mounted • Audio mixer on table inside BGM/AV Server room • AV Tie-in points with BGM DSP to play local music, follow drawings for locations. • FM/AM tuner with antenna and accessories BGM Speaker spec: • • • • • • 6.5-inch High Output High Quality Two-Way 70V/100V Autoformer: 60W, 30W, 15W, 7.5W (@70V only) Continuous Max Output: 114 dB (120 dB Peak) Operating Range: 65 Hz – 22 kHz Sensitivity (1W/1m): 94 dB Power Handling: 100W continuous @ 8 ohms BGM subwoofer spec: • • • • 10-inch High Output High Quality Subwoofer Operating Range: 42 Hz – 200 Hz Sensitivity (1W/1m): 93 dB Power Handling: 200W continuous @ 8 ohms 27 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification • • • Continuous Max Output: 116 dB (122 dB Peak) 70V/100V Autoformer: 200W, 100W, 50W, 25W (@70V only) Nominal Beam width (H x V): 180° Conical Two-Way 2.03 Audio Intercom System A. GENERAL 1. SECTION INCLUDES a. IP Audio Intercom to be installed in the Residential blocks. The system shall allow visitors to call individual apartments and establish a video and audio link from the main calling panel to the panel in the apartment. The tenant shall have the facility to release the door to allow the guest access into the building. 2. REFERENCES b. American National Standards Institute (ANSI/TIA/EIA) 568 - Commercial Building Telecommunications Cabling Standard. c. International Organization for Standards (ISO) 9001:2000 - Quality Management Systems - Requirements. 3. SYSTEM DESCRIPTION IP Network Compatible Audio Intercom System: A network-based communication and security system featuring video entry security, internal communication, emergency stations, and paging. All units and app in the systems shall be able to unlock doors remotely on a network, assist onsite visitors from an offsite location, broadcast emergency announcements, and communicate using a PoE network. 1) Power Source: Power over Ethernet (802.3af). 2) Network Interface: 10 BASE-T / 100 BASE-TX Ethernet (RJ-45). 3) Network Protocols: IPv4, IPv6, TCP, UDP, SIP, HTTP, HTTPS, MJPEG, RTSP, RTP, RTCP, IGMP, MLD, SMTP, DHCP, NTP, DNS. 4) Bandwidth Usage: • G.711: 64Kbps x 2 per video call. • 64Kbps per monitor. • H.264: 24Kbps ~ 2,048Kbps. 5) Communication: Hands-free (VOX), push-to-talk (simplex), or handset (full-duplex). 6) Door Release: Programmable Form C dry contact, 24V AC/ DC, 500mA - use EL-12S (use RY-24L for larger contact rating, which requires 24V DC power supply) or use RY-IP44 with 4 multipurpose relays. 7) Wire Type: CAT-5e or CAT-6. 8) Distance: • Door Station or RA Station to Network Node: 100 metres • Master Station to Network Node: 100 metres 4. SUBMITTALS a. Product Data: Manufacturer's data sheets on each product to be used, including: 28 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 1) 2) 3) Preparation instructions and recommendations. Storage and handling requirements and recommendations. Installation methods. b. Shop Drawings: Submit the following: 1) Wiring Diagrams: Indicate wiring for each item of equipment and interconnections between items of equipment. 2) Include manufacturer's names, model numbers, ratings, power requirements, equipment layout, device arrangement, complete wiring point-to-point diagrams, and conduit layouts. c. Installation and Operation Manuals: 1) Submit manufacturer's installation and operation manual, including operation instructions and component wiring diagrams. 2) Provide detailed information required for Owner to properly operate equipment. d. Warranty: Submit manufacturer's standard warranty. 5. QUALITY ASSURANCE a. Manufacturer Qualifications: ISO 9001:2008 certified company. b. Installer Qualifications: Factory trained and experienced with system installations of scope and size required for the Project. c. Mock-Up: Provide a mock-up for evaluation of surface preparation techniques and application workmanship. 1) Finish areas designated by Architect. 2) Do not proceed with remaining work until workmanship is approved by Architect. 3) Refinish mock-up area as required to produce acceptable work. 6. DELIVERY, STORAGE, AND HANDLING a. Delivery: Deliver materials to site in manufacturer's original, unopened containers and packaging, with labels clearly identifying product name and manufacturer. b. Storage: Store materials in clean, dry area indoors in accordance with manufacturer's instructions. c. Handling: Protect materials during handling and installation to prevent damage. 7. PROJECT CONDITIONS a. Maintain environmental conditions (temperature, humidity, and ventilation) within limits recommended by manufacturer for optimum results. Do not install products under environmental conditions outside manufacturer's absolute limits. B. 1. PRODUCTS FUNCTIONAL COMPONENTS: a. As indicated and as required to complete system. 1) Master Station 29 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification a) An IP addressable audio master station. It can be wall or desk mounted (desk stand included). The unit shall offer handset (duplex) and hands-free (VOX/PTT) communication and call up to 200 other units. It connects directly to a network using CAT-5e/6 cable. This station requires an 802.3af compliant Power-overEthernet network. 2) Audio Door Station a) Flush mount unit connects to a PoE network using CAT-5e/6 cable. The door station shall feature a stainless steel (or similar approved) face plate, a form C contact for door release, a 600-ohm output for paging or an amplified speaker, call placed/answered indication, and a contact input. C. 2. EXECUTION EXAMINATION a. Examine areas to receive integrated security and communication system. b. Notify Architect of conditions that would adversely affect installation or subsequent use. c. Do not begin installation until unacceptable conditions are corrected. 3. PREPARATION a. Verify the following compliance before starting installation. b. The unit turns inoperative during power failure. c. Keep the intercom wires at least 1 foot (30 cm) away from strong electrical wiring (AC 100-240 V) including, in particular, wiring for inverter electrical appliances. Noise and malfunction could result. d. If a strong light shine on the main unit screen, the picture may turn white or only silhouettes will be visible. e. Other manufacturer's devices (such as sensor, detectors, door releases) used with this system, comply with the manufacturer's installation requirements. f. The LCD panel is manufactured with very high precision techniques, inevitably will have a very small portion of its picture elements always lit or not lit at all. This is not considered a unit malfunction. Please be aware of this in advance. 4. INSTALLATION a. Install integrated security and communication system in accordance with manufacturer's instructions at locations indicated on the Drawings. b. Mount equipment plumb, level, square, and secure. For video entrance stations and video door stations, comply with manufacturer's design requirements to provide optimum picture quality of station monitoring. 5. SET-UP AND ADJUSTING a. Adjust integrated security and communication system for proper operation in accordance with manufacturer's instructions. 30 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 6. DEMONSTRATION AND TRAINING a. Demonstration: 1) Demonstrate that integrated security and communication system functions properly. 2) Perform demonstration at final system inspection by qualified representative of manufacturer. b. Instruction and Training: 1) Provide instruction and training of Owner's personnel as required for operation of integrated security and communication system. 2) Provide hands-on demonstration of operation of system components and complete system, including user-level program changes and functions. 3) Provide instruction and training by qualified representative of manufacturer. 7. PROTECTION Protect installed integrated security and communication END OF SECTION 31 CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 5. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 Technical Compliance of the Specification TABLE OF CONTENTS PART 1: GENERAL .............................................................................................................................. 3 A. OVERVIEW ............................................................................................................................. 3 B. SCOPE OF WORKS .................................................................................................................. 4 C. RELATED WORKS ................................................................................................................... 4 D. CODES, REGULATIONS AND STANDARDS .............................................................................. 5 E. SUBMITTALS .......................................................................................................................... 6 F. DELIVERY, STORAGE AND HANDLING .................................................................................... 8 G. WARRANTY AND CERTIFICATION .......................................................................................... 8 PART 2: PRODUCTS ........................................................................................................................... 8 A. GENERAL STRUCTURED CABLING COMPONENTS .................................................................. 8 B. ROOF TOP ROOM AND MOBILE SERVICE ROOM (GSM) ........................................................ 9 C. EQUIPMENT/SERVER CABINET ............................................................................................ 10 D. GENERAL IDF/FLOOR TELEPHONE ROOM (FTR) CABINET .................................................... 11 E. IDF/FTR STANDING CABINET ............................................................................................... 11 F. IDF/FTR WALL-MOUNTED CABINET ..................................................................................... 13 G. HORIZONTAL CABLING- CAT6A UTP .................................................................................... 13 H. CAT6A COPPER PATCH CORDS ............................................................................................. 14 I. CAT6A COPPER PATCH PANELS ........................................................................................... 15 J. DATA OUTLETS .................................................................................................................... 16 K. MULTIMODE FIBER OPTIC CABLES ....................................................................................... 16 L. SINGLE MODE FIBER OPTIC CABLES ..................................................................................... 17 M. FIBER OPTIC PATCH PANELS ............................................................................................ 18 N. FIBER CONNECTORS ............................................................................................................ 19 O. ACTIVE NETWORK SYSTEM BRIEF ........................................................................................ 21 P. CORE SWITCHES .................................................................................................................. 23 Q. CORE SWITCHES MODULES ................................................................................................. 24 R. ACCESS/EDGE SWITCHES ..................................................................................................... 24 S. UNINTERRUPTIBLE POWER SUPPLY (UPS) ........................................................................... 25 PART 3: EXECUTION ........................................................................................................................ 26 A. GENERAL ............................................................................................................................. 26 B. INSTALLATION ..................................................................................................................... 26 SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 1 C. INSPECTION ......................................................................................................................... 27 D. TEST EQUIPMENT ................................................................................................................ 27 E. DOCUMENT SUBMITTALS .................................................................................................... 27 F. WARRANTY ......................................................................................................................... 29 G. MAINTENANCE .................................................................................................................... 29 H. TRAINING ............................................................................................................................ 30 SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 2 ICT/TELECOMMUNCATION PART 1: GENERAL A. OVERVIEW 1. It is the Design Intent to provide an intra-building structured cabling system which will support 10 Gb/s switched, multi-protocol, ethernet-based networks. Comply 2. The networks shall be compliant with ANSI/TIA/EIA, ISO standards and Building Industry Consulting Service International (BICSI) Telecommunications Design Methods to the facility. Comply 3. The Structured Cabling shall support the following dedicated networks: a. Converge ICT network- for the residential intercom and Background Music System (BGM) which shall utilize common network and network switches for management and connectivity Noted, As per BGM specification & consultant comment seperate network proposed for BGM system. ICT network contains residential intercom only. b. Security Network- dedicated for the security systems for the connectivity of cameras, access control devices, etc. part of security submittal 4. Incoming services infrastructure should be provided from the Service Providers network to the Main Telecom Room which is dedicated for both the service provider of the facility. The Client shall determine the chosen lead services provider (Etisalat/Du) for the project. Comply 5. Fibre and copper connectivity shall be by the contactor between MTR, IDF rooms, Landlord Server Room and Tenant space as required providing adequate connectivity for data, telephone and TV services. Comply 6. All the active core equipment for the multiple networks (as detailed above) shall be located in the Server Room. The Server Room shall be sub-divided for each of the above networks providing physical separation and security. Comply 7. Multi-mode OM4, Single-mode OS2 Optical Fiber and Cat 6A Copper cables shall be provided for the backbone system in a hierarchical star arrangement which will terminate on fibre and copper patch panels at each IDF (Intermediate Distribution Frame). Noted & comply 8. The Backbone shall consist of Multi-mode, Single-mode Fiber and/or Cat6A UTP copper cables and shall be routed as per the IT single line diagrams through the main IT riser and IDFs. backbone consists of multimode fiber & for horizontal connectivity CAT6A UTP cable. 9. Horizontal cabling shall be ANSI/TIA/EIA Category 6A UTP (or equivalent), deployed in a “home- run” arrangement from the IDF to the Telecommunications Outlet (TO), floor boxes and consolidation points. Comply 10. Horizontal cabling shall be terminated within the IDF rooms using ANSI/TIA/EIA Category 6A Patch panels. Dedicated patch panels and lockable equipment cabinets shall be provided for the 2 networks. Each cable shall be terminated in the equipment cabinet and associated patch panel corresponding to the use of the end device. Comply 11. Patching within Server Room and IDF rooms shall be provided for 100% of outlets and active edge switch ports. Comply 12. The entire installation shall be fully certified by the manufacturer. A guaranteed Channel Performance with Product and Application Certification shall be provided for the entire cabling system installation (copper and fibre). Comply SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 3 13. Main Earthing & Bonding system clean earth shall be provided to each equipment rooms (Security Control room, IDF’s) by the Contractor. Connection from clean earth to Structured Cabling System by ELV / IT Contractor. scope of MEP 14. Training shall be provided from the manufacturer or an authorized training centre as described further herein. Comply 15. The Contractor shall be responsible for providing the requirements for Telecom room and Comply verifying space, selection of rack (dimension and door type), power and cooling requirements associated with this Section and coordinate with the relevant trades. 16. Use the same manufacturer throughout the SCS installation. Comply 17. Rack mountable UPS with backup of 30 minutes and SNMP card shall be considered with additional of 25% spare load. Comply 18. Communication link between lift and BMS room or between lift and security room shall be provided. Noted, there is no outlets shown in the lift & BMS room 0r lift & security room, B. SCOPE OF WORKS 1. The scope consists of all passive data network components for the building associated with all IP Network and telecom spaces (MMR, MTR, Server Room, IDFs etc.) throughout the facility, Telecommunication Outlets (TO) and all interconnecting copper and fibre cabling. 2. The scope also consists of all active data network components for the building associated with all IP network throughout the facility and IP Data transmission for all networkconnected systems. Comply 3. Building connectivity to MTR should through nearest existing Telecom manhole. Comply 4. This scope does not cover design for operational servers or data storage for operational systems such as Building Management, billing, etc. Comply 5. This scope does not cover design for systems provided by Third Parties such as the HighSpeed Internet Access (HSIA), IPTV, Wireless Internet Billing etc. Comply 6. All connections from core to access layers to be are 2 x 10GB providing a total of 20GB per access layer switch. Comply 7. All Access Layer switches will 10/100/1000 Mbps. Comply 8. Access switches enabled with PoE+ shall be provided to the Apartment Intercom and BGM system devices (as necessary). Access switches requirement for the security systems is detailed in the security systems specification. Comply Comply C. RELATED WORKS 1. Raceway, cable tray, ladder runway, sleeves, channels, conduits and pull boxes specified under electrical specifications 2. Standard-compliant telecommunications grounding system to be provided under earthing/grounding (electrical) specifications 3. Raised access flooring (specified under architectural design), if ever applicable 4. Cutting, patching and painting (generally civil works) 5. Conduit stubs below floors and above the finished ceilings at designated locations specified under electrical specifications 6. Double gang, deep back boxes at each wall mounted outlet location specified under electrical specifications 7. Shared power/telecom and shared power/telecom /AV raised access floor flush-mounted boxes specified under electrical specifications Comply in coordination with MEP SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 4 8. Security, audio-visual and BMS systems proprietary cabling and equipment designed and specified in each respective section 9. Installation of and cross-connection to hardware and cabling assemblies supplied by telephone system, data or data hardware vendors 10. Provision of inter-machine cabling and ancillary communications cabling within the equipment rooms, except as indicated on the drawings 11. Uninterruptible Power Supply (UPS) specified under electrical specifications comply in coordination with MEP D. CODES, REGULATIONS AND STANDARDS 1. Comply with the most recently issued requirements, standards, recommendations, rules, and regulations of: a. Telecommunications Regulatory Authority, UAE b. TRA/Common Du and Etisalat guidelines c. The National Electrical Code (NEC) d. National Fire Protection Act (NFPA) e. Occupational Safety and Health Administration (OSHA) f. Building Industry Consulting Services International (BICSI) g. Underwriter’s Laboratories (UL) h. Institute of Electrical and Electronic Engineers (IEEE) 2. Follow the most restrictive code or recommendations. Undistinguishable details shall be consulted to the responsible engineer for interpretation. 3. All equipment shall be equal to or shall exceed the minimum requirements of NEC, IEEE, ASME, ANSI and UL. 4. The requirements and recommendations of the following are included herein and made a part of these contract documents: a. Electrical Specifications Sections b. UAE laws and Telecommunications Regulations Authority (TRA) codes c. TRA/DU & Etisalat Design and Installation Guidelines d. ICT requirements for Residential Towers. e. ANSI/TIA-568-C: Generic Telecommunications Cabling for Customer Premises, published 2009 f. ANSI/TIA-568-C.1: Commercial Building Telecommunications Cabling Standard, 2009. g. ANSI/TIA-568-C.2: Balanced Twisted-Pair Telecommunication Cabling and Components Standard, 2009. h. ANSI/TIA-568-C.3: Optical Fiber Cabling Components Standard, 2008. i. ANSI/TIA-758-A: Customer-owned Outside Plant Telecommunications Infrastructure Standard, 2005. j. NSI/TIA-942-2: Telecommunications Infrastructure Standard for Data Centres Addendum 2- Additional Media and Guidelines for Data Centres – 2010. k. ANSI/TIA -492 Series: Single and Multimode series of specifications up to OS2 and OM4 Fibers. l. International Standards Organization/International Electro Technical Commission ISO/IEC 11801, Amendment 1, 2009: Generic Cabling for Customer Premises, Class EA. m. Underwriters Laboratories (UL®) Cable Certification and Follow up Program. n. BICSI Telecommunications Distribution Methods Manual 12th Edition SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 5 Noted & Comply o. L 910, Test for Flame-Propagation and Smoke Density Values for Electrical and Optical Fiber Cables in Spaces Transporting Environmental Air, 1997 p. UL 1685, Vertical-Tray Fire Protection and Smoke Release Test for Electrical and Optical Fiber Cables. q. IEEE 1100-2005, Powering and Grounding of Electronic Equipment. 5. All equipment shall be as per latest TRA requirements. Noted & Comply E. SUBMITTALS 1. Bid Submittal a. The contractor shall submit to the Consultant – four (4) copies of Descriptive Literature which also includes list of equipment, Technical Data, Catalogues, Installation Instructions and Maintenance recommendation of all the Products used. b. Provide a Schedule of values and quantities for the equipment where each piece of equipment shall be priced individually. c. Include on the above schedule non-equipment and service cost schedule. This will include: i. Engineering Design. ii. Pre-installation works. iii. Installation including wiring and site supervision. iv. Software programming (if applicable) v. Documentation vi. Training vii. Project management viii. Warranties d. Submit proposal for Alternates and associated equipment costs. e. Shop drawings – detailed schematic, layout, installation & rack details. f. Organization profile, chart and career & qualification records of Project manager / technical staff. g. The submittal must include all the electronic copies of the required documentations and the sample product. h. In addition to hard copy submittals, submit all files necessary to produce the above submittals as follows: i. Transportation media shall be on CD ROM format. ii. A Master File List in text format shall be placed on each CD ROM with a short description of files in the submittal. iii. The shop drawings shall be in AutoCAD R2015 or later drawing (.DWG) format. All XREFs, fonts, and other drawing parts necessary shall be included. iv. Manufacturers’ data sheets, equipment manuals, and other documentation provided by the Manufacturers to the Contractor or documents that are similarly not otherwise available to the Contractor in electronic format shall be excluded from this requirement. 2. Product Datasheet a. Submit catalogue data sheets, space for submittal stamps. List all proposed equipment. Indicate all accepted substitutions. b. Submit a schedule of finishes indicating proposed materials and color selections for all exposed items subject to Architect selection. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 6 Noted & Comply c. Submit a list showing coordination of selected frequencies for all wireless transmitters. 3. Construction Schedule a. The Contractor shall provide a Construction Schedule indicating general project deadlines with specific dates relating to the installation of the system. At a minimum, this construction schedule shall include the following milestones: i. Cabling Procurement Date ii. Equipment Procurement Date iii. Cabling Installation Start Date iv. Cabling Installation Completion Date v. Equipment Installation Start Date vi. Equipment Installation Completion Date vii. Equipment Testing Start Date viii. Equipment Testing Completion Date ix. Completion of Documentation 4. Shop Drawings a. Shop drawings must include, but not limited to: b. All drawings must be the same size as the project drawings. c. All drawings must follow the Project’s drafting standards. d. All plans drawn to project standard scales for floor plans, ceiling plans, sections, enlarged details, etc., and must be drawn in Landscape, not Portrait rotation. e. Submit as-installed point-to-point wiring diagrams and typed wire lists identifying every connection for information. Include electronic devices f. Submit system layouts showing all as-installed device locations, ceiling layouts. g. Submit conduit riser diagrams showing as-installed connection of all devices. h. Submit rack layouts indicating the as-installed arrangement of mounted equipment. i. Submit as-installed fully dimensioned construction details of all panels, plates. 5. Submit wiring diagrams identifying every connection for information including: a. All equipment such as distribution hub, power supply etc., complete with make and model numbers. b. Electronic devices such as distribution switches, transformers, and terminal blocks. c. Calculated voltage loss in each circuit and cable distance should be followed as per manufacture’s guidelines. d. Indicate locations of all components by room number. e. Identify cables by types, models, colors, and wire numbers. f. Identify all connector types including make and model along with cable termination details including connector pin-outs, conductor color codes and cable dressing details for each type of connector used in the system. g. Submit system plans showing all device locations, containment riser diagrams showing connection of all devices, required containment type and sizes along with types and quantities of cables to be used and cable identification tags. h. Submit Power and cooling requirements for each equipment rack / room. i. Submit fully dimensioned construction details of all panels. Include complete parts lists and, as required, schematic diagrams. j. Submit electronic copies of any custom programming including source codes. Include printed copies of all control screens, wiring pages, etc. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 7 Noted & Comply 6. Samples a. Label samples to indicate product, characteristics, and locations in the Work. Samples will be reviewed for color and appearance and workmanship. Compliance with all other requirements is the exclusive responsibility of the Contractor. Furnish samples of the following: b. All exposed plates and panels for approval of color, engraving, text size and material. c. Terminated cable samples. 7. Upon completion of the installation, Contractor shall prepare as built documentation of the entire installation. And should also include the electronic copies. F. DELIVERY, STORAGE AND HANDLING 1. Deliver, store and handling of the equipment will be at designated areas as defined by the Client. 2. Deliver and store materials in manufacturer’s original packaging labelled to show name, brand, type, and grade. Store materials in protected environment in accordance with manufacturer’s instructions, any loss or damage to the equipment will be fully responsible by the contractor. 3. Equipment damaged prior to system acceptance shall be replaced at no cost to the Employer. Noted & Comply Noted & Comply G. WARRANTY AND CERTIFICATION 1. The Contractor shall provide a letter from the Manufacturer confirming certifications and trained engineers under the employ of the company. The Contractor shall provide the Manufacturer’s Warranty, including the Manufacturers Performance Guarantee & Test Data and all applications supported under the warranty. The period of the warranty shall not be less than twenty five (25) years in accordance with the manufacturer’s extended warranty program. Comply 2. Warrant all other portions of the work against faulty and improper material and workmanship for a minimum period of five (5) years from the date of acceptance as defined herein. Where warranties for longer terms are offered through manufacturer/installer programs, such longer terms shall apply. Comply. 5 year warranty can be provided for material & 1 year warranty will be provided for workmanship PART 2: PRODUCTS A. GENERAL STRUCTURED CABLING COMPONENTS 1. All materials and products, excepting Owner Furnished Equipment (OFE), and materials, shall be appropriate for the intended use and shall meet all applicable UL, EN, BS, ISO and IEC Regulations. Comply 2. All system components shall be manufactured by ISO 9001:2008 certified companies and all packaging shall carry clear product identification (catalogue number, quality control number, etc.) Comply 3. All products shall be new of the latest version at time of Installation, and brought to the job site in original manufacturer's packaging. Electrical components shall bear the Underwriter's Laboratories label. This listing requirement applies to the entire assembly. Only systems and equipment that meet or exceed the level of quality and capabilities stated within this document will be considered for acceptance. Comply SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 8 4. Materials shall be listed and approved for the particular application and permitted by the authority having jurisdiction for the application. Comply 5. All system components of the entire cabling system (copper and fibre) shall be from a single manufacturer which will ensure that a single performance warranty covers all applications on vertical and horizontal links. This includes but is not limited to: a. Horizontal distribution b. Fiber optics distribution c. Copper distribution d. Patch Panels 6. All components and devices will be provided with labelling to the standards set out in ANSI/TIA/EIA 606-B. Prior written authorization must be obtained from the Client or Supervising Engineer for any deviation from this standard. 7. All components are to be accepted by the Engineer and afford the most aesthetic value possible while maintaining specified functionality. Hardware will adhere to the following guidelines: a. Fit and finish to the existing surrounding structure. b. Unobtrusiveness c. Functionality 8. All workstation termination hardware shall match the existing wall surface colour as closely as possible, to include mounting boxes, faceplates, and outlets. 9. Used equipment or damaged material will be rejected. B. ROOF TOP ROOM AND MOBILE SERVICE ROOM (GSM) 1. Roof top room and Service Room shall be provided based on the TRA requirement for a multi-tenant building which are up to G+10 floors or less at a minimum dedicated 3m x 3m x 3m (WLH). 2. GSM Room shall also be provided in the ground floor adjacent to the Main Telecom Room. This will be a dedicated room for GSM equipment. A cable tray 300mmx 150mm is required from GSM room to Main Telecom Room and will extend until the Roof top GSM Room. 3. The main requirements for the Roof Top Room for the residential building are below but not limited to: a. The roof-top room shall be connected to building riser through 300mm x 50mm vertical cable tray. b. The doors of this room shall open outwards and have a minimum opening of 1000mm x 2100mm (WxH). c. The following electromechanical must be provided while designing roof-top room. d. 4 x13A twin sockets fed from the essential power supply with dedicated 20A circuit breaker. e. 2 number of AC & DC earth bars connected to the dedicated earth pits with resistance less than 1ohm. f. Add 2 x 63A TP isolator fed with dedicated feeder from essential power supply (EDB); g. Dedicated A/C system (ducted split FCU) with duty & standby units with proper interlocking, to maintain the room temp. at 21°C ± 1°C; h. Heat dissipation can be considered at 36kW for roof-top Room; i. 2 nos. handheld CO2 cylinder extinguishers to be provided inside the room; SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 9 Comply Pat of ISP submittal j. 4. 5. 6. 7. 8. Room should be provided with adequate lighting with minimum of 200 Lux at table level; k. Room shall be compliant with the fire and safety requirements like smoke detector, fire alarm, emergency light etc. as per local authority standards. Any water sprinklers must be avoided. The floors of the roof-top rooms must have a minimum distributed load rating of 10kN/m2. Openings must be provided to the room to allow for cables to connect to external antennas. These openings must be 600mm x 400mm (W x H), 500mm below the room ceiling in walls facing the building’s roof-top area. Space must be reserved on the roof-top of the building for the installation of mobile-service antennas. This setup may vary from building to building scenario, but this will be typically at the corners of the building or on any raised structure on the roof-top. The requirements as stated above shall be coordinated by the contractor to the respective provider/contractor to ensure full compliance. C. EQUIPMENT/SERVER CABINET 1. The contractor shall provide Server racks in the main server room in the configuration shown on the design drawings. 2. The outside dimensions of the server cabinets shall be 800mm (W) x 1000mm (D). 3. Server Cabinets shall be constructed of rust free alloy, with a flange base, capable of minimum 42U of useable interior height. 4. Server Cabinets shall be fully enclosed, lockable, ventilated modular type steel construction and treated to resist corrosion. 5. Finish: Black/Grey, Powder coat pain with fingerprint and scratch resistant finish. 6. Server cabinets shall be provided with EIA 19” rack mounting frames with rack spaces (units) stamped every unit. 7. Cabinets shall be provided with modular cooling trays/panels to provide mechanical air circulation and heat extract from the active equipment. The cooling trays/panels are to be selected for the appropriate hot air flow directions from the active equipment, taking into account cold and hot aisle configurations and locations of computer room air conditioning distribution. 8. Server racks shall be provided with stabilizer feet attached to the front and sides of each enclosure for increased stability. 9. Accessories: Horizontal stabilization hardware, appropriate fasteners for mechanical attachment to structural floor. 10. Server racks shall be provided with a minimum of 2 (two) Power Distribution Units (PDU) for primary and secondary supplies to the equipment. Each PDU shall be sized to present a dedicated outlet for each piece of active equipment with an additional 20% for future installations. Each outlet must be rated to support the full load of each attached piece of equipment. 11. Integral vertical cable management: SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 10 part of ISP submittal Comply 12. 13. 14. 15. 16. 17. a. 150mm, 254mm, 300mm and 406.4mm wide vertical management cages, with individual 1-rack unit fingers, including spools and bend limiting clips. The cages will be covered by double hinged aluminum doors. Clip-on panels are not acceptable. b. Integral bend radius control to eliminate strain on cables. c. In the case where racks are assembled side by side, they shall be separated by minimum 200mm wide cable management cages. The bottom flange shall turn inwards, allowing it to fit on a floor tile. Provide adjustable (sliding type) equipment support bracket to ensure that all active equipment are adequately supported from the rear as well as the front. Equipment not adequately supported (front and rear) will not be accepted. Server cabinets shall be provided with Honeycomb style side rails and baffles which shall be combined to manage intake and exhaust air from side vented equipment to creating cold aisle / hot aisle air distribution. The Contractor shall provide blank panels for all unoccupied spaces within enclosure(s) to maintain correct air flow. All enclosures shall be provided with cable organizers. Comply All enclosures shall be provided with Grounding (Earthing) kit and shall be connected to the nearest clean earth bar with suitable earth wire as detailed in the electrical section of this specification. scope of MEP D. GENERAL IDF/FLOOR TELEPHONE ROOM (FTR) CABINET 1. IDFs shall be provided with dedicated cabinets for each of the networks installed in the development. Refer to the structured cabling schematic and voice data layout for details of the cabinets to be installed in each of the IDFs. 2. IDF equipment cabinets shall be sized accordingly to accommodate all active and passive equipment required to support the full functionality of the associated network design intent + 20% spare capacity for future use. 3. All cabinets shall be fully enclosed, lockable, ventilated modular type steel construction and treated to resist corrosion. 4. Wall mounted cabinets may be used where network requirements do not warrant full height floor standing cabinets. 5. Where multiple wall mounted cabinets are located on the same wall, they shall not be installed vertically aligned. The contractor shall offset the cabinets to ensure unobstructed vertical routes for containment to high level horizontal distribution. 6. The contractor shall ensure that wall mounted cabinets are installed at a height where installation and maintenance works can be undertaken without the use of a ladder or alternative elevating equipment. 7. Each cabinet shall be provided with dedicated power and connections to the local clean earth. E. IDF/FTR STANDING CABINET 1. The contractor shall provide Equipment racks in the IDF rooms in the configuration shown Comply on the design drawings. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 11 Comply Comply 2. The outside dimensions of the server cabinets shall be 800mm (W) x 800mm (D). 3. Equipment Cabinets shall be constructed of rust free alloy, with a flange base, capable of minimum 42U of useable interior height. 4. Equipment Cabinets shall be fully enclosed, lockable, ventilated modular type steel construction and treated to resist corrosion. 5. Finish: Black/Grey, Powder coat pain with fingerprint and scratch resistant finish. 6. Equipment cabinets shall be provided with EIA 19” rack mounting frames with rack spaces (units) stamped every unit. 7. Cabinets shall be provided with modular cooling trays/panels to provide mechanical air circulation and heat extract from the active equipment. The cooling trays/panels are to be selected for the appropriate hot air flow directions from the active equipment, taking into account cold and hot aisle configurations and locations of computer room air conditioning distribution. 8. Equipment racks shall be provided with stabilizer feet attached to the front and sides of each enclosure for increased stability. 9. Accessories: Horizontal stabilization hardware, appropriate fasteners for mechanical attachment to structural floor. 10. Equipment racks shall be provided with a minimum of 2 (two) Power Distribution Units (PDU) for primary and secondary supplies to the equipment. Each PDU shall be sized to present a dedicated outlet for each piece of active equipment with an additional 20% for future installations. Each outlet must be rated to support the full load of each attached piece of equipment. 11. Integral vertical cable management: a. 150mm, 254mm, 300mm and 406.4mm wide vertical management cages, with individual 1-rack unit fingers, including spools and bend limiting clips. The cages will be covered by double hinged aluminium doors. Clip-on panels are not acceptable. b. Integral bend radius control to eliminate strain on cables. c. In the case where racks are assembled side by side, they shall be separated by minimum 200mm wide cable management cages. 12. Provide adjustable (sliding type) equipment support bracket to ensure that all active equipment are adequately supported from the rear as well as the front. Equipment not adequately supported (front and rear) will not be accepted. 13. Equipment cabinets shall be provided with Honeycomb style side rails and baffles which shall be combined to manage intake and exhaust air from side vented equipment to creating cold aisle / hot aisle air distribution. 14. The Contractor shall provide blank panels for all unoccupied spaces within enclosure(s) to maintain correct air flow. 15. All enclosures shall be provided with cable organizers. 16. All enclosures shall be provided with Grounding (Earthing) kit and shall be connected to the nearest clean earth bar with suitable earth wire as detailed in the electrical section of this specification. scope of MEP SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 12 Comply F. IDF/FTR WALL-MOUNTED CABINET 1. The contractor shall provide wall mounted equipment racks in the IDF rooms in the configuration shown on the design drawings. 2. Wall mounted cabinet shall be sized accordingly to accommodate the associated active and passive requirements of the network supported. Cabinets shall have minimum dimensions of 15 U (Rack Units) (H) x 600mm (W) x 600mm (D). 3. Wall mounted cabinets shall be constructed of rust free alloy, welded construction. 4. Equipment Cabinets shall be fully enclosed, lockable, ventilated modular type steel construction and treated to resist corrosion. 5. Finish: Black/Grey, Powder coat pain with fingerprint and scratch resistant finish. 6. Equipment cabinets shall be provided with EIA 19” rack mounting frames with rack spaces (units) stamped every unit. 7. Cabinets shall be provided with modular cooling trays/panels to provide mechanical air circulation and heat extract from the active equipment. The cooling trays/panels are to be selected for the appropriate hot air flow directions from the active equipment, taking into account cold and hot aisle configurations and locations of computer room air conditioning distribution. 8. Cabinets shall be provided with Lockable glass front door with 180° opening, quick release pins and cable entry points at the top and rear with gland plates. 9. Cabinets shall be provided with hinged rear and front section providing easy access to the rear of installed equipment. The contractor shall ensure that all cabling is installed with enough "slack" to allow for full opening of front section of the cabinet without damage to cables. Installations not providing full opening and swing of front section will be rejected. 10. Cabinets shall be provided with removable, lockable vented sides. 11. Cabinets shall be provided with 4 x 19" adjustable mounting frames. 12. Equipment racks shall be provided with a minimum of 2 (two) Power Distribution Units (PDU) for primary and secondary supplies to the equipment. Each PDU shall be sized to present a dedicated outlet for each piece of active equipment with an additional 20% for future installations. Each outlet must be rated to support the full load of each attached piece of equipment. 13. The Contractor shall provide blank panels for all unoccupied spaces within enclosure(s) to maintain correct air flow. 14. All enclosures shall be provided with cable organizers. 15. All enclosures shall be provided with Grounding (Earthing) kit and shall be connected to the nearest clean earth bar with suitable earth wire as detailed in the electrical section of this specification. 16. The size and exact details of the cabinets may vary due to the location and installation conditions. Where proposed cabinets are proposed that deviate from the above details, the contractor is provide the appropriate material submittals and shop drawings for approval by the client’s representative. G. HORIZONTAL CABLING- CAT6A UTP 1. Be augmented category 6A component compliant out to 500MHz with operational bandwidth to 500 MHz. 2. Have a round LSOH cable jacket available with a nominal cable O.D. of less than or equal to 7.4mm SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 13 Not Applicable Comply 3. Have a construction comprised of 4-pairs of 0.57mm (0.02 in) (22AWG) solid bare copper conductors utilizing a centre isolation member to maintain pair geometry for optimal NEXT performance 4. Have a Foil tape surrounding the cable pairs with a drain wire with an aluminium foil tape surrounding the drain wire. 5. Have a rip cord installed under the jacket for jacket removal. Be available in both 305m, 500m and 1000m reels. 6. Be available in jacket colours of Blue – CMR, Gray – CMX and Violet - LSOH 7. Provide the following 100m, 4-connector topology performance (white cells – std ref. values in grey cells): Comply 8. Meet the following electrical characteristics: Max DC Resistance (@ 20°C) <8.5Ω /100m Characteristic Impedance (no impedance averaging allowed) 1-100 MHz: 100 ohms ± 15% 100 - 750MHz: 100 ohms ± 22% Nominal Velocity of Propagation (NVP) LSOH – 67% H. CAT6A COPPER PATCH CORDS 1. Category 6A RJ45, third party component verified to Cat 6A ANSI/TIA/EIA 568 B 2.1. and ISO/IEC 11801 Cat 6 channel compliant. 2. Support T568A and T568B wiring. 3. Support applications up to 500 MHz 4. Durable black powder coat finish with flame retardant UL 94V-0. 5. Connection of the cable will be carried out through rear IDC contacts with use of a standard 110 impact tool. 6. Shall consist of 24 ports on 1 RU of rack space. In the case of rack space shortages, 48 ports with 1RU space shall be available. 7. Angled Patch Panels shall be used for all patch panels. Patch panels shall be recessed from the 19” rails. 8. Rear-side cable support bracket far enough from the panel to accommodate the cable bend radius limitations. 9. Metal structure enabling it to be durably fixed to the uprights of the 19”chassis assuring ground SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 14 Comply 10. continuity with metal frames. 11. Modular contacts shall be plated with minimum 50 micro-inches of gold. Manufacturer will be the same as that selected for work area outlet jacks. 12. Allow for re-terminations without signal degradation below standards compliance limit. 13. Augmented category 6A component compliant out to 250MHz with operational bandwidth to 500MHz. 14. Factory assembled and 100% transmission tested with laboratory grade network analyzers for proper performance up to 250MHz. 15. Backwards compatible with lower performing categories. 16. Equipped with identical screened modular 8-position plugs on both ends, wired straight through with standards compliant wiring. 17. Utilize patented metallic isolator shields pairs inside plug for optimum NEXT performance and a 360 degree crimp for providing strain relief without causing pair deformation. 18. Use bend relief compliant boots (with optional color-coded icons) to ensure proper category 6 performance and feature a latch guard to protect against snagging. 19. Resistant to corrosion from humidity, extreme temperatures, and airborne contaminants. 20. Available in standard lengths of 1, 2, 3 and 5 meters with custom lengths available upon request 21. Made by an ISO 9001 Certified Manufacturer. 22. Certified by Underwriters Laboratories to United States Standards and C22.2 Canadian Telecommunications Standards. I. CAT6A COPPER PATCH PANELS 1. Patch panels shall be used in the cross-connect facilities to connect the four-twisted pair cables and their related outlet, to the active devices via patch cords. 2. Category 6A RJ45, third party component verified to Cat 6 ANSI/TIA/EIA 568 B 2.1. and ISO/IEC 11801 Cat 6 channel compliant. 3. Support T568A and T568B wiring. 4. Support applications of 1Gb/s at 500 MHz. 5. Compliant to FCC part 68500, section F and UL1863, dealing with the interface's physical 6. dimensions, including the 1.27μm gilding on the contacts, the traction force to be borne by the RJ45 socket, the plug (100 grams) and the maximum force authorized for connecting the plug in the jack (2.2 kg). 7. Durable black powder coat finish with flame retardant UL 94V-0. 8. Connection of the cable will be carried out through rear IDC contacts with use of a standard 110 impact tool. 9. Shall consist of 24 ports on 1 RU of rack space. In the case of rack space shortages, 48 ports with 2RU space shall be available. 10. Rear-side cable support bracket far enough from the panel to accommodate the cable bend radius limitations. 11. Slots in the front face for the insertion of designation tabs (icons for Voice- Data-Video) for ports and a label designation system in the front and in the back to provide identification marking that meets the requirements of standard ANSI/TIA/EIA –606-A. 12. Metal structure enabling it to be durably fixed to the uprights of the 19”chassis assuring ground continuity with metal frames. 13. Modular contacts shall be plated with minimum 50 micro-inches of gold. Manufacturer will be the same as that selected for work area outlet jacks. 14. Allow for re-terminations without signal degradation below standards compliance limit. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 15 Comply Comply 15. made by an ISO 9001 Certified Manufacturer. Comply J. DATA OUTLETS 1. All 500MHz category 6 information outlets designed for termination of 4-pair balanced twisted- pair category 6A copper cables must possess the following characteristics at the minimum: a. Exceed category 6A component compliance through the frequency range of 1 to 500MHz with usable bandwidth to 500MHz. b. Be available in black, white, red, grey, yellow, blue, green, orange, ivory, bright white, light ivory and alpine white. c. Universal design allows the same outlet to be mounted in flat or angled orientation. d. Be backwards compatible to allow lower performing categories of cables or connecting hardware to operate to their full capacity. e. Support industry standards for T568A or T568B wiring options on each individual outlet. f. Provide color-coded, snap-in icons available for circuit identification. g. Allow for a minimum of 5 terminations without signal degradation below standards compliance limits. h. Be constructed of high impact, glass reinforced nylon. i. Faceplates shall be a single or double gang as identified on drawings, Jacks shall be of the same manufacturer. j. Must be certified by Underwriters Laboratories to United States Standards and C22.2 Canadian Telecommunications Standards. K. MULTIMODE FIBER OPTIC CABLES 1. Backbone Fibre Cables shall be provided as per the structured cabling schematic. 2. The fibres shall meet ITU-T: G652 for multi-mode specifications. 3. Laser Optimized 50/125um multimode fiber optical fiber cables shall be in compliance with the following standards: a. ISO/IEC 11801:2002 Amendment 2 OM4 b. ANSI/TIA/EIA-568-C.3 c. ANSI/TIA-598-C d. ANSI/TIA-492 AAAD e. IEC 60793-2-10 Fiber type A1a.3 f. Telcordia GR-409-CORE g. IEC 60332-1-2(Single strand) h. IEC 60754-1(Non Halogens) i. IEC 60754-2(Acid gas) j. IEC 61034-2(Smoke Density) 4. All optical fiber cable shall be appropriate for the environment in which it is installed. 5. In addition to meeting the applicable performance specifications, all optical fiber cable shall be appropriate for the environment in which it is installed. 6. Have a round lead free cable jacket available in OFNR, OFNP and LSOH constructions. 7. Shall contain a Rip Cord applied longitudinally under the cable jacket for easy cable jacket removal 8. Shall contain a light weight central strength member located in the middle of the fibre bundles. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 16 Comply Comply 9. 10. 11. 12. Shall contain both colour-coded buffered fibres as well as colour-coded buffer tubes. Cables shall have length markings in 2 ft. increments. Fibre will be available in strand counts of 4, 6, 12, 24, 48, 72 and 96. Shall meet these minimum performance parameters: Minimum Performance Parameters for Qualified Cables Maximum Attenuation Minimum Bandwidth (MHz-km) Group Index of Refraction (dB/km) 850 nm 1300 nm 850 nm 1300 nm 850 nm 1300 nm Laser - 2000 OFL 1500 OFL - 500 3.5 1.0 1.483 1.479 13. Ethernet applications supported: Application Distance (m) 10GBASE-SX (850 nm) 10GBASE-LX4 (1300 nm) 1000BASE-SX (850 nm) 1000BASE-LX (1300 nm) Fibre Channel 266 (1300 nm) ATM 622 (1300 nm) ATM 155 (1300 nm) ATM 52 (1300 nm) FDDI (Original 1300 nm) 100BASE-FX (1300 nm) 300 300 900 600 1,500 500 2,000 3,000 2,000 2,000 Comply 14. Physical Characteristics 50/125um: L. