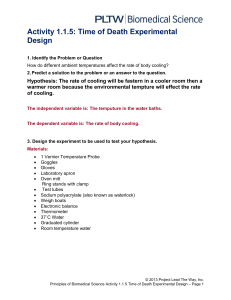

Instrumentation & Measurements: Probability & Statistics for Engineers

advertisement