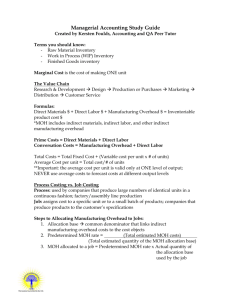

Introduction to Managerial Accounting UGBA102B Lecture 3 John Briginshaw Quick Check ✓ • Halleys.com is a new manufacturing company that wants help working out its costs. Costs consists of manufacturing costs ($1m plus $2 per unit) and sales costs ($200,000 salaries and $1 per unit commission). The company started last year, and made 2m units, of which 1.7m were sold. What were the year’s costs? PRODUCTION SALES Focus on costs (not a. $4.4m $1.9m expenses) but (bonus b. $5m $1.9m question!) what would c. $4.4m $2.2m be the cost of goods sold for the year? d. $5m $2.2m Lecture 3 Agenda Chapter 1: Quirks of variable and fixed costs Chapter 1: Incremental costs Chapter 2: What’s Job Order Costing? Introduction to next topics Topics – Chapter 1 wrap-up • What cost classifications do I use for different management purposes? Purpose Cost classification Chapter Assigning costs to cost objects (without excessive administration) Direct vs Indirect Reporting under US GAAP Product vs Period Predicting cost behavior as volume increases Variable vs Fixed 5 Making decisions on short and long time frames Differential cost (changes between choices) or not 12-13 Analyze fixed & variable costs vs Activity… UNIT COST BEHAVIOR Cost per unit Total cost VARIABLE COSTS TOTAL COST BEHAVIOR Volume Cost per unit Total Cost FIXED COSTS Volume Volume Volume Total Costs and Profit can be modeled as a function of volume • Fixed costs are constant, $F • Variable costs per unit are constant, UVC • Therefore total costs can be calculated as Total Costs, TC = F + UVC x Q Where Q is the number of units • Subtract TC from Revenue to get Operating Profit (Unit CM = price – UVC) Profit = Unit CM x Q - F Quirks and features (I) • Costs which are variable but non linear – Procedure: Include these in the cost equation by using a linear approximation to the cost curve Total Cost Economist’s Curvilinear Cost Function Relevant Range Accountant’s Straight-Line Approximation (constant unit variable cost) Activity Quirks and features (II) • Unit Costs depend on volume ▪ Unit cost = Total manufacturing cost Number of units manufactured ▪ Often used for pricing but if there are fixed costs, it is dependent on volume • If pricing is determined using a high volume (low fixed cost per unit) and sales is disappointing, then company may make an unexpected loss • If pricing is determined based on a low volume (this means unit cost is at the high end), then price may be too high to maximize sales Quirks and Features (III) • Fixed costs may “step up” as capacity limits are reached Quick Check • Padmans Inc gives the following information for activity level 10,000 units: ▪ Variable costs $10,000 ▪ Fixed costs $50,000 per plant of 20,000 units capacity • What are the unit costs at these three levels of production? 10K units 20K 25K A. B. C. D. $6 $6 $6 $5 $3.50 $3.50 $4.50 $3.50 $2.50 $5 $6.50 $5 Quirks and features (IV) • Mixed costs – These exhibit characteristics of both variable and fixed costs – Procedure: Analyze the mixed costs to break out their fixed and variable portions, then include in cost equation Analyzing Mixed Costs • Mixed costs have both variable and fixed components • Part of a mixed cost changes with volume or usage • Part is fixed over a particular period • Can we incorporate the costs into our analysis? Mixed Costs – Preview Ch 5A • For analysis, mixed costs must be divided into their variable and fixed components – These components can then be grouped with other variable and fixed costs in calculations • Methods used to separate mixed costs into variable and fixed components 1. High-low method 2. Scatter diagram method (visual determination of relationship) 3. Statistical methods such as least squares Quick Check • Hanbridge Inc. observes a mixed cost at two activity levels. The cost is $2000 when 100 units are produced and $3000 at 200 units. What is the variable cost per unit? A. B. C. D. $5 $10 $15 $20 Traditional vs Contribution Income Statements • The normal income statement calculates – Gross margin = Sales – COGS (product costs) – Net income = Gross margin – period costs • The contribution or variable costing income statement focuses on variable vs fixed not product vs period – Contribution margin = Sales – Variable costs – Net income = Contribution margin – Fixed costs Traditional and Contribution Income Statements - Example Used primarily for external reporting. Used primarily by management. Quick Check • In the previous slide, what is the contribution margin ratio (as a percentage of sales)? A. B. C. D. 10% 30% 40% 60% Net Operating Income • Net operating income is the same under traditional and contribution formats for the example on the previous slide and on pp. 39 • This is true for any merchandising company and for a manufacturing company which does not have any change in inventory • (This assumption is relaxed in later chapters) Contribution Format - usefulness • Contribution format statements are more useful for decision making because they encourage maximization of contribution margin • If fixed costs are constant, maximum contribution leads to maximum profit • (However, fixed costs are only fixed with respect to activity. A decision, such as a plant closure, could decrease fixed costs) Lecture 3 Agenda Chapter 1: Quirks of variable and fixed costs Chapter 1: Incremental costs Chapter 2: What’s Job Order Costing? Introduction to next topics What is Differential Cost