QualityPlan Training Compliance Program Improvements Rev 01 blank

advertisement

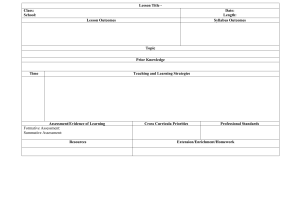

Doc PLAN Title 1.0 Rev PLAN 01 Page 1 of 5 QUALITY SYSTEM IMPROVEMENT PLAN, TRAINING COMPLIANCE PROGRAM PURPOSE The purpose of this project plan is to define the strategies and deliverables to improve training compliance program. The objective of this project is to establish a risk-based approach for determining training effectiveness for training curricula and/or events. 2.0 3.0 CURRENT STATE 2.1 Training Compliance is measured by Personnel’s ability to complete assigned/required training by effective date (date the training event/item will be implemented). Signatures in system provide acknowledgement of individual’s completion and understanding of the training item’s content. 2.2 Training and effectiveness methods utilized are not based upon risk or complexity. All revisions require training. All manufacturing procedures and test methods are trained by qualified personnel however effectiveness method is primarily discussion and understanding of the process and changes thereto. 2.3 Training is primarily conducted for quality system procedures and guidelines within computerized system in a read and understand method (i.e. user receives notification, link to copy of item is available, user reads procedure, user signs/acknowledges within system using e-signature process). 2.4 Equipment Manufacturing procedures and test methods require training. Training is completed upon release of new procedures or revised procedures by Manufacturing Engineers. The method used is “instructor-led” and is documented for established training audience or new training audience. Training event is documented utilizing a manual training form () which is attached to the Change Order (i.e. in Agile) releasing the item or where Manufacturing Department Training Coordinator document’s individuals completion within the computerized system (i.e ComplianceWire). 2.5 Training is considered effective through evaluation of personnel’s performance (bi-annual performance reviews, confirmation of understanding of instructor-led or computer based training resulting in the absence of product nonconformities. APPROACH Due to the high volume of curricula to review and potential training materials to develop implementation of this improvement will be completed in phases. This approach will prioritize the curricula with the highest potential to product or patient safety and/or used most widely across the site. 3.1 Phase 1 – Identify requirements for program improvement to comply with ISO13485:2016 risk based approach. Initiate assessment process appropriate for business. 3.2 Phase 2 – Identify manufacturing procedures and test methods previously determined to be used to mitigated risks or create product safety mechanisms that could impact patient’s safety or effectiveness of the equipment. Doc PLAN Title 5.0 PLAN 01 Page 2 of 5 QUALITY SYSTEM IMPROVEMENT PLAN, TRAINING COMPLIANCE PROGRAM 3.3 4.0 Rev Phase 3 – Identify cross functional quality system curricula where interrelated subsystems can impact safety and effectiveness, risks or risk controls. OBJECTIVES 4.1 Effectiveness Implementation: Implement a program where Originators of Training Events (i.e. Change Originators such as R&D Engineers, Manufacturing Engineers, Quality Assurance personnel) qualified in new or revised process conduct a training session where training is considered effective based upon assessments of trainees understanding of the content. 4.2 Impact assessment: Implement a process that utilizes a risk-based approach to identify the appropriate training method to use based upon the level of complexity or impact of the change to the process or release of a new process. Once a risk-based approach is established, existing training curricula will be reviewed, and where appropriate risk level determined and effectiveness verification methods developed 4.3 Training Content Determination: Provide responsible parties with guidance in appropriate method to utilize to ensure training objectives are identified, understood and implemented in applicable processes. 4.4 Training Assessment and Records: Provide responsible parties with ability to utilize current systems or methods to document assessments, training and evidence of effectiveness of training. ACTIVITIES AND DELIVERABLES 5.1 Primary responsible individual for project is Quality Systems Project Manager. 