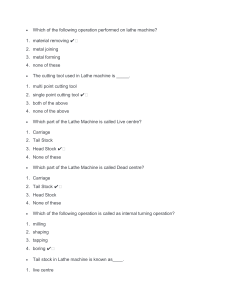

Unit 2.1: Lathe, Shaper and Planer Machines Unit 2.1 LATHE, SHAPING AND PLANING MACHINES 2.1.1 LATHE Lathe Machine Lathe Machine is one of the oldest machine tools in the production machine. This Machine is also known as the “mother of all machines”. The earliest evidence of a lathe dates back to 1300 BC in Egypt. The first lathe was a simple Lathe which is now called a twoperson lathe. Feed Principle of Operation The lathe is a machine tool which holds the workpiece between two rigid and strong supports called centers or in a chuck which revolves. The cutting tool is rigidly held and supported in a tool post which is fed against the revolving work. The normal cutting operations are performed with the cutting tool fed either parallel or at right angles to the axis of the work. 2.1.2 CLASSIFICATION OF LATHE Lathe machines are classified according to their construction and design. The classification is as follows: Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 1 Unit 2.1: Lathe, Shaper and Planer Machines 1. Bench lathe machine: Bench lathe is a small lathe usually mounted on a bench. This is used for small and precision work. 2. Speed lathe machine: Speed lathe is the simplest of all types of lathe in construction and operation. The spindle speed is about 4000 rpm. They named because of very High Speed of head stock spindle. 3. Engine lathe or center lathe machine: The term “engine” is associated with the lathe which is early driven by steam engines. An engine lathe is also known as a reproductive machine because of its production capabilities. Engine lathes are an excellent tool, which aids in the creation of many modern tools. 4. Tool room lathe machine: Tool room lathe is similar to an engine lathe. This lathe is mainly using for precision work on tools, Dies, Gauges and in making work where accuracy is necessary. It is used for making precision components in the tool room. 5. Capstan and turret lathe machine: It is used for repetitive production of duplicate parts. In a Capstan and turret lathes, a longitudinally feedable hexagon turret replaces the tail stock. 6. Special purpose lathe machine: Special Purpose lathe are using for special purposes and for jobs which cannot be accommodated or conveniently machined on a standard lathe. 7. Automatic lathe machine: In the automatic lathe, the various operations are automating like the change of the work piece. The working cycle is fully automatic that is repeated to produce duplicate parts without participation of operator. 2.1.3 CONSTRUCTIONAL FEATURES OF CENTRE LATHE Amongst the various types of lathes, centre lathes are the most versatile and commonly used. The major parts are: o HEADSTOCK: It holds the spindle and through that power and rotation are transmitted to the job at different speeds. Various work holding attachments such as three jaw chucks, collets, and centres can be held in the spindle. The spindle is driven by an electric motor through a system of belt drives and gear trains. Spindle rotational speed is controlled by varying the geometry of the drive train. o TAILSTOCK: The tailstock can be used to support the end of the work piece with a center, to support longer blanks or to hold tools for drilling, reaming, threading, or cutting tapers. It can be adjusted in position along the ways to accommodate different length work pieces. The tailstock barrel can be fed along the axis of rotation with the tailstock hand wheel. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 2 Unit 2.1: Lathe, Shaper and Planer Machines Basic parts of a Centre Lathe o BED: Headstock is fixed and tailstock is clamped on it. Tailstock has a provision to slide and facilitate operations at different locations. The bed is fixed on columns and the carriage travels on it. o CARRIAGE: It is supported on the lathe bed-ways and can move in a direction parallel to the lathe axis. The carriage is used for giving various movements to the tool by hand and by power. It carries saddle, cross-slide, compound rest, tool post and apron. • Saddle: It carries the cross slide, compound rest and tool post. It is an Hshaped casting fitted over the bed. It moves alone to guide ways. • Cross-slide: It carries the compound rest and tool post. It is mounted on the top of the saddle. It can be moved by hand or may be given power feed through apron mechanism. • Compound rest: It is mounted on the cross slide. It carries a circular base called swivel plate which is graduated in degrees. It is used during taper turning to set the tool for angular cuts. The upper part known as compound slide can be moved by means of a hand wheel. • Tool post: It is fitted over the compound rest. The tool is clamped in it. • Apron: Lower part of the carriage is termed as the apron. It is attached to the saddle and hangs in front of the bed. It contains gears, clutches and levers for moving the carriage by a hand wheel or power feed. o FEED ROD: The feed rod is a long shaft, used to move the carriage or cross-slide for turning, facing, boring and all other operations except thread cutting. Power is Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 3 Unit 2.1: Lathe, Shaper and Planer Machines transmitted from the lathe spindle to the apron gears through the feed rod via many