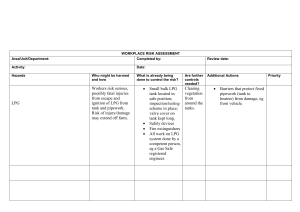

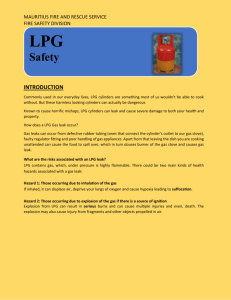

ULTRASONIC INSTRUMENTATION SYSTEM FOR DETECTING LIQUEFIED PETROLEUM GAS LEVEL IN 14 KILOGRAM CYLINDERS AHMAD „AKIF BIN ADAM A thesis submitted in fulfilment of the requirements for the award of the degree of Master of Engineering (Gas) Faculty of Petroleum and Renewable Energy Engineering Universiti Teknologi Malaysia JUNE 2015 iii Dedicated to my beloved parent, ummi and abah, and all my lovely siblings, thanks for your love and encouragement iv ACKNOWLEDGEMENT First of all, I would like to thank Allah The Almighty for giving me the strength and opportunity to finish this research study. In completing this project, I was in contact with many people, researchers, and academicians. They have contributed towards my understanding and thoughts. In particular, I wish to express my sincere appreciation to my research supervisor, Dr. Mariani Idroas, for encouragement, guidance, critics and motivation towards the completion. Without her continued support and interest, this thesis would not have been the same as presented here. A remarkable honor to Associate Professor Ir. Dr. Zainal Zakaria, my co-supervisor, for his knowledge sharing and thoughtful ideas. My sincere appreciation also extends to all my colleagues especially to Advanced Microprocessor Research (AMIR) Laboratory members and others who have provided assistance at various occasions. I am also grateful to all my family members. Their views and tips are useful indeed. May Allah S.W.T. rewards and blesses us all. v ABSTRACT Liquefied Petroleum Gas (LPG) is commonly stored in highly pressurized cylinder tank and needs to be measured using a non-invasive way. This approach has been constructed to facilitate the process of LPG level measurement inside a cylinder tank. Currently, liquid level of LPG inside a cylinder is measured using a weighing scale. In this research, a new method is developed by using a non-invasive ultrasonic instrumentation system for monitoring LPG level in the 14 kilogram cylinder. The instrumentation system was integrated with the designed experimental rig. Module ultrasonic sensors Truma.LCV1.15 were attached vertically outside of the cylinder wall on the sensor holder of the experimental rig. The ultrasonic sensors emit the ultrasonic signals and the signals will then propagate through the cylinder wall. The reflected signal was recorded again by the ultrasonic sensors. The reflection of the ultrasonic signal depends on the type of the medium's impedance. The generated signals from the transceiver type of sensors were sent to the Pico Scope Data Acquisition System (DAQ) for data reading. The output voltage signals were processed by the computational data process system, giving a result of the LPG liquid level inside the cylinder. An image of the LPG liquid level in the cylinder was constructed using javascript based programming. The image showed the liquid level in percentage value and html software was used as the interface in this program. The developed instrumentation system was also tested on 18-L testing cylinder and 14-kg LPG cylinder with various LPG liquid levels and it was able to detect the amount of LPG in the cylinders, with the maximum error of 5.68%. vi ABSTRAK Petroleum Gas Cecair (LPG) biasanya disimpan di dalam silinder bertekanan tinggi dan perlu diukur dengan cara tanpa musnah. Cara ini telah dibina untuk memudahkan proses pengukuran aras LPG di dalam tangki silinder. Pada masa kini, aras cecair LPG di dalam silinder diukur menggunakan alat penimbang berat. Dalam kajian ini, satu kaedah baru dibangunkan menggunakan sistem peralatan ultrasonik tanpa musnah untuk