Elastic Local Buckling Stress Formulae for Structural Sections

advertisement

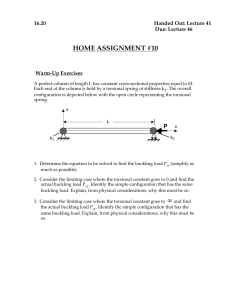

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/330548546 Formulae for Calculating Elastic Local Buckling Stresses of Full Structural Crosssections Article in Structures · February 2019 DOI: 10.1016/j.istruc.2019.01.012 CITATIONS READS 55 9,990 3 authors: Leroy Gardner Andreas Fieber Imperial College London Oceanbird 435 PUBLICATIONS 15,280 CITATIONS 6 PUBLICATIONS 172 CITATIONS SEE PROFILE SEE PROFILE L. Macorini Imperial College London 135 PUBLICATIONS 1,946 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: MultiCAMS - Multi-level Model Calibration for the Assessment of Historical Masonry Structures View project FRAMAB - Flood Risk Assessment and mitigation for Masonry Arch Bridges View project All content following this page was uploaded by Leroy Gardner on 22 September 2019. The user has requested enhancement of the downloaded file. Formulae for calculating elastic local buckling stresses of full structural cross-sections Leroy Gardner, Andreas Fieber, Lorenzo Macorini Imperial College London, SW7 2AZ London, UK March 2019 Abstract Formulae for determining the full cross-section elastic local buckling stress of structural steel profiles under a comprehensive range of loading conditions, accounting for the interaction between the individual plate elements, are presented. Element interaction, characterised by the development of rotational restraint along the longitudinal edges of adjoined plates, is shown to occur in cross-sections comprising individual plates with different local buckling stresses, but also in cross-sections where the isolated plates have the same local buckling stress but different local buckling half-wavelengths. The developed expressions account for element interaction through an interaction coefficient ζ that ranges between 0 and 1 and are bound by the theoretical limits of the local buckling stress of the isolated critical plates with simply-supported and fixed boundary conditions along the adjoined edges. A range of standard European and American hot-rolled structural steel profiles, including I-sections, square and rectangular hollow sections, channel sections, tee sections and angle sections, as well as additional welded profiles, are considered. The analytical formulae are calibrated against results derived numerically using the finite strip method. For the range of analysed sections, the elastic local buckling stress is typically predicted to within 5% of the numerical value, whereas when element interaction is ignored and the plates are considered in isolation with simply-supported boundary conditions along the adjoined edges, as is customary in current structural design specifications, the local buckling stress of common structural profiles may be under-estimated by as much as 50%. The derived formulae may be adopted as a convenient alternative to numerical methods in advanced structural design calculations (e.g. using the direct strength method or continuous strength method) and although the focus of the study is on structural steel sections, the functions are also applicable to cross-sections of other isotropic materials. 1 1 Introduction In structural steel design codes, such as EN 1993-1-1 [1] and AISC 360-16 [2], cross-section classification is used to assess the susceptibility of structural profiles to local buckling by specifying limiting width-to-thickness ratios on the individual plate elements that form the structural cross-section. Classification is performed on an element-by-element basis and the boundaries between plate elements (i.e. the flanges and webs) are conservatively assumed to be pinned. Depending on the resulting cross-section class, appropriate restrictions are placed on the cross-section strength and rotation capacity. In reality, the individual plate elements within structural cross-sections do not behave in isolation, and a substantially more accurate representation of the local buckling performance of full cross-section profiles can be obtained by considering the interaction between the elements. Recently established design methods, such as the Direct Strength Method (DSM) [3,4] and the Continuous Strength Method (CSM) [5–7], exploit the beneficial effects of element interaction by utilising the full crosssection elastic local buckling stress to determine the local slenderness and hence the capacity of cross-sections. Currently, numerical methods are typically employed to determine the elastic buckling stress of the full structural cross-section; for cold-formed sections of intricate geometry, this is the only practical option, but for more regular hot-rolled and welded profiles, simplified and explicit analytical formulae can be developed, as shown by Seif and Schafer [8]. The formulae presented in [8] are however limited to hot-rolled profiles under pure compression or pure bending, but, in the majority of practical applications, steel profiles are subjected to a combination of axial compression and bending. In the present paper, formulae for determining the elastic local buckling stress of a wide range of full structural steel profiles under compression, bending and combined actions are presented. The underlying concept is that the critical plate element within a cross-section is restrained by the neighbouring plate elements such that the cross-section elastic local buckling stress of the full cross-section is bound by that of the critical plate with simply-supported and fixed boundary conditions along the adjoined edges. Between these bounds, predictive functions are developed and calibrated against results derived using finite strip analysis. The accuracy of the functions is verified for a wide range of structural steel profiles and comparisons are made against predictions in which element interaction is ignored (i.e. the current design approach in Eurocode 3). Finally, worked examples are presented to demonstrate implementation of the developed functions. 2 2 Literature review 2.1 Elastic buckling of isolated plates The stability of flat plates has been of engineering interest for many years and solutions for the elastic buckling of rectangular plates are widely available for various boundary and loading conditions. The first comprehensive summary of a range of practical cases, including the buckling of rectangular plates under pure compression with all plate edges simply-supported or fixed, dates back to Timoshenko’s work based on energy methods [9], with additional problems covered in [10–12]. The elastic buckling stress σcr,p for a rectangular plate of width b and thickness t made of an elastic material with Young’s Modulus E and Poisson’s ratio ν is given by Eq. (1), where k is the buckling coefficient of the plate that depends on three principal factors: (1) the plate aspect ratio, (2) the boundary conditions along the plate edges and (3) the stress distribution arising from the applied loading. Considering the typical proportions of structural elements, plates are generally assumed to be long and the influence of the plate aspect ratio on the buckling stress is conservatively ignored. σcr,p π2 E =k 12(1 − ν 2 ) 2 t b (1) The boundary conditions along the longitudinal edges of isolated plates are typically idealised as simplysupported, fixed or free, and assumed to be unrestrained in-plane. Between simply-supported and fixed, varying degrees of rotational restraint can be expressed in terms of moment per unit length per unit rotation [12], whereby a simply-supported edge provides zero rotational restraint with no moment transferred, while a fixed edge provides infinite rotational restraint. Lundquist and Stowell [13, 14] analysed rectangular plates with varying restraint conditions using energy methods and showed how the buckling stress increases with increasing rotational edge fixity. The applied stress distribution along the loaded edges of plates in structural cross-sections typically varies from pure compression to pure bending. Uniform compression is the most severe loading condition and results in the lowest elastic buckling stress, while the buckling stress rises as the applied stress distribution becomes increasingly non-uniform. Linearly varying in-plane stress distributions in a plate can be defined through the parameter ψ, where σ1 is the maximum compressive stress (with compression taken as positive) and σ2 is the minimum compressive or maximum tensile stress. Note that if the condition σ1 > 0 is not satisfied then the element is subjected exclusively to tension and hence local buckling will not occur. 3 ψ= σ2 ≤1 σ1 (2) A stress distribution of ψ = 1 (i.e. σ2 = σ1 ) corresponds to pure compression, while ψ = −1 (i.e. σ2 = −σ1 ) corresponds to pure bending in symmetrical cross-sections. Solutions for the buckling coefficient k have been obtained for simply-supported internal and outstand flange plates (referred to as stiffened and unstiffened elements respectively in US steel design specifications) subjected to a variety of stress distributions [12, 15–17]. 