Analysis? (E1-16) • Differential cost analysis (also called incremental analysis or relevant cost analysis) looks only at the differential or relevant effects of a decision between action A and action B – Only focus on revenues or costs which change – Costs or revenues which stay the same whether we choose A or B, are ignored Intrinsic Motivators – Gaining new understanding • How can we optimize CVP? Credit: Garrison et al 16e • How will we make decisions if there are sunk costs? The analysis uses the differential cost and opportunity cost concepts • Irrelevant revenue or cost – Revenues/costs that will not differ between alternatives – Sunk costs are irrelevant costs: Costs that were incurred because of a previous decision and cannot be recovered through the current decision • Opportunity costs are the benefits that are forfeited or lost from forgoing the next best alternative use – these must be included Equipment-Replacement Decisions • Sometimes difficult due to amount of information at hand that is irrelevant: – Cost, Accumulated Depreciation, and Book Value of existing equipment – Any potential Gain or Loss on the transaction – a Financial Accounting phenomenon only • Decision Rule: Select the alternative that will generate the highest present value Sunk Costs Example – Replacing a truck that cost $120,000 • A cost is sunk if – it has already been spent or irrevocably committed – it cannot be recovered • Example of Sunk Cost – TransitCo Inc buys a Semi-Truck for $120,000 cash (15 y) – But the after 2 years Quantum Batteries are invented that use cheap solar power, making the non electric truck obsolete – New solar truck will cost $180K The company now has two choices – Option A: Go Solar - Option B: Stay Diesel – Loss on sale: $104,000 - No loss on sale – Pay $180,000 for new truck - Higher operating costs Real World Equipment Replacement Example – Tesla Semi • Option 1: Keep existing diesel truck – Startup cost: $0 (loss on sale is not a cash flow) – Annual Cash outflow: Diesel at ~$37,400 per year • Option 2: Tesla Semi electric truck – Startup cost: $180K – Suppose we can sell the old truck for resale value of $80,000… – Annual cash outflow: lower ongoing cost Relevant to trucking companies considering Tesla Semi Lecture 3 Agenda Chapter 1: Quirks of variable and fixed costs Chapter 1: Incremental costs Chapter 2: What’s Job Order Costing? Introduction to next topics Chapters 2-3: Job Order Costing • Job Order costing is one of the most common implementations of costing in US businesses • It is designed to cost customized tasks or product batches called “jobs” • Job order costing – Tracks direct materials and direct labor to the jobs – Allocates manufacturing overhead to the jobs Key Management/Measurement Question Chapter 2: What is the management question? (Exh P-5) • “How much does it cost us to manufacture customized jobs for each of our customers?” – Production costs are what we look at right now • Direct materials + Direct Labor + Manufacturing overhead (MOH) – An MOH allocation method is needed because some costs are shared between products • Job order costing uses a fairly simple MOH allocation method suitable for product portfolios of moderate complexity Job Order Costing - This time • Basic Job order costing • When do we need departmental costing? • Cost flow and accounting entries in the job order costing system • The wonders of year end adjustment to account for overhead allocation issues • How it all fits into financial statements – Cost of Goods Manufactured (COGM) – Cost of Goods Sold (COGS) • Applying job-costing to services Job-order costing systems are used when… • Many different products are produced each period. • Products are manufactured to order. • The unique nature of each order requires tracing or allocating costs to each job, and maintaining cost records for each job. Example of a Suitable “Job” • Batch of Diesel Jeans (page 61) – Different styles – requiring… • Different fabrics • Different buttons • Different stitching – BUT every batch or job makes use of shared factory costs • Production supervision • Rent, insurance, property taxes of the factory Other Examples of companies that would use job-order costing… • Boeing (aircraft manufacturing) • Bechtel International (large scale construction) • Hallmark (batches of greetings cards) • LSG Skychefs (batches of meals for different airlines and routes) • Columbia Pictures (movies, pp. 75) Reminder: What’s in DM, DL, MOH? • Examples of DM – Large parts in the product – Must be economical/worthwhile to track these costs • Examples of DL – Assembly line labor, work shop labor – Often they “touch” the product • Examples of MOH – Everything else in the manufacturing facility – Rent, heat, light, indirect labor, indirect materials Total Costs in Job Order Costing • Total manufacturing costs are calculated as TMC = Direct costs - tracked Direct Materials (DM) + Indirect costs – Direct Labor (DL) allocated + Manufacturing Overhead (MOH) The Job Cost Card/Sheet – the fundamental record of each job PearCo Job Cost Sheet Job Number A - 143 Department B3 Item Wooden cargo crate Direct Materials Req. No. Amount Date Initiated 3-4-11 Date Completed Units Completed Direct Labor Ticket Hours Amount Cost Summary Direct Materials Direct Labor Manufacturing Overhead Total Cost Unit Product Cost Manufacturing Overhead Hours Rate Amount Units Shipped Date Number Balance Job Cost Card holds data on direct and indirect costs • Direct materials used – write