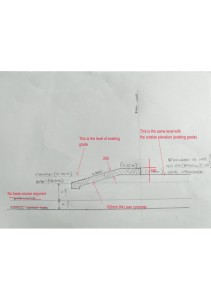

OCTOBER CONSTRUCTION COMPANY LTD METHOD STATEMENT FOR LEAN CONCRETE PROJECT TITLE: CONSTRUCTION OF 380KV UNDERGROUND CABLES FROM KING SALMAN PARK #9083 TO ALMURSALAT #9012 AND FROM KING SALMAN PARK TO ALRAWABE #9047. Rev. Date 19-Oct-2022 Rev No. 00 Docume nt Number 14890-SECOCC-MOS-C004-Rev-0 Page 1 of 7 OCTOBER CONSTRUCTION COMPANY LTD. PO Box 246327 | Riyadh-11312 | KSA Tel# (11) 2541 571 Fax# (11)2541571 ext-116 Method Statement For Lean Concrete 14870-OCC-SEC-MOS-C-Rev-00 Contract No.: 4400014870 PROJECT TITLE: CONSTRUCTION OF 380KV UNDERGROUND CABLES FROM KING SALMAN PARK #9083 TO ALMURSALAT#9012 AND FROM KING SALMAN PARK TO ALRAWBE#9047. OCTOBER CONSTRUCTION COMPANY LTD METHOD STATEMENT FOR LEAN CONCRETE PROJECT TITLE: CONSTRUCTION OF 380KV UNDERGROUND CABLES FROM KING SALMAN PARK #9083 TO ALMURSALAT #9012 AND FROM KING SALMAN PARK TO ALRAWABE #9047. Rev. Date 19-Oct-2022 Rev No. 00 Docume nt Number 14890-SECOCC-MOS-C004-Rev-0 Page 2 of 7 REVISION RECORD Rev Date Description 00 19/Oct/22 Method of Statement Prepared by Qc Engineer Checked Project Engineer Approved Project Manager OCTOBER CONSTRUCTION COMPANY LTD METHOD STATEMENT FOR LEAN CONCRETE PROJECT TITLE: CONSTRUCTION OF 380KV UNDERGROUND CABLES FROM KING SALMAN PARK #9083 TO ALMURSALAT #9012 AND FROM KING SALMAN PARK TO ALRAWABE #9047. Rev. Date 19-Oct-2022 Rev No. 00 Docume nt Number 14890-SECOCC-MOS-C004-Rev-0 Page 3 of 7 Table Of Contents 1. INTRODUCTION .......................................................................................4 2. OBJECTIVE ............................................................................................... 4 3. REFERENCE DRAWING AND STANDERD .................................................. 4 5. REQUIRED TOOLS AND EQUPIMENT ....................................................... 4 6. RESPONSSIBILITIES .................................................................................. 5 7. SAFETY .................................................................................................... 5 8. ACCESS .................................................................................................... 6 9. EQUIPMENT HANDLING ..............................Error! Bookmark not defined. 10. Application of Lean Concrete ............................................................... 6 11. HOUSE KEEPING AND CLOSING OF SITE ...............................................7 OCTOBER CONSTRUCTION COMPANY LTD METHOD STATEMENT FOR LEAN CONCRETE PROJECT TITLE: CONSTRUCTION OF 380KV UNDERGROUND CABLES FROM KING SALMAN PARK #9083 TO ALMURSALAT #9012 AND FROM KING SALMAN PARK TO ALRAWABE #9047. Rev. Date 19-Oct-2022 Rev No. 00 Docume nt Number 14890-SECOCC-MOS-C004-Rev-0 Page 4 of 7 1. INTRODUCTION The scope of Project is to carry out engineering design, procurement of necessary materials and equipment, construction and installation at site, inspection, testing and commissioning of 380kv. 2. OBJECTIVE The purpose of this is to describe the measures and ways of doing lean concrete / blinding works. Work will be carried out in compliance with the approved drawing and project specification. 3. REFERENCE DRAWING AND STANDERD TCS-Q-113.02.Rev.01 70-TMSS-03 ACI-347 ACI-318 4. PER-REQUISITES The following per-requisite activities shall be completed before starting the lean concrete work. Levels of the trench as per approved drawing. Compaction test results. Site cleaning and transforming any unwanted materials. Safety barrication of site 5. REQUIRED TOOLS AND EQUPIMENT Concrete Pump. RMC mixer. Boom loader. Wheel borrow OCTOBER CONSTRUCTION COMPANY LTD METHOD STATEMENT FOR LEAN CONCRETE PROJECT TITLE: CONSTRUCTION OF 380KV UNDERGROUND CABLES FROM KING SALMAN PARK #9083 TO ALMURSALAT #9012 AND FROM KING SALMAN PARK TO ALRAWABE #9047. Rev. Date 19-Oct-2022 Rev No. 00 Docume nt Number 14890-SECOCC-MOS-C004-Rev-0 Page 5 of 7 Dumpy Level. Meter tape. Masonry tools. 6. RESPONSSIBILITIES The Site Engineer shall be responsible for carrying out the work procedure and ensures that installation is carried out in accordance with the project specifications and manufacturer's instructions. He sees to it that all equipment shall be handled carefully during transport, handling, and storage and protected from any damage before and after installation. The Quality control Inspector shall be responsible to carry out the inspections of work. He shall prepare hold points inspections and the corresponding work releases by reviewing records and test results as proof that work inspected conforms to specifications. Foremen report to Site Civil Engineer and responsible for supervision at the job site and responsible for Site works and lead the team for safe work execution at site meeting required deadlines foremen