memantau aras LPG di dalam silinder simpanan berkapasiti 14 kilogram. Sistem peralatan ini disepadukan dengan rekaan pelantar eksperimen. Modul deria ultrasonik Truma.LCV1.15 telah dipasang pada pemegang sensor pelantar eksperimen. Deria ultrasonik tersebut dipasangkan secara menegak di luar dinding silinder. Deria ultrasonik memancarkan isyarat ultrasonik dan isyarat telah tersebar menembusi dinding silinder. Isyarat pantulan dirakam semula oleh deria ultrasonik. Pantulan isyarat ultrasonik bergantung kepada jenis galangan bahan perantara. Isyarat yang dihasilkan dari deria jenis penghantar-terima telah dihantar ke Pico Scope Data Sistem Perolehan (DAQ) untuk membaca data. Isyarat voltan keluaran diproses oleh sistem proses data perkomputeran untuk memberikan aras kandungan cecair LPG di dalam silinder. Pembinaan imej aras LPG dalam silinder dibina menggunakan pengaturcaraan berasaskan javascript. Imej tersebut menunjukkan imej aras LPG di dalam nilai peratusan dan perisian html digunakan sebagai perantara muka pada program ini. Sistem peralatan yang dibangunkan diuji pada 18-L silinder ujian dan 14-kg LPG silinder yang berbeza aras cecair LPG dan sistem ini berjaya mengesan jumlah LPG dalam silinder dengan ralat maksimum 5.68%. vii TABLE OF CONTENTS CHAPTER 1 2 TITLE PAGE DECLARATION ii DEDICATION iii ACKNOWLEDGEMENT iv ABSTRACT v ABSTRAK vi TABLE OF CONTENTS vii LIST OF TABLES x LIST OF FIGURES xi LIST OF ABBREVIATIONS xiv LIST OF SYMBOLS xv LIST OF APPENDICES xvii INTRODUCTION 1 1.1 Project Background 1 1.2 Problem Statement 4 1.3 Objective 6 1.4 Scope of Study 7 1.5 Thesis Outline 7 LITERATURE REVIEW 9 2.1 Introduction 9 2.2 Overview of Liquid Level Measurement 9 2.3 Types of Liquid Level Measurement 10 viii 3 2.4 Liquid Level Measurement 11 2.5 Use of Ultrasonic in Liquid Level Measurement 12 2.6 Current Method of LPG Cylinder Measurement 18 METHODOLOGY 19 3.1 Introduction 19 3.2 Overview of the Instrumentation System 20 3.3 Instrumentation Rig Configuration 21 3.3.1 Development of Platform 23 3.3.2 Development of Sensor Holder 26 3.4 Cylinder Specification 32 3.5 Sensoring System Optimization 36 3.5.1 Transmission and Reflection Effect 36 3.5.2 Ultrasonic Sensoring System 41 3.5.3 Arrangement of Ultrasonic Sensors 42 3.5.4 Image Grid Configuration 44 3.6 3.7 Development of Ultrasonic Instrumentation System 47 3.6.1 Module Sensor 48 3.6.2 Pico Scope Data Acquisition System (DAQ) 49 3.6.3 Computational Data Process 50 3.6.4 Image Generation 51 Experimental Procedures 3.7.1 Initial Testing on 18 L Cylinder Experimental Procedure 3.7.2 52 Calibration Testing on 14 kg LPG Cylinder Experimental Procedure 3.7.3 52 53 Measurement of 14 kg Cylinder Experimental Procedure 54 ix 4 RESULTS AND DISCUSSIONS 56 4.1 Introduction 56 4.2 Sensors Testing and Calibration of 18 L Testing Cylinder 4.2.1 Level Measurement of the 18 L Cylinder 4.2.2 Calibration Graph of 18 L Cylinder Level 4.2.3 4.3 57 Measurement 64 Discussions 65 Sensors Testing and Calibration of LPG Cylinder 14 kg 4.3.1 67 Data Collection of LPG Cylinder Measurement 4.3.2 4.3.3 4.4 4.5 5 67 Calibration Graph of LPG Cylinder Level Measurement 68 Discussions 69 Experimental Tests on LPG Cylinders 71 4.4.1 Data of Case 1 72 4.4.2 Data of Case 2 73 4.4.3 Data of Case 3 74 4.4.4 Data of Case 4 75 4.4.5 Discussions 76 Image of LPG Level 77 CONCLUSIONS AND RECOMMENDATIONS 80 5.1 Conclusions 80 5.2 Recommendations 81 REFERENCES Appendices A 57 83 87-104 x LIST OF TABLES TABLE NO. TITLE PAGE 3.1 Specification of both cylinders 35 3.2 Level and percentage fill relation information 47 4.1 Data collection of level measurement at 23.0 cm 58 4.2 Overall data collection of level measurement on testing