gears. o LEAD SCREW: The lead screw is long threaded shaft used as a master screw and brought into operation only when threads have to cut. In all other times the lead screw is disengaged from the gear box and remains stationary. The rotation of the lead screw is used to traverse the tool along the work to produce screw. The half nut makes the carriage to engage or disengage the lead screw. FEED MECHANISM The movement of the tool relative to the work piece is termed as “feed”. The lathe tool can be given three types of feed, namely, longitudinal, cross and angular. o When the tool moves parallel to the axis of the lathe, the movement is called longitudinal feed. This is achieved by moving the carriage. o When the tool moves perpendicular to the axis of the lathe, the movement is called cross feed. This is achieved by moving the cross slide. o When the tool moves at an angle to the axis of the lathe, the movement is called angular feed. This is achieved by moving the compound slide, after swiveling it at an angle to the lathe axis 2.1.4 CAPSTAN AND TURRET LATHES Capstan and turret lathes are production lathes used to manufacture any number of identical pieces in the minimum time. These lathes are development of centre lathes. The capstan lathe was first developed in the year 1860 by Pratt and Whitney of USA. Capstan lathe is one of the types of semi-automatic lathe. Functions other than machining like loading and unloading of a job, the positioning of tools coolant operations are done manually. In contrast to centre lathes, capstan and turret lathes: o Are relatively costlier. o Are requires less skilled operator. o Possess an axially movable indexable turret (mostly hexagonal) in place of tailstock. o Holds large number of cutting tools; up to four in indexable tool post on the front slide, one in the rear slide and up to six in the turret. o Are more productive for quick engagement and overlapped functioning of the tools in addition to faster mounting and feeding of the job and rapid speed change. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 4 Unit 2.1: Lathe, Shaper and Planer Machines o Enable repetitive production of same job requiring less involvement, effort and attention of the operator for pre-setting of work-speed and feed rate and length of travel of the cutting tools. o Are suitable and economically viable for batch production or small lot production. o Capable of taking multiple cuts and combined cuts at the same time. Capstan and turret lathes are very similar in construction, working, application and specification. Principle parts of a Capstan Lathe Principle parts of a Turret Lathe Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 5 Unit 2.1: Lathe, Shaper and Planer Machines o BED: The bed is a long box like casting provided with accurate guide ways upon which the carriage and turret saddle are mounted. The bed is designed to ensure strength, rigidity and permanency of alignment under heavy duty services. o HEADSTOCK: The head stock is a large casting located at the left-hand end of the bed. The headstock of capstan and turret lathes may be of the following types: • Step cone pulley driven headstock: This is the simplest type of headstock and is fitted with small capstan lathes where the lathe is engaged in machining small and almost constant diameter of workpieces. Only three or four steps of pulley can cater to the needs of the machine. • Electric motor driven headstock: In this type of headstock the spindle of the machine and the armature shaft of the motor are one and the same. Any speed variation or reversal is affected by simply controlling the motor. Three of four speeds are available and the machine is suitable for smaller diameter of workpieces rotated at high speeds. • All geared headstock: On the larger lathes, the headstocks are geared and different mechanisms are employed for speed changing by actuating levers. The speed changing may be performed without stopping the machine. • Pre-optive or pre-selective headstock: It is an all-geared headstock with provisions for rapid stopping, starting and speed changing for different operations by simply pushing a button or pulling a lever. The required speed for next operation is selected beforehand and the speed changing lever is placed at the selected position. o CROSS SLIDE AND SADDLE: In small capstan lathes, hand operated cross slide and saddle are used. They are clamped on the lathe bed at the required position. The larger capstan lathes and heavy duty turret lathes are equipped with usually two designs of carriage. • Conventional type carriage: This type of carriage bridges the gap between the front and rear bed ways and is equipped with four station type tool post at the front, and one rear tool post at the back of the cross slide. This is simple in construction. • Side hung type carriage: The side-hung type carriage is generally fitted with heavy duty turret lathes where the saddle rides on the top and bottom guide ways on the front of the lathe bed. The design facilitates swinging of larger diameter of workpieces without being interfered by the cross-slide. o RAM SADDLE: In a capstan lathe, the ram saddle bridges the gap between two bed ways, and the top face is accurately machined to provide bearing surface for the ram or