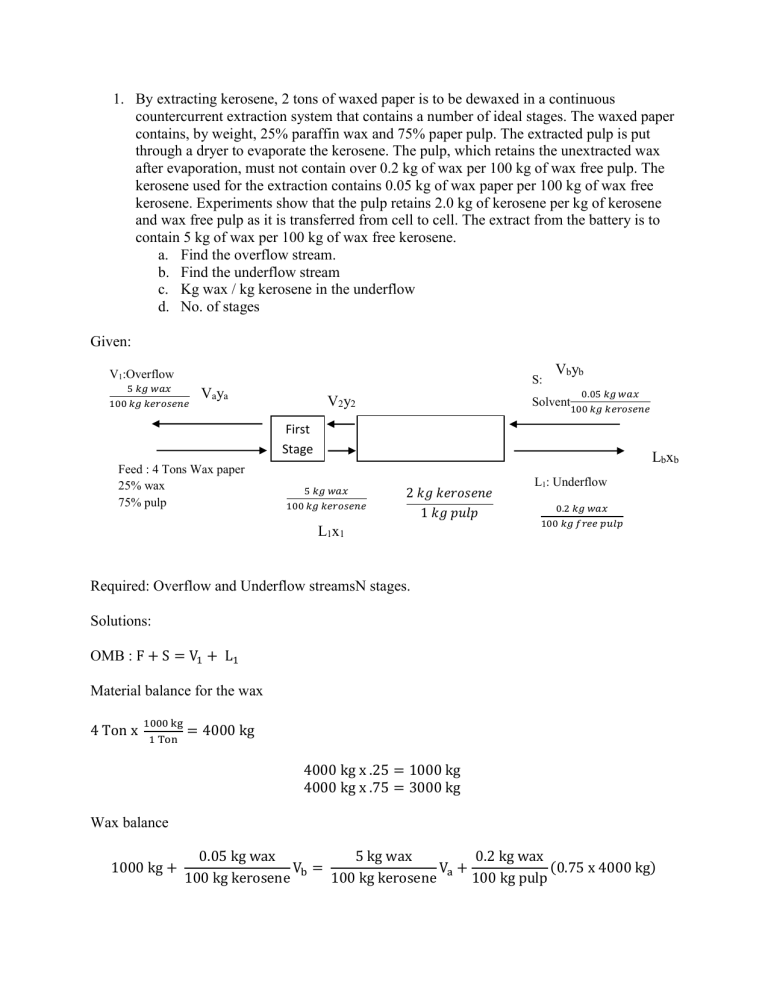

1. By extracting kerosene, 2 tons of waxed paper is to be dewaxed in a continuous countercurrent extraction system that contains a number of ideal stages. The waxed paper contains, by weight, 25% paraffin wax and 75% paper pulp. The extracted pulp is put through a dryer to evaporate the kerosene. The pulp, which retains the unextracted wax after evaporation, must not contain over 0.2 kg of wax per 100 kg of wax free pulp. The kerosene used for the extraction contains 0.05 kg of wax paper per 100 kg of wax free kerosene. Experiments show that the pulp retains 2.0 kg of kerosene per kg of kerosene and wax free pulp as it is transferred from cell to cell. The extract from the battery is to contain 5 kg of wax per 100 kg of wax free kerosene. a. Find the overflow stream. b. Find the underflow stream c. Kg wax / kg kerosene in the underflow d. No. of stages Given: V1:Overflow 5 𝑘𝑔 𝑤𝑎𝑥 100 𝑘𝑔 𝑘𝑒𝑟𝑜𝑠𝑒𝑛𝑒 S: Vaya V2y2 Vbyb Solvent 0.05 𝑘𝑔 𝑤𝑎𝑥 100 𝑘𝑔 𝑘𝑒𝑟𝑜𝑠𝑒𝑛𝑒 First Stage Feed : 4 Tons Wax paper 25% wax 75% pulp Lbxb 5 𝑘𝑔 𝑤𝑎𝑥 100 𝑘𝑔 𝑘𝑒𝑟𝑜𝑠𝑒𝑛𝑒 2 𝑘𝑔 𝑘𝑒𝑟𝑜𝑠𝑒𝑛𝑒 1 𝑘𝑔 𝑝𝑢𝑙𝑝 L1x1 L1: Underflow 0.2 𝑘𝑔 𝑤𝑎𝑥 100 𝑘𝑔 𝑓𝑟𝑒𝑒 𝑝𝑢𝑙𝑝 Required: Overflow and Underflow streamsN stages. Solutions: OMB : F + S = V1 + L1 Material balance for the wax 4 Ton x 1000 kg 1 Ton = 4000 kg 4000 kg x .25 = 1000 kg 4000 kg x .75 = 3000 kg Wax balance 1000 kg + 0.05 kg wax 5 kg wax 0.2 kg wax (0.75 x 4000 kg) Vb = Va + 100 kg kerosene 100 kg kerosene 100 kg pulp Solvent Balance Vb = Va + 2 kg kerosene (0.75 x 4000 kg) = Va + 6000 kg 1 kg pulp Solving simultaneously we get the streams 𝐕𝐚 = 𝟐𝟎𝟏𝟒𝟏. 𝟒𝟏𝟒𝟏 𝐤𝐠 𝐊𝐞𝐫𝐨𝐬𝐞𝐧𝐞 𝐕𝐛 = 𝐕𝟐 = 𝟐𝟎𝟎𝟖𝟏. 𝟒𝟏𝟒𝟏 𝐤𝐠 𝐤𝐞𝐫𝐨𝐬𝐞𝐧𝐞 undeflow = 6000 kg kerosene 0.2 kg wax x 0.75 x 4000 kg pulp 𝐤𝐠 𝐰𝐚𝐱 100 kg pulp xb = = 𝟎. 𝟎𝟎𝟏 6000 kg kerosene 𝐤𝐠 𝐤𝐞𝐫𝐨𝐬𝐞𝐧𝐞 Wax balance: 20081.4141 y2 + 1000 = 5 (20141.4141) + 6000x1 100 equilibrium condition x1 = ya = y2 = 0.05 kg wax kg kerosene y2 = 0.01529 No. of ideal stages 0.001 − 0.0005 ) 0.05 − 0.01529 + 1 = 4 .5398 ≈ 𝟓 𝑁= 0.01529 − 0.0005 ln ( ) 0.05 − 0.001 ln ( 2. In a single step solid-liquid extraction soybean oil has to be extracted from soybean flakes using hexane as solvent. 100 kg of the flakes with an oil content of 20 wt% are contacted with 100 kg fresh hexane. 1.5 kg of inert material hold back a constant value of 1 kg solution. extract (overflow) solvent V1 V2 extraction step L0 L1 feed underflow Total balance: L0 + V2 = M = L1 + V1 = 100 + 100 = 200 kg Balance for compound A: L0 wA,L0 + V2 wA,V2 = M wA,M with the feed concentration wA,L0 = 0.8 and the suggestion, that no solid particles are included in the overflow, so wA,V2 = 0 follows: 100 * 0.8 + 100 * 0 = 200 * wA,M wA,M = 0.4 Balance for compound B: L0 wB,L0 + V2 wB,V2 = M wB,M with the feed concentration wB,L0 = 0.2 and with the knowledge, that pure hexane is used as solvent, wB,V2 = 0, follows 100 * 0.2 + 100 * 0 = 200 * wB,M wB,M = 0.1 The concentration of compound C (solvent) in the mixing point M can be determined either by a mass balance for compound C L0 wC,L0 + V2 wC,V2 = M wC,M with wC,L0 = 0, because no solvent is included in the feed, and with wC,V2 = 1, pure hexane, follows 100 * 0 + 100 * 1 = 200 * wC,M wC,M = 0.5 or by the rule, that the sum of the mass percent of each compound in the point M has to be 1. wA,M + wB,M + wC.M = 1 0.4 + 0.1 + wC.M = 1 wC.M = 0.5 With these concentrations the mixing point M can be drawn in the diagram, which has to be on the connection line of feed point F and solvent C. It is given, that 1 kg inert material retains 1.5 kg solution (extractable substance + solvent = miscella = overflow). Therefore the concentration of the underflow is inert material w A,Underflow = A = inert material+extractable substance+solvent A+B+C 1.5 w A,Underflow =w A,L1 = = 0.6 1.5 + 1 The amount of the leaving flows L1 and V1 can be calculated from the mass balance for compound A M wA,M = V1 wA,V1 + L1 wA,L1 with wA,V1 = 0 (no solid material in the overflow) and wA,L1 = 0.6 (underflow) 𝐿1 = 𝑀 𝑊𝐴,𝑀 0.4 = 200 𝑊𝐴,𝐿1 . 0.6 𝐿1 = 133.333 𝑘𝑔 With the total balance M = L1+V1 follows V1 = M - L1 = 200 - 133.333 V1 = 66.666 kg The concentrations of B and C in the overflow V1 are calculated with the suggestion that no inert material A is included in the overflow. 𝑊𝐵,𝑉1 = 𝑊𝐶,𝑉1 = 𝐵 𝐴+𝐵+𝐶 = 20 0+20+100 𝐶 100 = 𝐴 + 𝐵 + 𝐶 0 + 20 + 100 𝑊𝐵,𝑉1 = 0.1667 𝑊𝐶,𝑉1 = 0.8333 The composition of the underflow can be calculated by mass balances for compound B and C. L1 wB,L1 + V1, wB,V1 = L0 wB,L0 + V2 wB,V2 𝑊𝐵,𝐿1 = 𝐿𝑂 × 𝑊𝐵,𝐿𝑜 − 𝑉1 × 𝑊𝐵,𝑉1 100 × 0.2 − 66.666 × 0.1667 = 𝐿1 133.333 𝑊𝐵,𝐿1 = 0.067 𝑊𝐴,𝐿1 + 𝑊𝐵,𝐿1 + 𝑊𝐶,𝐿1 = 1 𝑊𝐶,𝐿1 = 1 − 0.6 − 0.67 𝑊𝐶,𝐿1 = 0.333 Feed LO Solvent V2 Overflow V1 Underflow L1 Total mass (kg) 100 100 66.666 133.333 Wt% A 80 0 0 60 Wt% B 20 0 16.667 6.7 Wt%C 0 100 83.333 33.3 Situation for problems no. 23-28 By extraction with kerosene with 0.05 lb wax per 100 lb kerosene, 2 tons of waxed paper per day is to be dewaxed in a continuous countercurrent extraction system that contains a number of ideal