Deliverable-2013-440-Reduce Grinding Labor Final Report-Newport News Shipbuilding (AWSC4.1-77 SAMPLES)

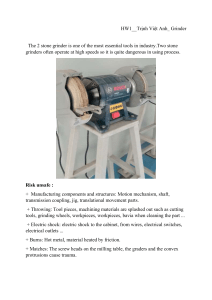

advertisement