auxiliary slide. The saddle may be adjusted on lathe bed ways and clamped at the desired position. The hexagonal turret is mounted on the ram or auxiliary slide. o TURRET SADDLE: In a turret lathe, the hexagonal turret is directly mounted on the top of the turret saddle and any movement of the turret is effected by the movement of the saddle. The movement of the turret may be effected by hand or power Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 6 Unit 2.1: Lathe, Shaper and Planer Machines o TURRET: The turret is a hexagonal-shaped tool holder intended for holding six or more tools. Each face of the turret is accurately machined. Through the centre of each face accurately bored holes are provided for accommodating shanks of different tool holders. The centre line of each hole coincides with the axis of the lathe when aligned with the headstock spindle. In addition to these holes, there are four tapped holes on each face of the turret for securing different tool holding attachments. Different tools mounted on a hexagonal turret BAR FEEDING MECHANISM Bar feeding mechanism The capstan and turret lathes while working on bar work require some mechanism for bar feeding. The long bars which protrude out of the headstock spindle require to be fed through the spindle up to the bar stop after the first piece is completed and the collet chuck is Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 7 Unit 2.1: Lathe, Shaper and Planer Machines opened. In simple cases, the bar may be pushed by hand. But this process unnecessarily increases the total production time by stopping, setting, and starting the machine. Therefore, various types of bar feeding mechanisms have been designed which push the bar forward immediately after the collet releases the work without stopping the machine, enabling the setting time to be reduced to the minimum. The bar is passed through the bar holding chuck, spindle of the machine and then through the collet chuck. The bar holding chuck rotates in the sliding block body which is mounted on a long guiding bar. The bar holding chuck grips the bar centrally by two set screws and rotates with the bar in the sliding block body. One end of the rope is connected to the pin fitted on the sliding block and the other end supports a weight. The rope running over two fixed pulleys mounted on the sliding bar. The weight constantly exerts end thrust on the bar chuck while it revolves on the sliding bracket and forces the bar through the spindle at the moment the collet chuck is released. Thus, bar feeding may be accomplished without stopping the machine. In this way the bar is fed without stopping the machine. After several such feedings, the bar chuck will approach the rear end of the head stock. Now the bar chuck is released from the bar and brought to the left extreme position. Then it is screwed on to the bar. DIFFERENCES BETWEEN CAPSTAN AND TURRET LATHES CAPSTAN LATHE TURRET LATHE 1 In capstan lathe, the turret tool head is In turret lathe, the turret tool head is mounted over the ram and that is mounted mounted over the saddle like a single unit. over the saddle. 2 For providing feed to the tool, ram is For providing feed to the tool, a saddle is moved. moved. 3 Capstan lathe is a Lightweight machine. Turret Lathe is a Heavyweight machine. 4 The turret head cannot be moved in The turret head can be moved crosswise the lateral direction of the bed. i.e., in the lateral direction of bed in some turret lathe. 5 In capstan lathe, the collet is used In turret lathe, power Jaw chuck is used to gripping the Job. to gripping the Job. 6 Capstan lathe is usually horizontal lathes. Turret lathes are available in horizontal and vertical lathes. 7 Capstan lathe working operations are Turret lathe working operations are slower faster because of lighter in construction. because of heavier in constructions. 8 Capstan lathe used for shorter workpiece Turret lathe used for longer workpiece because of limited ram movement. because of saddle movement along the bed. 9 In Capstan lathe used for machining In Turret lathe used for machining workpiece up to 60 mm diameter. workpiece up to 120 mm in diameter. 10 Heavy cuts on the workpiece cannot be Heavy cuts on the workpiece can be given given because of non-rigid construction. because of the rigid construction of the machine. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 8 Unit 2.1: Lathe, Shaper and Planer Machines 2.1.5 LATHE OPERATIONS 1. STRAIGHT TURNING: The workpiece is held on the chuck and it is made to rotate about the axis, and the tool is fed parallel to the lathe axis. The straight turning produces a cylindrical surface by removing excess metal from the workpiece. 