stages. The waxed paper contains, by weight, 25 percent paraffin wax and 75 percent paper pulp. The extracted pulp is put through a dryer to evaporate the kerosene. The pulp, which retains the unextracted wax after evaporation, must not contain over 0.2 lbs of wax per 100 lbs of wax-free kerosene-free pulp. Experiment show that the pulp retains 2.0 lb of kerosene per lb of kerosene and wax-free pulp as it is transferred from cell to cell. The extract from the battery is to contain 5 lb of wax paper per 100 lb of wax-free kerosene. Per 100 lb of wax-free kerosene-free pulp, 23. The kerosene in the exhausted pulp is equal to a. 150 lb c. 117 lb b. 200 lb d. 212 lb 24. The kerosene in the strong solution is equal to a. 561 lb c. 761 b. 651 lb d. 671 lb 25. The wax in the strong solution is equal to a. 35.35 lb c. 55.33 lb b. 33.55 lb d. 53.53 lb 26. The wax in the underflow to unit 2 is equal to a. 8 lb c. 12 lb b. 10 lb d. 14 lb 27. The wax in the overflow from the second cell to the first is a. 10.22 lb c. 12.11 lb b. 11.12 lb d. 13.19 lb 28. The total number of ideal stages is equal to a. 3 c. 5 b. 4 d. 6 Given: Solute = Wax Solvent = Kerosene Inert = Pulp Y YN Y2 1 +1 1 2 N X X 1 N F= 2 Tons 25% Solute 75% Inert Solution: In Feed: Inert = 100 lb 100 lb inert Feed = = 133.3333 lb 0.75 Solute = (0.25)(133.3333 lb) = 33.3333 lb In Final Underflow: Inert = 100 lb 0.2 lb solute Solute = 100 lb inert x 100 lb inert = 0.2 lb Solvent = 2 lb solvent lb inert x 100 lb inert = 𝟐𝟎𝟎 𝐥𝐛 Overall Solvent Balance 0 + VN+1 = V1 + 200 Equation 1 Overall Solute Balance 0.05 lb solute 5 lb solute 33.3333 + ( 100 lb solvent x VN+1) = (100 lb solvet x V1) + 0.2 Equation 2 From Equation 1: VN+1 – V1 = 200 From Equation 2: 5𝑥10−4 VN+1 – 0.05V1 = -33.1333 Equate Equation 1 and Equation 2, solve for VN+1 and V1: VN+1 = 871.3798 lb V1 = 671.3798 lb Solute in V1: 5 lb solute 100 lb solvent x 671.3798 = 33.5690 lb Solvent Balance in Stage 1: 0 + V2 = 671.3798 +200 V2 = 871.3798 lb Solute Balance in Stage 2: 5 lb solute 5 lb solute 33.3333 + solute in V2 = (100 lb solvent x 200 lb solvent) + (100 lb solvent) 𝑥671.3798 lb solvent Solute in V2 = 10.2357 lb 5 lb solute Solute in Y2 = `00 lb solvent x 200 lb solvent = 𝟏𝟎 𝐥𝐛 Solving for Number of Stages: N=1+ Y −X ln[ N+1 N ] Y2 −X1 Y −Y ln[ N+1 2 ] XN −X1 where: 0.05 lb solute YN+1 = 100 lb solvent = 5x10−4 0.2 lb solute XN = 200 lb solvent = 1x10−3 10.2357 lb solute Y2=871.3798 lb solvent = 0.0117 10 lb solute X1 = 200 lb solvent = 0.05 N=1+ 5𝑥10−4 −1𝑥10−3 ] 0.0117−0.05 5𝑥10−4 −0.0117 ln[ ] 1𝑥10−3 −0.05 ln[ N = 3.9396 = 4 stages Problems no. 29-31. 100 kg of solid containing 50% of a soluble material were treated with 200 kg of a solvent containing the same solute at 3% concentration in a vessel under the constant agitation. After a long time, pressing separated in the solution and the solid. The solid analyzed 0.75 kg of solvent per kg of inert solid. 29. The amount of solute in the final underflow is approximately equal to a. 10.82 kg c. 2.78 kg b. 8.54 kg d. 7.16 kg 30. The amount of solvent in the extract is approximately equal to a. 106.2 kg c. 178.3 kg b. 216.0 kg d. 156.5 kg 31. How much extract was collected? a. 201.68 kg c. 216.08 kg b. 106.21 kg d. 192.86 kg Given: Overflow, V1 Vo = 200 kg (Extract) 3% solute 97% solvent Feed, F = 100 kg Underflow, L1 50% solute solid = 0.75 kg solvent kg inert solid 50% solid Required: 29.) amount of solute in final underflow 30.) amount of solvent in the extract 31.) V1 Solution: In the Feed, F: 𝑠𝑜𝑙𝑢𝑡𝑒 = (0.5)(100𝑘𝑔) = 50 𝑘𝑔 𝑖𝑛𝑒𝑟𝑡 𝑠𝑜𝑙𝑖𝑑 = (0.5)(100 𝑘𝑔) = 50 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑒 = (0.03)(200 𝑘𝑔) = 6 𝑘𝑔 In Vo: 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 = (0.97)(200 𝑘𝑔) = 194 𝑘𝑔 In overflow, V1.: 𝑠𝑜𝑙𝑢𝑡𝑒 = 𝑎 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 = Vi − a Solute balance: 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐹 + 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉𝑜 = 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 + 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉1 50 + 6 = 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 + 𝑎 In underflow, 𝐿1 : 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 = (50 𝑘𝑔 𝑖𝑛𝑒𝑟𝑡𝑠) ( 𝑠𝑜𝑙𝑢𝑡𝑒 = 56 − 𝑎 0.75 𝑘𝑔 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑘𝑔 𝑖𝑛𝑒𝑟𝑡𝑠 ) = 37.5 𝑘𝑔 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 Continuation... Inerts balance: 𝑖𝑛𝑒𝑟𝑡𝑠 𝑖𝑛 𝐹 = 𝑖𝑛𝑒𝑟𝑡𝑠 𝑖𝑛 𝐿1 = 50 𝑘𝑔 Solution balance: 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑖𝑛 𝐹 + 𝑉𝑜 = 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑖𝑛 𝐿1 + 𝑉1 (50 + 0) + 200 = 93.5 − 𝑎 + 𝑉1 156.5 + 𝑎 = 𝑉𝑖 At Equilibrium: 𝑠𝑜𝑙𝑢𝑡𝑒 𝑠𝑜𝑙𝑢𝑡𝑒 ( ) =( ) 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝐿1 𝑎 56 − 𝑎 ) =( ) 156.5 + 𝑎 𝑉1 37.5 + 56 − 𝑎 𝐿1 ( 𝑎 = 45.1753 𝑘𝑔 29.) Amount of solute in underflow, L1: 𝒔𝒐𝒍𝒖𝒕𝒆 = 56 − 𝑎 = 56 − 45.1753 = 𝟏𝟎. 𝟖𝟐𝟒𝟕 𝒌𝒈 30.) Amount of solvent in Extract, Vi: 𝒔𝒐𝒍𝒗𝒆𝒏𝒕 = 𝑉1 − 𝑎 = 156.5 + 𝑎 − 𝑎 = 𝟏𝟓𝟔. 