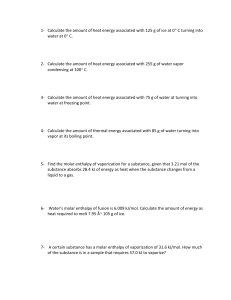

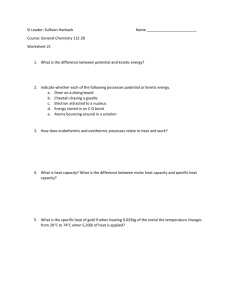

CHAPTER 8 Balances on Nonreactive Processes We have seen that for an open system in which shaft work and kinetic and potential energy changes can be neglected, the energy balance reduces to Q_ ΔH_ X ^i n_ i H X ^i n_ i H Q ΔU X ni U^ i X ^i ni U out in ^ i values are the specific enthalpies of the inlet and outlet stream components at their where the H respective process conditions (temperatures, pressures, and states of aggregation) relative to those components at some reference conditions. For an integral balance on a closed constant-volume system (W 0), the energy balance is final initial ^ i values are specific internal energies. where the U In Chapter 7, we dealt only with processes involving species for which specific enthalpies and internal energies at specified conditions could be found in tables. Unfortunately, you cannot count on finding such data for every species with which you work. This chapter presents procedures for ^ and U ^ are not available for all process species. Once these evaluating ΔH_ or ΔU when tables of H calculations have been performed, the energy balance may be written and solved as before. 8.0 LEARNING OBJECTIVES After completing this chapter, you should be able to do the following: • Define both formally (in terms of internal energies and enthalpies) and in words a high school senior could understand the variables C v T (heat capacity at constant volume), C p T (heat ^ v (heat of vaporizacapacity at constant pressure), ΔH^ m (heat of fusion or heat of melting), ΔH ^ tion), standard heats of fusion and vaporization, and ΔH s (heat of solution or heat of mixing). • Calculate ΔU^ and ΔH^ for the following changes in state of a species, when possible using enthalpies and internal energies, heat capacities, latent heats, and liquid and solid specific gravities tabulated in this text: (a) isothermal changes in pressure, (b) isobaric (constantpressure) changes in temperature, (c) isothermal isobaric phase changes, and (d) isothermal isobaric mixing of two or more species. State when the formulas you use for these calculations are exact, good approximations, and poor approximations. • Given a reference state (phase, temperature, and pressure) and a process state for a species, (a) choose a path from the reference state to the process state consisting of a series of isothermal pressure changes, isobaric temperature changes, and isothermal isobaric phase changes; ^ and H^ for the species at the process state relative to the species at the reference state. (b) calculate U • High school physics and chemistry texts commonly state that the heat (Q) required to raise the temperature of a mass m of a substance by an amount ΔT is Q mC p ΔT, where C p is defined as the heat capacity of the substance. Explain why this formula is only an 402 8.1 Elements of Energy Balance Calculations 403 approximation. List the assumptions required to obtain it from the closed-system energy balance (Q W ΔU ΔEk ΔEp ). • If your class covers Section 8.3e, evaluate Z T2 Cp T dT T1 using the trapezoidal rule or Simpson’s rule (Appendix A.3) from data for Cp at several temperatures between T 1 and T 2 . • Estimate the heat capacity of a liquid or solid species using Kopp’s rule. Estimate the heat of fusion and heat of vaporization of a species using correlations in Section 8.4b. • Given any nonreactive process for which the required heat transfer Q or heat transfer rate Q_ is to be calculated, (a) draw and label the flowchart, including Q or Q_ in the labeling; (b) carry out a degree-of-freedom analysis; (c) write the material and energy balances and other equations you would use to solve for all requested quantities; (d) perform the calculations; and (e) list the assumptions and approximations built into your calculations. • Given an adiabatic process or any other nonreactive process for which the value of Q (closed system) or Q_ (open system) is specified, write material and energy balances and solve them simultaneously for requested quantities. • Define the dry-bulb temperature, wet-bulb temperature, and humid volume of humid air. Given values of any two of the variables plotted on the psychrometric chart (dry-bulb and wet-bulb temperatures, absolute and relative humidity, dew point, humid volume), determine the remaining variable values and the specific enthalpy of the humid air. Use the psychrometric chart to carry out material and energy balance calculations on a heating, cooling, humidification, or dehumidification process involving air and water at 1 atm. • Explain the meaning of the apparently contradictory term adiabatic cooling. Explain how spray cooling and humidification, spray dehumidification, and spray drying work. Explain how it is possible to dehumidify air by spraying water into it. Use the psychrometric chart to carry out material and energy balance calculations on an adiabatic cooling operation involving air and water