cylinder 18 L 4.3 63 Level measurements for the actual level and from indicator sensor 66 4.4 LPG cylinder 14 kg measurement testing data collection 68 4.5 Table of weight, volume, level and its percentage from weight measurement 4.6 70 Comparison table of weight measurement and sensor measurement 70 4.7 Experimental data of empty cylinder (17.0 kg) 72 4.8 Experimental data of partially filled cylinder (21.7 kg) 73 4.9 Experimental data of partially filled cylinder (27.2 kg) 74 4.10 Experimental data of fully filled cylinder (30.5 kg) 75 xi LIST OF FIGURES FIGURE NO. TITLE PAGE 1.1 Cylinders with LPG 3 1.2 Manifold LPG system 4 1.3 Weighing measurement of LPG cylinder 6 2.1 The gas cylinder with liquid inside and the mechanical model of mass density 2.2 Block diagram of generation, propagation, and reception of lamb waves of tank wall 2.3 12 15 The arrangement of the prototype level sensing using lamb wave at the tank wall 15 2.4 Measuring level method 17 3.1 Overall setup of ultrasonic instrumentation system 19 3.2 Photo of Ultrasonic instrumentation system 20 3.3 Instrumentation rig diagram 22 3.4 Actual photo of instrumentation rig 22 3.5 Mechanical design of platform (side and top view) 24 3.6 Real image of the platform 24 3.7 Installed wheels and its mechanical design 25 3.8 Stopper and its mechanical design 25 3.9 Platform surface arrangement 26 3.10 Sensor holder 27 3.11 Vertical mounting of sensor on a sensors holder 28 3.12 Actual fabricated sensor holder 28 3.13 Design of sensor with casing 29 3.14 Image of sensor with casing 29 xii 3.15 Mechanical design of stand 30 3.16 Housing base of the instrumentation rig 31 3.17 Connector 31 3.18 Testing cylinder of 18 L capacity 33 3.19 Dimension of testing cylinder 33 3.20 Dimension of LPG cylinder tank 34 3.21 LPG cylinder of 14 kg 35 3.22 Ultrasonic signal transmission and reflection 37 3.23 Illustration on different medium of cylinder content 41 3.24 Sensors arrangement 42 3.25 Sensors touch to the cylinder wall 43 3.26 Photograph of sensor arrangement 44 3.27 Cylinder fraction due to sensor arrangement 45 3.28 Graphical illustration of ellipsoidal bottom cylinder 46 3.29 Process flow of ultrasonic instrumentation system 47 3.30 Ultrasonic Instrumentation system 48 3.31 Ultrasonic Truma.LC-V1.15 module sensor 49 3.32 Pico Scope DAQ 50 3.33 Image of percentage cylinder filling 51 4.1 Voltage signal at sensor 1, S1 = 3.53 V 59 4.2 Voltage signal at sensor 2, S2 = 3.67 V 59 4.3 Voltage signal at sensor 3, S3 = 3.46 V 59 4.4 Voltage signal at sensor 4, S4 = 3.71 V 60 4.5 Voltage signal at sensor 5, S5 = 3.81 V 60 4.6 Voltage signal at sensor 6, S6 = 4.62 V 60 4.7 Voltage signal at sensor 7, S7 = 4.83 V 61 4.8 Voltage signal at sensor 8, S8 = 4.69 V 61 4.9 Voltage signal at sensor 9, S9 = 4.97 V 61 4.10 Voltage signal at sensor 10, S10 = 4.61 V 62 4.11 Graph of output voltage (V) for S1 to S10 at 23.0 cm water level 62 4.12 Graph of actual water level against measured water levels 64 4.13 Graph of LPG cylinder calibration 69 xiii 4.14 Image interface of Case 1 with 8.14% 77 4.15 Image interface of Case 2 with 35.18% 78 4.16 Image interface of Case 3 with 63.29% 78 4.17 Image interface of Case 4 with 85.36% 79 xiv LIST OF ABBREVIATIONS ASTM - American Society for Testing and Materials CFC - Chloro Fluoro Carbon DAQ - Data Acquisition System DC - Direct Current GMB - Gas Malaysia Berhad HHV - Higher Heating Value HTML - Hyper Text Markup Language LHV - Lower Heating Value LPG - Liquefied Petroleum Gas MSDS - Material Safety Data Sheet NDT - Non Destructive Testing PC - Personal Computer PZT - Lead Zirconium Titanate PVC - Poly Vinyl Chloride STP - Standard Temperature and Pressure TOF - Time of Flight UT - Ultrasonic Testing xv LIST OF SYMBOLS π - Pi, 3.14 ρ - Density a - Depth of Head or Bottom θ - Angle atm - Atmospheric Pressure avg - Average c - Speed of Light cm - Centimeter D - Diameter g - Gram h - Height of Liquid Level kg - Kilogram J - Joule kHz - Kilohertz L - Length m - Meter mm - Millimeter MHz - Megahertz MJ - Megajoule r - Radius R - Reflection Coefficient Rayl - Rayleigh S - Sensor Number t - Time T - Transmission Coefficient xvi V - Voltage υ - Volume W - Weight Z - Acoustic Impedence ° - Degree °C - Degree Celcius °F - Degree Fahrenheit E - Wave Energy S - Sensor T - Transmitter C3H8 - Propane C4H10 - Butane %e - Percentage of Error xvii LIST OF APPENDICES APPENDIX A TITLE PAGE Technical Drawing of Ultrasonic Instrumentation Rig 87 CHAPTER 1 INTRODUCTION 1.1 Project Background Oil and gas are natural resources that contribute as the source of fuel to most of the countries in the world for its economic expansion. Many nations depend on these natural resources for growth and development of their countries. It is necessary to ensure that the natural resources can be transported safely from its original plant or storage to the consumers throughout the countries (Bannon, 2003). The transmission process and storage technique of oil and gas must be in control because of its natural characteristic that is highly volatile and flammable. There are many methods used to transfer these oil and gas supply to the market such as tanker, pipeline barge, rail and truck. Liquefied petroleum gas (abbreviated as LPG) is a chemical compound that usually used as a fuel for cooking, combusting and burning tool and also used for transportation energy source. This inflammable mixture is widely used as an aerosol propellant and a 2 refrigerant. The LPG replaced CFC in an effort to reduce the effect of green house and protect the ozone layer (Bejan, 1999). There are various types of LPG mixture available in the market and the mixture of their composition are different for each country and depend on the seasonal weather of the country. There will be more propane in winter while more butane in summer (Totten, 2003). There are types of mixes which are mainly propane (C3H8), and mainly butane (C4H10). The mostly common mixes were the mixture of both propane and butane in a certain percentage. Substance of propylene and butylenes are normally present but in a little concentration. LPG is basically in gas or liquid phase which is odourless and colourless. Therefore, it is difficult to detect whether there are any existence of LPG or not. The odorant like ethanethiol, is incorporated with LPG so that leaks can be recognize easily. In the United States, thiophene known also as amyl mercaptan is an approved odorants (Mahalingam, 2012). Figure 1.1 shows the example of LPG cylinders commonly used today. 3 Figure 1.1 Cylinders with LPG LPG will be vaporise when exist in room temperatures and pressures. LPG is pressurized in a special designed cylinder that is capable of storing large pressure content. The cylinder also designed appropriately in order to fulfil the supply and demand on market daily use. Typically percentage of filling is between 80% to 85% of their storage capacity. This would allow the thermal expansion of the LPG (Zakaria et al, 2006). Unlike natural gas, LPG is heavier than air, thus will flow along floors and tend to settle in lower spots, such as basements. (Soundarya et al, 2014). Large amounts of LPG usually stored in a bulk cylinders typically aboveground, underground or mounded. Periodic inspection and testing of the storage must be done to ensure safety standards are maintained. 