Physical and chemical properties of nano-sized aluminum hydroxide and oxide particles obtained by the electrochemical method

advertisement

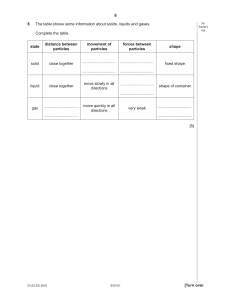

ISSN 00360244, Russian Journal of Physical Chemistry A, 2010, Vol. 84, No. 4, pp. 642–647. © Pleiades Publishing, Ltd., 2010. Original Russian Text © A.F. Dresvyannikov, E.V. Petrova, M.A. Tsyganova, 2010, published in Zhurnal Fizicheskoi Khimii, 2010, Vol. 84, No. 4, pp. 727–732. PHYSICAL CHEMISTRY OF NANOCLUSTERS AND NANOMATERIALS Physical and Chemical Properties of NanoSized Aluminum Hydroxide and Oxide Particles Obtained by the Electrochemical Method A. F. Dresvyannikov, E. V. Petrova, and M. A. Tsyganova Kazan State Technological University, Kazan, 420111 Russia email: katrinvv@mail.ru Received April 28, 2009 Abstract—The structure and properties of nanoparticles of aluminum hydroxides and oxides obtained by electrochemical, chemical, and combined methods were studied by transmission electron microscopy, Xray diffraction, thermal analysis, and atomic emission spectroscopy. The influence of synthesis conditions on the structure and morphology of nanoparticles was studied. It was shown that the effect of an electrochemical field allows monophasic systems to be obtained with a narrower range of particle sizes than in the case of chemical deposition. DOI: 10.1134/S0036024410040217 INTRODUCTION Nanosized particles of metal oxides are capable of exhibiting unusual properties due to the features of individual particles and the conglomerates formed by these particles, as well as to the nature of the interac tion between them [1, 2]. Nanodispersed metal oxides are widely used in industry: aluminum oxide, e.g., is used as a highly effective catalyst, sorbent, and catalyst carrier; for creating new functional materials with spe cial properties (magnetic, electrical, and optical); as fillers in modifying polymer materials to improve their qualities (mechanical, physicochemical, chemical, and so on); and in medicine, cosmetics, and other fields [1, 3, 4]. There are many different methods for preparing nanosized aluminum oxides; one of the most promis ing, however, is the electrochemical method of obtain ing metal oxides, since the ability to effectively regu late the parameters of electrochemical process allows us to obtain nanosized particles with a narrow range of sizes and control their shape, morphology, and phase composition [5, 6]. The purpose of this work was to study the effect of synthesis conditions on the shape, morphology, and phase composition of nanoparticles of aluminum hydroxides and oxides obtained by various methods. EXPERIMENTAL A coaxial electrochemical reactor, in which X18H10T steel was served as cathode and A5 alumi num was used as an anode, was used for aluminum hydroxide. Electrolysis was performed at different anodic current densities, with aqueous solutions of NaCl with different concentrations (chemically pure) being used as electrolyte (Table 1). In obtaining alumi num hydroxide by the chemical method, deposition was performed from solutions of salts of aluminum, with solutions of sodium and ammonium hydroxide being used as the nonsolvent. In the combined method, samples obtained by chemical deposition were subjected to a constant electric current in a coax Table 1. Profiles of obtained aluminum hydroxide No. cNaCl, M j, А/m2 T, min No. cNaCl, M j, А/m2 T, min No. 1 2 3 0.1 0.2 0.5 Electrochemical 166.7 130 4 0.1 166.7 120 5 0.2 166.7 60 6 0.5 83.3 83.3 83.3 150 120 150 7 8 9 10 Salt No. j, А/m2 Chemical 11 1 M AlCl3 0.2 M Al2(SO4)3 12 0.5 M Al(NO3)3 13 0.5 M Al(NO3)3 Combined 166.7 0.2 M Al2(SO4)3 166.7 0.2 M Al2(SO4)3 166.7 0.5 M Al(NO3)3 Note: In sample 10, 10 M NH4OH was added upon precipitation; 3 M NaOH was added to the other samples. 