2. FACING: It is an operation of reducing the length of the workpiece by feeding the perpendicular to the lathe axis. This operation of reducing a flat surface on the end of the workpiece. For this operation, regular turning tool or facing tool may use. 3. STEP TURNING: When a workpiece has different diameters and is to be turned, the surface forming steps from one diameter to the other and machining this part of the workpiece is called step turning. Straight turning Facing Step turning 4. TAPER TURNING: Taper turning means to produce a conical shape by a gradual reduction in diameter from a cylindrical workpiece. In the case of a lathe, the taper on a given workpiece is obtained by tuning the job and feeding the tool at an angle to produce a gradual increase or decrease in the diameter of the workpiece. Following are the methods of Taper turning (a) Using Form tool: Taper turning using Form tool A broad nose tool having straight cutting edge is set on to the work at half taper angle and is fed straight into the work to generate a tapered surface. In this method the tool angle should be properly checked before use. This method is limited to turn short length of taper only. This is due to the reason that the metal is removed by the entire cutting edge will require excessive cutting pressure, which may distort the work due to vibration and spoil the work surface. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 9 Unit 2.1: Lathe, Shaper and Planer Machines (b) Swiveling the compound rest: This method is used to produce short and steep taper. In this method, work is held in a chuck and is rotated about the lathe axis. The compound rest is swiveled to the required angle and clamped in position. The half taper angle is determined by using the formula, 𝐷−𝑑 ) 𝛼 = 𝑡𝑎𝑛−1 ( 2𝑙 where, D – Larger diameter of a taper d – Smaller diameter of a taper l – Length of a taper 𝛼 𝛼 Taper turning swiveling the compound rest Then the tool is fed by the compound rest hand wheel. This method is used for producing both internal and external taper. This method is limited to turn a short taper owing to the limited movement of the compound rest. The compound rest may be swiveled at 450 on either side of the lathe axis enabling it to turn a steep taper. The movement of the tool in this method being purely controlled by hand, this gives a low production capacity and poorer surface finish. (c) Offsetting the Tailstock: The principle of turning taper by this method is to shift the axis of rotation of the work piece, at an angle to the lathe axis, which is equal to half angle of the taper, and feeding the tool parallel to the lathe axis. This is done when the body of the tailstock is made to slide on its base towards or away from the operator by a set over screw. The amount of set over being limited, this method is suitable for turning small taper on long jobs. The main disadvantage of this method is that live and dead centres are not equally stressed and the wear is not uniform. Moreover, the lathe carrier being set at an angle, the angular velocity of the work is not constant. The offset is calculated using the formula, 𝐿(𝐷 − 𝑑) ℎ= 2𝑙 where, D – Larger diameter of a taper d – Smaller diameter of a taper L – Length of a workpiece l – Length of a taper Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 10 Unit 2.1: Lathe, Shaper and Planer Machines (d) Using Taper turning attachment: Taper turning using Taper turning attachment It consists of a bracket or frame which is attached to the rear end of the lathe bed and supports a guide bar pivoted at the centre. The guide bar having graduations in degrees may be swiveled on either side of the zero graduation and is set at the desired angle with the lathe axis. When this attachment is used the cross slide is delinked from the saddle by removing the binder screw. The rear end of the cross slide is then tightened with the guide block by means of a bolt. When the longitudinal feed is engaged, the tool mounted on the cross slide will follow the angular path, as the guide block will slide on the guide bar set at an angle to the lathe axis. The required depth of cut is given by the compound slide which is placed at right angles to the lathe axis. The guide bar must be set at half taper angle and the taper on the work must be converted in degrees. The maximum angle through which the guide bar may be swiveled is 100 to 120 on either side of the centre line. The angle of swiveling the guide bar can be determined from the following formula 𝐷−𝑑 ) 𝛼 = 𝑡𝑎𝑛−1 ( 2𝑙 where, D – Larger diameter of a taper d – Smaller diameter of a taper l – Length of a taper 5. CHAMFERING: It is the operation of getting a bevelled surface at the edge of a cylindrical workpiece. This operation is done in case of bolt ends and shaft ends. Chamfering helps to avoid damage to the sharp edges and protect the operation getting hurt during other operations. Chamfering on bolt helps to screw the nut easily. 6. KNURLING: It is an operation of obtaining a diamond shape on the workpiece for the gripping purpose. This is done to provide a better gripping surface when operated by hands. It is done using a knurling tool. The tool consists of a set of hardened steel roller, and it is held rigidly on the tool post. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 11 Unit 2.1: Lathe, Shaper and Planer Machines Chamfering Knurling 7. THREAD CUTTING: It is the important operation in the lathe to obtain the continuous ‘helical grooves’ or ‘threads’. When the threads or helical grooves are formed on the out surface of the workpiece is called external thread cutting. When the threads or helical grooves are formed on the inner surface of the workpiece is called internal thread cutting. Thread cutting Here the tool is moved longitudinally to obtain the required type of the thread. When the tool is moved from right to the left we get the left-hand thread. Similarly, when the tool is moved from left to the right we get the right-hand thread. The motion of the carriage is provided by the lead screw. A pair of change gears drives the lead screw and by rotating the handle the depth of cut can be controlled. 