5.2 Functional area resources identified by Management will review proposed improvements and provide feedback before implementation of deliverables. Activities Identify requirements Proposed Deliverables Target Completion Date 1. Revise current procedures to indicate effectiveness process. End of Q3 2017 2. Develop new guidance documents or procedures on determining appropriate training content’s objectives to ensure effectiveness assessments are favorable and process is sustainable. 3. Communicate proposed changes. Evaluate feedback and resolve or incorporate. 4. Acceptance of responsibility of appropriate functions is received, evaluated, incorporated or resolved. Doc PLAN Title Rev PLAN 01 Page 3 of 5 QUALITY SYSTEM IMPROVEMENT PLAN, TRAINING COMPLIANCE PROGRAM Activities Proposed Deliverables Target Completion Date Develop training impact assessment process 1. Create a new form or mechanism to identify and document Training Impact Assessment End of Q3 2017 2. Evaluate content of current form and revise as appropriate to identify Training Audience changes. Implement a “user-friendly” form Separate out forms to use for Training Audience changes only. For example: Separate out Manufacturing and Repair Depot into one form; Separate out Warehouse into its own form that may be needed in conjunction with updates to other forms. Separate out QS procedure plan updates add info regarding curriculum creation and changes. 3. Communicate changes to Department Training Coordinators and incorporate or resolve feedback. 4. Communicate with functional area managers proposed form and incorporate or resolve feedback. 5. Acceptance of responsibility of appropriate functions is received, evaluated, incorporated or resolved Identify and implement a new curricula creation process 1. Review current training assignments via training plans and training matrices with functional area managers to identify appropriate ‘tiered approach’ for job proficiency. 2. Revise Training Plans as necessary to align with proficiency training approach. 2. Implement a curricula creation process that provides personnel assignments based upon skills required for position as determined by functional area manager. End of Q1 2018 Doc PLAN Title Rev PLAN 01 Page 4 of 5 QUALITY SYSTEM IMPROVEMENT PLAN, TRAINING COMPLIANCE PROGRAM Activities Proposed Deliverables Target Completion Date Identify and rank manufacturing procedures and test methods (Phase 2) according to impact to product and complexity. 1. Develop training effectiveness materials to support risk level determination for Phase 2 curricula. End of Q1 2018 2. Implement new curricula or assessment template for items identified in Phase 2 and assign to users dependent upon personnel’s role and responsibilities as required. 3. Develop supporting process for reviewing Effectiveness Verification results. Identify and quality system procedures and supporting training aides (Phase 3) according to impact to safety and effectiveness of product. 1. Develop training effectiveness materials to support risk level determination for Phase 3 curricula. End of Q2 2018 2. Implement new curricula or assessment template for items identified in Phase 3 and assign to users dependent upon personnel’s role and responsibilities as required 3. Develop supporting process for reviewing Effectiveness Verification results. 6.0 Train users on new process Provide instructor-led training sessions with functional areas impacted by the improved process End of Q2 2018 Complete Project Prepare and release report to document completion of plan. End of Q2 2018 RISKS 6.1 7.0 The following risks may adversely affect the project: # Description Priority Mitigation 1 Resources- inability to obtain cross functional team participation due to daily responsibilities, and other projects competing High Ensure resources are assigned by site management. Track participation and maintain communication management 2 Potential Unknowns- e.g., additional associated documents that may require concurrent updates Medium Plan & track additional tasks as they are identified Communicate concerns QA staff meetings ISSUES 7.1 No issues currently adversely affect the project. Doc PLAN Title 8.0 PLAN 01 Page 5 of 5 QUALITY SYSTEM IMPROVEMENT PLAN, TRAINING COMPLIANCE PROGRAM ASSUMPTIONS 8.1 9.0 Rev Integration of Equipment Sites into ComplianeWire will not impact any deliverables to be implemented into the system. CONSTRAINTS # Description Priority Mitigation 1 Resources- Not all Department Training Coordinators accounts in ComplianceWire include role that allows ability to create curriculums or assessments/tests. Medium Ensure resources receive appropriate training to obtain role in system.