642 Salt T, min 30 30 30 PHYSICAL AND CHEMICAL PROPERTIES OF NANOSIZED ALUMINUM HYDROXIDE (а) 100 nm 643 100 nm (b) Fig. 1. Electron microscope image of nanoparticles of aluminum hydroxide obtained by (a) electrochemical and (b) combined methods. Magnification (a) 105000; (b) 55000. ial electrolytic cell; OPTA was used as anode, while steel X18H10T served as a cathode. For crystalliza tion, the precipitate was kept in the mother solution and then filtered and dried at 363–383 K. To obtain the oxides, the corresponding hydroxides were cal cined at 823 K. Xray analysis was performed on a D8 ADVANCE diffractometer (Bruker) employing monochromatic CuKα radiation in the step scan mode. The distance between the planes of the diffraction reflexes was cal culated automatically by the EVA program. Crystal line phases were identified by comparing the experi mental values of the interplanar distances and relative intensities with the control values. Thermal studies were carried out with use of an STA 409 PC Luxx synchronous thermoanalyzer (sam ples were heated at temperatures of 298 to 1273 K at a rate of 10 K/min). Water content in the samples was calculated from the results of thermogravimetric anal ysis by the formula n ( H 2 O ) = ω ( H 2 O )/100M H2 O , mol/g , where ω(H2O) is the total mass loss after heating to a temperature of 1273 K, %; n(H2O) is the amount of water in the sample, mol/g; and M H2 O is the molecular weight of water, g/mol. The size of the particles in the synthesized samples was determined by transmission electron microscopy (TEM) using an EMMA4 microscope microana lyzer. The series of studies to determine the percentage of impurities of iron, chromium, arsenic, bismuth, cobalt, manganese, stibium in oxides and hydroxides of aluminum was performed on an ICAP 6000 atomic emission spectrometer. RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A RESULTS AND DISCUSSION Our studies of hydroxides and oxides of aluminum by means of transmission electron microscopy revealed the dependence of particle size on the man ner and mode in which they were obtained (Fig. 1, Table 1). Samples of aluminum hydroxide 1–6 obtained by the electrochemical method are highly refined particles ~50 nm in size inclined to aggrega tion, against which there are clearly visible aggregates of ≥150–200 nm and larger ones with thicknesses of >1 μm. In hydroxide samples 7–10 obtained by tradi tional chemical precipitation, the particle size distri bution depends on the concentration of the initial solution of aluminum salt. In the case of samples obtained from concentrated solutions, we observe par ticles more varied in shape and size at submicron and micron ranges in the micrographs (needles, elongated plates, barlike, and granular in small quantities). Dilu tion of the solution promotes the formation of a super fine phase, against which nanoscale particles are clearly seen. For sample 8, rounded and slightly fac eted particles with dimensions of 20–30 nm, needle like particles measuring ~10 × 120 nm, and single elongated platelike units forming a package of thin shifted plates sizes of ~0.2 × 0.6 μm were detected. Finegrained particles measuring 7–10 nm, dark teardropshaped particles of 10–50 nm, and scaly aggregates with sizes ranging from 0.3 to 1 μm were found during study of sample 9. Increasing the concentration of solutions of alumi num (III) and precipitating agent promotes the for mation of particles with blurred contours, ranging in size from 50 to 250 nm, 80 × 500 nm packets of plates displaced relative to one another, and large aggregates measuring 0.2 × 3.5 μm. Increasing the concentration of aluminum salt in the solution from which deposition takes place, along with increasing the concentration of precipitant solu Vol. 84 No. 4 2010 644 DRESVYANNIKOV et al. (а) 100 nm 85 nm (b) Fig. 2. Electron microscope image of nanoparticles of aluminum oxide, obtained by (a) electrochemical and (b) combined meth ods. Magnification (a) 113000; (b) 98000. tion, thus contributes to the formation of larger parti cles due to aggregation. In samples of aluminum hydroxide 11–13, obtained by means of a combination of chemical methods (using dilute solutions of aluminum salts and precipitant) and electrochemical effects, a depen dence was observed for the size of the obtained parti cles on the nature of the initial salt. The deposition of aluminum sulfate solutions of different concentrations (samples 11 and 12) promoted the formation of nanos cale particles of needle shape with an average size of 10 × 70 nm, finegrained particles measuring 10–20 nm, and clear faceted aggregates of submicron size (~0.3 × 0.75 μm). The use of aluminum nitrate (Sample 13) as the initial solution led to more aggregated particles of rectangular shape ≤1 μm thick (linear dimensions var ied over the range 200–500 nm) and microaggregates of isometric habitus nanoparticles with