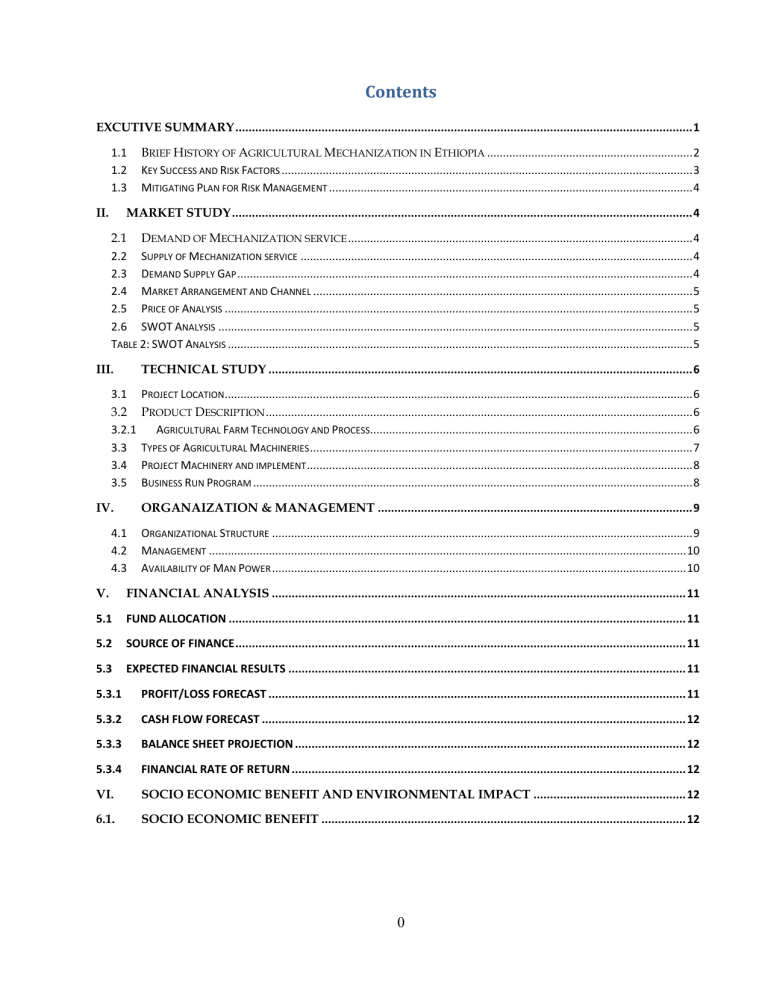

Contents EXCUTIVE SUMMARY .......................................................................................................................................... 1 1.1 1.2 1.3 II. BRIEF HISTORY OF AGRICULTURAL MECHANIZATION IN ETHIOPIA ................................................................. 2 KEY SUCCESS AND RISK FACTORS .................................................................................................................................. 3 MITIGATING PLAN FOR RISK MANAGEMENT ................................................................................................................... 4 MARKET STUDY ........................................................................................................................................... 4 2.1 DEMAND OF MECHANIZATION SERVICE ............................................................................................................. 4 2.2 SUPPLY OF MECHANIZATION SERVICE ............................................................................................................................ 4 2.3 DEMAND SUPPLY GAP ................................................................................................................................................ 4 2.4 MARKET ARRANGEMENT AND CHANNEL ........................................................................................................................ 5 2.5 PRICE OF ANALYSIS .................................................................................................................................................... 5 2.6 SWOT ANALYSIS ...................................................................................................................................................... 5 TABLE 2: SWOT ANALYSIS ................................................................................................................................................... 5 III. TECHNICAL STUDY ................................................................................................................................ 6 3.1 3.2 3.2.1 3.3 3.4 3.5 IV. PROJECT LOCATION.................................................................................................................................................... 6 PRODUCT DESCRIPTION ....................................................................................................................................... 6 AGRICULTURAL FARM TECHNOLOGY AND PROCESS...................................................................................................... 6 TYPES OF AGRICULTURAL MACHINERIES ......................................................................................................................... 7 PROJECT MACHINERY AND IMPLEMENT .......................................................................................................................... 8 BUSINESS RUN PROGRAM ........................................................................................................................................... 8 ORGANAIZATION & MANAGEMENT ............................................................................................... 9 4.1 4.2 4.3 ORGANIZATIONAL STRUCTURE ..................................................................................................................................... 9 MANAGEMENT ....................................................................................................................................................... 10 AVAILABILITY OF MAN POWER ................................................................................................................................... 10 V. FINANCIAL ANALYSIS ............................................................................................................................. 11 5.1 FUND ALLOCATION .......................................................................................................................................... 11 5.2 SOURCE OF FINANCE ........................................................................................................................................ 11 5.3 EXPECTED FINANCIAL RESULTS ........................................................................................................................ 11 5.3.1 PROFIT/LOSS FORECAST .............................................................................................................................. 11 5.3.2 CASH FLOW FORECAST ................................................................................................................................ 12 5.3.3 BALANCE SHEET PROJECTION ...................................................................................................................... 