2.2 Elastic local buckling of cross-sections Local buckling of structural profiles is typically considered by individually examining the stability of the isolated plates that make up the cross-section. The elastic buckling stress of the individual plates is determined through Eq. (1), with expressions to determine the plate buckling coefficient k for simply-supported plates under a range of loading conditions provided in EN 1993-1-5 [18]. While the design process is simplified by neglecting element interaction, the local buckling stress of the majority of cross-sections is under-predicted. To consider local buckling of the full cross-section, the interaction between the different cross-section elements must be considered. Plate interaction within a cross-section generally leads to increased local buckling resistance since the boundary conditions along the adjoining plate edges typically offer rotational restraint that is ignored when the plates are considered in isolation with simply-supported boundary conditions. The effects of element interaction on the local buckling of cross-sections was first considered by Lundquist [19,20], who published a series of studies analysing the local stability of a range of cross-section profiles, including I-, Z-, C- and SHS/RHS (square and rectangular hollow) sections subjected to axial compression. The basis to allow for element interaction was laid by considering outstand and internal rectangular plates restrained elastically along the unloaded adjoining edges. Since then, a number of analytical, experimental and numerical studies have been carried out examining the effects of element interaction on the elastic and inelastic local buckling behaviour of various cross-section profiles including I-sections [21–31], rectangular hollow sections [32–35], cold-formed sections [36–39] and hot-rolled steel profiles [8]. Recently, Generalized Beam Theory was used to develop semi-analytical expressions for the buckling coefficient k of rectangular hollow sections under combined axial force and bi-axial bending [35]. A common feature of the above studies is the conclusion that neglecting element interaction provides an overly simplistic representation of the complex phenomenon of cross-section local buckling and generally leads to conservative buckling stress predictions. Different approaches to quantifying the restraint provided by the non-critical plates to the critical plates within a cross-section have been taken in the past. The introduction of rotational springs to the edges of the 4 critical plate to represent the restraint from the non-critical plates is common and intuitive, but determining values for the rotational spring stiffness, which will range between zero and infinity, is not straightforward across the range of considered structural profiles and loading conditions and is not practical for engineering applications. Similarly, the ratio of plate flexural rigidities can be used to relate the cross-section geometry to the elastic restraint provided to the critical plate [31, 36, 37]. Brune [40] used both of these concepts to develop a general method to account for element interaction by modifying the buckling coefficient k based on a spring stiffness calculated from the flexural rigidity of the adjacent plates. Alternatively, it is possible to define a restraint index that ranges from zero (simply-supported) to one (fixed) through simple algebraic manipulation [41], providing a more tangible indication of the level of element interaction. The previous studies into the effects of element interaction on the local buckling of structural crosssections described above have generally only considered the isolated loading cases of pure compression or pure bending, particularly for open sections. A comprehensive study into the local buckling of full structural cross-sections under combined axial load and bending moments has yet to be performed; hence, this is the focus of the present study. 3 Cross-section local buckling stress: Concept and data generation 3.1 Concept The underlying concept for the approach presented herein is that the elastic local buckling stress of a full cross-section σcr,cs is bound by the local buckling stresses of the isolated critical plates with simply-supported SS F σcr,p and fixed σcr,p boundary conditions along the adjoined edges. The lower bound is the minimum buckling SS SS stress of the constituent plates (i.e. flange σcr,f or web σcr,w ) considered in isolation with simply-supported boundary conditions along the adjoined edges, while the upper bound is the minimum buckling stress of the F F constituent plates (i.e. flange σcr,f or web σcr,w ) with fixed boundary conditions along the adjoined edges. These lower and upper bounds to the cross-section buckling stress relate typically, but not always, to the same critical plate. Where the buckling stress of the cross-section lies between these two bounds depends on the relative proportions of the constituent plate elements and hence the level of element interaction, which is expressed through the interaction coefficient ζ. Following the concept described above, the elastic local buckling stress of the full cross-section σcr,cs can be expressed in the general form given by Eq. (3). SS F SS σcr,cs = σcr,p + ζ(σcr,p − σcr,p ) 5 where 0≤ζ≤1 (3) :σ :σ σ s s s s s s >s Figure 1: Comparison between local buckling stresses of SHS 100×100×4 and RHS 100×50×4 under pure compression – element interaction arises when isolated plates (i.e. the flanges and webs) with simplysupported boundary conditions have differing local buckling stresses. No element interaction arises when the isolated cross-section plates buckle at the same critical stress and have the same local buckling half-wavelength. Two common such cases include square hollow sections and equal angles under pure compression, where all respective cross-section plates have the same geometry, edge boundary conditions and applied stress distribution. 3.1.1 Element interaction due to constituent plates having differing local buckling stresses Element interaction arises first and foremost when the individual plates that make up the cross-section are of different slenderness and therefore buckle locally at different critical stresses when considered in isolation. As a result, the adjoined longitudinal edges of the critical plate are not simply-supported, but receive rotational restraint from the adjacent elements. This effect is demonstrated in Fig. 1 where the local buckling response of an SHS and RHS under uniform compression is compared. Note that in both cross-sections, the critical web plate is identical. In the case of an SHS under pure compression, both the isolated flange and web plates SS SS with simply-supported boundary conditions have the same local buckling stress (i.e. σcr,f = σcr,w ) and half- wavelength. Thus, when combined to form a square hollow section, the buckling stress of the cross-section σcr,cs is identical to that of the isolated plates (assuming centreline dimensions are used). By reducing the width of the flange plate to form a rectangular hollow section, the non-critical flange plate now provides rotational restraint to the longitudinal edges of the critical web plate. As a result, the local buckling stress of the full cross-section increases beyond that of the critical plate due to element interaction. In general, differences in buckling stresses of isolated plates within cross-sections may arise due to varying geometry, boundary conditions and loading conditions. 6 3.1.2 Element interaction due to constituent plates having differing local buckling half-wavelengths Element interaction can also occur in cross-sections that contain plates with same local buckling stress when considered in isolation. This effect can be explained with reference to the local buckling half-wavelength Lb of the isolated plates. Fig. 2 shows two isolated plates that buckle locally at the same applied stress (i.e. SS SS σcr,f = σcr,w ), yet have different buckling half-wavelengths (Lb,f and Lb,w for the flange and web respectively) due to their geometry, boundary conditions and/or stress distribution. When the plates are joined to form a structural cross-section, compatibility of axial strains and rotations along the adjoined edges results in a single characteristic local buckling half-wavelength for the full cross-section Lb,cs . Hence, since the plates cannot deform into their preferred isolated mode shapes, the cross-section may be said to be ‘geometrically SS SS ). frustrated’ and an increased buckling stress results (i.e. σcr,cs is greater than both σcr,f and σcr,w σ σ σ σ σ σ (a) Isolated plates (b) Cross-section Figure 2: Effect of continuity of local buckling half-wavelength on element interaction. (a) Isolated flange SS SS and web plates buckling at the same critical stress (i.e. σcr,f = σcr,w ) but with different local buckling half-wavelengths; (b) full cross-section buckling locally with a single half-wavelength resulting in element interaction and an increased full cross-section local buckling stress. This effect is demonstrated with a numerical example in Fig. 3 where the response of the isolated plates forming an IPE 140 cross-section is compared to the full cross-section response under combined compression and major axis bending. The isolated outstand flange and internal web plates have the same local buckling stress of 2916 MPa when the stress distributions in the web and flange are ψw = −0.43 and ψf = 1.0, respectively. The corresponding local buckling half-wavelength of the web plate is 125 mm, while the halfwavelength for the simply-supported outstand flange is equal to the plate length. Due to the different local buckling half-wavelengths and the resulting element interaction, the full cross-section local buckling stress of an IPE 140 under the same applied stress distribution, determined numerically [42], increases to 3440 MPa, 7 y σ y σ s s s s s >s SS Figure 3: Comparison between local buckling stresses of isolated plates σcr,p forming