𝟓 𝒌𝒈 31.) V1: 𝑽1 = 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑉1 + 𝑠𝑜𝑙𝑢𝑡𝑒 𝑉1 = 156.5 + 45.1753 = 𝟐𝟎𝟏. 𝟔𝟕𝟓𝟑 𝒌𝒈 Situation for problems no. 32-34 A solid B, contains a soluble component, A, of mass fractions xA = 0.25, xB = 0.75 and is to be recover A by a solvent extraction with C. Solid B and solvent C are mutually totally insoluble. The extracted solid is to be screw passed to a 0.75 kg of solution/kg of B underflow. The entrainment of B in the overflow can be neglected. Per kg of feed and to obtain 85% of A in the extract overflow. 32. The composition of the solution in the underflow is a. 0.04 c. 0.01 d. 0.10 b. 0.07 33. The amount of solvent in the underflow is a. 0.44 b. 0.53 34. How much solvent C (A free) must be fed? a. 3.5000 kg b. 2.5712 kg c. 1.7000 kg d. 5.2311 kg c. 0.88 d. 1.33 GIVEN: REQUIRED: 32. x1 in L1 33. solvent in L1 34. solvent C SOLUTION: In Feed, F: F = 1 kg Solute (A) : (0.25)(1) = 0.25 kg Inerts (B) : (0.75)(1) = 0.75 kg In Underflow , L1 : Inerts (B) : 0.75 kg Solution (A + C) : (0.75)(0.75) = 0.5625 kg Solute : (1 - 0.85)(0.25) = 0.0375 kg Solvent : (0.5625 - 0.0375) = 0.5250 kg x1 = solute solution = 0.0375 0.5625 = 𝟎. 𝟎𝟔𝟔𝟕 In Overflow , V1 : Solute (A) : (0.85)(0.25) = 0.2125 kg V1 = ? ? ? Solution Balance: (0.25 + 0) + C = V1 + 0.5625 V1 = C - 0.3125 @ equilibrium: solute (solution) solute V1 0.2125 = (solution) L1 0.0375 (C − 0.3125) V1 = (0.5625) C = 3.5000 kg L1 Situation for problems no. 35-38 Seeds containing 30% weight oil are extracted in a countercurrent plant and 88% of the oil is recovered in a solution containing 55% by weight of oil. The seeds are extracted with fresh solvent and 1 kg of solution is removed in the underflow in association with every 1.5 kg of insoluble material. 35. The amount of solvent in final extract is approximately equal to a. 26.4 kg c. 46.67 kg d. 43.07 kg b. 21.6 kg 36. The amount of solvent in final underflow is approximately equal to a. 26.4 kg c. 46.67 kg b. 21.6 kg d. 43.07 kg 37. The concentration of oil in the solvent stream for stage 1 is approximately equal to a. 0.55 c. 0.18 b. 0.08 d. 0.34 38. How many ideal stages are needed to attain the desired separation? a. 4 b. 6 c. 8 d. 10 GIVEN: REQUIRED: 35. Solvent in V1 36. Solvent in LN 37.Concentration of oil V2 38.N SOLUTION: Basis: 100 kg of Feed In Feed, F: Insoluble = 0.70(100 kg) = 70 kg Oil = 0.30(100 kg) = 30 kg In final Overflow, V1: Oil = 0.88 (30 kg) = 26.4 kg 45 Solvent = 26.4 kg(55 ) = 21.6 kg y1=x1=0.55 In final Underflow, LN=L1=46.6667 kg Oil= 0.12(30 kg) = 3.6 kg Insoluble = 70 kg 1 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 Solution = 70 kg(1.5 𝑘𝑔 𝑖𝑛𝑠𝑜𝑙𝑢𝑏𝑙𝑒)= 46.6667 kg Solvent = 46.6667 kg– 3.6 kg= 43.0667 kg 3.6 xN= 46.6667 = 0.0771 In Fresh Solvent, VN+1: Solvent = 21.6 kg + 43. 0667 kg = 64.6667 kg Solute = 0 yN+1 = 0 Solute Balance around Stage 1: 30 kg + 64.6667 kg (y2) = 26.4 kg + 46.6667 kg(0.55) y2= 0.3412 = x2 N= 1 + 0−0.0771 ) 0.3412−0.55 0−0.3412 ln( ) 0.0771−0.55 ln( = 4.05 Situation for problems 39-42 Calcium-carbonate precipitate can be produced by the reaction of an aqueous solution of sodium carbonate and calcium oxide. The by-product is aqueous sodium hydroxide. Following decantation, the slurry leaving the precipitation tank is 5 wt% calcium carbonate, 0.1 wt% sodium hydroxide, and the balance water. One hundred thousand lb/h of this slurry is fed to a two-stage, continuous, countercurrent washing system to be washed with 20,000 lb/h of fresh water. The underflow from each thickener will contain 20 wt% solids. 39. The amount of extract 40. The amount of sodium hydroxide in final extract 41. The amount of sodium hydroxide in final underflow 42. The percent recovery of sodium hydroxide in the extract Given: 20,000 lb/h (V2) (V1) 2 1 (F) 100,000 lb/h (V3) (L1) 5 wt% Calcium Carbonate 0.1 wt% Sodium Hydroxide 94.9 wt% Water Solution: In Feed: 𝐶𝑎𝑙𝑐𝑖𝑢𝑚 𝐶𝑎𝑟𝑏𝑜𝑛𝑎𝑡𝑒 = 0.05(100,000) = 5000 𝑙𝑏/ℎ 𝑆𝑜𝑑𝑖𝑢𝑚 𝐻𝑦𝑑𝑟𝑜𝑥𝑖𝑑𝑒 = 0.001(100,000) = 100 𝑙𝑏/ℎ 𝑊𝑎𝑡𝑒𝑟 = 0.949 (100,000) = 94900 𝑙𝑏/ℎ Solid Balance: 𝑆𝑜𝑙𝑖𝑑 𝑖𝑛 𝐹 = 𝑆𝑜𝑙𝑖𝑑 𝑖𝑛 𝐿2 5000 𝑙𝑏 = 0.20 (𝐿2) ℎ 𝐿2 = 25000 𝑙𝑏 ℎ (L2) 20wt% solid OMB: 𝐹 + 𝑉3 = 𝑉1 + 𝐿2 100,000 + 20,000 = 𝑉1 + 25,000 𝑉1 = 95000 𝑙𝑏 ℎ Stage 1 (@ equilibrium) 𝑆𝑜𝑙𝑢𝑡𝑒 𝑆𝑜𝑙𝑢𝑡𝑒 ( )(𝑉1) = ( ) 𝑆𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑆𝑜𝑙𝑢𝑡𝑖𝑜𝑛 (𝐿1) ( 𝐴𝑚𝑜𝑢𝑛𝑡 𝑜𝑓 𝑆𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑖𝑛 𝐿2 = 25,000 (0.80) = 20,000 𝑉3 = 𝑉2 ; 𝐿2 = 𝐿1 𝑆𝑜𝑙𝑢𝑡𝑒 𝑆𝑜𝑙𝑢𝑡𝑒 )(𝑉1) = ( ) 95,000 20,000 (𝐿1) 𝑆𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉1 = 4.75 𝑆𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 − − − 𝑒𝑞𝑛(1) Stage 2 (@ equilibrium) ( 𝑆𝑜𝑙𝑢𝑡𝑒 𝑆𝑜𝑙𝑢𝑡𝑒 )(𝑉2) = ( ) 𝑆𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑆𝑜𝑙𝑢𝑡𝑖𝑜𝑛 (𝐿2) ( 𝑆𝑜𝑙𝑢𝑡𝑒 𝑆𝑜𝑙𝑢𝑡𝑒 )(𝑉2) = ( ) 20,000 20,000 (𝐿2) 𝑆𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉2 = 𝑆𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿2 − − − 𝑒𝑞𝑛(2) Solute Balance in Stage 2 𝑆𝑜𝑙𝑢𝑡𝑒𝐿1 + 𝑆𝑜𝑙𝑢𝑡𝑒 𝑉3 = 𝑆𝑜𝑙𝑢𝑡𝑒𝑉2 + 𝑆𝑜𝑙𝑢𝑡𝑒 𝐿2 𝑆𝑜𝑙𝑢𝑡𝑒𝐿1 + 0 = 𝑆𝑜𝑙𝑢𝑡𝑒𝑉2 + 𝑆𝑜𝑙𝑢𝑡𝑒 𝐿2 𝑆𝑜𝑙𝑢𝑡𝑒𝐿1 = 𝑆𝑜𝑙𝑢𝑡𝑒𝐿2 + 𝑆𝑜𝑙𝑢𝑡𝑒 𝐿2 