GSCM & Sustainability Performance: A Research Paper

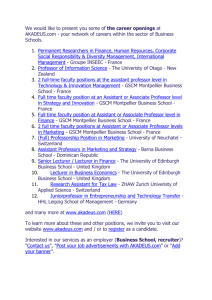

advertisement