4 1.2 Problem Statement Liquefied Petroleum Gas (LPG) becomes the most popular source for household and commercial uses. Basically, when compared to other liquid fuels, LPG is flexible to handle and having lesser pollution with minimum space used for storage. LPG will be delivered to the customer either by using cylinder, bulk tank or pipeline. There are several ways of LPG distribution to customers depends on the type of customer i.e. whether it is domestic, commercial or industry. Figure 1.2 shows an example of manifold LPG system installation for commercial use. Figure 1.2 Manifold LPG system (Primagas, 2009) LPG consumption for every customers were different depending on the rate of use. There were consumers who used LPG daily at a high rate such as the laundries that uses for the purpose of drying clothes. Numbers of users only use a small amount of LPG for home cooking. The different on LPG consumption rate of consumers carries variation of usage among consumer thus requiring friendly LPG cylinder measurement. This idea was not as important for some consumers, but it was very significant for customers who utilized the LPG on a large scale basis especially for those who use it for commercial purposes. 5 Therefore, this research study is intended to develop an ultrasonic instrumentation system to measure the LPG residual in the cylinder in a better way using ultrasonic sensors. This study focused on the ability of the developed system in monitoring the presence of LPG and its level. This is the initial study to detect the LPG level imposed on the household LPG cylinders of a 14 kg capacity. Most of LPG users, especially among commercial and industrial field were used weighing instrument in order to obtain the exact contents of LPG inside the cylinder. Some of them measured the amounts of LPG inside the cylinder by checking the content pressure. This method was often used by the refilling plant because this is the fastest way of measurement. This pressure type measurement was conducted in a rapid process because the filling process and the pressure readings were taken simultaneously. Figure 1.3 shows the example of weighing instrument for LPG cylinder. This machine was designed completed with the gas filler tool for LPG refilling process. Figure 1.3 Weighing measurement of LPG cylinder (Siraga, 2008) 6 Ultrasonic instrumental technique was an acceptable way to monitor the LPG content in the LPG cylinder. This method is proposed because it can help the process of measurement in easy way using non-invasive procedure. 1.3 Objectives The objectives of this project are: i. To develop a non-invasive ultrasonic instrumentation system for detecting the LPG content in LPG cylinder storage. ii. 1.4 To monitor LPG residual inside the cylinder. Scopes of Study In order to achieve the objectives of this project, the scopes are: i. Understanding the principal of ultrasonic measuring method on liquid level measurement. ii. Development of instrumentation rig of LPG cylinder measurement. iii. Performing the study on sensoring system optimization iv. Setting up the ultrasonic instrumentation system including module sensor, Pico Scope DAQ, computational data process and image reconstruction. 7 v. Carry out preliminary experiment on testing cylinder 18L and LPG cylinder of 14 kg for instrumentation system calibration and accomplish the experimental measurement on four different types of LPG cylinder. vi. Analyzing data receive from Pico Scope DAQ using computational data process system. vii. Generating the percentage of LPG content information using html based programming. 