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Core Size (Microns) Cladding Size (Microns) Coating Size (Microns) Buffer Size (Microns) Core Cladding Concentricity (Microns) 50 ± 3 125 ± 2 245 ± 10 900 ± 50 ≤3.0 SINGLE MODE FIBER OPTIC CABLES Backbone Fibre Cables shall be provided as per the structured cabling schematic. The fibres shall meet ITU-T: G652 for single mode specifications. Single mode optical fiber cable shall be used for Backbone and ISP applications only. Optical fiber backbone cable shall be plenum rated and meet the following fire performance standards: IEC 60332-1, IEC60332-3C, IEC 1034-1/2, IEC 754-1/2. Have a Yellow coloured round lead free cable jacket available in OFNR, OFNP and LSOH constructions. Shall contain a Rip Cord applied longitudinally under the cable jacket for easy cable jacket removal. Shall contain a lightweight Central Strength member located in the middle of the fibre bundles. Shall contain both colour-coded buffered fibres as well as colour-coded buffer tubes. Cables shall have length markings in 2 ft. increments. Fibre will be available in strand counts of 4, 6, 12, 24, 48, 72, and 96. Shall meet these minimum performance parameters: SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 17 Not Applicable for ICT network Minimum Performance Parameters for Qualified Cables Maximum Attenuation (dB/km) Cable Type Indoor 1310 nm 1550 nm 0.60 0.60 Zero dispersion Slope Wavelength (nm) (nm²-km) 1300-1324 <0.093 Index of Refraction 1310 nm 1550 nm 1.467 1.468 Not Applicable for ICT network 12. Ethernet Applications Supported: Application 10GBASE-L (1310 nm) 10GBASE-E (1550 nm) 10G Fibre Channel (Serial-1310 nm) 10G Fibre Channel (WDM-1310 nm) 1000BASE-LX (1300 nm) Fibre Channel 266/1062 (1300 nm) ATM 52/155/622 (1300 nm) Distance (m) 8,000 30,000 10,000 10,000 5,000 10,000 15,000 13. Physical Characteristics: Mode and Fiber Type Core Size (Microns) Cladding Size (Microns) Single mode 8.3 ± 1.0 125 ± 1.0 Coating Size Buffer Size (Microns) (Microns) 245 ± 10 900 ± 50 Core Cladding Concentricity (Microns) ≤ 0.8 M. FIBER OPTIC PATCH PANELS 1. All fiber patch panels, enclosures, and coupler inserts shall be of the same manufacturer and colour. 2. Shall be used in the cross-connect facilities to connect optical fiber cables to active devices via fiber jumpers. They shall be dimensioned to enable the connection of all fiber cores of the installed cables. 3. Shall be a black metallic box type modular structure, with front section comprising of standardized 19" chassis, and able to accommodate all standard optical connector such as: LC, SC, ST. They shall include all the appropriate cabling accessories (bend limiting clips for the cables and fiber jumper, cable-ties, label-holders, etc.), to ensure correct positioning of fiber cores and to maintain the minimum bend radius for all changes in direction. 4. Shall have removable doors/panels front and rear. They will be designed for cable entry from the rear of the enclosure and be equipped with appropriate means for physically securing the cable(s) in place. 5. All enclosure housings are required to be equipped with an integral bonding lug or stud for securing the fiber strength member. 6. Each 2U enclosure shall provide space for a minimum of 4 coupler panels and 4 splice trays. 7. Each 4U enclosure shall provide space for 12 coupler panels and 12 splice trays. 8. For connectors that employ a plastic housing, coupler panels will provide color-coding in accordance with industry standards (i.e. beige adapters for graded-index optical fiber, blue for single-mode optical fiber). 9. All optical fiber cables shall be fusion spliced to LC pigtails of 2m length. They shall meet the following performance: a. Ultra-Physical Contact (UPC) finish for single-mode: Insertion loss: 0.40dB maximum, 0.20 dB typical; Return loss: minimum 55db. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 18 Comply 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. b. Physical Contact (PC) finish for Multimode 50 micron: Insertion loss: 0.50dB maximum, 0.30 dB typical; Return loss: minimum 20db. All connectors and adaptors shall be provided with dust caps. Not be bigger than one rack mount space and accommodate up to 36 ports for SC, MT-RJ, LC or ST adapter plates. Have preloaded adapter plates with ST and SC fiber adapters in 6 and 8-port version, as well as a 12 port version for the SC, MT-RJ and LC adapters. Have blank adapter plates for future growth of the fiber infrastructure. Be modular in design with internal fiber managers that provide slack storage to comply with fiber bend radius and the recommended slack storage length. Have a snap-on front shield to be used as a labeling surface and to protect jumpers. This shield can also relocate to another position during termination to maintain circuit identification. All connectors and adaptors shall be provided with dust caps. Accommodates a splice tray for mechanical or fusion splices. Be available with a drawer mechanism, which allows the panel to slide forward or to the rear. The following solutions are not acceptable: a. Field polishing. b. Composite / Polymer ferrules. c. Mechanically splicing pigtails. Must be certified by Underwriters Laboratories to United States Standards and C22.2 Canadian Telecommunications Standards. N. FIBER CONNECTORS 1. LC Connectors- Multimode a. Meet the Fiber Optic Connector Intermateability Standards (FOCIS) specifications of TIA/EIA-604-10. b. Be available in simplex and duplex versions. c. Utilize same termination kit available for ST and SC versions with the addition of an LC upgrade kit. d. Terminate both 50/125um and 62.5/125um optical fiber. e. Have a quick field termination process, which does not require power. f. Have a termination process, which incorporates use of a reliable anaerobic adhesive, which has a high resistance to environmental extremes. g. Have jacketed and buffered versions. h. Meet the following performance specifications: Parameter Comply Performance(dB) Insertion Loss (typ) 0.1 Insertion Loss (max) < 0.2 Durability (500 cycles) < 0.1 Return Loss (min) Comply 20 2. LC Connectors- Single Mode a. Meet the Fiber Optic Connector Intermateability Standards (FOCIS) specifications of TIA/EIA-604-10A. b. Be available in simplex and duplex versions. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 19 Not applicable c. Utilize same termination kit available for ST and SC versions with the addition of an LC upgrade kit. d. Have a quick field termination process, which does not require power. e. Have a termination process, which incorporates use of a reliable anaerobic adhesive, which has a high resistance to environmental extremes. f. Have jacketed and buffered versions. g. An outer housing color-coded (blue) in accordance with TIA and ISO cabling standards. h. Meet the following performance specifications: Insertion Loss (typ) Performance (dB) 0.1 Insertion Loss (max) < 0.2 Durability (500 cycles) < 0.1 Parameter Return Loss (min) 55 3. LC Multimode Fiber Jumpers a. Be available in standard lengths of 1, 2, 3 and 5 meters with custom lengths available upon request. b. Utilize 50/125um duplex multimode fiber cable that is OFNR riser grade and meets the requirements of NEC/NFPA 70 Section 770-51(B) c. Meet IEEE 802.3ae 10 Gigabit Ethernet requirements as well as IEC 60793-2-10 and TIA 492AAAC specifications for laser bandwidth Differential Modal Delay (DMD) specifications. d. Meet Telcordia and ISO/IEC specifications for end-face geometry (including radius of curvature, apex offset, and spherical undercut). e. Use cable and connectors that are complaint with color coding specifications as listed in ANSI/TIA/EIA-568-B.3 and ANSI/TIA/EIA-598-B. f. Have LC-SC hybrid versions available. g. Include dust caps on all assemblies. h. Be 100% optically tested to meet the following performance specifications: Parameter Min. Cable Bandwidth (MHzkm) Max. Insertion Loss (dB) Min. Return Loss (dB) Not applicable 850nm 50/125m 1300nm 850nm* 1500 500 2000 Comply 0.50 (0.10 Typical) 30 (35 Typical) *laser bandwidth 4. LC Single Mode Fiber Jumpers a. Be available in standard lengths of 1, 2, 3 and 5 meters with custom lengths available upon request b. Utilize duplex single-mode fiber cable that is OFNR riser grade and meets the requirements of NEC/NFPA 70 Section 770-51(B). c. Offer a superior connector polish that meets Telcordia and ISO/IEC specifications for end- face geometry (including radius of curvature, apex offset, and spherical undercut) d. Use cable and connectors that are complaint with colour coding specifications as listed in ANSI/TIA/EIA-568-B.3 and ANSI/TIA/EIA-598-B e. Have SC-LC hybrid versions available SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 20 Not applicable f. Include dust caps on all assemblies g. Be 100% optically tested to meet the following performance specifications: Parameter Single Mode Max. Insertion Loss (dB) 0.40 (0.1 Typical) Min. Return Loss (dB) 55 (60 Typical) Not Applicable 5. LC Multimode Fiber Pigtails a. Be available in standard lengths of 1 meter with custom lengths available upon request b. requirements as well as IEC 60793-2-10 and TIA 492AAAC specifications for laser bandwidth Differential Modal Delay (DMD) specifications. c. Offer a superior connector polish that meets Telcordia and ISO/IEC specifications for end- face geometry (including radius of curvature, apex offset, and spherical undercut) d. Use connectors that are complaint with color coding specifications as listed in ANSI/TIA/EIA-568-B.3 and ANSI/TIA/EIA-598-B. e. Include dust caps on all connectors f. Be 100% optically tested to meet the following performance specifications: Parameter Min. Cable Bandwidth (MHzkm) Max. Insertion Loss (dB) Min. Return Loss (dB) 850nm 50/125m 1300nm 1500 500 Comply 850nm* 2000 0.50 (0.10 Typical) 30 (35 Typical) *laser bandwidth 6. LC Single Mode Fiber Pigtails a. Be available in standard lengths of 1 meter with custom lengths available upon request b. Offer a superior connector polish that meets Telcordia and ISO/IEC specifications for end- face geometry (including radius of curvature, apex offset, and spherical undercut) c. Use connectors that are complaint with colour coding specifications as listed in ANSI/TIA/EIA-568-B.3 and ANSI/TIA/EIA-598-B d. Include dust caps on all assemblies. e. Be 100% optically tested to meet the following performance specifications: Parameter Singlemode Max. Insertion Loss (dB) 0.40 (0.1 Typical) Min. Return Loss (dB) 55 (60 Typical) O. ACTIVE NETWORK SYSTEM BRIEF 1. Converged ICT & Security Networks – The development shall be provided with multiple independent networks. These networks shall provide dedicated services. These networks SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 21 Not applicable 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. shall run on independent infrastructure and utilize dedicated switching hardware. The current defined independent networks are : Comply a. Converged ICT Network b. Security Network Various building systems will use the networks as their transport method. It is the requirement of this Section to provide fully redundant network to meet these requirements. The various building systems will be separated onto the networks as follows: a. Converged ICT Network i. BGM and Apartment Intercom System comply for apartment intercom ii. Building Management Applications such as email, building management Comply as per IFc software, billing software, time attendance etc. (as required) drawing iii. Back of House Office computers and printers (as required) iv. Building Management System (BMS) b. Security Network i. Video Surveillance System Part of security ii. Access Control System and other related security systems submittal iii. Security Headend Equipment and Control Room Devices/Equipment All networks shall be configured to a fully dual-redundant star topology with the network cores in the server room and the edge switches in the IDFs. Comply The Contractor shall provide logical separation between different Networks. Each network shall be provided with a dedicated server room space, dedicated backbone cabling Comply dedicated racks in the IDF's. The contractor shall provide firewall, router, dedicated core and edge switches for each network as shown on the design drawings. Comply A dedicated MTR room has been provided on the B2 level to house all the IT equipment for the chosen Internet Service Providers (ISPs) incoming infrastructure from the site boundary and the service distribution to building networks. Part of ISP GSM rooms are provided to house the active GSM equipment for the 2 GSM service providers. Part of ISP The contractor is to provide dedicated UPS units for all IT related rooms to support the Comply installed equipment for a minimum of 30 minutes unless otherwise specified or agreed. The Contractor shall be responsible for providing the requirements for and verifying space, selection of rack (size and door type) power and cooling requirements associated with this Section and coordinate with the relevant trades. Comply It is the Design Intent to provide multiple intra-building infrastructures which shall support fully redundant, high-speed, standards-based, switched 10/100/1000 Mbps, multi-protocol, Ethernet network, providing IP services based on ANSI/TIA/EIA and ISO standards, and Building Industry Consulting Service Inter- national (BICSI) Telecommunications Design Methods Manual (TDMM). Comply All network end-points and outlets shall support 10/100/1000 Mbps operation and Power over Ethernet for optimum performance of all users and applications. Comply The system LAN configurations shall be a two-tier hierarchical star. Comply All services for the development will originate at the redundant Core Switches located in the Server room. Comply Core Switches will be interconnected to the optical fiber backbone by means of rackmounted fibre interconnect patch cords as detailed in the structured cabling section of this Comply document. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 22 15. The backbone will deliver data to and terminate at the Edge Switches located in the IDF’s located throughout the building. Comply 16. Firewalls shall be used for added network protection as detailed in the network topology Comply drawings. 17. The network is an IP network, therefore it is required that all Active components such as CCTV surveillance must support IP over the provided network. The data network extends to the structured cabling system, which must be capable of accommodating a variety of IP enabled devices as well as the above listed items. Systems for Security Cameras and Access control are not to be included in this network. security network will be part of security network 18. Access layer devices must support Power over Ethernet plus (PoE+) in order to provide electrical power to access layer devices capable of utilising the PoE+ standard. Comply 19. Access Switch stacks shall have Layer 3 capability and dual uplinks over multimode fibre, with a minimum bandwidth of 10G per uplink, connecting to the distribution / core layer. Comply 20. All materials and products, excepting Owner Furnished Equipment (OFE), and materials, shall be appropriate for the intended use and shall meet all applicable UL, EN, BS, ISO and IEC Comply Regulations 21. All products shall be new, of the latest version at time of Installation, and brought to the job Site in original manufacturer's packaging. Comply 22. The Contractor is to provide a written statement from all manufacturers that all installed hardware and software are the latest models at the time of Taking-Over. Comply 23. All software supplied for the Project shall be manufacturer furnished and supported applications. The Contractor “custom” software, written in-house, will not be accepted except in cases where a suitable application does not exist and only with prior written acceptance by the Engineer.Comply 24. Materials shall be listed and approved for the particular application and permitted by the authority having jurisdiction for the application. Comply 25. All workstation termination hardware shall match the existing wall surface color as closely as possible, to include mounting boxes, faceplates, and outlets. Not in scope 26. Used equipment or damaged material will be rejected.Comply P. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. CORE SWITCHES Fully redundant Core Switches shall be provided for all of the active networks on the project. Switches shall be provided with the premium build software and all required licenses. Each core switch is required to have redundant power supply and redundant supervisor module. Scalability and performance and port density across several chassis configuration and LAN, WAN and metropolitan-area network (MAN) interfaces. Redundant power supply and redundant supervisor module in each core switch. Enabled Hardware accelerated IPv6m MPLS, GRE and NAT. Integrating high performance forwarding capacity upto 150Mpps. with the new routing and forwarding engine including third generation policy features card (PFC3). Simplified network operations. Resilient and load-sharing Switching Fabrics in the core switches with a maximum stateful failover time at Layer 2 and Layer 3 of <1second. Synchronization of dynamic and static information shall be replicated on both processors modules In a multi-switch network scenario, either of primary or secondary core switches shall failover to the other in <1second by means of layer 2 resiliency techniques (having uplinks SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 23 Comply 11. 12. 13. 14. 15. 16. from edge switches split among the two core switches. All links between any given edge switch and all core switches shall be actively load-sharing traffic.) Hot Swappable Switch Fabric, Power Supplies and fan trays and Switching modules. Dual switch software and configuration file images on processors. Active Alternate locations for switch software and configuration file images (Flash, PCMCIA, Network Drive). Real-time operating system (RTOS) for mission critical applications which is Stable and reliable with no vulnerabilities in Software / configurations. The switch’s operating system or application-specific software(s) shall not, at any time, affect the operation by causing a system to: crash, reboot, enter a state of Denial of Service (DoS), fail to respond to any type of user/network traffic, fail to respond to any type of management traffic, use built-in user name/passwords to gain illegal access to the switch. Ability to Cluster both backbone switches to provide a single virtual Switch facing the Servers and the Edge switches. Thus all links between the (backbone switches – edge switches), (Backbone switches – Servers) shall be active and Load-Sharing using Standard 802.3ad. Q. CORE SWITCHES MODULES 1. Supervisor modules. 2 no supervisor modules shall be provided per core switch. 2. Supervisor modules must be configured to include network system virtualization technologies to cluster the core switches as a single virtual switch. 3. 10/100/1000-MBPS Ethernet Interface Modules for IP (over copper) connectivity to local devices within 100m from the core switch. 4. 10Gb fibre Ethernet modules for backbone uplinks to edge and server switches requiring higher bandwidth (greater than 1Gbps) availability. 10Gb modules should not be subject to oversubscription unless approved otherwise. 5. SFP modules as per the design requirements. R. ACCESS/EDGE SWITCHES 1. The contractor must maintain a single model of server/edge switch throughout the project to ensure the consistency of the design, reliability of the performance, efficacy of manageability and maintain lower overhead of the maintenance. 2. The contractor shall provide switches with capability of 10GB uplinks from the core switches for all 24 and 48 port switches. External switches (if any) must be provided with a minimum of 10GB uplink capability. 3. The number of ports on the active components design is based on the number of cable terminations to the IDF location. Effective schedule of area document will facilitate calculating the ports required per IDF location. 20% of active ports spare to be calculated for each IDF location. 4. All edge switches must connect directly to the redundant equivalent switch and directly to the core switch using the fiber uplink ports with primary uplink to first core switch and secondary uplink to the second core switch, cascading in any form is not permitted in the network. 5. 20% Spare uplink ports and associated cores must be available with the fiber infrastructure to accommodate future expansion. 6. Two servers farm switch type will be required to be installed in the CCTV Network servers‘ racks each with 48 Gigabit ports and two fiber uplinks to the core switches. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 24 Comply Comply Comply 7. The individual switches shall be ASIC based and have an internal switch fabric which operates at speed greater than or equal to 24 Gbps for the Giga Ethernet interfaces. Each shall have expansion slot, which has access to the internal switch fabric. The operating code in each switch shall be stored in Flash memory and to be upgraded by downloading new code to the switch. 8. Layer 2 requirements – Full 10/100/1000 UTP auto-negotiation. No Single Point of Failure. 9. All switches must be POE (Power over Ethernet) Enabled. 10. Support port monitoring. The edge switches shall support the port monitoring for at least once source/destination pair at a time. The source and the destination ports can be selected from any Ethernet port in any switch in the switching stacks. 11. Load-Balancing load uplink capabilities using link aggregation group (LAG) allows multiple links to be grouped. 12. The LAG shall load share the traffic between two switches allowing the bandwidth to be multiplied and the traffic to be averaged. The use of LAG in addition to boosting the performance of an uplink, also inherently increase the resilience of the solution since the links behaves as hot standby links to one another. 13. If the traffic is shared over multiple links, and one of the links is lost the traffic shall be automatically redistributed over the other links and communications shall continue without interruption. 14. Inter-module-Redundancy Provides link redundancy functionality in the event of module failure. 15. The switchover time between the ports in event of failure of the primary port shall be less than 1 second. 16. The traffic prioritization according to IEEE 802.1p tagged frames. 17. Leaky LAN: the switches shall support leaky LAN and support block broadcast traffic between VLANs but allows unicast traffic to be forwarded to VLANs. 18. Ability to download S/W images shall be in safe mode, check CRC, copy, compare, then to be active. 19. Backup code always to be present. Security on MAC address. 20. Ability to enable and disable port security as required. 21. Ability to implement port security by locking the addresses in the switch MAC tables, only allowing access to those devices whose MAC addresses are known. 22. Each switch shall have an integral network management agent. IP multicast filtering via IGMP snooping. 23. All switches shall comply with NEBS level 3 requirements and to be certified. 24. All switches shall meet the requirements of IR-NWT-000063 NEBS for shock criteria, vibration criteria, shock and vibration test methods and Layer 4 load balancing. 25. Support SSH and CRYPTO and central logging commands 26. For External devices such as the CCTV points, externally rated with operating temperatures of - 40 °C to 85°C. 27. All external switches must be externally rated as detailed above and must be mounted in an IP 65 enclosure as a minimum. All enclosures and mounting details must be submitted for approval by the clients’ representative prior to procurement and installation. S. UNINTERRUPTIBLE POWER SUPPLY (UPS) 1. Refer to the electrical specifications for the UPS requirement. Comply 2. Minimum of 15 mins backup, generator-powered power supply shall be considered for ICT equipment. com ply , 30mins backup will be provided SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 25 Comply 3. Security equipment shall comply with SIRA requirements of minimum 30mins UPS backup and 120mins backup for the security control room. Part of security submittal PART 3: EXECUTION A. GENERAL 1. All materials and products, excepting Owner Furnished Equipment (OFE), and materials, shall be appropriate for the intended use and shall meet all applicable UL, EN, BS, ISO and IEC Regulations 2. All system components shall be manufactured by ISO 9001:2008 certified companies and all packaging shall carry clear product identification (catalogue number, quality control number, etc) 3. All products shall be new, of the latest version at time of Installation, and brought to the job Site in original manufacturer's packaging. Electrical components shall bear the Underwriter's Laboratories label. This listing requirement applies to the entire assembly. Only systems and equipment that meet or exceed the level of quality and capabilities stated within this document will be considered for acceptance. 4. Materials shall be listed and approved for the particular application and permitted by the authority having jurisdiction for the application. 5. All system components of the entire cabling system (copper and fibre) shall be from a single manufacturer which will ensure that a single performance warranty covers all applications on vertical and horizontal links. This includes but is not limited to: a. Horizontal Distribution b. Fiber Optic Distribution c. Copper Distribution d. Patch Panels e. Copper and Fibre Outlet Modules B. INSTALLATION 1. Install components in accordance with Contract Drawings, manufacturer’s instructions and approved submittal data. 2. System installation and construction methods shall conform to the requirements of the applicable International Standards. 3. The Contractor shall install all system components including Employer Furnished Equipment, and appurtenances in accordance with the manufacturer's instructions, and adjustments required to deliver a complete and operable system. 4. Earthing and Bonding shall be installed as necessary to preclude ground loops, noise, and surges from adversely affecting system operation. 5. The Contractor shall adhere to the installation schedule of the Engineer and should attend all construction meetings scheduled by the Engineer. 6. Final configuration of the network equipment shall be performed to the satisfaction of the Employer’s IT Staff. This includes, but is not limited to; VLAN configuration, IP addressing schemas, final port assignments, and trunking/bonding configurations. The Contractor shall ensure that the proper documentation is provided to assist in the final system configuration. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 26 Noted & Comply Comply in coordinat ion with MEP 7. Mount all equipment to be installed over public areas in a manner adequate to support the equipment loads with a minimum safety factor of five. Do not use formed eyebolts or lag screws for support of suspended equipment. 8. Firmly and permanently, attach electrical boxes, enclosures, and permanent equipment to the building. Rigidly mounted equipment and devices shall be plumb and square. 9. Choose color and finishes of all exposed and custom fabricated items and labels to blend in with the surroundings as accepted by the Engineer. C. INSPECTION 1. The Contractor shall undertake testing and commissioning for all elements and aspects of the installation. Witnessing of testing and commissioning of the installation shall be offered to the Engineer for acceptance and sign-off. 2. Prior to an inspection, the Contractor shall issue, for acceptance, an Installation, Testing and Commissioning Plan detailing each test that will be conducted and the expected results required to pass the inspection. 3. Provide a statement of completion certifying that the system is installed and is ready for acceptance testing and equalization to The Engineer. 4. Schedule a time for The Engineer to perform system acceptance testing and equalization with at least 14 days advance notice. 5. Furnish a technician who is familiar with the system to assist The Engineer during the acceptance testing and equalization for the duration of time it takes to complete the adjustments (regular time or overtime as required). A minimum of 24 hours, as required to complete the adjustments. 6. Each cable shall be inspected for proper termination. 7. Record final settings on all equipment and submit with contract closeout documents. 8. Upon completion of initial tests and adjustments, submit written report of tests to the Employer along with all documents, diagrams, and record drawings required herein. 9. If the system does not meet criteria or if additional trips to the Site for testing or equalization are required, The Contractor shall reimburse the Employer for all expenses and professional time encountered by The Engineer. D. TEST EQUIPMENT 1. Furnish all test equipment necessary for the complete testing and commissioning of the system, to be available for the entire test period through final system testing and TakingOver. 2. Test equipment shall be calibrated no more than 1 month prior to the start of testing. All test equipment must be accompanied with a certificate from the equipment manufacturer showing date of last calibration. Comply in coordination with MEP Comply in coordinati on with MEP Comply E. DOCUMENT SUBMITTALS 1. Upon project completion and acceptance, submit the following to the property management: a. Technical Manuals: Provide documentation as follows: b. Block Diagrams: Detailed functional block diagrams that illustrate as-built conditions. i. Identify each equipment item by manufacturer and model number, label alpha numerically contractor furnished controls, relays, patch panel jacks, and similar devices. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 27 Comply c. d. e. f. g. h. i. j. k. l. m. n. ii. Reference the designations on fabrication drawings, patch panel details and related instruments. Fabrications: Detailed as-built drawings of contractor fabrications. Illustrate the mechanical and electrical construction, with manufacturer’s part numbers and values for components. Rack Elevations: Final rack elevation drawings. Manufacturer’s Literature: Descriptive literature and performance specifications, operating manuals, and servicing information. Control Settings: Schedule of nominal control settings for proper system operation. Test & Measurements: Documented data gathered during systems tests and commissioning. Systems Operating Instructions: Describe the functions, operation and maintenance for each installed system. Write the instructions in full detail in language sufficiently clear for comprehension by non-technical persons. Troubleshooting Guide: System operator’s procedures to follow in the event of an apparent equipment failure, written in logical outline format. Terms & Conditions: Restatement of the systems warranty terms and conditions and schedule of manufacturer’s warranties covering parts and labor for the provided equipment. Programming: Submit to the property management, a legal copy of the authoring software and unrestricted license and an archival electronic copy of the uncompiled operating code when submitting the record (as-built) documents for system programs. Upon completion of the installation, Contractor shall prepare as built documentation of the entire installation. This documentation should include the electronic copies. i. User Manuals 1. Systems Operating Instructions: Describe each provided system, specifically the functions, operation, and maintenance. Write the instructions in full detail and in language sufficiently clear for comprehension by non-technical persons. 2. Control Settings: Schedule of nominal control settings for proper system operation. 3. Troubleshooting Guide: Operator’s procedures to follow in the event of an apparent equipment failure, written in logical outline form. 4. Block Diagrams: Simplified as-built block diagrams with alpha numeric references to controls, relays, patch panel jacks and other similar devices. 5. Terms & Conditions: A restatement of the system warranty terms and conditions. Describe the terms of manufacturers’ warranties that extend beyond the two year provisions of the system warranty. 6. Document Revisions: Submit within four weeks official system acceptance, four complete sets of corrected and revised pages and drawings to update the operating and maintenance manuals described above to reflect adjustments and changes to the system during the final testing and acceptance. SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 28 Comply ii. Operation Manual 1. Table of Contents 2. Typed description of each system including key features 3. Setup diagrams as directed by the Consultant 4. Single-line detailed schematics and layout showing all major system components 5. Manufacturer's operation manuals for equipment intended for operation by system users 6. All software shall be fully documented, and that documentation included. 7. Any and all user definable software configurations and/or programming shall become the sole property of the employer. This includes all source code, source code copyrights, and related documentation. iii. Maintenance Manual 1. Bind each with tabbed dividers between sections and include a title page with space for submittal stamps. 2. Table of Contents 3. Company name, address, telephone number and contact name for system service or maintenance 4. Listing of all equipment and materials manufacturer's names, addresses, and telephone numbers, model or part numbers and catalogue data sheets 5. Product manufacturers' warranties and a typed system warranty explicitly covering all materials and labor 6. Manufacturers' service manuals for all major equipment items. 7. Test documentation showing results of source quality control tests, field quality control tests, acceptance testing, and equalization 8. List of spare equipment F. WARRANTY 1. The contractor will provide a written warranty valid for minimum 20 years from date of structured cabling acceptance or practical completion, whichever is the later. Advanced replacements should be available during this period. Comply 2. For Active Equipment, the contractor will provide a written warranty valid for minimum 3 Years from date of system acceptance or practical completion, whichever is the later. Advanced replacements should be available during this period. Comply 3. Acting as a franchised dealer, the contractor is required to provide agreed service of equipment including warranty claims and repairs; comply 4. Support costs required for 3 years (or show qty 3 x 1 year support cost) and should include new equipment / software and extend any existing contract to end approximately the same time as any new contract. Comply , will be provided seperately G. MAINTENANCE 1. Annual Maintenance Contract SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 29 Comply 2. Include along with pricing of AMC any services schedule, preventative maintenance scheduling and actual contract wording. 3. 24x7x4 terms are mandatory for all critical components 4. 8x5xnbd terms are acceptable for non-critical components such as telephone handsets. 5. Direct vendor support contracts are mandatory although the contractor can submit an alternative to direct vendor support if the contractor has extensive supplies of equipment in UAE and can match or exceed the service and expertise of the vendor. H. TRAINING 1. The manufacturers authorized and factory trained personnel must provide 5 Days of training sessions. Duration of each training session shall be at-least four hours long. Contractor to video record each session and provide six soft copies of the recording as part of the CloseOut Submittals. 2. The training must include at a minimum: a. Preventive maintenance service techniques and schedules. b. Overall system concepts, capabilities and functions. c. Explanation of all control functions. 3. Methods and means of troubleshooting and replacement of all distribution and drop wiring and devices. 4. Manuals, drawings and technical documentation must be used in training and shall be left with the Employer, or its designated representative at the completion of training for Employer use in the future. 5. The use of proprietary equipment does not justify failure to provide technical documentation, such as programming information, electronic schematic drawings and technical description, as part of training and documentation. It shall be the responsibility of the Contractor to ensure this documentation can be obtained prior to acceptance, as listed in this document. END OF SECTION SYSTEM SPECIFICATION ICT/TELECOMMUNICATION 30 Comply Comply Not applicable comply in coordination with MEO Not Applicable Not Applicable Comply Not Applicable Comply Not Applicable Comply Noted & comply Noted Noted & comply Noted Not Applicable Not Applicable Noted & comply in coordinati on with MEP Noted & comply in coordintio n with MEP Comply Noted & comply in coordintion with MEP Noted & comply in coordintion with MEP Noted & comply in coordintion with MEP Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable Not applicable Noted & comply, 30mins backup considered for ICT UPS specification as per specification Noted & comply, 60mins backup considered for ICT UPS specification as per specification Comply for FCC UPS. Security ,ICT UPS considered as per the specification under system specification Comply for FCC UPS. Security ICT UPS considered as per the specification under system specification. Not Applicable Not Applicab le Not Applicable Not Applicable Not Applicable Not Applicable Not Applicable Not Applicable Not Applicabl e Not Applicable Not Applicable Not Applicable Not Applicable Not Applicable Comply in coordinatio n with MEP Comply in coordinatio n with MEP Not applicable Not applicable comply Comply Comply Not applicable Not applicable Not applicable Noted & comply Not applicable MADINAT JUMEIRAH LIVING PHASE 3A DATA COMUNICATION SYSTEM SPECIFICATION (ICT, AV, INTERCOM) REV. A DESIGN COMPLIANCE PERFORMANCE CRITERIA 27TH JUNE 2019 Revision A Date 2019 06 27 By SN Description DESIGN COMPLIANCE PERFORMANCE CRITERIA Resp. Consult BW NOTE: THIS DOCUMENT TO BE READ IN CONJUNCTION WITH THE CONCEPT REPORT SCALE: NTS SHEET SIZE: A4 DATE STARTED: 2019 06 13 CHECKED: RT DWG № 18164E-TE-GEN-0-050-01 STAGE: CPT Rev: A Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Table of Contents PART 1 - GENERAL ................................................................................................................................ 3 1.01 PROJECT INTRODUCTION ...................................................................................................... 3 1.02 SCOPE OF SPECIFICATION ..................................................................................................... 3 1.03 TENDER SUBMITTAL .................................................................................................................. 4 1.04 TENDER DRAWINGS ................................................................................................................ 4 1.05 COORDINATION ..................................................................................................................... 4 1.06 QUALITY ASSURANCE ............................................................................................................. 5 PART 2 – DATA COMMUNICATIONS SYSTEMS ................................................................................... 6 2.01 – ICT (INFORMATION AND COMMUNICATIONS TECHNOLOGY) ............................................................. 6 2.02 AUDIO-VISUAL SYSTEM (BACKGROUND MUSIC SYSTEM) ................................................................ 25 2.03 AUDIO INTERCOM SYSTEM ........................................................................................................... 28 2 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification SECTION 27 0000 DATA COMMUNICATIONS SYSTEM (ICT, AV, INTERCOM) PART 1 - GENERAL Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. Comply 1.01 PROJECT INTRODUCTION A. B. C. Madinat Jumeirah Living (MJL) Project, Dubai. Madinat Living will share the same DNA as the Madinat Jumeirah. The site is accessible from the surrounding wellestablished road network (Sheikh Zayed Road, Umm Suqeim Road, Al Wasl Road and Jumeirah Beach Road). This specification focuses in the Building 6, 7 and 8 of the Madinat Jumeirah living development contained within Phase 3A of the Project and focuses on the Data Communication System (ICT, AV, Intercom) to be installed in MJL buildings 6, 7 and 8. Comply The underlying concepts behind the design of the Data Communication systems for this project are as follows: 1. The MJL development wish to provide Data Communication systems in specific areas of the development. This forms the basis of this specification. 2. Provision of features and services that will help differentiate the development from its competitors 3. Provision of systems that meet the guidelines of the MJL requirements and international best practices. In responding to this tender, the contractor shall consider the requirements and needs of the operator with specific regard to the following criteria:1. The nature of the development 2. The Intrinsic business nature of the residences. 3. The criteria provided by the client. 4. Current industry trends 1.02 SCOPE OF SPECIFICATION A. B. C. D. E. This specification covers Data Communications systems (ICT, AV, Intercom) as Comply described below for the MJL Development The objective is to provide professional systems, installed, acceptance tested, and Comply ready for use. Drawings pertaining to this specification shall be considered as a part of the specification and shall be a part of the Contract documents. System features that are mentioned in one part may not be shown in the others. In case of conflict between the written specifications and the drawings, Contractor must seek clarification from the Engineer. In the event that the Contractor fails to obtain such clarification, the interpretation of the Engineer will prevail. Comply The General Conditions, Particular Conditions, Electrical General Provisions, and the applicable requirements of the Main Contract apply to each and every contract, contractor, subcontractor or other persons supplying materials and/or labor for this project. Comply The security contractor must ensure that the developed detailed design provides a robust resilient system with considerable expansion capability throughout all 3 Noted & Comply Noted & Comply Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification F. G. H. I. J. K. L. M. N. security equipment with the purpose and functionality of all security subsystem components, combined to provide a fully functional and integral system. Comply In all cases guidance should be requested from the Client and Consultant. Comply Comprehensive method statement shall be submitted for approval and this statement must clearly include all aspects of installation. Comply The contractor shall comply with the project safety standards. Comply Liaise with and coordinate all works with the client and consultant. Comply This specification document outlines the design criteria, distribution routes and considerations which form the basis for the development of Security Services. Comply Contractor shall perform all work, coordination, aid to system integration, engineering design and testing, and shall install and provide all products in approved manner to ensure a fully operative system. Acceptance Test plan would be executed to verify the installation and operation of the system. Comply All material / installation shall be approved by the ID/Engineers/Client representative. Comply The contractor must ensure that the developed detailed design provides a robust resilient system with considerable expansion capability throughout all security equipment with the purpose and functionality of all security subsystem components, combined to provide a fully functional and integral system Comply Detailed specifications are provided within section 2.0 of this document. Comply 1.03 TENDER SUBMITTAL A. The following items are to be submitted with the tender return. 1. Provide a detailed Bill of Quantity with brands and model number. 2. Provide a schedule of equipment showing manufacturer and model 3. Provide a compliance statement stating if fully compliant, partially compliant or non-complaint with reasons if not fully complying. 4. Provide system description and schematic. 5. Provide all data sheets of the system being provided 6. Provide compliance with authorities 7. Provide company profile and highlight the projects done that are similar to this project 8. Provide project implementation plan 9. Provide Project team plan with resumes of probable team members 10. Provide training details. Comply 1.04 TENDER DRAWINGS A. The specification should be read with reference made to the tender drawings and reference to the contract electrical and architectural drawings. Comply B. It should be noted that tender drawings are detailed only to the extent necessary to show design intent and signal flow. It is understood and agreed by the contractor that the work herein described shall be complete in every detail so as to provide a complete and fully functional system even though every item necessarily involved is not specifically mentioned. Comply 1.05 COORDINATION A. Coordinate all work with the Architect, Interior Designer and Engineer. B. Coordinate the location of all active equipment with the location of all electrical mains power outlets. 4 Comply Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 1.06 QUALITY ASSURANCE A. Contractor Status: The Security Contractor shall be a registered, certified business partner and authorized installer for the proposed ACS manufacturer. Comply B. The contractor Have previously installed at least 5 projects of the same scale with the brands being proposed and has completed within the last five years. They must be currently certified by the manufacturers. Provide at least on such completed job for inspection by the Engineer. Proof of the same must be submitted at the presentation of bid proposal. Comply C. The Contractor shall have ten years’ experience with equipment and systems of the types specified, shall maintain a fully in house staffed and equipped service facility, and shall be an authorized service provider for the major brands specified for the project Comply D. The Contractor resumes of engineers and installers shall be provided as being planned for the project. This shall be presented during the Prequalification at the tender submission stage. Comply E. The Contractor shall have local presence within Dubai and provide 24/7 service support. Comply F. The integrator must have a good standing within Dubai on all current /previous projects. Proof to be provided of successful handing over of such projects. This is Comply subject to be verified by client. G. The contractor must submit proof for each of the below mentioned items in the Comply prequalification list at time of tender submission. H. Proof of all above items must be submitted during pre-qualifications at the time of Comply tender submission. 