an average size of ~50 nm. In the micrographs, there is also evidence of an amorphous structure that forms clusters at the edges of plates and isolated clusters with sizes of up to 300 nm. It should be noted that during the synthesis of alu minum hydroxide by electrochemical method, increasing the current density and concentration of the electrolyte solution led to the growth of microag gregates formed by nanoparticles. Hydroxides of aluminum obtained by chemical deposition show the greatest disposition toward aggre gation of particles; this decreases with subsequent treatment in solution by an electric current (a com bined method of acquisition). During our study of oxides of aluminum obtained from the respective hydroxides, we observed a clearer size distribution of particles, depending on the method and mode of acquisition (Table 2, Fig. 2). Fine aluminum oxide exists in the Xray amor phous state over a wide temperature range (as high as 1073–1273 K) [7, 8]. After reaching the specified tem peratures and the corresponding increase in particle size, metastable phase γAl2O3 is often formed, with stable crystalline phase Al2O3 finally forming as a rule at 1373–1473 K. A major task in the synthesis and application of aluminium oxides is studying the factors that increase the stability of metastable states. To date, there are two basic concepts of conservation of oxides in a metastable state [6, 8, 9]: the first involves the dimensional (dispersion) factor; the second, in addi tion to dispersion, takes into account an additional stabilizing factor—the presence and conservation of water in the crystal structure of oxides up to high tem peratures. The results from our study of the phase composi tion of hydroxides obtained by the electrochemical method reveal that samples 1–6 are a mechanical mix ture of boehmite and bayerite (Fig. 3). The peaks with interplanar distances (d/n) 4.71, 4.37, 3.20 and 2.22, 1.72 Å observed in the crystallo gram belong to bayerite [6, 8, 9]. In addition to the bayerite phase, the boehmite phase is present to one degree or another in all of the studied samples, as shown by the reflexes (d/n) 6.13, 3.20, 2.36, and 1.86 Å [6, 8, 9]. Xray diffraction analysis of the samples syn thesized by chemical deposition from solutions of alu minum salts showed less homogeneous phase compo sition, combining the simultaneous presence of two, three, or more phases, but the additional effect of the electric field (a combined method of acquisition) allows us to obtain monophasic systems (Table 3). The ratio of integrated intensities of the peaks of boehmite and bayerite corresponds to the quantitative ratio of these phases, measured by the ratio of the inte grated intensities of the peak of boehmite with d/n = 6.2 Å and the sum of the integrated intensities of the peaks of bayerite with d/n = 4.7 and 4.4 Å. It was found that among samples 1–3, synthesized at current den RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A Vol. 84 No. 4 2010 PHYSICAL AND CHEMICAL PROPERTIES OF NANOSIZED ALUMINUM HYDROXIDE 645 Table 2. Results from transmission electron microscopy of aluminium oxide upon different methods of acquisition No. Characteristics of particles Electrochemical 1 • needleshaped particles ≤10 nm wide and up to 100 nm long (prone to aggregation); • particles of finegrained structure (grain size, ≥10 nm); • aggregates formed by particles as small as 60 nm (form close to weakly faceted, hexagonal). 2 • needleshaped particles ≤10 nm wide and up to 100 nm long, • particles of finegrained structure (grain size ≤10 nm); • barshaped aggregates measuring ~0.7 × 2.5 μm. 3 • fine particles (~50 nm); • larger particles (up to 500 nm); • aggregates (5–10 μm). 4 • fine particles (~50 nm); • aggregates of isometric (~0.5 μm) to elongated (~1.5 to 5 μm). 