an IPE 140 and the full cross-section σcr,cs under combined compression and major axis bending with a stress distribution of ψw = −0.43 in the web; element interaction arises when isolated plates with simply-supported boundary conditions have differing local buckling half-wavelength even though the local buckling stresses of the flanges SS SS and web are equal (i.e. σcr,f = σcr,w ). with a corresponding local buckling half-wavelength of 142 mm. 3.1.3 Interaction coefficient ζ The degree of element interaction (i.e. the level of restraint afforded to the critical plate by the surrounding plates) is quantified through the interaction coefficient ζ in Eq. (3). For the case of ζ = 0 (i.e. no element interaction), Eq. (3) reduces to the elastic buckling stress of the critical isolated plate with simply-supported boundary conditions, while ζ = 1 corresponds to the elastic buckling stress of the critical isolated plate with fixed boundary conditions. Note that the critical isolated plate (i.e. flange or web) is that with the minimum elastic local buckling stress relative to the maximum applied compressive stress, as expressed by Eq. (4) and Eq. (5) for the lower (i.e. simply-supported) and upper (i.e. fixed) bounds, respectively. The latter point (i.e. the applied stress level) is important when the flanges and web that make up the cross-section are not subjected to the same common maximum applied compressive stress – for example, in I-sections under combined compression and minor axis bending, the maximum compressive stress applied to the web σmax,w is lower than that at the flange tips σmax,f . Consequently the web is less susceptible to local buckling and, without an appropriate correction, the influence of the applied stress distribution is not adequately recognised when comparing the isolated plate buckling stresses calculated according to Eq. (1). Hence, to account for SS F SS F this effect, the isolated plate buckling stresses (i.e. σcr,f and σcr,f for the flange and σcr,w and σcr,w for the web) are factored by βf and βw , which are defined in Eq. (6) and Eq. (7). The factors βf and βw are the ratios of the maximum applied compressive stress in the cross-section σmax,cs , given by Eq. (8), to the maximum 8 applied compressive stress in the flange σmax,f or web σmax,w respectively. It follows that if βf > 1, then βw = 1 and if βw > 1, then βf = 1, and that both βf and βw must be greater than or equal to one. SS SS SS σcr,p = min βf σcr,f , βw σcr,w (4) F F F σcr,p = min βf σcr,f , βw σcr,w (5) βf = σmax,cs σmax,f (6) βw = σmax,cs σmax,w (7) σmax,cs = max(σmax,f , σmax,w ) (8) Note that in most common cases, such as I-sections under compression and/or major axis bending and SHS/RHS under all loading combinations, the maximum applied compressive stresses along the centreline of the flange and web plates are equal (i.e. σmax,f = σmax,w ). Hence both βf and βw are equal to 1.0, and Eqs. (4) and (5) are simplified. It should also be re-emphasised that when a cross-section consists of two different types of element (i.e. internal elements and outstand flanges), the lower and upper bound critical stresses are not necessarily defined by the same plate – see Eqs. (4) and (5) and Section 5, as well as the worked example shown in Section 6.2. The functions for determining the interaction coefficient ζ are developed herein based on the results of finite strip analyses, in which the full cross-section elastic local buckling stress σcr,cs for a comprehensive range of structural profiles has been obtained (see Section 3.2). Hence, using the lower and upper bound elastic local buckling stresses of the critical plates, it is possible to back-calculate the value of ζ by rearranging Eq. (3) to Eq. (9). ζ= 3.2 SS σcr,cs − σcr,p F SS σcr,p − σcr,p but 0≤ζ≤1 (9) Finite strip analysis The elastic local buckling stresses of 2328 cross-sections were obtained through finite strip analysis (FSA) using the finite strip software CUFSM v4.03 [42]. European and American SHS/RHS, I-, C-, T-, and L-shaped structural steel profiles were considered, including most cross-sections listed in the AISC section database [2]. Each cross-section was simplified to its centreline geometry and analysed under 17 combinations of axial compression plus bending about either the major or minor axis, yielding a total of over 95000 data points. When considering non axis-symmetric bending, the number of analysis points was increased to ensure 9 sufficient resolution of the results across the loading range. A summary of the considered profiles and the limiting normalised cross-section dimensions for which the developed functions were assessed are given in Table 1. Within the analyses, the individual plates that made up the cross-sections were discretised into 10 strips along their centreline geometry. As mentioned by Seif and Schafer [8], the centreline approximation is slightly conservative as the small beneficial effects of fillets, which provide additional restraint and reduce the critical plate width, are ignored. The unconstrained finite strip method was used to replicate the possible buckling modes that cross-sections can experience in practice, as adopted in [8]; note that this can result in cross-section buckling stresses that are marginally below the buckling stresses of the isolated plates with simply-supported boundary conditions along the adjoined edges, as seen for some angle sections in Tables 11 and 12, with predicted/CUFSM values greater than unity. A Young’s modulus E = 210000 MPa, a shear modulus G = 81000 MPa and a Poisson’s ratio ν = 0.3 were used throughout. The proposed functions for σcr,cs do however apply to cross-sections of all isotropic materials. The performed finite strip analyses (FSA) were elastic, but a yield stress fy = 355 MPa was used as a reference value, whereby the input stress distributions were defined relative to fy at the extreme compressive fibre. The critical local buckling stress at the extreme compressive fibre was thus equal to the product of the yield stress and the FSA eigenvalue. Note that the FSA assumed uniform loading through the thickness of an element. When inputting the centreline stresses, appropriate geometric corrections were made to account for the difference between the extreme fibre and centreline membrane, which is typically located at a distance of t/2 from the extreme fibre. The critical local buckling stress at the centreline membrane is thus slightly lower than the extreme fibre value and equal to the product of the applied centreline stress and the FSA eigenvalue. The local buckling eigenvalues were extracted from the so-called signature curve [43] obtained from the results of the finite strip analyses – see Fig. 4. The considered eigenvalues typically correspond to the load factor minima at a half-wavelength less than the maximum cross-section dimension [44]. However, cases existed where no distinct local buckling minimum was observed. In such cases there may either be a distinct cut-off point at which member buckling becomes dominant or a continuous transition from the local modes to global member buckling. Such behaviour was most prominent in angles and T-sections under combined axial compression and bending. In these cases, the elastic critical buckling stress was defined at the point of inflection on the signature curve or the distinct cut-off point prior to the commencement of the global modes, as shown in Fig. 4. It was found that almost all analysed cross-sections had back-calculated ζ values between 0 and 1, with less than 1% of the analysed cross-sections, typically of rather unusual proportions, falling marginally outside this range, confirming the validity of the underlying concept adopted herein. Some discrepancies to the 10 Table 1: Analysed cross-section profiles and range of normalised cross-section dimensions considered. Profile Sections analysed Number of sections Normalised dimension range SHS/RHS European: SHS, RHS American: HSS Welded sections (tf 6= tw ) 376 367 179 1.00 ≤ h tf tw b ≤ 6.25 I/H European: IPE, HEA, HEB, UKC, UKB American: W, M, S, HP 198 340 0.89 ≤ h tf tw b ≤ 6.36 C European: Parallel flange, UPN, UPE American: C, MC 61 72 0.80 ≤ h tf tw b ≤ 10.97 T European: Equal and unequal sided American: WT, MT, ST 134 315 0.44 ≤ h tf tw b ≤ 3.17 Angle European: Equal and unequal leg American: L 159 127 1.00 ≤ h b ≤ 2.00 Figure 4: Typical signature curves obtained from CUFSM and the corresponding extracted critical local buckling load factors at (a) a local minimum, (b) a point of inflection or (c) a distinct transition between local and global buckling. 11 𝜎 𝜓 𝜎 𝜎 𝜓 𝜎 ─ 𝜎 𝜓 𝜎 ─ Figure 5: Back-calculated buckling coefficients for I-sections under combined axial compression and major axis bending in which the web is the critical element. theoretical plate buckling stresses may arise from minimal mode interaction with member buckling. Fig. 5 shows representative results of the back-calculated web buckling coefficients k of I-sections under combined axial load and major axis bending. It can be seen that the back-calculated buckling coefficients k lie within the theoretical limits defined by the isolated plates with simply-supported and fixed boundary conditions and that depending on the cross-section geometry, the level of element interaction can vary significantly for a given stress distribution. The back-calculated buckling coefficient k is shown so that all considered cross-sections can be compared in a single figure. In Fig. 5, a stress distribution of ψw = 1 corresponds to pure compression in the web, while ψw = −1 corresponds to pure bending in the web, as defined by Eq. (2). It should be emphasised that when comparing the FSA results to theoretical plate buckling limits, the centreline plate dimensions need to be used [8], as opposed to the flat plate widths used for the classification of cross-sections in AISC 360-16 [2] and EN 1993-1-1 [1]. 