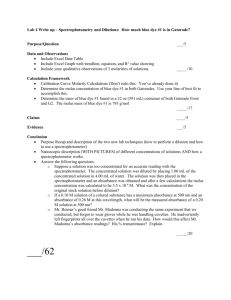

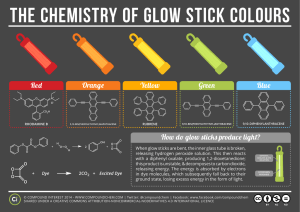

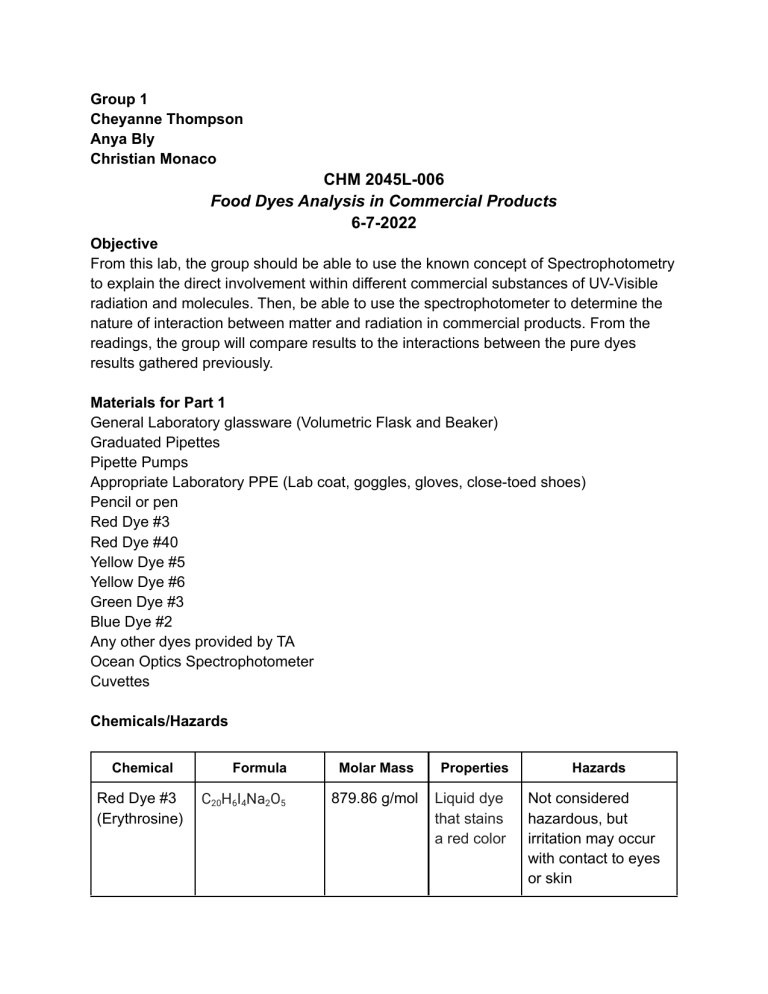

Group 1 Cheyanne Thompson Anya Bly Christian Monaco CHM 2045L-006 Food Dyes Analysis in Commercial Products 6-7-2022 Objective From this lab, the group should be able to use the known concept of Spectrophotometry to explain the direct involvement within different commercial substances of UV-Visible radiation and molecules. Then, be able to use the spectrophotometer to determine the nature of interaction between matter and radiation in commercial products. From the readings, the group will compare results to the interactions between the pure dyes results gathered previously. Materials for Part 1 General Laboratory glassware (Volumetric Flask and Beaker) Graduated Pipettes Pipette Pumps Appropriate Laboratory PPE (Lab coat, goggles, gloves, close-toed shoes) Pencil or pen Red Dye #3 Red Dye #40 Yellow Dye #5 Yellow Dye #6 Green Dye #3 Blue Dye #2 Any other dyes provided by TA Ocean Optics Spectrophotometer Cuvettes Chemicals/Hazards Chemical Red Dye #3 (Erythrosine) Formula C20H6I4Na2O5 Molar Mass 879.86 g/mol Properties Liquid dye that stains a red color Hazards Not considered hazardous, but irritation may occur with contact to eyes or skin Red Dye #40 (Allura Red AC) C18H14N2Na2O8S2 534.3 g/mol Liquid dye that stains a red color Not considered hazardous, but suspected of causing migraines/ triggering allergies Yellow Dye #5 (Tartrazine) C16H9N4Na3O9S2 534.3 g/mol Liquid dye that stains a yellow color Not considered hazardous but may trigger allergic reactions Yellow Dye #6 (Sunset Yellow FCF) C16H10N2Na2O7S2 452.37 g/mol Liquid dye that stains a yellow color Not considered hazardous but may trigger allergic reactions Green Dye #3 (Fast Green FCF) C₃₇H₃₄N₂Na₂O₁₀S₃ 808.86 g/mol Liquid dye that stains a turquoiseaquamarine color Not considered hazardous, but may cause irritation when exposed to eyes or skin Blue Dye #2 (Brilliant Blue FCF) C37H34N2Na2O9S3 792.85 g/mol Liquid dye that stains a blueindigo color Not considered hazardous, but may cause irritation to the eyes Methods and Procedures 1. Ensure all PPE is on correctly 2. Collect all necessary materials for the lab 3. Label the volumetric flasks (SS, A, B, C, D, E) 4. Add the stock solution to the SS flask 5. Create the standard solution using the following steps: a. Weigh the stock solution b. Add it to a clean volumetric flask c. Add the solvent, making sure it does not fill all the way to the line d. Once the solvent is dissolved, add more solute until the line is reached e. Repeat to create 5 more samples 6. Place stock solution into cuvette 7. Calibrate and properly use the spectrophotometer 8. Fill a cuvette with 10 mL of solution 9. Find λmax value with spectrophotometer 10. Repeat steps 8&9 five times to ensure accurate results 11. Record found values and apply the Beer-law 12. Record initial value on the table 13. Repeat steps with other samples and record the results 14. Repeat all steps using a different dilution process 1. Collect and label 6 clean volumetric flasks. 