8. GROOVING: It is the process of reducing the diameter of a workpiece over a very narrow surface. It is done by a groove tool. A grooving tool is similar to the parting-off tool. It is often done at the end of a thread or adjacent to a shoulder to leave a small margin. 9. FORMING: It is the process of turning a convex, concave, or of any irregular shape. This may be accomplished using a forming tool. 10. DRILLING: Drilling is the operation of producing a cylindrical hole in a workpiece. It is done by a rotating tool, the rotating side of the cutter, known as a drilling drill. In this Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 12 Unit 2.1: Lathe, Shaper and Planer Machines operation, The workpiece is revolving in a chuck or a faceplate and the drill is held in the tailstock drill holder or drill chuck. Grooving Forming 11. Reaming: Reaming is the operation of finishing and sizing a hole which has been already drilled or bored. The tool is used is called the reamer, which has multi-plate cutting edges. The reamer is held on the tailstock spindle, either directly or through a drill chuck, and is held stationary while the work is revolved at a very slow speed. Drilling Boring Reaming Tapping 12. Boring: Boring is the operation of enlarging the hole which is already drilled. In this operation, the workpiece is revolved in a chuck or a faceplate and the boring bar having a single-point cutting tool that enlarges the hole. It also corrects out of the roundness of a hole. This method adopted for boring small-sized works only. The speed of this process is slow. 13. Counterboring: Counterboring is the operation of enlarging the end of the hole through a certain distance. It is similar to shoulder work in external turning. The operation is similar to boring and plain boring tools or a counterbore may be used. The tool is used called a counterbore. The speed is slightly less than drilling. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 13 Unit 2.1: Lathe, Shaper and Planer Machines 14. Taper Boring: The principle of turning a tapered hole is similar to the external taper turning operation and is completed by rotating the work on a chuck or a faceplate. The feeding tool is at an angle to the axis of rotation of the workpiece. A boring tool is mounted on the tool post and by swivelling the compound slide to the desired angle, a short taper hole is machined by hand feeding. 15. Tapping: Tapping is the operation of cutting internal threads of small diameter using a multipoint cutting tool called the tap. In a lathe, the work is mounted on a chuck or on a faceplate and revolved at a very slow speed. A tap of the required size held on a special fixture is mounted on the tailstock spindle. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 14 Unit 2.1: Lathe, Shaper and Planer Machines 2.1.6 SHAPER Shaper Machine The shaper machine is a reciprocating type of machine basically used for producing the horizontal, vertical or flat surfaces. The shaper holds the single point cutting tool in ram and workpiece is fixed in the table. During the forward stroke, the ram is holding the tool is reciprocating over the workpiece to cut into the required shape. During the return stroke, no metal is cutting. In the shaper machine, the rotary motion of the drive is converted into reciprocating motion of ram holding the tool. Working Principle of a Shaper 2.1.7 MAIN PARTS OF A SHAPER o Base: It provides the necessary support to the machine tool. It is rigidly bolted to the shop floor. All parts are mounted on the base. It is made up of cast iron to resist vibration and take compressive load. It takes the entire load of the machine and the forces set up by the cutting tool during machining. o Column: It is a box like casting mounted upon the base. It encloses the drive mechanisms for the ram and the table. Two accurately machined guide ways are provided on the top of the column on which the ram reciprocates. The front vertical face of the column which serves as the guide ways for the cross rail is also accurately machined. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 15 Unit 2.1: Lathe, Shaper and Planer Machines Main parts of a Shaper o Cross rail: It is mounted on the front vertical ways on its top in the vertical plane that is perpendicular to the ram axis. The table may be raised or lowered to accommodate different sizes of jobs by rotating an elevating screw which causes the cross rail to slide up and down on the vertical face of the column. A horizontal cross feed screw which is fitted within the cross rail and parallel to the top guide ways of the cross rail actuates the table to move in a crosswise direction. o Saddle: It is mounted on the cross rail which holds the table firmly on its top. Crosswise movement of the saddle by rotating the cross-feed screw by hand or power causes the table to move sideways. o Table: It is bolted to the saddle receives crosswise and vertical movement from the saddle and cross rail. It is a box like casting having T universal shaper