4 Formulae for determining full cross-section elastic local buckling stresses 4.1 Introduction In this section, expressions for determining the full cross-section local buckling stress of steel profiles subjected to compression, bending and combined compression and bending are presented. The calculation is based on 12 Eq. (3), which requires (i) the local buckling stresses of the isolated plates that make up the cross-section with simply-supported and fixed boundary conditions and (ii) the interaction coefficient ζ. The input requirements are the elastic material properties, the cross-section geometry and the loading conditions. The parameter φ is introduced in Eq. (10) and defines the relative susceptibility of the flange and web to local buckling at the simply-supported lower bound. As explained in Section 3.1, the factors βf and βw are used to account for any differences in maximum applied compressive stresses between the flange and web plates, though in most cases (e.g. pure compression, major axis bending as well as combined compression plus major axis bending of SHS/RHS, I-, T- and channel sections) the maximum applied compressive stresses in the centreline model are common to both the web and flange; in these cases βf = βw = 1 and Eq. (10) simplifies to Eq. (11). SS βf σcr,f φ= = SS βw σcr,w φ= SS σcr,f SS σcr,w SS σcr,f SS σcr,w ! σmax,w σmax,f if σmax,f = σmax,w (10) (11) The proposed expressions for the interaction coefficient ζ feature φ as a governing term since the relative susceptibility of the flange and web plates to local buckling has a strong bearing on the resulting level of SS SS element interaction. Note that in cross-sections with more than one outstand flange or web, σcr,f and σcr,w are based on the critical (typically the most heavily compressed) plate. The proposed expressions are divided into flange-critical (i.e. φ < 1) and web-critical (i.e. φ ≥ 1) cases. When φ = 1, the isolated flange and SS SS web plates with simply-supported boundary conditions buckle at the same stress (i.e. σcr,f = σcr,w ). In this region (i.e. φ ≈ 1), the level of element interaction is at its minimum and the full cross-section local buckling stress σcr,cs is closest to, but not necessarily equal to, its lower bound, being that of the isolated critical SS SS plate with simply-supported boundary conditions σcr,p . The reason for σcr,cs often remaining above σcr,p at φ = 1 is explained with reference to the requirement for wavelength continuity described in Section 2.2. As the difference between the local buckling stresses of the isolated plates increases (i.e. as φ reduces in flangecritical cases and as φ increases in web-critical cases), the level of element interaction logically increases as the non-critical plate provides greater restraint to the critical plate. In cases where the flanges or web are purely in tension, φ should be assigned a value of infinity or zero respectively; an example of this includes channel sections under minor axis bending with the flange tips in compression and the web in pure tension. The suitability of using φ as a governing parameter in the prediction of ζ is shown in Figs. 6 to 9, which show a clear relationship between the level of element interaction (i.e. ζ) and the ratio φ for all analysed SHS, RHS and I-sections subjected to combined compression and major axis bending. However, it can also 13 be seen in Fig. 6(a) that there is significant scatter in the back-calculated interaction coefficients for webcritical SHS and RHS, indicating that the rotational restraint provided by the non-critical plate (i.e. ζ) is also dependent on other parameters. By multiplying the back-calculated values of ζ by the ratio of the web to flange thickness, the scatter is significantly reduced and functions of φ can be used to express the level of element interaction in all analysed cross-sections, as shown in Fig. 6(b) for the cases of h/b = 1 and h/b = 2. For the special case of hot-rolled SHS under pure compression, no element interaction occurs (i.e. ζ = 0) at φ = 1. The equivalent behaviour for flange critical SHS and RHS is shown in Fig. 7, where the inverse geometric ratio (i.e. tf /tw ) may be seen to reduce the scatter of the results. Analogous plots for I-sections subjected to combined compression and major axis bending are shown in Figs. 8 and 9; note that for these sections, as explained in Section 4.3, the minimum values of the interaction coefficient ζ occur at φ ≈ 0.6 and hence only the data points relevant to the plotted functions are shown in each respective plot. In principle, back-calculated interaction coefficients ζ as high as unity are possible, but in practice, for the range of typical cross-sections considered herein, the values of ζ were in the range 0 ≤ ζ ≤ 0.5 for the analysed hot-rolled SHS and RHS (tf = tw ) subjected to combined compression and major axis bending. Similarly, for the analysed I-sections subjected to combined compression and major axis bending the interaction coefficient ζ was found to be in the range of 0.1 ≤ ζ ≤ 0.9. The above-described behaviour for SHS and RHS was typical of all the examined cross-sections and, as discussed further in Section 4.3, the expressions for ζ developed herein are based primarily on φ, but often also feature other geometric or loading based parameters to achieve improved prediction accuracy. z ≠ z f z ─ z f ─ f f (a) Back-calculated ζ versus φ (b) Back-calculated ζ tw versus φ tf Figure 6: Illustration of developed ζ functions for web critical (i.e. φ ≥ 1) SHS and RHS subjected to combined compression and major axis bending: (a) scatter in back-calculated interaction coefficients ζ and (b) reduced scatter and proposed functions (for h/b = 1 and h/b = 2) incorporating the geometric factor tw /tf . 14 f) ─ z z z z f) ─ ≠ f f (a) Back-calculated ζ versus φ (b) Back-calculated ζ tf versus φ tw z Figure 7: Illustration of developed ζ functions for flange critical (i.e. φ < 1) SHS and RHS subjected to combined compression and major axis bending: (a) scatter in back-calculated interaction coefficients ζ and (b) reduced scatter and proposed functions (for h/b = 1 and h/b = 2) incorporating the geometric factor tf /tw . z f f≥1 z ─ z f f f<1 f (a) Back-calculated ζ versus φ (b) Back-calculated ζ tw versus φ tf Figure 8: Illustration of developed ζ functions for I-sections with φ greater than ≈ 0.6 subjected to combined compression and major axis bending: (a) scatter in back-calculated interaction coefficients ζ and (b) reduced scatter and proposed functions incorporating the geometric factor tw /tf . 15 z z z f f f (a) Back-calculated ζ versus φ (b) Back-calculated ζ tf versus φ tw Figure 9: Illustration of developed ζ functions for I-sections with φ less than ≈ 0.6 subjected to combined compression and major axis bending: (a) scatter in back-calculated interaction coefficients ζ and (b) reduced scatter and proposed function incorporating the geometric factor tf /tw . 4.2 Lower and upper bound elastic buckling stresses of isolated critical plates Following the concept adopted herein, the local buckling stress of the full cross-section requires knowledge of, and indeed lies between, the lower and upper bound elastic buckling stresses of the isolated critical plates within the cross-section – i.e. the elastic buckling stresses of the critical plates with simply-supported and fixed boundary conditions along the edges that adjoin to other plates within the cross-section. Formulae for determining these lower and upper bound elastic buckling stresses for internal elements and outstand flanges are considered in this sub-section. 4.2.1 4.2.1.1 Lower bound – simply-supported boundary conditions along adjoined edges Internal elements with both longitudinal edges simply-supported Buckling coefficients for internal plate elements with both longitudinal edges simply-supported are provided EN 1993-1-5 [18] as a function of the applied stress distribution ψ. These expressions are summarised in the upper part of Table 2. As shown in Fig. 10, the numerical results obtained from finite strip analyses performed herein on isolated plates with simply-supported edges match the Eurocode 3 expressions well. 4.2.1.2 Outstand flanges with one longitudinal edge simply-supported and the other free Buckling coefficients for outstand flanges with one longitudinal edge simply-supported and the other free are given in EN 1993-1-5 and are summarised in the lower part of Table 2. As shown in Fig. 11, the numerical results obtained from finite strip analyses performed herein on isolated plates with one edge simply-supported 16 and one edge free accurately match the Eurocode 3 expressions for cases where the free end is in compression. For the case of an outstand flange subjected to a linear stress gradient with the flange tip in tension, EN 1993-1-5 only provides expressions for determining the buckling coefficient for stress distributions in the range of −1 ≤ ψ ≤ 1. This covers the majority of practical cases for the critical plate, but since the governing ratio φ also requires the determination of the buckling stress of the non-critical plate, some cases, such as channel sections subjected to minor axis bending with the web in compression, may lie outside the scope of the current EN 1993-1-5 provisions. An extension is therefore proposed to cover the range from −3 ≤ ψ < −1. As shown in Fig. 12, a parabola is fitted to the back-calculated buckling coefficients obtained from the results of the finite strip analyses. The extended function intersects the current EN 1993-1-5 function at ψ = −1. The proposed function, shown in Fig. 12, provides a practical and conservative approximation for the buckling coefficient of an outstand plate and is compatible with the existing Eurocode 3 expressions. Table 2: EN 1993-1-5 and proposed expressions for the buckling coefficient k for internal and outstand plates with simply-supported boundary conditions along adjoined edges. (SS - SS) σ1 (SS - free) Outstand plates Internal plates Stress distributiona σ1 σ2 ψ = σ2 /σ1 1 σ2 1>ψ>0 0 σ2 σ1 0 > ψ > −1 k = 0.43 0 k = 0.57 -1 k = 0.85 1>ψ>0 0 > ψ > −1 σ2 -1 −1 > ψ ≥ −3 a b k = 9.78ψ 2 − 6.29ψ + 7.81 1 0 σ1 8.2 1.05 + ψ k = 7.81 k= k = 23.9 1 σ2 k=4 -1 1 > ψ ≥ −3 σ1 Buckling coefficient Compression taken as positive (shaded grey). Proposed extension to EN 1993-1-5. 