𝑆𝑜𝑙𝑢𝑡𝑒𝐿1 = 2𝑆𝑜𝑙𝑢𝑡𝑒 𝐿2 − − − 𝑒𝑞𝑛 (3) Overall Solute Balance 𝑆𝑜𝑙𝑢𝑡𝑒𝐹 + 𝑆𝑜𝑙𝑢𝑡𝑒 𝑉3 = 𝑆𝑜𝑙𝑢𝑡𝑒𝑉1 + 𝑆𝑜𝑙𝑢𝑡𝑒 𝐿2 100 + 0 = 𝑆𝑜𝑙𝑢𝑡𝑒𝑉1 + 𝑆𝑜𝑙𝑢𝑡𝑒𝐿2 − − − 𝑒𝑞𝑛 (4) Substitute eqn (1) to eqn (4) 100 = 4.75𝑆𝑜𝑙𝑢𝑡𝑒𝐿1 + 𝑆𝑜𝑙𝑢𝑡𝑒𝐿2 − − − 𝑒𝑞𝑛 (5) Substitute eqn (3) to eqn (5) 100 = 4.75(2)𝑆𝑜𝑙𝑢𝑡𝑒𝐿2 + 𝑆𝑜𝑙𝑢𝑡𝑒𝐿2 𝑆𝑜𝑙𝑢𝑡𝑒𝐿2 = 9.52 𝑙𝑏 ℎ Using eqn 4: 100 + 0 = 𝑆𝑜𝑙𝑢𝑡𝑒𝑉1 + 9.52 𝑆𝑜𝑙𝑢𝑡𝑒𝑉1 = 90.48 𝑙𝑏 ℎ 𝑃𝑒𝑟𝑐𝑒𝑛𝑡 𝑅𝑒𝑐𝑜𝑣𝑒𝑟𝑦 (𝑅) = 𝑅= (90.48 − 0 ) 𝑥 100 100 𝑅 = 90.48 % 𝑆𝑜𝑙𝑢𝑡𝑒𝑉1 − 𝑆𝑜𝑙𝑢𝑡𝑒𝑉3 𝑆𝑜𝑙𝑢𝑡𝑒𝐹 PROBLEM 43-46 Ground roasted coffee contains 8% soluble solids, 2% water, and 90% inert insoluble solids. In order to obtain an extract with high soluble solids content without having to concentrate it for spray drying, a countercurrent extraction process is to be used to prepare the extract. It is desired that the final extract contain 0.15kg soluble/kg water and that the soluble of the spent coffee grounds not to exceed 0.008 kg/kg dry inert solids. The coffee grounds carry 1 kg water/kg of soluble-free inert solids and this quantity is constant with the solute concentration in the extract. REQD: 43) The amount of final extract is approximately equal to a. 55.81 kg b. 48.54 kg c. 72.8 kg d. 28.1 kg 44) The concentration of the solution adhering to the extracted solids is approximately equal to a. 0.0936 b. 0.0079 c. 0.1304 d. 0.0032 45) The water/coffee ratio to be used in the extraction is a. 1.37 b. 2.88 c. 0.98 d. 1.87 46) The number of extraction stages needed for this process is a. 5 b. 6 c. 7 d. 8 SOLUTION: Overflow, V1 0.15 kg solute kg H2O V2 V3 V4 Y2 Y3 Y4 Solvent, Vn+1 Yn+1 1 2 3 N Solution: Feed, F R1 R2 R3 L1 L2 L3 8% Solute Final Underflow, Ln Xn Solute/Inerts = 0.008 2% H2O 90% Inerts X1 R= 1 kg H2O/kg X2Inerts X3 In the feed: basis(100 kg) Solute: 0.08(100)= 8kg Solvent: 0.02(100)= 2kg Inerts: 0.9(100)=90kg In final underflow: Inerts= inerts in F=90kg Solute=0.008(90)=0.72kg Solvent=90(1)=90 kg XN= 0.008 𝑆𝑜𝑙𝑢𝑡𝑒 0.72 (𝑆𝑜𝑙𝑢𝑡𝑖𝑜𝑛)in LN =90+0.72 = 𝟎. 𝟎𝟎𝟕𝟗(#44) In final overflow, V1: Solute balance: 8+0=0.72+Solute in V1 𝑆𝑜𝑙𝑢𝑡𝑒 Y1= X1=𝑆𝑜𝑙𝑣𝑒𝑛𝑡 = 0.15 Final Overflow(extract)=solute+solvent = 7.28+48.5333kg=V1 = 55. 8133 kg(#43) In solvent stream, Vn+1 Yn+1=0(pure water) Solvent= Vn+1=? Overall solvent bal: 2+Vn+1=90+48.5333 Vn+1=136.5333 Ratio: 𝑉𝑛+1 𝐹 = 136.5333 100 = 𝟏. 𝟑𝟔𝟓𝟑 (#45) Solute for Y2 using Solute balance around stage 1 8+ V2Y2=L1X1+7.28 V2= Vn+1=136.5333 Y2=? L1=LN=90 X1=Y1=0.15 8+136.5333=90(0.15)+7.28 Y2=0.0936 Solve for N: N=1+ 0.008 ) 0.0926−0.15 0−0.0936 𝑙𝑛( ) 0.008−0.15 ln( =5.69=6 stages(#46) Problem 47 Given: V1 V2 YN+1 1 Y1 2 Y2 Feed= 50 tons/hr N L1 LN X1` XN 48% H2O 40% Pulp R= 3 𝑡𝑜𝑛𝑠 𝐻20 𝑡𝑜𝑛𝑠 𝑃𝑢𝑙𝑝 12%Sugar Required: N = ? Solutions: In Feed: H2O = 0.48(50) = 24 𝑡𝑜𝑛𝑠 Pulp = 0.40(50) = 20 Sugar = 0.12(50) = 6 ℎ𝑟 𝑡𝑜𝑛𝑠 ℎ𝑟 𝑡𝑜𝑛𝑠 ℎ𝑟 In Final Overflow: Sugar = 0.97(6) = 5.82 5.82 𝑡𝑜𝑛𝑠 Solution = 0.15 = 38.8 ℎ𝑟 𝑡𝑜𝑛𝑠 ℎ𝑟 H2O = V1 = 38.8 – 5.82 = 32.98 Y1 = 5.82 32.98 𝑡𝑜𝑛𝑠 ℎ𝑟 = 0.1765 X1 = Y1 = 0.1765 at equilibrium In Final Underflow: Sugar = 0.03(6) = 0.18 𝑡𝑜𝑛𝑠 ℎ𝑟 H2O = LN = 20(3) = 60 XN = 0.18 60 𝑡𝑜𝑛𝑠 ℎ𝑟 = 0.003 In Fresh Solvent: OMB (Solvent): LN + V1 – Lo VN+1 = 60 + 32.92 – 24 H20 = VN+1 = 68.98 𝑡𝑜𝑛𝑠 ℎ𝑟 YN+1 = 0 (pure solvent) Sugar Balance Around Stage 1: Sugar in F + V2Y2 = L1X1 + V1Y1 V2 = V3 = V4 = ….. = VN+1 = 68.98 L1 = L2 = L3 = L4 = ….. = LN = 60 6 + 68.98Y2 = 60(0.1765) + 5.82 Y2 = 0.1509 Solving for N: N= 0 − 0.003 0.1509−0.1765 0−0.1509 𝑙𝑛 0.003−0.1765 ln N = 16.36 = 17 +1 𝑡𝑜𝑛𝑠 ℎ𝑟 𝑡𝑜𝑛𝑠 ℎ𝑟 Problem 48 Constant Solution Retention: L8V – solution flowrates : X8Y – solute/solution In Feed: H2O = 0.48(50) = 24 tons/hr Pulp = 0.40(50) = 20 tons/hr Sugar = 0.12(50) = 6 tons/hr In Final Overflow: Sugar = 0.97(6) = 5.82 tons/hr Y1 = 0.15 5.82 Solution = V1 = 0.15 = 38.8 tons/hr X1 = Y1 = 0.15 (@ equilibrium) In Final Underflow: R= 3 𝑡𝑜𝑛𝑠 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑡𝑜𝑛 𝑑𝑟𝑦 𝑝𝑢𝑙𝑝 Sugar = 0.03(6) = 0.18 tons/hr Solution = LN = 3(20) = 60 tons/hr XR = 0,18 60 = 0.003 In Fresh Solvent H2O = VN+1 = LN + V1 – L0 (overall solution balance) H2O = VN+1 = 60 + 38.8 – (24 + 6) VN+1 = 68.8 tons/hr YN+1 = 0 (pure solvent) Sugar Balance Around Stage 1: Sugar in F + V2Y2 = L1X1 + V1Y1 V2 = V3 = V4 = . . . = VN+1 = 68.8 tons/hr L1 + L2 + L3 = . . . = LN = 60 tons/hr 6 + 68.8Y2 = 60(0.15) + 38.8(0.15) Y2 = 0.1282 Solving for N: N= 0−0.003 ] 0.1282−0.15 0−0.1282 ln[ ] 0.003−0.15 ln[ N = 15.49 = 16 Situation for problems no. 49-52 A seashore sand contains 85% insoluble sand, 12% salt and 3% water. 