the table may be swiveled on a horizontal axis and the upper part of the table may be tilted up or down. In a heavier type shaper, the front face of the table is clamped with a table support to make it more rigid. o Ram: It holds and imparts cutting motion to the tool through reciprocation. It is connected to the reciprocating mechanism contained within the column. inside to make it more rigid. It houses a screwed shaft for altering the position of the ram with respect to the work and holds the tool head at the extreme forward end. o Tool head: It holds the tool rigidly, provides the feed movement of the tool and allows the tool to have an automatic relief during its return stroke. The vertical slide of the tool head has a swivel base which is held on a circular seat on the ram. So the vertical slide may be set at any desired angle. By rotating the down feed screw handle, the vertical slide carrying the tool executes the feed or depth of cut. The tool post is mounted upon the clapper block. On the forward cutting stroke the clapper block fits securely to the clapper box to make a rigid tool support. On the return stroke a slight Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 16 Unit 2.1: Lathe, Shaper and Planer Machines frictional drag of the tool on the work lifts the block out of the clapper box a sufficient amount preventing the tool cutting edge from dragging surface is also prevented from any damage due to dragging. Tool head of a Shaper 2.1.8 QUICK RETURN MECHANISM o In a shaper, material is removed only in the forward cutting stroke and no material is removed during the return stroke. o The shaper mechanism (Quick return mechanism) allows the ram to move at a slower speed during forward cutting stroke. o Since the return stroke is idle, quick return mechanism is used which allows the ram to move faster speed than the cutting stroke. o There are three types of Quick return Mechanism. They are: 1. Hydraulic mechanism. 2. Crank and slotted lever mechanism. 3. Whitworth mechanism. CRANK AND SLOTTED LEVER MECHANISM In this mechanism the ram is actuated by gear drives associated with electric motor. First, the electric motor drives the pinion gear. Next, the pinion gear drives the bull gear which rotates in opposite direction due to external gear meshing. A radial slide is provided on the bull gear. A sliding block is assembled on this slide. The block can be positioned in radial direction by rotating the stroke adjustment screw. The sliding block has a crank pin. A rocker arm is freely fitted to this crank pin. The rocker arm sliding block slides in the slot provided in the rocker arm called as slotted link. The upper end has fork which is connected to the ram block by a pin while the bottom end of the rocker arm is pivoted. When the pinion gear rotates along with the bull gear, the crank will also rotate. Due to this, the rocker arm sliding block also rotates in the same circle. Simultaneously, the sliding block slides up and down in the slot. This movement is transmitted to the ram which reciprocates. Hence, the rotary motion is converted in reciprocating motion. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 17 Unit 2.1: Lathe, Shaper and Planer Machines 𝜶 𝜷 Crank and slotted lever mechanism In Crank and slotted lever mechanism, Cutting time 𝛼 𝛼 = = Return time 𝛽 360° − 𝛼 where, 𝛼 − Angle of Forward stroke 𝛽 − Angle of Return stroke 2.1.9 CLASSIFICATION OF SHAPER 1. ACCORDING TO THE TYPE OF MECHANISM USED: a) Crank shaper: This is the most common type of shaper. In construction, the crank shaper employs a crank mechanism to change circular motion of “bull gear” to reciprocating motion of the ram. b) Geared shaper: The reciprocating motion of the ram is some type of shaper is effect by means of a rack and pinion. The rack teeth which are cut directly below the ram mesh with a spur gear. The pinion meshing with the rack is driven by a gear train. The speed and the direction in which the ram will traverse depend on the number of gears in the gear train. c) Hydraulic shaper: In a hydraulic shaper, reciprocating movement of the ram is obtained by hydraulic power. Oil under high pressure is pumped into the operating cylinder fitted with a piston. The end of the piston rod is connected to the ram. The high-pressure oil first acts on one side of the piston and then on the other causing the piston to reciprocate and the motion is transmitted to the ram. 2. ACCORDING TO THE POSITION AND TRAVEL OF RAM: a) Horizontal shaper: In a horizontal shaper, the ram holding the tool reciprocates in a horizontal axis. Horizontal shapers are mainly used to produce flat surfaces. b) Vertical shaper: In a vertical shaper, the ram holding the tool reciprocates in a vertical axis. The worktable of a vertical shaper can be given cross, longitudinal, and rotary Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 18 Unit 2.1: Lathe, Shaper and Planer Machines movement. Vertical shapers are very convenient for machining internal surfaces, keyways, slots or grooves. c) Traveling head shaper: The ram carrying the tool while it reciprocates moves crosswise to give the required feed. Heavy jobs which are very difficult to hold on the table of a standard shaper and fed past the tool are held static on the basement of the machine while the ram reciprocates and supplies the feeding movements. 