The Yield Criterion of

Laminated Media

P. C. CHOU, B. M. McNAMEE

AND

D. K. CHOU

Drexel

University

. 19104

Philadelphia Pa

,

(Received December 27, 1972)

ABSTRACT

This study examines the yield criteria for anisotropic laminated media.

It will be shown that for laminated media with isotropic layers, the critenon of Tsai and Wu is a direct extension of Von Mises’. Also presented

here is a set of equations governing the relative positions of the yield

ellipses. Furthermore, a general expression for the yield condition of a

laminated medium composed of generally anisotropic layers is obtained.

INTRODUCTION

criterion for a laminated medium with anisothe independent yield strength constants of the

in terms of the strength constants and elastic properties of the individual

In formulating the yield criterion, the laminated medium is transformed into

yield

Tcomposite

tropic layers by characterizing

HIS STUDY PROPOSES a

layers.

an equivalent medium which is homogeneous but anisotropic.

In studying the yielding of homogeneous, anisotropic media, Hill [ 1] proposed a

criterion that is quadratic in form. In his criterion there are only six independent

constants, the principal strength constants. His interaction terms are not independent ; they are in terms of three of the six principal strength constants. Furthermore, his criterion is limited to specially orthotropic materials with plastic incompressibility, and with equal strength in tension and compression. It is defined only

in the coordinate of material symmetry. Thus, Hill’s criterion can not be used for

materials with general anisotropy.

More recently, Tsai and Wu [2] proposed a general strength theory for anisotropic materials based on the concept of characterizing the independent strength

constants as tensor quantities as suggested by Gol’denblat and Kopnov [3]. These

strength components, as they are called, satisfy the invariant requirements of

J. COMPOSITE MATERIALS, Vol. 7 (January 1973),

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

22

coordinate transformation similar to the compliance matrix. The number of independent strength tensors is reduced for materials exhibiting symmetry. It is a very

convenient form which is easily applicable to practical problems. Nevertheless, the

general form of Tsai and Wu’s criterion is an assumption made arbitrarily.

In this paper, we will show that a yield criterion for a laminated medium with

isotropic layers will have the same form as the one proposed by Tsai and Wu when

the Von Mises’ yield criterion is applied to the individual layers. The formulation of

this yield criterion is based on the assumptions made according to a smearing

technique proposed by Chou, Carleone and Hsu [4]. The Von Mises’ yield criterion

is applied to the individual layers to determine the incipient yielding conditions of

the composite.

Further, we will show that when the laminated composite consists of anisotropic

layers and each layer yields according to the criterions of Tsai and Wu, the yield

locus of the composite is an envelope formed by many intersecting ellipses. Each

ellipse represents the yield locus of one layer under a combined state of equivalent

stresses.

All tensors are represented in contracted notation and superscripts designate the

quantities associated with the corresponding layer. Quantities without superscripts

are associated with the equivalent medium.

YIELD CRITERION FOR A LAMINATED MEDIUM

WITH ISOTROPIC LAYERS

Consider a laminate made up of n layers of different isotropic materials rigidly

bonded together and subjected to a general state of loads. The materials in the

layers are assumed to be homogeneous and have equal strength in tension and

compression. The laminate is then smeared into an equivalent medium by the

lamination theory proposed by Chou, Carleone, and Hsu [4]. In this case, the

equivalent medium is transversely isotropic with the 1-2 plane as the isotropic plane.

According to the lamination theory of Reference [4], the stress-strain relation

of the equivalent medium can be expressed as

where Sq are functions of the

the lamina stress components

following form [5] :

properties of the layers. Further, it can be shown that

related by the equivalent stress components in the

are

where

23

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

and for isotropic

layers

determine which layer will first reach the

limiting state of stress established by the yield criteria for each layer. Here, the Von

Mises yield criterion will be used to govern the yielding of each layer,

Thus, Equation (2) enables

When

us to

expressed in tensor form, for the kth layer, Equation (3) becomes

where

and

Xk

is the

yield stress in uniaxial

tension.

24

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

Substituting Equation (2) into Equation (4) and simplifying yields,

where

Equation (5) is the yield criterion for the equivalent medium caused by yielding

layer k. Therefore, the yield condition of a laminate is, in general, represented by n equations like Equation (5) and each equation is a hyper-ellipsoid in

in the

the six-dimensional equivalent stress space. These ellipsoids can intersect one

another or can enclose one another. For the former case, a yield envelope is

produced. For the latter case, the smallest ellipsoid governs the yielding of the

composite under the combined equivalent stress states.

in terms of the

Due to the lengthy expression, no explicit formula for

strength and elastic properties of the individual layers will be presented. However,

m Equation (5) becomes:

by permutating the indices,

F~

F§

It can be immediately seen that Equation (6) has the same form as the one

derived by Tsai and Wu [2] for a transversely isotropic material and both have five

independent constants.