1000 lb/hr of this mixture is to be extracted in a countercurrent washing system with 2000 lb/hr of pure water so that after drying it will contain only 0.2% salt. The sand retains 0.5 lb of water per pound of insoluble sand. 49. The mass of salt in the final underflow is equal to a. 1.7 lb/hr c. 2.3 lb/hr b. 1.2 lb/hr d. 2.5 lb/hr 50. The concentration of salt in the final overflow is equal to a. 0.03 c. 0.07 b. 0.05 d. 0.09 51. The concentration of salt in the solvent stream for stage 1 is approximately equal to a. 0.023 c. 0.07 b. 0.015 d. 0.19 52. The number of washing is approximately equal to a. 3 c. 5 b. 4 d. 6 Given: Y 2000 lb/hrY Y2 N 1 +1 1 2 L N LN 1 F= 1000 lb/hr 12% Solute 85% Inert 3% Solvent Solution: In Feed : Inert = 1000 lb/hr (0.85) = 850 lb/hr Solute = 1000 lb/hr (0.12) = 120 lb/hr Solvent = 1000 lb/hr (0.03) = 30 lb/hr In Final Underflow : after drying = 0.2% salt Inert = 850 lb/hr 0.5 𝑙𝑏 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 Solvent = 𝑙𝑏 𝑖𝑛𝑒𝑟𝑡 × 850 𝑙𝑏 𝑖𝑛𝑒𝑟𝑡 = 425 𝑙𝑏 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 Solute : 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿𝑁 = 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿𝑁 = 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿𝑁 = 0.2 (𝑖𝑛𝑒𝑟𝑡 + 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿𝑁 ) 100 0.2 0.2 𝑖𝑛𝑒𝑟𝑡 + 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿𝑁 100 100 0.2 𝑙𝑏 0.2 (850 ) + 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿𝑁 100 ℎ𝑟 100 𝒔𝒐𝒍𝒖𝒕𝒆 𝒊𝒏 𝑳𝑵 = 𝟏. 𝟕𝟎𝟑𝟒 𝒍𝒃/𝒉𝒓 Final underflow = inert +solvent + solute 𝑙𝑏 = (850 + 425 + 1.7034) ℎ𝑟 𝐹𝑖𝑛𝑎𝑙 𝑈𝑛𝑑𝑒𝑟𝑓𝑙𝑜𝑤 = 1276.7034 𝑙𝑏/ℎ𝑟 Overall Material Balance (OMB) : 𝐹 + 𝑉𝑁+1 = 𝐿𝑁 + 𝑉1 1000 𝑙𝑏 𝑙𝑏 𝑙𝑏 + 2000 = 1276.7034 + 𝑉1 ℎ𝑟 ℎ𝑟 ℎ𝑟 𝑉1 = 1723.2966 𝑙𝑏 ℎ𝑟 Overall Solute Balance : 𝐹𝑠𝑜𝑙𝑢𝑡𝑒 + 𝑉𝑁+1 𝑠𝑜𝑙𝑢𝑡𝑒 = 𝑉1𝑆𝑜𝑙𝑢𝑡𝑒 + 𝐿𝑁 𝑠𝑜𝑙𝑢𝑡𝑒 120 𝑙𝑏 𝑙𝑏 + 0 = 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑒 + 1.7034 ℎ𝑟 ℎ𝑟 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑒 = 118.2966 𝑙𝑏 ℎ𝑟 𝑐𝑜𝑛𝑐𝑒𝑛𝑡𝑟𝑎𝑡𝑖𝑜𝑛 𝑜𝑓 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉1 = 118.2966 1723.2966 𝒄𝒐𝒏𝒄𝒆𝒏𝒕𝒓𝒂𝒕𝒊𝒐𝒏 𝒐𝒇 𝒔𝒐𝒍𝒖𝒕𝒆 𝒊𝒏 𝑽𝟏 = 𝟎. 𝟎𝟔𝟖𝟔𝟓 ≈ 𝟎. 𝟎𝟕 𝑙𝑏 𝑙𝑏 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑖𝑛 𝑉1 = (1723.2966 − 118.2966) ℎ𝑟 = 1605 ℎ𝑟 In Stage I : V1=1605 lb/hr V2 = 2000 lb/hr LN= 425 lb/hr F= 30 lb/hr ( 𝑠𝑜𝑙𝑢𝑡𝑒 𝑠𝑜𝑙𝑢𝑡𝑒 )𝑉1 = ( )𝐿 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 1 𝑙𝑏 ℎ𝑟 = 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 𝑙𝑏 𝑙𝑏 1605 425 ℎ𝑟 ℎ𝑟 118.2966 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 = 31.3246 𝑙𝑏 ℎ𝑟 Solute Balance in Stage I : 𝐹𝑠𝑜𝑙𝑢𝑡𝑒 + 𝑉2 𝑠𝑜𝑙𝑢𝑡𝑒 = 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑒 + 𝐿1 𝑠𝑜𝑙𝑢𝑡𝑒 120 𝑙𝑏 𝑙𝑏 𝑙𝑏 + 𝑉2 𝑠𝑜𝑙𝑢𝑡𝑒 = 118.2966 + 31.3246 ℎ𝑟 ℎ𝑟 ℎ𝑟 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉2 = 29.6212 𝑙𝑏 ℎ𝑟 𝑐𝑜𝑛𝑐𝑒𝑛𝑡𝑟𝑎𝑡𝑖𝑜𝑛 𝑜𝑓 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉2 = 29.6212 2000 𝒄𝒐𝒏𝒄𝒆𝒏𝒕𝒓𝒂𝒕𝒊𝒐𝒏 𝒐𝒇 𝒔𝒐𝒍𝒖𝒕𝒆 𝒊𝒏 𝑽𝟏 = 𝟎. 𝟎𝟏𝟒𝟖𝟏 ≈ 𝟎. 𝟎𝟏𝟓 Solving for Number of Stages: N=1+ Y −X ln[ N+1 N ] Y2 −X1 YN+1 −Y2 ln[ ] XN −X1 where: YN+1 = 0 XN = 1.7034 lb solute 29.6212 lb solute Y2= X1 = N=1+ = 4.008x10−3 425 lb solvent 2000 lb solvent = 0.01481 31.3246 lb solute 425 lb solvent 0−4.008𝑥10−3 ] 0.01481−0.0737 0.01481−0 ln[ ] 0.07370−4.008𝑥10−3 ln[ N = 2.7352 = 3 stages = 0.07370 55. A slurry of flaked soybeans weighing 100 kg contains 75 kg inert solids and 25 kg of solution 10 weight % oil and 90 weight % solvent hexane. This slurry is contacted with 100 kg pure hexane in a single stage so that the value of retention for the outlet underflow is 1.5 kg on insoluble solid per kg solvent in the adhering solution. The composition of underflow leaving the extraction stage in percent by weight oil is GIVEN: V1 V0 = 100 kg hexane y1 y0 F = 100 kg Inert = 75 kg Sol’n = 25 kg L1 x1 𝑅 = 1.5 𝑘𝑔 𝑖𝑛𝑒𝑟𝑡 𝑘𝑔 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 REQUIRED: The composition of underflow leaving the extraction SOLUTION: In Feed: F = 100 kg Inert = 75 kg Sol’n = 25 kg Oil (solute) = .10(25 kg) = 2.5 kg Inert balance: Inert in feed = Inert in L1 Inert in L1= 75 kg In Underfeed (L1): Inert = 75 kg Solvent = ? = 50 kg solvent = 75 kg inert kg inert 1.5 kg solvent Solute = ? Solute balance: Solute in F + Solute inV0 = Solute in V1 + Solute in L1 2.5 kg + 0 = Solute in V1 + Solute in L1 Eq. 1 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉1 = 2.5 − 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 Solvent balance: Solvent in F + Solvent in V0 = Solvent in V1 + Solvent in L1 22.25 kg + 100 kg = solvent in V1 + 50 kg Solvent in V1 = 72.5 kg At Equilibrium: 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 = 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑖𝑛 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑖𝑛 𝐿1 Eq. 2 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿2 = 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉1 + 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑖𝑛 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿2 + 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑖𝑛 𝐿2 Subs. Eq. 1 to Eq. 2: 2.5 − 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 = (2.5 − 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 ) + 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑖𝑛 𝑉1 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 + 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑖𝑛 𝐿1 Solute in L1 = 1.0204 kg Subs to Eq. 1 Solute in V1 = 1.4795 Composition on underflow leaving: 𝑉1 𝐿1 1.4795 𝑘𝑔 = 1.0204 𝑘𝑔 = = 1.45 56. Tung meal containing 55% oil is to be extracted at a rate of 4000 