5 • needleshaped particles ≤10 nm wide and up to 100 nm long (prone to aggregation); • aggregates ~3.5 × 4 μm wide and ~4.5 × 6 μm long. 6 • fine particles (~50 nm); • particle measuring ≥300 nm. Chemical 7 • aggregates of particles measuring ~70 × 100 nm; • clusters of platetype particles measuring 200 × 400 nm. 8 • pseudorhombic aggregates formed by plates measuring ~350 × 400 nm; • pseudotube structure aggregates 0.25 μm wide and ~1.5 μm long. 9 • particles measuring 10–30 nm; • lamellar particles of quasirectangular shape with sizes ranging from ~50 × 100 to 100 × 150 nm; • pseudotube aggregates of semicurtail tubes with diameters of 5–10 nm and lengths of ~200 nm; • finegrained particles with a grain sizes up to 10 nm. 10 • isometric fine particles with sizes up to 50 nm arranged in a unique chain of arbitrary shape and tending to form aggregates of sizes up to 500 nm; • translucent platetype particles having no definite shape, with sizes of 400 to 600 nm. Combined 11 • isometric particles measuring up to 50 nm (prone to aggregation); • platetype particles measuring 400–600 nm. 12 • thin, isometric nanoparticles measuring 10–20 nm and forming microaggregates; • particles measuring 20–30 nm, clearly defined at edges of aggregates; • multilayer large formations (up to several microns) and individual particles of arbitrary shape and thickness; some particles form bends along the edges (characteristic of squamous morphostructures). 13 • elongated platelike particles with sizes varying from 100 × 250–300 × 600 nm; • wedgeshaped objects of irregular thickness with linear dimensions: base ~450–600 nm, height ~800–900 nm; • amorphous substance forming clusters of varying thickness and linear dimensions (up to 1.2 μm); isolated iso metric particles that form these clusters measuring 50–70 nm. RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A Vol. 84 No. 4 2010 646 DRESVYANNIKOV et al. 3 2 1 10 20 30 40 50 60 70 80 2θ, deg Fig. 3. Typical diffraction patterns of samples of aluminum hydroxide obtained by (1) electrochemical, (2) chemical, and (3) combined methods. sity j = 166.7 A/m2, a reduction in the proportion of boehmite with increasing electrolyte concentration is observed; a similar dependence is characteristic for samples 4–6, synthesized at lower current density j = 83.3 A/m2. In general, lowering the current density by a factor of 2 promotes the formation of large amounts of boehmite phase. High current density and low electrolyte concen tration is to a greater extent more conducive to the for mation of boehmite phase: when the concentration of electrolyte is increased, the proportion of bayerite phase rises. Reducing the density while simulta neously increasing the electrolyte concentration leads to a drop in the proportion of boehmite. Phase transformations of crystalline hydroxides according to their heating characteristics are deter mined by features of the two main stages: the removal of hydroxyl groups and the transition of the crystal structure of the hydroxide in the crystal structure of the oxide. At a heating rate of ~10 K/min, the above Table 3. Results from studying the phase composition of aluminum hydroxide Method of acquisition Electrochemical Chemical Combined Phase Boehmite + bayerite Boehmite + bayerite + gibbsite + nordstrand Bayerite Note: RFA of oxides revealed only the presence of γAl2O3 phase. stages are combined; thus, from one to three or four endothermic effects accompanied by mass loss heating are observed in the curves from differential thermal analysis of the studied hydroxides. Mass loss (in recal culation to H2O) in different temperature ranges was calculated for quantitative interpretation of the results from differential thermal analysis of the studied sam ples. These data are listed in Table 4. According to [8–12], the low temperature endot hermic effect of the dehydration of aluminum hydrox ides is due to the removal of physically bounded water. It is also known that the process of bayerite dehydra tion is characterized by the presence of endothermic effects with maxima at 373, 513, 573, and 768 K. We may consequently assume that for all the samples, the first endothermic effect in the 298–466 K range is caused by the removal of physically bounded water and the dehydration of bayerite. The second endothermic peak at 550 K is caused by bayerite dehydration and the formation of two phases: boehmite and lowtem perature aluminum oxide (ηAl2O3). The high tem perature endothermic effect in the 584–973 K range characterizes the removal of water from the boeh mite’s structure and the formation of γAl2O3. The endothermic effects at 383, 583, and 773 K, due to the removal of physically adsorbed water, the dehydration of trihydroxide, and the crystallization of lowtemperature aluminium oxide, respectively, are characteristic for the thermochemical transformations of aluminium oxide obtained