at 1 atm. • Explain to a first-year engineering student why a beaker containing acid gets hot if you add water to it. • Use the heat of solution data in Table B.11 and solution heat capacity data to (a) calculate the enthalpy of a hydrochloric acid, sulfuric acid, or sodium hydroxide solution of a known composition (solute mole fraction) relative to the pure solute and water at 25°C; (b) calculate the required rate of heat transfer to or from a process in which an aqueous solution of HCl, H2SO4, or NaOH is formed, diluted, or combined with another solution of the same species; and (c) calculate the final temperature if an aqueous solution of HCl, H2SO4, or NaOH is formed, diluted, or combined with another solution of the same species adiabatically. • Perform material and energy balance calculations for a process that involves solutions for which enthalpy–concentration charts are available. 8.1 ELEMENTS OF ENERGY BALANCE CALCULATIONS In this section, we outline a procedure for solving energy balance problems that will be applied to both nonreactive processes (this chapter) and reactive processes (Chapter 9). Section 8.1a reviews the concept of a reference state for specific internal energy and enthalpy calculations, and 404 C H AP T E R 8 Balances on Nonreactive Processes ^ and H ^ are state properties, so that the values of ΔU or ΔH Section 8.1b reviews the fact that U _ (closed system) and ΔH (open system) calculated for a process are independent of the reference states chosen for calculations of U^ i and H^ i . Section 8.1c outlines a procedure for organizing energy balance calculations and presents an extended illustrative example. The remainder of the chapter presents formulas and methods for calculating ΔU, ΔH, and ΔH_ for processes that involve heating and cooling, compression and decompression, phase changes, mixing of liquids, and dissolving of gases and solids in liquids. 8.1a Reference States—A Review ^ and H ^ for a species at a given state. Recall that we can never know the absolute values of U ^ U(kJ/mol) is the sum of the energies of motion of all 6:02 1023 molecules in one gram-mole of the species plus the intramolecular kinetic and potential energies of all the atoms and subatomic ^U ^ PV^ and we cannot know the particles, which are quantities we cannot determine. Since H ^ we also cannot know the value of H^ at a specified state. value of U, ^ or H ^ at specified states: we only Fortunately, we never need to know the absolute values of U ^ and ΔH ^ for specified changes of state, and we can determine these quantities need to know ΔU experimentally.1 We may therefore arbitrarily choose a reference state for a species and ^U ^ U ^ ref for the transition from the reference state to a series of other states. determine ΔU ^ ΔU ^ for a specified state is the specific internal energy at that If we set U^ ref equal to zero, then U state relative to the reference state. The specific enthalpies at each state can then be calculated ^U ^ PV, ^ provided that the specific volume V ^ of the species at the given from the definition, H temperature and pressure is known. ^ and H^ in the steam tables were generated using this procedure. The reference The values of U state was chosen to be liquid water at the triple point [H2O(l, 0.01°C, 0.00611 bar)], at which point U^ was defined to be zero. According to Table B.7, for water vapor at 400°C and 10.0 bar, ^ for water in the specified state is U^ 2958 kJ/kg. This does not mean that the absolute value of U ^ ^ of water vapor at 2958 kJ/kg; remember, we cannot know the absolute value of U. It means that U 400°C and 10.0 bar is 2958 kJ/kg relative to water at the reference state, or H2 O l; 0:01°C; 0:00611 bar ! H2 O v; 400°C; 10:0 bar; ^ 2958 kJ/kg ΔU Relative to water at the same reference state, the specific enthalpy of water vapor at 400°C and 10.0 bar is ^ U ^ PV^ H 2958 kJ/kg 10 bar 0:307 m3 kg 103 L lm 8:314 10 3 3 kJ/ molK 0:08314 Lbar/ molK 3264 kJ/kg The quantities 8:314 10 3 and 0.08314 are values of the gas constant R expressed in different units (see inside back cover). Test Yourself (Answers, p. 658) ^ is defined to be Suppose water vapor at 300°C and 5 bar is chosen as a reference state at which H zero. Relative to this state, what is the specific enthalpy of liquid water at 75°C and 1 bar? What is the specific internal energy of liquid water at 75°C and 1 bar? (Use Table B.7.) 