kg per hour using nhexane containing 5% wt oil as solvent. A counter current multiple stage extraction system is to be used. The meal retains 2 kg of solvent per kg of oil free meal while the residual charge contains 0.11 kg oil per kg oil free meal while the product is composed of 15 weight percent oil. The theoretical number of ideal stages is (A) 3 (C) 5 (B) 4 (D) 6 Given: 𝑉1 𝑉𝑛+1 15% oil 5% oil 1 2 3 𝑘𝑔 𝐹 = 4000 ℎ𝑟 n 𝐿𝑛 55% oil 0.11 𝑘𝑔 𝑜𝑖𝑙 𝑘𝑔 𝑜𝑖𝑙 𝑓𝑟𝑒𝑒 𝑚𝑒𝑎𝑙 2 𝑘𝑔𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑅 = 𝑘𝑔 𝑓𝑟𝑒𝑒 𝑚𝑒𝑎𝑙 Required: Theoretical number of ideal stages Solution: Basis: 1 hr In the Feed, 𝑘𝑔 𝑜𝑖𝑙: 0.55𝑥 4000 = 2200 𝑘𝑔 𝑘𝑔𝑚𝑒𝑎𝑙: 0.45 𝑥 4000 = 1800 𝑘𝑔 In the final underflow, 0.11 𝑘𝑔 𝑜𝑖𝑙 𝑘𝑔𝑜𝑖𝑙: 𝑥 1800 𝑘𝑔 = 198 𝑘𝑔 𝑘𝑔 𝑜𝑖𝑙 𝑓𝑟𝑒𝑒 𝑚𝑒𝑎𝑙 2 𝑘𝑔 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑘𝑔 𝑠𝑜𝑙𝑣𝑒𝑛𝑡: 𝑥 1800 𝑘𝑔 = 3600 𝑘𝑔 𝑘𝑔 𝑓𝑟𝑒𝑒 𝑚𝑒𝑎𝑙 𝑘𝑔 𝑚𝑒𝑎𝑙: 1800 𝑘𝑔 Overall Solution Balance: 2200 + 𝑉𝑛+1 = 𝑉1 + 3600 + 198 𝑉𝑛+1 = 𝑉1 + 1598 eq. 1 Overall Solute Balance: 2200 + 0.05𝑉𝑛+1 = 198 + 0.15𝑉1 eq 2 𝑉1 = 20819 𝑘𝑔 𝑉𝑛+1 = 22417 𝑘𝑔 At equilibrium condition, 𝑠𝑜𝑙𝑢𝑡𝑒 𝑠𝑜𝑙𝑢𝑡𝑒 ( ) 𝑉1 = ( )𝐿 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 1 ( 0.15𝑥20819 𝑘𝑔𝑜𝑖𝑙 𝑖𝑛 𝐿1 )=( ) 20819 3600 + 𝑘𝑔 𝑜𝑖𝑙 𝑖𝑛 𝐿1 Kg oil in L1= 635.29 kg Solute balance in stage 1: 2200 + 𝑘𝑔 𝑜𝑖𝑙 𝑖𝑛 𝑉2 = 0.15𝑥20819 + 635.29 Kg oil in V2= 1558.14 kg Solvent balance in stage 1: 0 + 𝑘𝑔 𝑠𝑜𝑙𝑣𝑒𝑛𝑡 𝑖𝑛 𝑉2 = 3600 + 0.85𝑥20819 Kg solvent in V2= 21296.15 kg 𝑦2 : 1558.14 = 0.0682 1558.14 + 21296.15 198 𝑥𝑛 : = 0.0521 3600 + 198 635.29 𝑥1 : = 0.15 635.29 + 3600 At constant underflow, 𝑦𝑛+1−𝑥 𝑙𝑜𝑔 𝑦 − 𝑥 𝑛 2 1 𝑁−1= 𝑦𝑛+1 − 𝑦2 log 𝑥 − 𝑥 𝑛 1 0.05 − 0.0521 𝑙𝑜𝑔 0.0682 − 0.15 𝑁−1= 0.05 − 0.0682 𝑙𝑜𝑔 0.0521 − 0.15 N= 3.1665 ≈ 4 stages 57. Coconut oil is to be produced from dry copra in two stages. First, through expellers to squeeze out part of the coconut oil and then through a counter current multi stage solvent extraction process. After expelling, the dry copra cake contains 20% residual oil. In the solvent extraction operation, 90% of the residual oil in the expeller cake is extracted as a solution containing 50% by weight oil. If fresh solvent is used and on kg of solution with every 2 kg of insoluble cake is removed with the underflow, the number of ideal stages is (A) 4 (C) 6 (B) 5 (D) 7 Given: 𝑉1 𝑉𝑛+1 90% recovery 50% oil 𝑉𝑛+1 1 2 3 𝐿𝑛 F Copra 𝑅= 20% oil 1 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 2 𝑘𝑔 𝑐𝑎𝑘𝑒 Required: Number of Ideal Stages Solution: Basis: 100 kg Copra In the Feed, F= 100 kg Kg oil: 0.20 x 100= 20 kg Kg inert: 0.80 x 100= 80 kg In the Solvent, V(n+1) 𝑦𝑛+1 = 𝑠𝑜𝑙𝑢𝑡𝑒 =0 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 In the Final Underflow, Ln, Kg inert= 80 kg Kg solution: n 1 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 2 𝑘𝑔 𝑖𝑛𝑒𝑟𝑡 𝑥 80 𝑘𝑔 𝑖𝑛𝑒𝑟𝑡 = 40 𝑘𝑔 𝐿𝑛 : 80𝑘𝑔 + 40 𝑘𝑔 = 120 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑒: 0.10 𝑥 20 = 2 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑒 2 : = 0.05 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 40 In the Final Overflow, V1 𝑦1 = 0.50 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑒: 0.90 𝑥 20 = 18 𝑘𝑔 18𝑘𝑔 𝑉1 : = 36 𝑘𝑔 0.50 In the first undeflow, L1 𝑠𝑜𝑙𝑢𝑡𝑒 = 𝑦1 = 0.50 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 Kg inert: 80 kg Kg solution: 40 kg 𝐿1 : 80𝑘𝑔 + 40𝑘𝑔 = 120 𝑘𝑔 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑒: 0.50 𝑥 40 𝑘𝑔 = 20 𝑘𝑔 In the Ovreflow 2, V2, OMB on stage 1, 𝐹 + 𝑉2 = 𝐿1 + 𝑉1 100 + 𝑉2 = 120 + 36 𝑉2 = 56 𝑘𝑔 Solute balance on stage 1, 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐹 + 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉2 = 𝑆𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝐿1 + 𝑠𝑜𝑙𝑢𝑡𝑒 𝑖𝑛 𝑉1 20 + 𝑦2 𝑥 56 = 20 + 18 𝑦2 = 0.3214 For constant underflow, 𝑦𝑛+1−𝑥 𝑙𝑜𝑔 𝑦 − 𝑥 𝑛 2 1 𝑁−1= 𝑦𝑛+1 − 𝑦2 log 𝑥 − 𝑥 𝑛 1 0 − 0.05 𝑙𝑜𝑔 0.3214 − 0.50 𝑁−1= 0 − 0.3214 𝑙𝑜𝑔 0.05 − 0.50 N= 5 stages 58. Roasted copper ore containing the copper as CuSO4 is to be extracted in countercurrent stage extractor. Each hour, a charge consisting of 10 tons gangue, 1.2 tons CuSO4 and 0.5 ton water is to be treated. The strong solution produced is to consist of 90% wt. water and 10% wt. CuSO4. The recovery of CuSO4 is to be 98% of that in the ore. Pure water is to be used as fresh solvent. After each stage, one ton inert gangue retained 2 tons of water plus the copper sulfate dissolve in that water. Equilibrium is attained in each stage. The number of stages required is. Given: OverFlow water) 90% water, 10% CuSO4 Solvent(Pure Feed Underflow 1 𝑡𝑜𝑛 𝑔𝑎𝑛𝑔𝑢𝑒 𝑅 = 2 𝑡𝑜𝑛 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 10 tons gangue 1.2 tons CuSO4 0.5 tons water Solution: Inert in feed = inert in underflow Amount of solution in underflow 10 𝑡𝑜𝑛 𝑖𝑛𝑒𝑟𝑡 𝑥 2 𝑡𝑜𝑛 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 1 𝑡𝑜𝑛 𝑖𝑛𝑒𝑟𝑡 = 20 𝑡𝑜𝑛 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 Amount of overflow 1.2 𝑡𝑜𝑛𝑠 𝑥 0.98 0.10 = 11.76 𝑡𝑜𝑛𝑠 Overall balance of solute and solvent 11.76 + 20 = 0.5 + solvent stream Solvent stream = 30.06 tons