17 k = 0.07ψ 2 − 0.21ψ + 0.57 k = 0.43 0.578 k= 0.34 + ψ k = 1.70 k = 17.1ψ 2 − 5ψ + 1.7 k = 23.8 k b = 5.78ψ 2 − 12.8ψ + 5.22 4.2.2 Upper bound – fixed boundary conditions along adjoined edges 4.2.2.1 Internal elements with both longitudinal edges fixed For the upper bound case of fixed boundary conditions along the adjoined plate edges, expressions for determining the buckling coefficient k are not provided in EN 1993-1-5 [18]. Equivalent expressions to those presented in Table 2 are therefore developed herein. The expressions are calibrated from back-calculated buckling coefficients obtained from finite strip analyses of isolated plates, as described in Section 3.2. For internal elements with both longitudinal edges fixed, the generated finite strip data and developed expressions for determining the buckling coefficient k are illustrated in Fig. 10. The expressions take a similar form to the existing Eurocode 3 expressions for simply-supported boundary conditions and are presented in the upper part of Table 3. 4.2.2.2 Outstand flanges with one longitudinal edge fixed and the other free The same approach was carried out for outstand flanges with fixed boundary conditions along the adjoined plate edge and free boundary conditions along the flange tip. The generated finite strip data and developed expressions for determining the buckling coefficient k are illustrated in Figs. 11 and 12 for the cases of the flange tip in compression and tension respectively, while the expressions are presented in the lower part of Table 3. The proposed expressions accurately predict the numerical results. Similar to simply-supported outstand plates, a single parabola is found to be slightly conservative in the range of −1 ≤ ψ ≤ 0, where the stiffening behaviour of the tensioned flange tip is not fully captured. 4.3 Formulae for determining full cross-section local buckling stress σcr,cs The developed formulae for determining the interaction coefficient ζ, required for the calculation of the full cross-section local buckling stresses of square hollow sections, rectangular hollow sections, I-sections, channel sections, tee sections and angle sections, are presented in Tables 5 to 9. For each cross-section profile, the functions are subdivided into combined compression and major or minor axis bending. For each load case, an expression is provided for flange and web critical cases (φ < 1 and φ ≥ 1, respectively). For each cross-section profile, the flange and web definitions are independent of the loading axis and are given in Table 4. In conjunction with the lower and upper bound elastic buckling stresses of the critical plate with simply-supported and fixed boundary conditions (described in Section 4.2), the full cross-section elastic local buckling stress is calculated according to Eq. (3). The functions presented in Tables 5 to 9 require minimal input parameters (only the section geometry, elastic material properties and the applied stress distribution) and can be easily coded into software packages. 18 Table 3: Proposed expressions for the buckling coefficient k for internal and outstand plates with fixed boundary conditions along adjoined edges. (Fixed - Fixed) (Fixed - free) Outstand plates Internal plates Stress distributiona 1 σ1 σ2 1≥ψ≥0 0 σ1 σ2 σ1 σ2 0 > ψ > −1 σ2 σ2 k = 6.97 14.29 k= 1.05 + ψ k = 13.6 k = 14.5ψ 2 − 11.5ψ + 13.6 k = 39.6 1 k = 1.25 0 k = 1.62 -1 k = 2.13 1 σ1 Buckling coefficient -1 1 > ψ ≥ −1 σ1 a ψ = σ2 /σ1 k = 0.07ψ 2 − 0.44ψ + 1.62 0 k = 1.25 1.58 k= 0.263 + ψ k = 6.01 -1 k = 37.3 1>ψ>0 0 > ψ ≥ −3 k = 9.8ψ 2 − 21.5ψ + 6 Compression taken as positive (shaded grey). σ1 σ2 Figure 10: Buckling coefficient k for internal plates with simply-supported and fixed boundary conditions along the adjoined edges. 19 σ1 σ2 Figure 11: Buckling coefficient k for outstand plates with simply-supported and fixed boundary conditions along the adjoined edges and maximum compression at the flange tip. σ1 σ2 Figure 12: Buckling coefficient k for outstand plates with simply-supported and fixed boundary conditions along the adjoined edges and maximum compression at the supported edge. Table 4: Definitions of flange (f) and web (w) plates for each cross-section profile, irrespective of loading case. Section SHS/RHS I/H Channel Flange (f) Web (w) 20 Tee Angle The functions for ζ have been defined such that the following continuity requirements are met: (1) functions of different load cases for the same cross-section profile are continuous at the point of pure compression; and (2) the flange critical and web critical expressions for a given load case are continuous at φ = 1. While φ is the driving parameter in the prediction of ζ, where necessary, loading or geometry dependent terms were introduced to improve the accuracy of the proposed functions. Upper limits are included in Tables 5 to 9 on some of the expressions for ζ to avoid excessive over-predictions, particularly for unusually shaped sections. The proposed functions for the interaction coefficient ζ are centred at φ = 1. The flange critical ζ functions increase as φ approaches zero, reflecting the increasing level of element interaction (i.e. higher ζ values) for reducing φ values. The reverse applies to the web critical functions, which generally relate ζ to a (1 − 1/φ) style term to ensure a defined upper limit for high φ values and increasing levels of element interaction (i.e. higher ζ values) for increasing φ values. SS For I-sections subjected to combined compression and major axis bending, although the ratio σcr,cs /σcr,p is lowest at φ = 1, it was found that the lowest interaction coefficient ζ actually occurs at φ ≈ 0.6. The difference to the expected minimum at φ = 1 is explained by the fact that there is a region between approximately 0.6 ≤ φ ≤ 1 where the upper bound limit for the cross-section local buckling stress is defined by the web, even though the lower bound is defined by the flange plate. Hence, since the interaction coefficient ζ also depends on the upper bound limit, which tends to increases at a higher rate than the full cross-section local buckling stress in this transition region, the minimum value of ζ is shifted to the point where the local buckling stresses of the isolated flange and web plates with fixed boundary conditions are approximately F F equal (i.e. σcr,f ≈ σcr,w ). This effect is accounted for in the proposed functions through the use of a bilinear approximation for the interaction coefficient ζ in flange critical cases for I- and H-sections, whereby ζ is related to a (1 − φ) dependent term (see Section 3.1) but limited by a φ dependent term, thereby shifting the minimum value of ζ to approximately φ = 0.6, with the exact value depending on the cross-section geometry. 21 Table 5: Interaction coefficient ζ for square and rectangular hollow sections. Section Geometrya SHS/RHS σ σ Load case Flange critical (φ < 1) Compression and major axis bending ζ= σ tw 0.6 (0.24 − af φ) tf 1 " # 2 0.6 tf h af = 0.24 − 0.1 −1 tw b Web critical (φ ≥ 1) tf aw ζ= 0.53 − tw φ aw = 0.63 − 0.1 but af ≤ 0.24 but aw ≤ 0.53 N/Ab ζ= h b σ 22 σ Compression and minor axis bending σ σ tf tw aw φ h aw = 0.63 − 0.1 b but aw ≤ 0.53 0.53 − σ a Compression is positive and shaded grey. For hot-rolled SHS/RHS with tf = tw , and for welded SHS and RHS with tf ≥ tw , the flange is never critical under compression and minor axis bending loading cases. b Table 6: Interaction coefficient ζ for I- and H-sections. Section Geometrya (only for tf ≥ tw ) I/H σ σ Load case Flange critical (φ < 1) Compression and major axis bending ζ = 0.15 Compression and minor axis bending ζ = af tf tw φ≥ (0.4 − 0.25φ) tw tf Web critical (φ ≥ 1) tf 0.3 ζ= 0.45 − 2 tw φ σ σ 23 σ σ σ af = 0.9 − 0.75ψf ≤ 0.35 af1 = 1 − 0.6ψf ≤ 0.7 σ σ2,f = stress in web a tf tw φ≥ (af1 − 0.25φ) tw tf Compression is positive and shaded grey. ζ= tf tw 0.45 − aw φ2 aw = 0.8ψf − 0.5 ≥ 0.1 Table 7: Interaction coefficient ζ for channel sections. Section Geometrya (only for tf ≥ tw ) Load case Flange critical (φ < 1) Channel (C-) σ Compression and major axis bending ζ = 0.05 σ tf tw (1 + φ) ≥ 0.5 (1 − φ) tw tf Web critical (φ ≥ 1) tf 0.3 ζ= 0.4 − 2 tw φ σ σ 24 σ σ σ Compression and minor axis bending (σ2,f at flange tip) tf tw ζ = 0.05 (1 + φ) ≥ 0.5 (1 − φ) tw tf tf ζ= tw tf tw 0.3 0.4 − 2 φ 0.3 φ2 σ σ σ σ a σ Compression is positive and shaded grey. Compression and minor axis bending (σ2,f at web) ζ = 0.05 tf tw (1 + φ) ≥ 0.5 (1 − φ) tw tf ζ= 