3. ACCORDING TO THE TYPE OF DESIGN OF THE TABLE: a) Standard shaper: shaper is termed as standard or plain when the table has only two movements, vertical and horizontal, to give the feed. The table may or may not be supported at the outer end. b) Universal shaper: In this type, in addition to the two movements provided on the table of a standard shaper, the table can be swiveled about an axis parallel to the ram ways, and the upper portion of the table can be tilted about a second horizontal axis perpendicular to the first axis. As the work mounted on the table can be adjusted in different planes, the machine is most suitable for different types of work and is given the name “Universal”. 4. ACCORDING TO THE TYPE OF CUTTING STROKE: a) Push type shaper: This is the most general type of shaper used in common practice. The metal is removed when the ram moves away from the column, i.e., during the forward stroke. b) Draw type shaper: In this type, the metal is removed when the ram moves towards the column of the machine, i.e., during the return stroke. The tool is set in a reversed direction to that of a standard shaper. 2.1.10 OPERATIONS ON A SHAPER 1. Machining Horizontal surfaces: It is the most common shaper machine operations. In this, the work is fed in a horizontal direction under the reciprocating tool and the surface produced is horizontal and flat. Machining Horizontal surface Machining Vertical surface Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa Machining Angular surface 19 Unit 2.1: Lathe, Shaper and Planer Machines 2. Machining Vertical surfaces: A vertical cut is made while machining the end of a workpiece, squaring up a block or cutting a shoulder. The work is attached in the vice or directly on the table and the surface to be machined is carefully aligned with the axis of the ram. The down–feed is given by rotating the down feed screw by hand. 3. Machining Angular surfaces: An angular cut is done at any angle other than a right angle to the horizontal or to the vertical plane. The work is set on the table and the vertical slide of the tooth head is swivelled to the required angle either towards the left or towards right from the vertical position. The down feed is given by rotating the down feed screw. The angular surface can also be machined in a universal shaper or by using a universal vice without swivelling the tool head. 4. Machining Irregular surfaces: A shaper can also produce a contoured surface, i.e., a convex or concave surface or a combination of any of the above surfaces. To manufacture a small contoured surface a forming tool is used. If the curve is large, round nose tool is used and power cross feed in conjunction with manual down feed is so adjusted that the wool will trace the required contour. Machining Irregular surfaces 5. Cutting Slots and Keyways: A shaper can very conveniently machine slots or grooves on work or cut external keyways on shafts and internal keyways on pulleys or gears. For cutting slots or keyways on shafts and internal keyways on pulleys or gears. For cutting keyways or slots a square nose tool similar to a parting tool is used. Machining External keyway Machining Internal keyway Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 20 Unit 2.1: Lathe, Shaper and Planer Machines 2.1.11 PLANER Planer is machine that use to generate accurate flat surfaces. It is similar to a shaper, but it is larger than shaper machine and with the entire workpiece moving beneath the cutter. The work table is moved back and forth on the bed beneath the cutting head either by mechanical means, such as a rack and pinion gear, or by a hydraulic system. Planer Machine PRINCIPLE OF OPERATION Working Principle of a Planer The work is rigidly held on the worktable of the machine and the tool is held vertically in the tool head mounted on the cross-rail. The worktable with the job reciprocates back and forth past the vertically held tool. The feed is given by moving the tool head along the cross rail and the vertical feed is given by moving down the tool. The feed can be given by manually or automatically. Feed is given after each cut during the idle stroke of the table Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 21 Unit 2.1: Lathe, Shaper and Planer Machines 2.1.12 MAIN PARTS OF A DOUBLE HOUSING PLANER Parts of a Double housing Planer o Bed: Bed of a planer is large in size and heavy in weight. It supports the column and all other moving parts of machine. It is made slightly longer than twice the length of the table so that the full length of the table may be moved on it. There is a V guide way on the bed which help to reciprocate or back and forth motion to the table. o Columns: They are rigid box like vertical structures placed on each side of the bed and are fastened to the sides of the bed. The front face of each housing is accurately machined to provide precision guide ways on which the cross-rail may be made to slide up and down for accommodating different heights. Two tool heads also slide upon it. o Table: It supports the work and reciprocates along the ways of the bed. The top face of the planer table is accurately finished to locate the workpiece correctly. T-slots are provided on the entire length of the