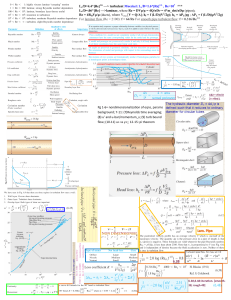

GROUP NAME: Charlie and the Charlie’s Angels DATE: July 26, 2010 NAME: Mujette G. Godmalin Instructor’s Signature:_______ ACTIVITY NO. 3 DETERMINATION OF REYNOLDS’ NUMBER OBJECTIVE: To determine the Reynolds’ number for the different types of flow of fluids. THEORETICAL BACKGROUND: In fluid mechanics, a number that indicates whether the flow of a fluid (liquid or gas) is absolutely steady (laminar flow) or on the average steady with small, unsteady changes (in turbulent flow) is the Reynolds number. The Reynolds number serves as a criterion of the type of fluid motion. In a pipe, for example, laminar flow normally exists at Reynolds numbers less than 2100, and turbulent flow at Reynolds numbers above about 4000. Studies have shown that the transition from laminar to turbulent flow in tubes is not only a function of velocity but also of density and viscosity of the fluid flow in the tube. These variables are combined into the Reynolds number, which is dimensionless. Reynolds number can be calculated by the equation, 𝑁𝑅𝑒 = D𝜈𝜌 𝜇 Where NRe is the Reynolds number, D the diameter in m, ρ the fluid density in kg/m3, μ the fluid viscosity in Pa • s, and ν the average velocity of the fluid in m/s (where average velocity is defined as the volumetric rate of floe divided by the cross sectional area of the pipe). Source: McCabe, W. L., and J. C. Smith, Unit Operation of Chemical Engineering, 2nd edition, McGraw-Hill, 1967. http://www.answers.com/topic/reynolds-number SKETCHES: MOVEMENT OF THE FLUID TYPES OF FLUID FLOW TURBULENT LAMINAR APPARATUS: Dye Meter stick ● ● One liter beaker Transparent glass pipe PROCEDURE: 1. Measure the inner diameter of the glass pipe. 2. Slowly open the A value of the equipment. 3. Inject a continuous but small amount of dye near the opening of the pipe. This indicates the pattern of water flow. 4. Determine the volume of water collected over a certain period of time. 5. Repeat the same procedure by turning two, three and four turns of the valve opening and observe the type of flow, respectively. 6. Observe the thread of the dye pattern. For laminar flow, this will be straight. As the velocity is increased the thread becomes a wave form until when the flow is becoming turbulent where the thread of the dye will be broken and will be flowing at random directions. This condition will occur but when the flow is changing from laminar to turbulent. TABLE OF RESULTS: Density of water: 995.68 kg/m3 Viscosity of water: 0.8007 kg/m.s Diameter of Pipe: 2.54 cm Length of Pipe: 95.0 cm No. of Turns Duration of run (sec) Vol. of water collected (cm3) V (m/s) NRE Type of flow 1 2 4 5 4.56 2.10 1.63 1.7 400 593.33 596.67 656.67 0.16910 0.55204 0.71123 0.75345 5341.0578 TURBULENT TURBULENT TURBULENT TURBULENT COMPUTATIONS: @ 30oC ID: 1 inch or 2.54 cm ( Perry’s Chemical Engineering Handbook) Density: 995.68 kg/m3 Viscosity: 0.8007 x 10-3 kg/m•s D𝜈𝜌 𝑁𝑅𝑒 = 𝜇 Fluid Velocity: Area of the pipe = 5.06707439𝑥 10−4 𝑚2 17436.2954 22464.3439 23797.8712 1𝑚 V= 87.72 𝑐𝑚 3 𝑥 100 𝑐𝑚 (0.0254 )2 𝜋 4 3 𝑚2 𝑚3 = (8.772𝑥 10 −5 𝑠 ) (5.06707439 𝑥 10 −4 𝑚 2 ) = 0.169099566 𝑚/𝑠 Reynolds’ Number: NRe for 1 turn = 𝑚 𝑘𝑔 𝑥(995.68) 3 𝑠 𝑚 0.8007 𝑥10−3𝑘𝑔 0.0254𝑚 𝑥 0.16910 = 5341.0578 𝑚𝑠 𝑚 NRe for 2 turns = 0.8007 𝑥10 −3 𝑘𝑔 𝑚 𝑠 𝑚 NRe for 4 turns = = 17436.2954 𝑘𝑔 0.0254𝑚 𝑥 0.71123 𝑠 𝑥(995.68) 3 𝑚 = 22464.3439 0.8007 𝑥 10 −3 𝑘𝑔 𝑚 𝑠 𝑚 NRe for 5 turns = 𝑘𝑔 0.0254𝑚 𝑥 0.55204 𝑠 𝑥(995.68) 3 𝑚 