0.4 − Table 8: Interaction coefficient ζ for T-sections. Section Geometrya Tee (T-) Load caseb σ σ σ Compression and bending perpendicular to web (stem) – σ2,w at web tip Flange critical (φ < 1) h 1.16 ζ= − 0.58 b 1 + φ0.28 Web critical (φ ≥ 1) tf 1 ζ = aw 1− tw φ aw = 0.35 + 0.1ψw ≥ 0.35 σ σ σ σ ζ=0 Compression and bending parallel to web (stem) ζ = 0.34 1 1− φ 25 Compression and bending perpendicular to web (stem) – σ2,w at flanges tf ζ = 0.45 tw σ σ σ σ tf (1 − ψf ) ≤ 0.3 tw tf aw 0.45 − ≤ 0.3φ tw φ aw = 0.11 + 0.34ψf ≥ 0.15 ζ= σ σ2,f = stress in web (stem) a b Compression is positive and shaded grey. Orientation of major/minor axis bending depends on section geometry. Load cases based on stress distribution in web (stem) and flange respectively. Table 9: Interaction coefficient ζ for equal and unequal angle sections. Geometrya Section σ Angles Load case Flange critical (φ < 1) Compression and major axis bending – σ2,w at web tip ζ= h 1 (1 − φ) b (2.4 + ψf ) Web critical (φ ≥ 1) b 2 1 ζ= 1− h (4.3 + ψw ) φ σ σ σ σ Compression and major axis bending – σ2,w at corner ζ=0 b 2 ζ= h (4.3 + ψw ) Compression and minor axis bending – σ2,f at flange tip ζ= 1 b 2.65 h ζ=0 Compression and minor axis bending – σ2,f at corner ζ= 1 b 2.65 h ζ= 1 1− φ σ σ 26 σ 1 φ 1− 1 φ 1− σ σ σ σ σ σ σ a σ Compression is positive and shaded grey. 1− b h (1 − φ) Table 10: Summary of simplified expressions for φ and interaction coefficient ζ for SHS, RHS and I-/H-sections subjected to pure compression or pure major axis bending. Section Load case φ ζ – flange critical (φ < 1) ζ – web critical (φ ≥ 1) SHS Compression 1 0 0 Major axis bending 0.167 0.381 N/A RHS Compression Major axis bending h−t b−t 2 0.167 (0.24 − af φ) h−t b−t I/H Compression Major axis bending 4.4 0.108 0.018 0.6 1/0.6 h af = 0.24 − 0.1 −1 b but af ≤ 0.24 2 2tf h − tf b tw 2 2tf h − tf b tw 2 0.15 tf tw φ ≥ (0.4 − 0.25φ) tw tf 0.53 − aw φ h aw = 0.63 − 0.1 b but aw ≤ 0.53 tf tw 0.3 0.45 − 2 φ Simplified σcr,cs formulae for common cases The functions presented in Tables 5 to 9 are given in general form to cover all load cases from pure compression to pure major or minor axis bending. However, for common cases, such as I- and H-sections, as well as hotrolled SHS and RHS with constant thickness t, in pure compression or pure major axis bending, the functions can be simplified by substituting in the known parameters; the resulting simplified functions for φ and ζ are given in Table 10. 4.5 Extension to combined compression and bi-axial bending For compression and bi-axial bending, it is proposed to use Eqs. (3) to (8), together with the expressions for ζ in Tables 5 to 9, but with the following modification: to account for the effects of bi-axial bending, the interaction coefficient ζ may be calculated by conservatively assuming that the non-critical plate restraining the critical plate is subjected to pure compression of magnitude equal to the maximum stress across the plate width (i.e σcomp + σmajor + σminor for the case shown in Fig. 13, where σcomp is the uniform applied compressive stress, σmajor is the maximum major axis bending stress and σminor is the maximum minor axis bending stress). The elastic buckling stresses of the isolated plates continue to be calculated using the applied stress distribution under combined compression and bi-axial bending using the buckling coefficients provided in Tables 2 and 3 for simply-supported and fixed boundary conditions, respectively. This approximation for bi-axial bending is conservative since the level of restraint provided by the non-critical plate is under- 27 σ σ σ σ σ σ σ σ σ σ z Figure 13: Extension of concept to cross-sections under combined compression and bi-axial bending; the case where the web is critical and hence the N + My formulae are used in the calculation of ζ is shown. estimated by assuming in the calculation of ζ that it is under the most severe loading condition of uniform compression. This concept is illustrated in Fig. 13 and in a worked example given in Section 6.4. 5 Evaluation of developed formulae In this section, the full cross-section elastic local buckling stresses determined based on the proposed expressions are compared against the results of finite strip analysis (FSA) and the elastic buckling stress of the isolated critical plate from within the cross-section (i.e. mirroring the approach traditionally adopted for cross-section classification). The comparisons are shown in the form of probability distributions for the different cross-section types under compression plus major axis bending (Table 11) and compression plus minor axis bending (Table 12). Numerical comparisons for all cases are shown in Table 13. Values in Tables 11 to 13 less than 1.0 indicate conservative results, while lower coefficients of variation (CoV) indicate higher accuracy in the prediction of the finite strip results. Overall, the proposed functions may be seen to be very accurate. The mean full cross-section local buckling stress prediction is 0.962 of the finite strip results with a CoV of 0.076, compared to a mean prediction of 0.686 with a CoV of 0.167 when neglecting element interaction, as currently done in Eurocode 3. Particularly for SHS/RHS and I-sections under combined compression and major axis bending the improvements are significant for practical applications, with an average benefit of around 20% for SHS/RHS and 40% for I-/H28 sections over the isolated plate predictions and a reduction in CoV from around 0.100 to 0.040. For some cases, the benefits are even greater; for I-sections under minor axis bending the average benefit of considering element interaction in the prediction of σcr,cs is around 60%, while for T-sections the benefit increases to around 100%. While providing significant improvements over traditional approaches, the proposed functions are also reliable, with fewer than 1% of the analysed cases being over-predicted by more than 10%, and generally only cross-sections with unusual geometries fall into this category. The significant scatter in the isolated plate predictions underline the fact that the response of the wide range of considered cross-section types and loading conditions cannot be adequately covered without accounting for the effects of element interaction. Note that the proposed functions have been developed and validated based on the results of finite strip analyses performed on a comprehensive database of cross-sections (see Table 1) and applying the proposed expressions to cross-sections of proportions outside the analysed range requires further investigation. The local buckling response of representative cross-sections, an IPE 140 and a RHS 400×200×8, under combined axial compression and major axis bending are shown in Fig. 14. The lower and upper bound limits based on the critical isolated plates create an envelope around the cross-section response, while the proposed functions provide an accurate prediction of the full cross-section local buckling stress across the considered loading scenarios, ranging from pure compression to pure bending. The level of element interaction may be seen to be at its lowest at the point where φ = 1. However, even at this minimum point, the level of element interaction is not insignificant; in the case of the IPE 140 cross-section, for example, an increase in the local buckling stress of the cross-section over that of the isolated plates with simply-supported edge conditions of 15% arises at φ = 1. (a) IPE 140 response (b) RHS 400×200×8 response Figure 14: Cross-section elastic local buckling stresses based on centreline dimensions across a range of loading conditions from pure compression to pure major axis bending for (a) an IPE 140 and (b) a RHS 400×200×8. 29 Table 11: Probability distributions for predicted full cross-section and isolated plate elastic buckling stresses versus FSA results for combined compression and major axis bending. Section Combined compression and major axis bending SHS/RHS I/H C T Web (stem) in bending – σ2,w at web tip Web (stem) in bending – σ2,w at flanges L Major – σ2,w at web tip Major – σ2,w at corner Legend: Full cross-section using proposed functions. 30 Isolated critical plate. Table 12: Probability distributions for predicted full cross-section and isolated plate elastic buckling stresses versus FSA results for combined compression and minor axis bending. Section Combined compression and minor axis bending SHS/RHS I/H C Minor (σ2,f at flange tip) T Flange bending L Minor – σ2,f at flange tip Legend: Minor (σ2,f at web) Minor – σ2,f at corner Full cross-section using proposed functions. 