table so that the work and work holding devices may be bolted upon it. At each end of the table a hollow space is left which acts as a trough for collecting chips. o Cross Rail: A rigid casting mounted horizontally on the column. Can be moved up & down by elevating screw. The front face of the cross rail is accurately machined to provide a guide surface for the tool head. Usually two tool heads are mounted upon the cross rail which are called railheads. o Tool Head: Tool heads are mounted on the cross rail by saddle. Tool post (clapper block) is hinged to the head. During return stroke cutting tool will be lifted. Tool heads can be swivelled through 60⁰ on either side of its vertical position Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 22 Unit 2.1: Lathe, Shaper and Planer Machines 2.1.13 TYPES OF PLANERS 1. DOUBLE HOUSING PLANER: It is most widely used in workshops. It has a long heavy base on which a table reciprocates on accurate guide ways. It has one drawback. Because of the two housings, one on each side of the bed, it limits the width of the work that can be machined. 2. OPEN SIDE PLANER: Open side planer It has a housing only on one side of the base and the cross rail is suspended from the housing as a cantilever. This feature of the machine allows large and wide jobs to be clamped on the table. As the single housing has to take up the entire load, it is made extra-massive to resist the forces. Only three tool heads are mounted on this machine. The constructional and driving features of the machine are same as that of a double housing planer. 3. PIT PLANER: Pit planer Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 23 Unit 2.1: Lathe, Shaper and Planer Machines It is massive in construction. It differs from an ordinary planer in that the table is stationary and the column carrying the cross rail reciprocates on massive horizontal rails mounted on both sides of the table. This type of planer is suitable for machining a very large work which cannot be accommodated on a standard planer and the design saves much of floor space. The length of the bed required in a pit type planer is little over the length of the table. 4. EDGE (or) PLATE PLANER: Edge Planer The design of a plate or edge planer is totally unlike that of an ordinary planer. It is specially intended for squaring and beveling the edges of steel plates used for different pressure vessels and ship building works. 5. DIVIDED TABLE PLANER: This type of planer has two tables on the bed which may be reciprocated separately or together. This type of design saves much of idle time while setting the work. To have a continuous production one of the tables is used for setting up the work and the other is used for machining. This planer is mainly used for machining identical work pieces. The two sections of the table may be coupled together for machining long work. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 24 Unit 2.1: Lathe, Shaper and Planer Machines Divide table planer 2.1.14 OPERATIONS ON A PLANER 1. PLANING HORIZONTAL SURFACES: o Horizontal planning is carried to produce flat surfaces on the top face of the workpiece o Fix the work properly on the table and set the required cutting speed. o Set suitable depth of cut for rough cuts and finishing. o Give required feed of the tool. 2. PLANING VERTICAL SURFACES: o Vertical planning is carried to produce flat surfaces on the vertical faces of the workpiece o Fix the job on the table firmly. o Vertical slide is adjusted perpendicular to the table o Swivel the toolhead at an angle to avoid contact of the tool body with workpiece as the tool progresses down. o Rotate down feed screw by hand to give down feed. 3. PLANING ANGULAR SURFACES: o Angular planing is carried to produce dove tails & V grooves. o Set the work on the table. o Swivel the tool head to the required angle. o Give the feed using down feed screw. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 25 Unit 2.1: Lathe, Shaper and Planer Machines 4. PLANING FORMED SURFACES: o Fix up a square nose tool in tool head. o Required form is obtained by feeding the tool simultaneously in both horizontal and vertical directions. o This can also be done with the aid of a special fixture. 2.1.15 DIFFERENCES BETWEEN A PLANER AND SHAPER SHAPER PLANER 1. The tool reciprocates and the work is stationary. 2. Feed is given to the work during the idle stroke of the ram. 3. It gives more accuracy as the tool is rigidly supported during cutting. 4. Suitable for machining small work pieces. 5. Only light cuts can be applied. 6. Only one tool can be used at a time. So machining takes longer time. 7. Setting the work piece is easy. 8. Only one work piece can be machined at a time. 9. Tools are smaller in size. 10. Shapers are lighter and smaller. The work reciprocates and the tool is stationary. Feed is given to the tool during the idle stroke of the worktable. Less accuracy due to the overhanging of the ram. Suitable for machining large work pieces. Heavy cuts can be applied. Vertical and side tool heads can be used at a time. So machining is quicker. Setting the work piece is difficult. Several work pieces can be machined at a time. They are larger in size. Planers are heavier and larger. Prof. Shiva Krishna J, Dept. of Mech Engg, AITD Assagao, Goa 26