responsible for all material and Equipment to keep in store after work done. 7. SAFETY Before starting any job, a toolbox meeting will be conducted for explaining the job nature and safety policies to be practiced. All personal protective equipment shall be manufactured to recognized international standards. Failure to used issued personnel protective equipment, when exposed to the hazard for which it was provided, shall be a disciplinary offence Hard hat, safety shoes, safety glasses, chemicals goggles, uniforms, Ids warning tapes, protection, foot protection, hearing protection, earplugs, Earmuffs, Safety harness and full body harness. All personals involve in work, must be briefed on the safety, health and environmental issues associated with the work. Only trained personnel, with relative experience, shall be allowed to handle Equipment. OCTOBER CONSTRUCTION COMPANY LTD METHOD STATEMENT FOR LEAN CONCRETE PROJECT TITLE: CONSTRUCTION OF 380KV UNDERGROUND CABLES FROM KING SALMAN PARK #9083 TO ALMURSALAT #9012 AND FROM KING SALMAN PARK TO ALRAWABE #9047. Rev. Date 19-Oct-2022 Rev No. 00 Docume nt Number 14890-SECOCC-MOS-C004-Rev-0 Page 6 of 7 Appropriate safety signboard, barriers, lighting and other safeguards shall be provided as per nature and location of the works. All operations shall be carried out in accordance with safety requirement. All the safe practices shall be adopted during work activities. Maintain good housekeeping around work area. Provide facilities for emergency requirement. To ensures that Work Permit is valid, if applicable and all works done in the safest possible manner consistent with good construction practices. 8. ACCESS Access pathways to be kept clear from any obstruction. Conduct housekeeping before, during and after work to ensure free access/egress. Provision of proper work access. Any obstructions shall be removed and kept materials away from any access. Keep work area free from loose tools and materials. Place a appropriate signage around the operating area and assign a watchman to keep unauthorized persons away. Appropriate use of lifting attachments and related. Supervisor and safety officer shall monitor the lifting work. 9. Application of Lean Concrete Before pouring of lean concrete surveyor should confirm the levels of excavation area and make marking of lean concrete level as per the approved drawing. FDT result should be equal or above 95% of proctor value to start concreting work. The form-work of 100mm thickness for blinding will be fixed, alignment and leveling should be done properly prior to start pouring concrete. Lean concrete will Casted at the joint of cable area wide of 2700mm x 8000mm in a length. OCTOBER CONSTRUCTION COMPANY LTD METHOD STATEMENT FOR LEAN CONCRETE PROJECT TITLE: CONSTRUCTION OF 380KV UNDERGROUND CABLES FROM KING SALMAN PARK #9083 TO ALMURSALAT #9012 AND FROM KING SALMAN PARK TO ALRAWABE #9047. Rev. Date 19-Oct-2022 Rev No. 00 Docume nt Number 14890-SECOCC-MOS-C004-Rev-0 Page 7 of 7 QA/QC Engineer will check the alignment,dimension and level of the shutter of the blinding as per approved drawing and raise the inspection to NG. A two layers of polyethylene sheet of 150 micron will install on the compacted blinding area by using the approved material. Sketch drawing will submit to NG showing the casting area,pump location and access of the concrete trucks and check point. Safety precaution shall be taken into consideration starting from the site entrance including the pump and trucks access till casting area. Proper light will be available when concrete pouring continues till night. The concrete trucks will be unloaded at work site within 90 minutes of batch loading time of concrete. Casted blinding will be cured properly with covering hessian clothes before start installation of hessian clothes it should be wet. The concrete will be cure for two to three times in day for a period of seven days. The surface preparation will fallows to make surface of concrete smooth,crack free and reduce undulation of the surface with approved material prior to start waterproofing work After the surface preparation of the lean concrete raise the inspection to NG prior to start waterproofing. 10. HOUSE KEEPING AND CLOSING OF SITE The required standard of housekeeping must be established on site and all personal informed of this standard. Trash, debris and refuse should be collected daily. All employees shall clean their respective work areas daily before and after starting work. Covered containers drum etc., should be provided at various locations throughout the work site and must be clearly marked. The containers should be emptied daily at approved rubbish dumps. All nails should be removed from the work area. The area should be free from obstructions for safe working practices