2. Fill one flask with the dye stock solution (this will be used to create the following solutions) 3. Ensure the spectrophotometer is turned on and properly connected to the computer 4. Calibrate the spectrophotometer using clear and opaque cuvettes. provided 5. Fill a clear cuvette with the collected stock solution and insert it into the spectrophotometer 6. Identify the λmax of the stock solution, and record the data 7. Ensuring that you end with a 10 mL solution, create a new solution by adding water (the solvent) and an amount of the collected stock solution into a new volumetric flask 8. Mix the solution so that the appearance is uniform 9. Fill a clean, clear cuvette with the new solution and insert it into the spectrophotometer. 10. Using the previous λmax found using the stock solution, find the value on the new solution’s calibration plot that corresponds and record 11. Repeat steps 7-10 until a total of 5 solutions containing varying dye concentrations have been created and the corresponding λmax values have been recorded Calculations Concentration: Example: (20)(0.1)=(M2)(0.5) M2=(20)(0.1)/(0.5)=4 Beer’s Law: A=εCl (y=mx+b) C=A/lε A= absorbance ε= molar absorptivity (L/mol-cm) C= concentration of absorbing species (mol/L) l= path length (cm) Example: ε= 4.5 L/mol-cm C= 0.95 mol/L l= 1 cm A= (4.5)(0.95)(1) = 4.275 Dilutions: Stock Concentration: 0.1 Dilutions to concentrations 0.09, 0.075, 0.05, 0.025, and 0.01 0.09 Parallel dilution: Transfer 90 mL of solution to a 100 mL volumetric flask and fill the rest with water to receive a 0.09 M concentration (Ratio 9/10). 0.075 Parallel dilution: Transfer 75 mL of concentration to a 100 mL volumetric flask and fill the rest with water to receive a 0.075 M concentration (Ratio 7.5/10). 0.05 and 0.025 Serial dilution: Start with 50 mL of solution, transfer 25 mL to a new flask and add 25 mL of water. This will result in a 0.05 M concentration (Ratio 5/10). Take the resulting solution and transfer 25 mL to a new flask and add 25 mL of water. This will result in a 0.025 M concentration (Ratio 2.5/10). 0.01 Parallel dilution: Transfer 10 mL of concentration to a 100 mL volumetric flask and fill the rest with water to receive a 0.01 M concentration (Ratio 1/10). Table for data collection: Colors λMax (cm-1) ε (Lmol-1cm-1) Experimental Theoretical Experimental Theoretical R2 Concentration Concentration (M) sample 1 (M) sample 2