by calcination of chem ically precipitated gibbsite. Similar endothermic effects are also observed for sample 9, in which Xray RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A Vol. 84 No. 4 2010 PHYSICAL AND CHEMICAL PROPERTIES OF NANOSIZED ALUMINUM HYDROXIDE 647 Table 4. Results from thermogravimetric determination of mass loss (Δmi , wt %) in different temperature ranges for sam ples of aluminum hydroxide No. Т1, К Т1max , К Δm1 Т2, К Т2max, К Δm2 Т3, К Т3max, К Δm3 n(H2O), mol/g 1 2 3 4 5 6 7 8 9 10 11 298–496 298–466 298–466 298–465 298–465 298–458 298–425 298–493 298–422 298–480 298–498 351 353 377 363 369 370 360 358 339 401 360 18.9 7.68 15.99 13.54 11.15 11.92 4.01 20.82 0.27 72.45 15.67 496–606 466–607 466–594 465–584 465–584 458–600 425–510 493–628 422–513 480–628 498–627 549 555 550 543 564 550 – 555 492 480 559 11.25 12.81 10.59 7.43 15.10 15.99 3.08 13.99 8.26 3.86 15.11 606–810 607–791 594–780 584–779 584–779 600–766 510–616 628–1263 513–639 – 627–954 696 680 657 664 674 633 558 680 570 – – 10.01 8.05 7.36 8.93 5.59 5.31 22.46 10.92 17.48 – 6.80 0.0383 0.0175 0.0211 0.0183 0.0192 0.0211 0.0208 0.0285 0.0174 0.0431 0.0267 Note: For samples 9 and 11 in the range of T4 value 639–865 and 955–1271 K (T4max = 657 and 1138 K) value Δm4 = 5.95 and 0.11 wt %, respectively. Table 5. Contents of chemical elements (wt %) in test sample 2 of aluminum hydroxide and oxide according to the atomic emission spectroscopy Sample Aluminum hydroxide Aluminum oxide Bi Co Cr Fe Mn Sb 0.120 0.020 – 0.002 0.004 0.150 0.003 0.040 0.002 0.013 0.007 0.01 diffraction analysis revealed the presence of gibbsite phase, and a fourth peak with a maximum at 492 K was caused by the removal of physically bounded water and the dehydration of bayerite [8–12]. We also evaluated the chemical composition of the obtained aluminum hydroxide and oxide for the pres ence of impurities. The quantitative content of impu rities of iron, chromium, arsenic, bismuth, cobalt, manganese (Table 5), antimony was determined by atomic emission spectroscopy for sample 2. CONCLUSIONS Analysis of the results of our studies demonstrates the greater effectiveness of the electrochemical method as compared to traditional chemical deposi tion in acquisition nanosized particles of aluminum hydroxide and oxide. It was established that control ling the parameters of the electrochemical processes makes it possible to obtain nanosized particles of alu minum hydroxide and oxide with sizes of 10–300 nm, while the size of particles obtained by the chemical method, range from 50 nm to 3.5 μm. Using Xray phase and thermal analysis, it was revealed that the samples of aluminum hydroxide and oxide are in fact a biphasic system, and changing the process parame ters (e.g., current density and concentration of elec trolyte solution) allows the ratio of phases to be changed in one direction or another. The last is very important in acquisition aluminum oxide nanopowder with a particular crystal structure. RUSSIAN JOURNAL OF PHYSICAL CHEMISTRY A REFERENCES 1. A. I. Gusev, Nanomaterials, Nanostructures, Nanotech nologies (Fizmatlit, Moscow, 2007) [in Russian]. 2. Li Hongyan, Yan Yan, Bin Liu, et al., Powder Technol. 178, 203 (2007). 3. B. G. Linsen, Physical and Chemical Aspects of Adsor bents and Catalysts, Ed. by B. G. Linsen (Academic, London, 1970; Mir, Moscow, 1973), p. 653. 4. Y.H. Choa, S.H. Kim, D.J. Park, et al., Mater Integr. 18 (1), 48 (2004). 5. YongXin Pang and Xujin Bao, J. Mater. Chem., No. 12, 3699 (2002). 6. M. Edrissi and R. Norouzbeigi, Chin. J. Chem. 26, 1401 (2008). 7. N. A. Toropov, V. P. Barzakovskii, I. A. Bondar’, and Yu. P. Udalov, State Diagrams of Silicate Systems, The Handbook, No. 2: MetalOxygen Compounds of Silicate Systems (Nauka, Leningrad, 1970) [in Russian]. 8. A. S. Ivanova, Zh. Prikl. Khim. 69, 1790 (1996) [Russ. J. Appl. Chem. 69, 1764 (1996)]. 9. R. G. Romanova and E. V. Petrova, Zh. Fiz. Khim. 80 (6), 110 (2006) [Russ. J. Phys. Chem. A 80, 974 (2006)]. 10. A. N. Kharlanov, E. V. Lunina, and V. V. Lunin, Zh. Fiz. Khim. 71, 1672 (1997) [Russ. J. Phys. Chem. A 71, 1504 (1997)]. 11. A. S. Sinitskii, V. A. Ketsko, I. V. Pentin, et al., Zh. Neorg. Khim. 48, 484 (2003) [Russ. J. Inorg. Chem. 48, 406 (2003)]. 12. A. Rai, K. Park, L. Zhou, and M. R. Zachariah, Com bust. Theory Model. 10, 843 (2006). Vol. 84 No. 4 2010