12 5.3.4 FINANCIAL RATE OF RETURN ....................................................................................................................... 12 VI. SOCIO ECONOMIC BENEFIT AND ENVIRONMENTAL IMPACT .............................................. 12 6.1. SOCIO ECONOMIC BENEFIT .............................................................................................................. 12 0 Excutive Summary Sileshi Urgessa Agricultural Mechanization is a private limited company which is established in 2022 with a registered paid up capital of Birr 2,000,00.00 to provide agricultural mechanization service to South West Shoa Zone; Becho and Ilu Woreda which is catchment area of the project. The Zonal farmers has accomplished so many agricultural practices to increase the production and productivity of the sector on which most of their economy is relaying on; which is rain feed and irrigation agricultural practice. Currently, the regional and federal gov’ts are insisting all farmers to mechanize their agricultural practices using different agricultural mechanizations machines, impliments and inputs for better productivies. I am applying to you for procurements of two tractotrs with all accessories materials (two agricultural tractors and two discs plougher and additional two discs plougher for reserve purpose) using lease financing modality of banks. . Sileshi Urgessa Agricultural mechanization sole-propretership is found in Oromia Regional State Sebeta town. The project is located in Ilu and Becho Woreda by renting shade for shalter, where about more than 20,393 ha of land demands agricultural mechanization technologies and inputs as per the data from South West Shoa Zone. These machineries and their impliments can facilitate the achievement of agri- mechanization goal of the zone through enhancing farming practices; by this project around 1,760 hectars of land to be ploughed per annum; which is going to be established as Private Limited Company in 2014 E.C with a paid up of Capital birr 2,000,000 with a capacity of 110 HP each. Regarding to the business management, the owner, Ato Sileshi Urgessa is proposed to manage this standard Agricultural Machinazation as a General Manager. He has well strengthened educational background, and has more than 10 years work experience in government and private institutions. Based on this ample experience, he can manage the campony in right ways that make it the cammpany profitable. The project will have a significant socio-economic contribution through improving agicultural productivity, replacing traditional farming labour force by aricultural machineries and impliments which can reduces working hours per hectar of cultivable farm, creating exposure of such types of technological agricultural practices, create employment opportunities for those who has agricultural technology operation and implementation skills and for other who has vital role in comencement of 1 this project ,and satisfying the governmental agenda of transforming our countries agricultural practices. The financial projections indicate that the project is viable. And, the total investment of the project is estimated to be Birr 5,600,000.00 out of which Birr 20%(ETB 1,120,000.00) down payment covered by the owner and the remaining 80% which is birr 4,480,000 is covered by Development Bank of Ethiopia, DBE. The financial analysis prevails that the project will generate revenue of Birr 6,720,000.00 in the first year and Birr 7,567,812.00 at the second year. The cash flow projection also indicates that there is a positive growth throughout the projection year i.e., initially the cumulative cash flow is Birr 657,758.00 which rises to Birr 2,517,842.00 at the seventh year which implies that there will not be a problem in cash throughout the projection year. The total loan amount will be repaid in five years with 10 installments starting with equal installment of Birr 751,874.296. The interest calculated on the outstanding balance will be paid together with the principal repayment. Table 1:Source of Finance Amount in ETB Debt Equity Total D/E Ratio 4,480,000.00 1,120,000.00 5,600,000.00 80% 20% 100% 1.1 Brief History of Agricultural Mechanization in Ethiopia Though Ethiopia has a long history of agricultural practices, the development of agricultural mechanization is still minimal. Farm power is mainly dependent on oxen-draft and human muscle operating using traditional farm implements. Oxen-pulled maresha is the dominant farm implement in cereal-based systems whereas hand-hoe is the main farm implement used in agroforestry systems. Agricultural Development Units, attempts were made to develop and promote different agricultural technologies (including farm implements) that fit to smallholder farmers. The level of tractor-based agricultural machinery use is relatively better in wheat dominated cropping systems where harvesting and threshing are done using combiners. This particular sector determines the growth of all other sectors and consequently the whole national economy. Unless supported by agricultural mechanization, achieving sustainable development goals is generally challenging in sub-Saharan African countries, specifically so in Ethiopia. Hence it is the country’s major focus under the second growth and transformation plan with attention given to productivity and production increase which is crucial for the country’s effort to attain food security and increase export earnings. 