31 Isolated critical plate. Table 13: Assessment of accuracy of elastic critical buckling stress predictions using proposed functions and the isolated plate assumption (EC3) versus the numerical (CUFSM) results. Section SHS/RHS I-sections Channels T-sections Angles Functions / CUFSM EC3 / CUFSM Mean CoV >10% (%) Mean CoV Mean N + My 0.996 0.037 1.05 0.808 0.103 1.245 N + Mz 0.996 0.036 1.12 0.724 0.075 1.384 N + My 0.975 0.038 0.24 0.693 0.112 1.421 N + Mz 0.949 0.064 0.82 0.605 0.138 1.590 N + My 0.949 0.061 1.58 0.711 0.126 1.353 N + Mz (σ2,f at flange tip) 0.975 0.047 1.70 0.685 0.098 1.433 Load case N + Mz (σ2,f at web) 0.987 0.053 2.28 0.698 0.142 1.437 N + My (σ2,w at stem tip) 0.908 0.107 0.52 0.635 0.234 1.505 N + My (σ2,w at flanges) 0.928 0.080 0.50 0.456 0.215 2.094 N + Mz 0.904 0.115 0.57 0.490 0.231 1.915 N + My (σ2,w at web tip) 0.952 0.065 0.00 0.658 0.270 1.529 N + My (σ2,w at corner) 0.984 0.053 0.00 0.671 0.212 1.518 N + Mz (σ2,f at flange tip) 0.957 0.283 4.56 0.848 0.283 1.156 N + Mz (σ2,f at corner) 1.003 0.023 0.00 0.942 0.095 1.070 0.962 0.096 0.90 0.690 0.241 1.475 Average 6 6.1 Functions / EC3 Summary of proposals and worked examples Summary of proposals A summary of the proposed concept and the calculation steps required to determine the full cross-section local buckling stress σcr,cs is given in Table 14. Note that the adopted functions and required calculations are straightforward and explicit, lending themselves to programming and tabulation. The three worked examples below illustrate how the presented functions in Tables 5 to 9 are used as an alternative to numerical methods to determine the full cross-section local buckling stress for the following cases: (1) an I-section subjected to combined compression and major axis bending, (2) an I-section subjected to combined compression and minor axis bending and a (3) RHS subjected to combined compression and bi-axial bending. These examples have been chosen to highlight the different aspects that must be considered when applying the proposed functions, including the effect of the β factors (given by Eqs. (6) and (7)) and the extension to bi-axial bending. Note that for all worked examples, the section geometry of the centreline cross-sections has been used (i.e. the effects of fillets and corner radii are ignored). 32 Table 14: Overview of proposed method to determine the full cross-section elastic buckling stress σcr,cs . Step 1 Establish the stress distributions ψw and ψf along the centreline dimensions of the web and flange plates. 2 Determine the buckling coefficients k for the isolated flange and web plates with simplysupported and fixed boundary conditions from Tables 2 and 3. 3 SS F SS Calculate the elastic buckling stresses of the isolated web (σcr,w and σcr,w ) and flange (σcr,f F and σcr,f ) with simply-supported and fixed boundary conditions from Eq. (1). 4 If required, determine load correction βw from Eqs. (6) and (7). factors βf and SS SS SS and upper Determine the lower σcr,p = min βf σcr,f , βw σcr,w F F F σcr,p = min βf σcr,f , βw σcr,w bounds to the full cross-section local buckling stress. SS βf σcr,f Calculate φ = and determine which plate is critical: flange is critical when φ < 1; SS βw σcr,w web is critical when φ ≥ 1. 5 6 6.2 Description 7 Determine the interaction coefficient ζ which ranges between 0 and 1 from Tables 5 to 9. 8 SS F SS ). − σcr,p + ζ(σcr,p Calculate the full cross-section local buckling stress from σcr,cs = σcr,p Worked example 1: I-section under combined axial compression and major axis bending An IPE 180 cross-section in S355 steel with E=210000 MPa and ν=0.3 is subjected to combined axial compression NEd = 99.1 kN and major axis bending moment My,Ed = 44.1 kNm as shown in Fig. 15. Determine the full cross-section local buckling stress σcr,cs . s s y s × y ─ s Figure 15: Worked example 1: IPE 180 cross-section under combined compression and major axis bending. Firstly, determine the stress distribution ψw in the web of the cross-section. Note that the centreline fibre 33 of the cross-section is located a distance of (90 − 4) = 86 mm from the major axis and that compression is taken as positive. σ1,w = σ2,w = NEd My,Ed z 99.1 × 103 44.1 × 106 × (90 − 4) = 341 MPa + = + A Iy 2325 1.272 × 107 (12) NEd My,Ed z 99.1 × 103 44.1 × 106 × (90 − 4) = −256 MPa − = − A Iy 2325 1.272 × 107 (13) The corresponding extreme fibre stresses are 355 MPa and -270 MPa. Using the centreline stresses: ∴ ψw = σ2,w −256 = = −0.75 σ1,w 341 (14) Since no minor axis bending is present, σ1,f = σ2,f and ψf = 1.0. Then calculate the elastic buckling stresses of the isolated web and flange plates (use centreline geometry) with simply-supported and fixed boundary conditions. Note that βf = 1.0 and βw = 1.0 since the maximum compressive stress in the flange and web are the same. The buckling coefficients k are obtained from Tables 2 and 3. For the flange (ψf = 1.0), kfSS = 0.43 and kfF = 1.25. Hence: 210000π 2 12(1 − 0.32 ) 210000π 2 = 1.25 12(1 − 0.32 ) SS σcr,f = 0.43 F σcr,f 8 45.5 2 8 45.5 2 = 2523 MPa (15) = 7334 MPa (16) F SS = 30.38. Hence: = 18.03 and kw For the web (ψw = −0.75), kw 210000π 2 12(1 − 0.32 ) 210000π 2 = 30.38 12(1 − 0.32 ) SS σcr,w = 18.03 F σcr,w 5.3 172 2 5.3 172 2 = 3249 MPa (17) = 5475 MPa (18) Hence: φ= 2523 = 0.777 3249 ∴ Flange is critical since φ < 1 The interaction coefficient ζ for I-sections with the flange being critical is: 34 (19) ζ = 0.15 tf tw φ≥ (0.4 − 0.25φ) tw tf = 0.15 × 8/5.3 × 0.777 = 0.176 (but ≥ 5.3/8(0.4 − 0.25 × 0.777)) (20) (but ≥ 0.136) = 0.176 Finally: σcr,cs = 2523 + 0.176 (5475 − 2523) = 3043 MPa (21) F F Note that in this case the upper bound limit is given by the web plate (i.e. σcr,w < σcr,f ). For comparison, the finite strip analysis result from CUFSM is 3054 MPa, only 0.4% higher than the predicted value using the formulae developed herein. The elastic local buckling stress of the isolated critical plate with simplysupported boundary conditions is 2523 MPa. This corresponds to a 20.6% increase in local buckling stress by allowing for the effects of element interaction. 6.3 Worked example 2: I-section under combined compression and minor axis bending An IPE 550 cross-section in S355 steel with E=210000 MPa and ν=0.3 is subjected to combined axial compression NEd = 2528 kN and minor axis bending moment Mz,Ed = 50 kNm as shown in Fig. 16. Determine the full cross-section local buckling stress σcr,cs . s s y s × y s Figure 16: Worked example 2: IPE 550 cross-section under combined compression and minor axis bending. Firstly, determine the stress distribution ψf in the most heavily loaded outstand flange of the cross-section. For minor axis bending, the centreline fibres are located at the tip of the flange and at the centreline of the 35 web. σ1,f = NEd Mz,Ed y 2528 × 103 50 × 106 × 105 = 392.6 MPa + + = A Iz 12947 2.661 × 107 (22) NEd Mz,Ed y 2528 × 103 50 × 106 × 0 = 195.3 MPa − = − A Iz 12947 2.661 × 107 (23) σ2,f 195.3 = 0.5 = σ1,f 392.6 (24) σ2,f = ∴ ψf = No major axis bending is present, hence σ1,w = σ2,w and ψw = 1.0. Since σmax,f > σmax,w , the difference in the maximum applied compressive stresses in the flange and the web must be accounted for. βw = 1 =2 0.5 (25) Note that βf = 1 since the maximum compressive stress applied to the cross-section is at the flange tip. Next, calculate the elastic buckling stresses of the isolated web and flange plates (using the centreline geometry), factored to account for difference in the maximum applied compressive stress. The buckling coefficients k are obtained from Tables 2 and 3. For the flange (ψf = 0.5), kfSS = 0.483 and kfF = 1.418. Hence: 210000π 2 12(1 − 0.32 ) 210000π 2 = 1.0 × 1.418 12(1 − 0.32 ) SS βf σcr,f = 1.0 × 0.483 F βf σcr,f 17.2 105 2 17.2 105 2 = 2460 MPa (26) = 7222 MPa (27) = 659 MPa (28) = 1148 MPa (29) F SS = 6.97. Hence: = 4.0 and kw For the flange (ψw = 1.0), kw SS βw σcr,w 210000π 2 = 2.0 × 4.0 12(1 − 0.32 ) 210000π 2 12(1 − 0.32 ) F βw σcr,w = 2.0 × 6.97 11.1 532.8 2 11.1 532.8 2 Hence: φ= 2460 = 3.733 659 ∴ Web is critical since φ ≥ 1 The interaction coefficient ζ for I-sections with the web critical is: 36 (30) tf aw ζ= 0.45 − 2 tw φ 17.2 0.1 = 0.45 − 11.1 3.7332 where aw = 0.8ψf − 0.5 = 0.686 (but ≥ 0.1) (31) = 0.8 × 0.5 − 0.5 ≥ 0.1 = 0.1 Finally: σcr,cs = 659 + 0.686 (1148 − 659) = 995 MPa (32) F F < σcr,f ). For Note that in this case the upper bound limit is also given by the web plate (i.e. σcr,w comparison, the finite strip analysis predicts a cross-section local buckling stress of 1026 MPa, only 3.0% higher than the predicted value using the formulae developed herein. The elastic local buckling stress of the isolated critical plate with simply-supported boundary conditions is 659 MPa. This corresponds to a 35% increase in local buckling stress by allowing for the effects of element interaction. 6.4 Worked example 3: RHS under combined compression and bi-axial bending A RHS 200×100×4 in S355 steel with E=210000 MPa and ν=0.3 is subjected to combined compression NEd = 192 kN and bi-axial bending (My,Ed = 17.6 kNm and Mz,Ed = 4.9 kNm) as shown in Fig. 17. Determine the full cross-section local buckling stress σcr,cs . 37 s y s s s z s s s × s × × × y s Figure 17: Worked example 3: RHS 200×100×4 under combined compression and bi-axial bending. Firstly, determine the stress distribution ψw and ψf across the most heavily loaded web and flange of the cross-section. Note that the centreline fibre of the cross-section is located 2 mm from the extreme fibre and that compression is taken as positive. σ1,f = σ1,w = = σ2,w = = σ2,f = = My,Ed z NEd Mz,Ed y + + A Iy Iz (33) 17.6 × 106 × (100 − 2) 4.9 × 106 × (50 − 2) 192 × 103 + + = 277 MPa 2336 1.240 × 107 4.208 × 106 NEd My,Ed z Mz,Ed y − + A Iy Iz (34) 192 × 103 17.6 × 106 × (100 − 2) 4.9 × 106 × (50 − 2) + = −1 MPa − 2336 1.240 × 107 4.208 × 106 My,Ed z NEd Mz,Ed y + − A Iy Iz (35) 192 × 103 17.6 × 106 × (100 − 2) 4.9 × 106 × (50 − 2) + − = 165 MPa 2336 1.240 × 107 4.208 × 106 ∴ ψw = σ2,w −1 = = 0.0 σ1,w 277 38 (36) ∴ ψf = σ2,f 165 = = 0.6 σ1,f 277 (37) Then calculate the elastic buckling stresses of the isolated web and flange plates (use centreline geometry) with simply-supported and fixed boundary conditions. Note that βf = 1.0 and βw = 1.0 since the maximum compressive stress in the flange and web are the same. The buckling coefficients k are obtained from Tables 2 and 3. For the flange (ψf = 0.6), kfSS = 4.97 and kfF = 8.66. Hence: SS σcr,f 210000π 2 = 4.97 12(1 − 0.32 ) 210000π 2 12(1 − 0.32 ) F σcr,f = 8.66 4 96 2 4 96 2 = 1638 MPa (38) = 2854 MPa (39) F SS = 13.6. Hence: = 7.81 and kw For the flange (ψw = 0.0), kw SS σcr,w 210000π 2 = 7.81 12(1 − 0.32 ) 210000π 2 12(1 − 0.32 ) F σcr,w = 13.6 4 196 4 196 2 = 617 MPa (40) = 1075 MPa (41) 2 Hence: φ= 1638 = 2.65 617 ∴ Web is critical since φ ≥ 1. (42) The bi-axial cross-section response is approximated by assuming the restraint provided to the web is provided by the flange plate subjected to pure compression. Hence, the proposed functions for ζ for RHS under combined compression and major axis bending from Table 5 are used. For hot-rolled RHS with constant thickness t and the web being critical, the interaction factor ζ is: aw φ 0.43 = 0.53 − = 0.368 2.65 h aw = 0.63 − 0.1 b 200 = 0.63 − 0.1 = 0.43(≤ 0.53) 100 ζ = 0.53 − where Finally: 39 (43) σcr,cs = 617 + 0.368 (1075 − 617) = 786 MPa (44) The CUFSM prediction for the full cross-section local buckling stress is 835 MPa, only 5.9% higher than the predicted value using the formulae developed herein. The elastic local buckling stress of the isolated critical plate with simply-supported boundary conditions is 617 MPa. This corresponds to a 21% increase in local buckling stress by allowing for the effects of element interaction. 