Composition of final underflow Solute in underflow = 1.2 – 1.2x0.98 =0.024 tons 0.024 %wt. = 20 = 1.2 𝑥 10−3 For stage 1 11.76 tons 30.06 tons 1.2 tons CuSO4 0.5 tons Water At equilibrium 𝑠𝑜𝑙𝑢𝑡𝑒 20 tons 𝑠𝑜𝑙𝑢𝑡𝑒 (𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛)𝑜𝑣𝑒𝑟𝑓𝑙𝑜𝑤 = (𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛)𝑢𝑛𝑑𝑒𝑟𝑓𝑙𝑜𝑤 = 0.10 Solute balance ; let x = fraction of solute at solvent stream 1.2 = 30.06 x =1.176 + 2 X = 0.065735 Number of stages =1+ 0−1.2𝑥10−3 ] 0.065735− .10 0−0.065735 ln[ ] 1.2𝑥10−3 −.10 ln[ = 9.226 = 10 stages Situation for Problems 59-63 Oil is to be extracted from meal by means of benzene using a continuous countercurrent extractor. The unit is to be treat 1000 kg of meal (based on completely exhausted solid) per hour. The untreated meal contains 400 kg of oil and is contaminated with 25 kg of benzene. The fresh solvent mixture contains 10 kg of oil and 655 kg of benzene. The exhausted solids are to contain 60 kg of unextracted oil. Experiments carried out under conditions identical with those of the projected battery show that the solution retained depends on the concentration of the solution, as shown in table below. All quantities are given in an hourly basis. Concentration, kg oil/kg solution 0.0 0.1 0.2 0.3 Solution retained, kg/kg solid 0.500 0.505 0.515 0.530 Concentration, kg oil/kg solution 0.4 0.5 0.6 0.7 Solution retained, kg/kg solid 0.550 0.571 0.595 0.620 59. The concentration of the strong solution or extract is approximately equal to a. 0.56 b. 0.58 c. 0.60 d. 0.62 60. The concentration of the solution adhering to the extracted solids is approximately equal to a. 0.193 b. 0.218 c. 0.021 d. 0.118 61. The mass of the solution leaving with the extracted meal is approximately equal to a. 507 kg/h b. 306 kg/h c. 418 kg/h d. 621 kg/h 62. The mass of the extract is approximately equal to a. 583 kg/h b. 512 kg/h c. 536 kg/h d. 571 kg/h 63. The number of stages required is a. 3 b. 4 c. 6 d. 7 Given: Final Overflow, Vi V2, 1 y2 VN, 2 yN Solvent, VN+1 N 10 kg oil 655 kg benzene Feed, F = 1000 kg meal/hr L1, L2, 400 kg oil x1 x2 LN 60 kg unextracted oil 25 kg benzene 575 kg solid Solution: In the feed: F = 1000 kg meal/hr 10 bVn+1 = 665 = 0.015 Solute: 400 kg oil Solvent: 25 kg benzene Inert Solid: 1000 – (400+25) = 575 kg Solution: 400 + 25 = 425 kg/h solution 400 af = 425 = 0.941 By trial and error, Assume aVn+1 = 0.1, 𝑘𝑔 from table, Solution in Ln = 0.505 𝑘𝑔 𝑠𝑜𝑙𝑖𝑑 LN = 0.505 (1000) = 505 kg/hr 60 In the Solvent: VN+1 = 10+655 = 665 kg Solute: 10 kg oil avn+1 = 505 = 0.119 @ avn+1 = 0.119, 𝑘𝑔 Solvent: 655 kg benzene from table, Solution Ln = 0.507 𝑘𝑔 𝑠𝑜𝑙𝑖𝑑 Ln = 0.507(1000) = 507 kg/h 60 In the Final Underflow: LN avn+1 = Solute: 60 kg unextracted oil @ Final Underflow, Ln: Benzene: Ln – 60 Benzene: 507 – 60 = 447 kg/h 507 = 0.118 @ Final Overflow Let: a = mass fraction of oil in final underflow OMB Solute: Feed + Solvent = Final (Underflow + Overflow) b = mass fraction of oil in final overflow Oil: 400 + 10 = 60 + Final Overflow Final Overflow Solute: 350 kg/h OMB Solvent: Feed + Solvent = Final (Underflow + Overflow) Benzene: 25 + 655 = 447 + Final Overflow Final Overflow Solvent: 233 kg/h Vi = 350 + 233 = 583 kg/h extracted 350 b = 583 = 0.60 At equilibrium: a = bvi = 0.60, 𝑘𝑔 from table, Solution = 0.595 𝑘𝑔 𝑠𝑜𝑙𝑖𝑑 At stage 1: MB: Feed + V2 = V1 + L1 425 + V2 = 583 + 595 V2 = 953 kg Oil Balance: 595 (0.60) + 583 (0.6) = 425 (0.) + 753Y2 y2 = 0.408 N=1+ 0.015−0.118 ] 0.408−0.6 0.015−0.408 ln[ ] 0.118−0.6 ln[ = 4.05 = 4 64. An oil-sand mixture that is 25% (by mass) oil and 75% (by mass) sand is to be extracted or leached with 75 tons/day of naphtha in a countercurrent extractor. The feed consists of 100 tons/day of mixture. The final extract (overflow) produced contains 35% (by mass) oil and 65% (by mass) naphtha, and the underflow from each unit consists of 32% (by mass) oil and 68% (by mass) sand. The overall efficiency of the extraction is 80% (by mass). Assume the solvent is miscible with the oil in all portions and the extractor has reached equilibrium conditions in each stage. Assume there is no sand in the overflow. The number stages required to effect the desired separation of oil from sand is a. 3 c. 5 b. 4 d. 6 Given: 75 tons/day of naphtha OverFlow Yoil = 0.35 Ynaphtha = 0.65 Feed, F 100 tons/day Xsolution = 0.32 Xoil =0.25 Xsand = 0.68 Xsand = 0.75 Overall efficiency = 80% Required: Number of stages Solution: Assume: 1 day *in the feed* (100 𝑡𝑜𝑛𝑠 𝑑𝑎𝑦 of mixture)(1 day) = 100 tons of mixture *amount of raffinate* 75 𝑡𝑜𝑛𝑠 𝑜𝑓 𝑠𝑎𝑛𝑑 0.68 = 110.29 Sand = 100(0.75) = 75 Oil = 100(0.25) = 25 *OMB* Feed + naphtha = raffinate + extract 100 + 75 = 110.29 + extract Extract = 64.71 *Naphtha balance* Amount of naphtha entering = amount of naphtha extract + amount of naphtha raffinate Let X = mass fraction of naphtha in raffinate 75 = (64.71) (0.65) + (110.29) (X) X= 0.2986 Mass fraction of oil in raffinate = 1- 0.2986 – 0.68 = 0.0214 The further solution will be subjected to