1.07 WARRANTY A. Contractor to provide Owner with exact beginning and ending dates of the warranty period. Include the name of the person to call for service and telephone number. This information to be part of Project Record Drawings and handover. Comply B. Manufacturer shall provide a limited 3-year warranty for Manufacturer supplied hardware to be free of defects in material and workmanship. Comply C. Manufacturer shall provide software support and updates for a period of 12 months. Extended support options shall be available. Comply D. Client software shall not require a license and have no limitations on number of client users. This excludes third-party plug-ins. Comply 1.08 TRAINING A. Provide on-site training for Owner's representatives as appointed. All manufacturers’ equipment manuals for each system described in these specifications will be on-site during training. Unless training is provided, this Contract will not be considered complete. Comply B. Provide required training sessions for all the supplied and installed system. Comply 5 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification PART 2 – DATA COMMUNICATIONS SYSTEMS 2.01 – ICT (Information and Communications Technology) A. SCOPE OF WORK 1. Supply, delivery, supervision, coordination, and installation, of equipment specified herein and shown on the Tender and Contract Drawings.Comply 2. Supervision, coordination and installation of Structured Cabling System (SCS) as required by Etisalat and Du. Comply 3. Incorporation of Client Furnished Equipment as required, providing a complete installation. Comply 4. Termination, testing, documentation and instruction of equipment specified herein and shown on the Tender and Contract Drawings. Comply 5. The Contractor shall verify space, power and cooling requirements associated with the Structured Cabling System as described within this and related documents. Scopr of MEP. 6. Provide all equipment, materials, labour, and services, not specifically mentioned or shown, which may be necessary to complete or perfect all aspects of the installation. Ensure that they comply with requirements stated or reasonably inferred by the specifications. Comply 7. Provide calculations and analysis to support design and engineering decisions as specified in submittals. Comply 8. Comply with codes, ordinances, regulations, and other legal requirements of public authorities which bear on performance of work. Comply 9. The Contractor shall provide system performance warranty for the SCS from the cabling system manufacturer to ensure all end-to-end connectivity channels can support up to 1 Gigabits per second. Comply 10. The Contractor shall provide proper earthing of all components in the SCS including but not be limited to equipment cabinets / racks. The Contractor shall coordinate with the Client / MEP Contractor for the locations of the nearest earth nodes from where the Contractor shall install the equipotential bonding to the SCS equipment. Scope of MEP. 11. The Contractor shall ensure that all of their works are coordinated both in terms of design and on-site integration with the works of other contractors, including but not be limited to the contractors for other systems installations, any sub-contractors employed by the Contractor and other relevant parties including the Employer and / or the Consultant and / or its representatives. Comply 12. The Contractor shall liaise and co-ordinate with appropriate statutory authorities as required. Comply 13. The Contractor shall designate qualified person(s), other than the Project Manager, to be responsible for the on-site quality control and attendance of regular design with Employer implementation progress meetings. The Contractor shall furnish adequate information and drawings in a timely manner to the Employer and / or the Consultant in ensuring smooth SCS implementations. Comply 14. The Contractor shall provide SCS documentation including system schematics, design topology, wiring schemes, labelling conventions, rack layout plans, SCS outlet layout plans, and also other information relevant to utilizing this infrastructure Comply 15. The Contractor shall provide a complete SCS that includes components including but not be limited to all cables and wirings, drop cables and patch cords for connecting outlets to equipment, under-floor outlet back-boxes, outlets, jacks, faceplates, cable terminations, cable ties, cable labelling and outlet labelling, patch panels, patch cords, equipment racks, plywood and frames, termination boxes (back-box and junction boxes), cable containment (including trunking, cable trays, cable ladders, riser trunking, conduits, etc.) within the Main Telecom Room, IDF Rooms, Electrical Rooms, 6 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. • and equipment racks, and all necessary printed warning notices, signage and labels and the like as specified in this Technical Specification. Comply The contractor shall be responsible to have anti-static paint in all technical room floors including main telecom room, floor telecom rooms, GSM rooms, AV rooms…etc. Comply The Contractor shall be responsible in developing requirements into a fully functional and complete system to produce a detailed SCS design that is fully co-ordinated with other building services, the building structure and architectural features and all furniture, fittings, and equipment. Comply The Contractor shall also provide fire stopping materials to fill the holes after the trunking / tray has been installed. The fire stopping materials shall meet the original fire rating of the floors and walls that the holes are on. Scope of mep It shall be the Contractor's responsibility to coordinate and liaise with the Employer and or the Main Contractor to ensure the final cable containment sizing shall meet the Employer's requirements. Scope of MEP The Contractor shall coordinate with other contractors for the termination of cables required by other systems. Comply The Contractor shall supply and install all equipment cabinets and racks for the System. The Contractor shall coordinate with others for cabinet / rack standards and quantities required for the Project. These shall include but not be limited to the cabinets / racks in the Main Telecom Room, IDF rooms and other locations specified by the Consultant / the Employer. The Contractor shall refer to the Tender Drawings for the arrangement of cabinets / racks. Comply The Contractor shall provide all patch cords and drop cables (equipment leads) for all systems on Day One. All patch cables and drop cables shall be patched to the cabling patch panels and punch down frames and neatly dressed within cabinets, racks and wall frames. Final connection to active equipment shall be undertaken by other respective contractors, unless otherwise stated or requested. Comply The Contractor shall provide weather proof termination boxes for outlets installed at outdoor locations. Comply as per IFC drawing The Contractor shall perform full (100%) testing and commissioning of all installed cables, including drop cables at two ends and connectors, and submit test reports accordingly. The Contractor shall provide patching records (in the format agreed by the Employer and / or the Consultant), prepare and submit Operation & Maintenance Manuals to document the SCS installation and include the test reports into the manuals. The Contractor shall provide full documentation with labelling of the entire SCS, including cables and connectors, cabling cabinets / racks, equipment cabinets / racks, patch cords, patch panels, etc. for the Project. Comply The Contractor shall conduct on-site user training on the System to the Employer's operation team and relevant representatives. Comply The Contractor shall be responsible for running the fibre cable from the Telecom Equipment Cabinet to the equipment rack and respective termination need to be carried out. Comply The Contractor shall ensure that all of their works are co-ordinated both in terms of design and on-site integration with the works of other contractors, including but not be limited to the contractors for other systems installations, any sub-contractors employed by the Contractor and other relevant parties including the Client and / or the Consultant and / or its representatives. Comply Related work specified elsewhere: The work described in this document includes hardware, installation, training, and support activities related to providing complete systems as described within this, and related sections. Comply 7 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Where specifications require exact match or conformance to an established sample or quality standard or objective, the Consultant’s decision will be final on whether a proposed product or installation practices matches satisfactorily. Comply • Requirements for inconspicuous or concealed installation, as one example, establish such a standard and objective. If required, fabricate custom-made enclosures and or chassis with careful consideration being given to aesthetic, technical, and functional aspects of the components and their installation. Comply 29. Coordination will be required between the Contractor and the following entities to ensure a complete working system, including, but not limited to: Comply • Du • Etisalat • Other Trades • B. SYSTEM & PRODUCT 1. System Description a. The intra-building infrastructure shall support a high-speed1Gb switched, multiprotocol, Ethernet based network providing converged IP-based services based on ANSI/TIA/ETA, ISO standards and BICSI TDMM (Telecommunications Design Methods Manual). Comply b. The backbone connectivity shall be subdivided into the following: • ISP (Combined DU and Etisalat - TRA guidelines) - Backbone for Apartments Part of ISP submittal Comply • Building ICT Backbone (Building CNS Backbone) c. Madinah Jumeirah Living will have latest ISP design guidelines called TRA guidelines, and the same need to be implemented in this project. Part of ISP submittal d. As per TRA design guidelines combined (Du & Etisalat) MTR room should be Part of ISP submittal provided in the building. e. Single infrastructure to be provided inside building for ISP connectivity to every Part of ISP submittal f. g. h. i. j. k. l. m. n. o. p. residential apartment. Madinah Jumeirah Living buildings having one Main Telecommunication Room (combined DU and Etisalat) at Ground Level provided as per latest TRA design guidelines. Part of ISP submittal Four-core single mode fibre cable shall be linked between Mini ODF and every residential apartment HCC (Home consolidation Cabinet) as per latest ISP (TRA) design guidelines.Part of ISP submittal Multicore Fibre should be pulled between Mini ODFs at different levels of telecom room and ISP - MTR room at Ground level, refer Schematic layouts. Part of ISP submittal Horizontal cabling inside each apartment shall be ANSI/TIA/EIA Category 6 UTP, deployed in a "home-run" arrangement. Cat.6a horizontal cable permanent link shall not exceed 90 meters. Part of ISP submittal Horizontal cables inside each apartment shall be terminated on 1U patch panels in HCC (Home Consolidation Cabinet). Part of ISP submittal Each residential apartment will have 12U HCC panel (600mm H x 600mm W x Part of ISP submittal 150mm D) as per TRA guidelines. All pairs of all horizontal cables will terminate to a modular 8-Position, 8-Conductor outlet at the telecommunications outlet. Part of ISP submittal MDF Rack for ICT Backbone shall be located in ground floor MTR room. Comply GSM services should be provided as per TRA design guidelines. Part of ISP submittal GSM containment should be provided between MTR room and GSM room Part of ISP submittal Main GSM room in GF and Roof be considered as shown in the schematic layouts. Part of ISP submittal 8 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification q. Multi core (24 core as per TRA Guidelines) single mode fibre cable shall be pulled between MTR room and GSM rooms as per latest design guidelines. Part of ISP submittal r. Space shall be provided to allow for the development of a Tetra system. Comply s. Tenderer to assure that no fibre and copper cables is manufactured in China, shipped, assembled or repackaged in other country. Comply t. Tenderer to provide confirmation on manufacturer letterhead on Country of Origin and country of manufacture, details/locations of their own manufacturing facilities, including ISO certificates Comply u. Tenderer to provide letter from manufacturer to confirm Country of Origin / Country of manufacture, details/locations of their own manufacturing facilities, including ISO certificates. Comply 2. Design Topology a. The Contractor shall refer schematics and Drawings for the detail such as locations and quantities of IT related equipment rooms and the quantities of cables required between the rooms. Comply b. The Contractor shall undertake site surveys to familiarize themselves with the site conditions. Comply C. ISP (DU and Etisalat) Backbone for Apartments 1. Madinah Jumeirah Living-buildings 6, 7 and 8 will have single telecom (ISP) infrastructure for Du & Etisalat service as per latest design guidelines (TRA) inside building. 2. Entry ducts should be provided from ISP (Internet Service Provider) OSP manhole to combined MTR room inside building. 3. Four Core indoor rated Single-mode Optical Fibre Cables shall be considering for ISP connectivity to apartments as per latest ISP (TRA) Standards. 4. Four core single mode fibre cable shall be provided between Home Consolidation cabinet (HCC) located in each apartment and Mini ODF located in Floor Telecommunication rooms at different levels in the tower. 5. fibre cable shall be of continuous lengths free from joints, branches or patching. 6. Four core fibre cable should be ITU-T standard compliant with G.652D as per ISP guidelines. 7. Jacket of the cable shall be Low Smoke Zero Halogen(LSZH) or Flame-retardant polythene sheath(FRP). 8. Multicore Single mode fibre cable shall be connected between Mini ODF at different levels and Main Telecommunication Room(MTR). 9. Contractor must follow latest ISP design guidelines for the calculation of multicore single mode fibre core count and fibre termination details. 10. The contractor shall terminate the fibre cable in MTR, Mini ODFs as well as a dedicated, secure HCC (Home Consolidation Cabinet) in each Apartment as per latest TRA design guidelines. 11. Contractor shall be responsible for the installation of cable containments / conduits within the MTR’s, Mini ODFs or other designated rooms. 12. The fibre cables should be labelled at both ends with a unique reference for the consolidation point served, Mini ODFs and the MTR. 13. Contractor shall make sure that all the installation should be in accordance with ISP (TRA) latest standards. 14. The Contractor shall undertake site surveys to familiarize themselves with the site conditions. 9 Part of ISP submittal Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification D. Building ICT backbone 1. ICT communication network will establish communication between: • IP based devices for Background Music System. Comply Building intercom system – Outdoor unit in Reception and all units will have intercom handset. Noted & Comply. apartments units are handsfree as per client requirement MDF Rack for ICT Backbone shall be located in ground floor FTR (Floor Telecom Room) Comply Fiber Backbone (2 x 2 core multi-mode fibre cable) shall be connected between GF Floor Telecom Room and Floor Communication Network Racks (IDF’s) at different levels. Noted& comply,2x6core multimode fiber cable proposed from IDF to MDF OM4 multi-mode indoor LSZH (Low Smoke Zero Halogen) Tight Buffered fibre shall be provided for Building ICT Backbone. Comply OM4 Multimode fibre shall be completed with graded index optical fibre waveguide with mode field diameter of 50µm ±0.5µm and cladding diameter of 125µm ±2 µm. Comply Optical fibre shall conform to the OM4 standard defined in ISO-11801 2" Edition, to Comply support 10 GB Ethernet over increased distances. All fibres shall operate in both 850nm and 1300nm optical windows with maximum attenuation of 3.5dB/km and 1.5dB/km respectively. Comply All fibre shall have its minimum information transmission capacity for 850nm and 1300nm optical windows as 200 MHz-km and 500 MHz-km respectively. Comply All fibre cables shall be of a dry and dielectric construction. No gel or metallic content shall be allowed. Comply The sheath of the cable shall be of LSZH construction. The sheath of the cable shall be extruded free from pin holes, joints, mended places and other defects. It shall be reasonably circular and the curvature of the external surface shall not be concave at any point. The minimum allowable bending radius of the cable shall be 10D and 20D during and after installation respectively where D stands for the overall cable diameter. Comply The cable shall have water sellable yarn located with the fibres to prevent the migration of water should the sheath material become punctured. Comply The cable shall operate within the stated specifications for temperatures ranging from Comply -10°C to +65 °C • 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. ICT and ISP (Telecom) will share the Riser space, however 50mm gap should be provisioned between each trucking as mentioned in the floor layouts. Noted& comply 14. Communication network riser shall be established between Control room and mechanical floors & designated floors and should have dedicated wall mount Comply cabinet. 15. Wall mount cabinet shall have 13Amps Dual Power socket and rack-mounted 2 kVA UPS. Comply 16. Wall mount rack will accommodate Network Access Switch. Comply 17. Main ICT rack in Ground floor FTR room - should have a dedicated 42U rack (800 mm x 1000mm) allocated, this rack includes: • Riser fiber patch panels • Core switch – connecting to all mechanical floors and designated floors as per building ICT requirements such as Intercom Systems etc. Comply • IP based connections such as server, workstation or other devices via access switch. Comply • 3kva UPS Comply Comply 10 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 18. Communication network will be used for services/devices which supports IP based communications such as Intercom and BGM …etc. as per client requirements. Comply E. Apartment ICT Requirements 1. Each apartment will have 12U Home Consolidation Cabinet (HCC) (600mm H x 600mm W X 150mm D) with dual 13Amps power sockets. Part of ISP submittal 2. Home Consolidation Cabinet(HCC) will accommodate the service provider’s ONUs. Part of ISP submittal 3. CAT 6a, UTP cable should be used inside apartment for horizontal cabling. Comply 4. All Cat.6a Cable inside apartment should be terminated in 1U Cat.6a patch panel Comply 5. Cable organizer should be provided for proper management of patch cords inside Part of ISP submittal HCC panel 6. ISP 4 core fibre cable should be terminated inside HCC panel as per ISP design guidelines. Part of ISP submittal 7. Proper Labelling should be provided for Cat.6a patch panels, Cat.6a Cables, Face plates and patch cords inside apartment, and the labelling scheme should be approved by client/ consultant. Comply F. GSM Services 1. GSM services should be provided as per latest TRA design guidelines 2. Every GSM room should be connected to MTR room with multicore single mode fiber optic cables, refer TRA guidelines. 3. GSM room should have 4 x 13 Amps twin power sockets fed from essential power supply with dedicated 20A circuit breaker. 4. 2 numbers of ac & dc earth bars connected to the dedicated earth pits with resistance less than 1 ohm. 5. 2 x 63 Amps TP isolator fed from dedicated feeder from essential power supply should be provided inside GSM rooms 6. Cross connect cabinet with fiber cable termination devices should be provided in GSM rooms as per design guidelines 7. Firefighting & fire safety requirements should be provided inside GSM room based on design guidelines. 8. GSM antenna locations and equipment details will be designed by GSM service provider. 9. Scope of Installation and termination should be done as per TRA guidelines, by service provider. G. Horizontal Cabling (CAT 6a) Topology 1. Category 6a(UTP) Standard, structured cabling shall be considered for horizontal cabling. Comply 2. The physical topology of the horizontal cabling should be configured as a star with each outlet connected directly to a Home Consolidation Cabinet(HCC) inside Apartment. Part of ISP submittal 3. The Contractor shall ensure that the end-to-end length of each individual run of any fixed horizontal cable from the Distribution Box / Equipment rack to the SCS outlets shall not exceed 90 meters. Comply 4. All Horizontal Cables inside each Apartments shall be terminated on 1U patch panel provided in 12U Home Consolidation cabinets (600mm h x 600mm W x 150 mm D), flush mount Cabinet. Part of ISP submittal 11 Part of ISP network Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 5. The maximum combined length of any work area equipment patch cable /cord and equipment patch cable / cord shall not exceed 10 meters. Comply 6. The Contractor shall leave an extra length of 3m of cable on either end for terminations. The cable must be suitably labelled. Comply 7. The Contractor shall leave an extra length of 5m of cable, for Wireless Access Point. The cable must be suitably labelled. Comply 8. The Contractor shall provide horizontal cabling connectivity to the RJ45 outlets to support the following services / applications: Comply • Data • Voice (VoIP) • Other services / applications as requested by the Client 9. Refer to schematics & Drawings to develop schedule for the location and quantity of outlets required. Comply 10. The Contractor shall coordinate regularly with other parties such as the Client, architect, other contractors for the final quantities and locations of SCS outlets. Comply H. Components 1. General a. Between any two termination points, all installed cables shall be continuous and without any joints or splices. Comply b. All indoor cables shall not be laid on areas exposed to external weather conditions. Cables shall not be laid on wet or damp concrete surfaces. Comply c. The SCS shall be designed and installed to make the best use of the installed containment in terms of diversity, system resilience, utilization and room for expansion.Comply d. All cable bundles shall not run over hard or sharp edges. Comply e. All cable bends shall not be tighter than the manufacturer's minimum bending radius requirements. Comply f. All the installed cables shall be terminated at both ends and labelled neatly on patch panels inside racks and faceplates on slab-mounted boxes or outer termination boxes where appropriate. Comply g. The Contractor shall provide the manufacturer's original certificates for cables or related components of the Work for review by the Employer and / or the Consultant. Comply h. All cable types shall be proposed by the Contractor and quoted in the Tender Returns. Generally, all wiring shall be run in conduit and trunking systems. Comply i. Tenderer to assure that no fiber and copper cables is manufactured in China, shipped, assembled or repackaged in other country Comply j. Tenderer to provide confirmation on manufacturer letterhead on Country of Origin and country of manufacture, details/locations of their own manufacturing facilities, including ISO certificates Comply 2. Horizontal Cabling (Cat.6a UTP) a. All Category 6a UTP cables shall be of Low Smoke Zero Halogen (LSZH) type. b. All cables shall be accompanied with traceable serial numbers from the manufacturer indicated on the packaging to assist in quality validation of the installed cables. c. All cables shall have cable markings – “Category 6a UTP" imprinted on the cable sheath in a color that contrasts with the sheath color. d. The length of each individual run of fixed horizontal cable from the ACP/equipment rack to the SCS outlet shall not exceed 90 meters and within 4 connections. 12 Comply Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification e. All cables shall be 4-pair (Unshielded twisted pair UTP) cables meeting or exceeding the quality and performance requirements for Category 6a UTP cables stipulated in Class 'E' ANSI/TIA/EIA 568B-2.1:2001 and ISO/IEC 11801:2002. f. The UTP copper cabling system shall be properly ground and bond. The grounding and bonding requirements specified in the current TIA J-STD-607-A Commercial Building Grounding (Earthing) and Bonding Requirements for Telecommunications shall be applied to the copper cabling systems. Scope of MEP 3. Patch Panels a. Copper Patch Panels 1) The Category 6a patch panels shall meet or exceed the quality and performance requirements for Category 6a cross-connect panel stipulated in EIA/TIA-568-B.2. 2) The patch panels shall incorporate enough space to accommodate a label for each port to indicate its function / termination / application. 3) The patch panels shall pass the reliability test of no more than 1 failure in 500 insertions for each modular jack port. b. 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) Comply Comply Optical Fiber Patch Panels Fiber patch panels shall be used to terminate all optical fiber cables with LC type connections, using fusion splicing technology. Patch panels shall be modular in design, equipped with patch-cord routing troughs and suitable for mounting in the frames/racks supplied. The patch panels shall provide protection from mechanical stresses, and macro bending losses on the cables. The patch panels shall provide means to locate and clamp the incoming cables without causing damage to the cable or affecting the quality and performance of the link. Patch panels shall provide patch guides, with a closed front to protect the patch cords. Patch panels shall be designed to allow termination and maintenance work, that can be carried out without having to remove the entire panel. Patch panels shall provide enough space to accommodate the bending radius for the patch cords, once connected to the panel. Patch panels shall provide enough management space and tools to store the fiber after breaking the fibers out from the cable. Patch panels shall be provided with either a screw-in or lockable dustcover to protect unused connector adapters. Patch panels shall have enough space in its front, to accommodate a minimum of one label. The label shall indicate its function/termination/application for each connection. Com ply 4. Patch Cords & Connectors a. Copper Patch Cords 1) The patch cords and work area cords shall be pre-terminated rather than fieldterminated. 2) All patch cords shall exceed or be an equivalent of TIA/EIA and ISO/IEC Category 6a 3) The patch cords shall provide air-tight connections and shall comply with ISO 11801 and EIA/TIA-568-B.2 Category 6a requirement. 4) The Contractor shall provide different colors of patch cords to distinguish between different services / applications. 13 Comply Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 5) The color and length of patch cords to be used for each service shall be agreed with the Employer and / or the Consultant. Normally patch cords shall come in 1m, 2m and 5m in length, excluding modular plugs at both ends. 6) Patch cords shall have built-in exclusion features to prevent accidental polarity reversals and split pairs. They shall have a latching mechanism to prevent accidental dislodging of the plug from the termination module or modular jack panel. 7) All cordage shall be round, and shall consist of 22-24 AWG copper, stranded conductors, tightly twisted into individual pairs. 8) The Contractor shall provide and include adequate quantities of copper and fiber patch cords. Compl y b. Horizontal Cable Connectors 1) All horizontal cables shall be terminated with RJ-45 modular jacks at the user outlet end and IDC-type patch modules at the equipment rack/HCC end. 2) Cable connectors shall be wired to the T568B wiring pattern. 3) Cable connectors shall be constructed with a housing of polycarbonate of rating 94V-0. 4) Cable connectors shall be mechanically and electrically compatible with the Category 6a UTP cables supplied under this Contract. 5) Communications outlets shall be Underwriter's Laboratories (UL) listed. 6) Communications outlets shall be of RJ-45 type, with Insulation Displacement Connectors (IDC) used to terminate the cable. 7) Horizontal cables shall terminate on RJ-45 sockets, 4-pair terminated, housed in closures agreed with the Employer as acceptable. 8) The installed connectors shall meet or exceed the quality and performance characteristics for Category 6a connector stipulated in EIA/TIA-568-B.2. Comply c. Single-mode Optical Fiber Patch Cords 1) 2) 3) 4) 5) 6) 7) The single-mode fiber patch cords shall be single fiber cords, flexible in nature with factory terminated fiber connectors at both ends. The color and length of patch cords to be used for each service shall be agreed with the Employer and / or the Consultant. Normally the length of each single-mode fiber patch cord shall come in various lengths of 1 m, 2 m, and 5 m, excluding the mechanical structure of the connectors. The single-mode fiber patch cords shall have core diameter of 8.7pm ±0.5µm and cladding diameter of 125µm ± 2µm. The outer jacket of the single-mode fiber patch cord shall be made of LSZH. The cable marking shall include traceable part numbers from the manufacturer packaging to assist in quality validation of the installed cable. The outer jacket shall be color coded and imprinted with cable markings "Singlemode" in a contrasting color. The outer diameter of the single-mode fiber cord shall not exceed 3mm. Comply d. Fiber Connectors 1) LC type duplex fiber connector /adaptors shall be used for single mode and multimode fiber cables and have a locking feature on the duplex coupler. 2) Pigtail shall be field installable, compatible with other fibers supplied in this project. 14 Comply Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 3) Pigtail shall allow the use of PC polishing on the tip, to provide high yield during installation. 4) Fiber connectors shall be able to operate within specification in temperatures ranging from - 10 to +65°C. 5) The insertion loss of mated connectors shall have a mean value of 0.35dB and a standard deviation of 0.2dB. 6) The insertion loss change due to temperature variations within the operating temperature shall be less than 0.3dB. 7) Insertion loss change after 1,000 reconnections shall be less than 0.2dB. 8) The return loss of the connector for the connections shall be better than -20dB for multimode connections and -40dB for single mode connections. 9) The tip material of the fiber connector shall be made of ceramic. 10) Refer ISP Standards for DU and Etisalat cable termination and type of connectors. 5. Faceplates, Outlets, Trunking a. Faceplates 1) Flush mount (flush-fitted wall-mounted) outlets shall be used for wall mounted outlets and wherever else possible. 2) Where space does not permit mounting of a flush face plate, modular surface mounted boxes shall be used. 3) Modular faceplates for mounting either at 90 degrees (straight) or 45 degrees (angled) RJ-45 modular jacks shall be installed for the floor slab-mounted outlet boxes where a raised floor is provided. 4) All face plates shall be constructed of ABS mounding compound and be compatible with standard electrical outlet boxes used by the MEP contractor. 5) Shutter covers shall be provided for each RJ-45 modular jack. Insertion of an RJ-45 jack shall cause the shutter to open. When the plug is removed, the shutter shall close automatically to protect the jack from ingress of dust. 6) Dust cover / blanks shall be provided for unused jacks. 7) Flush plates shall be mounted on skirting wiring duct cover section, metal wall box for outlets in masonry walls or metal mounting brackets for outlets in plasterboard lined stud walls. 8) The Contractor shall coordinate with the Employer and / or the IT Consultant, and architect on the colour and finish of faceplates to be provided and the same should be match with electrical accessories. 6. Cable Laying a. Cable Laying Principles 1) Cables shall be fixed in straight parallel runs and shall be held in place by broad cable ties at not more than 900mm centers on horizontal trays and 900mm on vertical trays. Comply 2) Cables shall not be held so tightly or by sufficiently narrow cable ties that permanent indentation (enough to measurably affect the transmission characteristics of the cable) or cutting of the outer sheath or conductor insulation occurs. Comply 3) The manufacturer's minimum bending radius requirements shall be adhered during Comply cable installation. 4) Cables running along horizontal and vertical cable ladder system shall be neatly dressed, tied and wrapped at regular intervals. Different types of cables shall be 15 Comply Faceplate s& adaptors for faceplates excluded from our scope. Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 5) 6) 7) 8) 9) grouped separately. Velcro type cable ties shall be used for all 4-pair twisted pair cabling; PVC cable ties shall be acceptable for larger multi-core cables. Comply Sufficient protection shall be provided to all installed cables and terminations to prevent damages from other trades on the construction site. Any damaged cables shall be replaced at Contractor's own costs. Comply Installed cable shall take the shortest route consistent with the defined routes, and shall not, unless specified, contain length in excess of the distance required. Comply All cables which cross service pipes carrying hot or refrigerant fluids shall be protected from excessive high or low temperatures or condensation. This may require separation and / or thermal insulation. Comply Cables shall be kept clear of fire suppression outlets, heat and smoke detectors and water detector strips. Installed cables shall not be subject to vibration or movement. Comply Cables shall not be fixed with staples, Cables should be properly routed with velcro Comply tapes. 7. Separation from power cables a. The communications cables shall not be tied to power cables or run along the same conduits/ducts or run through the same connection box. b. Any internal cables running in metal enclosed trunking or conduit shall be separated from external parallel runs of power cables by a minimum of 600mm. All other power and communications cables shall be separated according to the recommendations stated in CIBSE AM7. c. Where busbar inter-connecting power cables cross communications cable trays these cables shall cross at 90-degree angles. These power cables shall be shielded to minimize any interference with communications cabling data signals. Comply 8. Cables in Trunking / Conduit a. Trunking compartments shall be no more than 60% full to allow for future installation of cables. b. Cables shall enter and exit trunking via bridges to ensure complete separation between communications and power compartments, if any. c. The number of cables in each conduit shall be controlled to allow for future cable installation and to stay within the manufacturers' maximum allowable cable pulling tension. d. All draw wires shall be replaced during each cable pull. e. After cabling in trunking that passes through a fire-resistant structural element that has been designated as fire barrier, such as floor and wall, approved type of fire resisting material with the appropriate degree of fire protection shall be provided to prevent the spread of fire or smoke through the trunking. Supply and installation of all firestopping materials at the openings to walls, ceiling and partitions shall be by the Contractor 16 Scope of MEP Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 9. Equipment Cabinets & Racks a. Preferable Dimensions of the racks shall be as follows: Location ICT Rack in MTR Room (MDF) ICT Racks in different levels (Telecommunication Rooms) HCC Cabinets in Apartments Rack Dimension 800mm (W) x 1000mm (D) x 42U (H) Comply 600mm (W) x 600mm (D) x 15U (H) Wall Mount Enclosure 600mm (W) x 150mm (D) x 15U (H) Flush Mount Part of ISP submittal b. Power Sockets Requirement for ICT MDF, ICT IDF, and HCC/RCC: Location ICT Rack in GF FTR Room (MDF) ICT Racks in different levels (Telecommunication Rooms) HCC Cabinets in Apartments/Shops. c. d. e. f. g. h. i. j. Socket Rating No. of Sockets Backup – UPS + Generator 16 Amps Industrial Type (Surface Mounted) X 02 2 kva mount Rack 13 Amps X 01 1 kva mount Rack 13 Amps X 01 Not Required Scope of MEP For exact dimension and location of the racks, the Contractor shall verify at site and submit for Employer and Consultant's approval.Comply The Contractor shall supply and install one 13Amps twin power sockets power inside the HCC for powering the network equipment. Scope of MEP The Contractor shall supply and install 1 no 13 Amps rated non-switched 6- way power strip as a minimum for each 12U equipment rack at HCC and earth bonded Scope of MEP to the rack frame. The Contractor shall supply and install one 13Amps twin power sockets power inside the ICT racks in telecommunication room’s for powering the network equipment Scope of MEP The Contractor shall supply and install one 13 Amps rated non-switched 6- way power strip as a minimum for each 12U ICT equipment rack floor telecommunication rooms of Building 1 and Building 2 and earth bonded to the cabinet frame / rack frame. Scope of MEP The Contractor shall supply and install 2Nos. 16 Amps twin power sockets power for the ICT MDF rack in Ground floor MTR room for powering the ICT network equipment Scope of The Contractor shall supply and install 2 Nos. 16 Amps rated non-switched 10- way MEP C13 & 4-way C19 power strip as a minimum for 42U ICT MDF rack in Ground floor MTR room and earth bonded to the cabinet frame / rack frame. ICT MDF rack (800mm W x 1000mm D) characteristics as listed below: 1) Rack shall have a roof panel with 2 apertures of not less than 300mm x 50mm finished with brush strip (to prevent air leakage) to allow entry of high-level data cabling. 17 Compl y Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 2) Rack shall have a roof panel with 2 apertures of not less than 300mm x 50mm finished with brush strip (to prevent air leakage) to allow entry of high-level data cabling. 3) Rack shall be with 50mm, minimum, wiring space on any side where terminations are made, the wiring space shall be adjusted (increased) to suit the quantities and types of cables entering and leaving the equipment rack. 4) Rack shall be provided with four roofs mounted fans and have no loss of installation height. 5) Rack shall be provided with suitable means of securing the complete assembly to floors and / or walls. 6) The rack shall be able to support a maximum equipment load of 1000kg. 7) Racks shall be provided with self-levelling feet/castors and shall sit directly on to the access floor or concrete slab. The feet/castors shall be able to support the maximum load capacity of the rack. 8) The surfaces of the rack shall be protected by good quality paintwork. The paint shall be smooth, continuous and free from blemishes and scratches. The colour of the paintwork shall be agreed with the Employer before installation. 9) The front and rear doors shall be provided mechanical barrel type locks and with two sets of mechanical keys. The front and rear doors shall be the same lock on each rack. 10) A full height and width side infill panel complete with vertical wire ways finished with brush strip for inter-rack and frame cabling shall be provided by the Contractor. 11) Three (x3) slotted component shelves per 42U rack shall be provided. 12) All racks shall be provided with removal panels, escutcheon plates (Doors Locks), and covers. 13) The Rack shall have suitable clearance to ensure that the closure of the rack door shall not interfere with any device within the enclosure. Comp ly 10. Power Strip for Equipment Rack a. The power strips for the equipment racks shall be designed to comply with the following standards: • BS 7671 (IEE Wiring Regulation) • BS 5733 (General requirements for electrical accessories) b. The main housing of the power strips shall be made of anodized aluminium extrusion and mouldings shall be made of high impact, flame retardant grade of polycarbonate. c. The internal wiring shall be single cables insulated in low smoke, low fume grade of material to BS 711. The power leads shall be multi-core flexible cables complying with BS 6500, and shall be low smoke and fume. d. The sockets are designed and tested to BS 1363 Part 2 (Specification for 13A switched and unswitched socket-outlets). They shall be individually fused as 5A. e. The tape-off lead shall be at least 3 metre and the terminating plug shall be fused as 13A. f. Power requirements for racks: Location Power Rating Quantity ICT Rack 16 Amps PDU x02 Min. no. of Outlets 10 way : C13 04 way : C19 Comply Remarks Vertically mounted 18 Comply Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification ICT Racks at different levels HCC/RCP Cabinets in Apartments/Shops. 13 Amps Power Strip 13 Amps Power Strip x01 x01 x06 : 3pin UK type x06 : 3pin UK type 1U;600m m horizontal 1U;600m m horizontal Comply Part of ISP 11. Uninterruptible Power Supply a. An Uninterruptible Power Supply (UPS) shall be provided for the ICT MDF Room, & ICT IDF to provide uninterruptible electrical supply to the IT and electronic equipment inside the rooms. Comply b. For the input to ICT MDF rack , the UPS shall be supplied by 1-phase essential power in- feeds from the electrical rooms with full back up by emergency generators. Comply c. In addition to supplying all the loads inside the ICT Racks, the UPS shall have sufficient spare capacity of 20% to ensure its service reliability to support any surge loads and also cater for future expansion of the IT and electronic equipment inside Comply the rooms. d. The rated capacity of each UPS shall be expandable at least 30% for future Comply expansion. e. The UPS capacity shall comply with the following rating requirements. f. UPS Rating Comply • ICT MDF Rack : 02 kVA • ICT IDF Racks : 01 kVA g. The battery bank of each UPS shall have sufficient capacity for support the normal equipment operation under full loads for at least 15 minutes in case of city mains failure. Comply h. The electrical provisions shall be equipped with the necessary by-pass mechanism to main the normal supply to all connected loads during the routine maintenance and / or enhancement of the UPS. Comply i. In case of UPS breakdowns, the loads shall be automatically transferred to the city mains bypass via the system static bypass unit without any interruption. Comply j. Each UPS shall be equipped with necessary interface and network card for connection to Local-Area-Network via SNMP protocol for remote monitoring of the UPS status including mains failure, output on battery, low battery, mains restored and return on UPS, etc. Comply k. UPS management system shall be able to forward all type of alarm to an e-mail or SNMP trap. Comply l. UPS management system shall have the ability to monitor and control UPS systems connected via network-based SNMP card. Comply m. UPS management system shall be able to generate connected UPS health report. Comply n. The UPS equipment shall comply with the following specifications as a minimum: 1 2 Description Type Configuration 3 Construction Specification On-line type N; with flexibility to upgrade to N+1, 2N configuration, if required in future High reliability rack-mounted modular UPS, with no limit of scalability and paralleling for IDF rooms (Service Floors) 19 Compl y Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Standalone UPS for ICT MDF Room 200% of phase busbar (double neutral) Minimum 65% capacity within 10 times of discharge time (i.e. 300 minutes) 400V / 230V, +10% to -15% (read + confirm) <5% 4 Neutral Busbar 5 Recharge Time 6 Input Voltage 7 8 Total Harmonic Distortion Power Factor - at 100% load - at 50% load 9 Efficiency - at 100% load - at 50% load 10 11 12 Output Rating Output Voltage Adjustment Output Voltage (Transient) 13 14 Output Voltage Transient Response Overload Capability 15 16 17 18 19 20 21 Short Circuit Current Capability Audible Noise Operating Temperature Operating Humidity Mean Time Between Failure (MTBF) Automatic Battery Test Battery Care Voltage Compensation : >0.9 : >0.83 : 92% p.f. 0.8 lagging : 91.5% As mentioned in Section 2.3.7 220V, 50Hz 20% load step, ± 4% 30% load step, ± 5% 50% load step, ± 8% <50ms 110% 60 minutes 125% 10 minutes 150% 60 seconds 200% 200 ms 150% for 0.3 second <50dB (A) 0 – 40⁰C Up to 905 (90%) non-condensing Up to 200,000 hours Yes Yes Comply o. The battery unit shall comply with the following specifications as a minimum: Description Specification 1. Type Sealed Lead Acid Inbuilt battery 2. Backup Time 15 minutes 3. Accommodation arrangement Inbuilt with UPS 12. Entry Duct 1. The contractor must provide lead-in ducts from the plot boundary to the main telecom room (MTR). The exact connection points at the plot boundary will depend on the DU/ Etisalat manhole location. 2. The contractor shall connect to the DU/ Etisalat ICT Infrastructure ducting system. 3. The ISP construction NOC will identify the location and quantity of their lead-in ducts. 4. Refer ISP guidelines (TRA) for lead-in duct specifications. 20 Scope of MEP Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification I. Performance Requirements 1. Contractor shall provide enough skilled labour to complete testing within the agreed upon test period. Comply 2. Cabling system need to be tested with latest technology testing equipment as per the guidelines of TIA/EIA 568. C Comply 3. Contractor shall have a minimum of 5 years’ experience installing and testing fibre optic, Unshielded Twisted Pair and coaxial cabling systems. All installers assigned by the Contractor to the installation shall have a minimum of 2 years’ experience in the installation of cabling systems. Comply 4. Contractor is responsible for supplying all of the required test equipment used to conduct acceptances tests. Comply 5. Installation, Termination and testing shall be done by manufacturer’s certified Comply technicians. 6. Testing Equipment shall be calibrated as per the manufacturer’s instructions and Comply specifications 7. Contractor shall produce testing equipment calibration certificate prior to the testing carried out at site. Comply 8. NVP testing shall be carried out in room temperature as well as high ambient temperature as per the manufacture specifications. Noted. Fluke test & OTDR will be performed. 9. Testing of all horizontal cabling shall be performed prior to system cutover. Voice and data horizontal wiring pairs shall be tested from the telecommunications outlet to the copper Patch Panel. The cable runs shall be tested for conformance to the specifications of EIA/TIA 568B Category 6a Testing Comply 10. Horizontal cabling testing shall be done with a TIA/EIA TSB-67 UL Certified Level 3 test set. Test shall include length, mutual capacitance, characteristic impedance, attenuation, and near-end crosstalk. Near end crosstalk measurements shall be done at both the information outlet and the cross connect. Comply 11. All fibre testing shall be performed on all fibres in the completed end-to-end system. Testing shall consist of a bidirectional end to end OTDR trace performed. The system loss measurements shall be provided at 850 and 1310 nanometres for multimode fibres Comply and 1310 and 1550 for single mode fibres. Fibre Splicing and testing shall be performed in clean, neat and dust free atmosphere Comply J. EXECUTION 1. Pre –Installation Site Survey a. Prior to start of systems installation, meet at the project site with the owner's representative and representatives of trades performing related work to coordinate efforts. Review areas of potential interference and resolve conflicts before proceeding with the work. Facilitation with the General Contractor will be necessary to plan the crucial scheduled completions of the equipment room and Comply telecommunications closets. b. Examine areas and conditions under which the system is to be installed. Do not proceed with the work until satisfactory conditions have been achieved. Comply 2. Installation a. Receive, check, unload, handle, store, and adequately protect equipment and materials to be installed as part of the contract. Store in areas as directed by the 21 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification b. c. owner's representative. Include delivery, unloading, setting in place, fastening to walls, floors, ceilings, or other structures where required, interconnecting wiring of system components, equipment alignment and adjustment, and other related work whether or not expressly defined herein. Comply Install materials and equipment in accordance with applicable standards, and manufacturer requirements, recommendations and manufacturer's printed instructions. Comply Adhere to manufacturer's published specifications for pulling tension, minimum Comply bend radii, and sidewall pressure when installing cables 3. Grounding a. b. c. Grounding shall conform to ANSI/TIA/EIA 607 - Commercial Building Grounding and Bonding Requirements for Telecommunications, and manufacturer's grounding requirements as minimum Ground equipment racks, housings, messenger cables, and raceways. Connect cabinets, racks, and frames to single-point ground which is connected to building ground system via #6 AWG green insulated copper grounding conductor. Scope of MEP 4. Labelling a. b. c. Labelling shall conform to ANSI/TIA/EIA-606(A) standards. Provide labelling at each outlet, both end of the cables, Patch Panel port, patch panel, rack...etc. Labelling scheme/schedule shall be approved by client/Consultant prior to implement at site Labelling scheme/Schedule shall be reflected in as built drawings Comply 5. Submittals 1. Submit Four (4) Sets of electronic copies and (4) Sets of hard copies for all below Items 3 to 7. 2. Electronic copies shall have: • Transportation media shall be in IBM-type structure on DVD format. • A Master File List in text format shall be placed on each DVD with a short description of files in the submittal. • The shop drawings shall be in AutoCAD 2018 or later drawing (.DWG) format. Drawing Exchange File Format (.DXF) is not acceptable. All XREFs, fonts, and other drawing parts necessary shall be included. • Word processing files shall be in latest MS Word format. Graphs and charts shall be in MS Excel format. Any graphic images necessary for the reproduction of the submittals shall be included in the files, and shall be included in JPEG (.JPG) file format. • Manufacturers' data sheets, equipment manuals, and other documentation provided by the Manufacturers to the Contractor or documents that are similarly not otherwise available to the Contractor in electronic format shall be excluded from this requirement. • Detailed Network Map (High level and Low level designs) 22 Comply Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification 3. The Contractor shall provide a detailed network map to be utilized as a road map during the implementation of the Structured Cabling System. This map shall show all segments, all interconnects between segments and all active network devices. This network map shall not include the individual nodes interconnected to each concentrator but shall have the modules, interfaces, protocols, addresses and other identifying features for each concentrator and other active device. Comply 4. The Contractor shall provide a Cable Plant interconnectivity chart showing all fiber patch panels and individual identifiers for each fiber associated with the interconnectivity of each network device. Comply 5. The Contractor shall also provide a time scaled Construction Schedule indicating general project deadlines with specific dates relating to the installation of the system. At a minimum, this Construction Schedule shall include the following milestones per floor: • Equipment Installation Start Date • Equipment Installation Completion Date Comply • Equipment Testing Start Date • Equipment Testing Completion Date • Potential Slippage Periods • Contingent Tasks • Concurrent Tasks • Completion of Documentation 6. Product Data • Submit catalogue data sheets, neatly bound with title page, space for submittal stamps, and tabbed dividers between sections. List all proposed equipment with reference to corresponding specification paragraph numbers or equipment title. Comply Indicate all accepted substitutions. • Submit a schedule of finishes indicating proposed materials and color selections for all exposed items subject to Consultant selection. • Submit a list showing coordination of selected frequencies for all wireless transmitters. 7. Shop Drawings • Submit point-to-point wiring diagrams and typed wire lists identifying every connection for information. Include electronic devices such as switches, transformers, and terminal blocks. Indicate locations of all components. Identify cables by types, colors, and wire numbers. • Submit system plans showing all device locations and ceiling distributed loudspeaker layouts with wattage tap settings. • Submit conduit riser diagrams showing connection of all devices, required conduit sizes along with types and quantities of cables to be used and cable identification Comply tags. • Submit rack layouts indicating the proposed arrangement of mounted equipment including junction boxes and locations of conduit penetrations. • Submit fully dimensioned construction details of all panels, plates and other custom fabricated items or modifications (e.g. installation of audio/visual equipment in lecterns). Include complete parts lists and, as required, schematic diagrams. • Submit mounting and support details for distributed ceiling loudspeakers, and all other items mounted overhead complete with parts lists and dimensions. Include a full plan view, front elevation, and side elevation of each item with corresponding support structure and mounting hardware. Verify load ratings of all hanging components including attachment hardware. 23 Madinat Jumeirah Living – Phase 3A Design Compliance Performance Criteria Data Communication System Specification Submit electronic copies of any custom programming including source codes. Include printed copies of all control screens, wiring pages, etc. 8. Samples submit for Consultant's action. Label samples to indicate product, characteristics and locations in the work. Samples will be reviewed for color, appearance, and workmanship. Compliance with all other requirements is the exclusive responsibility of the Contractor. • Label samples to indicate product, characteristics, and locations in the Work. Samples will be reviewed for color and appearance and workmanship. Compliance with all other requirements is the exclusive responsibility of the Contractor. • Furnish samples of the following:o All exposed plates and panels for approval of color, engraving, text size and material. o All exposed equipment’s such as display trims, projector assembly panels etc. o Terminated cable samples. • 9. The Contractor shall provide the username and password for all levels (hardware, operating system, application) of each programmable device. 10. The Contractor shall provide complete TAFV project-related configuration files of programmable devices including final program /codes. 11. The Contractor shall provide the related license details and program software of systems. 12. The Contractor shall provide details of Warranty and prepare asset register with all details as per forms provided by consultant. 3.1 Product Warranty 1. Materials, workmanship and performance specifications hereinafter specified and furnished shall be fully guaranteed by the manufacturer for 20 years from transfer of title against any defects. Defects, which may occur as the result of faulty materials or workmanship within 20 years after installation and acceptance by The Customer, shall be corrected by The Vendor at no additional cost to The Customer. Comply 2. This warranty shall in no manner cover equipment that has been damaged or rendered unserviceable due to negligence, misuse, acts of vandalism, or tampering by The Customer or anyone other than employees or agents of The Vendor. The Vendor’s obligation under its warranty is limited to the cost of repair of the warranted item or replacement thereof, at The Vendor’s option Comply 3. Contractor has to provide 1-year free maintenance starting since hand over of the project. Comply 24 Comply CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 6. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 List of Proposed material with model number SCHEDULE OF PROPOSED MATERIALS S.NO MANUFACT URER PART NO DESCRIPTION QTY (PCS) REF PG NO LS SECTION 09 PG 01 330 SECTION 09 PG 06 17 SECTION 09 PG 08 17 SECTION 09 PG 30 330 SECTION 09 PG 04 LS SECTION 11 PG 10 9 SECTION 09 PG 21 9 SECTION 09 PG 30 72 SECTION 09 PG 19 144 SECTION 09 PG 17 36 SECTION 09 PG 14 LS SECTION 09 PG 10 2 SECTION 09 PG 21 2 SECTION 09 PG 30 48 SECTION 09 PG 19 48 SECTION 09 PG 17 LS SECTION 09 PG 23 48 SECTION 09 PG 26 2 SECTION 09 PG 28 2 SECTION 09 PG 30 6 SECTION 09 PG 32 1 SECTION 09 PG 32 ISP NETWORK 1 OPTERNA SCSUUTPC6ALSZHGY 2 OPTERNA SCSJAC6AUTPBK 3 OPTERNA SCSPPU24UTP10G 4 OPTERNA 5 OPTERNA SCSCMM1UBK SCSPCC6AUTP02MLSZ HGY 6 OPTERNA FCOM4TBCNA006FRL ZHV 7 OPTERNA FPSLSCSX0241B 8 OPTERNA SCSCMM1UBK 9 OPTERNA ADLCLCPCDHV 10 OPTERNA 11 OPTERNA CALCP09OM4TBL015 HV CALDP20OM4DXLLDP 030HV 12 OPTERNA FCOS2TBCNA024FRLZ YL 13 OPTERNA FPSLSCSX0241B 14 OPTERNA SCSCMM1UBK 15 OPTERNA ADSCSCACSGR 16 OPTERNA CASCA097A2TBL015Y L 17 OPTERNA SCSUTP4C6LSZHGN 18 OPTERNA SCSJAC6UTPBK 19 OPTERNA SCSPPU24UNI 20 OPTERNA SCSCMM1UBK 21 OPTERNA CABFMS27600800707 2BK 22 OPTERNA CABFMS42800100070 72BK HORIZONTAL COPPER CABLING CAT6A 23AWG U/UTP LSZH 4P CABLE 305MTR/BOX GREY 180° CAT 6A UNSHIELDED KEYSTONE JACK 19" MODULAR 10G UTP CAT6A PATCH PANEL 24 PORTS, 1U 19” CABLE MANAGER, 1U OPTERNA PATCH CORD UTP, CATEGORY 6A, STANDARD PLUG, LSZH, 2-METER, GREY BACKBONE FIBER CABLING – IDF TO MDF OPTERNA 50U 6C OM4 T/B INTERNAL CABLE, FLAME RETARDANT IEC 60332-3-24, HEATHER VIOLET LSZH JACKET OPTERNA 19" UNLOADED 1U SLIDING PATCH PANEL 24 SC SIMPLEX (LC DUPLEX) PORT - BLACK OPTERNA 19” CABLE MANAGER WITH METAL RINGS, 1U OPTERNA MM OM4 DUPLEX LC ADAPTOR, VIOLET, FLANGED OPTERNA 50U OM4 LC/PC T/BUFF FIBER 900UM PIGTAIL 1.5MTR OPTERNA OM4 DUPLEX LC/PC LC/PC PATCH CORD LSZH 3MTR, HEATHER VIOLET BULKSERVICE CONNECTION - MDF TO MTR OPTERNA 9U 24C OS2 T/B INTERNAL CABLE, FLAME RETARDANT IEC 60332-3-24, YELLOW LSZH JACKET OPTERNA 19" UNLOADED 1U SLIDING PATCH PANEL 24 SC SIMPLEX (LC DUPLEX) PORT - BLACK OPTERNA 19” CABLE MANAGER WITH METAL RINGS, 1U OPTERNA SM SIMPLEX SC/APC ADAPTOR, GREEN, FLANGED OPTERNA G657A2 SC/APC T/BUFF FIBER 900UM PIGTAIL 1.5MTR OPTERNA CAT6 SOLID 23AWG UTP LSZH 4-PAIR CABLE 305MTR/BOX, GREEN OPTERNA 180° CAT 6 UNSHIELDED KEYSTONE JACK WITH T568A/B LABEL, BLACK OPTERNA 19” MODULAR UNIVERSAL PATCH PANEL, 24 PORTS, 1U, WITHOUT MODULES, WITH REAR CABLE MANAGEMENT OPTERNA 19” CABLE MANAGER WITH METAL RINGS, 1U CABINETS OPTERNA FLOOR STANDING STEEL CABINET, 27U, 600MM (W) X 800MM (D), INCLUDING 4 FANS AND 6 WAY UNIVERSAL SOCKET PDU, FRONT GLASS DOOR, REAR SINGLE PERFORATED DOOR OPTERNA FLOOR STANDING STEEL CABINET, 42U, 800MM (W) X 1000MM (D), INCLUDING 4 FANS AND 6 23 DMEPROLINK D63210134191632PBK 24 DMEPROLINK D6325-6PDU133BK 25 HUAWEI 26 HUAWEI LST7MPUE0001 LST7SFUEX100 27 HUAWEI LST7X24BX6S0 28 HUAWEI S5735-S48T4X 29 HUAWEI S5735-L48P4X-A1 30 HUAWEI SFP-10G-CU3M 31 HUAWEI OMXD30000 32 EATON 33 EATON 34 EATON 5PX2200IRT2UG2 5PXEBM72RT2UG2 5PX3000IRT3UG2 35 EATON 5PXEBM72RT3UG2 36 EATON NETWORK-M2 37 FORCEPOIN T NGFW 60 WAY UNIVERSAL SOCKET PDU, FRONT GLASS DOOR, REAR SINGLE PERFORATED DOOR PDU COMBO VERTICAL MOUNT-TYPE, 14WAY WITH 10 (C13) SOCKETS,(10A) AND 4 (C19) SOCKETS (16A), 3M 4MM² CABLE WITH 16A,3-CORE INDUSTRIAL PLUG 250VAC WITH 2P CIRCUIT BREAKER, BLACK PDU 19" HORIZONTAL MOUNT-TYPE, 6WAY, 1U, 13AMP, 3M CABLE &,LED INDICATOR ON/OFF ROCKER SWITCH, BLACK ACTIVE FOR ICT NETORK SWITCHES S12700E MAIN CONTROL UNIT E- CORE SWITCH S12700E SWITCH FABRIC UNIT E(X1)- CORE SWITCH 24-PORT 10GE SFP+ INTERFACE AND 24-PORT GE SFP INTERFACE CARD (X6S,SFP+)- CORE SWITCH S5735-S48T4X (48*10/100/1000BASE-T PORTS, 4*10GE SFP+ PORTS, WITHOUT POWER MODULE)SERVER FARM SWITCH S5735-L48P4X-A1 (48*10/100/1000BASE-T PORTS, 4*10GE SFP+ PORTS, POE+, AC POWER) SFP+,10G,HIGH SPEED DIRECT-ATTACH CABLES,3M,SFP+20M,CC2P0.254B(S),SFP+20M,USED INDOOR OPTICAL TRANSCEIVER,SFP+,10G,MULTI-MODE MODULE(850NM,0.3KM,LC) UPS SYSTEM EATON 5PX 2200I RT2U G2 EATON 5PX EBM 72V RT2U EATON 5PX 3000I RT3U G2 EATON 5PX EXTENDED BATTERY MODUEL (EBM), 3U, 72V, GIGABIT NETWORK CARD FIREWALL SYSTEM FIREWALL SYSTEM 6 SECTION 09 PG 35 2 SECTION 09 PG 36 4 4 SECTION 09 PG 37 SECTION 09 PG 37 2 SECTION 09 PG 37 2 SECTION 09 PG 64 10 SECTION 09 PG 90 20 SECTION 09 PG 135 24 SECTION 09 PG 138 6 6 1 SECTION 09 PG 140 SECTION 09 PG 140 SECTION 09 PG 140 2 SECTION 09 PG 140 7 - 1 SECTION 09 PG 142 CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 7. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 Valid Trade License رخصة تجارية Commercial License License Details / تفاصيل الرخصة License No. رقم الرخصة 531525 Company Name )ايبام للنظمة (ش ذ م م اسم الشركة )ايبام للنظمة (ش ذ م م السم التجارى ذات مسئولية محدودة الشكل القانونى IBAM SYSTEMS )L L C( Trade Name IBAM SYSTEMS )L L C( Legal Type Limited Liability Company)LLC( Expiry Date 21/01/2023 تاريخ النتهاء D&B D-U-N-S ® No. Register No. 561287020 الرقم العالمي Issue Date رقم السجل التجارى 67468 تاريخ الصدار 22/01/2002 Main License No. 531525 رقم الرخصة الم DCCI No. 66864 عضوية الغرفة License Members / الطراف Share / الحصص Role / الصفة Nationality / الجنسية Manager / مدير Name / السم No./رقم الشخص عاشق سلم 274782 India / الهند ASHIK SALAM License Activities / نشاط الرخصة التجارية Security Equipment Installation & Maintenance تركيب الجهزة والمعدات المنية وصيانتها Internal Communication Network Installation & Maintenance Satellite Receiving Equipment Installation & Maintenance Security Control & Alarm Equipment Trading تركيب شبكات التصال الداخلي وصيانتها تركيب وصيانة معدات إستقبال القنوات التلفزيونية الفضائية تجارة أجهزة ومعدات النذار والمراقبة Address / العنوان Phone No 971-4-3397989 تليفون P.O. Box 283623 صندوق بريد Fax No 971-4-3397901 فاكس Parcel ID 358-607 رقم القطعة Mobile No 971-50-8116771 هاتف متحرك القوزالثالثة- صندوق دبى للدعم المالى212 مكتب رقم ashik@ibamsystems.com Email / البريد اللكتروني Remarks / الملحظات 27/1/2013 تم اضافة النشاط في Print Date 26/01/2022 20:28 تاريخ الطباعة Receipt No. اتصالت) للحصول/ (دو6969 أرسل رقم الرخصة إلى،يمكنك الن تجديد رخصتك التجارية من خلل الرسائل النصية القصيرة .على اذن الدفع Now you can renew your trade license by sending a text message )SMS(. Send your trade license number to 6969 )Du/ Etisalat( to receive payment voucher. 14242722 Get FREE access to Zoho One for the first year ( احصل على زوهو ون مجانا للسنة الولى رقم اليصال Zoho.com/ded لمراجعة صحة البيانات الواردة في الرخصة يرجي مسح رمزالستجابة السريعة. وثيقة إلكترونية معتمدة وصادرة بدون توقيع من دائرة القتصاد والسياحة في دبي this is a certified e-document issued without signature by the department of Economy and Tourism .Kindly Scan the QR Code to Verify the certificate CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 8. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 Local Authorities approval for the proposed material NOT APPLICABLE CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 9. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 Country of Origin Certificate COUNTRY OF ORIGIN S.NO MANUFACT URER PART NO DESCRIPTION COO ISP NETWORK HORIZONTAL COPPER CABLING 1 OPTERNA 2 OPTERNA 3 OPTERNA 4 OPTERNA 5 OPTERNA 6 OPTERNA 7 OPTERNA 8 OPTERNA 9 OPTERNA 10 OPTERNA 11 OPTERNA 12 OPTERNA 13 OPTERNA 14 OPTERNA 15 OPTERNA 16 OPTERNA 17 OPTERNA 18 OPTERNA SCSUUTPC6AL SZHGY SCSJAC6AUTP BK SCSPPU24UTP 10G SCSCMM1UB K SCSPCC6AUTP 02MLSZHGY FCOM4TBCNA 006FRLZHV FPSLSCSX0241 B SCSCMM1UB K ADLCLCPCDH V CALCP09OM4 TBL015HV CALDP20OM4 DXLLDP030HV FCOS2TBCNA 024FRLZYL FPSLSCSX0241 B SCSCMM1UB K ADSCSCACSG R CASCA097A2T BL015YL SCSUTP4C6LS ZHGN SCSJAC6UTPB K 19 OPTERNA SCSPPU24UNI 20 OPTERNA SCSCMM1UB K 21 OPTERNA CABFMS2760 08007072BK 22 OPTERNA CABFMS4280 010007072BK CAT6A 23AWG U/UTP LSZH 4P CABLE 305MTR/BOX GREY INDIA 180° CAT 6A UNSHIELDED KEYSTONE JACK TAIWAN 19" MODULAR 10G UTP CAT6A PATCH PANEL 24 PORTS, 1U TAIWAN 19” CABLE MANAGER, 1U OPTERNA PATCH CORD UTP, CATEGORY 6A, STANDARD PLUG, LSZH, 2-METER, GREY BACKBONE FIBER CABLING – IDF TO MDF OPTERNA 50U 6C OM4 T/B INTERNAL CABLE, FLAME RETARDANT IEC 60332-3-24, HEATHER VIOLET LSZH JACKET OPTERNA 19" UNLOADED 1U SLIDING PATCH PANEL 24 SC SIMPLEX (LC DUPLEX) PORT - BLACK CHINA CHINA CHINA CHINA OPTERNA 19” CABLE MANAGER WITH METAL RINGS, 1U CHINA OPTERNA MM OM4 DUPLEX LC ADAPTOR, VIOLET, FLANGED CHINA OPTERNA 50U OM4 LC/PC T/BUFF FIBER 900UM PIGTAIL 1.5MTR OPTERNA OM4 DUPLEX LC/PC LC/PC PATCH CORD LSZH 3MTR, HEATHER VIOLET BULKSERVICE CONNECTION - MDF TO MTR OPTERNA 9U 24C OS2 T/B INTERNAL CABLE, FLAME RETARDANT IEC 60332-3-24, YELLOW LSZH JACKET OPTERNA 19" UNLOADED 1U SLIDING PATCH PANEL 24 SC SIMPLEX (LC DUPLEX) PORT - BLACK CHINA CHINA CHINA CHINA OPTERNA 19” CABLE MANAGER WITH METAL RINGS, 1U CHINA OPTERNA SM SIMPLEX SC/APC ADAPTOR, GREEN, FLANGED CHINA OPTERNA G657A2 SC/APC T/BUFF FIBER 900UM PIGTAIL 1.5MTR OPTERNA CAT6 SOLID 23AWG UTP LSZH 4-PAIR CABLE 305MTR/BOX, GREEN OPTERNA 180° CAT 6 UNSHIELDED KEYSTONE JACK WITH T568A/B LABEL, BLACK OPTERNA 19” MODULAR UNIVERSAL PATCH PANEL, 24 PORTS, 1U, WITHOUT MODULES, WITH REAR CABLE MANAGEMENT OPTERNA 19” CABLE MANAGER WITH METAL RINGS, 1U CABINETS OPTERNA FLOOR STANDING STEEL CABINET, 27U, 600MM (W) X 800MM (D), INCLUDING 4 FANS AND 6 WAY UNIVERSAL SOCKET PDU, FRONT GLASS DOOR, REAR SINGLE PERFORATED DOOR OPTERNA FLOOR STANDING STEEL CABINET, 42U, 800MM (W) X 1000MM (D), INCLUDING 4 FANS AND 6 WAY UNIVERSAL CHINA CHINA CHINA CHINA CHINA CHINA CHINA DME23 PROLINK 24 DMEPROLINK 25 HUAWEI 26 HUAWEI 27 HUAWEI 28 HUAWEI 29 HUAWEI 30 HUAWEI 31 HUAWEI 32 EATON 33 EATON 34 EATON 35 EATON 36 EATON D63210134191632 PBK D63256PDU133BK LST7MPUE00 01 LST7SFUEX10 0 LST7X24BX6S 0 S5735-S48T4X S5735L48P4X-A1 SFP-10GCU3M OMXD30000 5PX2200IRT2 UG2 5PXEBM72RT 2UG2 5PX3000IRT3 UG2 5PXEBM72RT 3UG2 Network-M2 SOCKET PDU, FRONT GLASS DOOR, REAR SINGLE PERFORATED DOOR PDU Combo Vertical Mount-Type, 14way with 10 (C13) Sockets,(10A) and 4 (C19) Sockets (16A), 3m 4mm² Cable with 16A,3-core Industrial Plug 250VAC with 2P circuit breaker, Black PDU 19" Horizontal Mount-Type, 6way, 1U, 13amp, 3m Cable &,Led Indicator On/Off Rocker Switch, Black ACTIVE FOR ICT NETORK SWITCHES S12700E main control unit E- core switch S12700E switch fabric unit E(X1)- core switch 24-port 10GE SFP+ interface and 24-port GE SFP interface card (X6S,SFP+)- core switch S5735-S48T4X (48*10/100/1000BASE-T ports, 4*10GE SFP+ ports, without power module)-server farm switch S5735-L48P4X-A1 (48*10/100/1000BASE-T ports, 4*10GE SFP+ ports, PoE+, AC power) SFP+,10G,High Speed Direct-attach Cables,3m,SFP+20M,CC2P0.254B(S),SFP+20M,Used indoor Optical Transceiver,SFP+,10G,Multi-mode Module(850nm,0.3km,LC) UPS SYSTEM Eaton 5PX 2200i RT2U G2 Eaton 5PX EBM 72V RT2U Eaton 5PX 3000i RT3U G2 Eaton 5PX extended battery moduel (EBM), 3U, 72V, Gigabit Network Card CHINA CHINA CHINA CHINA CHINA CHINA CHINA CHINA CHINA CHINA/ PHILIPINES CHINA/ PHILIPINES CHINA/ PHILIPINES CHINA/ PHILIPINES - CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 10. Quality Assurance and Third-Party Certification CERTIFICATE OF REGISTRATION This is to certify that the Management System of IBAM Systems LLC P.O. Box:283623, AI Quoz Industrial Area 1, Dubai, United Arab Emirates. has been assessed and registered by Veritas Assurance International as conforming to the requirements of ISO 14001 :2015 Environmental Management System The Environmental Management System is applicable to : - Security Equipment Installation & Maintenance. - Satellite Receiving Equipment Installation & Maintenance. - Internal Communication Network Installation & Maintenance. - Security Control & Alarm Equipment Trading. Certificate No : 321182084 Certificate issue date : 05-1 0-2021 I Certificate expiry date : 04-1 0-2024 1" Surveillance due before : 04-10-2022 1'l!" Surveillance due before : 04-10-2023 Authorised Signatory Yer.ita.s Assuta nee. .lntetlliltional Accredited by : UAF (United Accreditation Foundation) Member of IAF (International Accreditation Forum) www.veritasassurance.com RE!I!istered Accreditation Office: 400 North Center DR, STE 202, Norfolk, VA 23502. United States of America (USA) This certificate remains valid while the hokler maintains the management system in accordance with the standard(s} above, which will be periodicaHy audited by Veritas Assurance International. This certificate remains the property of Veritas Assurance International and must be returned on request. In the issuance of this certificate, Veritas Assurance International assumes no liability to any party other than to the client, and then only in accordance with the agreed upon certtftcaHon agreement. Validity of this certificate may be confirmed at www.veritasassurance.com, directly through OR code by using any device with correct information or email to admin@veritasassurance.com. 76 77 78 79 80 81 CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 11. Original Product Catalogue Data Sheet DSCU02013AR Copper Structured Cabling, Cable, CAT6A U/UTP, Indoor Features and benefits Category 6A/Class EA compliant Compliant to ISO/IEC 11801 Ed 2.2, ANSI/TIA568-C.2, EN 50173-1 IEC 61156-5, EN 50288-11-1 IEC 60332-1-2, IEC 60754-2, IEC 61034-2 Reliable performance Super-standard performance margin Description Opterna Category 6A 4-pair U/UTP copper cable forms the foundation of 10 Gigabit Ethernet networks. The cable exceeds Category 6A performance ensuring reliability in delivering 10G network speed, low BER and high data throughput. Opterna 4 pair category 6A solid cables (U/UTP) has been designed for indoor applications fully supporting the more demanding office and industrial communications requirements including voice, data, VoIP, Video Conferencing, security, IP based cameras and other demanding real-time applications. rized up to 500 MHz suitable for transmitting data over local area networks (LANs). -Pairs) are of solid bare copper with high density polyethylene (HDPE) insulation and a PVC/LSZH jacket. The two insulated conductors are twisted together to form a pair and the four pairs with different twist ratio are laid up to form the basic cable unit. Applications Horizontal Distribution and Backbone Cabling 4/16 Mbps Token Ring (IEEE 802.5) 10/100/1000/10G BASE-T (IEEE 802.3) 155/622 Mbps & 1.2 GB ATM 100 Mbps TP-PMD Analogue Voice, ISDN, ADSL HVAC alarm systems and other signalling Standards UL 444 ANSI/TIA-568-C.2 ISO/IEC 11801:2011 (Ed 2.2) Class EA CENELEC EN 50173-1:2011 IEC 61156-5 EN 50288-11-1 Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 1 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSCU02013AR Technical data Mechanical data Dimensions (W x D x H) Material Value See technical drawing Conductor material - Solid bare copper Conductor insulation - HDPE Cable jacket - PVC/LSZH 23 AWG 1.03 0.03 mm 7.8 0.2 mm 0.52mm 0.3 mm 110N 8 times outer diameter Conductor diameter Insulated conductor diameter Outer cable diameter Jacket thickness Pulling strength Minimum bend-radius Fire rating PVC jacket LSZH jacket IEC60332-1-2 IEC 60332-1-2, IEC 60754-1,2 & IEC 61034-2 Electrical data Frequency (MHZ) RL ( dB) ATT 20 C ( dB) NEXT ( dB) PS NEXT ( dB) ELFEXT ( dB) PSELFEXT ( dB) 1 4 8 10 16 20 25 31.25 62.5 100 200 250 300 400 500 20.0 23.0 24.5 25.0 25.0 25.0 24.3 23.6 21.5 20.1 18.0 17.3 16.8 15.9 15.2 1.9 3.8 5.3 5.9 7.5 8.4 9.4 10.5 15.0 19.1 27.6 31.1 34.3 40.1 45.3 74.3 65.3 60.8 59.3 56.2 54.8 53.3 51.9 47.4 44.3 39.8 38.3 37.1 35.3 33.8 72.3 63.3 58.8 57.3 54.2 52.8 51.3 49.9 45.4 42.3 37.8 36.3 35.1 33.3 31.8 68.0 56.0 49.9 48.0 43.8 42.0 40.0 38.1 32.1 28.0 22.0 20.0 18.5 16.0 14.0 65.0 53.0 46.9 45.0 40.9 39.0 37.0 35.1 29.1 25.0 19.0 17.0 15.5 13.0 11.0 Electrical characteristics DC resistance max DC resistance unbalance Mutual capacitance Capacitance unbalance pair Impedance 1-250 MHz Propagation delay Dielectric strength Propagation delay skew Insulation resistance Nominal velocity of propagation Middle East +971 4 299 7676 sales.me@opterna.com PSANEXT ( dB) PSAELFEXT ( dB) 67.0 67.0 67.0 67.0 67.0 67.0 67.0 67.0 65.6 62.5 58.8 56.5 55.3 53.5 52.0 67.0 66.2 60.1 58.2 54.1 52.2 50.2 48.3 42.3 38.2 32.2 30.2 28.7 26.2 24.2 Value 9.38 Ohm/100m Max 5% Max 5.6 nF/100m Max 330pF/100m 100 15 Max. 534 ns/100m@ 500 MHz DC KV/sec. 2.5/2 Max 45 ns/100m Min.5000 69% Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 2 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 Data Sheet DSCU02013AR Environmental data Temperature range Operation Value -20 C to +75 C Technical drawing Ordering information Description Unshielded Twisted Pair Cable (U/UTP), Category 6A, 4 Pairs, solid PVC, 305m box Unshielded Twisted Pair Cable (U/UTP), Category 6A, 4 Pairs, solid LSZH, 305m box Part code SCS-UUTP-C6A-PVC-GY SCS-UUTP-C6A-LSZH-GY Also, available in Black (BK), Blue (BL), Green(GN), Orange (OR), Red (RD), White (WH), Yellow (YL) for bulk orders Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 3 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 3 Data Sheet DSCU03007AR Copper Structured Cabling, Patch cord, CAT6A, U/UTP Features and benefits Molded strain relief snag-less boot 8-pin high quality RJ45 plugs with 50-micron gold plated contacts Cable constructed from stranded wire for flexibility and minimum crosstalk Compliant to ISO/IEC 11801 Ed 2.2, ANSI/TIA-568-C.2, EN 50173-1 IEC 61156-6, EN 50288-10-2 IEC 60332-1-2, IEC 60754-2, IEC 61034 Reliable performance Super-standard performance margin Description Opterna UTP Patch cords conform to ANSI/TIA/EIA-568-C.2, ISO/IEC 11801:2011 edition 2.2 and CENELEC EN 50173 (2011) for Category 6A/Class EA applications. The products have been tested up to 500 MHz and are designed for high speed protocols such as 10 Gigabit Ethernet (10G) applications. The patch cords are constructed of a U/FTP stranded wire cable and comprises two modular plugs at both ends of the cables. The U/FTP cable eliminate alien-crosstalk near the panel end. The RJ45 plugs are protected with molded snag-less boots that prevents the latch on the RJ45 plugs from getting damaged during installation. Applications Cross connect, Patch Panel and Work Area 4/16 Mbps Token Ring (IEEE 802.5) 10/100/1000 BASE-T,10G (IEEE 802.3) 155 Mbps ATM 100 Mbps TP-PMD Analogue Voice, ISDN, ADSL Standards ANSI/TIA-568-C.2 ISO/IEC 11801:2011 (Ed 2.2) Class EA CENELEC EN 50173-1:2011 ANSI/TIA-1096-A (formerly FCC Part 68) IEC 60603-7-41 Technical data Mechanical data Dimensions (W x D x H) Middle East +971 4 299 7676 sales.me@opterna.com Value See technical drawing Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 4 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSCU03007AR Cable construction Number of pairs Colors of twisted pairs Material Conductor diameter Plugs Fire resistance Total contact force Retention Insertion/extraction Insulation resistance Dielectric withstanding voltage Contact resistance Category 6A U/FTP 4 Blue-white/blue, Orange-white/orange, Green-white/green, Brown-white/brown Conductor material - Stranded copper conductor Conductor insulation - HDPE Contact - Phosphor Bronze contact area is plated with 50microinches of Gold Over 100 micro-inches of Nickel Molded boot - Fire retardant PVC/LSZH compounds Cable jacket - PVC/LSZH Cable Diameter - <6.35mm 26 AWG, 7 stranded copper wire conductors RJ45 8P8C 94V0 Flame retardant PC CMG 800 grams 50N 750 cycles minimum 1000V d.c 20m Max. Environmental data Temperature range Operation Storage Relative humidity (operational) Value -10 C to +60 C - 40 C to +70 C Maximum non-condensing 93% Technical drawing Ordering information Description Patch cord UTP, category 6A, standard plug, PVC Patch cord UTP, category 6A, standard plug, LSZH yy xx Part code SCS-PC-C6A-UTP-yyM-PVC-xx SCS-PC-C6A-UTP-yyM-LSZH-xx length:0.5m,1m,1.5m,2m,3m,5m,10m color: Black (BK), Blue (BL), Green (GN), Gray (GY), Orange (OR), Red (RD), White (WH), Yellow (YL) Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 5 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 Data Sheet DSCU04007AR Copper Structured Cabling, Keystone Jack, CAT6A UTP Features and benefits Category identification on the front side of the jack 50-micron gold plated contacts Universal color-coding according to T568A and T568B Suitable for 110 and Krone type tools IDC contacts that allow re-termination for wiring changes without damaging the unit IDC termination point at 180° to jack Metallic wire retaining caps for strain relief and eliminating alien-crosstalk Mounts in faceplates or patch panels Compatible with a wide range of international faceplates Characterized up to 500 MHz Description Opterna category 6A unshielded jacks are designed and manufactured to meet or exceed the current and future requirements for high bandwidth and forms an essential element of the structured cabling system. Compatible with 24-port snap-in UTP patch panels and together with high quality performance, the category 6A UTP jack provides flexibility for your field installation together with high quality performance. The jack also forms part of the faceplate. Metallic wire retaining caps are supplied which provide additional cable strain relief and eliminates aliencrosstalk. The keystone jacks are color-coded for both 568A and 568B standards and can be terminated using a standard 110 or Krone type punch down termination tool. Applications Horizontal Distribution and Backbone Cabling 4/16 Mbps Token Ring (IEEE 802.5) 10/100/1000/10G BASE-T (IEEE 802.3) 155/622 Mbps & 1.2 GB ATM 100 Mbps TP-PMD Analogue Voice, ISDN, ADSL HVAC alarm systems and other signalling Standards ANSI/TIA-568-C.2 ISO/IEC 11801:2011 (Ed 2.2) Class EA CENELEC EN 50173-1:2011 Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 6 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSCU04007AR ANSI/TIA-1096-A (formerly FCC Part 68) IEC 60603-7-41 Technical data Mechanical data Dimensions (W x D x H) Material Total contact force Retention Insertion/extraction Electrical characteristics Current rating DC resistance Contact resistance Insulation resistance Voltage rating Dielectric Withstanding Voltage IDC Wire Gauge Value See technical drawing Housing UL 94 V0 High impact flame retardant plastic Jack contacts Phosphor bronze plated (50 micro-inch gold over 100 micro-inch nickel) IDC contacts - Phosphor bronze with 100 micro-inch tin 800 grams 50N 750 cycles minimum Value 1.5 Amps 200 m max (per pin) 2.5m max (IDC) 20 m max (insert) 60V 1000V, RMS @ 60Hz for 1 minute 22-26 AWG Environmental data Temperature range Storage Operation Relative Humidity (operational) Value -40 C to +70 C -10 C to +60 C Maximum non-condensing 93% Technical drawing Ordering information Description 180° Cat 6A Unshielded Keystone jack with T568A/B label, Black Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 7 2104 779 +91 (0) 484 sales.ap@opterna.com Part code SCS-JA-C6A-UTP-BK Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 Data Sheet DSCU05007AR Copper Structured Cabling, Patch Panel, 10G, UTP Features and benefits Rack mounted snap-in CAT 6A patch panel provides excellent performance for high speed networks Numerical marking of ports on the front side of the panel Integral rear plastic cable management Modern design and simplified mounting Suitable for 10G category 6A UTP keystone jacks Unused ports can be covered with blanking modules Description Opterna snap-in type UTP patch panel is designed for customized connectors. Based on your design requirements, you can snap your preferred connectors in and make your own style patch panel. The 10G patch panel has a staggered front port as well as staggered rear cable management to minimize alien crosstalk between jacks and cables and to achieve peak 10G performance. The evenly designed patch panel provides an efficient and effective method of reducing alien crosstalk (AXT) from neighbouring connectors. Applications Suitable for UTP keystone jacks Height: 1U (24 ports), 2U (48 ports) Standards ANSI/TIA-568-C.2 ISO/IEC 11801:2011 (Ed 2.2) Class EA CENELEC EN 50173-1:2011 UL 94 V-0 Technical data Mechanical data Dimensions (W x D x H) Material Middle East +971 4 299 7676 sales.me@opterna.com Value See technical drawing Housing Steel 1.5mm Front mounting UL94 V-0 Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 8 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSCU05007AR Technical drawing Ordering information Description Part code SCS-PPU-24-UTP-10G management Blanking Plug, Keystone Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com SCS-PPU-BLNK Asia Pacific 9 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 Data Sheet DSFO02011AR Fiber Optic, Tight Buffer cable, aramid yarns, 900 microns Features and benefits Fiber-count 2-144 fibers 900 microns buffered design for easy termination Tight buffered construction LSZH compliance for riser application OS2, OM3 and OM4 performance types Color-coded fibers for easy identification Compact design for limited conduit space RoHS compliant Description Opterna fiber optic tight buffered cables are rugged, high performance optical communication cables suitable for inside plant installations. These cables are ideally used in backbone or computer room / data center cabling. The fiber optic tight buffered cable contains 2 to 144 fibers individually buff buffer construction and color coded as per Telcordia requirements. m in a tight The cable structure depends on the number of fibers and is available as an individual and subunit construction. The 2 to 24 fiber cables contain individual 90 fibers without sub-units, the individual fibers are protected by aramid yarn, contains a rip cord and an overall jacket. In the 18 to 36 fiber cables, the fibers are grouped into sub-units which are laid helically along the cable axis. Each sub-unit contains 6 fibers surrounded by glass yarn, ripcord and an overall jacket. The 48 ~ 144 fiber cable consists of twelve fibers in each sub-unit. The cable is available in a wide range of jacket such as LSZH, riser grade and plenum. A ripcord is located under the sub-unit and outer jacket to facilitate jacket removal. Applications Data centers Indoor riser backbone applications Standards ITU.T G.652D / G.657A/B / G.651.1 ANSI/TIA-568-C.3 / ISO/IEC 11801 IEC 60793 / IEC 60794 IEC 60332-1-2, IEC 60332-3-24, IEC 60754-1,2 & IEC 61034-2 Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 10 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSFO02011AR Specifications Optical Characteristics: Singlemode Fiber Type Wavelength Attenuation Chromatic dispersion Zero dispersion wavelength Zero dispersion slope PMD Cut-off wavelength Mode-field diameter 30mm radius x 100 turns 15mm radius x 10 Macro turns Bend 10mm radius x 1 Loss turns 7.5mm radius x 1 turns Core/Clad Concentricity Error Cladding Diameter Cladding Non-circularity Coating Diameter Proof Test Level Fiber curl OS2 - G.652D, G.657A/B Unit OS2 G.652D nm dB/km Ps/nm.km nm ps/nm2.km 1310 G.657A 1550 1310 1300 ~ 1324 G.657B 1550 0.21 1310 1300 ~ 1324 1550 1300 ~ 1324 nm 9.2 ± 0.4 10.4 ± 0.5 - 8.6 ± 0.4 8.6 ± 0.4 - - - 0.05 - - - - - - - - - 0.25 (A1) 0.03 (A2) 0.75 (A1) 0.1 (A2) dB 0.8 125 ± 1 1.0 245 ± 15 % % Kpsi M 10.4 ± 0.5 0.5(A2) 0.6 125 ± 1 1.0 245 ± 15 10.4 ± 0.5 0.03(B2) 0.03 (B3) 0.1 (B2) 0.08 (B3) 0.5 (B2) 0.15 (B3) 0.6 125 ± 1 1.0 245 ± 15 - Specifications Optical Characteristics: Multimode - 62.5 Fiber Type Wavelength Attenuation Over filled Launch Bandwidth (LED based sources) Effective Modal Bandwidth (850 nm Laser based sources) Numerical aperture Core diameter Core Non-Circularity Cladding diameter Cladding Non-Circularity Core / Cladding Concentricity Error Coating diameter Proof test level nm dB/km OM1 850 1300 3.5 1.0 0M2 850 1300 3.0 1.0 0M3 850 1300 3.0 1.0 0M4 - - 0.275 ± 0.015 62.5 ± 3.0 0.20 ± 0.015 50 ± 3.0 0.20 ± 0.015 50 ± 3.0 0.20 ± 0.015 50 ± 3.0 125 ± 2.0 125 ± 2.0 125 ± 2.0 125 ± 2.0 850 3.0 1300 1.0 MHz.km MHz.km % % 2.0 2.0 2.0 2.0 3.0 3.0 3.0 3.0 245 ± 5.0 245 ± 5.0 245 ± 5.0 245 ± 5.0 kpsi Cable construction Construction of single unit cables Number of fibers Type of fiber Tight Buffer Coating Dielectric Strength Member Ripcord Material Middle East +971 4 299 7676 sales.me@opterna.com 2-24 Singlemode 9/125 m (OS2 G.652D), G.657A1/A2, B1, B2 Multimode 62.5/125 m (OM1), 50/125 m (OM2, OM3, OM4) Outer diameter: 900 50 m Aramid yarn One ripcord (for 6 - 24 fiber cable) LSZH Compound Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 11 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 Data Sheet DSFO02011AR Outer Jacket Material Nominal 1.0mm for 2 ~ 12 F Nominal 1.5mm for 2 ~ 24 F Thickness Cable construction Construction of multi-unit cables Number of fibers Type of fiber Tight Buffer Coating No. of tight buffers Sub-unit Dielectric strength member Sub-unit jacket Dielectric strength member Ripcord Material Outer Jacket Material Thickness 36-144 Singlemode 9/125 m (OS2 G.652D), G.657A1/A2, B1, B2 Multimode 62.5/125 m (OM1), 50/125 m (OM2, OM3, OM4) Outer diameter: 900 50 m 6 Fiber: For 18 ~ 36 Fiber Cable 12 Fiber: For 48 ~ 144 Fiber Cables Aramid yarn LSZH compound FRP or FRP with LSZH coating One ripcord LSZH Compound Nominal 1.5mm Color of buffer No. Color 1 Blue 2 Orange 3 Green 4 Brown 5 Grey 6 White 7 Red 8 Black 9 Yellow 10 Violet 11 Pink 12 Aqua No. Color 13 Blue 14 Orange 15 Green 16 Brown 17 Grey 18 White 19 Red 20 Black 21 Yellow 22 Violet 23 Pink 24 Aqua Jacket colors No. SM OM1/OM2 OM3 OM4 Color Yellow Orange Aqua Heather Violet RAL RAL 1018 RAL 2003 RAL 6027 RAL 4003 Transmission performance Application 100Base-FX, Ethernet, @ 1300nm 100Base-LX, @ 1310nm 1000Base-SX, Gigabit, Ethernet @850nm 100Base-LX, Gigabit Ethernet, @1310nm 10GBase-SR, 10Gbps @ 850nm 10GBase-LR, 10Gbps @ 1310nm 40GBase-SR, 40Gbps @ 850nm 40GBase-LR4, 40Gbps @ 1310nm 100GBase-SR10, 100Gbps @ 850nm 100Base-LR4, 100Gbps, @ 1310nm 100Base-ER4, 100Gbps, @ 1550nm OS1/OS2 Singlemode (1310/1383/1550) 10000m 10000m 10000m 10000m 10000m 30000m OM1 Multimode (850/1300) 2000m 275m 550m 33m - OM2 Multimode (850/1300) 2000m 550m 550m 82m - OM3 Multimode (850/1300) 2000m 550m 550m 300m 100m 100m - OM4 Multimode (850/1300) 2000m 550m 550m 550m 150m 150m - Environmental data Temperature range Storage Installation Operation Middle East +971 4 299 7676 sales.me@opterna.com Value - 30 C to +60 C - 10 C to +60 C - 20 C to +60 C Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 12 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 3 Data Sheet DSFO02011AR Mechanical specifications Tensile Load / Strength IEC 60794-1-2-E1 Crush Resistance IEC 60794-1-2-E3 Impact Resistance IEC 60794-1-2-E4 Torsion Test Cable Bend Temperature Cycling IEC 60794-1-2-E7 IEC 60794-1-2-E11 IEC 60794-1-2-F1 Single unit: 2~12F, 400N for 30 minutes 18~24F, 400N for 30 minutes Multi-unit: 18~144F, 400N for 30 minutes Single unit: 2 ~ 18F, 500N/10 cm for 10 minutes 24F, 1000N/10cm for 10 minutes Multi-unit: 24~ 144F, 1000N/10 cm for 10 minutes 1 impacts @ 3 points, 1Nm /1J Radius of impact mass12.5mm ± 180°, ± 1 turn/2m 20 D for 4 turns, 10 Cycles -20° - Physical specifications Construction No. of fibers Nominal cable diameter Nominal weight mm 4.5 5.3 5.7 6.0 6.4 8.5 9.8 14.8 17.1 18.7 22.5 26.2 29.8 Kg/km 20 25 30 35 40 70 90 185 250 270 425 565 645 2 4 6 8 12 16 24 24 36 48 72 96 144 Single-Unit Multi-Unit Maximum tensile load Short term Long term N 400 400 400 400 400 400 400 400 400 400 400 400 400 N 165 165 165 165 165 330 330 375 330 330 330 330 330 Crush load Short term N/cm 500 500 500 500 500 500 500 500 500 500 500 500 500 Long term N/cm 200 200 200 200 200 200 200 200 200 200 200 200 200 Maximum bend radius Under No load load mm mm 20 x 10 x 10 x 20 x 10 x 20 x 20 x 10 x 10 x 20 x 10 x 20 x 20 x 10 x 20 x 10 x 10 x 20 x 20 x 10 x 10 x 20 x 20 x 10 x 10 x 20 x Part numbers Description Part code Fiber Optic tight buffered cable, 900 µm aramid yarns strength member, LSZH jacket FC-xxx-TBC-NA-yyy-FRLZ-zz xxx = OS1, OS2, 7A1, 7A2, 7B2, 7B3, 655, OM1, OM2, OM3, OM4 yyy = Number of Cores zz = YL, OR, AQ, HV Standard reel length 4000m Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 13 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 4 Data Sheet DSFO03001AR Fiber Optic, Patch cords Features and benefits Available with all fiber optic connector types High quality ferrules and housings Low insertion loss and high return loss Individual test results and traceability number Mating Durability: 1000 cycles; <0.2 dB change IEC, EIA/TIA and GR-326-CORE compliant Customized on request Description Opterna offers high performance patch cords for use in all types of fiber optic networks. The Opterna patch cords are manufactured using state-of-the-art controlled manufacturing processes to operate over the full range of singlemode and multimode wavelengths. Opterna patch cords are terminated with high quality connectors, which provide low insertion loss and high return loss. Each patch cord is individually tested and supplied with test certificates. The unique serial number provides traceability of every single product. Available in all types of singlemode and multimode fiber types. Applications All types of FTTH networks and Enterprise networks Standards ITU.T G.652D / G.657A/B / G.651.1 ANSI/TIA-568-C.3 / ISO/IEC 11801 IEC 60793 / IEC 60794 IEC 60332-1-2, IEC 60754-1,2 & IEC 61034-2 Technical data Optical data Fiber type Connector Insertion Loss* Connector Return Loss* Value OS2, G657A1, G657A2, G657B2, G657B3, OM1, OM2, OM3, OM4 0.3dB for SC, LC, FC, ST, E2000; 0.7dB for MTRJ 50dB UPC, 60dB APC *Different specifications available on request Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 14 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSFO03001AR Environmental data Description Operating temperature Free of halogen 2011/65/EC RoHS Value -40C to +70C Yes (when LSZH cable is specified) Fully compliant Technical Drawing Description Length of assembly (L) Value L -0/+100mm (for L<0.5.m) L -0/+150mm (for 0.5m>L<5m) L -0/+200mm (for L>5m) 150 ± 25mm 200 ± 25mm (from one end) Split length (L1) Traceability label distance (l2) Ordering information CA 1 1. 2. 2 Connector A SC = SC connector SD = SC duplex ST = ST connector FC = FC connector LC = LC connector LD = LC duplex MT = MTRJ E2 = E2000 MU = MU simplex MD = MU duplex FD = FDDI ES = ESCON SMA = SMA SS = Shuttered SC Connector A finish P = PC Middle East +971 4 299 7676 sales.me@opterna.com 4 3 3. 4. Cable diameter 12 = 1.2mm 16 = 1.6mm 18 = 1.8mm 20 = 2.0mm 28 = 2.8mm 09 = 900um Fiber type OM1 = OM1 OM2 = OM2 OM3 = OM3 OM4 = OM4 OS2 = SM G652D 7A1 = SM G657A1 7A2 = SM G657A2 7B2 = SM G657B2 7B3 = SM G657B3 Americas (703) 653-1130 sales.us@opterna.com 5 6 7 8 5. Cable type SX = Simplex DX = Duplex 6. Material L = LSZH V = PVC R = Riser P = Plenum 7. Connector B SC = SC connector SD = SC duplex ST = ST connector FC = FC connector LC = LC connector LD = LC duplex MT = MTRJ Asia Pacific 15 2104 779 +91 (0) 484 sales.ap@opterna.com 9 10 8. Connector B finish P = PC U = UPC A = APC 9. Cable length 010 = 1.0m 015 = 1.5m 150 = 15.0m 10. Cable colour BL = Blue YL = Yellow WH = White OR = Orange AQ = Aqua HV = Heather Violet Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 Data Sheet DSFO03001AR U = UPC A = APC Middle East +971 4 299 7676 sales.me@opterna.com 655 = SM G655 656 = SM G656 Americas (703) 653-1130 sales.us@opterna.com E2 = E2000 MU = MU simplex MD = MU duplex FD = FDDI ES = ESCON SMA = SMA SS = Shuttered SC Asia Pacific 16 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 3 Data Sheet DSFO03033AR Fiber Optic, Pigtails Features and benefits 900µm buffered fiber; available in other diameter Available with all fiber optic connector types High quality ferrules and housings Low insertion loss and high return loss 100% optical tested with individual test results and traceability number Mating Durability: 1000 cycles; <0.2 dB change IEC, TIA and GR-326-CORE compliant Description Opterna fiber optic pigtails are manufactured using state-of-the-art controlled manufacturing processes with superior quality connectors and are factory polished to provide low insertion loss and low back reflection. The Pigtails are available in SC, LC, ST, FC and MTRJ type connector versions with both singlemode and multimode 900µm buffered fiber types. All pigtails are 100% factory tested for insertion loss after polishing. Each pigtail is individually tested and supplied with test certificates. The unique serial number provides traceability of every single product. Applications Suitable for fusion or mechanical splicing All types of FTTH networks and Enterprise networks Standards ITU.T G.652D / G.657A/B / G.651.1 ANSI/TIA-568-C.3 / ISO/IEC 11801 IEC 60793 / IEC 60794 IEC 60332-1-2, IEC 60754-1,2 & IEC 61034-2 Technical data Optical data Fiber type Connector Insertion Loss* Connector Return Loss* Value G.652D, G.657A1, G.657A2, G.657B2, G.657B3, G.655, G.656 OM1, OM2, OM3, OM4 0.3dB for SC, LC, FC, ST, E2000; 0.7dB for MTRJ *Different specifications available on request Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 17 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSFO03033AR Environmental data Description Operating temperature Free of halogen 2011/65/EC RoHS Value -40C to +70C Yes (when LSZH cable is specified) Fully compliant Technical Drawing Description Length of assembly (L) Value L -0/+100mm (for L<0.5.m) L -0/+150mm (for 0.5m>L<5m) L -0/+200mm (for L>5m) 200 ± 25mm (from one end) Traceability label distance (l2) Ordering information CA 1 1. 2. 2 Connector SC = SC connector ST = ST connector FC = FC connector LC = LC connector MT = MTRJ E2 = E2000 MU = MU connector FD = FDDI ES = ESCON SMA = SMA Connector finish P = PC U = UPC A = APC Middle East +971 4 299 7676 sales.me@opterna.com 4 3 3. Cable diameter 12 = 1.2mm 16 = 1.6mm 18 = 1.8mm 20 = 2.0mm 28 = 2.8mm 09 = 900um 06 = 600um 02 = 250um 5 6 5. Cable type SX = Simplex TB = Tight buffered ES = Easy strip LT = Loose tube 6. Material L = LSZH V = PVC R = Riser P = Plenum 7. Cable length 010 = 1.0m 015 = 1.5m 150 = 15.0m 4. Fiber type OM1 = OM1 OM2 = OM2 OM3 = OM3 OM4 = OM4 OS2 = SM G652D 7A1 = SM G657A1 7A2 = SM G657A2 7B2 = SM G657B2 7B3 = SM G657B3 655 = SM G655 656 = SM G656 Americas (703) 653-1130 sales.us@opterna.com 8 7 Asia Pacific 18 2104 779 +91 (0) 484 sales.ap@opterna.com 8. Cable colour BL = Blue YL = Yellow WH = White OR = Orange AQ = Aqua HV = Heather Violet Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 19 20 Data Sheet DSFO06005AR Fiber Optic, Patch Panel, Sliding (unloaded) Features and benefits Fast and easy access to front and read connectors Wide range of connector types (SC and LC standard) Suitable for pigtail splicing or IFC Breakout cables Wide range of cable types can be installed at the rear Various anchoring points for incoming cables Clear port identification strip on front plate Fiber-management kits and splice cassette are offered as accessories All panels are available pre-loaded with adapters, pigtails and splice accessories Description esigned to facilitate internal fiber management and also to maximize fiber density in 1U, 2U and 4U height increments. The sliding tray provides easy access to fi applications. The panel supports 24 way, 48 way and 96 way configurations in SC Simplex, SC Duplex, ST/FC (D cut out), LC Duplex (SC simplex foot print), LC Quad (SC Duplex foot print). Versions are available with MTP MPO cut-outs on the back for use with pre-terminated MTP/MPO trunks. Technical data Mechanical data Dimensions (W x D x H) Material Height variants Value See technical drawing Steel powder-coated 1U,2U and 4U Technical drawing Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 21 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSFO06005AR Ordering information FPSL- 1. 2. 1 2 3 4 Select cut-out type SCSX- = SC simplex SCDX- = SC duplex DCSX-out 3. Number of fibers per panel 4. 1 = 1U 2 = 2U 4 = 4U Select panel colour 012 = 12 fibers G = Gray powder coated 024 = 24 fibers 048 = 48 fibers B = Black powder coated Accessories Universal splice cassette for two splice holders, unloaded Part code OPFC-STGR24 Cover for splice cassette Holder for 12 ANT sandwich splice protectors Holder for 6 heatshrink splice protectors Stacking hinge for OPFC-STGR24 12-way stackable splice cassette with splice holder and cover (180mm x 108mm x 13mm) 24-way stackable splice cassette with splice holder and cover (225mm x 108mm x 13mm) 24-way stackable splice cassette with splice holder and cover (160mm x 105mm x 10mm) 24-way splice bridge with adhesive strip and cover PG13.5 (5-9mm) cable gland and nut, black nylon material PG16 (10-14mm) cable gland and nut, black nylon material Bunny clip Fiber management kit consisting of 1 x FP-AC-CG-13B and 8 x FP-AC-BC SC simplex blanking plug SC duplex blanking plug ST/FC simplex blanking plug 60mm x 3mm heatshrink splice sleeve 60mm x 2.5mm heatshrink splice sleeve OPFC-STGR24-L OPFC-STGR24-CH OPFC-STGR24-SH OPFC-STGR24-CH SPTR-1224-BK SPTR-1224-WH SPTR-1224-BL FP-AC-SB-24 FP-AC-CG-13B FP-AC-CG-16B FP-AC-BC FP-AC-FMK FP-AC-BLNK-SCSX FP-AC-BLNK-SCDX FP-AC-BLNK-DCSX PSCL-600-15-30 PSCL-600-15-25 Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 22 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 Copper Structured Cabling, Cable, CAT6 U/UTP, Indoor Features and benefits • • • • • • • Category 6/Class E compliant Low flame-spread LSZH jacket material Compliant to ISO/IEC 11801 Ed 2.0, ANSI/TIA568-C.2, EN 50173-1, IEC 61156-5, EN 50288-6-1 IEC 60332-1-2, IEC 60754-2, IEC 61034-2 Reliable performance Super-standard performance margin Description Opterna 4-pair unshielded category 6 solid cables (U/UTP) has been designed for indoor applications and suitable for flawless 1G Ethernet networking, fully supporting the more demanding office communications including voice, data, VoIP, Video Conferencing, security, IP based cameras and other demanding real-time applications. The cable covers the category 6 requirements for unshielded twisted pair cables of 100 Ω and is characterized up to 250 MHz suitable for transmitting data over local area networks (LANs). The cable’s 8 conductors (4-Pairs) are of solid bare copper with high density polyethylene (HDPE) insulation and a PVC/LSZH jacket. Two insulated conductors are twisted together to form a pair and the four pairs with different twist ratio are laid up to form the basic cable unit. Applications • • • • • • • Horizontal Distribution and Backbone Cabling 4/16 Mbps Token Ring (IEEE 802.5) 10/100/1000 BASE-T (IEEE 802.3) 155 Mbps, 1.2G ATM 100 Mbps TP-PMD Analogue Voice, ISDN, ADSL HVAC alarm systems and other signalling Standards • • • • • • UL 444 ANSI/TIA-568-C.2 ISO/IEC 11801:2011 (Ed 2.2) Class E IEC 61156-5 CENELEC EN 50173-1:2011 EN50288-6-1 23 Technical data Mechanical data Dimensions (W x D x H) Material Conductor diameter Insulated conductor diameter Outer cable diameter Jacket thickness Pulling strength Minimum bend-radius Fire rating PVC jacket LSZH jacket Value See technical drawing Conductor material - Solid bare copper Conductor insulation - HDPE Cable jacket - PVC/LSZH 23 AWG 1.01 0.02 mm 6.3 0.3 mm 0.55mm 0.05 mm 110N 4 times outer diameter IEC60332-1-2 IEC 60332-1-2, IEC 60754-1,2 & IEC 61034-2 Electrical data Frequency (MHZ) RL (dB) ATT 20C (≤dB) NEXT (dB) NEXT PS NEXT (dB) ELFEXT (dB) PSELFEXT (dB) 1 4 8 10 16 20 25 31.25 62.5 100 200 250 20.0 23.0 24.5 25.0 25.0 25.0 24.3 23.6 21.5 20.1 18.0 17.3 1.9 3.7 5.3 5.9 7.5 8.4 9.5 10.6 15.4 19.8 29.0 32.8 74.0 63.3 60.7 59.0 56.0 55.0 53.3 52.0 47.0 44.0 40.0 38.0 72.3 63.3 58.8 57.3 54.2 52.8 51.3 49.9 45.4 42.3 37.8 36.3 68.0 56.0 49.9 48.0 43.8 42.0 40.0 38.1 32.1 28.0 22.0 20.0 65.0 53.0 46.9 45.0 40.9 39.0 37.0 35.1 29.1 25.0 19.0 17.0 Electrical characteristics DC resistance max DC resistance unbalance Mutual capacitance Capacitance unbalance pair Impedance 1-250 MHz Propagation delay Dielectric strength Propagation delay skew Insulation resistance - MΩ/km Nominal velocity of propagation Value 9.38 Ohm/100m Max 5% Max 5.6 nF/100m Max 330pF/100m 100 15 Max. 536 ns/100m@ 250 MHz DC KV/sec. 2.5/2 Max 45 ns/100m Min.5000 69% Environmental data Temperature range Operation Value -20 C to +75 C 24 Technical drawing Ordering information Description Unshielded Twisted Pair Cable (U/UTP), Category 6, 4 Pairs, solid PVC, 305m box Unshielded Twisted Pair Cable (U/UTP), Category 6, 4 Pairs, solid LSZH, 305m box Part code SCS-UTP4-C6-PVC-GY SCS-UTP4-C6-LSZH-GN Also, available in Black (BK), Blue (BL), Green(GN), Orange (OR), Red (RD), White (WH), Yellow (YL) for bulk orders 25 Copper Structured Cabling, Keystone Jack, CAT6 UTP Features and benefits • • • • • • • • • • • • Category identification on the front side of the jack 50-micron gold plated contacts Universal color-coding according to T568A and T568B Suitable for 110 and Krone type tools IDC contacts that allow re-termination for wiring changes without damaging the unit IDC termination point at 180° to jack Clear wire retaining caps for easy inspection Mounts in faceplates or patch panels Compatible with a wide range of international faceplates Characterized up to 250 MHz Component level 3P certified Description Opterna category 6 unshielded jacks are designed and manufactured to meet and exceed the current and future requirements for high bandwidth and forms an essential element of the structured cabling system. The keystone jacks are highly reliable and offers optimal network performance. The jack forms part of the faceplate as well as part of the modular patch-panel. Clear wire retaining caps are supplied which provide additional cable strain relief. The keystone jacks are color-coded for both 568A and 568B standards and can be terminated using a standard 110 termination tool. Applications • • • • • • • Horizontal Distribution and Backbone Cabling 4/16 Mbps Token Ring (IEEE 802.5) 10/100/1000 BASE-T (IEEE 802.3) 155 Mbps ATM 100 Mbps TP-PMD Analogue Voice, ISDN, ADSL HVAC alarm systems and other signalling Standards • • • • • ANSI/TIA-568-C.2 ISO/IEC 11801:2011 (Ed 2.2) Class E CENELEC EN 50173-1:2011 ANSI/TIA-1096-A (formerly FCC Part 68) IEC 60603-7-4 Technical data Mechanical data Value 26 Dimensions (W x D x H) Material Total contact force Retention Insertion/extraction See technical drawing Housing – UL 94 V0 High impact flame retardant plastic Jack contacts – Phosphor bronze alloy plated (50 micro-inch gold over 70-100 micro-inch nickel) IDC contacts - Phosphor bronze with 100 micro-inch tin 800 grams 50N 750 cycles minimum Electrical characteristics Current rating DC resistance Contact resistance Insulation resistance Voltage rating Dielectric Withstanding Voltage IDC Wire Gauge Value 1.5 Amps 200 m max (per pin) 2.5 m max (IDC) / 20 m max (insert) 500MΩ min (100V D.C) 60V 1000V, RMS @ 60Hz for 1 minute 22-26 AWG Environmental data Temperature range Storage Operation Relative Humidity (operational) Value -40 C to +70 C -10 C to +60 C Maximum non-condensing 93% Technical drawing Ordering information Description 180° Cat 6 Unshielded Keystone jack with T568A/B label, Black Part code SCS-JA-C6-UTP-BK Replace BK (Black) with BL (Blue), GN (Green), GY (Gray), OR (Orange), RD (Red), WH (White), YL (Yellow) 27 Copper Structured Cabling, Patch Panel, UTP Features and benefits • • • • • • • Modular panel for installation flexibility Window style label strips with port numbers Integral rear plastic cable management Modern design and simplified mounting Suitable for category 5e/6 UTP keystone snap-in jacks Unused ports can be covered with blanking modules SC, ST and LC fiber adaptors can be added with additional keystone fiber adaptor Description Opterna snap-in type UTP keystone patch panel are designed for customized connectors. Based on the installers specific design requirements, connector can be snapped into the panel. The UTP keystone patch panels are compatible for use with the category 5e and 6 keystone jacks and come as an unloaded panel. The patch panel is constructed of high quality plastic and metal back plate to provide the maximum strength and durability. The UTP keystone patch panel has an integrated rear cable management feature for cable routing and strain relief requirements. The rear cable management easily mounts at the back of the panel. The patch panel has an integrated label identification slot which allows the installer to design labels based on the project requirement making the panel TIA 606 compliant. Applications • • • Standard 19” rack compatible Suitable for UTP keystone jacks Height: 1U (24 ports), 2U (48 ports) Standards • • • • ANSI/TIA-568-C.2 ISO/IEC 11801:2011 (Ed 2.2) Class D/E CENELEC EN 50173-1:2011 UL 94 V-0 Technical data Mechanical data Dimensions (W x D x H) Material Value See technical drawing Housing – Steel 1.5mm Front mounting – UL94 V-0 28 Technical drawing Ordering information Description 19” Modular UTP patch panel, 24 ports, 1U, without modules, with rear cable management 19” Modular UTP patch panel, 48 ports, 1U, without modules, with rear cable management Blanking Plug, Keystone 29 Part code SCS-PPU-24-UTP SCS-PPU-48-UTP SCS-PPU-BLNK Hardware, Cable Manager, 19" Features and benefits Secures and retains patch cables Maintains proper bend radius Cable transition from horizontal to vertical channels Standard size for mounting in 19” racks and cabinets Modern design and simplicity of mounting Description Opterna cable management products deliver excellent cable management support when used in conjunction with other Opterna 19” products. The cable managers are designed for use in 19” rack environments for managing patch cords that are connected between patch panels and the network switch. It is recommended that one cable manager is mounted between every patch panels or a network switch. All cable managers are design to meet EIA-310-E standard and hence all compatible with any 19” racks or cabinets. Cable Manager with rings The 19” 1U/2U cable managers are constructed using steel and finished in powder coated black, with 50mm deep steel rings. Brush Cable Manager The 19” 1U steel cable management with brush allows the installer to pass patch cords through to the back of the cable management giving an aesthetically pleasing look to the cabinet. Duct Cable Manager The 19” 1U/2U duct cable managers are constructed using steel and finished in powder coated black. The duct cable manager comes with a cover and a finger guide channel on the base. These finger guide channels allow patch cords to exit at any point and provide a pleasing look to the cabinet. Applications Standard 19” rack compatible Data Center and MDF / IDF racks and cabinets Used between patch panel and network switch in racks and cabinets 30 Standards IEC 60297-3 EIA-310-E DIN 41494-1, 7 Technical data Mechanical data Dimensions (W x D x H) Material Finish Value See technical drawing Housing – Steel 1.5mm RAL 9017, Black, fine texture finish RAL 7032, Grey, fine texture finish Technical drawing Ordering information Description Part code 19” Cable manager with metal rings, 1U 19” Cable manager with metal rings, 2U 19” Brush cable manager, 1U 19” Brush cable manager, 2U 19” Duct type cable manager with cover, 1U 19” Duct type cable manager with cover, 2U SCS-CMM-1U-BK SCS-CMM-2U-BK SCS-CMB-1U-BK SCS-CMB-2U-BK SCS-CMD-1U-BK SCS-CMD-2U-BK Also available in Grey (GY), replace BK with GY. 31 Data Sheet DSHW01005AR Hardware, Cabinet, Steel Frame Floor Standing Features and benefits Steel frame structure Vented top cover with cable entry provision and entry plate Fan housing unit Bottom cover with cable entry provision and entry plate Side panels with slam latches and locking facility Front tempered glass door with lock Optional arc or flat 71% perforated front door with lock Rear steel door with lock and 71% perforation for airflow Side mounting angles 19-inch equipment mounting angles 800 mm wide cabinets are available with spacer and vertical patch cord management Levelling feet and heavy-duty castors Optional plinth for under base cable entry Description Opterna floor standing steel cabinets are robust and flexible cabinets that can be configured to suit a wide range of equipment types and applications. Perforated steel doors provide excellent cold air circulation through the rack and internal mounting rails can be adjusted to suit different equipment types and depths. Opterna racks are available in 600mm and 800mm widths depending on the application and the amount of vertical cable management space required. Generally, we recommend that the 800mm rack is used for high-density switch applications or situations where many copper and fiber cables are being request. Applications Data Centers LAN & WAN Networking Telecommunications Network Wiring Closets Audio / Video System Security System Standards IEC 60297-3 EIA-310-E DIN 41494-1, 7 IEC 60529 (IP 20) Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 32 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 1 Data Sheet DSHW01005AR Technical data Mechanical data Dimensions (W x D x H) Material Loading Capacity Finish Value See technical drawing Mounting profiles 2.0 mm Mounting angles - 1.5mm Other elements - 1.2 mm Door - Tempered glass 600 KG RAL 9017, Black, fine texture finish Technical drawing Ordering information CAB-FMS1 Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com 2 3 Asia Pacific 33 2104 779 +91 (0) 484 sales.ap@opterna.com 4 5 Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 2 Data Sheet DSHW01005AR 1. Select the rack unit 18 = 18U internal mounting space 22 = 22U internal mounting space 24 = 24U internal mounting space 27 = 27U internal mounting space 32 = 32U internal mounting space 37 = 37U internal mounting space 42 = 42U internal mounting space 45 = 45U internal mounting space 47 = 47U internal mounting space 3. Depth of the cabinet 600 = 600 mm 800 = 800 mm 1000 = 1000 mm 1200 = 1200 mm 5. 