2 Along with other farm inputs, mechanization, such as fertilizers improved seed and pesticides can significantly improve agricultural productivity in Ethiopia. Farm mechanization can help to increase labour and land productivity through performing the power intensive and ergonomically laborious tasks. It can also mitigate the growing seasonal labour constraints that are experienced by farmers in several parts of the country. It also helps compensate for the migration of rural youth who are disappointed with the work involved in agriculture. Thus mechanization contrary to the restricted view on labour disappointed stands to compliment human labour in improving agriculture production in Ethiopia. In general, Agricultural Mechanization deals with the use of any mechanical aid in agricultural production. These mechanical aids could be simple hand tools, animal drawn implements or sophisticated mechanically powered agricultural machines. The source of energy ranges from humans, animals to engine or electrical power.It includes three main power sources like human, animal and mechanical. The manufacture distribution, repair, maintenance, management and utilization of agricultural tools, implements and machines is covered under this discipline with regard as to how to supply mechanization inputs to the farmer in an efficient and effective manner. For different purposes of farm activities, mechanization tools of equipment of various types are required for crop production starting from farm land preparation to post harvest activities. A tractor is vehicle designed to provide a high tractive effort at slow speeds in order to describe the distinctive farm vehicle. The farm tractor is used for pulling or pushing agricultural machinery or trailers for ploughing, tilling, disking, harrowing, planting and similar tasks. 1.2 Key Success and Risk Factors Success Factors o Availability of cultivated land in catchment area of borrowers o Special support from government for the sector o The Development Bank of Ethiopia has set agricultural mechanization as a priority area for investment o Good management system may affect the overall effectiveness of the project. Risk Factors Risk is the threat or probability that an action or event will adversely affect an organization ability to achieve its objectives. The major risks of the sector are: Sector Level Risk Factors o Rain-fed nature of Ethiopianagricultural production system 3 1.3 Mitigating Plan for Risk Management - decrease dependence on rain fed agriculture by increasesing the irrigation agriculture. II. Market Study In Ethiopia, agriculture is the backbone of the economy, accounts for almost half of gross domestic product (GDP), 83.9% of export, and 80% of total employment. It do supports other sectors through backward and forward linkage. In our country, it is dominated by small holder and largely subsistence farming with low productivity. Hence, to improve the productivity of the sectors, mechanization along with other farm inputs such as fertilizers, improved seeds and pesticides should be applied. Farm mechanization can help to increase labor and land productivity through performing the power intensive economically laborious tasks. 2.1 Demand of Mechanization service As per the data collection from agricultural and natural resource management office there are about 20,393 ha and 615 ha cultivated annually using both rain feed and irregation respectively using mechanization technology implimentations. 2.2 Supply of Mechanization service As per the data from already mentioned catchament area of Agricultural and Natural Resource Management Office, there are eleven tractors are found and out of which only three tractors were ingaged in mechanization (rent) service within the catchment area, and the available tractors in the area is not enough for the demand . This shows that the available tractors in the area is not sufficient from the total potencial land to be cultivated using mechanization . 