1.5 Thesis Outline Chapter 1 briefly presents the background information about oil and gas industry around the world. LPG is one of oil and gas product which is essential in our daily needs for household use, industry and transportation. LPG characteristics, transmission and storage system have been briefly defined. This chapter includes the problem statement, objectives and the scopes of the project. Chapter 2 explains the literature review about the measurement of LPG storage on recent industrial usage. The configuration systems of measurement and the suitable type of sensors are described in more detailed. Chapter 3 describes the methodology on LPG instrumentation system based on ultrasonic sensors to detect the LPG level. The outcome signals are explained to show the LPG level in suitable image. Chapter 4 presents results obtained from the experiments. Specific justifications and explanations about the output results are explained to validate and verify the correctness of the experiment. Chapter 5 combines the overall conclusions and some of recommendations for future improvements. REFERENCES Bannon, I. and Collier, P. (2003). Natural resources and violent conflict: options and actions, World Bank. Bejan, A., Vadász, P. and Kröger, D. G. (1999). Energy and the environment: Kluwer. Hisham, C. B. (1994). Pengukuran Secara Kualitatif Baki Gas Petroleum Cecair. Universiti Teknologi Malaysia: Tesis Sarjana Muda. Chan, K. T. and Zhang, J. Z. (1995). Free vibration of a cantilever tube partially filled with liquid. Journal of Sound and Vibration. 182, 185-190. Cheeke, J. D. N. (2012). Fundamentals and Applications of Ultrasonic Waves, (2nd ed.). Taylor & Francis. Desoutter, D. M. (1971). Your Book of Sound, Faber. Elvers, B. (2008). Handbook of fuels: energy sources for transportation. Wiley-VCH. Hao, H.H.,and Xiong, J.Q. (2010). A Method of Liquid Level Measurement Based on Ultrasonic Echo Characteristics, Computer Application and System Modeling (ICCASM), 2010 International Conference. Vol.11.22-24 Oct. 682-684. Hofer, M. (2005). Ultrasound Teaching Manual: the Basics of Performing and Interpreting Ultrasound Scans, Thieme. Iain, S. (2011). The Energy and Fuel Data Sheet. University of Birmingham, United Kingdom. Jones, D. (2003) Calculating Tank Volume Saving Time, Increasing Accuracy. P.P.1-12. Juvanna, I. and Meenakshi, N. (2014) Gas Level Detection and Leakage Monitoring System using a Specific Technique, Journal of Computer Science and Information Technology, IJCSMC, Vol. 3, Issue. 2, February 2014, pg.591 – 595. Kennedy, J. L. (1993). Oil and gas pipeline fundamentals: PennWell Books. 84 Licznerski, T. J., Jaroński, J., Kosz, D. (2011). Ultrasonic system for accurate distance measurement in the air. Ultrasonics 51(8): 960-965. Mahalingam, A., Naayagi, R. T., Mastorakis, N. E. (2011). Design and Implementation of an Economic Gas Leakage Detector. Recent Researches in Applications of Electrical and Computer Engineering. P.P. 20-24. Meribout, M., Habli, M., Al-Naamany, A., Al-Busaidi, K. (2004). A New UltrasonicBased Device for Accurate Measurement of Oil, Emulsion, and Water Levels in Oil Tanks, Instrumentation and Measurement Technology Conference, 2004. IMTC 04. Proceedings of the 21st IEEE, 18-20 May 2004, Vol.3, 1942-1947. Meyer, W. J. (2004). Concepts of Mathematical Modeling: Dover Publications. Meenakshi, P. V., Abinaya, S., Rajeswari, G.G., Guna, N. (2014). Automatic LPG Leakage Detection and Hazard Prevention for Home Security. Proceeding of 5th National Conference on VLSI, Embedded, and Communication & Networks on April 17, 2014.1-5. Mogami, K., Saito, S., Makishita, H.Ando, K. Ogura, N, (1986). Failure Analysis of a Liquid Propane Gas Cylinder Analyzing Failures: The Problems and the Solutions. 