2. Width of the cabinet 600 = 600 mm 800 = 800 mm 4. Front & Rear Door 70 = Glass Door 71 = Arc Door with perforation 72 = Flat Door with perforation 73 = Twin Flat Door with perforation 74 = Glass Door without perforation 75 = Rear Door without perforation Select cabinet colour GY = Grey powder coated BK = Black powder coated Package: Available as flat packed or fully assembled Default components included are: 6 Way PDU, universal sockets support BS plug or Schuko plugs 4 Fans Levelling Feet Heavy Duty Castors Middle East +971 4 299 7676 sales.me@opterna.com Americas (703) 653-1130 sales.us@opterna.com Asia Pacific 34 2104 779 +91 (0) 484 sales.ap@opterna.com Europe +44(0)2031 301 716 sales.eu@opterna.com www.opterna.com 3 Description DME PROLINK’s Power Distribution Units (PDUs) are units which are mounted into a data/server cabinet, to provide power for the housed active equipments. PDUs comes in Horizontal and Vertical Mount options. This PDU complies with BS5733 and BS EN IEC 62368-1 standards. Components / Specs Product Series Socket Type Output Unit Power Input Bracket Install Cable with plug Shell Color Cable Specification Rating voltage Current Rating for Sockets Current Rating for Plug Safety Authentication Socket assemble Detailed Description Combo VM-PDU C13 (10A) & C19 (16A) 14 Way Left single input Vertically installed 3M cable with 16A Industrial Plug Black 3m x 3G x 4mm² 250VAC 10A for C13 & 16A for C19 16A Industrial 3-core Plug CE / RoHS 10Way C13 (10A) + 4Way C19(16A) Sockets Single C13 Socket Standard IEC320 C13 Parameter 10A 250VAC Single C19 Socket Standard IEC320 C19 Parameter 16A 250VAC 2- Pole Mini Circuit Breaker Parameter 1A – 60A Industrial Plug 3-core Standard IEC60309 Parameter 16A 250VAC Part Number D632-10134191632PBK PDU Combo Vertical Mount-Type, 14way with 10 (C13) Sockets (10A) and 4 (C19) Sockets (16A), 3m 4mm² Cable with 16A 3-core Industrial Plug, 250VAC with 2P circuit breaker, Black Technical Assistance Middle East HQ: +971 (4) 8118000 35 www.dmeprolink.com Product Image is only for reference DME PROLINK Power Distribution Unit (PDU) Combo VM, 10-Way C13 Sockets + 4-Way C19 Sockets, 3m Cord, with 16A Industrial Plug, with 2-Pole Circuit Breaker DME PROLINK Power Distribution Unit (PDU), 19” Rack Mount Description DME PROLINK’s Power Distribution Units (PDUs) are units which are mounted into a data/server cabinet, to provide power for the housed active equipments. The 1U plastic bodied PDUs are ideal for Floor/wall mounted cabinets, where weight is an important factor, and rack space is vital. Available in 4, 5 and 6 Nos. of BS1363 sockets, a shrouded switch with switch cover, and 2m leads as standard. Components / Specs Product Series Socket Type Output Unit Power Input Bracket Install Cable with plug Control Function Shell Color Cable Specification Product Size Mounting Length Case Length Rating voltage Rating Current Max. Current Max. Power Safety Authentication Detailed Description 1U, 19” Rack Mount BS1363 BS1363 Left single input Horizontal install BS1363 plug Switch Black H05VV-F3G x 1.5mm2 x 2m L x W x H= 485 x 44.45 x 44.45mm 450mm 435mm 250VAC 50/60Hz 13A 13A 3250W CE. RoHS. Part Number D 6 3 2 x - n P D x Pin assigned by ECS 0-9 Inventory Management Index n No. of Sockets 4 4 5 5 6 6 The shrouded switch of the PDU is protected by a switch cover, preventing accidental switching off of the PDU Part No: Description D6325-6PDU133BK PDU 19" Horizontal Mount-Type, 6way, 1U, 13amp, 3m Cable &Led Indicator On/Off Rocker Switch, Black Technical Assistance Middle East HQ: +971 (4) 8118000 36 U11 www.dmeprolink.com U Datasheet CloudEngine S12700E Series Switches Datasheet Huawei CloudEngine S12700E series switches are new core switches designed for nextgeneration high-quality campus networks. These purpose-built switches help create a campus network that improves user experiences, reduces operating costs, and delivers unm Product Overview Huawei CloudEngine S12700E series switches ("S12700E switches") are flagship core switches in Huawei's CloudCampus portfolio. By building an intelligent campus core, these feature-rich switches help customers head towards a service experiencecentric campus network that is intelligent and simplified. CloudEngine S12700E stands out with massive capacity expansion and flexible service upgrade capabilities to protect customer investments and facilitate their long-term network evolution. Built on Huawei's high-performance full-programmable chipsets, CloudEngine S12700E delivers 4.8 Tbps of single-slot bandwidth,which can easily scale to 7.2 Tbps simply by upgrading SFUs in the future. CloudEngine S12700E also offers a broad range of line cards, including 100GE, 40GE, 25GE, 10GE,and GE line cards, and provides up to 288 x 100GE ports, the unmatched port density in the industry. These give customers flexible choices to meet their capacity expansion and upgrade needs. By integrating large-capacity WLAN AC capabilities, a single CloudEngine S12700E can manage up to 10,240 WLAN APs. This capability, combined with free mobility functionality, achieves fully converged wired and wireless networks and policies, greatly simplifying network management with users and services at the core. With a holistic set of reliability, security, and trusted features, CloudEngine S12700E is ideal for building a reliable, secure, and trustworthy campus core. By using a next-generation cell switching architecture, CloudEngine S12700E ensures non-blocking service data forwarding on core nodes and guarantees service quality in high-concurrency, large-capacity, and high-load environments. Models and Appearances The S12700E series is available in three models: S12700E-4, S12700E-8, S12700E-12. 37 CloudEngine S12700E Series Switches Datasheet 1 S12700E-4 S12700E-8 S12700E-12 Product Model Product Description S12700E-4 A maximum of 96 x 100GE, 96 x 40GE, 160 x 25GE or 192 x 10GE ports 4 slots for line cards, 2 slots for Switch Fabric Units (SFUs), 2 slots for Main Processing Units (MPUs), and 4 slots for power modules Switching capacity: 19.2 Tbit/s Forwarding performance: 14,400 Mpps A maximum of 192 x 100GE, 192 x 40GE, 320 x 25GE or 384 x 10GE ports 8 slots for line cards, 4 slots for SFUs, 2 slots for MPUs, and 6 slots for power modules Switching capacity: 38.4 Tbit/s Forwarding performance: 28,800 Mpps A maximum of 288 x 100GE, 288 x 40GE, 480 x 25GE or 576 x 10GE ports 12 slots for line cards, 4 slots for SFUs, 2 slots for MPUs, and 6 slots for power modules Switching capacity: 57.6 Tbit/s Forwarding performance: 43,200 Mpps S12700E-8 S12700E-12 Features and Highlights Switch Highlights Fully-programmable Architecture Built on chipsets with a fully-programmable architecture, CloudEngine S12700E adapts to the changing forwarding processes driven by protocol evolution and technology advances. It enables fast and flexible provisioning of new services simply by upgrading software, without having to replace hardware, thereby protecting customers' investment. In contrast, traditional ASIC chips use a fixed forwarding architecture and follow a fixed forwarding process; as a result, new services cannot be provisioned until new hardware is developed to support the services, which may take 1 to 3 years. 38 CloudEngine S12700E Series Switches Datasheet 2 Wired and Wireless Convergence By integrating WLAN AC capabilities, CloudEngine S12700E eliminates the need to purchase additional WLAN AC hardware. Each CloudEngine S12700E can manage up to 10,240 APs. With up to 4 Tbps WLAN AC forwarding capacity, CloudEngine S12700E avoids the performance bottleneck on independent WLAN AC devices. As such, organizations are well poised to cope with challenges in the high-speed wireless era. CloudEngine S12700E supports the unified user management function that authenticates both wired and wireless users, ensuring a consistent user experience no matter whether they are connected to the network through wired or wireless access devices. CloudEngine S12700E supports various authentication methods, including PPPoE, 802.1X, MAC address, and Portal authentication, and is capable of managing users based on user groups, domains, and time ranges. These functions intuitively control user and service management and enable the transformation from data switching-centered management to service experience-centered management. Note: The CloudEngine S12700E series switches can manage 16 APs by default. You can purchase licenses for more AP management on demand. Service Experience Assurance CloudEngine S12700E supports a 4 GB buffer to cope with the burst data traffic pressure caused by massive concurrent users. This alleviates the data packet loss and even connection interruption caused by traffic burst. In addition, based on the industry-leading HQoS, hierarchical scheduling is performed on network-wide data traffic on the core nodes of the network to provide differentiated services for different users and applications, fully ensuring the service quality of key users and key applications and ensuring service experience. Refined Network Management Packet Conservation Algorithm for Internet (iPCA) changes the traditional method that uses simulated traffic for fault location. iPCA technology monitors network quality for any service flow at any network node, at any time, and without extra costs. It can quickly detect intermittent service interruptions and accurately identify faulty ports. This cutting-edge fault detection technology turns "extensive management" into "fine granular management." Super Virtual Fabric 2.0 (SVF 2.0) technology can not only virtualize fixed-configuration switches into modular switch line cards but also virtualize APs as switch ports. With this virtualization technology, a physical network with core/aggregation switches, access switches, and APs can be virtualized into a "super switch", simplifying network management. CloudEngine S12700E series manages access switches in a similar way a WLAN AC manages APs, saving the trouble of laborious configuration on access switches. It manages access switches and APs uniformly, allowing them to connect to the network with zero configuration. System Openness Capability CloudEngine S12700E supports NETCONF/YANG through which users can perform automated configuration. CloudEngine S12700E supports the Open Programmability System (OPS), an open programmable system based on the Python language. IT administrators can program the O&M functions of CloudEngine S12700E through Python scripts to quickly innovate functions and implement intelligent O&M. Secure and Trustworthy System Digital signatures of codes are used to identify software sources and the real identities of software developers to ensure that code is not tampered with after being signed. To protect software, CloudEngine S12700E uses two levels of signature mechanisms: inner signature and outer signature. CloudEngine S12700E supports secure boot based on the hardware trust root. Starting from the trusted hardware anchor, the software code to be loaded is checked level by level. This approach ensures that the MPUs, line cards, and SFUs are not intruded since the boot phase. The chipsets provide a secure Random Number Generator (RNG) module certified by NIST SP 800-90A and NIST SP 80090B to generate true secure random numbers for system running, thereby ensuring secure and trustworthy encryption. Network-Level Reliability CloudEngine S12700E uses link detection technologies such as hardware Eth-OAM and BFD, and adopts standard/standards-compatible link switching technologies like G.8032 and Smart Ethernet Protection (SEP). These technologies achieve end-to-end 50 ms hardware-level switchover and help build highly responsive campus network that provides highly reliable services. 39 CloudEngine S12700E Series Switches Datasheet 3 CloudEngine S12700E supports High-speed Self Recovery (HSR) technology that implements end-to-end IP MPLS transmission network protection switchover within 50 ms, improving network reliability. Easy Operation CloudEngine S12700E supports EasyDeploy that implements plug-and-play for newly deployed devices and centrally manages all devices running on the network. Typical Easy Deploy functions include the following: Implementing Zero Touch Provisioning (ZTP) to automatically load the boot files such as version files, configuration files, and patches Upgrading network devices and delivering configurations in batches Quickly replacing old devices with new ones that are plug-and-play without configuration Intelligent Diagnosis CloudEngine S12700E supports Open Intelligent Diagnosis System (OIDS). By integrating the device health monitoring and fault diagnosis functions – that are typically deployed on a Network Management System (NMS) – into the switch software, OIDS implements intelligent diagnosis on a single switch. After OIDS is deployed on a switch, the switch periodically collects and records the running information and automatically determines whether a fault occurs. If a fault occurs, the switch automatically locates the fault or helps locate the fault. All these merits increase fault locating efficiency of O&M staff while improving device maintainability. Solution Benifits Simplified Management Deployment automation: CloudEngine S12700E supports VXLAN and BGP-EVPN, and builds a Unified Virtual Fabric (UVF) to automate deployment of up to 512 Virtual Networks (VNs). In this way, multiple service networks or tenant networks can be deployed and isolated from each other on the same physical network, truly achieving one network for multiple purposes. Policy automation: CloudEngine S12700E automates deployment of wired and wireless user policies on the entire network and implements refined management and control based on SDN to achieve free mobility. Intelligent O&M CloudEngine S12700E provides telemetry technology to collect device data in real time and send the data to the CampusInsight (a campus network analysis component of Huawei iMaster NCE). The CampusInsight then analyzes network data based on the intelligent fault identification algorithm, accurately displays the real-time network status, effectively demarcates and locates faults in a timely manner, and identifies network problems that affect user experience, accurately guaranteeing user experiences. CloudEngine S12700E supports a variety of intelligent O&M features for audio and video services, including the enhanced Media Delivery Index (eMDI). With the eMDI function, the switch can function as a monitored node to periodically conduct statistics and report audio and video service indicators to the CampusInsight. In this way, the CampusInsight can quickly demarcate audio and video service quality faults based on the results of multiple monitored nodes. Big Data Security Collaboration CloudEngine S12700E uses NetStream to collect campus network data and then report such data to the Huawei HiSec Insight. The purposes of doing so are to detect network security threats, display the security posture across the entire network, and enable automated or manual response to security threats. The HiSec Insight delivers the security policies to the iMaster NCE-Campus(or Agile Controller). The iMaster NCE-Campus(or Agile Controller) then delivers such policies to switches that will handle security events accordingly. All these ensure campus network security. Licensing CloudEngine S12700E supports both the traditional feature-based licensing mode and the latest Huawei IDN One Software (N1 mode for short) licensing mode. The N1 mode is ideal for campus network deployments in enterprise private cloud mode, and greatly enhances the customer experiences in purchasing and upgrading software services with simplicity. 40 CloudEngine S12700E Series Switches Datasheet 4 Software Package Features in N1 Mode Switch Functions N1 Basic Software N1 Foundation Software Package N1 Advanced Software Package Basic network functions: √ √ √ × √ √ × × √ Layer 2 functions, IPv4, IPv6, MPLS, SVF, and others Note: For details, see the Functions and Features Basic network automation based on the Agile Controller: Basic automation: Plug-and-play, SSID, and AP group management Basic monitoring: Application visualization NE management: Image and topology management and discovery WLAN enhancement: Roaming and optimization for up to 128 APs Advanced network automation and intelligent O&M: VXLAN, user access authentication, free mobility, and CampusInsight basic functions Note: Only V200R019C00 and later versions can support N1 mode Product Specifications Functions and Features Except for special instructions, the following features are supported by CloudEngine S12700E with N1 basic software. Category Service Features CloudEngine S12700E User management Unified user management Yes PPPoE, 802.1X, MAC, and Portal authentication Yes Traffic- and duration-based accounting Yes User authorization based on user groups, domains, and time ranges Yes Number of MAC address entries 1M(MAX) Automatic MAC address learning and aging Yes Static, dynamic, and blackhole MAC address entries Yes Source MAC address filtering Yes MAC address learning limiting based on ports and VLANs Yes 4K VLANs Yes Access, trunk, and hybrid interface types; auto-negotiation of LNP link types Yes Default VLAN Yes VLAN switching Yes MAC address VLAN 41 CloudEngine S12700E Series Switches Datasheet 5 Category ARP IP routing Multicast MPLS VXLAN QoS Service Features CloudEngine S12700E QinQ and enhanced selective QinQ Yes Dynamic VLAN assignment based on MAC addresses Yes Maximum number of ARP entries 384K(MAX) ARP Snooping √ Maximum number of IPv4 routing entries 3M(MAX) Maximum number of IPv6 routing entries 1M(MAX) IPv4 dynamic routing protocols such as RIP, OSPF, IS-IS, and BGP Yes IPv6 dynamic routing protocols such as RIPng, OSPFv3, ISISv6, and BGP4+ Yes Maximum number of multicast routing entries(IPv4) 64K(MAX) Maximum number of multicast routing entries(IPv6) 64K(MAX) IGMPv1/v2/v3 and IGMP v1/v2/v3 Snooping Yes PIM-DM, PIM-SM, and PIM-SSM Yes MSDP and MBGP Yes Fast-leave mechanism Yes Multicast traffic control Yes Multicast querier Yes Multicast protocol packet suppression Yes Multicast Call Admission Control (CAC) Yes Multicast ACL Yes Basic MPLS functions Yes MPLS OAM Yes MPLS TE Yes MPLS VPN/VLL/VPLS Yes VXLAN Layer 2 gateway Yes, require additional license VXLAN Layer 3 gateway Yes, require additional license Centralized gateway Yes, require additional license Distributed gateway Yes, require additional license BGP-EVPN Yes, require additional license Configures VXLANs through NETCONF Yes, require additional license Number of ACL rules(IPv4) 32K(MAX) 42 CloudEngine S12700E Series Switches Datasheet 6 Category iPCA SVF 2.0 Ring network protection Reliability Configuration and Service Features CloudEngine S12700E Number of ACL rules(IPv6) 16K(MAX) Traffic classification based on Layer 2 headers, Layer 3 protocols, Layer 4 protocols, and 802.1p priority Yes Actions such as ACL, Committed Access Rate (CAR), re-marking, and scheduling Yes Queuing algorithms, such as PQ, WRR, DRR, PQ+WRR, and PQ+DRR Yes Congestion avoidance mechanisms such as WRED and tail drop Yes HQoS Yes Traffic shaping Yes Marks the real service packets to obtain real-time count of dropped packets and packet loss ratio Yes Counts the number of dropped packets and packet loss ratio on devices and L2/L3 networks Yes Up to 10K clients (access switches and APs) virtualized into a single device Yes Two layers of ASs allowed in an SVF system Yes Third-party devices allowed between SVF parent and clients Yes STP (IEEE 802.1d), RSTP (IEEE 802.1w), and MSTP (IEEE 802.1s). Yes SEP Yes BPDU protection, root protection, and loop protection Yes BPDU tunnel Yes G.8032 Ethernet Ring Protection Switching (ERPS) Yes Link Aggregation Control Protocol (LACP) and E-Trunk Yes Virtual Router Redundancy Protocol (VRRP) and Bidirectional Forwarding Detection (BFD) for VRRP Yes BFD for BGP/IS-IS/OSPF/static routes Yes Non-Stop Forwarding (NSF) and Graceful Restart (GR) for BGP/ISIS/OSPF/LDP Yes TE Fast ReRoute (FRR) and IP FRR Yes Eth-OAM 802.3ah and 802.1ag (hardware-based) Yes High-speed Self Recovery (HSR) Yes ITU-Y.1731 Yes Device Link Detection Protocol (DLDP) Yes Smart Link Yes Monitor Link Yes Easy Operation Yes 43 CloudEngine S12700E Series Switches Datasheet 7 Category Service Features CloudEngine S12700E maintenance Terminal access services such as console port login, Telnet, and SSH Yes Network management protocols, such as SNMPv1/v2/v3 Yes File uploading and downloading through FTP and TFTP Yes BootROM upgrade and remote in-service upgrade Yes Hot patches Yes User operation logs Yes Open Programmability System (OPS) Yes Streaming Telemetry Yes eMDI Yes MAC address, Portal, 802.1X, and DHCP snooping-triggered authentication Yes MACsec Yes NAC Yes RADIUS and HWTACACS authentication for login users Yes Command line authority control based on user levels, preventing unauthorized users from using command configurations Yes Defense against DoS attacks, Transmission Control Protocol (TCP) SYN Flood attacks, User Datagram Protocol (UDP) Flood attacks, broadcast storms, and heavy traffic attacks Yes 1K CPU hardware queues to implement hierarchical scheduling and protection for protocol packets on the control plane Yes Remote Network Monitoring (RMON) Yes Secure boot (need to use MPU that supports secure boot) Yes Big data security collaboration Yes Mesh networking Yes N+N cold backup for devices with integrated WLAN AC functionality Yes Hot backup for devices with integrated WLAN AC functionality in cluster mode Yes WLAN terminal location Yes Locating of interference sources Yes Spectrum analysis function Yes 2.4G & 5G load balancing Yes 5G-prior access Yes Total number of managed APs 10K An IPv4 network between an AP and a WLAN AC Yes AP blacklist Yes Security and management Wireless management (integrated WLAN AC): Basic WLAN services Wireless management (integrated WLAN AC): AP management 44 CloudEngine S12700E Series Switches Datasheet 8 Category Wireless management (integrated WLAN AC): Wireless user management Wireless management (integrated WLAN AC): CAPWAP Wireless management (integrated WLAN AC): RF management Wireless management (integrated WLAN AC): WLAN QoS Interoperability Service Features CloudEngine S12700E AP whitelist Yes Sets the AP access control mode Yes AP configuration and management Yes AP energy saving Yes AP LLDP topology awareness Yes Adjustable priority of traffic on wired interfaces of APs Yes Rate limiting on wired interfaces of APs Yes User roaming within a WLAN AC Yes AP-based user location Yes User roaming between WLAN ACs Yes 802.1X authentication Yes Portal authentication Yes MAC address authentication Yes Direct data forwarding on L2/L3 networks Yes Tunnel-based data forwarding on L2/L3 networks Yes Dual-link load balancing for CAPWAP tunnels Yes CAPWAP tunnel encryption Yes 802.11a/b/g/n Yes 802.11ac wave1/wave2 Yes 802.11ax Yes Sets RF interference monitoring and avoidance Yes Detects co-channel interference, adjacent interference, and interference from other devices and STAs Yes Automatically selects channels and power when APs go online Yes Dynamic power and channel optimization Yes Mapping from wireless-side priority to wired-side priority Yes Mapping from wireless-side priority to CAPWAP channel priority Yes Rate limiting of upstream and downstream traffic on the air interface based on the VAP Yes Rate limiting of upstream and downstream traffic on the air interface based on users Yes SSID-based CAR Yes CAR for WLAN users Yes Interoperable with VBST (compatible with PVST/PVST+/RPVST) Yes Interoperable with LNP (similar to DTP) Yes Interoperable with VCMP (similar to VTP) Yes 45 CloudEngine S12700E Series Switches Datasheet 9 Hardware Specifications Item CloudEngine S12700E-4 CloudEngine S12700E-8 CloudEngine S12700E-12 Switching capacity 19.2 Tbps 38.4 Tbps 57.6Tbps Forwarding performance 14,400 Mpps 28,800 Mpps 43,200 Mpps MPU slots 2 2 2 SFU slots 2 4 4 LPU slots 4 8 12 Fan trays 2 4 5 Power 4 6 6 Buffering capacity Up to 200 ms data buffering per port Up to 200 ms data buffering per port Up to 200 ms data buffering per port Redundancy design MPU, SFU, power module, and fan module MPU, SFU, power module, and fan module MPU, SFU, power module, and fan module Virtualization CSS service port clustering CSS service port clustering CSS service port clustering Dimensions (H x W x D) 441.7*442*517.4,10U 663.95*442*517.4, 15U 841.75*442*517.4, 19U Weight (empty/fully configured) 24.5kg/66kg 42.5kg/114kg 71.8kg/184kg Note Note Note Empty configuration indicates that the switch has no line card, MPU, or power supply installed. Filler panels are used, instead. Empty configuration indicates that the switch has no line card, MPU, or power supply installed. Filler panels are used, instead. Full configuration indicates that the switch is fully configured with MPUs, SFUs, line cards, and power supplies. Their maximum weights are used during calculation. Full configuration indicates that the switch is fully configured with MPUs, SFUs, line cards, and power supplies. Their maximum weights are used during calculation. Operating voltage Empty configuration indicates that the switch has no line card, MPU, or power supply installed. Filler panels are used, instead. Full configuration indicates that the switch is fully configured with MPUs, SFUs, line cards, and power supplies. Their maximum weights are used during calculation. DC:–48V~–60V AC:90V~290V Maximum power consumption 3344W 6950W 8981W Operating temperature –60 m to +1800 m: 0°C to 45°C 1800 m to 4000 m: The maximum operating temperature decreases by 1°C each time the altitude increases by 220 m. 4000 m: 0°C to 35°C Relative humidity 5% to 95% (non-condensing) Heat dissipation mode Left-to-rear airflow, air-cooled heat dissipation, and intelligent fan speed adjustment 46 CloudEngine S12700E Series Switches Datasheet 10 Hardware Introduction MPU The Main Processing Unit (MPU) provides the control and management planes for the entire system. The control plane is mainly responsible for protocol processing, service processing, route calculation, forwarding control, service scheduling, traffic statistics, and system security. The management plane provides functions like monitoring the system running status, monitoring the environment, processing logs and alarms, loading the system, and upgrading the system. The following table lists the MPU supported by Huawei S12700E series switches. Models and Appearance Description Supported Version S12700E main processing unit E V200R019C00 and later versions S12700E main processing unit E V200R020C10 and later versions LST7MPUE0000 LST7MPUE0001 The following table lists the functions of MPUE Function Description Basic functions The LST7MPUE0000/LST7MPUE0001 integrate the main control unit, clock unit, and system maintenance unit. OAM The LST7MPUE0000/LST7MPUE0001 support the following OAM functions: 802.1ag: identifies, detects, and sends continuity check (CC) packets. Multiprotocol Label Switching (MPLS OAM): identifies, detects, and sends MPLS OAM packets. OAM UNCFG_MEP. Memory 16 GB Flash 64 MB/128 MB NAND Flash 2 GB The system configuration data, startup files, system software package, and system logs are saved in the NAND Flash by default. Redundancy backup 1+1 hot standby Main control board is mandatory for switches. Each switch must be configured with one or two main control boards. When one main control board is configured for a switch, the main control board can be installed in either main control board slot of the switch. When two main control boards are configured, the two main control boards work in hot standby mode to improve reliability of the switch. The active and standby main control boards monitor the status of each other. If the active main control board fails, the standby main control board automatically becomes active to ensure uninterrupted services. Hot swapping Supported Before removing the active card, perform an active/standby switchover. SFU The Switch Fabric Unit (SFU) provides the data plane for the entire system. The data plane provides high-speed and nonblocking data channels for service switching between service modules. 47 CloudEngine S12700E Series Switches Datasheet 11 The following table lists the SFU supported by Huawei S12700E series switches. Models and Appearance Description Supported Version S12700E Switch Fabric Unit E (X1) V200R019C00 and later versions, only used in S12700E-4 and S12700E-8 S12700E Switch Fabric Unit H (X1) V200R019C00 and later versions, only used in S12700E-4 and S12700E-8 S12700E Switch Fabric Unit M (X1) V200R019C00 and later versions, only used in S12700E-12 LST7SFUEX100 LST7SFUHX100 LST7SFUMX100 The following table lists the functions of SFUE/SFUH/SFUM. Function SFUE SFUH SFUM Basic function Core of data switching Core of data switching Core of data switching Memory 1 GB 2 GB 2 GB Flash 128 MB 128 MB 128 MB Redundancy backup N+1 hot standby N+1 hot standby N+1 hot standby Hot swapping Supported Supported Supported SFU cards in a chassis can work in redundancy mode to improve system reliability. If one SFU fails, service traffic on this card will be switched to other SFUs to ensure uninterrupted services CMU The Centralized Monitoring Unit(CMU) manages power modules and fan modules in a chassis. The CMU is hot swappable. Two CMU cards can be installed in a chassis to work in active/standby mode. The following table lists the CMU supported by Huawei S12700E series switches. Models and Appearance Description Supported Version Centralized Monitoring Unit V200R019C00 and later versions EH1D200CMU00 The following table lists the functions of CMU. Function Description Fan module management Fan module presence detection Fan module registration management Fan speed monitoring 48 CloudEngine S12700E Series Switches Datasheet 12 Function Power module management Description Fan speed control Management and report of fan module alarms Query of fan module electronic labels Power module presence detection Power module shutdown Power module registration management Voltage and current monitoring Management and report of power module alarms Query of power module electronic labels Interface Card An interface card, or called LPU, processes all traffic on the network data plane of a switch. The S12700E supports a broad set of interface cards that offer varying numbers of 100GE, 40GE, 25GE, 10GE, and GE ports. Customers can flexibly select them as required. Card Name Description Supported Version LST7G48TX5E1 48-port 10/100/1000BASE-T interface card (X5E, RJ45) V200R019C00 and later versions LST7G48TX5S1 48-port 10/100/1000BASE-T interface card (X5S, RJ45) V200R019C00 and later versions LST7G48SX6E0 48-port 1000M Ethernet optical interface card (X6E, SFP) V200R019C00 and later versions LST7G48SX6S0 48-port 1000M Ethernet optical interface card (X6S, SFP) V200R019C00 and later versions LST7X24BX6E0 24-port 10GBASE-X and 24-port 1000BASE-X interface card (X6E, SFP+) V200R019C00 and later versions LST7X24BX6S0 24-port 10GBASE-X and 24-port 1000BASE-X interface card (X6S, SFP+) V200R019C00 and later versions LST7X48SX6E0 48-port 10GBASE-X interface card (X6E, SFP+) V200R019C00 and later versions LST7X48SX6S0 48-port 10GBASE-X interface card (X6S, SFP+) V200R019C00 and later versions LST7Y40SX6H0 40-port 25GE SFP28 interface card (X6H,SFP28) V200R019C10 and later versions LST7C02BX6E0 2-port 100GE QSFP28 interface and 4-port 40GE QSFP28 interface card (X6E,QSFP28) V200R020C00 and later versions LST7C06HX6E0 6-port 100GE QSFP28 interface card (X6E, QSFP28) V200R019C00 and later versions LST7C06HX6S0 6-port 100GE QSFP28 interface card (X6S, QSFP28) V200R019C00 and later versions LST7C24HX6E0 24-Port 100GE QSFP28 Interface Card (X6E, QSFP28) V200R019C00 and later versions Power Module Power Module Backup Modes The S12700E power modules support the backup mode. Three power module configuration modes are recommended: N+N backup, N+1 backup, and N+0 without backup. The value of N is determined by the maximum power required by the system. N multiplied by the maximum output power of each power module must be larger than the maximum power required by the system. The system can automatically identify the backup mode, without the need of manual configuration through CLIs. Assume that the maximum power required by the system is 4,000 W. If two 2,200 W power modules are installed, the backup mode is 2+0 without backup. If three 2,200 W power modules are installed, the backup mode is 2+1 backup. If four 2,200 W power modules are installed, the backup mode is 2+2 backup. 49 CloudEngine S12700E Series Switches Datasheet 13 The S12700E supports 2,200 W DC and 3,000 W AC power modules. The following table lists the maximum output power of the entire system in different backup modes. Models and Appearance W2PSD2200 PAC3KS54NE Backup Mode Maximum Output Power of the S12700E-4 Maximum Output Power of the S12700E-8 Maximum Output Power of the S12700E-8 N+N backup A maximum of four (2+2) 2,200 W DC power modules can be configured, providing the maximum power supply capability of 4,400 W. A maximum of six (3+3) 2,200 W DC power modules can be configured, providing the maximum power supply capability of 6,600W. A maximum of six (3+3) 2,200 W DC power modules can be configured, providing the maximum power supply capability of 6,600W. N+1 backup A maximum of four (3+1) 2,200 W DC power modules can be configured, providing the maximum power supply capability of 6,600 W. A maximum of six (5+1) 2,200 W DC power modules can be configured, providing the maximum power supply capability of 11,000 W. A maximum of six (5+1) 2,200 W DC power modules can be configured, providing the maximum power supply capability of 11,000 W. N+0 without backup A maximum of four (4+0) 2,200 W DC power modules can be configured, providing the maximum power supply capability of 8,800 W. A maximum of six (6+0) 2,200W DC power modules can be configured, providing the maximum power supply capability of 12,000 W. A maximum of six (6+0) 2,200W DC power modules can be configured, providing the maximum power supply capability of 13,200 W. N+N backup A maximum of four (2+2) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 6,000 W. A maximum of six (3+3) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 9,000 W. A maximum of six (3+3) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 9,000 W. N+1 backup A maximum of four (3+1) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 9,000 W. A maximum of six (5+1) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 12,000 W. A maximum of six (5+1) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 14,000 W. N+0 without backup A maximum of four (4+0) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 9,000 W. A maximum of six (6+0) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 12,000 W. A maximum of six (6+0) 3,000 W AC power modules can be configured, providing the maximum power supply capability of 14,000 W. Power Module Specifications The following table lists the specifications of each power module. Parameter W2PSD2200(DC Power Module) PAC3KS54-CE(AC Power Module) Dimensions (H x W x D) 41 mm × 393 mm × 130 mm 41 mm × 417.4 mm × 130 mm Weight < 2.5 kg < 3.0 kg Rated input voltage -48 V DC/-60 V DC 220 V AC/110 V AC; 50/60 Hz Rated input -40 V DC to -72 V DC 200 V AC to 240 V AC (rated input voltage: AC input 50 CloudEngine S12700E Series Switches Datasheet 14 Parameter W2PSD2200(DC Power Module) voltage range Maximum input voltage range PAC3KS54-CE(AC Power Module) 220 V AC)/100 V AC to 130 V AC (rated input voltage: 110 V AC); 47 Hz to 63 Hz -40 V DC to -72 V DC 90 V AC to 290 V AC; 47 Hz to 63 Hz (When the input voltage range is 90 V AC to 175 V AC, the maximum output power of the power module is reduced by half.) The maximum current of the power cable used by the 3,000 W AC power module is 16 A. When the 220 V input is used, the minimum voltage cannot be lower than 200 V. When the 110 V input is used, the minimum voltage cannot be lower than 100 V. Maximum input current 60 A 16 A Rated input voltage - 240 V DC Maximum input voltage range - 190 V DC to 290 V DC Maximum input current - 14 A Maximum output current 42 A 56.1 A (rated input voltage: 220 V AC)/28.1 A (rated input voltage: 110 V AC) Maximum output power 2,200 W 3,000 W (rated input voltage: 220 V AC or 240 V DC)/1,500 W (rated input voltage: 110 V AC) Hot swap Supported Supported Environment parameters Operating temperature: 0°C to 45°C Operating temperature: 0°C to 45°C Operating relative humidity: 5%RH to 95%RH, non-condensing Operating relative humidity: 5%RH to 95%RH, non-condensing Storage temperature: -40°C to +70°C Storage temperature: -40°C to +70°C Storage relative humidity: 5%RH to 95%RH, non-condensing High-voltage DC input Output Storage relative humidity: 5%RH to 95%RH, non-condensing Fan Module Each fan module has two fans and can work for a short time when one fan fails. When any fan in a fan module fails, handle the failure immediately to ensure that the fan module can work normally. The following table lists the fan module supported by Huawei S12700E series switches. Models and Appearance Description Supported Version FAN-770A-B fan box V200R019C00 and later versions FAN-770A-B 51 CloudEngine S12700E Series Switches Datasheet 15 Fan Module Functions Function Description Supported Version Hot swapping Supported V200R019C00 and later versions Other fan modules are not affected when you install or remove a fan module. Intelligent fan speed adjustment The S12700E series switches provide intelligent fan speed adjustment based on temperature in each zone, and correlate speeds of fans in the entire chassis. The system monitors the temperature of key components, and adjusts the fan speed based on temperature changes. This intelligent fan speed adjustment function ensures that the system stays within the proper operating temperature range, and reduces power consumption and noise. V200R019C00 and later versions Fan Module Specifications Function Description Supported Version Dimensions (H x W x D) 126.6 mm x 323.9 mm x 65 mm (5.0 in. x 12.8 in. x 2.6 in.) V200R019C00 and later versions Number of fans 2 V200R019C00 and later versions Weight 2.5 kg (5.51 lb) V200R019C00 and later versions Maximum power consumption 395 W V200R019C00 and later versions Operating voltage range -30 V DC to -73 V DC V200R019C00 and later versions Environment specifications Operating temperature: 0°C to 45°C (32°F to 113°F) V200R019C00 and later versions Operating relative humidity: 5% RH to 95% RH (noncondensing) Storage temperature: -40°C to +70°C (-40°F to +158°F) Storage relative humidity: 5% RH to 95% RH (noncondensing) Networking and Applications In a Campus Network CloudEngine S12700E series switches are deployed on the core layer of an enterprise campus network. ACs are built in to the switches to achieve the following purposes: Wireless networks can be constructed without any additional AC devices, reducing network construction costs. With the wired and wireless convergence capability, they can deliver a consistent experience to wired and wireless users through uniform device management, user management, and service management. The T-bit AC capability avoids performance bottlenecks on independent ACs and enables a migration to 802.11ax networks. In a MAN CloudEngine S12700E series switches can be used as core or aggregation switches on a metro television broadcasting or education network. Providing millions of FIB entries for large-scale routing on the network. 52 CloudEngine S12700E Series Switches Datasheet 16 Supporting comprehensive L2/L3 MPLS VPN features, ensuring high reliability, security, and scalability on the metropolitan bearer network. Single-link 100G hardware clustering technology delivers carrier-grade reliability. In a Data Center CloudEngine S12700E series switches can be deployed on the core or aggregation layer of an enterprise data center network Providing large throughput using high-density line cards, such as 24*100GE,6*100GE,40*25GE and 48*10GE/GE cards. CloudEngine S12700E series switches support single-link 100G hardware clustering. This technology helps to build a data center network with high performance, high reliability, and low latency. In an Education Campus Network CloudEngine S12700E series switches are deployed on the core layer of a college campus network. Allowing for a large number of concurrent access users. As they support unified user management, you do not need to buy additional hardware components, construction costs. reducing network The H-QoS feature implements fine granular user and service management. With the wired and wireless convergence capability, they can deliver a consistent experience to wired and wireless users through uniform device management, user management, and service management. In a Bearer Network for Video Conferencing, Desktop Cloud, and Video Surveillance Applications CloudEngine S12700E series switches have a large buffer to prevent packet loss when traffic bursts occur, delivering highquality video streams. CloudEngine S12700E series switches support millions of hardware entries, which allow for a large number of terminals and facilitate evolution to IPv6 and the Internet of Things. Employing end-to-end hardware reliability technologies and iPCA, CloudEngine S12700E series switches offer a highly reliable, high-quality, scalable video conferencing and surveillance solution. Safety and Regulatory Compliance The following table lists the safety and regulatory compliance of CloudEngine S12700E. Safety and regulatory compliance of CloudEngine S12700E series Certification Category Specification Safety IEC 60950-1 EN 60950-1 UL 60950-1 CSA C22.2 No 60950-1 AS/NZS 60950.1 BS EN 60950-1 CNS 14336-1 CISPR22 Class A CISPR24 EN55022 Class A EN55024 ETSI EN 300 386 Class A Electromagnetic Compatibility (EMC) 53 CloudEngine S12700E Series Switches Datasheet 17 Certification Category Environment Laser safety Specification CFR 47 FCC Part 15 Class A ICES 003 Class A AS/NZS CISPR22 Class A VCCI Class A IEC61000-6-2 IEC61000-6-4 IEC61000-4-2 ITU-T K 20 ITU-T K 21 ITU-T K 44 CNS13438 RoHS REACH WEEE IEC60825-1 IEC60825-2 EN60825-1 EN60825-2 EMC: electromagnetic compatibility CISPR: International Special Committee on Radio Interference EN: European Standard ETSI: European Telecommunications Standards Institute CFR: Code of Federal Regulations FCC: Federal Communication Commission IEC: International Electrotechnical Commission AS/NZS: Australian/New Zealand Standard VCCI: Voluntary Control Council for Interference UL: Underwriters Laboratories CSA: Canadian Standards Association IEEE: Institute of Electrical and Electronics Engineers RoHS: restriction of the use of certain hazardous substances REACH: Registration Evaluation Authorization and Restriction of Chemicals WEEE: Waste Electrical and Electronic Equipment MIB and Standards Compliance Supported MIBs The following table lists the MIBs supported by CloudEngine S12700E series. MIBs supported by the S12700E series Category Specification Public MIB BGP4-MIB BRIDGE-MIB 54 CloudEngine S12700E Series Switches Datasheet 18 Category Specification DISMAN-NSLOOKUP-MIB DISMAN-PING-MIB DISMAN-TRACEROUTE-MIB ENTITY-MIB EtherLike-MIB IF-MIB IP-FORWARD-MIB IPMCAST-MIB IPv6-ICMP-MIB IPv6-MIB IPv6-TCP-MIB IPv6-UDP-MIB ISIS-MIB LAG-MIB LLDP-EXT-DOT1-MIB LLDP-EXT-DOT3-MIB LLDP-MIB MGMD-STD-MIB MPLS-FTN-STD-MIB MPLS-L3VPN-STD-MIB MPLS-LDP-GENERIC-STD-MIB MPLS-LDP-STD-MIB MPLS-LSR-STD-MIB MPLS-TE-STD-MIB MSDP-MIB NOTIFICATION-LOG-MIB NQA-MIB OSPF-MIB OSPF-TRAP-MIB P-BRIDGE-MIB PIM-BSR-MIB PIM-STD-MIB Q-BRIDGE-MIB RFC1213-MIB RIPv2-MIB RMON2-MIB RMON-MIB SAVI-MIB SNMP-FRAMEWORK-MIB SNMP-MPD-MIB SNMP-NOTIFICATION-MIB SNMP-TARGET-MIB SNMP-USER-BASED-SM-MIB SNMPv2-MIB SNMP-VIEW-BASED-ACM-MIB 55 CloudEngine S12700E Series Switches Datasheet 19 Category Huawei-proprietary MIB Specification TCP-MIB UDP-MIB VRRP-MIB VRRPv3-MIB HUAWEI-AAA-MIB HUAWEI-ACL-MIB HUAWEI-ALARM-MIB HUAWEI-ALARM-RELIABILITY-MIB HUAWEI-BASE-TRAP-MIB HUAWEI-BFD-MIB HUAWEI-BGP-VPN-MIB HUAWEI-BRAS-RADIUS-MIB HUAWEI-BRAS-SRVCFG-EAP-MIB HUAWEI-BRAS-SRVCFG-STATICUSER-MIB HUAWEI-BULKSTAT-MIB HUAWEI-CBQOS-MIB HUAWEI-CCC-MIB HUAWEI-CONFIG-MAN-MIB HUAWEI-CLOCK-MIB HUAWEI-CPU-MIB HUAWEI-DAD-MIB HUAWEI-DC-TRAP-MIB HUAWEI-DATASYNC-MIB HUAWEI-DEVICE-MIB HUAWEI-DHCPR-MIB HUAWEI-DHCPS-MIB HUAWEI-DHCP-SNOOPING-MIB HUAWEI-DIE-MIB HUAWEI-DNS-MIB HUAWEI-DLDP-MIB HUAWEI-ERPS-MIB HUAWEI-ERRORDOWN-MIB HUAWEI-ENERGYMNGT-MIB HUAWEI-EASY-OPERATION-MIB HUAWEI-ENTITY-EXTENT-MIB HUAWEI-ENTITY-TRAP-MIB HUAWEI-ETHARP-MIB HUAWEI-ETHOAM-MIB HUAWEI-E-TRUNK-MIB HUAWEI-FLASH-MAN-MIB HUAWEI-FTP-MIB HUAWEI-FWD-RES-TRAP-MIB HUAWEI-GARP-APP-MIB HUAWEI-GTL-MIB 56 CloudEngine S12700E Series Switches Datasheet 20 Category Specification HUAWEI-GTSM-MIB HUAWEI-HGMP-MIB HUAWEI-HQOS-MIB HUAWEI-HWTACACS-MIB HUAWEI-IF-EXT-MIB HUAWEI-INFOCENTER-MIB HUAWEI-IPFPM-MIB HUAWEI-IPLPM-MIB HUAWEI-IPMCAST-MIB HUAWEI-IPPOOL-MIB HUAWEI-IPSESSION-MIB HUAWEI-IPV6-MIB HUAWEI-ISOLATE-MIB HUAWEI-KOMPELLA-MIB HUAWEI-L2IF-MIB HUAWEI-L2MAM-MIB HUAWEI-L2MULTICAST-MIB HUAWEI-L2VLAN-MIB HUAWEI-L2VPN-MIB HUAWEI-LDT-MIB HUAWEI-LSP-PING-TRACE-TRAP-MIB HUAWEI-LINE-MIB HUAWEI-LLDP-MIB HUAWEI-MAC-AUTHEN-MIB HUAWEI-MDNS-RELAY-MIB HUAWEI-MEMORY-MIB HUAWEI-MFF-MIB HUAWEI-MFLP-MIB HUAWEI-MGMD-STD-MIB HUAWEI-MPLS-EXTEND-MIB HUAWEI-MPLSLDP-MIB HUAWEI-MPLSLSR-EXT-MIB HUAWEI-MPLSOAM-MIB HUAWEI-MSDP-MIB HUAWEI-MSTP-MIB HUAWEI-MULTICAST-MIB HUAWEI-NETSTREAM-MIB HUAWEI-NTPV3-MIB HUAWEI-OSPFV2-MIB HUAWEI-OSPFV3-MIB HUAWEI-PERFORMANCE-MIB HUAWEI-PIM-BSR-MIB HUAWEI-PIM-STD-MIB HUAWEI-PERFMGMT-MIB HUAWEI-PORT-MIB 57 CloudEngine S12700E Series Switches Datasheet 21 Category Specification HUAWEI-PORTAL-MIB HUAWEI-PWE3-MIB HUAWEI-PWE3-TNL-MIB HUAWEI-QINQ-MIB HUAWEI-RIPv2-EXT-MIB HUAWEI-RM-EXT-MIB HUAWEI-RRPP-MIB HUAWEI-RSVPTE-MIB HUAWEI-SECURITY-MIB HUAWEI-SEP-MIB HUAWEI-SMARTLINK-MIB HUAWEI-SNMP-EXT-MIB HUAWEI-SSH-MIB HUAWEI-STACK-MIB HUAWEI-SWITCH-L2MAM-EXT-MIB HUAWEI-SWITCH-SRV-TRAP-MIB HUAWEI-SYS-MAN-MIB HUAWEI-TASK-MIB HUAWEI-TCP-MIB HUAWEI-TFTPC-MIB HUAWEI-TRNG-MIB HUAWEI-TUNNEL-MIB HUAWEI-TUNNEL-TE-MIB HUAWEI-UNIMNG-MIB HUAWEI-USC-MIB HUAWEI-VPLS-EXT-MIB HUAWEI-VPLS-TNL-MIB HUAWEI-VPN-DIAGNOSTICS-MIB HUAWEI-VRRP-EXT-MIB HUAWEI-WLAN-DEVICE-MIB HUAWEI-WLAN-QOS-MIBB HUAWEI-WLAN-RADIO-MIB HUAWEI-WLAN-SECURITY-MIB HUAWEI-WLAN-SERVICE-MIB HUAWEI-WLAN-SYS-MIB HUAWEI-WLAN-UPDATE-MIB HUAWEI-WLAN-WIDS-MIB HUAWEI-XQOS-MIB For more information about MIBs supported by CloudEngine S12700E series, visit https://support.huawei.com/enterprise/en/switches/s12700e-pid-250450822 Standard Compliance The following table lists the standards that CloudEngine S12700E complies with. 58 CloudEngine S12700E Series Switches Datasheet 22 Standard compliance list of CloudEngine S12700E series Standard Organization Standard or Protocol IETF RFC 768 User Datagram Protocol (UDP) RFC 792 Internet Control Message Protocol (ICMP) RFC 793 Transmission Control Protocol (TCP) RFC 826 Ethernet Address Resolution Protocol (ARP) RFC 854 Telnet Protocol Specification RFC 951 Bootstrap Protocol (BOOTP) RFC 959 File Transfer Protocol (FTP) RFC 1058 Routing Information Protocol (RIP) RFC 1112 Host extensions for IP multicasting RFC 1157 A Simple Network Management Protocol (SNMP) RFC 1256 ICMP Router Discovery RFC 1305 Network Time Protocol Version 3 (NTP) RFC 1349 Internet Protocol (IP) RFC 1493 Definitions of Managed Objects for Bridges RFC 1542 Clarifications and Extensions for the Bootstrap Protocol RFC 1643 Ethernet Interface MIB RFC 1757 Remote Network Monitoring (RMON) RFC 1901 Introduction to Community-based SNMPv2 RFC 1902-1907 SNMP v2 RFC 1981 Path MTU Discovery for IP version 6 RFC 2131 Dynamic Host Configuration Protocol (DHCP) RFC 2328 OSPF Version 2 RFC 2453 RIP Version 2 RFC 2460 Internet Protocol, Version 6 Specification (IPv6) RFC 2461 Neighbor Discovery for IP Version 6 (IPv6) RFC 2462 IPv6 Stateless Address Auto configuration RFC 2463 Internet Control Message Protocol for IPv6 (ICMPv6) RFC 2474 Differentiated Services Field (DS Field) RFC 2740 OSPF for IPv6 (OSPFv3) RFC 2863 The Interfaces Group MIB RFC 2597 Assured Forwarding PHB Group RFC 2598 An Expedited Forwarding PHB RFC 2571 SNMP Management Frameworks RFC 2865 Remote Authentication Dial In User Service (RADIUS) RFC 3046 DHCP Option82 RFC 3376 Internet Group Management Protocol, Version 3 (IGMPv3) RFC 3513 IP Version 6 Addressing Architecture RFC 3579 RADIUS Support For EAP RFC 4271 A Border Gateway Protocol 4 (BGP-4) RFC 4760 Multiprotocol Extensions for BGP-4 draft-grant-tacacs-02 TACACS+ IEEE 802.1D Media Access Control (MAC) Bridges IEEE 59 CloudEngine S12700E Series Switches Datasheet 23 Standard Organization Standard or Protocol IEEE 802.1p IEEE 802.1Q Virtual Bridged Local Area Networks IEEE 802.1ad Provider Bridges IEEE 802.2 IEEE Std 802.3 IEEE Std 802.3ab 1000BASE-T specification IEEE Std 802.3ad Aggregation of Multiple Link Segments IEEE Std 802.3ae 10GE WEN/LAN Standard IEEE Std 802.3x Full Duplex and flow control IEEE Std 802.3z Gigabit Ethernet Standard IEEE802.1ax/IEEE802.3ad Link Aggregation IEEE 802.3ah Ethernet in the First Mile. IEEE 802.1ag Connectivity Fault Management IEEE 802.1ab Link Layer Discovery Protocol IEEE 802.1D Spanning Tree Protocol IEEE 802.1w Rapid Spanning Tree Protocol IEEE 802.1sMultiple Spanning Tree Protocol IEEE802.1x Port based network access control protocol ITU SG13 Y.17ethoam ITU SG13 QoS control Ethernet-Based IP Access ITU-T Y.1730 ETH OAM performance monitor ITU-T Y.1731 ETH OAM performance monitor ITU-T Y.1710 Requirements for OAM functionality for MPLS networks ITU-T Y.1711 Operation and maintenance mechanism for MPLS networks ITU-T Y.1720 Protection switching for MPLS networks ISO ISO 10589IS-IS Routing Protocol MEF MEF 2 Requirements and Framework for Ethernet Service Protection MEF 9 Abstract Test Suite for Ethernet Services at the UNI MEF 10.2 Ethernet Services Attributes Phase 2 MEF 11 UNI Requirements and Framework MEF 13 UNI Type 1 Implementation Agreement MEF 15 Requirements for Management of Metro Ethernet Phase 1 Network Elements MEF 17 Service OAM Framework and Requirements MEF 20 UNI Type 2 Implementation Agreement MEF 23 Class of Service Phase 1 Implementation Agreement ITU Virtual Bridged Local Area Networks Logical Link Control CSMA/CD Ordering Information S12700E Basic Configuration LE2BN66ED000 N66E DC assembly cabinet (eight 60A outputs, maximum 2200W, 600 × 600 × 2200 mm) LE2BN66EA000 N66E AC assembly cabinet (four 16 A outputs, a maximum of 2500W, 600 × 600 × 2200 mm) 60 CloudEngine S12700E Series Switches Datasheet 24 S12700E Basic Configuration ET1BS12704E0 S12700E-4 assembly chassis ET1BS12708E0 S12700E-8 assembly chassis ET1BS12712E1 S12700E-12 assembly chassis FAN-770A-B Fan box (-5degC–55degC, 48V, 400W, 2, indoors, VA) Main Processing Unit LST7MPUE0000 S12700E Main Processing Unit E LST7MPUE0001 S12700E Main Processing Unit E Monitoring Unit EH1D200CMU00 Centralized Monitoring Unit Switch Fabric Unit LST7SFUEX100 S12700E Switch Fabric Unit E(X1) LST7SFUHX100 S12700E Switch Fabric Unit H (X1) LST7SFUMX100 S12700E Switch Fabric Unit M (X1) 100G/40G Ethernet optical interface card LST7C02BX6E0 2-port 100GE QSFP28 interface and 4-port 40GE QSFP28 interface card (X6E,QSFP28) LST7C06HX6E0 6-port 100GE QSFP28 interface card (X6E,QSFP28) LST7C06HX6S0 6-port 100GE QSFP28 interface card (X6S,QSFP28) LST7C24HX6E0 24-port 100GE QSFP28 interface card (X6E,QSFP28) 25GE optical interface card LST7Y40SX6H0 40-port 25GE SFP28 interface card (X6H,SFP28) 10GE/1000M Ethernet optical interface card LST7X24BX6E0 24-port 10GE SFP+ interface and 24-port GE SFP interface card (X6E,SFP+) LST7X24BX6S0 24-port 10GE SFP+ interface and 24-port GE SFP interface card (X6S,SFP+) Gigabit Ethernet optical interface card LST7G48SX6E0 48-port GE SFP interface card (X6E,SFP) 61 CloudEngine S12700E Series Switches Datasheet 25 Gigabit Ethernet optical interface card LST7G48SX6S0 48-port GE SFP interface card (X6S,SFP) Gigabit Ethernet electrical interface card LST7G48TX5E1 48-port 10/100/1000BASE-T interface card (X5E,RJ45) LST7G48TX5S1 48-port 10/100/1000BASE-T Interface Card (X5S, RJ45) Power supply Supported Version W2PSD2200 2200W DC power module PAC3KS54-CE 3000W AC power module (black) V200R019C00 and later versions PAC3KS54-NE 3000W AC power module (black) V200R020C10 and later versions License L-1AP-S127E S127E Series,Wireless Access Controller AP Resource License-1AP L-VxLAN-S127E S127E Series,VxLAN License, Per Device RTU-800G-S127E S127E Series,800G Capacity Right to Use License,Per Device N1-S127E-F-Lic N1-CloudCampus,Foundation,S127E Series,Per Device N1-S127E-F-SnS1Y N1-CloudCampus,Foundation,S127E Series,SnS,Per Device,1Year N1-S127E-A-Lic N1-CloudCampus,Advanced,S127E Series,Per Device N1-S127E-A-SnS1Y N1-CloudCampus,Advanced,S127E Series,SnS,Per Device,1Year N1-S127E-FToA-Lic N1-Upgrade-Foundation to Advanced,S127E,Per Device N1-S127E-FToASnS1Y N1-Upgrade-Foundation to Advanced,S127E,SnS,Per Device,1Year N1-S127E-M-Lic N1-CloudCampus,Device Management,S127E Series,Per Device N1-S127E-M-SnS1Y N1-CloudCampus,Device Management,S127E Series,,SnS,Per Device,1Year N1-AC1.0-AM-15-Lic N1-CloudCampus,Access Management-AC1.0,15 Terminals N1-AC1.0-AM-15SnS1Y N1-CloudCampus,Access Management-AC1.0,15 Terminals,SnS,1Year CI-X7MSwitch-U CampusInsight-Upgrade-Foundation to Advanced, X7 Series Modular