2.3 Demand Supply Gap According to the data depicted on the above captioned headlines the project has sufficient demand for the service that the project is expected of; almost all of the farmers in the catchment area are expected to mechanize their agricultural practices using the machineries by which the bank is going to supply using lease financing modality. In the other hand around South West Shoa zone and Kersa Malima woredas mechanizetion technology application is not in significant level, this can be good opportunity for having vast market share coverage of the project. Therefore, theoretically the demand of this project ought weights the existing supply of the service in the area. 4 2.4 Market Arrangement and Channel The project is expected to provide ploughing service to the catchment area for 20 working days of ploughing by which about 2400 hectors of land per year is expected to be ploughed . This service is expected to be delivered not only to the individual farmers but also cooperatives with in and around the catchment of the project. Lesse Farmers Assossation Farmers/Consumers 2.5 Price of Analysis The price of the service is expected to be fair and affordable to the clients; as per the collected data form Agriculture and Natural Resource Management Office, the current price to charge average price of Birr 2,800.00 for ploughing one hectar of land. 2.6 SWOT Analysis Table 2: SWOT Analysis Strength - General manager and the owner of the Weakness - It creats a few job opportunity. project has life long experience. - Enough capital to run the project. Opportunity - Increase in mechanized farmer users in the area - Project establishment area near by the user. - Strong support and initiation from the gov’t. Threat - Compitition in sectors - Repair and maintenance service may not exist easily - Machinery users have only small area of land - The most users are highly depending on rain. 5 Based on the SWOT analysis the credit team has to made regular follow up with providing advisory and technical supports to enhance the strengths, alleviate weaknesses, utilize opportunities and minimize threats to the project’s success. III. Technical Study 3.1 Project Location Sileshi UrgessaAgricultural Mechanization will engaged in agricultural sector in Oromia Regional State specifically, Ilu and Becho woredas. The total cultivated land of the woredas is 35,581 hectar out of which 20,393 hectar of cultivated land is ready for mechanized agriculture. 3.2 Product Description Depending on various factors, there can be wide variation in maturity & harvesting periods of time for some of agricultural projects. Among these, the climatic factors which include rainfall and water, light, temperature, relative humidity, air , water, topography and soil. Besides these, variety of crops being produced on the area is cereal crops (i.e. Teff, Maize, Wheat, Barley, Pea , Chick bean and Bean), vegetables (i.e. onion,tomato, potato and others) are the major ones. 3.2.1 Agricultural Farm Technology and Process Agricultural Machinery technology devices used to till soil and to plant, cultivate, and harvest crops. Since ancient times, when cultures first began cultivating plants, people have used tools to help them grow and harvest crops. They used pointed tools to dig and keep soil loosened, and sharp, knifelike objects to harvest ripened crops. Modifications of these early implements led to the development of small hand tools that are still used in small-scale gardening, such as the spade, hoe, rake, trowel, and scythe, and larger implements, such as plows and larger rakes that are drawn by humans, animals, or simple machines. Agricultural implements are equipments used in a farm operation to help with farming having no driven moving parts. The agricultural implements include ploughs, harrows, threshers, axes, chaff cutter machine, cultivators, seed drills, etc. These implements are used for agricultural work to improve the efficiency and reduce the labour. Large varieties of agricultural implements are also used as attachments to tractors. 6 The operations of farming for which implements are used are diverse. For crop production they include handling of residues from previous crops; primary and secondary tillage of the soil, fertilizer distribution and application, seeding, planting, and transplanting, cultivation, pest control, harvesting, transportation, storage, pre-marketing processing, drainage, irrigation and erosion control, and water conservation. 3.3 Types of Agricultural Machineries 3.3.1 Machinery Used for Land Development Land development entails those activities which come before any other tillage systems; Farm land preparation for any crop production is undertaken hiring professional consultants and contractors authorized for such undertakings. As the required farm land development requires, the contractor to be hired shall be furnished with heavy duty bulldozers, excavators, loaders, and transporting tipping trucks. 