𝑘𝑔 0.0254𝑚 𝑥 0.75345 𝑠 𝑥(995.68) 3 𝑚 0.8007 𝑥10 −3 𝑘𝑔 𝑚 𝑠 = 23797.8712 DISCUSSION: The water flow was observed in a Reynolds number counter with aide of a dye. The dye trace made it easier to observe the flow as the valve was opened according to specified turns. When the valve was turned once, the dye pattern was initially straight but then became a wave. The flow was initially laminar but changes to turbulent as manifested by the wave. The calculated Reynolds number of 5341.0578 (>4000) was calculated affirming the observation of the group. When the valve was turned twice, the wave was immediately observed in the fluid flow. The calculated Reynolds number is 17436.2954 which lie in the turbulent range. When the valve was turned four to five times, the wave of the dye thread that was initially observed was immediately broken going to random directions. It was very clear that turbulent flow was observed in the pipe which is also affirmed by the calculated Reynolds number of 22464.3439 to 23797.8712. The fluid flow as observed was affected by the volumetric flow rate of the fluid, the size of the pipe and the density and the viscosity of the fluid. These are the same factors affecting the calculation of the Reynolds number. When viscosity is increased, a straight pattern in the flow is expected approaching laminar flow. When velocity is increased, random directions will be observed in the flow reflecting turbulence. Laminar (steady) or turbulent flow of the fluid can be determined by observing the behavior of the flow but quantifying the steadiness or turbulence of the flow needs the calculation of the Reynolds number. CONCLUSION: The major factors affecting the fluid flow is fluid velocity and viscosity. At low velocities fluid flow is laminar, and the fluid can be pictured as a series of parallel layers, or lamina, moving at different velocities. The fluid friction between these layers gives rise to viscosity. The viscous stresses within a fluid tend to stabilize and organize the flow. Thus, as the fluid becomes viscous, the flow becomes laminar. On the other hand, as the fluid flows more rapidly, it reaches a velocity, known as the critical velocity, at which the motion changes from laminar to turbulent, with the formation of eddy currents and vortices that disturb the flow. This is due to the fluid inertia that tends to disrupt organized flow leading to chaotic turbulent behavior. The behavior of the fluid flow is quantified by the Reynolds number. Reynolds number is defined as the ratio of inertial and viscous force to characterize the types of flow patterns. With increase in flow velocity, the initial forces increase so as the Reynolds Number. The Reynolds number is significant in the design of a model of any system in which the effect of viscosity is important in controlling the velocities or the flow pattern. REFERENCES: 1. McCabe, W. L., and J. C. Smith, Unit Operation of Chemical Engineering, 2nd edition, McGraw-Hill, 1967. 2. http://www.brighthub.com/engineering/civil/articles/47264.aspx#ixzz0ukdJVV5s APPENDIX: Raw Data No. of Turns Trial No. Duration of run (sec) Vol. of water collected (cm3) 𝑽 (cm3/s) 1 1 2 3 2 1 2 3 4 1 2 3 5 1 2 3 4.59 4.88 4.21 4.56 1.87 2.39 2.03 2.10 1.51 1.70 1.67 1.63 1.55 1.84 1.71 1.7 450 400 350 400 600 580 600 593.33 650 590 550 596.67 730 570 670 656.67 98.04 81.97 83.13 87.72 320.86 242.68 295.57 286.37 430.46 347.06 329.34 368.95 470.97 309.78 391.81 390.85