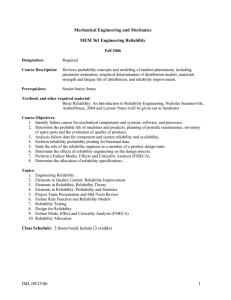

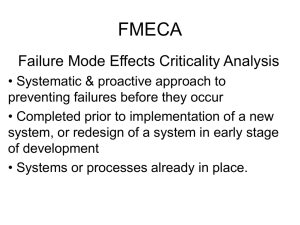

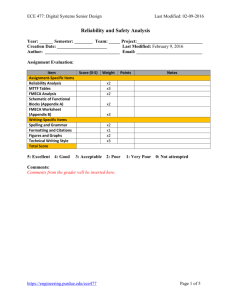

FMECA: Failure Mode, Effects, Criticality Analysis Technical Report

advertisement