3.3.2 Machineries Used for Land Preparation Tractor is a traction machine that provides mechanical, hydraulic, and/or electrical power to implements to perform a wide range of crop production and handling operations. Tractors are most often used to perform drawbar work (pulling equipment through the field) and PTO (power take-off) (power to rotate equipment components) work. Tractors can be equipped with rubber tires, rubber belts, or steel tracks. A modern farm tractor is almost always equipped with a diesel engine and tractor size is measured by the amount of power that the tractor can produce at the PTO. Plow is an implement used to perform primary tillage. A number of types of plows are in common use including the mouldboard plow, the chisel plow, and the disk plow. The mouldboard plow has a large frame that is equipped with a series of "bottoms," each of which consists of a steel coulter to slice through residue followed closely by a steel share that cuts the soil and an attached mouldboard that is used to raise and turn over the cut "slice" of soil. Disk plows work in a similar manner to laterally displace and invert soil through the use of concave steel disk blades. Chisel plows use curved shanks to penetrate and "stir" the soil without inverting a soil layer. Chisel plows cause less residue disturbance than mouldboard plows and are often used in conservation tillage systems. 7 Disk Harrows (or Disk) - are implements that uses steel blades to slice through crop residues and soil. Disk blades are mounted in groups or gangs that rotate as they move forward through the soil. Front gangs move soil toward the outside of the disk while rear gangs move soil back toward the canter of the disk. A disk can be used for primary or secondary tillage. Field Cultivator -an implement used to perform secondary tillage operations such as seedbed preparation and weed eradication. Field cultivators are equipped with steel shanks that are typically spring mounted to permit the shank to move within the soil and shatter clods. Field cultivators are constructed similarly to chisel plows, but are more lightly built. Large chisel plows can exceed 50 feet in width in the field. 3.4 Project Machinery and implement The machinery and implement requirement of the envisaged project is summarized in the following table below which is ETB 5,600,000.00. Table -3: List of machineries/implements and the Estimated Cost Sr. No. 1 2 Description Tractor Disc Plough Unit Pcs Pcs Qty. 2 4 Unit Cost 2,200,000.00 300,000.00 Total Total Cost (ETB) Total 4,400,000.00 1,200,000.00 5,600,000.00 3.5 Business Run Program The project’s implementation activities include lease processing, machinery procurement, Employee recruitment and Test the machinery. It is expected that these activities will be executed within 1 year. 8 Table 4: Business Run Program Schedule IV. Organaization & Management 4.1 Organizational Structure The planned organizational structure of the project presented here under: General Manager Secretar yyy Tractor Operator Accountant & Cashier ry 9 MAR FEB JAN DEC NOV OCT SEP AUG JULY JUN MAY Description Bank Loan Process Resource mobilization Procurement of Machinery & equipments Installation of Machinery& Equipment Procurement local raw material Commencement of Operation and test Run APR 2022 4.2 Management In any farming practices the qualification and experiences of the management is very indispensable. The management has to be educated and experienced in terms of its ability to work with selected machines. The management is also expected to properly identify the opportunities and the ways to exploit them; too well forecast risks and know threats and thereby to design ways to diversify the risks; and also the capacity of the management in changing the threats to opportunities is also very important. The proposed farm project will be led by the adminstrators and recruited experienced professionals as per the following. Table-5: Minimum Man Power Requirement and Respective Salary Description Number Monthly Salary /person in ETB Annual Salary General Manager 1 9,000.00 108,000 Accountant 1 4,500.00 54,000 Secretary 1 2,000 Tractor Operators 2 4,000.00 Assistant Tractor Operators 2 2,000.00 Cashier 1 3000.00 36,000 Guard 1 1500.00 18,000 24,000 96,000 48,000 Total 9 26,000 384,000 4.3 Availability of Man Power Agricultural farming is labor intensive. Man power is an essential factor in the successful production of agricultural farming. Especially in commercial farms, a large scale farm requires proportional number of skilled and unskilled manpower. The intended project requires 9 permanent workers to carry out the farm activities smoothly with machines. 