7 Conclusions Formulae for calculating the elastic local buckling stresses of structural cross-sections have been devised and are presented in this paper. The finite strip method was used to determine the elastic local buckling stresses of over 2000 European and American hot-rolled and welded steel profiles subjected to combined loading conditions ranging from pure compression to pure major or pure minor axis bending. It was found that the full cross-section local buckling stress lies between the buckling stresses of the critical isolated cross-section plates with simply-supported and fixed boundary conditions along the adjoined edges. On the basis of this concept, the effects of element interaction are accounted for through an interaction coefficient ζ that ranges between 0 (no element interaction) and 1 (full element interaction). It is hence possible to predict the full cross-section local buckling stress for any combined load combination between pure compression and pure major or minor axis bending. Through a conservative modification to the applied stress distribution in the non-critical plate, the proposed concept was extended to biaxial bending. Worked examples show how the expressions can be used as a convenient alternative to numerical methods within both traditional and advanced (e.g. DSM and CSM) structural design frameworks. The developed formulae typically predict the elastic local buckling stress to within 5% of the numerical value, whereas when element interaction is ignored, as is customary in current structural design specifications, the local buckling stress of steel profiles may be under-estimated by as much as 50%. References [1] EN 1993-1-1. Eurocode 3: Design of steel structures - Part 1-1: General rules and rules for buildings. European Committee for Standardization, Brussels, 2005. [2] AISC 360-16. Specification for Structural Steel Buildings. American Institute of Steel Construction, 2016. 40 [3] B. W. Schafer. Review: The Direct Strength Method of cold-formed steel member design. Journal of Constructional Steel Research, 64:766–778, 2008. [4] Committee on Specifications for the Design of Cold-Formed Steel Structural Members. Direct Strength Method (DSM) Design Guide. American Iron and Steel Institute, 2006. [5] L. Gardner. The continuous strength method. Proceedings of the Institution of Civil Engineers - Structures and Buildings, 161(3):127–133, 2008. [6] S. Afshan and L. Gardner. The continuous strength method for structural stainless steel design. ThinWalled Structures, 68:42–49, 2013. [7] A. Liew and L. Gardner. Ultimate capacity of structural steel cross-sections under compression, bending and combined loading. Structures, 1:2–11, 2015. [8] M. Seif and B. W. Schafer. Local buckling of structural steel shapes. Journal of Constructional Steel Research, 66(10):1232–1247, 2010. [9] S. P. Timoshenko. Theory of elastic stability. McGraw Hill, New York, 1936. [10] F. Bleich. Buckling strength of metal structures. McGraw Hill, New York, 1952. [11] S. P. Timoshenko and J. Gere. Theory of elastic stability. McGraw Hill, New York, 2nd edition, 1963. [12] P. S. Bulson. The stability of flat plates. Chatto & Windus Ltd, London, 1970. [13] E. Lundquist and E. Stowell. Critical compressive stress for flat rectangular plates supported along all edges and elastically restrained against rotation along the unloaded edges. National Advisory Committee for Aeronautics, Special Report 189, 1941. [14] E. Lundquist and E. Stowell. Critical compressive stress for outstanding flanges. National Advisory Committee for Aeronautics, Report No. 734, 1942. [15] K. Nölke. Biegungs-beulung der Rechteckplatte mit eingespannten Längsrändern. Der Bauigenieur, 17:111, 1936. [16] C. F. Kollbrunner and G. Herrmann. Stabilität rechteckiger, durch linear verteilte Randkräfte beanspruchter Platten im elastischen Bereich. Schweizerische Bauzeitung, 67(22):307–308, 1949. [17] J. M. Cohen. Elastic buckling coefficients for long, unstiffened plates. Journal of Engineering Mechanics, 118(12):2491–2496, 1992. 41 [18] EN 1993-1-5. Eurocode 3: Design of steel structures Part 1-5: Plated structural elements. European Committee for Standardization, Brussels, 2006. [19] E. Lundquist. Local instability of symmetrical rectangular tubes under axial compression. National Advisory Committee for Aeronautics, Report No. 686, 1939. [20] E. Lundquist. Local instability of centrally loaded columns of channel section and Z-section. National Advisory Committee for Aeronautics, Report No. 722, 1939. [21] G. Haaijer. Buckling of uniformly compressed steel plates in the strain-hardening range. Fritz Laboratory Report No. 205E.7, 1956. [22] G. Haaijer and B. Thurlimann. On inelastic buckling in steel. Fritz Laboratory Report No. 205E.9, 1957. [23] M. G. Lay and T. V. Galambos. The inelastic behavior of beams under moment gradient. Fritz Laboratory Report No. 197, 1964. [24] M. G. Lay. Some studies of flange local buckling in wide-flange shapes. Fritz Laboratory Report No. 297.10, 1964. [25] D. Johnson. An investigation into the interaction of flanges and webs in wide flange shapes. In Proceedings SSRC Annual Technical Session, pages 395–405, Cleveland (OH), 1985. [26] M. Möller. Local Flange Buckling. PhD thesis, Lulea University of Technology, 1995. [27] A. Rusch and J. Lindner. Tragfähigkeit von beulgefährdeten I-Profilen bei Biegung um die z-Achse. Stahlbau, 68(6):457–467, 1999. [28] M. Madhavan and J. S. Davidson. Elastic buckling of I-beam flanges subjected to a linearly varying stress distribution. Journal of Constructional Steel Research, 63:1373–1383, 2007. [29] O. Bedair. Stability of web plates in W-shape columns accounting for flange/web interaction. ThinWalled Structures, 47:768–775, 2009. [30] W. F. Ragheb. Local buckling of welded steel I-beams considering flange-web interaction. Thin-Walled Structures, 97:241–249, 2015. [31] K. H. Han and C. H. Lee. Elastic flange local buckling of I-shaped beams considering effect of web restraint. Thin-Walled Structures, 105:101–111, 2016. [32] T. R. Graves Smith. The local buckling of box girders under bending stresses. International Journal of Mechanical Sciences, 11:603–612, 1969. 42 [33] S. Jakubowski. Buckling of thin-walled girders under compound load. Thin-Walled Structures, 6:129– 150, 1988. [34] M. Bock and E. Real. Effective width equations accounting for element interaction for cold-formed stainless steel square and rectangular hollow sections. Structures, 2:81–90, 2015. [35] L. Vieira, R. Gonçalves, and D. Camotim. On the local buckling of RHS members under axial force and biaxial bending. Thin-Walled Structures, 129:10–19, 2018. [36] W. D. Kroll, G. Fisher, and G. Heimerl. Charts for calculation of the critical stress for local instability of columns with I-, Z-, channel and rectangular-tube sections. National Advisory Committee for Aeronautics, Report No. 429, 1943. [37] V. Kalyanaraman. Local buckling of cold formed steel members. Journal of the Structural Division, ASCE, 105(5):813–828, 1979. [38] D. Polyzois and P. Charnvarnichborikarn. Web-flange interaction in cold-formed steel Z-section columns. Journal of Structural Engineering, ASCE, 119(9):2607–2628, 1993. [39] D. Ungermann, S. Lübke, and B. Brune. Tests and design approach for plain channels in local and coupled local-flexural buckling based on Eurocode 3. Thin-Walled Structures, 81:108–120, 2014. [40] B. Brune. Biegeknicken von druck- und biegebeanspruchten Stahlbauteilen mit beulschlanekn Blechen, Mitteilung Nr. 23. Technical report, Lehrstuhl für Stahlbau, Universität Dortmund, 2000. [41] A. Szychowskl. Computation of thin-walled cross-section resistance to local buckling with the use of the critical plate method. Archives of Civil Engineering, 62(2), 2016. [42] Z. Li and B. W. Schafer. Buckling analysis of cold-formed steel members with general boundary conditions using CUFSM: Conventional and constrained finite strip methods. In Twentieth International Speciality Conference on Cold-Formed Steel Structures. Saint Louis, Missouri, USA, 2010. [43] G. J. Hancock. Local, distortional, and lateral buckling of I-beams. Journal of the Structural Division, ASCE, 104(11):1787–1798, 1978. [44] AISC. Commentary on Appendix 1: Design of cold-formed steel structural members with the direct strength method. Technical report, AISC, 2004. 43 View publication stats