2-6 Dec. 1985. Salt Lake City; Utah, USA, pp. 75-80. Morris, A. S. and Langari, R. (2012). Measurement and Instrumentation: Theory and Application: Academic Press. Oxenham, M. (2013). Higher Education in Liquid Modernity: Taylor & Francis. Onda, C., (2003). Acoustic Properties of Liquids, Gases and Solids :Onda Corporation. Petrauskas, A. (2008) Experimental determination of sound velocity in liquefied propanebutane gas mixture (LPG), Ultragarsas (Ultrasound), Vol. 63, No. 3. Priya, K. P., Surekha, M., Preethi, R., Devika, T., Dhivya, N. (2014). Smart Gas Cylinder Using Embedded System. International Journal Of Innovative Research In Electrical, Electronics, Instrumentation And Control Engineering, Vol. 2, Issue 2,958-962. Raj, B., Jayakumar, T. and Thavasimuthu, M. (2002). Practical non Destructive Testing: Woodhead. Saad, F. F. M. (2009) The Design And Development Of Warning Device For Low Pressure LPG Tank. Universiti Teknikal Malaysia. Sakharov, V. E., S. A. Kuznetsov, S.A., Zaitsev, B.D., Kuznetsova, I.E., Joshi, S.G. (2003). Liquid level sensor using ultrasonic Lamb waves. Ultrasonics 41(4): 319322. 85 Shih, H., C. and H. H. P. Wu (2010). Liquid level detection of the sealed gas tank based on digital signal processing. Image and Signal Processing (CISP), 2010 3rd International Congress. Singh, S. K. 2003. Industrial Instrumentation & Control,2e, McGraw-Hill Education (India) Pvt Limited. Singh, H.K., Chakroborty, S.K.,Talukdar, H., Singh, N.M., Bezboruah, T. (2011) A New Non-Intrusive Optical Technique to Measure Transparent Liquid Level and Volume, Sensors Journal, IEEE. Vol.11, no.2, pp.391-398. Singh, H.K., Meitei, N.C., Sarkar, S.T., Tiwari, D., Bezboruah, T., (2013) Truly Nonintrusive Liquid-Level-Sensing Method Based on Lateral Displacement Effect of Light Rays. Sensors Journal, IEEE , vol.13, no.2, pp.801-806. Soundarya, T., Anchitaalagammai, J.V., Priya G. D., Kumar, S.S. K (2014). IOSR Journal of Electronics and Communication Engineering (IOSR-JECE) Volume 9, Issue 1, Ver. VI, PP 53-58. Totten, G. E., Westbrook, S. R., Shah, R. J. (2003). Fuels and Lubricants Handbook: Technology, Properties, Performance, and Testing: ASTM International. Torbay Council (2001) Liquefied Petroleum Gas (LPG) Safe Working Practices 3 L 04 Page 1-4. Vesovic, V. (2007) The influence of ice formation on vaporization of LNG on water surfaces. Journal of Hazardous Materials, 140, pp. 518–526. Yogeesh, A., Ashwini, Shruthi, B. (2013). Automated Unified System For LPG Refill Booking & Leakage Detection: A Pervasive Approach. International Journal of Advanced Technology & Engineering Research (IJATER), Volume 3, Issue 3, 6973. Wang, T.-H., Lu, M.-C., Hsu, C.-C., Chen, C.-C., Tan, J.-D. (2009). Liquid-Level Measurement Using a Single Digital Camera. Measurement, 42, 604-610. Zakaria, Z. and Mustafa, A. (2005) Investigation of temperature profile for liquefied petroleum gas storage operations. 2nd International Conference on Chemical and Bioprocess Engineering in conjunction with 19th Symposium of Malaysian Chemical Engineers (SOMChE 2005), 8-10 December 2005, Kota Kinabalu, Sabah. Zakaria, Z., Mat, H. and Yusoff, Z. (2006) Heat and Mass Transfer Studies in Liquefied Petroleum Gas Storage Operations. Project Report. Faculty of Chemical and Natural Resources Engineering, Skudai, Johor. 86 Zakaria, Z., Mustafa, A. (2011) The Influence Of Compositions On Liquefied Petroleum Gas Residue In Storage. International Journal of Research and Reviews in Applied Sciences. 7 (4) 360-367. Zakaria, Z., Mustafa, A. (2013) The Effect of Filling Weights to Liquefied Petroleum Gas Residue in Storage. International Journal of Engineering, Business and Enterprise Applications (IJEBEA). 4 (1), March-May, 2013, pp. 35-43.