Switch, Per Device CI-X7MSwitch-USnS1Y CampusInsight-Upgrade-Foundation to Advanced, X7 Series Modular Switch, SnS, Per Device, 1 Year More Information For more information about Huawei Campus Switches, visit http://e.huawei.com or contact us in the following ways: Global service hotline: http://e.huawei.com/en/service-hotline 62 CloudEngine S12700E Series Switches Datasheet 26 Logging in to the Huawei Enterprise technical support website: http://support.huawei.com/enterprise/ Sending an email to the customer service mailbox: support_e@huawei.com Copyright © Huawei Technologies Co., Ltd. 2020. All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means without prior written consent of Huawei Technologies Co., Ltd. Trademarks and Permissions and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd. All other trademarks and trade names mentioned in this document are the property of their respective holders. Notice The purchased products, services and features are stipulated by the contract made between Huawei and the customer. All or part of the products, services and features described in this document may not be within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information, and recommendations in this document are provided "AS IS" without warranties, guarantees or representations of any kind, either express or implied. The information in this document is subject to change without notice. Every effort has been made in the preparation of this document to ensure accuracy of the contents, but all statements, information, and recommendations in this document do not constitute a warranty of any kind, express or implied. Huawei Technologies Co., Ltd. Address:Huawei Industrial Base Bantian, Longgang Shenzhen 518129 People's Republic of China Website:e.huawei.com 63 CloudEngine S12700E Series Switches Datasheet 27 Datasheet CloudEngine S5735-S Series Switches Huawei CloudEngine S5735-S series are standard gigabit Ethernet switches that provide all GE downlink ports and 10GE uplink ports. Introduction CloudEngine S5735-S series switches are developed based on next-generation high-performing hardware and the Huawei Versatile Routing Platform (VRP). CloudEngine S5735-S switches support simplified operations and maintenance (O&M), and flexible Ethernet networking. It also provides enhanced Layer 3 features and mature IPv6 features. CloudEngine S5735-S switches can be used in various scenarios. For example, it can be used as an access or aggregation switch on a campus network or as an access switch in a data center. Product Overview Models and Appearances Models and appearances of the CloudEngine S5735-S series Models and Appearances CloudEngine S5735-S24T4X CloudEngine S5735-S24P4X CloudEngine S5735-S48T4X CloudEngine S5735-S48P4X Description 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports 1+1 power supply backup Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports 1+1 power supply backup PoE+ Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbp 48 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports 1+1 power supply backup Forwarding performance: 132 Mpps Switching capacity: 176 Gbps/432 Gbps 48 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports 1+1 power supply backup PoE+ Forwarding performance: 132 Mpps 64 CloudEngine S5735-S Series Switches 1 Models and Appearances Description CloudEngine S5735-S32ST4X CloudEngine S5735-S48S4X Switching capacity: 176 Gbps/432 Gbps 24 x GE SFP ports, 8 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports 1+1 power supply backup Forwarding performance: 108 Mpps Switching capacity: 144 Gbps/432 Gbps 48 x GE SFP ports, 4 x 10 GE SFP+ ports 1+1 power supply backup Forwarding performance: 132 Mpps Switching capacity: 176 Gbps/432 Gbps Power Supply Technical specifications of the power supplies applicable to the CloudEngine S5735-S series Power Module Technical Specifications Applied Switch Model Dimensions (H x W x D): 40 mm x 90 mm x 215 mm (1.6 in. x 3.5 in. x 8.5 in.) CloudEngine S5735-S24P4X Weight: 1.1 kg (2.43 lb) Rated input voltage range: CloudEngine S5735-S48P4X − 100 V AC to 130 V AC, 50/60 Hz PAC1000S56-CB − 200 V AC to 240 V AC, 50/60 Hz − 240 V DC Maximum input voltage range: − 90 V AC to 290 V AC, 45 Hz to 65 Hz − 190 V DC to 290 V DC Input current: − 100 V AC to 130 V AC: 12 A − 200 V AC to 240 V AC: 8 A − 240 V DC: 8 A Maximum output current: − 100 V AC to 130 V AC input: 16.08 A − 200 V AC to 240 V AC input and 240 V DC input: 17.86 A Maximum output power: − Total power: 900 W (100 V AC to 130 V AC input)/1000 W (200 V AC to 240 V AC input and 240 V DC input) PAC150S12-R Hot swap: Supported Dimensions (H x W x D): 40 mm x 90 mm x 215 mm (1.6 in. x 3.5 in. x 8.5 in.) Weight: 0.8 kg (1.76 lb) Rated input voltage range: 100 V AC to 240 V AC, 50/60 Hz Maximum input voltage range: 90 V AC to 264 V AC, 47 Hz to 63 Hz Maximum input current: 3 A Maximum output current: 12.5 A CloudEngine S5735-S48S4X 65 CloudEngine S5735-S Series Switches 2 Power Module Technical Specifications PDC1000S12-DB Applied Switch Model Maximum output power: 150 W Hot swap: Supported Dimensions (H x W x D): 40 mm x 90 mm x 215 mm (1.6 in. x 3.5 in. x 8.5 in.) Weight: 1.02 kg (2.25 lb) Rated input voltage range: -48 V DC to -60 V DC Maximum input voltage range: -38.4 V DC to -72 V DC Maximum input current: 30 A Maximum output current: 83.3 A Maximum output power: 1000 W Hot swap: Supported Dimensions (H x W x D): 40 mm x 90 mm x 215 mm (1.6 in. x 3.5 in. x 8.5 in.) Weight: 0.68 kg (1.5 lb) Rated input voltage range: CloudEngine S5735-S24T4X CloudEngine S5735-S32ST4X CloudEngine S5735-S48S4X CloudEngine S5735-S48T4X CloudEngine S5735-S24T4X CloudEngine S5735-S32ST4X CloudEngine S5735-S48T4X − 100 V AC to 240 V AC, 50/60 Hz PAC60S12-AR − 240 V DC Maximum input voltage range: − 90 V AC to 264 V AC, 47 Hz to 63 Hz − 190 V DC to 290 V DC Maximum input current: − 100 V AC to 240 V AC: 2 A − 240 V DC: 2 A Maximum output current: 5 A Maximum output power: 60 W Hot swap: Supported CloudEngine S5735-S24P4X is a PoE switch. It has two power module slots, each of which can have a 1000 W PoE power module installed. The following table lists its power supply configurations. Power supply configurations of CloudEngine S5735-S24P4X Power Module 1 Power Module 2 Available PoE Power Maximum Number of Ports (Fully Loaded) 1000 W (220 V) – 874 W 802.3af (15.4 W per port): 24 802.3at (30 W per port): 24 802.3af (15.4 W per port): 24 802.3at (30 W per port): 24 802.3af (15.4 W per port): 24 802.3at (30 W per port): 24 802.3af (15.4 W per port): 24 802.3at (30 W per port): 24 1000 W (110 V) 1000 W (220 V) 1000 W (110 V) – 1000 W (220 V) 1000 W (110 V) 779 W 1600 W 1558 W 66 CloudEngine S5735-S Series Switches 3 CloudEngine S5735-S48P4X is a PoE switch. It has two power module slots, each of which can have a 1000 W PoE power module installed. The following table lists its power supply configurations. Power supply configurations of CloudEngine S5735-S48P4X Power Module 1 Power Module 2 Available PoE Power Maximum Number of Ports (Fully Loaded) 1000 W (220 V) – 874 W 802.3af (15.4 W per port): 48 802.3at (30 W per port): 29 802.3af (15.4 W per port): 48 802.3at (30 W per port): 25 802.3af (15.4 W per port): 48 802.3at (30 W per port): 48 802.3af (15.4 W per port): 48 802.3at (30 W per port): 48 1000 W (110 V) 1000 W (220 V) 1000 W (110 V) – 1000 W (220 V) 1000 W (110 V) 779 W 1600 W 1558 W When a switch has two power modules installed, the two power modules work in redundancy mode to provide power for the chassis and in load balancing mode to provide power for PDs. Product Features and Highlights Powerful Service Processing Capability and Multiple Security Control Mechanisms CloudEngine S5735-S supports a broad set of Layer 2/Layer 3 multicast protocols, such as PIM SM, PIM DM, PIM SSM, MLD, and IGMP snooping. This capability is ideal for high-definition video surveillance and video conferencing access. CloudEngine S5735-S provides multiple Layer 3 features including OSPF, IS-IS, BGP, and VRRP, meeting enterprises' access and aggregation service needs and enabling a variety of voice, video, and data applications. CloudEngine S5735-S supports MAC address authentication, 802.1X authentication, and Portal authentication, and implements dynamic delivery of policies (VLAN, QoS, and ACL) to users. CloudEngine S5735-S provides a series of mechanisms to defend against DoS attacks and user-targeted attacks. DoS attacks are targeted at switches and include SYN flood, Land, Smurf, and ICMP flood attacks. User-targeted attacks include bogus DHCP server attacks, IP/MAC address spoofing, DHCP request flood, and changing of the DHCP CHADDR value. CloudEngine S5735-S sets up and maintains a DHCP snooping binding table, and discards the packets that do not match the table entries. The DHCP snooping trusted port feature ensures that users connect only to the authorized DHCP server. CloudEngine S5735-S supports strict ARP learning, which protects a network against ARP spoofing attacks to ensure that users can connect to the Internet normally. Easy O&M CloudEngine S5735-S supports Super Virtual Fabric (SVF), which innovatively virtualizes the "core/aggregation switch + access switch + AP" into one logical device. This simplifies device management and achieves plug-and-play for access switches and APs. In addition, CloudEngine S5735-S supports service configuration templates. The templates are configured on core devices and automatically delivered to access devices, enabling centralized control, simplified service configuration, and flexible configuration adjustment. CloudEngine S5735-S functions as a client in an SVF system. CloudEngine S5735-S supports Huawei Easy Operation, a solution that provides zero-touch deployment, replacement of faulty devices without additional configuration, USB-based deployment, batch device configuration, and batch remote upgrade. The capabilities facilitate device deployment, upgrade, service provisioning, and other management and maintenance operations, and also greatly reduce O&M costs. CloudEngine S5735-S can be managed using SNMP v1/v2c/v3, CLI, webbased network management system, or SSH v2.0. Additionally, it supports RMON, multiple log hosts, port traffic statistics collection, and network quality analysis, which facilitate network optimization and reconstruction. 67 CloudEngine S5735-S Series Switches 4 CloudEngine S5735-S supports the Sampled Flow (sFlow) function. It uses a method defined in the sFlow standard to sample traffic passing through it and sends sampled traffic to the collector in real time. The collected traffic statistics are used to generate statistical reports, helping enterprises maintain their networks. Multiple Reliability Mechanisms CloudEngine S5735-S is equipped with two pluggable power modules that work in 1+1 redundancy backup mode. Mixed installation of AC and DC power modules is supported, allowing for flexible configuration of AC or DC power modules according to service requirements. In addition to supporting traditional Spanning Tree Protocol (STP), Rapid Spanning Tree Protocol (RSTP), and Multiple Spanning Tree Protocol (MSTP), CloudEngine S5735-S is also designed with Huawei-developed Smart Ethernet Protection (SEP) technology and the industry's latest Ethernet Ring Protection Switching (ERPS) technology. SEP is a ring protection protocol specific to the Ethernet link layer, and applies to various ring network topologies, such as open ring topology, closed ring topology, and cascading ring topology. This protocol is reliable, easy to maintain, and implements fast protection switc hing within 50 ms. ERPS is defined in ITU-T G.8032, and it implements millisecond-level protection switching based on traditional Ethernet MAC and bridging functions. CloudEngine S5735-S supports Smart Link, which implements backup of uplinks. One CloudEngine S5735-S switch can connect to multiple aggregation switches through multiple links, significantly improving reliability of access devices. CloudEngine S5735-S supports Ethernet OAM (IEEE 802.3ah/802.1ag) to fast-detect link faults. Mature IPv6 Technologies CloudEngine S5735-S uses the mature, stable VRP platform and supports IPv4/IPv6 dual stack, IPv6 RIPng, and IPv6 over IPv4 tunnels (including manual, 6-to-4, and ISATAP tunnels). CloudEngine S5735-S can be deployed on a pure IPv4 network, a pure IPv6 network, or a shared IPv4/IPv6 network, helping achieve IPv4-to-IPv6 transition. iStack CloudEngine S5735-S supports intelligent stack (iStack). This technology combines multiple switches into a logical switch. Member switches in a stack implement redundancy backup to improve device reliability and use inter-device link aggregation to improve link reliability. iStack provides high network scalability. You can increase ports, bandwidth, and processing capacity of a stack by simply adding member switches to the stack. iStack also simplifies device configuration and management. After a stack is set up, multiple physical switches are virtualized into one logical device. You can log in to any member switch in the stack to manage all the member switches in the stack. CloudEngine S5735-S support stacking through electrical ports. PoE Function Perpetual PoE: When a PoE switch is abnormal Power-off or the software version is upgraded, the power supply to PDs is not interrupted. This capability ensures that PDs are not powered off during the switch reboot. Fast PoE: PoE switches can supply power to PDs within seconds after they are powered on. This is different from common switches that generally take 1 to 3 minutes to start to supply power to PDs. When a PoE switch reboots due to a power failure, the PoE switch continues to supply power to the PDs immediately after being powered on without waiting until it finishes reboot. This greatly shortens the power failure time of PDs. Intelligent O&M CloudEngine S5735-S provides telemetry technology to collect device data in real time and send the data to Huawei campus network analyzer CampusInsight. The CampusInsight analyzes network data based on the intelligent fault identification algorithm, accurately displays the real-time network status, effectively demarcates and locates faults in a timely manner, and identifies network problems that affect user experience, accurately guaranteeing user experience. CloudEngine S5735-S supports a variety of intelligent O&M features for audio and video services, including the enhanced Media Delivery Index (eMDI). With this eDMI function, the switch can function as a monitored node to periodically conduct statistics and report audio and video service indicators to the CampusInsight platform. In this way, the CampusInsight platform can quickly demarcate audio and video service quality faults based on the results of multiple monitored nodes. 68 CloudEngine S5735-S Series Switches 5 Intelligent Upgrade CloudEngine S5735-S supports the intelligent upgrade feature. Specifically, CloudEngine S5735-S obtains the version upgrade path and downloads the newest version for upgrade from the Huawei Online Upgrade Platform (HOUP). The entire upgrade process is highly automated and achieves one-click upgrade. In addition, preloading the version is supported, which greatly shortens the upgrade time and service interruption time. The intelligent upgrade feature greatly simplifies device upgrade operations and makes it possible for the customer to upgrade the version independently. This greatly reduces the customer's maintenance costs. In addition, the upgrade policies on the HOUP platform standardize the upgrade operations, which greatly reduces the risk of upgrade failures. Cloud Management The Huawei cloud management platform allows users to configure, monitor, and inspect switches on the cloud, reducing on-site deployment and O&M manpower costs and decreasing network OPEX. Huawei switches support both cloud management and on-premise management modes. These two management modes can be flexibly switched as required to achieve smooth evolution while maximizing return on investment (ROI). OPS CloudEngine S5735-S supports Open Programmability System (OPS), an open programmable system based on the Python language. IT administrators can program the O&M functions of a CloudEngine S5735-S switch through Python scripts to quickly innovate functions and implement intelligent O&M. Product Specifications Functions and Features Function and feature metrics for the CloudEngine S5735-S series Function and Feature Description CloudEngine S5735-S Ethernet features Full-duplex, half-duplex, and autonegotiation Yes Rate auto-negotiation on an interface Yes Auto MDI and MDI-X Yes Flow control on an interface Yes Jumbo frames Yes Link aggregation Yes Load balancing among links of a trunk Yes Transparent transmission of Layer 2 protocol packets Yes Device Link Detection Protocol (DLDP) Yes Link Layer Discovery Protocol (LLDP) Yes Link Layer Discovery Protocol-Media Endpoint Discovery (LLDP-MED) Yes Interface isolation Yes Broadcast traffic suppression on an interface Yes Multicast traffic suppression on an interface Yes Ethernet basics 69 CloudEngine S5735-S Series Switches 6 Function and Feature Description CloudEngine S5735-S Unknown unicast traffic suppression on an interface Yes VLAN broadcast traffic suppression Yes VLAN multicast traffic suppression Yes VLAN unknown unicast traffic suppression Yes VLAN specification 4094 VLANIF interface specification 1024 Access mode Yes Trunk mode Yes Hybrid mode Yes QinQ mode Yes Default VLAN Yes VLAN assignment based on interfaces Yes VLAN assignment based on protocols Yes VLAN assignment based on IP subnets Yes VLAN assignment based on MAC addresses Yes VLAN assignment based on MAC address + IP address Yes VLAN assignment based on MAC address + IP address + interface number Yes Adding double VLAN tags to packets based on interfaces Yes VLAN mapping Yes Selective QinQ Yes MUX VLAN Yes Voice VLAN Yes Guest VLAN Yes GARP Yes GVRP Yes VCMP VCMP Yes MAC MAC address 16512 Automatic learning of MAC addresses Yes Automatic aging of MAC addresses Yes Static, dynamic, and blackhole MAC address entries Yes VLAN GVRP 70 CloudEngine S5735-S Series Switches 7 Function and Feature Description CloudEngine S5735-S Interface-based MAC address learning limiting Yes Sticky MAC Yes MAC address flapping detection Yes MAC address spoofing defense Yes Port bridge Yes Static ARP Yes Dynamic ARP Yes ARP entry 8000 ARP aging detection Yes Intra-VLAN proxy ARP Yes Routed proxy ARP Yes STP Yes RSTP Yes MSTP Yes VBST Yes BPDU protection Yes Root protection Yes Loop protection Yes Defense against TC BPDU attacks Yes Loopback detection Loop detection on an interface Yes SEP SEP Yes Smart Link Smart Link Yes Smart Link multi-instance Yes Monitor Link Yes RRPP Yes Single RRPP ring Yes Tangent RRPP ring Yes Intersecting RRPP ring Yes Hybrid networking of RRPP rings and other ring networks Yes G.8032 v1 Yes G.8032 v2 Yes ERPS semi-ring topology Yes ERPS closed-ring topology Yes ARP Ethernet loop protection MSTP RRPP ERPS 71 CloudEngine S5735-S Series Switches 8 Function and Feature Description CloudEngine S5735-S IPv4/IPv6 forwarding IPv4 static routing Yes VRF Yes DHCP client Yes DHCP server Yes DHCP relay Yes Routing policies Yes IPv4 routes 8192 RIPv1 Yes RIPv2 Yes OSPF Yes Policy-based routing (PBR) Yes IGMPv1/v2/v3 Yes PIM-DM Yes PIM-SM Yes MSDP Yes IPv4 multicast routes 1500 IPv6 multicast routes 1500 Multicast routing policies Yes RPF Yes IPv6 protocol stack Yes ND Yes ND entry 3072 ND snooping Yes DHCPv6 snooping Yes RIPng Yes DHCPv6 server Yes DHCPv6 relay Yes OSPFv3 Yes IPv6 routes 3072 VRRP6 Yes MLDv1/v2 Yes PIM-DM for IPv6 Yes PIM-SM for IPv6 Yes IGMPv1/v2/v3 snooping Yes IPv4 and unicast routing Multicast routing features IPv6 features Layer 2 multicast - 72 CloudEngine S5735-S Series Switches 9 Function and Feature Description CloudEngine S5735-S features IGMP snooping proxy Yes MLD snooping Yes Multicast traffic suppression Yes Inter-VLAN multicast replication Yes Service interface-based stacking Yes Maximum number of stacked devices 9 Stack bandwidth (Unidirectional) 40Gbps(MAX) VRRP VRRP standard protocol Yes EFM (802.3ah) Automatic discovery of links Yes Link fault detection Yes Link troubleshooting Yes Remote loopback Yes Software-level CCM Yes 802.1ag MAC ping Yes 802.1ag MAC trace Yes OAM association Association between 802.1ag and 802.3ah Yes Y.1731 Unidirectional delay and jitter measurement Yes Bidirectional delay and jitter measurement Yes Traffic classification based on ACLs Yes Configuring traffic classification priorities Yes Matching the simple domains of packets Yes Traffic filtering Yes Traffic policing (CAR) Yes Modifying the packet priorities Yes Modifying the simple domains of packets Yes Modifying the packet VLANs Yes Traffic shaping on an egress interface Yes Traffic shaping on queues on an interface Yes Congestion avoidance Tail drop Yes Congestion management Priority Queuing (PQ) Yes Weighted Deficit Round Robin (WDRR) Yes PQ+WDRR Yes Stacking Device reliability Ethernet OAM CFM (802.1ag) QoS features Traffic classification Traffic behavior Traffic shaping 73 CloudEngine S5735-S Series Switches 10 Function and Feature ACL Configuration and maintenance Packet filtering at Layer 2 to Layer 4 Login and configuration management File system Monitoring and maintenance Description CloudEngine S5735-S Weighted Round Robin (WRR) Yes PQ+WRR Yes Number of rules per IPv4 ACL 2K Number of rules per IPv6 ACL 2K Basic IPv4 ACL Yes Advanced IPv4 ACL Yes Basic IPv6 ACL Yes Advanced IPv6 ACL Yes Layer 2 ACL Yes User-defined ACL Yes Command line interface (CLI)-based configuration Yes Console terminal service Yes Telnet terminal service Yes SSH v1.5 Yes SSH v2.0 Yes SNMP-based NMS for unified configuration Yes Web page-based configuration and management Yes EasyDeploy (client) Yes SVF Yes Cloud management Yes OPS Yes Directory and file management Yes File upload and download Yes eMDI Yes Hardware monitoring Yes Log information output Yes Alarm information output Yes Debugging information output Yes Port mirroring Yes Flow mirroring Yes Remote mirroring Yes Energy saving Yes 74 CloudEngine S5735-S Series Switches 11 Function and Feature Description CloudEngine S5735-S Version upgrade Yes Version rollback Yes ARP packet rate limiting Yes ARP anti-spoofing Yes Association between ARP and STP Yes Dynamic ARP Inspection (DAI) Yes Static ARP Inspection (SAI) Yes Egress ARP Inspection (EAI) Yes ICMP attack defense Yes IPSG for IPv4 Yes IPSG user capacity 1K IPSG for IPv6 Yes IPSGv6 user capacity 512 Local attack defense CPU attack defense Yes MFF MFF Yes DHCP snooping DHCP snooping Yes Option 82 function Yes Dynamic rate limiting for DHCP packets Yes Defense against malformed packet attacks Yes Defense against UDP flood attacks Yes Defense against TCP SYN flood attacks Yes Defense against ICMP flood attacks Yes Defense against packet fragment attacks Yes Local URPF Yes Local authentication Yes Local authorization Yes RADIUS authentication Yes RADIUS authorization Yes RADIUS accounting Yes HWTACACS authentication Yes HWTACACS authorization Yes HWTACACS accounting Yes 802.1X authentication Yes Version upgrade Security ARP security IP security Attack defense User access and authentication AAA NAC 75 CloudEngine S5735-S Series Switches 12 Function and Feature Network management Interoperability Description CloudEngine S5735-S MAC address authentication Yes Portal authentication Yes Hybrid authentication Yes Policy association Functioning as the access device Yes - Ping Yes Tracert Yes NQA Yes NTP Yes sFlow Yes SNMP v1 Yes SNMP v2c Yes SNMP v3 Yes HTTP Yes HTTPS Yes NETCONF/YANG Yes RMON Yes VLAN-based Spanning Tree (VBST) Yes Link-type Negotiation Protocol (LNP) Yes VLAN Central Management Protocol (VCMP) Yes - This content is applicable only to regions outside mainland China. Huawei reserves the right to interpret this content. Hardware Specifications Hardware specifications of the CloudEngine S5735-S24P4X/-S24T4X/-S32ST4X models Item Physical specificatio ns Fixed port Manageme nt port CloudEngine S5735S24P4X CloudEngine S5735S24T4X CloudEngine S5735S32ST4X Dimensions (W x D x H, mm) 43.6 mm x 442 mm x 420 mm 43.6 mm x 442 mm x 420 mm 43.6 mm x 442 mm x 420 mm Chassis height 1U 1U 1U Chassis weight (including packaging) 7.39 kg 7.21 kg 7.47 kg GE port 24 24 32 10GE port 4 4 4 ETH management port Supported Supported Supported 76 CloudEngine S5735-S Series Switches 13 Item CPU Storage Power supply system CloudEngine S5735S24P4X CloudEngine S5735S24T4X CloudEngine S5735S32ST4X Console port (RJ45) Supported Supported Supported USB port USB 2.0 USB 2.0 USB 2.0 Frequency 1000 MHz 1000 MHz 1000 MHz Cores 4 4 4 Memory (RAM) 1 GB 1 GB 1 GB Flash memory Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Power supply type 1000 W AC PoE 60 W AC 60 W AC 1000 W DC 1000 W DC Power supply redundancy 1+1 1+1 1+1 NOTE NOTE NOTE The backup power supply is optional. Rated voltage range Maximum voltage range AC input (1000 W AC PoE): 100 V AC to 240 V AC, 50/60 Hz The backup power supply is optional. The backup power supply is optional. AC input (60 W AC ): 100 V AC to 240 V AC, 50/60 Hz AC input (60 W AC ): 100 V AC to 240 V AC, 50/60 Hz DC input (1000 W DC): 48 VDC to -60 V DC DC input (1000 W DC): -48 VDC to -60 V DC AC input (1000 W AC PoE): 90 V AC to 290 V AC, 45 Hz to 65 Hz AC input (60 W AC ): 90 V AC to 264 V AC, 47 Hz to 63 Hz AC input (60 W AC ): 90 V AC to 264 V AC, 47 Hz to 63 Hz High-voltage DC input (1000 W AC PoE): 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) High-voltage DC input (60 W AC): 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) High-voltage DC input (60 W AC): 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) DC input (1000 W DC): 36 V DC to -72V DC DC input (1000 W DC): -36 V DC to -72V DC 60 W AC: 2 A 60 W AC: 2 A 1000 W DC: 30 A 1000 W DC: 30 A Maximum input current 8A Maximum power consumption of the device 65 W (without PD) 847 W (with PD, PD power consumption of 720 W) Power consumption in the case of 30% traffic load1 Power consumption in the case of 100% traffic 46 W 66 W 51 W 31 W 47 W 56 W 35 W 49 W 77 CloudEngine S5735-S Series Switches 14 Item CloudEngine S5735S24P4X CloudEngine S5735S24T4X CloudEngine S5735S32ST4X Heat dissipation mode Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Number of fan modules 2 2 2 Airflow Air flows in from the left,right sides and front panel, exhausts from the rear panel Air flows in from the left,right sides and front panel, exhausts from the rear panel Air flows in from the left,right sides and front panel, exhausts from the rear panel Maximum heat dissipation of the device (BTU/hour) Without PDs: 221.8 157 225.2 With PDs: 2890 Long-term operating temperature 0-1800 m altitude: 0°C to +50°C 0-1800 m altitude: 0°C to +50°C 0-1800 m altitude: 0°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Short-term operating temperature3 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: 5°C to +55°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5% to 95% (non-condensing) 5% to 95% (non-condensing) 5% to 95% (noncondensing) Operating altitude 5000 m 5000 m 5000 m Noise under normal temperature (sound power) 58.9 dB(A) 58.9 dB(A) 59.3 dB(A) Noise under high temperature (sound power) 75 dB(A) 75 dB(A) 75.4 dB(A) Noise under normal temperature (sound pressure) 43.8 dB(A) 43.8 dB(A) 44.2 dB(A) load1 Heat dissipation system Environmen t parameters 78 CloudEngine S5735-S Series Switches 15 Item Reliability CloudEngine S5735S24P4X CloudEngine S5735S24T4X CloudEngine S5735S32ST4X Surge protection specification (RJ45 service port) ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode Surge protection specification (power port) ±6 kV in differential mode, ±6 kV in common mode AC power port: ±6 kV in differential mode, ±6 kV in common mode DC power port: ±2 kV in differential mode, ±4 kV in common mode AC power port: ±6 kV in differential mode, ±6 kV in common mode DC power port: ±2 kV in differential mode, ±4 kV in common mode MTBF (year)2 59.88 69.42 68.59 MTTR (hour) 2 1.73 1.75 Availability > 0.99999 > 0.99999 > 0.99999 EMC certification EMC certification EMC certification Safety certification Safety certification Safety certification Manufacturing certification Manufacturing certification Manufacturing certification Certification Hardware specifications of the CloudEngine S5735-S48P4X/-S48S4X/-S48T4X models Item Physical specificatio ns Fixed port Manageme nt port CPU Storage CloudEngine S5735S48P4X CloudEngine S5735S48S4X CloudEngine S5735S48T4X Dimensions (W x D x H, mm) 43.6 mm x 442 mm x 420 mm 43.6 mm x 442 mm x 420 mm 43.6 mm x 442 mm x 420 mm Chassis height 1U 1U 1U Chassis weight (including packaging) 7.64 kg 8.27 kg 7.69 kg GE port 48 48 48 10GE port 4 4 4 ETH management port Supported Supported Supported Console port (RJ45) Supported Supported Supported USB port USB 2.0 USB 2.0 USB 2.0 Frequency 1000 MHz 1000 MHz 1000 MHz Cores 4 4 4 Memory (RAM) 1 GB 1 GB 1 GB Flash memory Hardware: 512 MB, of which Hardware: 512 MB, of which Hardware: 512 MB, of 79 CloudEngine S5735-S Series Switches 16 Item Power supply system CloudEngine S5735S48P4X CloudEngine S5735S48S4X CloudEngine S5735S48T4X 306 MB is available for users 306 MB is available for users which 306 MB is available for users Power supply type 1000 W AC PoE 150 W AC 60 W AC 1000 W DC 1000 W DC Power supply redundancy 1+1 1+1 1+1 NOTE NOTE NOTE The backup power supply is optional. Rated voltage range Maximum voltage range Heat dissipation system AC input (1000 W AC PoE): 100 V AC to 240 V AC, 50/60 Hz The backup power supply is optional. The backup power supply is optional. AC input (150 W AC ): 100 V AC to 240 V AC, 50/60 Hz AC input (60 W AC ): 100 V AC to 240 V AC, 50/60 Hz DC input (1000 W DC): 48 VDC to -60 V DC DC input (1000 W DC): -48 VDC to -60 V DC AC input (1000 W AC PoE): 90 V AC to 290 V AC, 45 Hz to 65 Hz AC input (150 W AC ): 90 V AC to 264 V AC, 47 Hz to 63 Hz AC input (60 W AC ): 90 V AC to 264 V AC, 47 Hz to 63 Hz High-voltage DC input (1000 W AC PoE): 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) DC input (1000 W DC): 36 V DC to -72V DC High-voltage DC input (60 W AC): 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) DC input (1000 W DC): -36 V DC to -72V DC 150 W AC: 3 A 60 W AC: 2 A 1000 W DC: 30 A 1000 W DC: 30 A Maximum input current 8A Maximum power consumption of the device 77 W (without PD) 1661 W (with PD, PD power consumption of 1600 W) Power consumption in the case of 30% traffic load1 89 W 59 W 59 W 67 W 40 W Power consumption in the case of 100% traffic load1 68 W 71 W 48 W Heat dissipation mode Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Number of fan modules 2 3 2 Airflow Air flows in from the left,right sides and front panel, exhausts from the rear panel Air flows in from the left,right sides and front panel, exhausts from the rear panel Air flows in from the left,right sides and front panel, exhausts from the rear panel 80 CloudEngine S5735-S Series Switches 17 Item Environme nt parameter s Reliability CloudEngine S5735S48P4X CloudEngine S5735S48S4X CloudEngine S5735S48T4X Maximum heat dissipation of the device (BTU/hour) Without PDs: 262.7 303.7 201.3 With PDs: 5667 Long-term operating temperature 0-1800 m altitude: 0°C to +50°C 0-1800 m altitude: 0°C to +50°C 0-1800 m altitude: 0°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Short-term operating temperature3 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: 5°C to +55°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5% to 95% (non-condensing) 5% to 95% (non-condensing) 5% to 95% (noncondensing) Operating altitude 5000 m 5000 m 5000 m Noise under normal temperature (sound power) 58.9dB (A) 61dB (A) 58.9dB (A) Noise under high temperature (sound power) 75dB (A) 75.7dB (A) 75dB (A) Noise under normal temperature (sound pressure) 43.8dB (A) 46dB (A) 43.8dB (A) Surge protection specification (RJ45 service port) ±7 kV in common mode NA ±7 kV in common mode Surge protection specification (power port) ±6 kV in differential mode, ±6 kV in common mode AC power port: ±6 kV in differential mode, ±6 kV in common mode AC power port: ±6 kV in differential mode, ±6 kV in common mode DC power port: ±2 kV in differential mode, ±4 kV in common mode DC power port: ±2 kV in differential mode, ±4 kV in common mode MTBF (year)2 54.88 66.33 74.7 81 CloudEngine S5735-S Series Switches 18 Item Certification CloudEngine S5735S48P4X CloudEngine S5735S48S4X CloudEngine S5735S48T4X MTTR (hour) 2.19 1.81 1.61 Availability > 0.99999 > 0.99999 > 0.99999 EMC certification EMC certification EMC certification Safety certification Safety certification Safety certification Manufacturing certification Manufacturing certification Manufacturing certification 1: The power consumption under different load conditions is calculated according to the ATIS standard. Additionally, the EEE function is enabled and there is no PoE power output. 2: The reliability parameter values are calculated based on the typical configuration of the device. The parameter values vary according to the modules configured by the customer. 3: Short term indicates that the successive operating time is no more than 96 hours, the total operating time is no more than 360 hours, or the number of times the operating temperature is over 45°C is no more than 15 in a year. Networking and Applications Large-Sized Enterprise Campus Networks As shown in the following figure, the CloudEngine S5735-S series switches are located at the access layer to build a highperformance, reliable enterprise campus network. Position of the CloudEngine S5735-S on a large-sized enterprise network The CloudEngine S5735-S provides various terminal security management features, and supports functions such as PoE, voice VLAN, and QoS. The CloudEngine S5735-S can be used for desktop access and provides gigabit access speed. 82 CloudEngine S5735-S Series Switches 19 The CloudEngine S5735-S provides various security features, including ARP security, IP security, IP source guard, and user access control policies such as NAC and ACLs, to control access of user terminals. In addition, the CloudEngine S5735-S supports the Link Aggregation Control Protocol (LACP) to provide multi-link access for servers, improving link bandwidth and reliability. Safety and Regulatory Compliance Safety and regulatory compliance of the CloudEngine S5735-S series Certification Category Description Safety IEC 60950-1 EN 60950-1/A11/A12 UL 60950-1 CSA C22.2 No 60950-1 AS/NZS 60950.1 CNS 14336-1 IEC60825-1 IEC60825-2 EN60825-1 EN60825-2 CISPR22 Class A CISPR24 EN55022 Class A EN55024 ETSI EN 300 386 Class A CFR 47 FCC Part 15 Class A ICES 003 Class A AS/NZS CISPR22 Class A VCCI Class A IEC61000-4-2 ITU-T K 20 ITU-T K 21 ITU-T K 44 CNS13438 RoHS REACH WEEE Electromagnetic Compatibility (EMC) Environment EMC: electromagnetic compatibility CISPR: International Special Committee on Radio Interference EN: European Standard ETSI: European Telecommunications Standards Institute CFR: Code of Federal Regulations FCC: Federal Communication Commission IEC: International Electrotechnical Commission AS/NZS: Australian/New Zealand Standard 83 CloudEngine S5735-S Series Switches 20 VCCI: Voluntary Control Council for Interference UL: Underwriters Laboratories CSA: Canadian Standards Association IEEE: Institute of Electrical and Electronics Engineers RoHS: restriction of the use of certain hazardous substances REACH: Registration Evaluation Authorization and Restriction of Chemicals WEEE: Waste Electrical and Electronic Equipment MIB and Standards Compliance Supported MIBs Supported MIBs of the CloudEngine S5735-S series Category MIB Public MIB BRIDGE-MIB DISMAN-NSLOOKUP-MIB DISMAN-PING-MIB DISMAN-TRACEROUTE-MIB ENTITY-MIB EtherLike-MIB IF-MIB IP-FORWARD-MIB IPv6-MIB LAG-MIB LLDP-EXT-DOT1-MIB LLDP-EXT-DOT3-MIB LLDP-MIB NOTIFICATION-LOG-MIB NQA-MIB OSPF-TRAP-MIB P-BRIDGE-MIB Q-BRIDGE-MIB RFC1213-MIB RIPv2-MIB RMON-MIB SAVI-MIB SNMP-FRAMEWORK-MIB SNMP-MPD-MIB SNMP-NOTIFICATION-MIB SNMP-TARGET-MIB SNMP-USER-BASED-SM-MIB SNMPv2-MIB TCP-MIB UDP-MIB HUAWEI-AAA-MIB HUAWEI-ACL-MIB Huawei-proprietary MIB 84 CloudEngine S5735-S Series Switches 21 Category MIB HUAWEI-ALARM-MIB HUAWEI-ALARM-RELIABILITY-MIB HUAWEI-BASE-TRAP-MIB HUAWEI-BRAS-RADIUS-MIB HUAWEI-BRAS-SRVCFG-EAP-MIB HUAWEI-BRAS-SRVCFG-STATICUSER-MIB HUAWEI-CBQOS-MIB HUAWEI-CDP-COMPLIANCE-MIB HUAWEI-CONFIG-MAN-MIB HUAWEI-CPU-MIB HUAWEI-DAD-TRAP-MIB HUAWEI-DC-MIB HUAWEI-DATASYNC-MIB HUAWEI-DEVICE-MIB HUAWEI-DHCPR-MIB HUAWEI-DHCPS-MIB HUAWEI-DHCP-SNOOPING-MIB HUAWEI-DIE-MIB HUAWEI-DNS-MIB HUAWEI-DLDP-MIB HUAWEI-ELMI-MIB HUAWEI-ERPS-MIB HUAWEI-ERRORDOWN-MIB HUAWEI-ENERGYMNGT-MIB HUAWEI-EASY-OPERATION-MIB HUAWEI-ENTITY-EXTENT-MIB HUAWEI-ENTITY-TRAP-MIB HUAWEI-ETHARP-MIB HUAWEI-ETHOAM-MIB HUAWEI-FLASH-MAN-MIB HUAWEI-FWD-RES-TRAP-MIB HUAWEI-GARP-APP-MIB HUAWEI-GTSM-MIB HUAWEI-HGMP-MIB HUAWEI-HWTACACS-MIB HUAWEI-IF-EXT-MIB HUAWEI-INFOCENTER-MIB HUAWEI-IPPOOL-MIB HUAWEI-IPV6-MIB HUAWEI-ISOLATE-MIB HUAWEI-L2IF-MIB HUAWEI-L2MAM-MIB HUAWEI-L2VLAN-MIB HUAWEI_LDT-MIB HUAWEI-LLDP-MIB 85 CloudEngine S5735-S Series Switches 22 Category MIB HUAWEI-MAC-AUTHEN-MIB HUAWEI-MEMORY-MIB HUAWEI-MFF-MIB HUAWEI-MFLP-MIB HUAWEI-MSTP-MIB HUAWEI-MULTICAST-MIB HUAWEI-NAP-MIB HUAWEI-NTPV3-MIB HUAWEI-PERFORMANCE-MIB HUAWEI-PORT-MIB HUAWEI-PORTAL-MIB HUAWEI-QINQ-MIB HUAWEI-RIPv2-EXT-MIB HUAWEI-RM-EXT-MIB HUAWEI-RRPP-MIB HUAWEI-SECURITY-MIB HUAWEI-SEP-MIB HUAWEI-SNMP-EXT-MIB HUAWEI-SSH-MIB HUAWEI-STACK-MIB HUAWEI-SWITCH-L2MAM-EXT-MIB HUAWEI-SWITCH-SRV-TRAP-MIB HUAWEI-SYS-MAN-MIB HUAWEI-TCP-MIB HUAWEI-TFTPC-MIB HUAWEI-TRNG-MIB HUAWEI-XQOS-MIB For more detailed information of MIBs supported by the CloudEngine S5735-S series, visit https://support.huawei.com/enterprise/en/switches/s5700-pid-6691579?category=reference-guides&subcategory=mib-reference. Standard Compliance Standard Organization Standard or Protocol IETF RFC 768 User Datagram Protocol (UDP) RFC 792 Internet Control Message Protocol (ICMP) RFC 793 Transmission Control Protocol (TCP) RFC 826 Ethernet Address Resolution Protocol (ARP) RFC 854 Telnet Protocol Specification RFC 951 Bootstrap Protocol (BOOTP) RFC 959 File Transfer Protocol (FTP) RFC 1058 Routing Information Protocol (RIP) RFC 1112 Host extensions for IP multicasting RFC 1157 A Simple Network Management Protocol (SNMP) 86 CloudEngine S5735-S Series Switches 23 Standard Organization IEEE Standard or Protocol RFC 1256 ICMP Router Discovery RFC 1305 Network Time Protocol Version 3 (NTP) RFC 1349 Internet Protocol (IP) RFC 1493 Definitions of Managed Objects for Bridges RFC 1542 Clarifications and Extensions for the Bootstrap Protocol RFC 1643 Ethernet Interface MIB RFC 1757 Remote Network Monitoring (RMON) RFC 1901 Introduction to Community-based SNMPv2 RFC 1902-1907 SNMP v2 RFC 1981 Path MTU Discovery for IP version 6 RFC 2131 Dynamic Host Configuration Protocol (DHCP) RFC 2328 OSPF Version 2 RFC 2453 RIP Version 2 RFC 2460 Internet Protocol, Version 6 Specification (IPv6) RFC 2461 Neighbor Discovery for IP Version 6 (IPv6) RFC 2462 IPv6 Stateless Address Auto configuration RFC 2463 Internet Control Message Protocol for IPv6 (ICMPv6) RFC 2474 Differentiated Services Field (DS Field) RFC 2740 OSPF for IPv6 (OSPFv3) RFC 2863 The Interfaces Group MIB RFC 2597 Assured Forwarding PHB Group RFC 2598 An Expedited Forwarding PHB RFC 2571 SNMP Management Frameworks RFC 2865 Remote Authentication Dial In User Service (RADIUS) RFC 3046 DHCP Option82 RFC 3376 Internet Group Management Protocol, Version 3 (IGMPv3) RFC 3513 IP Version 6 Addressing Architecture RFC 3579 RADIUS Support For EAP RFC 4271 A Border Gateway Protocol 4 (BGP-4) RFC 4760 Multiprotocol Extensions for BGP-4 draft-grant-tacacs-02 TACACS+ IEEE 802.1D Media Access Control (MAC) Bridges IEEE 802.1p Traffic Class Expediting and Dynamic Multicast Filtering IEEE 802.1Q Virtual Bridged Local Area Networks IEEE 802.1ad Provider Bridges IEEE 802.2 Logical Link Control IEEE Std 802.3 CSMA/CD IEEE Std 802.3ab 1000BASE-T specification IEEE Std 802.3ad Aggregation of Multiple Link Segments IEEE Std 802.3ae 10GE WEN/LAN Standard IEEE Std 802.3x Full Duplex and flow control IEEE Std 802.3z Gigabit Ethernet Standard IEEE802.1ax/IEEE802.3ad Link Aggregation 87 CloudEngine S5735-S Series Switches 24 Standard Organization Standard or Protocol IEEE 802.3ah Ethernet in the First Mile IEEE 802.1ag Connectivity Fault Management IEEE 802.1ab Link Layer Discovery Protocol IEEE 802.1D Spanning Tree Protocol IEEE 802.1w Rapid Spanning Tree Protocol IEEE 802.1s Multiple Spanning Tree Protocol IEEE 802.1x Port based network access control protocol IEEE 802.3af DTE Power via MIDI IEEE 802.3at DTE Power via the MDI Enhancements ITU SG13 Y.17ethoam ITU SG13 QoS control Ethernet-Based IP Access ITU-T Y.1731 ETH OAM performance monitor ISO ISO 10589 IS-IS Routing Protocol MEF MEF 2 Requirements and Framework for Ethernet Service Protection MEF 9 Abstract Test Suite for Ethernet Services at the UNI MEF 10.2 Ethernet Services Attributes Phase 2 MEF 11 UNI Requirements and Framework MEF 13 UNI Type 1 Implementation Agreement MEF 15 Requirements for Management of Metro Ethernet Phase 1 Network Elements MEF 17 Service OAM Framework and Requirements MEF 20 UNI Type 2 Implementation Agreement MEF 23 Class of Service Phase 1 Implementation Agreement XMODEM/YMODEM Protocol Reference ITU Ordering Information The following table lists ordering information of the CloudEngine S5735-S series switches. Model Product Description CloudEngine S5735-S24T4X CloudEngine S5735-S24T4X (24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports, without power module) CloudEngine S5735-S24P4X CloudEngine S5735-S24P4X (24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports, PoE+, without power module) CloudEngine S5735-S48T4X CloudEngine S5735-S48T4X (48 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports, without power module) CloudEngine S5735-S48P4X CloudEngine S5735-S48P4X (48 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports, PoE+, without power module) CloudEngine S5735-S32ST4X CloudEngine S5735-S32ST4X (24 x GE SFP ports, 8 of which are dual-purpose 10/100/1000 or SFP, 4 x 10 GE SFP+ ports, without power module) CloudEngine S5735-S48S4X CloudEngine S5735-S48S4X (48 x GE SFP ports, 4 x 10 GE SFP+ port, without power module) PAC1000S56-CB 1000 W AC PoE power module,used in PoE models 88 CloudEngine S5735-S Series Switches 25 Model Product Description PDC1000S12-DB 1000 W DC power module,used in Non-PoE models PAC150S12-R 150 W AC power module, used in CloudEngine S5735-S48S4X PAC60S12-AR 60 W AC power module More Information For more information about Huawei Campus Switches, visit http://e.huawei.com or contact us in the following ways: Global service hotline: http://e.huawei.com/en/service-hotline Logging in to the Huawei Enterprise technical support website: http://support.huawei.com/enterprise/ Sending an email to the customer service mailbox: support_e@huawei.com Copyright © Huawei Technologies Co., Ltd. 2019. All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means without prior written consent of Huawei Technologies Co., Ltd. Trademarks and Permissions and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd. All other trademarks and trade names mentioned in this document are the property of their respective holders. Notice The purchased products, services and features are stipulated by the contract made between Huawei and the customer. All or part of the products, services and features described in this document may not be within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information, and recommendations in this document are provided "AS IS" without warranties, guarantees or representations of any kind, either express or implied. The information in this document is subject to change without notice. Every effort has been made in the preparation of this document to ensure accuracy of the contents, but all statements, information, and recommendations in this document do not constitute a warranty of any kind, express or implied. Huawei Technologies Co., Ltd. Address:Huawei Industrial Base Bantian, Longgang Shenzhen 518129 People's Republic of China Website:e.huawei.com 89 CloudEngine S5735-S Series Switches 26 Datasheet CloudEngine S5735-L Series Switches Datasheet Huawei CloudEngine S5735-L series are simplified gigabit Ethernet switches that provide all GE downlink ports and GE or 10GE uplink ports. Introduction CloudEngine S5735-L series switches are ideal for scenarios such as enterprise campus network access and gigabit to the desktop. Built on next-generation, high-performance hardware and the Huawei Versatile Routing Platform (VRP), CloudEngine S5735-L switches stand out with compelling features such as intelligent stack (iStack), flexible Ethernet networking, and diversified security control. They support multiple Layer 3 routing protocols and provide high performance and service processing capabilities. Product Overview Models and Appearances The following models are available in the CloudEngine S5735-L series. Models and appearances of the CloudEngine S5735-L series Models and Appearances CloudEngine S5735-L8T4S-QA1 CloudEngine S5735-L8P4S-QA1 CloudEngine S5735-L24T4S-QA1 Description 8 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply Forwarding performance: 18 Mpps Switching capacity: 24 Gbps/336 Gbps 8 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply PoE+ Forwarding performance: 18 Mpps Switching capacity: 24 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply Forwarding performance: 42 Mpps Switching capacity: 56 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply 90 CloudEngine S5735-L Series Switches Datasheet 1 Models and Appearances Description CloudEngine S5735-L24T4X-QA1 Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbps 8 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply Forwarding performance: 18 Mpps Switching capacity: 24 Gbps/336 Gbps 8 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply PoE+ Forwarding performance: 18 Mpps Switching capacity: 24 Gbps/336 Gbps 8 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply Forwarding performance: 72 Mpps Switching capacity: 96 Gbps/336 Gbps 8 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply PoE+ Forwarding performance: 72 Mpps Switching capacity: 96 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply Forwarding performance: 42 Mpps Switching capacity: 56 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply PoE+ Forwarding performance: 42 Mpps Switching capacity: 56 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports DC power supply Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply PoE+ Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbps CloudEngine S5735-L8T4S-A1 CloudEngine S5735-L8P4S-A1 CloudEngine S5735-L8T4X-A1 CloudEngine S5735-L8P4X-A1 CloudEngine S5735-L24T4S-A1 CloudEngine S5735-L24P4S-A1 CloudEngine S5735-L24T4X-A1 CloudEngine S5735-L24T4X-D1 CloudEngine S5735-L24P4X-A1 91 CloudEngine S5735-L Series Switches Datasheet 2 Models and Appearances CloudEngine S5735-L48T4S-A1 CloudEngine S5735-L48P4S-A1 CloudEngine S5735-L48T4X-A1 CloudEngine S5735-L48P4X-A1 CloudEngine S5735-L12T4S-A CloudEngine S5735-L12P4S-A CloudEngine S5735-L24T4S-A CloudEngine S5735-L24P4S-A Description 48 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply Forwarding performance: 78 Mpps Switching capacity: 104 Gbps/432 Gbps 48 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply PoE+ Forwarding performance: 78 Mpps Switching capacity: 104 Gbps/432 Gbps 48 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply Forwarding performance: 132 Mpps Switching capacity: 176 Gbps/432 Gbps 48 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply PoE+ Forwarding performance: 132 Mpps Switching capacity: 176 Gbps/432 Gbps 12 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply Forwarding performance: 24 Mpps Switching capacity: 32 Gbps/336 Gbps 12 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply PoE+ Forwarding performance: 24 Mpps Switching capacity: 32 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply Forwarding performance: 42 Mpps Switching capacity: 56 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply PoE+ Forwarding performance: 42 Mpps Switching capacity: 56 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports DC power supply CloudEngine S5735-L24T4X-A 92 CloudEngine S5735-L Series Switches Datasheet 3 Models and Appearances Description CloudEngine S5735-L24T4X-D Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbps 24 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply PoE+ Forwarding performance: 96 Mpps Switching capacity: 128 Gbps/336 Gbps 48 x 10/100/1000Base-T ports, 4 x GE SFP ports AC power supply Forwarding performance: 78 Mpps Switching capacity: 104 Gbps/432 Gbps 48 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply Forwarding performance: 132 Mpps Switching capacity: 176 Gbps/432 Gbps 48 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply PoE+ Forwarding performance: 132 Mpps Switching capacity: 176 Gbps/432 Gbps 24 x GE SFP ports, 8 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports AC power supply Forwarding performance: 108 Mpps Switching capacity: 144 Gbps/432 Gbps 24 x GE SFP ports, 8 x 10/100/1000Base-T ports, 4 x 10 GE SFP+ ports DC power supply Forwarding performance: 108 Mpps Switching capacity: 144 Gbps/432 Gbps CloudEngine S5735-L24P4X-A CloudEngine S5735-L48T4S-A CloudEngine S5735-L48T4X-A CloudEngine S5735-L48P4X-A CloudEngine S5735-L32ST4X-A CloudEngine S5735-L32ST4X-D Note:The value before the slash (/) refers to the device's switching capability, while the value after the slash (/) means the system's switching capability. Power Supply Technical specifications of the power supplies applicable to the CloudEngine S5735-L series Power Module PAC1000S56-DB Technical Specifications Applied Switch Model Dimensions (H x W x D): 40 mm x 90 mm x 215 mm (1.6 in. x 3.5 in. x 8.5 in.) Weight: 1.1 kg (2.43 lb) Rated input voltage range: − 100 V AC to 130 V AC, 50/60 Hz − 200 V AC to 240 V AC, 50/60 Hz − 240 V DC CloudEngine S5735-L48P4X-A 93 CloudEngine S5735-L Series Switches Datasheet 4 Power Module Technical Specifications Maximum input voltage range: − 90 V AC to 290 V AC, 45 Hz to 65 Hz − 190 V DC to 290 V DC Input current: − 100 V AC to 130 V AC: 12 A − 200 V AC to 240 V AC: 8 A − 240 V DC: 8 A Maximum output current: − 100 V AC to 130 V AC input: 16.08 A − 200 V AC to 240 V AC input and 240 V DC input: 17.86 A Maximum output power: − Applied Switch Model Total power: 900 W (100 V AC to 130 V AC input)/1000 W (200 V AC to 240 V AC input and 240 V DC input) Hot swap: Supported CloudEngine S5735-L48P4X-A is a PoE switch. It has one power module slot, which can have a 1000 W PoE power module installed. The following table lists its power supply configurations. Power supply configurations of CloudEngine S5735-L48P4X-A Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) 1000 W AC PoE (220 V) 874 W 802.3af (15.4 W per port): 48 802.3at (30 W per port): 29 802.3af (15.4 W per port): 48 802.3at (30 W per port): 25 1000 W AC PoE (110 V) 779 W Power supply configurations of CloudEngine S5735-L48P4X-A1 Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 380 W 802.3af (15.4 W per port): 24 802.3at (30 W per port): 12 Power supply configurations of CloudEngine S5735-L48P4S-A1 Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 380 W 802.3af (15.4 W per port): 24 802.3at (30 W per port): 12 94 CloudEngine S5735-L Series Switches Datasheet 5 Power supply of CloudEngine S5735-L24P4X-A Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 380 W 802.3af (15.4 W per port): 24 802.3at (30 W per port): 12 Power supply of CloudEngine S5735-L24P4X-A1 Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 380 W 802.3af (15.4 W per port): 24 802.3at (30 W per port): 12 Power supply of CloudEngine S5735-L24P4S-A Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 380 W 802.3af (15.4 W per port): 24 802.3at (30 W per port): 12 Power supply of CloudEngine S5735-L24P4S-A1 Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 380 W 802.3af (15.4 W per port): 24 802.3at (30 W per port): 12 Power supply of CloudEngine S5735-L12P4S-A Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 360 W 802.3af (15.4 W per port): 12 802.3at (30 W per port): 12 Power supply of CloudEngine S5735-L8P4X-A1 Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 124 W 802.3af (15.4 W per port): 8 802.3at (30 W per port): 4 Power supply of CloudEngine S5735-L8P4S-A1 Power Module Available PoE Power Maximum Number of Ports (Fully Loaded) Built-in AC Power Module 124 W 802.3af (15.4 W per port): 8 802.3at (30 W per port): 4 95 CloudEngine S5735-L Series Switches Datasheet 6 Product Features and Highlights Flexible Ethernet Networking In addition to supporting traditional Spanning Tree Protocol (STP), Rapid Spanning Tree Protocol (RSTP), and Multiple Spanning Tree Protocol (MSTP), CloudEngine S5735-L is also designed with Huawei-developed Smart Ethernet Protection (SEP) technology and the industry's latest Ethernet Ring Protection Switching (ERPS) technology. SEP is a ring protection protocol specific to the Ethernet link layer, and applies to various ring network topologies, such as open ring topology, closed ring topology, and cascading ring topology. This protocol is reliable, easy to maintain, and implements fast protection switching within 50 ms. ERPS is defined in ITU-T G.8032, and it implements millisecond-level protection switching based on traditional Ethernet MAC and bridging functions. CloudEngine S5735-L supports Smart Link, which implements backup of uplinks. One CloudEngine S5735-L switch can connect to multiple aggregation switches through multiple links, significantly improving reliability of access devices. CloudEngine S5735-L supports Ethernet OAM (IEEE 802.3ah/802.1ag) to fast-detect link faults. Diversified Security Control CloudEngine S5735-L supports 802.1X authentication, MAC address authentication, and hybrid authentication on a per port basis, as well as Portal authentication on a per VLANIF interface basis, and implements dynamic policy delivery (VLAN, QoS, and ACL) to users. CloudEngine S5735-L provides a series of mechanisms to defend against DoS attacks and user-targeted attacks. DoS attacks are targeted at switches and include SYN flood, Land, Smurf, and ICMP flood attacks. User-targeted attacks include bogus DHCP server attacks, IP/MAC address spoofing, DHCP request flood, and changing of the DHCP CHADDR value. CloudEngine S5735-L sets up and maintains a DHCP snooping binding table, and discards the packets that do not match the table entries. The DHCP snooping trusted port feature ensures that users connect only to the authorized DHCP server. CloudEngine S5735-L supports strict ARP learning. This feature prevents ARP spoofing attackers from exhausting ARP entries so that users can connect to the Internet normally. Easy Operation and Maintenance CloudEngine S5735-L supports Huawei Easy Operation, a solution that provides zero-touch deployment, replacement of faulty devices without additional configuration, USB-based deployment*, batch device configuration, and batch remote upgrade. The Easy Operation solution facilitates device deployment, upgrade, service provisioning, and other management and maintenance operations, and also greatly reduces O&M costs. CloudEngine S5735-L can be managed and maintained using Simple Network Management Protocol (SNMP) V1, V2, and V3, Command Line Interface (CLI), web-based network management system, or Secure Shell (SSH) V2.0. Additionally, it supports remote network monitoring (RMON), multiple log hosts, port traffic statistics collection, and network quality analysis, paving the way for network optimization and reconstruction. CloudEngine S5735-L supports the EasyDeploy function. Specifically, the Commander collects the topology information of the downstream clients and saves client startup information based on the topology. Clients can be replaced without configuration. Configuration and scripts can be delivered to clients in batches. In addition, the configuration delivery result can be queried. The Commander can also collect and display power consumption information on the entire network. CloudEngine S5735-L can use the GARP VLAN Registration Protocol (GVRP) to implement VLAN dynamic distribution, registration, and attribute propagation. GVRP reduces manual configuration workload and ensures correct configuration. CloudEngine S5735-L supports MUX VLAN, which involves a principal VLAN and multiple subordinate VLANs. Subordinate VLANs are classified into group VLANs and separate VLANs. Ports in the principal VLAN can communicate with ports in subordinate VLANs. Ports in a subordinate group VLAN can communicate with each other, whereas ports in a subordinate separate VLAN cannot communicate with each other. CloudEngine S5735-L also supports VLAN Central Management Protocol (VCMP) and VLAN-Based Spanning Tree (VBST) protocol. Note: Only those switches with USB ports can USB-based deployment. iStack CloudEngine S5735-L supports intelligent stack (iStack). This technology combines multiple switches into a logical switch. Member switches in a stack implement redundancy backup to improve device reliability and use inter-device link aggregation to improve link reliability. iStack provides high network scalability. You can increase ports, bandwidth, and processing capacity of a stack by simply adding member switches to the stack. 