An explicit yield equation in terms of the yield strength and elastic properties of

the individual layers will be given for a repeated bilaminar medium composed of

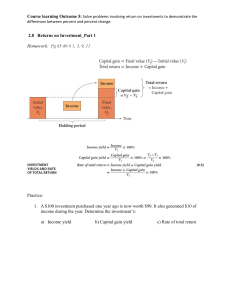

two isotropic materials subjected to a state of plane stress in the 1-2 plane as

shown m Figure 1. Thus, the previous three-dimensional formulation is reduced to a

two-dimensional stress problem. If the loads are applied in the 1-2 plane, and a3

0, Ft in Equation (5) can be expressed as follows:

a4

Qs

=

=

=

25

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

+7gure

l. 7 1

where Ek and ph

respectively. The

pit al olement of a repeated bllammar medium

under a

plane load

modulus and the Poisson’s ratio of the kth layer

Vk

symbol

represents the volume fraction of layer k. Also, it can

are

the

Young’s

26

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

which agrees with the stability condition

be shown that

surface

failure

as discussed in [2].

closed

a

for

required

Therefore, we arrive at the conclusion that the yield criterion presented here for

the laminated medium is a direct extension of the Von Mises criterion; it has the

same requirements as the criterion proposed by Tsai and Wu. In other words, Tsai

and Wu’s criterion can be viewed as a direct extension of the Von Mises criterion

for a laminated medium.

An example will now be presented in which we will study the yield surfaces of

three layered plates with isotropic layers subjected to loads applied in the 1-2

plane. Each plate is composed of two materials that are arranged in a repeated

fashion (Figure 1 ). The first plate consists of structural steel and annealed

aluminum. The second is made up of structural steel and aluminum, but the

aluminum has been heat treated. The third is layered with high strength steel and

malleable cast iron. All the physical properties of the laminas of the three bilaminar

media are listed in Table 1. In all three cases, the laminas are of equal thickness.

Equations of this plane stress problem have been coded on a computer, and the

results are plotted in the two-dimensional equivalent stress space in Figures 2, 3,

and 4.

(F11 )2 - (Fkl 2 )2 > 0

Table 1.

Physical Properties of Laminas in Example

1

For Case 1, the ellipse for yielding in the aluminum layer is enclosed by the

ellipse for the steel as shown in Figure 2. Thus, aluminum always yields first in this

case. However, if the aluminum is first heat treated and attains a higher yield

strength, the ellipse for the steel is enclosed by the ellipse for the aluminum, see

Figure 3. Thus, the steel always yields first for Case 2. For Case 3, where the cast

iron has both higher Young’s modulus and yield strength than aluminum Figure 4

shows that the ellipses intersect one another to form a failure envelope for the

composite. Thus, the materials with a lower yield stress in a laminated composite

do not necessarily reach the established yield criteria first under combined stress

states.

27

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

Figure 2. Yield loci plotted on

Figure 3. Yield loci plotted on

a, - a2

plane, steel and aluminum.

a, - az plane, steel and aluminum.

28

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

Figure 4. Yield loci plotted on a, - (Tplane, steel and cast iron.

Equation (5) which is the equation of an ellipse, when written in terms

principal state of stress and for a plane stress loading condition reduces to

where k

these

=

1, 2. It

ellipses have

can

the

be shown that the

of the

major axis, ak, and the minor axis bk, of

following form

where

Therefore, the criteria for the ellipses to intersect one another is either a’ > a2

and bl < b2, or a’ < a2 and b’ > b2. From Equation (9) the factors Ak and Bk

determine the ellipses will enclose one another or intersect one another, and the

29

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

following conclusions

can

be drawn:

the

ellipses will

the

ellipses will intersect

enclose

one

another.

one

another.

Both Ak and Bk are independent of the thickness of the lamina. Thus,

the thickness of the laminae does not determine the relative position of ellipses.

3)

LAMINATES WITH ANISOTROPIC LAYERS

The formulation for the laminates with isotropic layers discussed above can be

generalized to laminates with anisotropic layers. The only change to be made is that

the Von Mises yield criterion for each layer can be replaced by an anisotropic yield

criterion, e.g., Tsai and Wu’s strength criterion. Similar to Equation (2), the lamina

stresses and equivalent stresses are related by the following equation, [5, 6] .

where

and

Tsai and Wu’s criterion for the individual

layers are of the following form,

30

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

where

strength tensors of the second and fourth rank respectively.

By substituting Equation (10) mto Equation (11), the yield equation for

laminate with anisotropic layers is obtained as follows:

Fkand F~,.

i

are

’I

the

where

and

Therefore, Equation (12) is the yield condition for a laminate with anisotropic

layers caused by yielding in the kth layer. In addition, Equation (12) takes into

consideration materials in which the magnitude of the tensile yield stress is

different from the compression yield stress.

In the following example, the material under study is S-Glass/xP-251 Resin [7].