cost on card • Direct labor used – write on card • MOH – allocation of MOH is added to card based on a systematic method of “sharing out” the overhead cost Now, job cost cards are often computerized e.g. Workforce scans bar codes when they commence work on a new job (see page 64) Quick Check • Which of the following would have actual costs noted on a job cost card for an auto? (more than one answer can be correct) A. B. C. D. Sheet metal components of the auto body Cost of workers doing quality control Sales commissions specifically for the car Cost of workers assembling car Calculating the MOH for jobs • The total MOH must be “shared out” or allocated between all of the jobs • It is allocated relative to the usage of an indicator of the overhead used • This indicator of the overhead used is called an allocation base • An example of an allocation base is direct labor hours Using an allocation base • All of the MOH costs for the year must be allocated • To help ensure this, an overhead rate (OHR) is calculated at the start of the year:POHR = Estimated total manufacturing overhead cost for the coming period Estimated total units in the allocation base for the coming period • P means “predetermined” Quick Check Question ✓ • Tiger, Inc. had budgeted overhead of $1.2m and budgeted machine hours of 300,000 in 2019. Actual manufacturing overhead costs were $1,210,000. Tiger, Inc. worked 290,000 machine hours during the period. What was Tiger’s POHR (in $ per machine hour) during 2019? a. b. c. d. $4 per machine hour. $4.09 per machine hour. $4.17 per machine hour. $8.19 per machine hour. Who are Yost? • Yost Precision Machining are the example company in Chapter 2 • They are making some special order couplings (Job 2B47) for a new customer • Sample job to try and attract the new business – Done on small volume (2 units) – They will charge the cost to the customer – Appropriate costing demonstrates the system to us and shows honesty to the customer Ref: page 68 Cost of the Special Order Couplings (Job 2B47) • Pages 62-69 discuss the “Special Order Couplings” job in more detail • Page 68 shows the total costs • Calculating the cost of the job:TMC = DM+DL+MOH TMC = $1404 + $446 + MOH??? -To get the MOH, examine the detail of the cost card -We see 27 hours => MOH is 27x$20 (POHR) = $540 →TMC = $1404 + $446 + $540 = $2390 How do they calculate the $540 MOH for the job (page 67)? • They know that the job took 27 hours of work • Then they recall the beginning of year calculations of POHR where Yost estimated… – Total MOH cost this year of $800,000 – Total Direct Labor Hours expected to be 40,000 – POHR = $800,000/40,000DLH = $20/DLH • Allocation: 27 hours used x $20 rate = $540 Quick Check Question ✓ • A batch of 40 car batteries required $200 of direct materials and 10 direct labor hours at $15 per hour. Estimated total overhead for the year was $760,000 and estimated direct labor hours were 20,000. What would be recorded as the cost of the batch? a. $200. b. $350. c. $380. d. $730. Costing Approaches • Actual Costing – allocates indirect costs based on the actual indirect-cost rates times the actual activity consumption • Normal Costing – allocates indirect costs based on the budgeted indirect-cost rates times the actual activity consumption • Both methods track direct costs to a cost object the same way: by using actual directcost rates times actual consumption Normal Costing is the Practical System • In practice we need to estimate total costs (including indirect) before we know total indirect costs for PRICING • So we estimate how much indirect cost there will be per direct labor hour, and use that to estimate total cost during the year • At the end of the year we may have to make an adjustment if indirect cost overshoots Lecture 3 Agenda Chapter 1: Quirks of variable and fixed costs Chapter 1: Incremental costs Chapter 2: What’s Job Order Costing? Introduction to next topics Job Order Costing - Next time • Basic Job order costing • When do we need departmental costing? • Cost flow and accounting entries in the job order costing system • The wonders of year end adjustment to account for overhead allocation issues • How it all fits into financial statements – Cost of Goods Manufactured (COGM) – Cost of Goods Sold (COGS) • Applying job-costing to services Departmental Costing and Overhead Rates • Machining department – May be more automated – Allocation base: machine hours • Finishing department – May be more labor intensive – Allocation base: direct labor hours • Allows more accuracy as the allocation bases drive costs more closely SUMMARY DIAGRAM BALANCE SHEET INCOME STATEMENT Inventoriable Costs (costs that can be “stored” in inventory) Materials purchased DL used MOH applied When finished COGM When sold COGS DM moved Revenues deduct Cost of Goods Sold (an expense) Equals Gross Margin deduct Raw Materials Inventory Work in Process Inventory Finished Goods Inventory (receiving dock) (factory floor) (FG warehouse) Period Costs: must be expensed immediately, we assume no “benefit” carries over to next period R&D costs G&A Costs Marketing Costs Distribution Costs Customer-Service Costs Equals Operating Income Simple Principle of calculating raw materials used and other flows • What I end up with = what I start with + what I put in – what I take out • For any inventory account “I” ▪ I1 = I0 + Inflow – Outflow ▪ Outflow = I0 + Inflow – I1 • Example of the Raw Materials (RM) account ▪ RM_Used = RM0 + RM_purchased – RM1