96 CloudEngine S5735-L Series Switches Datasheet 7 iStack also simplifies device configuration and management. After a stack is set up, multiple physical switches are virtualized into one logical device. You can log in to any member switch in the stack to manage all the member switches in the stack. CloudEngine S5735-L support stacking through electrical ports. Note:Mixed stacking between CloudEngine S5735-L-A/D and CloudEngine S5735-L-A1/D1 is not supported. Excellent Network Traffic Analysis CloudEngine S5735-L supports the sFlow function. It uses a method defined in the sFlow standard to sample traffic passing through it and sends sampled traffic to the collector in real time. The collected traffic statistics are used to generate statistical reports, helping enterprises maintain their networks. PoE Function Perpetual PoE: When a PoE switch is abnormal Power-off or the software version is upgraded, the power supply to PDs is not interrupted. This capability ensures that PDs are not powered off during the switch reboot. Fast PoE: PoE switches can supply power to PDs within seconds after they are powered on. This is different from common switches that generally take 1 to 3 minutes to start to supply power to PDs. When a PoE switch reboots due to a power failure, the PoE switch continues to supply power to the PDs immediately after being powered on without waiting until it finishes reboot. This greatly shortens the power failure time of PDs. Intelligent O&M CloudEngine S5735-L provides telemetry technology to collect device data in real time and send the data to Huawei campus network analyzer CampusInsight. The CampusInsight analyzes network data based on the intelligent fault identification algorithm, accurately displays the real-time network status, effectively demarcates and locates faults in a timely manner, and identifies network problems that affect user experience, accurately guaranteeing user experience. CloudEngine S5735-L supports a variety of intelligent O&M features for audio and video services, including the enhanced Media Delivery Index (eMDI). With this eDMI function, the switch can function as a monitored node to periodically conduct statistics and report audio and video service indicators to the CampusInsight platform. In this way, the CampusInsight platform can quickly demarcate audio and video service quality faults based on the results of multiple monitored nodes. Intelligent Upgrade CloudEngine S5735-L supports the intelligent upgrade feature. Specifically, CloudEngine S5735-L obtains the version upgrade path and downloads the newest version for upgrade from the Huawei Online Upgrade Platform (HOUP). The entire upgrade process is highly automated and achieves one-click upgrade. In addition, preloading the version is supported, which greatly shortens the upgrade time and service interruption time. The intelligent upgrade feature greatly simplifies device upgrade operations and makes it possible for the customer to upgrade the version independently. This greatly reduces the customer's maintenance costs. In addition, the upgrade policies on the HOUP platform standardize the upgrade operations, which greatly reduces the risk of upgrade failures. Cloud Management The Huawei cloud management platform allows users to configure, monitor, and inspect switches on the cloud, reducing on-site deployment and O&M manpower costs and decreasing network OPEX. Huawei switches support both cloud management and on-premise management modes. These two management modes can be flexibly switched as required to achieve smooth evolution while maximizing return on investment (ROI). OPS CloudEngine S5735-L supports Open Programmability System (OPS), an open programmable system based on the Python language. IT administrators can program the O&M functions of a CloudEngine S5735-L switch through Python scripts to quickly innovate functions and implement intelligent O&M. Licensing CloudEngine S5735-L supports both the traditional feature-based licensing mode and the latest Huawei IDN One Software (N1 mode for short) licensing mode. The N1 mode is ideal for deploying Huawei CloudCampus Solution in the on-premises scenario, as it greatly enhances the customer experiences in purchasing and upgrading software services with simplicity. 97 CloudEngine S5735-L Series Switches Datasheet 8 Software Package Features in N1 Mode Switch Functions N1 Basic Software N1 Foundation Software Package N1 Advanced Software Package Basic network functions: √ √ √ × √ √ × × √ Layer 2 functions, IPv4, IPv6, SVF, and others Note: For details, see the Service Features Basic network automation based on the iMaster NCECampus: Basic automation: Plug-and-play Basic monitoring: Application visualization NE management: Image and topology management and discovery Advanced network automation and intelligent O&M: User access authentication and CampusInsight basic functions Note: Only V200R019C10 and later versions can support N1 mode. Product Specifications Functions and Features Function and feature metrics for the CloudEngine S5735-L series Function and Feature Description CloudEngines S5735-L Ethernet features Full-duplex, half-duplex, and auto-negotiation Yes Rate auto-negotiation on an interface Yes Auto MDI and MDI-X Yes Flow control on an interface Yes Jumbo frames Yes Link aggregation Yes Load balancing among links of a trunk Yes Transparent transmission of Layer 2 protocol packets Yes Device Link Detection Protocol (DLDP) Yes Link Layer Discovery Protocol (LLDP) Yes Link Layer Discovery Protocol-Media Endpoint Discovery (LLDP-MED) Yes Interface isolation Yes Broadcast traffic suppression on an interface Yes Multicast traffic suppression on an interface Yes Ethernet basics 98 CloudEngine S5735-L Series Switches Datasheet 9 Function and Feature Description CloudEngines S5735-L Unknown unicast traffic suppression on an interface Yes VLAN broadcast traffic suppression Yes VLAN multicast traffic suppression Yes VLAN unknown unicast traffic suppression Yes VLAN specification 4094 VLANIF interface specification 1024 Access mode Yes Trunk mode Yes Hybrid mode Yes QinQ mode Yes Default VLAN Yes VLAN assignment based on interfaces Yes VLAN assignment based on protocols Yes VLAN assignment based on IP subnets Yes VLAN assignment based on MAC addresses Yes VLAN assignment based on MAC address + IP address Yes VLAN assignment based on MAC address + IP address + interface number Yes Adding double VLAN tags to packets based on interfaces Yes VLAN mapping Yes Selective QinQ Yes MUX VLAN Yes Voice VLAN Yes Guest VLAN Yes GARP Yes GVRP Yes VCMP VCMP Yes MAC MAC address 32896(MAX) Automatic learning of MAC addresses Yes Automatic aging of MAC addresses Yes Static, dynamic, and blackhole MAC address entries Yes Interface-based MAC address learning limiting Yes VLAN GVRP 99 CloudEngine S5735-L Series Switches Datasheet 10 Function and Feature Description CloudEngines S5735-L Sticky MAC Yes MAC address flapping detection Yes MAC address spoofing defense Yes Port bridge Yes Static ARP Yes Dynamic ARP Yes ARP entry 4096(MAX) ARP aging detection Yes Intra-VLAN proxy ARP Yes Routed proxy ARP Yes STP Yes RSTP Yes MSTP Yes VBST Yes BPDU protection Yes Root protection Yes Loop protection Yes Defense against TC BPDU attacks Yes Loopback detection Loop detection on an interface Yes SEP SEP Yes Smart Link Smart Link Yes Smart Link multi-instance Yes Monitor Link Yes RRPP Yes Single RRPP ring Yes Tangent RRPP ring Yes Intersecting RRPP ring Yes Hybrid networking of RRPP rings and other ring networks Yes G.8032 v1 Yes G.8032 v2 Yes ERPS semi-ring topology Yes ERPS closed-ring topology Yes IPv4 static routing Yes ARP Ethernet loop protection MSTP RRPP ERPS IPv4/IPv6 forwarding IPv4 and unicast 100 CloudEngine S5735-L Series Switches Datasheet 11 Function and Feature routing Multicast routing features IPv6 features Layer 2 multicast features - Description CloudEngines S5735-L VRF Yes DHCP client Yes DHCP server Yes DHCP relay Yes Routing policies Yes IPv4 routes 4096(MAX) RIPv1 Yes RIPv2 Yes OSPF Yes Policy-based routing (PBR) Yes IGMPv1/v2/v3 Yes PIM-DM Yes PIM-SM Yes MSDP Yes IPv4 multicast routes 1500(MAX) IPv6 multicast routes 1500(MAX) Multicast routing policies Yes RPF Yes IPv6 protocol stack Yes ND Yes ND entry 1024(MAX) ND snooping Yes DHCPv6 snooping Yes RIPng Yes DHCPv6 server Yes DHCPv6 relay Yes OSPFv3 Yes IPv6 routes 1024(MAX) VRRP6 Yes MLDv1/v2 Yes PIM-DM for IPv6 Yes PIM-SM for IPv6 Yes IGMPv1/v2/v3 snooping Yes IGMP snooping proxy Yes 101 CloudEngine S5735-L Series Switches Datasheet 12 Function and Feature Device reliability Ethernet OAM Description CloudEngines S5735-L MLD snooping Yes Multicast traffic suppression Yes Inter-VLAN multicast replication Yes Service interface-based stacking Yes Maximum number of stacked devices 9 Stack bandwidth (Bidirectional) 80Gbps(MAX) VRRP VRRP standard protocol Yes EFM (802.3ah) Automatic discovery of links Yes Link fault detection Yes Link troubleshooting Yes Remote loopback Yes Software-level CCM Yes 802.1ag MAC ping Yes 802.1ag MAC trace Yes OAM association Association between 802.1ag and 802.3ah Yes Y.1731 Unidirectional delay and jitter measurement Yes Bidirectional delay and jitter measurement Yes Traffic classification based on ACLs Yes Configuring traffic classification priorities Yes Matching the simple domains of packets Yes Traffic filtering Yes Traffic policing (CAR) Yes Modifying the packet priorities Yes Modifying the simple domains of packets Yes Modifying the packet VLANs Yes Traffic shaping on an egress interface Yes Traffic shaping on queues on an interface Yes Congestion avoidance Tail drop Yes Congestion management Priority Queuing (PQ) Yes Weighted Deficit Round Robin (WDRR) Yes PQ+WDRR Yes Weighted Round Robin (WRR) Yes PQ+WRR Yes Stacking CFM (802.1ag) QoS features Traffic classification Traffic behavior Traffic shaping 102 CloudEngine S5735-L Series Switches Datasheet 13 Function and Feature ACL Configuration and maintenance Packet filtering at Layer 2 to Layer 4 Login and configuration management File system Monitoring and maintenance Version upgrade Security ARP security Description CloudEngines S5735-L Number of rules per IPv4 ACL 2K Number of rules per IPv6 ACL 2K Basic IPv4 ACL Yes Advanced IPv4 ACL Yes Basic IPv6 ACL Yes Advanced IPv6 ACL Yes Layer 2 ACL Yes User-defined ACL Yes Command line interface (CLI)-based configuration Yes Console terminal service Yes Telnet terminal service Yes SSH v1.5 Yes SSH v2.0 Yes SNMP-based NMS for unified configuration Yes Web page-based configuration and management Yes EasyDeploy (client) Yes SVF Yes Cloud management Yes OPS Yes Directory and file management Yes File upload and download Yes eMDI Yes Hardware monitoring Yes Log information output Yes Alarm information output Yes Debugging information output Yes Port mirroring Yes Flow mirroring Yes Remote mirroring Yes Energy saving Yes Version upgrade Yes Version rollback Yes ARP packet rate limiting Yes ARP anti-spoofing Yes 103 CloudEngine S5735-L Series Switches Datasheet 14 Function and Feature Description CloudEngines S5735-L Association between ARP and STP Yes Dynamic ARP Inspection (DAI) Yes Static ARP Inspection (SAI) Yes Egress ARP Inspection (EAI) Yes ICMP attack defense Yes IPSG for IPv4 Yes IPSG user capacity 1K IPSG for IPv6 Yes IPSGv6 user capacity 512 Local attack defense CPU attack defense Yes MFF MFF Yes DHCP snooping DHCP snooping Yes Option 82 function Yes Dynamic rate limiting for DHCP packets Yes Defense against malformed packet attacks Yes Defense against UDP flood attacks Yes Defense against TCP SYN flood attacks Yes Defense against ICMP flood attacks Yes Defense against packet fragment attacks Yes Local URPF Yes Local authentication Yes Local authorization Yes RADIUS authentication Yes RADIUS authorization Yes RADIUS accounting Yes HWTACACS authentication Yes HWTACACS authorization Yes HWTACACS accounting Yes 802.1X authentication Yes MAC address authentication Yes Portal authentication Yes Hybrid authentication Yes Functioning as the access device Yes IP security Attack defense User access and authentication AAA NAC Policy association 104 CloudEngine S5735-L Series Switches Datasheet 15 Function and Feature Description CloudEngines S5735-L Network management Ping Yes Tracert Yes NQA Yes NTP Yes sFlow Yes SNMP v1 Yes SNMP v2c Yes SNMP v3 Yes HTTP Yes HTTPS Yes RMON Yes NETCONF/YANG Yes VLAN-based Spanning Tree (VBST) Yes Link-type Negotiation Protocol (LNP) Yes VLAN Central Management Protocol (VCMP) Yes Interoperability - - This content is applicable only to regions outside mainland China. Huawei reserves the right to interpret this content. Hardware Specifications Hardware specifications of CloudEngine S5735-L8T4S-QA1/-L8P4S-QA1/-L24T4S-QA1/-L24T4X-QA1 models Item Physical specifications Fixed port Management port CPU Storage CloudEngine S5735-L8T4SQA1 CloudEngine S5735-L8P4SQA1 CloudEngine S5735-L24T4SQA1 CloudEngine S5735-L24T4XQA1 Dimensions (H x W x D) 43.6 mm x 320 mm x 210 mm 43.6 mm x 320 mm x 210 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm Chassis height 1U 1U 1U 1U Chassis weight (including packaging) 3.10 kg 4.06 kg 4.45 kg 4.45 kg GE port 8 8(PoE+) 24 24 GE SFP pot 4 4 4 NA 10GE port NA NA NA 4 Console port (RJ45) Supported Supported Supported Supported USB Port NA NA NA USB 2.0 Frequency 1000 MHz 1000 MHz 1000 MHz 1000 MHz Core 2 2 2 2 Memory (RAM) 512 MB 512 MB 512 MB 512 MB 105 CloudEngine S5735-L Series Switches Datasheet 16 Item Power supply system Heat dissipation system Environment parameters CloudEngine S5735-L8T4SQA1 CloudEngine S5735-L8P4SQA1 CloudEngine S5735-L24T4SQA1 CloudEngine S5735-L24T4XQA1 Flash memory Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Power supply type Built-in AC AC Adapter Built-in AC Built-in AC Rated voltage range AC input: 100 V AC to 240 V AC, 50/60 Hz AC input: 100 V AC to 240 V AC, 50/60 Hz AC input: 100 V AC to 240 V AC, 50/60 Hz AC input: 100 V AC to 240 V AC, 50/60 Hz Maximum voltage range Maximum input current 0.8 A 3A Maximum power consumption of the device 22 W 28 W (without PD) 159 W (with PD, PD power consumption of 114 W) Power consumption in the case of 30% traffic load1 20.5 W Power consumption in the case of 100% traffic load1 AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz 2A 2A 33 W 34 W 26.3 W 29.8 W 30.8 W 20.8 W 27.9 W 31.8 W 33.2 W Heat dissipation mode Natural heat dissipation Natural heat dissipation Natural heat dissipation Natural heat dissipation Number of fan modules NA NA NA NA Airflow NA NA NA NA Maximum heat dissipation of the device (BTU/hour) 69.95 89.74 101.68 105.09 Long-term operating temperature 0-1800 m altitude: -5°C to +45°C 0-1800 m altitude: -5°C to +45°C 0-1800 m altitude: -5°C to +45°C 0-1800 m altitude: -5°C to +45°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 106 CloudEngine S5735-L Series Switches Datasheet 17 Item Reliability CloudEngine S5735-L8T4SQA1 CloudEngine S5735-L8P4SQA1 CloudEngine S5735-L24T4SQA1 CloudEngine S5735-L24T4XQA1 Short-term operating temperature3 NA NA NA NA Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) Operating altitude 5000 m 5000 m 5000 m 5000 m Noise under normal temperature (sound power) fanless, noise-free, fanless, noisefree, fanless, noisefree, fanless, noisefree, <30dB (A) <30dB (A) <30dB (A) Noise under high temperature (sound power) fanless, noise-free, fanless, noisefree, fanless, noisefree, fanless, noisefree, <30dB (A) <30dB (A) <30dB (A) Noise under normal temperature (sound pressure) fanless, noise-free, fanless, noisefree, fanless, noisefree, fanless, noisefree, <20dB (A) <20dB (A) <20dB (A) Surge protection specification (RJ45 service port) ±10 kV in common mode ±10 kV in common mode ±10 kV in common mode ±10 kV in common mode Surge protection specification (power port) Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ±6 kV MTBF (year)2 71.82 66.56 66.16 62.05 MTTR (hour) 2 2 2 2 Availability > 0.99999 > 0.99999 > 0.99999 > 0.99999 EMC certification EMC certification EMC certification EMC certification Safety certification Safety certification Safety certification Safety certification Manufacturing certification Manufacturing certification Manufacturing certification Manufacturing certification Certification <30dB (A) <30dB (A) <20dB (A) Hardware specifications of CloudEngine S5735-L8T4S-A1/-L8P4S-A1/-L8T4X-A1/-L8P4X-A1/-L24T4S-A1 models Item Physical specification s CloudEngine S5735L8T4S-A1 CloudEngine S5735L8P4S-A1 CloudEngin e S5735L8T4X-A1 CloudEngin e S5735L8P4X-A1 CloudEngin e S5735L24T4S-A1 Dimensions (H x W x D) 43.6 mm x 250 mm x 180 mm 43.6 mm x 300 mm x 220 mm 43.6 mm x 250 mm x 180 mm 43.6 mm x 300 mm x 220 mm 43.6 mm x 442 mm x 220 mm Chassis height 1U 1U 1U 1U 1U Chassis weight (including 2.02 kg 3.17 kg 2.08 kg 3.17 kg 3.34 kg 107 CloudEngine S5735-L Series Switches Datasheet 18 Item CloudEngine S5735L8T4S-A1 CloudEngine S5735L8P4S-A1 CloudEngin e S5735L8T4X-A1 CloudEngin e S5735L8P4X-A1 CloudEngin e S5735L24T4S-A1 GE port 8 8(PoE+) 8 8(PoE+) 24 GE SFP pot 4 4 NA NA 4 10GE port NA NA 4 4 NA Console port (RJ45) Supported Supported Supported Supported Supported USB Port NA NA USB 2.0 USB 2.0 NA Frequency 1000 MHz 1000 MHz 1000 MHz 1000 MHz 1000 MHz Core 2 2 2 2 2 Memory (RAM) 512 MB 512 MB 512 MB 512 MB 512 MB Flash memory Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Power supply type Built-in AC Built-in AC Built-in AC Built-in AC Built-in AC Rated voltage range AC input : 100 V AC to 240 V AC, 50/60 Hz AC input : 100 V AC to 240 V AC, 50/60 Hz 100 V AC to 240 V AC, 50/60 Hz AC input : 100 V AC to 240 V AC, 50/60 Hz AC input : 100 V AC to 240 V AC, 50/60 Hz Maximum voltage range Maximum input current 0.8 A 3A Maximum power consumption of the device 26.3 W 38.6 W (without PD) 162.6 W (with PD, PD power consumptio n of 124 W) packaging) Fixed port Management port CPU Storage Power supply system Heat dissipation AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz 0.8 A 3A 26.3 W 39.1 W (without PD) 163.1 W (with PD, PD power consumptio n of 124 W) AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz 2A 47.6 W Power consumption in the case of 30% traffic load1 21.2 W 28.4 W 21.1 W 28.7 W 32.7 W Power consumption in the case of 100% traffic load1 21.5 W 28.6 W 21.4 W 28.9 W 33.6 W Heat dissipation Air-cooled heat dissipation and Air-cooled heat dissipation and Air-cooled heat dissipation and Air-cooled heat dissipation and Air-cooled heat dissipation and 108 CloudEngine S5735-L Series Switches Datasheet 19 Item system Environment parameters CloudEngine S5735L8T4S-A1 CloudEngine S5735L8P4S-A1 CloudEngin e S5735L8T4X-A1 CloudEngin e S5735L8P4X-A1 CloudEngin e S5735L24T4S-A1 mode intelligent fan speed adjustment intelligent fan speed adjustment intelligent fan speed adjustment intelligent fan speed adjustment intelligent fan speed adjustment Number of fan modules 1 1 1 1 1 Airflow Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Maximum heat dissipation of the device (BTU/hour) 101.34 Without PDs: 131.71 103.1 Without PDs: 133.41 162.42 With PDs: 554.81 With PDs: 556.51 Long-term operating temperature 0-1800 m altitude: 5°C to +50°C 0-1800 m altitude: 5°C to +50°C 0-1800 m altitude: 5°C to +50°C 0-1800 m altitude: 5°C to +50°C 0-1800 m altitude: 5°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperatur e reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperatur e reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperatur e reduces by 1ºC every time the altitude increases by 220 m. Short-term operating temperature3 NA NA NA NA NA Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) Operating altitude 5000 m 5000 m 5000 m 5000 m 5000 m Noise under normal temperature (sound power) 43 dB(A) 42.2 dB(A) 43 dB(A) 42.2 dB(A) 39 dB(A) Noise under high temperature (sound power) 68 dB(A) 70.2 dB(A) 68 dB(A) 70.2 dB(A) 73 dB(A) Noise under normal temperature 31.5 dB(A) 30.5 dB(A) 31.5 dB(A) 30.5 dB(A) 27.2 dB(A) 109 CloudEngine S5735-L Series Switches Datasheet 20 Item CloudEngine S5735L8T4S-A1 CloudEngine S5735L8P4S-A1 CloudEngin e S5735L8T4X-A1 CloudEngin e S5735L8P4X-A1 CloudEngin e S5735L24T4S-A1 Surge protection specification (RJ45 service port) ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode Surge protection specification (power port) Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ±6 kV (sound pressure) Reliability MTBF (year)2 71.82 66.56 67.07 62.46 66.16 MTTR (hour) 2 2 2 2 2 Availability > 0.99999 > 0.99999 > 0.99999 > 0.99999 > 0.99999 EMC certification EMC certification EMC certification EMC certification EMC certification Safety certification Safety certification Safety certification Safety certification Safety certification Manufacturi ng certification Manufacturi ng certification Manufactur ing certification Manufactur ing certification Manufactur ing certification Certification Hardware specifications of CloudEngine S5735-L24P4S-A1/-L24T4X-A1/D1,-L24P4X-A1 models Item Physical specification s Fixed port Managemen t port CPU Storage CloudEngine S5735-L24P4SA1 CloudEngine S5735-L24T4XA1 CloudEngine S5735-L24T4X-D1 CloudEngine S5735-L24P4XA1 Dimensions (H x W x D) 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm Chassis height 1U 1U 1U 1U Chassis weight (including packaging) 3.91 kg 3.48 kg 3.28 kg 3.93 kg GE port 24(PoE+) 24 24 24(PoE+) GE SFP pot 4 NA NA NA 10GE port NA 4 4 4 Console port (RJ45) Supported Supported Supported Supported USB Port NA USB 2.0 USB 2.0 USB 2.0 Frequency 1000 MHz 1000 MHz 1000 MHz 1000 MHz Core 2 2 2 2 Memory (RAM) 512 MB 512 MB 512 MB 512 MB 110 CloudEngine S5735-L Series Switches Datasheet 21 Item Power supply system Heat dissipation system CloudEngine S5735-L24P4SA1 CloudEngine S5735-L24T4XA1 CloudEngine S5735-L24T4X-D1 CloudEngine S5735-L24P4XA1 Flash memory Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Power supply type Built-in AC Built-in AC Built-in DC Built-in AC Rated voltage range AC input : 100 V AC to 240 V AC, 50/60 Hz AC input : 100 V AC to 240 V AC, 50/60 Hz -48V DC~-60V DC AC input : 100 V AC to 240 V AC, 50/60 Hz Maximum voltage range AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz -38.4V DC~-72V DC High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V highvoltage DC certification) AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz Maximum input current 6A Maximum power consumption of the device 53.2W(without PD) 433.2W(with PD,PD Power consumption of :380W) Power consumption in the case of 30% traffic load1 41.7 W 33.2 W 34 W 42.4 W Power consumption in the case of 100% traffic load1 42.3 W 33.7 W 34.5 W 43 W Heat dissipation mode Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Number of fan modules 2 1 1 2 Airflow Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Maximum heat dissipation of the 155.59 127.27 Without PDs: 181.52 2A 6A 6A 45.6 W 37.3 W 53.8W(without PD) 433.8W(with PD,PD Power consumption of :380W) Without PDs: 183.57 111 CloudEngine S5735-L Series Switches Datasheet 22 Item Environment parameters CloudEngine S5735-L24P4SA1 CloudEngine S5735-L24T4XA1 device (BTU/hour) With PDs: 1478.12 Long-term operating temperature 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 0-1800 m altitude: -5°C to +55°C NA 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Short-term operating temperature3 CloudEngine S5735-L24T4X-D1 0-1800 m altitude: -5°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. NA CloudEngine S5735-L24P4XA1 With PDs: 1480.17 0-1800 m altitude: -5°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 0-1800 m altitude: -5°C to +55°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) Operating altitude 5000 m 5000 m 5000 m 5000 m Noise under normal temperature (sound power) 50 dB(A) 39 dB(A) 39 dB(A) 50 dB(A) Noise under high temperature (sound power) 73 dB(A) 73 dB(A) 73 dB(A) 73 dB(A) Noise under normal temperature (sound pressure) 38.2 dB(A) 27.2 dB(A) 27.2 dB(A) 38.2 dB(A) Surge protection specification (RJ45 service port) ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode Surge protection specification Differential Differential Differential mode: Differential 112 CloudEngine S5735-L Series Switches Datasheet 23 Item CloudEngine S5735-L24P4SA1 (power port) mode: ± 6 kV Reliability CloudEngine S5735-L24T4XA1 Common mode: ± 6 kV CloudEngine S5735-L24T4X-D1 mode: ± 6 kV Common mode: ± 6 kV CloudEngine S5735-L24P4XA1 ± 2 kV mode: ± 6 kV Common mode: ± 4 kV Common mode: ± 6 kV MTBF (year)2 55.72 62.05 62.05 52.74 MTTR (hour) 2 2 2 2 Availability > 0.99999 > 0.99999 > 0.99999 > 0.99999 EMC certification Safety certification EMC certification Manufacturing certification Safety certification Manufacturing certification Certification EMC certification Safety certification Manufacturing certification EMC certification Safety certification Manufacturing certification Hardware specifications of CloudEngine S5735-L48T4S-A1/-L48P4S-A1/-L48T4X-A1/-L48P4X-A1 models Item Physical specification s Fixed port Manageme nt port CPU Storage Power supply system CloudEngine S5735-L48T4SA1 CloudEngine S5735-L48P4SA1 CloudEngine S5735-L48T4XA1 CloudEngine S5735-L48P4XA1 Dimensions (H x W x D) 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm Chassis height 1U 1U 1U 1U Chassis weight (including packaging) 3.74 kg 4.28 kg 3.79 kg 4.28 kg GE port 48 48(PoE+) 48 48(PoE+) GE SFP pot 4 4 NA NA 10GE port NA NA 4 4 Console port (RJ45) Supported Supported Supported Supported USB Port NA USB 2.0 USB 2.0 USB 2.0 Frequency 1000 MHz 1000 MHz 1000 MHz 1000 MHz Core 2 2 2 2 Memory (RAM) 512 MB 512 MB 512 MB 512 MB Flash memory Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Power supply type Built-in AC Built-in AC Built-in AC Built-in AC Rated voltage range AC input : 100 V AC to 240 V AC, 50/60 Hz AC input : 100 V AC to 240 V AC, 50/60 Hz AC input : 100 V AC to 240 V AC, 50/60 Hz AC input : 100 V AC to 240 V AC, 50/60 Hz Maximum voltage AC input: 90 V AC input: 90 V AC input: 90 V AC input: 90 V 113 CloudEngine S5735-L Series Switches Datasheet 24 Item CloudEngine S5735-L48T4SA1 range CloudEngine S5735-L48P4SA1 AC to 264 V AC, 47 Hz to 63 Hz AC to 290 V AC, 45 Hz to 65 Hz Heat dissipation system Environmen t parameters CloudEngine S5735-L48T4XA1 AC to 264 V AC, 47 Hz to 63 Hz CloudEngine S5735-L48P4XA1 AC to 290 V AC, 45 Hz to 65 Hz High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) Maximum input current 2A 6A 2A 6A Maximum power consumption of the device 50.4 W 76.1W(without PD) 51.9 W 76.1W(without PD) 456.1W(with PD,PD Power consumption of :380W) 456.1W(with PD,PD Power consumption of :380W) Power consumption in the case of 30% traffic load1 43.3 W 58.7 W 43.2 W 58.7 W Power consumption in the case of 100% traffic load1 43.7 W 60.5 W 44 W 60.5 W Heat dissipation mode Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Number of fan modules 1 2 1 2 Airflow Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Air flows in from the left side and front panel, exhausts from the right panel Maximum heat dissipation of the device (BTU/hour) 171.97 Without PDs: 259.66 177.09 Without PDs: 259.66 With PDs: 1556.26 With PDs: 1556.26 Long-term operating temperature 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude 114 CloudEngine S5735-L Series Switches Datasheet 25 Item CloudEngine S5735-L48T4SA1 CloudEngine S5735-L48P4SA1 increases by 220 m. Short-term operating temperature3 Reliability Certification CloudEngine S5735-L48T4XA1 increases by 220 m. CloudEngine S5735-L48P4XA1 increases by 220 m. increases by 220 m. 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) Operating altitude 5000 m 5000 m 5000 m 5000 m Noise under normal temperature (sound power) 48 dB(A) 50 dB(A) 48 dB(A) 50 dB(A) Noise under high temperature (sound power) 70.7 dB(A) 73 dB(A) 70.7 dB(A) 73 dB(A) Noise under normal temperature (sound pressure) 36.2 dB(A) 38.2 dB(A) 36.2 dB(A) 38.2 dB(A) Surge protection specification (RJ45 service port) ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode Surge protection specification (power port) Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Common mode: ± 6 kV Common mode: ± 6 kV Common mode: ± 6 kV Common mode: ± 6 kV MTBF (year)2 56.7 44.9 53.67 44.03 MTTR (hour) 2 2 2 2 Availability > 0.99999 > 0.99999 > 0.99999 > 0.99999 EMC certification EMC certification EMC certification EMC certification Safety certification Safety certification Safety certification Safety certification Manufacturing certification Manufacturing certification Manufacturing certification Manufacturing certification 115 CloudEngine S5735-L Series Switches Datasheet 26 Hardware specifications of CloudEngine S5735-L12T4S-A/-L12P4S-A/-L24T4S-A/-L24P4S-A models Item Physical specificatio ns Fixed port Manageme nt port CPU Storage Power supply system CloudEngine S5735-L12T4S-A CloudEngine S5735-L12P4S-A CloudEngine S5735-L24T4S-A CloudEngine S5735-L24P4S-A Dimensions (H x W x D) 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm Chassis height 1U 1U 1U 1U Chassis weight (including packaging) 3.83 kg 4.24 kg 4.08 kg 4.31 kg GE Base-T port 12 12(PoE+) 24 24(PoE+) GE SFP port 4 4 4 4 10GE port NA NA NA NA Console port (RJ45) Supported Supported Supported Supported USB port USB 2.0 USB 2.0 USB 2.0 USB 2.0 Frequency 1000 MHz 1000 MHz 1000 MHz 1000 MHz Core 4 4 4 4 Memory (RAM) 1 GB 1 GB 1 GB 1 GB Flash memory Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Power supply type Built-in AC Built-in AC Built-in AC Built-in AC Rated voltage range 100 V AC to 240 V AC, 50/60 Hz 100 V AC to 240 V AC, 50/60 Hz 100 V AC to 240 V AC, 50/60 Hz 100 V AC to 240 V AC, 50/60 Hz Maximum voltage range AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) Maximum input current 2A 6A Maximum power consumption of the device 29 W 49 W (without PD) 441 W (with PD, PD power consumption of 360 W) Power consumption in the case of 30% traffic load1 23 W 38 W 2A 6A 34 W 53 W (without PD) 451 W (with PD, PD power consumption of 380 W) 28 W 39 W 116 CloudEngine S5735-L Series Switches Datasheet 27 Item Heat dissipation system Environmen t parameters CloudEngine S5735-L12T4S-A CloudEngine S5735-L12P4S-A CloudEngine S5735-L24T4S-A CloudEngine S5735-L24P4S-A Power consumption in the case of 100% traffic load1 25 W 40 W 32 W 44 W Heat dissipation mode Natural heat dissipation Air-cooled heat dissipation and intelligent fan speed adjustment Natural heat dissipation Air-cooled heat dissipation and intelligent fan speed adjustment Number of fan modules NA 2 NA 2 Airflow NA Air flows in from the left side and front panel, exhausts from the right side NA Air flows in from the left side and front panel, exhausts from the right side Maximum heat dissipation of the device (BTU/hour) 98.95 without PD :167.2 116 without PD :180.8 Long-term operating temperature 0-1800 m altitude: -5°C to +45°C 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +45°C 0-1800 m altitude: -5°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 0-1800 m altitude: -5°C to +55°C NA 0-1800 m altitude: -5°C to +55°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Short-term operating temperature3 with PD:1505 NA with PD:1539 Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) Operating altitude 5000 m 5000 m 5000 m 5000 m Noise under normal temperature (sound power) Silent (fan-free) 57.7dB(A) Silent (fan-free) 57.7dB(A) Noise under high temperature (sound Silent (fan-free) 74.2dB(A) Silent (fan-free) 74.2dB(A) 117 CloudEngine S5735-L Series Switches Datasheet 28 Item CloudEngine S5735-L12T4S-A CloudEngine S5735-L12P4S-A CloudEngine S5735-L24T4S-A CloudEngine S5735-L24P4S-A Noise under normal temperature (sound pressure) Silent (fan-free) 43dB(A) Silent (fan-free) 43dB(A) Surge protection specification (RJ45 service port) ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode Surge protection specification (power port) Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ±6 kV MTBF (year)2 98.6 85.52 111.94 92.2 MTTR (hour) 1.22 1.4 1.07 1.3 Availability > 0.99999 > 0.99999 > 0.99999 > 0.99999 EMC certification EMC certification EMC certification EMC certification Safety certification Safety certification Safety certification Safety certification Manufacturing certification Manufacturing certification Manufacturing certification Manufacturing certification power) Reliability Certification Hardware specifications of CloudEngine S5735-L24T4X-A/D-L24P4X-A/-L48T4S-A models Item Physical specificatio ns Fixed port Manageme nt port CPU Storage CloudEngine S5735-L24T4X-A CloudEngine S5735-L24T4X-D CloudEngine S5735-L24P4X-A CloudEngine S5735-L48T4S-A Dimensions (H x W x D) 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm Chassis height 1U 1U 1U 1U Chassis weight (including packaging) 4 kg 4 kg 4.31 kg 4.42 kg GE Base-T port 24 24 24(PoE+) 48 GE SFP port NA NA NA 4 10GE port 4 4 4 NA Console port (RJ45) Supported Supported Supported Supported USB port USB 2.0 USB 2.0 USB 2.0 USB 2.0 Frequency 1000 MHz 1000 MHz 1000 MHz 1000 MHz Core 4 4 4 4 Memory (RAM) 1 GB 1 GB 1 GB 1 GB Flash memory Hardware: 512 MB, of which 306 MB is Hardware: 512 MB, of which 306 MB is Hardware: 512 MB, of which 306 MB is Hardware: 512 MB, of which 306 MB is 118 CloudEngine S5735-L Series Switches Datasheet 29 Item Power supply system Heat dissipation system Environmen t parameters CloudEngine S5735-L24T4X-A CloudEngine S5735-L24T4X-D CloudEngine S5735-L24P4X-A CloudEngine S5735-L48T4S-A available for users available for users available for users available for users Power supply type Built-in AC Built-in DC Built-in AC Built-in AC power Rated voltage range 100 V AC to 240 V AC, 50/60 Hz -48V DC~-60V DC 100 V AC to 240 V AC, 50/60 Hz 100 V AC to 240 V AC, 50/60 Hz Maximum voltage range AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz -38.4V DC~-72V DC AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) Maximum input current 2A 2A 6A 2A Maximum power consumption of the device 43 W 43 W 56 W (without PD) 458 W (with PD, PD power consumption of 380 W) Power consumption in the case of 30% traffic load1 27 W 27 W 43 W 37 W Power consumption in the case of 100% traffic load1 32 W 32 W 47 W 46 W Heat dissipation mode Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Number of fan modules 1 1 2 1 Airflow Air flows in from the left side and front panel, exhausts from the right side Air flows in from the left side and front panel, exhausts from the right side Air flows in from the left side and front panel, exhausts from the right side Air flows in from the left side and front panel, exhausts from the right side Maximum heat dissipation of the device (BTU/hour) 146.7 146.7 without PD :191.1 180.8 Long-term operating temperature 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC 1800-5000 m altitude: The operating temperature reduces by 1ºC 1800-5000 m altitude: The operating temperature reduces by 1ºC 1800-5000 m altitude: The operating temperature reduces by 1ºC 53 W with PD:1563 119 CloudEngine S5735-L Series Switches Datasheet 30 Item CloudEngine S5735-L24T4X-A CloudEngine S5735-L24T4X-D every time the altitude increases by 220 m. Short-term operating temperature3 Reliability Certification CloudEngine S5735-L24P4X-A every time the altitude increases by 220 m. CloudEngine S5735-L48T4S-A every time the altitude increases by 220 m. every time the altitude increases by 220 m. 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) 5%-95%(noncondensing) Operating altitude 5000 m 5000 m 5000 m 5000 m Noise under normal temperature (sound power) 50.8 dB(A) 47.3 dB(A) 57.7 dB(A) 53.3dB (A) Noise under high temperature (sound power) 71 dB(A) 71 dB(A) 74.2 dB(A) 71.5dB (A) Noise under normal temperature (sound pressure) 36 dB(A) 32.5 dB(A) 43 dB(A) 38.5dB (A) Surge protection specification (RJ45 service port) ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode Surge protection specification (power port) Differential mode: ± 6 kV Differential mode: ± 2 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Common mode: ±6 kV Common mode: ± 4 kV Common mode: ±6 kV Common mode: ±6 kV MTBF (year)2 50.68 50.68 57.07 46.36 MTTR (hour) 2.37 2 2.1 2.59 Availability > 0.99999 > 0.99999 > 0.99999 > 0.99999 EMC certification EMC certification EMC certification EMC certification Safety certification Safety certification Safety certification Safety certification Manufacturing certification Manufacturing certification Manufacturing certification Manufacturing certification 120 CloudEngine S5735-L Series Switches Datasheet 31 Hardware specifications of CloudEngine S5735-L48T4X-A/-L48P4X-A/-L32ST4X-A/D models Item Physical specifications Fixed port Management port CPU Storage Power supply system CloudEngine S5735-L48T4X-A CloudEngine S5735-L48P4XA CloudEngine S5735-L32ST4XA CloudEngine S5735-L32ST4XD Dimensions (H x W x D) 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 420 mm 43.6 mm x 442 mm x 220 mm 43.6 mm x 442 mm x 220 mm Chassis height 1U 1U 1U 1U Chassis weight (including packaging) 4.42 kg 8.7 kg 4.31 kg 4.31 kg GE port 48 48(PoE+) 8 8 GE SFP port NA NA 24 24 10GE port 4 4 4 4 Console port (RJ45) Supported Supported Supported Supported USB port USB 2.0 USB 2.0 USB 2.0 USB 2.0 Frequency 1000 MHz 1000 MHz 1000 MHz 1000 MHz Core 4 4 4 4 Memory (RAM) 1 GB 1 GB 1 GB 1 GB Flash memory Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Hardware: 512 MB, of which 306 MB is available for users Power supply type Built-in AC power 1000 W AC PoE Built-in AC Built-in DC Rated voltage range 100 V AC to 240 V AC, 50/60 Hz AC input : 100 V AC to 240 V AC, 50/60 Hz 100 V AC to 240 V AC, 50/60 Hz -48V DC~-60V DC Maximum voltage range AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz AC input: 90 V AC to 264 V AC, 47 Hz to 63 Hz -38.4V DC~-72V DC High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) AC input: 90 V AC to 290 V AC, 45 Hz to 65 Hz High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V highvoltage DC certification) High-voltage DC input: 190 V DC to 290 V DC (meeting 240 V high-voltage DC certification) Maximum input current 2A 8A Maximum power consumption of the device 54 W 80 W (without PD) 914 W (with PD, PD power consumption of 874 W) 2A 2A 65 W 65 W 121 CloudEngine S5735-L Series Switches Datasheet 32 Item Heat dissipation system Environment parameters CloudEngine S5735-L48T4X-A CloudEngine S5735-L48P4XA CloudEngine S5735-L32ST4XA CloudEngine S5735-L32ST4XD Power consumption in the case of 30% traffic load1 39 W 59 W 46 W 46 W Power consumption in the case of 100% traffic load1 48 W 68 W 48 W 48 W Heat dissipation mode Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Air-cooled heat dissipation and intelligent fan speed adjustment Number of fan modules 1 2 2 2 Airflow Air flows in from the left side and front panel, exhausts from the right side Air flows in from the left,right sides and front panel, exhausts from the rear panel Air flows in from the left side and front panel, exhausts from the right side Air flows in from the left side and front panel, exhausts from the right side Maximum heat dissipation of the device (BTU/hour) 184.3 Without PDs: 262.7 221.8 221.8 With PDs: 5667 Long-term operating temperature 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 0-1800 m altitude: -5°C to +50°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 0-1800 m altitude: -5°C to +55°C 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. 1800-5000 m altitude: The operating temperature reduces by 1ºC every time the altitude increases by 220 m. Short-term operating temperature3 Storage temperature -40°C to +70°C -40°C to +70°C -40°C to +70°C -40°C to +70°C Relative humidity 5%-95%(non- 5%-95%(non- 5%-95%(non- 5%-95%(non- 122 CloudEngine S5735-L Series Switches Datasheet 33 Item Reliability Certification CloudEngine S5735-L48T4X-A CloudEngine S5735-L48P4XA CloudEngine S5735-L32ST4XA CloudEngine S5735-L32ST4XD condensing) condensing) condensing) condensing) Operating altitude 5000 m 5000 m 5000 m 5000 m Noise under normal temperature (sound power) 53.3dB (A) 58.9dB (A) 53.3 dB(A) 53.3 dB(A) Noise under high temperature (sound power) 71.5dB (A) 75dB (A) 74.5 dB(A) 74.5 dB(A) Noise under normal temperature (sound pressure) 38.5dB (A) 43.8dB (A) 38.5 dB(A) 38.5 dB(A) Surge protection specification (RJ45 service port) ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode ±7 kV in common mode Surge protection specification (power port) Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 6 kV Differential mode: ± 2 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ±6 kV Common mode: ± 4 kV MTBF (year)2 41.48 61.7 85.87 85.87 MTTR (hour) 2.89 1.94 1.4 1.4 Availability > 0.99999 > 0.99999 > 0.99999 > 0.99999 EMC certification EMC certification EMC certification EMC certification Safety certification Safety certification Safety certification Safety certification Manufacturing certification Manufacturing certification Manufacturing certification Manufacturing certification 1: The power consumption under different load conditions is calculated according to the ATIS standard. Additionally, the EEE function is enabled and there is no PoE power output. 2: The reliability parameter values are calculated based on the typical configuration of the device. The parameter values vary according to the modules configured by the customer. 3: Short term indicates that the successive operating time is no more than 96 hours, the total operating time is no more than 360 hours, or the number of times the operating temperature is over 45°C is no more than 15 in a year. Networking and Applications Large-Scale Enterprise Campus Network CloudEngine S5735-L series switches can be deployed at the access layer of a campus network to build a high-performance and highly reliable enterprise network. 123 CloudEngine S5735-L Series Switches Datasheet 34 Small- or Medium-scale Enterprise Campus Network CloudEngine S5735-L series switches can be deployed at the aggregation layer of a campus network to build a highperformance, multi-service, and highly reliable enterprise network. Small-scale Enterprise Campus Network With powerful aggregation and routing capabilities of CloudEngine S5735-L series switches make them suitable for use as core switches in a small-scale enterprise network. Two or more S5735-L switches use iStack technology to ensure high reliability. They provide a variety of access control policies to achieve centralized management and simplify configuration. 124 CloudEngine S5735-L Series Switches Datasheet 35 Application on a MAN CloudEngine S5735-L series switches can be deployed at the access layer of a MAN(Metropolitan Area Network) to build a high-performance, multi-service, and highly reliable ISP MAN network. Application in Public Cloud CloudCampus Solution is a network solution suite based on Huawei public cloud. CloudEngine S5735-L series switches can be located at the access layer. The switches are plug-and-play. They go online automatically after being powered on and connected with network cables, without the need for complex configurations. The switches can connect to the management and control system (CloudCampus@AC-Campus for switches running V200R019C00 and earlier versions; iMaster NCE-Campus for switches running V200R019C10 and later versions), and use bidirectional certificate authentication to ensure management channel security. The switches provide the NETCONF and YANG interfaces, through which the management and control system delivers configurations to them. In addition, remote maintenance and fault diagnosis can be performed on the management and control system. 