10 V. FINANCIAL ANALYSIS 5.1 Fund Allocation Initial investment cost which referred as capital expenditure is equivalent to the total financial outlay of the Business which will be required in order to establish the business before enter into operational stage. The capital expenditure are constitute of fixed investment costs and initial working capitals including costs that would be incurred before operation. Hence the total investment of the business is calculated based on the owner’s objective, plan and the requirement of investment items for the intended purpose which is estimated and found to be birr 5,600,000. Table 6: Estimated Initial and Fixed Investment Cost of the Business Ser. No. Description 1 Tractors and plough disk Sub-total 3 Working Capital 4 pre-operating cost Sub-total Total Percentage Debit Equity Ratio Investment Total Percentage Cost (In Investment Proportion (%) Birr) Cost (In Birr) 5,600,000 5,600,000 5,600,000 5,600,000 1,120,000.00 1,120,000.00 560,000.00 80,000 80,000 33,000 1,200,000.00 1,200,000.00 6,800,000.00 6,800,000.00 21.43% 78.57% 443,000 - 443,000 80% 20% 100% 5.2 Source of Finance The total planned investment cost of the project is estimated to be 6,800,000.00 birr of which, Birr 1,200,000.00, 21.43%) is equity contribution and the remaining Birr (78.57%) is finacing from the bank.. 5.3 Expected Financial Results As seen the excel part of the appraisal the team try to show all financial analysis like Profit/loss or income statement forecast, cash flow and balance sheet projection, financial rate of return and sensitivity of the project for potential variables. 5.3.1 Profit/loss forecast Profit/loss forecast presents the results of project’s operations during a period of time. It shows income earning from the project and expenses incurred in attaining the income. The projected 11 profit/loss statement of the project reveals that the project will earn net profit of Birr 1,010,720.00 during its first year of its operation and earn net profit of Birr 1,424,750.00 at the 10th end year of projection. This indicates that the project could run profitable business venture and can maintain objective of its establishment at competitive price. 5.3.2 Cash Flow Forecast Cash flow projection provides a look at the movement of cash in and out of the project. It is important in determining whether or not a project has enough cash to pay its bills, handle expenses and acquire assets. Thus, it is important to give due attention to identify whether the total inflows of the project have the capacity to cover all cash outflows during its operational period. Unless, the project will faces liquidity crisis and fail before achieving its objective of establishment. Based on this fact, the forecasted cumulative cash balance shows a balance of Birr 467,316.00 in the first year and will grow up to Birr 9,156,476.00 at the end of project period, demonstrating that the project will not face liquidity constraint to finance its operational costs as well as debt obligation. 5.3.3 Balance Sheet Projection Balance Sheet Projection is used to provide insight into assets and debts of the project at a particular point in time. Total assets of the project is expected to rise from Birr 7,721,956.00 during the first operational year to Birr 9,514,748.00 at the end project year. 5.3.4 Financial Rate of Return Table 7: Estimated Initial and Fixed Investment Cost of the Business Scenario Internal Rate of Return Before Tax 10,782,710.00 64% After Tax 6,904,782.00 46% VI. 6.1. Net Present Value (NPV) SOCIO ECONOMIC BENEFIT AND ENVIRONMENTAL IMPACT Socio Economic Benefit Agriculture in Ethiopia is the foundation of the country's economy, accounting for half of gross domestic product (GDP), 83.9% of exports, and 80% of total employment. This particular sector 12 determines the growth of all other sectors and consequently, the whole national economy.Based on this fact Agricultural Mechanization Service has enormous contributions: Source of Government Income: - from this sector government get income in the form of profit tax. The government gets income in the form of employee tax from permanent and temporary employee. Employment Opportunities Creation:-The importance of crop production practice in creating employment is not only limited to the farming practice but also to agro processing industries too. The expansion of such farms increases the establishment of related factories, thereby huge employment opportunity ensured along the value chain. Linkage Effects:- The expansion of crop production in the country with advanced technology would have forward and backward linkages. The forward linkages would be the expansion of factories and packaging material industries while the backward linkages are the expansion of input producing and supplying firms in the country. Technology and Knowledge Transfer:- The development of this subsector transfer new technology and knowledge by introducing modern production techniques that optimize production and productivity. GDP Contribution:- crop production contributes to the GDP of the country, increases the income of the workers employed in and the owner too. 13