a graphical method 65. A copper ore containing 10.3% by mass copper sulfate, 85.4% by mass inert and 4.3 % by mass water is to be extracted with pure water in a counter current extractor. The daily feed consist of 281 tons. The final extract produced contains 10% by mass copper sulfate and 90% by mass water. The underflow from each stage consist of 66.7% by mass solution and 33.3% by mass inert. The process is to recover 92% of the copper sulfate from the ore. Assume the extractor has reached equilibrium conditions in each stage the minimum number of stages required to effect the desired separation of copper sulfate from the inert. Given: Overflow 10% CuSO4, 90% water Solvent %recovery = 92 Feed 281 tons 10.3 % CuSO4 solution 85.4 % inert 4.3 % water Solution: Basis: 281 tons feed .103(281) = 28.943 kg CuSO4 .854(281) = 239.974 kg inert .043(2810 = 12.083 kg water Inert in feed = inert in underflow Amount of solution in underflow 239.974 .333 (. 667) = 480.6686 tons solution Amount of overflow 0.92(28.943) 0.10 = 266.2756 66.7 % 33.3 % inerts %solute in underflow 28.943−(28.943 𝑥 0.92) 480.6636 = 4.817 𝑥 10−3 Solvent balance 12.083 + solvent stream = 0.90(266.2756) + 480.6636 – 2.31544 Solvent stream =705.9182 At stage 1 266.2756 tons solution 28.943 tonsCuSO4 12.083 tons water 705.9182 tons solution 480.6686 tons solution At equilibrium 𝑠𝑜𝑙𝑢𝑡𝑒 𝑠𝑜𝑙𝑢𝑡𝑒 (𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛)𝑜𝑣𝑒𝑟𝑓𝑙𝑜𝑤 = (𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛)𝑢𝑛𝑑𝑒𝑟𝑓𝑙𝑜𝑤 = 0.10 Solute balance; let x be fraction of solute at solvent stream .10(266.2756) + .10(480.6686) = 28.943 + 705.9182x X = 0.0648 Number of stages =1+ 0−4.817𝑥10−3 ] 0.0648− .10 0−0.0648 ln[ ] 4.817𝑥10−3 −.10 ln[ = 6.1727 = 7 stages 1. 60 tons per day oil sand (25 wt% oil and 75 wt % sand) is to be extracted with 40 tons per day of naphthalene in a counter current extraction battery. The final extract from the battery is to contain 40 wt% oil and 60 wt% naphthalene and the underflow from each unit is expected to consists of 35 wt% solution and 65 wt% sand. If the overall efficiency of the battery is 50%, how many stages will be required? GIVEN: Final Vo Vn+1 F Final Ln Final Vo ( Final Overflow) Final Ln ( Final Underflow) X oil= 0.40 X naphthalene+ X oil= 0.35 X naphthalene= 0.60 X sand= 0.65 Feed= 60 tons/day Vn+1= 40 tons/day X oil= 0.25 X sand= 0.75 Required: N (Number of Stages) =? X naphthalene= 1 Detailed Solution: Let A= Oil (Solute) B= Sand (Insoluble Solid) C= Naphthalene (Solvent) In the Feed F= 60 tons/day A= 0.25(60) = 15 tons/day B= 0.75(60) = 45 tons/day Overall Insoluble Solid Balance: (B)FEED=(B)UNDERFLOW (B)UNDERFLOW= 45 tons/day In the underflow (B)UNDERFLOW= 45 tons/day=0.65 (underflow) Underflow= 69.53 tons/day Ln=(69.23)(0.35)= 24.23 tons/day Liquid Balance: ( Solute+Solvent) 15+40=24.23+Vo Vo= 30.67 tons/day Solvent Balance: 40= (C)UNDERFLOW + (0.60)(30.67) (C)UNDERFLOW= 21.598 tons/day In the Underflow: Xc = ((C)UNDERFLOW/ Ln)= 21.598/24.23= 0.89 Xn= Xa= 1-0.89= 0.11 No. of Stages: N THEO= 1+ ln( (Yn+1- XN)/ (Y2-X1))/ln(((Yn+1- Y2)/ (XN-X1))) Balance at Stage 1: 0.25(60)+ Y2(40)= 0.40( 30.77)+0.40(24.23) Y2= 0.175 Substitute: Yn+1= 0 XN= 0.11 Y2= 0.175 X1= 0.40 N THEO = 1+ ln( (Yn+1- XN)/ (Y2-X1))/ln(((Yn+1- Y2)/ (XN-X1))) N THEO= 2.42 stages N ACTUAL= N THEO/EFFECIENCY= 2.42/ 0.50 N ACTUAL= 4.84= 5 STAGES (Principles of Mass Transfer and Separation Processes by Binay K. Dutta) A solid feed containing 22% of solute, 3% water and 75% inerts (insoluble) is to be leached a rate of 1 ton per hour with water in a countercurrent leaching cascade. The strong leachate leaving the unit should have 16% of the solute in it. Desired recovery of the solute in the feed is 99%. The overflow does not have any entrained inert in it, and the amount of solution retained in the sludge is 0.45 kg solution per kg inert. Analytically determine the number of stages required for the separation. Given: Final V1 Vn+1 F Final Ln Solution: Basis: 1 hour operation 1 ton = 1000 kg In Feed Solute: 1000(0.22) = 220 kg Water: 1000(0.03) = 30 kg Inert: 1000(0.75) = 750 kg In Underflow: 0.45 𝑘𝑔 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛 𝑥 750 𝑘𝑔 𝑖𝑛𝑒𝑟𝑡 = 337.5 𝑘𝑔 𝑘𝑔 𝑖𝑛𝑒𝑟𝑡 LN = 337.5 kg solution Mass of solute leaving with the sludge (99% recovery) = (220)(0.01) = 2.2 kg Solute = 2.2 kg Solvent = 335.3 kg 𝑥𝑁 = 2.2 = 0.00652 337.5 In Overflow: Solvent balance: Solvent in F + VN+1 = LN + V1 30 + VN+1 = 335.3 + V1 V1 = VN+1 – 305.3 Solute balance : Solute in F + VN+1 = LN + V1 220 + 0 = 2.2 + (VN+1 – 305.3) (0.16/0.84) VN+1 = 1448.75 kg V1 = 1143.45 kg Solute in V1 = 182.95 kg Solvent in V1 = 960.5 kg Solute Balance at Stage 1: VN+1 = 1448.75 = V2 X1 = Y1 = 0.16 YN+1 = 0 Pure solvent 220 + V2y2 = L1x1 + 182.95 220 + 1448.75y2 = 337.5 (0.16) + 182.95 Y2 = 0.0117 𝑥𝑁 = 0.00652 Using the equation: 𝑦 − 𝑥𝑁 ln( 𝑁+1 𝑦2 − 𝑥1 ) 𝑁−1= 𝑦 − 𝑦2 ln( 𝑁+1 𝑥𝑁 − 𝑥1 ) 𝑁−1= 0 − 0.00652 ln(0.0117 − 0.16) ln( N= 2.2 N= 3 STAGES N = 3 stages 0 − 0.0117 ) 0.00652 − 0.16