Its properties are shown in Table 2. We will first investigate a laminate with a

cross-ply of [0°/90°] [ [8] and then one with an angle-ply [45°/-45°] s. Also, we

will study each lammate for two assumed possible cases. One case is that the yield

strengths of the laminas are equal in tension and compression; the other case is that

they are not equal. The results of these four examples are plotted in the equivalent

stress space, as shown m Figure 5 to Figure 9. Since experimental data for the

interaction term

are not available for the S-Glass/xP-251Resin, we choose the

theoretical upper bound value [2] for the present analysis. Furthermore, we will

consider the loads are applied in the 1-2 plane.

Because the mteraction term

is the theoretical upper bound value, the

results of this example show that the yield loci become open curves (Figures 5, 6,

and 8), which have been indicated by Collins and Crane [9] . Moreover, the angle of

inclination of the elhpses, 6 is defined by the following form (Figure 8)

Fi

Fi

It is interesting to note that the direction of 0 depends not only on the sign

but also on the sign of the difference of

Thus this explains why the

and

of P121

Fl

F22.

31

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

Table 2. Physical Properties of the Fibrous

Composite in Example 2

Figure 5. Yield loci plotted on

a, - a plane,

S-Glass/xP-251 resin, [00/900Js

0° yield locus rotate in a clockwise (negative) direction and the 90° rotates in

counter-clockwise (positive) direction in Figures 5, 6 and 8 for the chosen Fi 2 .

a

CONCLUDING REMARKS

By applying the Von Mises Yield Criterion to each layer of a laminated medium

isotropic layers, we are able to arrive at a yield equation for the composite

with

32

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

Figure

6. Yield loci plotted

Figure

7. Yield loci

on

plotted on

a, - a2 plane,

°1 - °2

S-Glass/xP-251 resin, {O° /900s.

plane, S Glass/xR251 resin,

/45°%45°Js .

33

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

Figure 8. Yield loci plotted on

°1 - °2

plane, S Glass/xR251 resin,

[0° /900J S.

Figure 9. Yield loci plotted on

a, - a,

plane, S-Glass/xP-251 resin,

/45&dquo;/45’ / s’

34

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015

I

same form as the one proposed by Tsai and Wu for anisotropic elastic

it

bodies.Thus,

may be considered as direct extension of the Von Mises criterion.

Furthermore, we have obtained a set of equations governing the relative position of

which has the

yield

layers.

the

loci. These may be used

as

design guidelines for a laminate with isotropic

For the laminates with anisotropic layers, we have shown that for the examples

studied all the ellipses intersect one another, but we are unable to conclude whether

there could be other cases where the ellipses enclose one another.

The yield surface of a laminated composite is the inscribed envelope of many

ellipses. If this envelope can be approximated by another ellipse, the yield problem

of laminates can be greatly simplified.

It should be noted that the presented approach can be applied to a threedimensional state of stress. It is not limited to the conventional &dquo;plate bending and

stretching&dquo; type of loading. In applying our approach to plane stress problems, we

have neglected the effect of bending-stretching coupling. For certain arrangement

of the layers in a laminate, such as symmetric stacking or thin repeated layers, the

coupling effect disappears or becomes negligible.

ACKNOWLEDGMENT

This research was partially supported by Army Ballistic Research Laboratory

DAADOS-70-C-0175 and a NASA grant for the University Development Program at

Drexel University.

REFERENCES

1. R. Hill, The Mathematical Theory ,

of Plasticity Oxford, 1956.

2. S. W. Tsai and E. M. Wu, "A General Theory of Strength for Anisotropic Materials," J

.

, Vol. 5 (1971), p. 58.

Composite Materials

3. I. I. Gol’denblat and V. A. Kopnov, "Strength of Glass Reinforced Plastics in the Complex

Stress State," Mekhanika Polimerov

, Vol. 1, No. 2 (1965), p. 70.

4. P. C. Chou, J. Carleone and C. M. Hsu, "Elastic Constants of Layered Media," J

. Composite

, Vol. 6 (1972), p. 80.

Materials

5. P. C. Chou, B. M. McNamee and D. K. Chou, "The Yield Criterion of Laminated Media,"

will appear in the Proceedings of the Sixth St. Louis Symposium of Composite Materials in

Engineering Design, May 1972. Also DU Mechanics and Structures Report 72-5, 1972.

6. N. J. Pagano, "Exact Moduli of Anisotropic Laminates" will appear in Composite Materials

edited by G. P. Sendeckyj, Academic Press.

7. "Plastic for Aerospace Vehicles, Part I Reinforced Plastics," Military Handbook, MILHDBK-17A, January 1971, p. 3-72, Department of Defense.

8. "Structural Design Guide for Advanced Composite Application," Advanced Composite

Division, Air Force Material Laboratory, Air Force Systems Command, Wright-Patterson Air

Force Base, Ohio, August 1969.

9. B. R. Collins and R. L. Crane "A Graphical Representation of the Failure Surface of a

. ,

Composite," J

Composite Materials Vol. 5 (1971), p. 408.

35

Downloaded from jcm.sagepub.com at UNIV OF MICHIGAN on June 18, 2015