125 CloudEngine S5735-L Series Switches Datasheet 36 Safety and Regulatory Compliance Safety and regulatory compliance of the CloudEngine S5735-L series Certification Category Description Safety IEC 60950-1 EN 60950-1/A11/A12 UL 60950-1 CSA C22.2 No 60950-1 AS/NZS 60950.1 CNS 14336-1 IEC60825-1 IEC60825-2 EN60825-1 EN60825-2 CISPR22 Class A CISPR24 EN55022 Class A EN55024 Laser safety Electromagnetic Compatibility (EMC) 126 CloudEngine S5735-L Series Switches Datasheet 37 Certification Category Environment Description ETSI EN 300 386 Class A CFR 47 FCC Part 15 Class A ICES 003 Class A AS/NZS CISPR22 Class A VCCI Class A EN61000-3-2 EN61000-3-3 IEC61000-4-2 ITU-T K 20 ITU-T K 21 ITU-T K 44 CNS13438 RoHS REACH WEEE EMC: electromagnetic compatibility CISPR: International Special Committee on Radio Interference EN: European Standard ETSI: European Telecommunications Standards Institute CFR: Code of Federal Regulations FCC: Federal Communication Commission IEC: International Electrotechnical Commission AS/NZS: Australian/New Zealand Standard VCCI: Voluntary Control Council for Interference UL: Underwriters Laboratories CSA: Canadian Standards Association IEEE: Institute of Electrical and Electronics Engineers RoHS: restriction of the use of certain hazardous substances REACH: Registration Evaluation Authorization and Restriction of Chemicals WEEE: Waste Electrical and Electronic Equipment MIB and Standards Compliance Supported MIBs Supported MIBs by the CloudEngine S5735-L series Category MIB Public MIB BRIDGE-MIB DISMAN-NSLOOKUP-MIB DISMAN-PING-MIB DISMAN-TRACEROUTE-MIB ENTITY-MIB 127 CloudEngine S5735-L Series Switches Datasheet 38 Category Huawei-proprietary MIB MIB EtherLike-MIB IF-MIB IP-FORWARD-MIB IPv6-MIB LAG-MIB LLDP-EXT-DOT1-MIB LLDP-EXT-DOT3-MIB LLDP-MIB NOTIFICATION-LOG-MIB NQA-MIB P-BRIDGE-MIB Q-BRIDGE-MIB RFC1213-MIB RMON-MIB SAVI-MIB SNMP-FRAMEWORK-MIB SNMP-MPD-MIB SNMP-NOTIFICATION-MIB SNMP-TARGET-MIB SNMP-USER-BASED-SM-MIB SNMPv2-MIB SNMP-VIEW-BASED-ACM-MIB TCP-MIB UDP-MIB HUAWEI-AAA-MIB HUAWEI-ACL-MIB HUAWEI-ALARM-MIB HUAWEI-ALARM-RELIABILITY-MIB HUAWEI-BASE-TRAP-MIB HUAWEI-BRAS-RADIUS-MIB HUAWEI-BRAS-SRVCFG-EAP-MIB HUAWEI-BRAS-SRVCFG-STATICUSER-MIB HUAWEI-CBQOS-MIB HUAWEI-CDP-COMPLIANCE-MIB HUAWEI-CONFIG-MAN-MIB HUAWEI-CPU-MIB HUAWEI-DAD-TRAP-MIB HUAWEI-DATASYNC-MIB HUAWEI-DEVICE-MIB HUAWEI-DHCPR-MIB HUAWEI-DHCPS-MIB HUAWEI-DHCP-SNOOPING-MIB HUAWEI-DIE-MIB HUAWEI-DNS-MIB 128 CloudEngine S5735-L Series Switches Datasheet 39 Category MIB HUAWEI-DLDP-MIB HUAWEI-ERPS-MIB HUAWEI-ERRORDOWN-MIB HUAWEI-ENERGYMNGT-MIB HUAWEI-EASY-OPERATION-MIB HUAWEI-ENTITY-EXTENT-MIB HUAWEI-ENTITY-TRAP-MIB HUAWEI-ETHARP-MIB HUAWEI-ETHOAM-MIB HUAWEI-FLASH-MAN-MIB HUAWEI-FWD-RES-TRAP-MIB HUAWEI-GARP-APP-MIB HUAWEI-GTL-MIB HUAWEI-HGMP-MIB HUAWEI-HWTACACS-MIB HUAWEI-IF-EXT-MIB HUAWEI-INFOCENTER-MIB HUAWEI-IPPOOL-MIB HUAWEI-IPV6-MIB HUAWEI-ISOLATE-MIB HUAWEI-L2IF-MIB HUAWEI-L2MAM-MIB HUAWEI-L2VLAN-MIB HUAWEI_LDT-MIB HUAWEI-LLDP-MIB HUAWEI-MAC-AUTHEN-MIB HUAWEI-MEMORY-MIB HUAWEI-MFF-MIB HUAWEI-MFLP-MIB HUAWEI-MSTP-MIB HUAWEI-MULTICAST-MIB HUAWEI-NTPV3-MIB HUAWEI-PERFORMANCE-MIB HUAWEI-PERFMGMT-MIB HUAWEI-PORT-MIB HUAWEI-PORTAL-MIB HUAWEI-QINQ-MIB HUAWEI-RM-EXT-MIB HUAWEI-RRPP-MIB HUAWEI-SECURITY-MIB HUAWEI-SEP-MIB HUAWEI-SNMP-EXT-MIB HUAWEI-SSH-MIB HUAWEI-STACK-MIB HUAWEI-SWITCH-L2MAM-EXT-MIB 129 CloudEngine S5735-L Series Switches Datasheet 40 Category MIB HUAWEI-SWITCH-SRV-TRAP-MIB HUAWEI-SYS-MAN-MIB HUAWEI-TCP-MIB HUAWEI-TFTPC-MIB HUAWEI-TRNG-MIB HUAWEI-UNIMNG-MIB HUAWEI-USA-MIB HUAWEI-XQOS-MIB For more detailed information of MIBs supported by the CloudEngine S5735-L series, visit https://support.huawei.com/enterprise/en/switches/s5700-pid-6691579?category=reference-guides&subcategory=mib-reference. Standard Compliance Standard compliance list of the CloudEngine S5735-L series Standard Organization Standard or Protocol IETF RFC 768 User Datagram Protocol (UDP) RFC 792 Internet Control Message Protocol (ICMP) RFC 793 Transmission Control Protocol (TCP) RFC 826 Ethernet Address Resolution Protocol (ARP) RFC 854 Telnet Protocol Specification RFC 951 Bootstrap Protocol (BOOTP) RFC 959 File Transfer Protocol (FTP) RFC 1058 Routing Information Protocol (RIP) RFC 1112 Host extensions for IP multicasting RFC 1157 A Simple Network Management Protocol (SNMP) RFC 1256 ICMP Router Discovery RFC 1305 Network Time Protocol Version 3 (NTP) RFC 1349 Internet Protocol (IP) RFC 1493 Definitions of Managed Objects for Bridges RFC 1542 Clarifications and Extensions for the Bootstrap Protocol RFC 1643 Ethernet Interface MIB RFC 1757 Remote Network Monitoring (RMON) RFC 1901 Introduction to Community-based SNMPv2 RFC 1902-1907 SNMP v2 RFC 1981 Path MTU Discovery for IP version 6 RFC 2131 Dynamic Host Configuration Protocol (DHCP) RFC 2460 Internet Protocol, Version 6 Specification (IPv6) RFC 2461 Neighbor Discovery for IP Version 6 (IPv6) RFC 2462 IPv6 Stateless Address Auto configuration RFC 2463 Internet Control Message Protocol for IPv6 (ICMPv6) RFC 2474 Differentiated Services Field (DS Field) RFC 2863 The Interfaces Group MIB RFC 2597 Assured Forwarding PHB Group 130 CloudEngine S5735-L Series Switches Datasheet 41 Standard Organization IEEE ITU MEF Standard or Protocol RFC 2598 An Expedited Forwarding PHB RFC 2571 SNMP Management Frameworks RFC 2865 Remote Authentication Dial In User Service (RADIUS) RFC 3046 DHCP Option82 RFC 3513 IP Version 6 Addressing Architecture RFC 3579 RADIUS Support For EAP draft-grant-tacacs-02 TACACS+ RFC 6241 Network Configuration Protocol (NETCONF) RFC 6020 YANG - A Data Modeling Language for the Network Configuration Protocol (NETCONF) IEEE 802.1D Media Access Control (MAC) Bridges IEEE 802.1p Traffic Class Expediting and Dynamic Multicast Filtering IEEE 802.1Q Virtual Bridged Local Area Networks IEEE 802.1ad Provider Bridges IEEE 802.2 Logical Link Control IEEE Std 802.3 CSMA/CD IEEE Std 802.3ab 1000BASE-T specification IEEE Std 802.3ad Aggregation of Multiple Link Segments IEEE Std 802.3ae 10GE WEN/LAN Standard IEEE Std 802.3x Full Duplex and flow control IEEE Std 802.3z Gigabit Ethernet Standard IEEE802.1ax/IEEE802.3ad Link Aggregation IEEE 802.3ah Ethernet in the First Mile IEEE 802.1ag Connectivity Fault Management IEEE 802.1ab Link Layer Discovery Protocol IEEE 802.1D Spanning Tree Protocol IEEE 802.1w Rapid Spanning Tree Protocol IEEE 802.1s Multiple Spanning Tree Protocol IEEE 802.1x Port based network access control protocol IEEE 802.3af DTE Power via MIDI IEEE 802.3at DTE Power via the MDI Enhancements IEEE 802.3az Energy Efficient Ethernet ITU SG13 Y.17ethoam ITU SG13 QoS control Ethernet-Based IP Access ITU-T Y.1731 ETH OAM performance monitor MEF 2 Requirements and Framework for Ethernet Service Protection MEF 9 Abstract Test Suite for Ethernet Services at the UNI MEF 11 UNI Requirements and Framework MEF 15 Requirements for Management of Metro Ethernet Phase 1 Network Elements MEF 17 Service OAM Framework and Requirements MEF 20 UNI Type 2 Implementation Agreement MEF 23 Class of Service Phase 1 Implementation Agreement XMODEM/YMODEM Protocol Reference 131 CloudEngine S5735-L Series Switches Datasheet 42 The listed standards and protocols are fully or partially supported by Huawei switches. For details, visit http://e.huawei.com/en or contact your local Huawei sales office. Ordering Information Model Product Description CloudEngine S5735-L8T4SQA1 CloudEngine S5735-L8T4S-QA1 (8*10/100/1000BASE-T ports, 4*GE SFP ports, AC power, Fanless) CloudEngine S5735-L8P4SQA1 CloudEngine S5735-L8P4S-QA1 (8*10/100/1000BASE-T ports, 4*GE SFP ports, PoE+, AC power, Fanless) CloudEngine S5735L24T4S-QA1 CloudEngine S5735-L24T4S-QA1 (24*10/100/1000BASE-T ports, 4*GE SFP ports, AC power, Fanless) CloudEngine S5735L24T4X-QA1 CloudEngine S5735-L24T4X-QA1 (24*10/100/1000BASE-T ports, 4*10GE SFP+ ports, AC power, Fanless) CloudEngine S5735-L8T4SA1 CloudEngine S5735-L8T4S-A1 (8*10/100/1000BASE-T ports, 4*GE SFP ports, AC power) CloudEngine S5735-L8P4SA1 CloudEngine S5735-L8P4S-A1 (8*10/100/1000BASE-T ports, 4*GE SFP ports, PoE+, AC power) CloudEngine S5735-L8T4XA1 CloudEngine S5735-L8T4X-A1 (8*10/100/1000BASE-T ports, 4*10GE SFP+ ports, AC power) CloudEngine S5735-L8P4XA1 CloudEngine S5735-L8P4X-A1 (8*10/100/1000BASE-T ports, 4*10GE SFP+ ports, PoE+, AC power) CloudEngine S5735L24T4S-A1 CloudEngine S5735-L24T4S-A1 (24*10/100/1000BASE-T ports, 4*GE SFP ports, AC power) CloudEngine S5735L24P4S-A1 CloudEngine S5735-L24P4S-A1 (24*10/100/1000BASE-T ports, 4*GE SFP ports, PoE+, AC power) CloudEngine S5735L24T4X-A1 CloudEngine S5735-L24T4X-A1 (24*10/100/1000BASE-T ports, 4*10GE SFP+ ports, AC power) CloudEngine S5735L24T4X-D1 CloudEngine S5735-L24T4X-D1 (24*10/100/1000BASE-T ports, 4*10GE SFP+ ports, DC power) CloudEngine S5735L24P4X-A1 CloudEngine S5735-L24P4X-A1 (24*10/100/1000BASE-T ports, 4*10GE SFP+ ports, PoE+, AC power) CloudEngine S5735L48T4S-A1 CloudEngine S5735-L48T4S-A1 (48*10/100/1000BASE-T ports, 4*GE SFP ports, AC power) CloudEngine S5735L48P4S-A1 CloudEngine S5735-L48P4S-A1 (48*10/100/1000BASE-T ports, 4*GE SFP ports, PoE+, AC power) CloudEngine S5735L48T4X-A1 CloudEngine S5735-L48T4X-A1 (48*10/100/1000BASE-T ports, 4*10GE SFP+ ports, AC power) CloudEngine S5735L48P4X-A1 CloudEngine S5735-L48P4X-A1 (48*10/100/1000BASE-T ports, 4*10GE SFP+ ports, PoE+, AC power) CloudEngine S5735L12T4S-A CloudEngine S5735-L12T4S-A (12 x 10/100/1000BASE-T ports, 4 x GE SFP ports, AC power) CloudEngine S5735- CloudEngine S5735-L12P4S-A (12 x 10/100/1000BASE-T ports, 4 x GE SFP ports, PoE+, AC 132 CloudEngine S5735-L Series Switches Datasheet 43 Model Product Description L12P4S-A power) CloudEngine S5735L24T4S-A CloudEngine S5735-L24T4S-A (24 x 10/100/1000BASE-T ports, 4 x GE SFP ports, AC power) CloudEngine S5735L24P4S-A CloudEngine S5735-L24P4S-A (24 x 10/100/1000BASE-T ports, 4 x GE SFP ports, PoE+, AC power) CloudEngine S5735L24T4X-A CloudEngine S5735-L24T4X-A (24 x 10/100/1000BASE-T ports, 4 x 10 GE SFP+ ports, AC power) CloudEngine S5735L24T4X-D CloudEngine S5735-L24T4X-D (24 x 10/100/1000BASE-T ports, 4 x 10 GE SFP+ ports, DC power) CloudEngine S5735L24P4X-A CloudEngine S5735-L24P4X-A (24 x 10/100/1000BASE-T ports, 4 x 10 GE SFP+ ports, PoE+, AC power) CloudEngine S5735L48T4S-A CloudEngine S5735-L48T4S-A (48 x 10/100/1000BASE-T ports, 4 x GE SFP ports, AC power) CloudEngine S5735L48T4X-A CloudEngine S5735-L48T4X-A (48 x 10/100/1000BASE-T ports, 4 x 10 GE SFP+ ports, AC power) CloudEngine S5735L48P4X-A CloudEngine S5735-L48P4X-A bundle (48 x 10/100/1000BASE-T ports, 4 x 10 GE SFP+ ports, PoE+, 1*1000W PoE AC power module) CloudEngine S5735L32ST4X-A CloudEngine S5735-L32ST4X-A (24 x GE SFP ports, 8 *10/100/1000Base-T, 4 x 10 GE SFP+ ports, AC power) CloudEngine S5735L32ST4X-D CloudEngine S5735-L32ST4X-D (24 x GE SFP ports, 8 *10/100/1000Base-T, 4 x 10 GE SFP+ ports, DC power) PAC1000S56-DB 1000W AC PoE power module,can be used in CloudEngine S5735-L48P4X-A N1-S57L-M-Lic S57XX-L Series Basic SW,Per Device N1-S57L-M-SnS1Y S57XX-L Series Basic SW,SnS,Per Device,1Year N1-S57L-F-Lic N1-CloudCampus,Foundation,S57XX-L Series,Per Device N1-S57L-F-SnS N1-CloudCampus,Foundation,S57XX-L Series,SnS,Per Device N1-S57L-A-Lic N1-CloudCampus,Advanced,S57XX-L Series,Per Device N1-S57L-A-SnS N1-CloudCampus,Advanced,S57XX-L Series,SnS,Per Device N1-S57L-FToA-Lic N1-Upgrade-Foundation to Advanced,S57XX-L,Per Device N1-S57L-FToA-SnS N1-Upgrade-Foundation to Advanced,S57XX-L,SnS,Per Device More Information For more information about Huawei Campus Switches, visit http://e.huawei.com or contact us in the following ways: Global service hotline: http://e.huawei.com/en/service-hotline Logging in to the Huawei Enterprise technical support website: http://support.huawei.com/enterprise/ Sending an email to the customer service mailbox: support_e@huawei.com 133 CloudEngine S5735-L Series Switches Datasheet 44 Copyright © Huawei Technologies Co., Ltd. 2021. All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means without prior written consent of Huawei Technologies Co., Ltd. Trademarks and Permissions and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd. All other trademarks and trade names mentioned in this document are the property of their respective holders. Notice The purchased products, services and features are stipulated by the contract made between Huawei and the customer. All or part of the products, services and features described in this document may not be within the purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information, and recommendations in this document are provided "AS IS" without warranties, guarantees or representations of any kind, either express or implied. The information in this document is subject to change without notice. Every effort has been made in the preparation of this document to ensure accuracy of the contents, but all statements, information, and recommendations in this document do not constitute a warranty of any kind, express or implied. Huawei Technologies Co., Ltd. Address:Huawei Industrial Base Bantian, Longgang Shenzhen 518129 People's Republic of China Website:e.huawei.com 134 CloudEngine S5735-L Series Switches Datasheet 45 OMXD30000 Datasheet Get a Quote Overview Huawei OMXD30000 is a 10GBASE-iLR Optical Transceiver. It’s a Single-mode Module. Quick Specs Table 1 shows the Quick Specs. Product Code OMXD30000 Transceiver form factor SFP+ Transmission speed 10 Gbit/s Center wavelength (nm) 1310 Standard compliance 10GBASE-iLR Connector type LC Applicable cable and maximum transmission distance Single-mode fiber: 1.4 km Transmit power (dBm) -8.2 to +0.5 Maximum receiver sensitivity (dBm) -14.4 Overload power (dBm) 0.5 Extinction ratio (dB) 3.5 Operating temperature -40°C to +85°C (-40°F to +185°F) The Supported Switches Figure 1. OMXD30000 can be installed in the switch’s SFP slot. Table 2 shows the Huawei hot switches which support OMXD30000. 135 Model Description S5700-28P-LI-AC 24 x Ethernet 10/100/1000 ports, 4 Gig SFP, AC 110/220V S5700-28TP-LI-AC 24 x Ethernet 10/100/1000ports,2 Gig SFP and 2 dual-purpose 10/100/1000 or SFP,AC 110/220V S5700S-52P-LI-AC 48 x Ethernet 10/100/1000 ports, 4 Gig SFP, AC 110/220V S5700-28P-PWR-LI-AC 24 x Ethernet 10/100/1000 PoE+ ports, 4 Gig SFP, AC 110/220V S5700-10P-PWR-LI-AC 8 x Ethernet 10/100/1000 PoE+ ports, 2 Gig SFP, AC 110/220V S5720-36C-EI-AC 28 x Ethernet 10/100/1000 ports,4 of which are dual-purpose 10/100/1000 or SFP,4 10 Gig SFP+, 1 interface slot, with 150W AC S5700-28C-EI-AC 24 x Ethernet 10/100/1000 ports, with 1 interface slot, with 150W AC power supply S5720-56C-HI-AC 48 x Ethernet 10/100/1000 ports, 4 10 Gig SFP+, with 2 interface slots, with 600W AC power supply S5720-56PC-EI-AC 48 x Ethernet 10/100/1000 ports,4 Gig SFP, with 1 interface slot, with 150W AC power supply S5720-56C-PWR-HI-AC 48 x Ethernet 10/100/1000 POE+ ports,4 10 Gig SFP+, with 2 interface slots, with 1150W AC power supply Compare to Similar Items Table 3 shows the comparison of OSX010000 andOMXD30000. Item OSX010000 OMXD30000 Transceiver form factor SFP+ SFP+ Transmission speed 10 Gbit/s 10 Gbit/s Center wavelength (nm) 1310 1310 Standard compliance 10Gbase-LR 10GBASE-iLR Connector type LC LC Applicable cable and maximum transmission distance Single-mode fiber: 10 km Single-mode fiber: 1.4 km Transmit power (dBm) -8.2 to +0.5 -8.2 to +0.5 Maximum receiver sensitivity (dBm) -12.6 -14.4 Overload power (dBm) 0.5 0.5 Extinction ratio (dB) 3.5 3.5 Operating temperature 0°C to 70°C (32°F to 158°F) -40°C to +85°C (-40°F to +185°F) Get more information Do you have any question about the OMXD30000? Contact us now via Live Chat or sales@router-switch.com. Specification OMXD30000 Specification Transceiver form factor SFP+ Transmission speed 10 Gbit/s 136 Center wavelength (nm) 1310 Standard compliance 10GBASE-iLR Connector type LC Applicable cable and maximum transmission distance Single-mode fiber: 1.4 km Transmit power (dBm) -8.2 to +0.5 Maximum receiver sensitivity (dBm) -14.4 Overload power (dBm) 0.5 Extinction ratio (dB) 3.5 Operating temperature -40°C to +85°C (-40°F to +185°F) Want to Buy Order Now Get a Quote Why Router-switch.com As a leading network hardware supplier, Router-switch.com focuses on original new ICT equipment of Cisco, Huawei, HPE, Dell, Hikvision, Juniper, Fortinet, etc. 200+ 18,000+ $20,000,000 50%-98% 100% Countries we Sold Customers Trusted Inventory Available Off Global List Price Safe Online Shopping Contact Us ● Tel: +1-626-655-0998 (USA) +852-3050-1066 / +852-3174-6166 ● Fax: +852-3050-1066 (Hong Kong) ● Email: sales@router-switch.com 137 SFP-10G-CU3M Datasheet Get a Quote Overview The SFP+ DAC copper cable is programmed to be compatible with a wide range of HW network equipment for in-rack connections such as 10 Gigabit Ethernet (10 GbE) Switches, Routers, Network Interface Cards (NICs) and Network Storage Systems. It’s proven to be a cost-effective alternative to high-cost HW SFP-10GCU3M 10G SFP+ 3m direct attach the copper cable. Quick Specs Table 1 shows the Quick Specs. Product Code SFP-10G-CU3M Supply Voltage 3.3V Cable Length 3m Cable impedance 100 Ω Cable Type Twinax Wire Gauge 30AWG Product Details Huawei SFP-10G-CU3M provides these features: • lower cost than SFP+ optical transceiver and active optical cable (AOC) • Support for multi-gigabit data rates up to 10.5Gbps • Support for 1x, 2x, 4x and 8x Fibre Channel data rates • Hot-pluggable SFP 20PIN footprint • I/O Connector designed for high-speed differential signal applications • Improved Pluggable Form Factor (IPF) compliant for enhanced EMI/EMC performance • Single 3.3V power supply • Compatible to SFP+ MSA • Operating temperature range: 0 to 70°C • RoHS Compliant and Lead-Free Get More Information Do you have any question about the SFP-10G-CU3M? Contact us now via Live Chat or sales@router-switch.com. Specification SFP-10G-CU3M Specification Compatible OEM Part Number SFP-10G-CU3M Form Factor SFP+ DAC Cable Data Rate 10.5Gb/s Passive or actively equalized Passive Supply Voltage 3.3V Cable Length 3m 138 Cable impedance 100 Ω Cable Type Twinax Wire Gauge 30AWG Minimum cable bend radius 25 mm Cable Jacket Type PVC Connector SFP+/SFP+ Digital Diagnostic Monitoring N/A Environment Operating: 0°C to 70°C Storage: -40°C to 85°C Application Storage Area Networks (SAN) Network Attached Storage The switched fabric I/O High-density connections between networking equipment Data center cabling infrastructure Compliance SFF-8472, SFF-8431 IEC/EN 61000-4-2 MIL-STD -883E, RoHS Want to Buy Order Now Get a Quote Why Router-switch.com As a leading network hardware supplier, Router-switch.com focuses on original new ICT equipment of Cisco, Huawei, HPE, Dell, Hikvision, Juniper, Fortinet, etc. 200+ 18,000+ $20,000,000 50%-98% 100% Countries we Sold Customers Trusted Inventory Available Off Global List Price Safe Online Shopping Contact Us ● Tel: +1-626-655-0998 (USA) +852-3050-1066 / +852-3174-6166 ● Fax: +852-3050-1066 (Hong Kong) ● Email: sales@router-switch.com 139 Network and server Single phase UPS Eaton 5PX Gen2 UPS 1000/1500/2200/3000 VA Exceptional efficiency, manageability and energy metering capabilities for IT managers Performance and efficiency Rack/Tower versatile • Eaton 5PX Gen 2 provides Unity power factor (W=VA) capability. With 11% more power than other UPS it can protect more servers. • Energy Star 2.0 certified, 5PX Gen2 offers best-in-class efficiency performance to reduce energy consumption and cooling costs. • When operating in battery mode the 5PX provides a high-quality output signal for any sensitive equipment connected, such as active PFC (power factor corrected) servers. • Each 5PX Gen2 battery configuration provides the best size/ runtime ratio. Management and Cybersecurity Intuitive LCD display for ease of configuration and management Advanced protection for: • • • • Servers Switches Routers Storage devices • Innovative graphical LCD display brings all operating information at first sight. It also enhances commissioning and configuration capabilities. • 5PX Gen2 Netpack models are delivered with Eaton Gigabit network management card, which provides Dual cybersecurity certifications (UL 2900-1 & IEC 62443-4-2) and enables connection to Eaton Cyber Secured Monitoring solutions. • Together with 5PX Gen2, Eaton Gigabit network management card allows both remote UPS settings and remote firmware upgrade to ensure easy deployment (fleet management) and reduced maintenance cost. • 5PX Gen2 meters energy consumption right down to the managed outlet groups. kWh values can be monitored using the LCD or Eaton’s Intelligent Power Software. • Eaton’s Intelligent Power Software seamlessly integrates with leading virtualization environments and cloud orchestration tools. Availability and flexibility • 5PX Gen2 2200VA & 3000VA are available in RT2U format (optimized for rack mounting) or RT3U (for tower installation or short-depth racks). Pedestals and rail kits are included with all models. • 5PX Gen2 load segment control enables prioritized shutdowns of non-essential equipment to maximize battery runtime for critical devices (2 groups). • Eaton ABM® battery management technology uses a threestage charging technique that optimizes battery health and extends lifetime by up to 50%. • Up to 4 external hot-swappable battery modules can be added for longer power availability. 140 Eaton 5PX Gen2 UPS 1 USB port + 1 serial port + remote ON/OFF and remote power OFF input + output relays Graphical LCD display : - Clear information on UPS status and measurements External battery (EBM) connector - Enhanced configuration capabilities - Available in 7 languages 8 IEC 10A + 2 IEC 16A sockets with energy metering (including 5 remote controlled sockets) anel for batteries replacement P (Hot-swappable) Communication card slot Eaton 5PX Gen2 2200i RT3U Technical specifications 1000 1000VA / 1000W RT2U Rating (VA/W) Format (RT: Tower / Rack) Electrical characteristics Technology Input voltage range without using batteries Input frequency range without using batteries Output voltage Connections Input Outputs 1500 1500VA / 1500W RT2U 2200 2200VA / 2200W RT2U & RT3U 3000 3000VA / 3000W RT2U & RT3U Line-Interactive High Frequency (Pure Sinewave, Booster + Fader) 160V-294V (adjustable to 150V-294V) 47 to 70 Hz (50 Hz system), 56.5 to 70 Hz (60 Hz system), 40 Hz in low-sensitivity mode 230 V (+6/-10 %) (Adjustable to 200V* / 208V / 220V / 230V / 240V), 50/60 Hz +/- 0.1 Hz (autosensing) IEC C20 (16A) IEC C20 (16A) 8 x IEC C13 (10A) 8 x IEC C13 (10A) 2 x IEC C19 (16A) 2 x IEC C19 (16A) 1 group of 2 x IEC C13 (10A) 2 groups of 2 x IEC C13 (10A) 2 groups of 2 x IEC C13 (10A) 1 group of 2 x IEC C13 (10A) + 1 x IEC C19 (16A) 4 FR / Schuko sockets or 3 BS sockets or 6 IEC 10A sockets or terminal blocks (HW version) 8 FR / Schuko sockets or 6 BS sockets or 12 IEC 10A sockets Remote controlled sockets Additional outputs with HS MBP Additional outputs with FlexPDU Batteries Typical backup times ** 5PX 1000 5PX 1000 + 1 EBM / + 4EBM 5PX 1500 5PX 1500 + 1 EBM / + 4EBM 5PX 2200 5PX 2200 + 1 EBM / + 4EBM 5PX 3000 5PX 3000 + 1 EBM / + 4EBM Battery management IEC C14 (10A) IEC C14 (10A) 8 x IEC C13 (10A) 8 x IEC C13 (10A) 300W 500W 800W 1200W 1800W 2500W 30 17 8 148 / 591 83 / 332 48 / 192 44 24 13 7 164/611 92 / 346 53 / 199 33 / 123 50 28 16 9 4 242 / 958 138 / 551 80 / 319 49 / 197 30 / 121 68 39 23 13 7 4 255 / 950 146 / 546 86 / 323 54 / 201 33 / 124 22 / 84 ABM® & Temperature compensated charging method (user selectable), Automatic battery test, deep discharge protection, automatic recognition of external battery units Interfaces Communication ports Communication slot Operating conditions, standards and approvals Operating temperature Noise level Safety EMC, Performance Approvals Dimensions W x D x H / Weight UPS Dimensions (mm) 1 USB port + 1 serial RS232 port + 1 mini-terminal block for Remote ON/OFF + 1 mini-terminal block for Remote Power OFF + 1 mini-terminal block for output relay 1 slot for Network M2 (included in Netpack version), INDGW-M2 or Relay-MS cards 0 to 40°C <40 dB @ typical load IEC/EN 62040-1, UL1778, CSA22.2 IEC/EN 62040-2, FCC Class B, CISPR22 class B CE / CB report (TUV) / cTUVus / EAC / UKCA / Ukr / Cm 438x448x85.5 438x448x85.5 438x603x85.5 (RT2U) 438x483x129 (RT3U) 438x603x85.5 (RT2U) 438x483x129 (RT3U) UPS Weight (kg) 19.6 22.4 EBM dimensions (mm) 438x448x85.5 438x448x85.5 28.2 (RT2U) / 27.5 (RT3U) 438x603x85.5 (RT2U) 438x483x129 (RT3U) 31.7 (RT2U) / 31.1 (RT3U) 438x603x85.5 (RT2U) 438x483x129 (RT3U) EBM weight (kg) 27.8 27.8 40.4 (RT2U) / 39.7 (RT3U) 40.4 (RT2U) / 39.7 (RT3U) Customer service & support Warranty 3 years on electronics, 2 years on battery (3 years full warranty upon registration) * 5% derating @ 200V. ** Backup times are approximate and may vary with equipment, configuration, battery age, temperature, etc. Part numbers* 1000 1500 2200 3000 UPS RT2U UPS RT2U with Network card** UPS RT3U EBM 2 m battery connection cable 5PX1000IRT2UG2 5PX1000IRTNG2 5PX1500IRT2UG2 5PX1500IRTNG2 5PXEBM48RT2UG2 EBMCBL48RT 5PXEBM48RT2UG2 EBMCBL48RT 5PX2200IRT2UG2 5PX3000IRT2UG2 5PX2200IRTNG2 5PX3000IRTNG2 5PX2200IRT3UG2 5PX3000IRT3UG2 5PXEBM72RT2UG2 (RT2U) / 5PXEBM72RT3UG2 (RT3U) EBMCBL72 EBMCBL72 * All 5PX UPS and EBM are delivered with rack kit. ** Network Management Card included as standard in Netpack versions. Eaton Industries Manufacturing GmbH Electrical Sector EMEA Route de la Longeraie 7 1110 Morges, Switzerland Eaton.eu © 2021 Eaton All Rights Reserved Printed in Europe Publication No. BR153152EN July 2021 Changes to the products, to the information contained in this document, and to prices are reserved; so are errors and omissions. Only order confirmations and technical documentation by Eaton is binding. Photos and pictures also do not warrant a specific layout or functionality. Their use in whatever form is subject to prior approval by Eaton. The same applies to Trademarks (especially Eaton, Moeller, and Cutler-Hammer). The Terms and Conditions of Eaton apply, as referenced on Eaton Internet pages and Eaton order confirmations. Eaton is a registered trademark. All other trademarks are property of their respective owners. 141 Datasheet Next-Generation Firewall 60 Series Reliability and security for the distributed enterprise—introducing Forcepoint Next-Generation Firewall 60 Series with secure SD-WAN Remote offices, branches, and stores can connect directly to the cloud more easily and affordably than ever before. The Forcepoint Next-Generation Firewall 60 Series integrates full secure SD-WAN connectivity, advanced high-availability clustering and strong security in a compact, desktop appliance—all managed at enterprise scale from the renowned Forcepoint Security Management Center (SMC). Key Benefits › The most compact Forcepoint Next-Generation Firewall › Direct-to-cloud and site-tosite connectivity › Simple, robust and costeffective site solution › Centralized management Direct-to-cloud connectivity and security for digital transformation Digital transformation is all about connecting distributed workforces to the resources they need, no matter where they are, without compromising the security of your infrastructure. With applications and data moving to the cloud, organizations are increasingly finding that old “hub-and-spoke” networking technologies such as MPLS can no longer handle the load. The Forcepoint Next-GenerationFirewall 60 series provides the networking and security needed to safely connect stores, branches, and remote offices directly to the internet for maximum performance and productivity using the cloud. › Designed for reliability to help secure business continuity Reduced costs and footprint with integrated SD-WAN and Next-Generation Firewall › High-availability clustering The Forcepoint Next-Generation Firewall 60 Series unites networking and security in a compact desktop appliance that is easy to install in even the smallest locations. It integrates multi-ISP SD-WAN connectivity, site-to-site Multi-Link™ VPN, and highavailability clustering with best-of-breed Next-Generation Firewall and intrusion prevention (IPS) security to find, fix, and finish advanced threats before they infiltrate your infrastructure. › Best-of-breed security technology with anti-evasion IPS › Accelerated inspection of encrypted traffic › Built-in anti-virus and antibot defenses › Access to updates and security policies in just a few clicks › Optional Advanced Malware Detection sandboxing › Optional URL Filtering powered by Forcepoint ThreatSeeker You can centrally administer Forcepoint Next-Generation Firewalls from the same Forcepoint Security Management Center (SMC) that controls up to 2,000 physical, virtual, and cloud appliances on a single pane of glass. Our SMC allows you to deploy Forcepoint Next-Generation Firewall 60 Series devices quickly throughout the world and update them easily, with just a few clicks. Relentless reliability to help secure business continuity Downtime is not an option for most organizations. Forcepoint Next-Generation Firewall 60 Series offers advanced clustering that groups multiple appliances together (including other Forcepoint Next-Generation Firewall models) to keep branch networks running— even in the middle of firmware updates or hardware failure. Built-in SD-WAN traffic management lets you use links from more than one ISP at the same time to further reduce the chance of outages. Forcepoint Next-Generation Firewall helps you ensure business continuity by keeping your organization connected, despite challenges that may arise. 142 forcepoint.com Forcepoint Next-Generation Firewall N60 Appliance PERFORMANCE1 N60 PHYSICAL N60 Next-Generation Firewall/NGIPS throughput (HTTP 64 KB payload) 350 Mbps Form factor Desktop Maximum firewall throughput (UDP 1518 byte) 2 Gbps Maximum inspection throughput (UDP 1518 byte) 800 Mbps TLS 1.2 inspection performance (44 KB payload) 110 Mbps IPsec VPN throughput (AES-GCM-256) 1 Gbps Concurrent IPsec VPN tunnels 1,000 Mobile VPN clients Max 25 Maximum inspected concurrent HTTP connections 18,500 Concurrent connections (no inspection) 2,000,000 VLAN tagging Unlimited 1 Dimensions W x H x D Net weight / Appliance + package weight AC power supply Typical power consumption Max power consumption Max BTU/Hour MTBF Performance values reflect maximums measured under test conditions and may vary based on configuration and features enabled Operating temperature Storage temperature ORDERING N60 Forcepoint Next-Generation Firewall N60 Appliance N60 Forcepoint Next-Generation Firewall N60 spare unit N60SPU Forcepoint Next-Generation Firewall Appliance Evaluation N60 URL Filtering FPURL1X Advanced Malware Detection FPAMD1X 60 Series Power Supply Kit Relative humidity non-condensing Safety certification EMI certification 1.070 kg / 2.145 kg 100-240 VAC 50-60 Hz, 40 W 15 W 21.72 W 74.06 BTU Minimum 652,732 hours MTBF at 25°C 0° to ~40° C (32° to ~104°F) -20° to ~80° C (-4° to ~176°F) 10% - 90% CE, CB, UL, LVD, RoHS 3. REACH, FCC, BIS, KCC FCC Sub Part 47 “B” NETWORK INTERFACES N60 Fixed Ethernet interfaces 4 x 1 GbE, RJ45 Wireless Connectors ACP120 225 x 44 x 150 mm / 8.9 x 1.7 x 5.9 in — 2 x USB 3.0, Serial Console, DC in 12V forcepoint.com/contact © 2021 Forcepoint. Forcepoint and the FORCEPOINT logo are trademarks of Forcepoint. All other trademarks used in this document are the property of their respective owners. [NGFW-60-Series-Datasheet-EN] 10Feb2021 143 2 CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-01 Rev. 03 Date 25-10-2022 12. System Architect/Schematic Diagram LEGENDS & ABBREVIATIONS : SYMBOLS DESCRIPTION CAT6A CABLE SLAB 2x6 CORE MULTIMODE FIBRE CABLE RISER 24CORE SINGLE MODE FIBRE CABLE RISER INTERCOM SYSTEM MAIN ENTRANCE PANEL SECURITY INTERCOM GUARD UNIT (CONNECTS TO SECURITY RACK) INTERCOM RECEPTION GUARD UNIT (CONNECTS TO ICT RACK) APARTMENT AUDIO INTERCOM HANDFREE SET HELP POINT MOUNTING HEIGHT VIDEO HELP POINT INTERCOM PANEL SINGLE OUTLET BMS PHASE-03A MASTER KEY PLAN: N Bldg 8 Q 1300mm FFL FCC ROOM RECEPTION DESK 1300mm FFL SHEET-4 of 4 Bldg 6 1300mm FFL/ PEDESTAL POST SHEET-2 of 4 TO BE CONFIRMED WITH BMS CONTRACTOR Bldg 7 SHEET-3 of 4 SHEET-1 of 4 MJL-PH3A 2 MJL-PH3A-O-SE-40002 I SCHEMATIC DIAGRAM ACCESS CONTROL SYSTEM 1 MJL-PH3A-S-IN-32001 E INTERCOM SCHEMATIC DIAGRAM NO. DRG. NO. REV DESCRIPTION REFERENCES 1 1 2 2 3 3 4 4 5 5 6 7 8 9 9 10 10 11 11 12 12 13 13 14 18 19 CABLE MANAGER 24 PORT FIBRE PATCH PANEL 14 15 17 24 PORT CAT6 PATCH PANEL 6 7 8 16 48 POE NETWORK EDGE SWITCH 24 POE NETWORK EDGE SWITCH 48 POE NETWORK EDGE SWITCH 24 POE NETWORK EDGE SWITCH 24 PORT CAT6 PATCH PANEL CABLE MANAGER 24 PORT FIBRE PATCH PANEL 1 2 2 3 3 4 4 5 5 6 7 8 7 9 8 8 10 9 9 11 11 10 10 12 12 11 11 13 13 12 12 14 CABLE MANAGER 24 PORT FIBRE PATCH PANEL 14 15 B7-4F-ICT RACK 27U 16 17 13 19 18 20 20 19 21 21 20 22 22 23 23 23 24 24 24 25 25 25 26 26 27 U 27 27 FTR ROOM 15 16 17 18 23 14 15 19 22 13 14 16 17 18 2KVA UPS 6 9 22 27 U 4 7 20 2KVA UPS 3 5 6 17 21 2 3 5 19 21 27 1 2 4 18 20 26 1 10 16 16 48 POE NETWORK EDGE SWITCH 24 POE NETWORK EDGE SWITCH 24 PORT CAT6 PATCH PANEL 6 7 8 15 15 B6-4F-ICT RACK 27U 1 3KVA UPS 21 17 B8-4F-ICT RACK 27U 18 19 20 22 24 23 23 25 24 24 26 27 FTR ROOM 00 10.08.22 REV DATE FOR APPROVAL NM PK CHKD APP. 21 22 25 25 26 26 27 27 FTR ROOM DESCRIPTION REVISIONS CLIENT: PROJECT: Design and Construction of Madinat Jumeirah Living (Phase 3A) Residential Buildings Asayel 1 (Building-06) G+10, Asayel 2 (Building-07) G+7 & Asayel 3 (Building-08) G+8 on Plot No. 3660509, Umm Suqeim 3, Dubai. CLIENT REPRESENTATIVE: ARCHITECTURAL CONSULTANT: LEAD D&B CONSULTANT: MAIN ICT RACK 1 1 2 2 3 3 4 5 6 48 POE NETWORK EDGE SWITCH 24 PORT CAT6 PATCH PANEL CABLE MANAGER GATE BARRIER HELP POINT GUARD ROOM HELP POINT 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 18 19 20 21 22 8 23 23 9 10 5 5 5 5 6 6 6 6 7 7 7 7 8 8 8 9 24 24 10 25 25 11 11 11 11 11 11 26 26 12 12 12 12 12 27 27 13 13 13 13 13 28 28 14 14 14 14 14 29 29 15 15 15 15 15 15 30 30 16 16 16 16 16 16 31 31 17 17 17 17 17 17 32 32 18 18 19 19 20 20 B6-GF-ICT RACK 18 18 19 19 20 27U B7-GF-ICT RACK 20 21 21 27U B8-GF-ICT RACK 33 18 21 36 22 22 22 23 23 23 23 38 38 39 39 37 3KVA UPS 37 24 24 24 24 25 25 25 25 25 40 40 26 26 26 26 26 26 41 41 27 27 27 27 27 FTR ROOM 27 42 FTR ROOM 27U 1 1 2 1 2 1 2 2 Khalifa Juma Al Nabooda & Khalid Khalifa Al Nabooda & Company 36 24 25 27U AL SAHEL 35 22 23 2KVA UPS D&B MAIN CONTRACTOR: 34 35 21 22 23 2KVA UPS CORE SWITCH 33 34 19 20 27U 21 22 24 Tel: 9714 2857324 Fax: 9714 2851609 P.O. Box: 3815 Dubai 42 SYSTEM INTEGRATOR: 42U 1 1 2 2 3 3 3 4 4 4 5 5 3 3 3 3 3 4 4 4 4 4 5 5 5 5 5 5 6 6 6 6 6 6 6 1 2 6 7 7 7 7 7 7 7 7 8 8 8 8 8 8 8 8 9 9 9 9 9 9 9 9 10 10 10 10 10 10 10 10 11 11 11 11 11 11 11 11 12 12 12 12 12 12 12 12 13 13 13 13 13 13 13 13 14 14 14 14 14 14 14 14 15 15 15 15 15 15 15 15 16 16 16 16 16 16 16 16 17 17 17 17 17 17 17 17 18 18 18 18 18 18 18 18 19 19 19 19 19 19 19 19 20 20 20 20 20 20 20 20 21 21 21 21 21 21 21 21 22 22 22 22 22 22 22 22 23 23 23 23 23 23 23 23 24 24 24 24 24 24 24 24 25 25 25 25 25 25 25 25 26 26 26 26 BUILDING-08 SEC.CONTROL ROOM SECURITY RACK MTR RACK 26 26 26 26 27 27 27 27 27 27 27 28 28 28 28 28 28 29 29 29 29 29 29 29 29 30 30 30 30 30 30 30 30 31 31 31 31 31 31 31 31 32 32 32 32 32 32 32 32 33 33 33 33 33 33 34 34 34 34 34 34 35 35 35 35 35 35 27 28 33 34 B6-BF-IDF-RACK 35 36 42U 36 36 36 36 36 36 37 37 37 37 37 37 37 38 38 38 38 38 38 38 39 39 39 39 39 39 39 40 40 40 40 40 40 40 B8-BF-IDF-RACK SAIFCO Electromechanical Works (LLC) DRAWING TITLE: 34 35 42U 36 37 38 39 40 41 41 41 41 41 41 41 42 42 42 42 42 42 42 ICT SCHEMATIC 42U MTR ROOM Office 312, Safina Building Oud Metha, Dubai U.A.E Tel: 043366602 www.saifcomep.com 33 41 SECURITY EQUIPMENT ROOM SUB CONTRACTOR: 28 42 47U ELEC. ROOM CABLE MANAGER 14 21 2 17 22 4 13 20 1 14 21 4 9 13 14 16 4 10 13 20 4 9 11 12 15 3 10 10 11 12 19 2 3 9 10 18 1 2 3 10 9 15 1 2 3 9 9 12 19 FTR ROOM CABLE MANAGER 48 POE NETWORK EDGE SWITCH 24 PORT CAT6 PATCH PANEL 7 8 17 1 2 CABLE MANAGER 6 7 8 16 1 10 18 2KVA UPS 48 POE NETWORK EDGE SWITCH 24 PORT CAT6 PATCH PANEL 24 PORT FIBRE PATCH PANEL 4 5 FTR. ROOM SCALE DATE DRAWN BY N.T.S 10.08.2022 SH CHECKED BY APPROVED BY NM DRAWING NO. J260-SFCO-CO-SD-INT-SCH-003 PK REVISION 00 CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 13. List of Project Executed STRUCTURED CABLING SYSTEM S No: 1. Project Name Zayed Miltary Hospital Avenue Retail Development Location Abu Dhabi Systems Structured Cabling System, Dubai Structured Cabling System 3. Dana Mall Ajman Structured Cabling System 4. Jumeirah Retail Development Dubai 5. Yahar Mall Al Ain 6. Scholar’s Academy Sharjah 7. Foremarke School Dubai Structured Cabling System 8. ADNOC Filling Station (14 nos) Ajman, Samran, Wasit, Maeeha, UAQ, Khaleej Al Arabi, Batha al Hayer, Al magma, Al Wagan, Al Haffar, Al Marfaa,Al Dhafra. Structured Cabling System 9. Legnano FZE Factory and Office Building Dubai 2. Structured Cabling System Structured Cabling System Structured Cabling System Structured Cabling System Client CMW Meraas Development Abdullah Amin Group Consultant Amana Dewan Architect & Engineers Contractor Amana Mazaya Contral Contracting Wasl Bel Yoahah Al Shirawi Magdi Ghareed Naser Al Ahbaby Scholars International Group City Foundation Engineering Consultants Al Futtaim MEP John R. Harris & Partners Jasaf Evolvence Brewer Smith Brewer Gulf Bilt Middle East ADNOC Al Thorath Engineering Consultants Ali Moosa & Sons Legnano Al Futtaim MEP Bridgeway 10. Light Industrial Unit, Silicon Oasis Dubai Structured Cabling System DSOA Naga System Construct 11. Technohub Dubai Structured Cabling System DSOA NEB Al Andalos 12. Dynergy Factory Dubai Structured Cabling System Dynergy Ian Banham & Associates Omega 13. Emirates Flight Catering Dubai Airport Structured Cabling System Emirates NEB Transgulf 14. Emirates Flight Catering Staff Accommodation Dubai Structured Cabling System Emirates Archon Fawaz 15. Emirates NBD Building Dubai Structured Cabling System Emirates NBD 16. Kaloti Gold Refinery Dubai Structured Cabling System Kaloti Group 17. ADNOC Filling Station 18. 19. 20. 21. City Seasons Hotel Royal City Seasons Sir Baniyas Island Hotel Tiffany Tower 22. Vision Hotel Apartments (3 towers) Abu Dhabi Structured Cabling System 23. Flamingo Hotel Abu Dhabi Structured Cabling System 24. The First Group Hotel (G+32)(Wyndham Hotel) Dubai 25. Reflections Hotel Dubai Ghabat Baynounah, Abu Dhabi Abu Dhabi Abu Dhabi Abu Dhabi Dubai Transgulf Ian Banham Al Andalous Al Thorath Bridgeway APG Nael Energy Norr WS Atkins Hilaco Trinity Syr Consult Al Nasr Middle East Flamingo Syr Consult Square General Structured Cabling System New Dubai Properties Al Ajmi Sterling Structured Cabling System Falaknaz Archgroup Al Shirawi ADNOC Structured Cabling System Structured Structured Structured Structured Cabling Cabling Cabling Cabling System System System System City Seasons City Seasons TDIC Tiffany Realty Mr. Ahamad Mobroak Al mazroay Yas Marina 26. Yas Marina Enhancement Abu Dhabi Structured Cabling System 27. Al Khaili Tower Dubai Structured Cabling System Dubai Structured Cabling System Dubai Structured Cabling System Bhatia Group Federal Dubai Structured Cabling System Bhatia Group Federal Sharjah Structured Cabling System Dubai Structured Cabling System Emirates Engineering Khatib & Alami Dubai Structured Cabling System Yousef Ahmed Khalil Al Baker Cayan Damac 32. Akoya Golf Community (Hotel Apartments) 127 Villas at Jumeirah Village 46 Villas at Jumeirah Village Al Nahda Tower (G+5P+40+R) Infinity Tower (G+6P+72) 33. Burj Damac 5 28. 29. 30. 31. 34. B+G+8+R Dubai Structured Cabling System Al Khaili Group Damac Aecom Al Nasr Shadeed REMCO NAGA Conversion MEP Bhatia General Cont. Bhatia General Cont. Zoom Emirates Drake & Scull Lacasa Fawaz Abdul Mohd. Ahmed Al Zarooni Al Bafta Abdul Rahim Architectural Consultants GCC Contracting Gheyath Mohammad Al Ajmi GINCO Electromechanical EM Square Bhatia General Cont. 35. B+G+9+R Dubai Structured Cabling System 36. G+6+Pool+Gym Residential Plot 20-006 Dubai Structured Cabling System 37. SCA Building 4B+G+10+HC Dubai Structured Cabling System Emirates real estate Co Op Archon Engineering Consultant Bu Haleeba Contracting 38. Park Corner Dubai Structured Cabling System Drake & Scull TNQ. Drake & Scull Bhatia Group 39. 40. 41. 42. 43 44. 45 46 47 48 49 50 Akoya Golf Community (G+7) Golf Residences B+G+16 @ Business Bay Hatta Staff Accommodation ADNOC Staff accommodation Mall of Emirates Expansion Damac Ghalia G+14 @ Business Bay G+18 @ Business Bay G+22 Hotel @ Marina G+18 Hotel @ Business Bay Intercity Hotel @ Jadaf Damac Paramount Dubai Structured Cabling System Damac Mr. Abdulrehman Mohd. Taher Dubai Structured Cabling System Dubai Structured Cabling System Ministry of Health Ruwais Structured Cabling System ADNOC Dubai Structured Cabling System MAF Dubai Structured Cabling System Damac Dubai Structured Cabling System Mr. Abdulrehman Mohd. Wali Dubai Structured Cabling System Mr. Abdulrehman Mohd. Wali Dubai Structured Cabling System New Dubai Properties Dubai Structured Cabling System The First Group Dubai Structured Cabling System Intercity Hotels Dubai Structured Cabling System Damac NAGA Fawaz Al Ajmi Fawaz Bel Yoahah Drake & Scull ECG Engineering Consultant Group Holford Associates/WSP Engg. Consortium Al Ajmi Al Ajmi Al Ajmi Al Ajmi Erga Progress KEO System Construct Drake & Scull Conversion Remco Remco Wafa Electromechanical Technomech Technomech TAV 51 52. 53 54 55 Arkiteknik International Consulting Engineers Wafi Mall & Hotel Expansion Dubai Structured Cabling System MKM Holdings Khalidiya Plaza Views Abu Dhabi Structured Cabling System TMKV Property Bayati Architects 81 villas ,Al Furjan Dubai Structured Cabling System DIGO Real Estate Developments B+G+16 Hotel Dubai Structured Cabling System AlSahil Alakhder Al Ajmi commercial brokers LLC Technomech Dubai Creek Harbour Development Plot !8 A Dubai Structured Cabling System Emaar Properties Atkins Emirates Falcon Electromechanical LLC Drake & Scull Drake & Scull Barbuda Arkiplan Consulting Architects & Engineers Electromechanical LLC CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 14. Company Profile ,%$06\VWHPVVWDUWHGLWVRSHUDWLRQVLQDVDILUPVXSSO\LQJWHOHFRPHTXLSPHQWVLQ 'XEDL 8QLWHG $UDE (PLUDWHV ,%$0 ZDV LQFRUSRUDWHG LQWR D /LPLWHG /LDELOLW\ &RPSDQ\DVSDUWRIDQH[SDQVLRQVWUDWHJ\LQ6XEVHTXHQWO\,%$0H[SDQGHGLWV SURGXFWSRUWIROLRWRLQFOXGHYRLFHGDWDQHWZRUNLQJSURGXFWVDQGVHFXULW\V\VWHPV ,QWKHFRPSDQ\H[SDQGHGLWVRSHUDWLRQVWRLQFOXGHWKHFRPSOHWHUDQJHRIVDIHW\ VHFXULW\ EXLOGLQJ DXWRPDWLRQPDQDJHPHQW V\VWHPV ,EDP SURYLGHV HQG WR HQG VROXWLRQV IRU WKH /9 DQG (/9 V\VWHPV 7KLV LQFOXGHV VXSSRUW IRU GHVLJQ VDOHV PDUNHWLQJ LQVWDOODWLRQ FRPPLVVLRQLQJ SURMHFW PDQDJHPHQW VHUYLFH DQG VXSSRUW WUDLQLQJHWF«LQ/RZ9ROWDJH /9 DQG([WUD/RZ9ROWDJH (/9 V\VWHPVWRFOLHQWV JRYHUQPHQW GHSDUWPHQWV RLO ILHOGV FRPSDQLHV KRWHOV FRQVXOWDQWV SURMHFW PDQDJHUV FRQWUDFWRUVGHYHORSHUVRIKLJKULVHFRPPHUFLDOUHVLGHQWLDOSURMHFWVHWF«6RPHRIWKH SURGXFWVVHUYLFHVSURYLGHGE\,%$0DUH • #EEGUU%QPVTQN • #KTETCHV9CTPKPI.KIJVU • #WFKQ8KFGQ+PVGTEQO5[UVGOU • #WFKQ8KUWCN5[UVGOU #WFKQ8KFGQ%QPHGTGPEG5[UVGOUGVE • $WKNFKPI/CPCIGOGPV5[UVGOU $/5 • %CT2CTM/CPCIGOGPV5[UVGO • %%685[UVGOU • %GPVTCN$CVVGT[CPF'OGTIGPE[.KIJVKPI5[UVGOU • %QPHGTGPEKPICPF5KOWNVCPGQWU+PVGTRTGVCVKQP5[UVGOU • &CVC$CPFYKFVJ/CPCIGOGPV5[UVGOU • (KTG#NCTO5[UVGOU • *GNKRCF.KIJVKPI5[UVGOU • *QOG#WVQOCVKQP5[UVGOU • *QVGN+PVGTCEVKXG68 • *QVGN4QQO/CPCIGOGPV5[UVGOU • +65GEWTKV[5[UVGOU • /CUVGT%NQEM5[UVGOU • 0WTUG%CNN5[UVGOU • 2WDNKE#FFTGUUCPF/CUU0QVKHKECVKQP5[UVGOU • 4(+&Ō2GTUQPPGN6TCEMKPICPF#UUGV/CPCIGOGPV • 5GEWTKV[5[UVGOU • 5/#68+2685[UVGOU • 5VTWEVWTGF%CDNKPI8QKEG&CVC0GVYQTMKPI5[UVGOU #DW&JCDK21$QZ#DW&JCDK6GN (CZ 2CIGQH ,%$0KDVH[HFXWHGDQXPEHURIFRPPHUFLDODQGUHVLGHQWLDOSURMHFWVLQ'XEDLGXULQJ WKH SDVW ILYH \HDUV ,Q DGGLWLRQ WR WKH 8$( PDUNHW ,%$0 KDV EHHQ VXSSO\LQJ HTXLSPHQWWRRWKHU0LGGOH(DVWDQG$IULFD 0($ FRXQWULHVDVZHOO ,%$0SURYLGHVWKHFRPSOHWHUDQJHRISURGXFWVDQGV\VWHPVLQWKH(/9VHFWRU7KHVH SURGXFWV DUH HLWKHU GLUHFWO\ UHSUHVHQWHG E\ ,%$0 RU RXWVRXUFHG EDVHG RQ SURMHFW UHTXLUHPHQWV ,%$0 ZLWK LWV WHDP RI H[SHULHQFHG HQJLQHHUV DQGWHFKQLFLDQV RIIHUV D FRPSUHKHQVLYH UDQJH RI VHUYLFHV OLNH GHVLJQ VXSSRUW VXSSO\ WHVWLQJ FRPPLVVLRQLQJ DQGWUDLQLQJ,%$0RIIHUVDFDOORXWIDFLOLW\WRVXSSRUWXQGHUZDUUDQW\MREVDQG $0&V 0DQXIDFWXUHUVUHSUHVHQWHGE\,%$0 7KH IROORZLQJ DUH VRPH RI WKH PDQXIDFWXUHV FXUUHQWO\ UHSUHVHQWHG E\ ,%$0 LQ WKH 8$(,%$0LVLQWKHSURFHVVRIDFTXLULQJDGGLWLRQDOSURGXFWVWRSURYLGHDFRPSOHWH SDFNDJHRI/9(/9V\VWHPV )TQUXGPQT6GEJPQNQI[8. *URVYHQRU 7HFKQRORJ\ LV D JOREDO OHDGHU LQ WKH KLJKO\ VSHFLDOL]HG VHFWRU RI CEEGUU EQPVTQN CPF CFXCPEGF UGEWTKV[ OCPCIGOGPV U[UVGOU *URVYHQRU 7HFKQRORJ\ HQJDJHV WKH NHHQHVW DQG PRVW FUHDWLYH ,7 PLQGV WR FRQIURQW DQG PDQDJH WKH FRPSOH[LWLHV RI FRUSRUDWH VHFXULW\ 6WURQJ HPSKDVLV RQ LQQRYDWLYH WKLQNLQJ DQG PHWLFXORXVV\VWHPGHVLJQOHDGVWKHZD\DQGHQDEOHV*URVYHQRU7HFKQRORJ\WRLQLWLDWH QHZSURGXFWVLQDQWLFLSDWLRQRIPDUNHWQHHGV ZZZJURVYHQRUWHFKQRORJ\FRP %QQRGT+PFWUVTKGU86$ &RRSHU LV D OHDGLQJ PDQXIDFWXUHU RI HOHFWULFDO DQG OLIH VDIHW\VHFXULW\ SURGXFWV ZLWK IDFLOLWLHV DURXQG WKH JOREH 6RPH RI WKH SURGXFWV WKDW &RRSHU PDQXIDFWXUHV DUH )LUH $ODUP 6\VWHPV &HQWUDO %DWWHU\ DQG (PHUJHQF\ 6\VWHPV 0DVV 1RWLILFDWLRQ 6\VWHPV6HFXULW\6\VWHPVHWF&RRSHULVODUJHVWPDQXIDFWXUHRIHPHUJHQF\OLJKWLQJ V\VWHPV ZZZFRRSHULQGXVWULHVFRP %NKRUCN$XVWUDOLD 7KH ZRUOG IDPRXV &OLSVDO EUDQG LV $XVWUDOLD·V QXPEHU RQH EUDQG RI HOHFWULFDO DFFHVVRULHV (VWDEOLVKHG LQ &OLSVDO LV D PDUNHW OHDGHU LQ OLJKWLQJ FRQWURO VROXWLRQVDQGKRPHDXWRPDWLRQV\VWHPV&OLSVDO·VSURGXFWUDQJHLVPDQXIDFWXUHGDW LWVKHDGRIILFHLQ%RZGHQ6RXWK$XVWUDOLDDVZHOODVUHJLRQDOVDWHOOLWHIDFWRULHV ZZZFOLSVDOFRPDX &GNVC%QPVTQNU&DQDGD )RU PRUH WKDQ \HDUV 'HOWD &RQWUROV KDV RIIHUHG GHSHQGDEOH DQG XVHUIULHQGO\ EXLOGLQJ PDQDJHPHQW %06 VROXWLRQV WR FRPPHUFLDO JRYHUQPHQW DQG UHWDLO EXLOGLQJVDVZHOODVVFKRROVXQLYHUVLWLHVKRVSLWDOVDLUSRUWVDQGPRUH'HOWDGHOLYHUHG WKHZRUOG·VILUVWIXOO\LQWHJUDWHGQDWLYH%$&QHWEXLOGLQJVROXWLRQHQFRPSDVVLQJ+9$& /LJKWLQJDQG$FFHVVSURGXFWV ZZZGHOWDFRQWUROVFRP $NCPMQO*HUPDQ\ 7HOHYHV GHYHORSV PDQXIDFWXUHV DQG SURYLGHV LQQRYDWLYH DQG VWDWHRIWKHDUW KHDGHQG VROXWLRQV IRU ,3 79 GLJLWDO DQG DQDORJ YLGHR GLVWULEXWLRQ DQG PHHWV WKH KLJKHVW 2CIGQH TXDOLW\VWDQGDUGV0RGHUQSURGXFWLRQIDFLOLWLHVDVZHOODVLPSOHPHQWDWLRQRIKLJKTXDOLW\ FRPSRQHQWVDVVXUHH[FHOOHQWWHFKQLFDOSURGXFWFKDUDFWHULVWLFVDQGORQJOLIHWLPH ZZZWHOHYHVFRP #':5[UVGO*QNFKPIU2V[.6&$XVWUDOLD $(; 6\VWHP ZDV IRXQGHG LQ ZLWK D YLVLRQ RI GHYHORSLQJ DQG PDQXIDFWXULQJ 3XEOLF$GGUHVV 3$ 6\VWHPV(YHQLQWKHHDUO\GD\VRILQFHSWLRQ$(;6\VWHPKDG VWURQJO\ EHOLHYHG WKDW WKH PRVW LPSRUWDQW IXQFWLRQ RI D 3$ 6\VWHP ZDV WR VDYH OLYHV GXULQJDQHPHUJHQF\%DVHGRQWKDWSULQFLSOHXSWRWRGD\$(;6\VWHPKDVDGYDQFHG WUHPHQGRXVO\ LQ WKH GHVLJQ FUHDWLRQDQG PDUNHWLQJRI DFUHGLWDEOH UDQJH RISURGXFWV &RQVWDQW LQYHVWPHQW LQ UHVHDUFKDQG GHYHORSPHQW KDV HQDEOHG $(; 6\VWHP WR FRPH XS ZLWK SURGXFWV WKDW UDQN DPRQJ WKH WRS LQ WKH ZRUOG V SURIHVVLRQDO SXEOLF DGGUHVV DQG VRXQG UHLQIRUFHPHQW WHFKQRORJ\ VHFWRU $(; 6\VWHP SURGXFWV DUH FXUUHQWO\ LQVWDOOHGLQRYHUORFDWLRQVIRUPLQJWKHFRUQHUVWRQHRIKLJKTXDOLW\VRXQGV\VWHPV LQVRPHRIWKHPRVWWHFKQRORJLFDOO\DGYDQFHGDQGVRSKLVWLFDWHGEXLOGLQJVLQWKHZRUOG ZZZDH[V\VWHPVFRP /KFKVGE*HUPDQ\ 0LGLWHF PDQXIDFWXUHV GHYHORSV DQG LPSOHPHQWV UHOLDEOH DQG FUHDWLYH SURMHFWVROXWLRQV IRUWLPHUHFRUGLQJDQG VHFXULW\V\VWHPV²ZLWKFXVWRPL]HGKDUGZDUHDQGVRIWZDUH IURP RQH VRXUFH +RZHYHU ODUJH WKH FRPSDQ\ ZKDWHYHU WKH LQGXVWU\ 0LGLWHF KDV VROXWLRQVIURPVLQJOHXVHUWRFRPSOH[V\VWHPV0LGLWHFVROXWLRQVDUHH[SDQGDEOHDWDQ\ WLPH DQG ZLWKRXW UHVWULFWLRQ 6ROXWLRQV FDQ EH FXVWRPL]HG RSWLPDOO\ WR PHHW DQ\ UHTXLUHPHQWVDQGFDQEHFRQWUROOHGLQDQDEVROXWHO\XVHUIULHQGO\IDVKLRQYLDLQWUDQHW DQGLQWHUQHW1DWXUDOO\WKHVHVROXWLRQVDUHPXOWLOLQJXDODQGKDYHPXOWLFOLHQWFDSDELOLW\ ZZZPLGLWHFGH 7TOGV,WDO\ 8UPHW'RPXVLVWKHOHDGLQJ,WDOLDQFRPSDQ\VSHFLDOL]HGLQWKHKRPHFRPPXQLFDWLRQV DQG RIILFH DXWRPDWLRQ VHFWRU ,WV DUHDV RI DFWLYLW\ DUH KRPH HQWU\SKRQHV YLGHR HQWU\SKRQHVGLJLWDOWHFKQRORJ\V\VWHPVIRULQWHJUDWLQJVHUYLFHVDQGLQWHJUDWHG SKRQHHQWU\SKRQHV\VWHPV ZZZXUPHWGRPXVFRP $QUEJ5GEWTKV[86$ %RVFKGHVLJQVDQGPDQXIDFWXUHVSRZHUIXOKDUGZDUHSODWIRUPVDQGIOH[LEOHV\VWHPVIRU VHFXULW\YLGHRVXUYHLOODQFH &&79 OLIHVDIHW\FRPPXQLFDWLRQDQGSURIHVVLRQDO DXGLR ZZZERVFKVHFXULW\FRP 6GNGEQT&DQDGD 7HOHFRU FRPSDQ\ IRUPHG LQ GHVLJQV DQG PDQXIDFWXUHV D UDQJH RI LQQRYDWLYH KLJKTXDOLW\FRPPXQLFDWLRQVSURGXFWV7HOHFRUSUHVHQWO\PDQXIDFWXUHVVWDWHRIWKHDUW 0DVWHU &ORFN 6\VWHPV 1XUVH &DOO 6\VWHPV &RQIHUHQFLQJ 6\VWHPV 3& EDVHG 3%6V\VWHPV$GPLQLVWUDWLYH&RPPXQLFDWLRQ6\VWHPVHWF ZZZWHOHFRUFRP 8KORGZ7- 9LPSH[ DUH VSHFLDOLVW PDQXIDFWXUHUV DQG ZRUOGZLGH GLVWULEXWRUV RI DODUP DQG DQFLOODU\ SURGXFWV IRU WKH ILUH DQG VHFXULW\ LQGXVWU\ DQG ZDWHU OHDN GHWHFWLRQ V\VWHP 7KH +\GURVHQVH :DWHU 'HWHFWLRQ 6\VWHP LV GHVLJQHG WR SURWHFW DUHDV ZKHUH 2CIGQH ZDWHUOHDNDJHFRXOGVHULRXVO\GDPDJHHOHFWULFDOFRPPXQLFDWLRQDQGFRPSXWHUQHWZRUNV DQGFDQEHLQVWDOOHGLQDZLGHUDQJHRIDSSOLFDWLRQV ZZZYLPSH[FRXN (/5*QURKVCNKV[2VG5KPICRQTG )06 +RVSLWDOLW\ 3WH /WG )RUPHO\ NQRZQ DV (NGEQP 0XOWL 6\VWHP 3WH /WG LV WKH RULJLQDO SLRQHHU DQG VSHFLDOLVW LQ WKH +RWHO ,QURRP &RQWURO DQG 0DQDJHPHQW 6\VWHPV (VWDEOLVKHG VLQFH )06 KDV QRW RQO\ GHYRWHG WR SURYLGH VROXWLRQV WR PHHWHDFKKRWHOLHU VXQLTXHUHTXLUHPHQWVEXWDOVRWRRWKHUFXVWRPHUVLQWKHKRVSLWDOLW\ LQGXVWULHV )RU RYHU GHFDGHV )06 V VROXWLRQV KDYH EHHQ VXFFHVVIXOO\ LQVWDOOHG DQG LPSOHPHQWHGLQPRUHWKDQURRPVJOREDOO\ ZZZIOHFRQFRPVJ 8KUKQP/KUUKQPCPF8CNWGU 8KUKQP 7R EH WKH SURYLGHU RI FKRLFH IRU VDIHW\ VHFXULW\ EXLOGLQJ DXWRPDWLRQPDQDJHPHQW V\VWHPVDQGVHUYLFHVLQWKH8$(DQGWKHUHVWRIWKH*&& /KUUKQP ,%$0 VKDOO PHHW DQG H[FHHG WKH QHHGV DQG H[SHFWDWLRQV RI RXU FXVWRPHUV WKHUHE\ SURYLGHFRPSOHWHFXVWRPHUVDWLVIDFWLRQ 8CNWGU +PVGITKV[ ,%$0 DGKHUHV WR D FRQVLVWHQW VWDQGDUG RI KRQHVW\ DQG UHOLDELOLW\ :H DUH FRPPLWWHG WR PDNLQJ WKH ULJKW GHFLVLRQV EDVHG RQ WKH KLJKHVW VWDQGDUGV RI SURIHVVLRQDOSUDFWLFH 5VGYCTFUJKR :H DUH GHYRWHG WR WKH FXOWLYDWLRQ RI ORQJWHUP DQG PXWXDOO\ UHZDUGLQJ UHODWLRQVKLSV ZLWK RXU HPSOR\HHV FOLHQWV EXVLQHVV SDUWQHUV DQG DVVRFLDWHV DQG WDNHSHUVRQDOUHVSRQVLELOLW\WRKHOSHDFKRWKHUVXFFHHG +PXGUVOGPV :H LQYHVW LQ RXU EXVLQHVV DQG RXU SHRSOH ZH JURZ DQG GHYHORS WR DQWLFLSDWH DQGPHHWFKDQJLQJQHHGV 6GCOYQTM :HFRRSHUDWHFROODERUDWHDQGFUHDWHLQQRYDWLYHVROXWLRQV 'ZEGNNGPEG :HVWULYHWRH[FHHGH[SHFWDWLRQVDQGH[SHFWQRWKLQJOHVVWKDQWKHKLJKHVWOHYHO RISHUIRUPDQFH:HDUHFRPPLWWHGWRXQFRPSURPLVLQJTXDOLW\ 6JGUGXCNWGU • )XHORXUPLVVLRQ • /D\WKHJURXQGZRUNIRUODVWLQJUHODWLRQVKLSVZLWKRXUVWDIIFXVWRPHUV DQGSDUWQHUV • $UH WKH TXDOLWLHV ZH VHHN HQFRXUDJH DQG UHZDUG LQ ,%$0 WHDP PHPEHUV 2CIGQH Quality Policy: Our Quality Policy starts and ends with the customer as a focal point: understanding the customer’s requirements, designing optimal solutions to meet those requirements, building systems and processes in place to ensure quality at every stage, and achieving our commitments on delivery and service before and after sales. It is our endeavor to create a culture of Total Quality where continuous improvement of our people, our processes and our products become a way of life. Health Safety and Environmental (HSE) Policy: IBAM aligns its business practices and principles by committing to excellence in environmental performance, and the health and safety of our employees, customers, and communities. Meeting this commitment is a primary management objective and the individual and collective responsibility of all IBAM employees. Our objectives are to: Meet or exceed applicable environmental, health, and safety laws and regulations and other requirements; Continually improve our performance-based HSE Management Systems; Ensure that our business practices and services are aligned with our HSE policies and goals; Minimize the environmental impact of our operations by conserving natural resources, eliminating waste, reusing and recycling materials, and responsibly managing energy use; Motivate and prepare all employees to take personal accountability for protecting the environment and creating a safe and healthy workplace; and Be a leader in deploying and promoting innovative, cost-effective environmental, health, and safety programs and procedures. IBAM will periodically review and improve this policy, communicate it to all employees. ****** Page 5 of 5 CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 15. Valid Civil Defence/SIRA card/Local Authority (certificate) ﺷﻬﺎدة ﺗﺴﺠﻴﻞ Registration Certificate ﻓﻲ ﺷﺄن ﺗﻨﻈﻴﻢ ﻗﻄﺎع اﻟﺎﺗﺼﺎﻟﺎت وﻟﺎﺋﺤﺘﻪ اﻟﺘﻨﻔﻴﺬﻳﺔ2003 ﻟﺴﻨﺔ3 اﺳﺘﻨﺎدا اﻟﻰ اﺣﻜﺎم اﻟﻤﺮﺳﻮم ﺑﻘﺎﻧﻮن اﺗﺤﺎدي رﻗﻢ ﻗﺎﻣﺖ اﻟﻬﻴﺌﺔ اﻟﻌﺎﻣﺔ ﻟﺘﻨﻈﻴﻢ اﻟﺎﺗﺼﺎﻟﺎت ﺑﺘﺴﺠﻴﻞ،وﺗﻌﺪﻳﻠﺎﺗﻬﺎ Based on the Federal Law by Decree No. 3 of 2003 - Regarding Organization of the Telecommunication Sector and its Executive Order and their amendments The Telecommunication Regulatory Authority (TRA) registers. اﻳﺒﺎم ﻟﻠﺎﻧﻈﻤﺔ ش ذ م م IBAM SYSTEMS LLC Certificate Number : 0023179/10 : رﻗﻢ اﻟﺸﻬﺎدة وذﻟﻚ وﻓﻘﺎ ﻟﻠﺸﺮوط واﻟﻠﻮاﺋﺢ واﻟﺴﻴﺎﺳﺎت واﻟﺄﻧﻈﻤﺔ اﻟﻤﻄﺒﻘﺔ ﻟﺪى اﻟﻬﻴﺌﺔ اﻟﻌﺎﻣﺔ ﻟﺘﻨﻈﻴﻢ ﻗﻄﺎع اﻟﺈﺗﺼﺎﻟﺎت According to the terms, conditions, policies and regulation of the TRA for the periodDate of Issue : 14-Nov-2020 14-Nov-2020 : ﺗﺎرﻳﺦ اﻟﺈﺻﺪار Date of Expiry : 13-Nov-2025 13-Nov-2025 : ﺗﺎرﻳﺦ اﻧﺘﻬﺎء اﻟﺼﻠﺎﺣﻴﺔ CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 16. Method Statement/Fixing detail for installation will be provided seperately CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 17. Storing/Handling the Material MATERIAL HANDLING & STORAGE On receipt of the SCS Material at site necessary precautions shall be taken for unloading, shifting and storage, as follows: All delivered material shall be inspected on arrival at the site. The delivered materials shall be inspected in accordance with the approved design, approved shop drawing; materials approvals and all applicable documentation and certification shall be available with the delivery. Any material delivered to the site that not conforming to the above shall be returned to the point of supply and to be replaced with approved materials. No materials will be permitted to enter the works locations without being inspected on arrival to the site. Inspect the materials visually for any mechanical/physical damage that may occur during transport. Any Discrepancies, damage etc., shall be notified immediately for further action. Materials shall be stored in protected environment and in accordance with manufacturer’s recommendations. Proper care shall be taken while moving and handling the materials. The storage area must be free from loose debris above so as not to damage the materials. CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 18. Scope Of Work SCOPE OF WORK MATRIX SNO 1 LIST OF SYSTEM STRUCTURED CABLING SYSTEM WORK DESCRIPTION SHOP DRAWING PREPARATION CONSTRUCTION NOC CONTAINMENT CABLE PULLING CABLE TERMINATION/PATCHING CABLE TESTING DEVICE INSTALLATION IDENTIFICATION LABEL IDF RACK INSTALLATION 42U RACK INSTALLATION 3PHASE ISOLATOR GROUNDING PANEL SIDE CABLE TERMINATION/PATCHING/SPICING TESTING AND COMMISSIONING AUTHORITY APPROVAL WARRANTY FROM TOC HANDOVER DLP FOR ONE YEAR SCOPE OF WORKS SAIFCO IBAM ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ REMARKS CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 19. Load Calculation UPS LOAD CALCULATION IDF cabinet at B6 Ground floor ; B7 Ground floor& B8 Ground Floor Items Qty Wattage Total Wattage 48 Port POE Switch 1 456.00 456.00 456.00 Total Consumption (watts) Considering 20% spare = 547.20 W Assuming power factor 0.9 , kVA rating = 0.61 kVA Hence, a Standard 2 kVA UPS is proposed. IDF cabinet at B6 Fourth Floor ,B7 Fourth Floor Items Qty Wattage 48 Port POE Switch 2 456.00 Total Consumption (watts) Total Wattage 912.00 912.00 Considering 20% spare = 1,094.40 W Assuming power factor 0.9 , kVA rating = 1.22 kVA Hence, a Standard 2 kVA UPS is proposed IDF cabinet at B8 Fourth Floor Items Qty Wattage 48 Port POE Switch 3 456.00 Total Consumption (watts) Total Wattage 1,368.00 1,368.00 Considering 20% spare = 1,641.60 Assuming power factor 0.9 , kVA rating = 1.82 kVA Hence, a Standard 2 kVA UPS is proposed MAIN ICT RACK at B8 Ground Floor Items Qty Wattage Core Switch 2 159.00 Core Switch main control unit 4 48.00 Core Switch fabric unit 4 137.00 firewall 1 21.72 Server farm switch 2 59.00 Total Consumption (watts) Total Wattage 318.00 192.00 548.00 21.72 118.00 1,197.72 Considering 20% spare = 1,437.26 Assuming power factor 0.9 , kVA rating = 1.60 kVA Hence, a Standard 3 kVA UPS is proposed considering future expansion. UPS RUNTIME CHART 3KVA UPS 2KVA UPS CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 20. Rack Details & Patch Panel Schedule WILL BE PROVIDED SEPERATELY ALONG WITH SHOP DRAWING SUBMISSION. CLIENT MAIN CONTRACTOR Project Title: MEP SUBCONTRACTOR Madinat Jumeirah Living Phase – 3A, Jumeriah Umm Suqiem Doc. Title : Material Submittal for ICT Network & Active System 21. Submittal Ref. No. J260-SFCO-MEP-MAT-EL-034-02 Rev. 03 Date 25-10-2022 Annexure PORT SCHEDULE & BANDWIDTH NETWORK EDGE SWITCH BUILDING B6 FLOOR IDF OUTLETS BF GF 1F 2F 3F 4F 5F 6F 7F 8F 9F 10F RF TO GF 1 TO GF TO 4F TO 4F 1 TO 4F TO 4F TO 4F TO 4F TO 4F TO 4F TO 4F 3 15 11 11 8 8 8 8 8 8 6 4 1 OUTLETS OUTLETS+ SPARE 20% / IDF BANDWIDTH 24POE 48POE 29 34.8 1 70 84 2 BW PER OUTLET= 1MBPS 3 15 11 11 8 8 8 8 8 8 6 4 1 TOTAL BW 29 70 BUILDING B7 FLOOR IDF OUTLETS BF GF 1F 2F 3F 4F 5F 6F 7F RF TO GF 1 TO GF TO 4F TO 4F 1 TO 4F TO 4F TO 4F TO 4F 2 17 13 13 13 13 13 6 5 1 FLOOR IDF OUTLETS BF GF 1F 2F 3F 4F 5F 6F 7F 8F RF TO GF 1 TO GF TO 4F TO 4F 1 TO 4F TO 4F TO 4F TO 4F TO 4F 4 16 16 16 16 16 16 15 11 11 1 OUTLETS OUTLETS+ SPARE 20% / IDF 24POE 48POE 32 38.4 1 64 76.8 2 BUILDING B8 OUTLETS OUTLETS+ / IDF & SPARE 20% MDF 36 43.2 102 24POE 48POE 1 122.4 3 BW PER OUTLET= 1MBPS 2 17 13 13 13 13 13 6 5 1 BW PER OUTLET= 1MBPS 4 16 16 16 16 16 16 15 11 11 1 TOTAL BW 32 64 TOTAL BW 36 102 POE SWITCH AT MDF (BUILDING 8) BUILDING 8 OUTLETS OUTLETS+ SPARE 20% 24POE SWITCH CORE SWITCH SEVER FARM WITCH 2 11 2.4 13.2 2 48POE 2 BW PER OUTLET TOTAL BW 132 20 264 220