Acrylonitrile Air Emissions: Locating & Estimating Sources

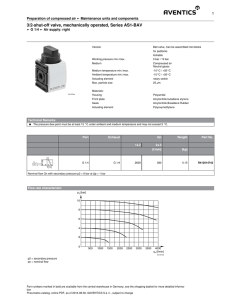

advertisement