1 The method is to transfer a measured amount of energy, Q, to a known mass of a species, m, in a closed system under conditions such that W 0, ΔE k 0, and ΔE p 0; measure any changes in temperature, pressure, and phase; and ^ corresponding to these changes from the energy balance, Q mΔU. ^ calculate ΔU 8.1 Elements of Energy Balance Calculations 405 8.1b Hypothetical Process Paths ^ and H ^ are state properties of a species: that is, their values In Chapter 7, we observed that U depend only on the state of the species—primarily on its temperature and state of aggregation (solid, liquid, or gas) and, to a lesser extent, on its pressure (and for mixtures of some species, on its mole fraction in the mixture). A state property does not depend on how the species reached its ^ for the state. Consequently, when a species passes from one state to another, both ΔU^ and ΔH process are independent of the path taken from the first state to the second one. In most of this chapter and in Chapter 9, you will learn how to calculate internal energy and enthalpy changes associated with certain processes: specifically, 1. Changes in P at constant T and state of aggregation (Section 8.2). 2. Changes in T at constant P and state of aggregation (Section 8.3). 3. Phase changes at constant T and P—melting, solidifying, vaporizing, condensing, sublimating (Section 8.4). 4. Mixing of two liquids or dissolving of a gas or a solid in a liquid at constant T and P (Section 8.5). 5. Chemical reaction at constant T and P (Chapter 9). For example, compressing hydrogen gas from 1 atm to 300 atm at 25°C is a Type 1 process; melting ice at 0°C and then heating the liquid water to 30°C, all at 1 atm, is a Type 3 process followed by a Type 2 process; mixing sulfuric acid and water at a constant temperature of 20°C and a constant pressure of 1 atm is a Type 4 process. Once we know how to calculate ΔU^ and ΔH^ for these five types of processes, we can ^ and H ^ are state calculate these quantities for any process by taking advantage of the fact that U properties. The procedure is to construct a hypothetical process path from the initial state to the final state consisting of a series of steps of the given five types. Having done this, we calculate ΔH^ ^ for the steps to calculate ΔH ^ for the total process. for each of the steps, and then add the ΔH’s ^ ^ Since H is a state property, ΔH calculated for the hypothetical process path—which we ^ for the path actually followed by the process. constructed for convenience—is the same as ΔH ^ for any process. The same procedure can be followed to calculate ΔU ^ for a process in which solid phenol at Suppose, for example, that we wish to calculate ΔH 25°C and 1 atm is converted to phenol vapor at 300°C and 3 atm. If we had a table of enthalpies for ^ at the initial state from H ^ at the final state, or phenol, we could simply subtract H ^H ^ vapor; 300°C; 3 atm ΔH ^ solid; 25°C; 1 atm H However, we do not have such a table. Our task is then to construct a hypothetical process path from the solid at 25°C and 1 atm to the vapor at 300°C and 3 atm. To do so, we will look ahead a bit and note that Table B.1 gives enthalpy changes for the melting of phenol at 1 atm and 42.5°C (the normal melting point of phenol) and for the vaporization of phenol at 1 atm and 181.4°C (the normal boiling point of phenol). We therefore choose the following hypothetical process path: Ph = phenol(C6H5OH) Ph (s, 25°C, 1 atm) (True path) Ph (v, 300.0°C, 3 atm) ΔĤ1 ΔĤ ΔĤ6 Ph (s, 42.5°C, 1 atm) ΔĤ2 Ph (v, 300.0°C, 1 atm) ΔĤ3 ΔĤ5 Ph (l, 42.5°C, 1 atm) Ph (l, 181.4°C, 1 atm) Ph (v, 181.4°C, 1 atm) ΔĤ4 406 CHAPTER 8 Balances on Nonreactive Processes Notice that in this path, the first, third, and fifth steps are Type 2 (change in T at constant P), the second and fourth steps are Type 3 (change in phase at constant T and P), and the sixth step is Type 1 (change in P at constant T). Also notice that the phase changes were made to occur at the conditions for which tabulated enthalpy changes are available. The next step in the calculation would be to determine the values of ΔH^ for Steps 1, 3, 5, and 6 ^ 4 from Table B.1; and ^ 2 and ΔH using methods to be given in Section 8.2; read the values of ΔH then use the fact that enthalpy is a state property to calculate the desired ΔH^ (ΔH^ for the upper dashed line in the figure) as ^ 2 ΔH^ 3 ΔH ^ 4 ΔH ^ 5 ΔH^ 6 ^ 1 ΔH ΔH^ ΔH Test Yourself (Answers, p. 658) Construct a process path for each of the following processes consisting of sequential steps of the five types listed in the preceding section. (An illustrative solution is given for the first process.) 1. Nitrogen at 20°C and 200 mm Hg is heated and compressed to 140°C and 40 atm. (One of an infinite number of possible solutions: Heat at 200 mm Hg from 20°C to 140°C, then compress isothermally from 200 mm Hg to 40 atm.) 2. Cyclohexane vapor at 180°C and 5 atm is cooled and condensed to liquid cyclohexane at 25°C and 5 atm. The enthalpy change for the condensation of cyclohexane at 80.7°C and 1 atm is known. 3. Water at 30°C and 1 atm and NaOH at 25°C and 1 atm are mixed to form an aqueous NaOH solution at 50°C and 1 atm. The enthalpy change for the dissolution of NaOH in water at 25°C and 1 atm is known. 4. O2 at 170°C and 1 atm and CH4 at 25°C and 1 atm are mixed and react completely to form CO2 and H2O at 300°C and 1 atm. The enthalpy change for the reaction occurring at 25°C and 1 atm is known. 8.1c Procedure for Energy Balance Calculations Most of the problems at the end of this chapter and Chapter 9 look very much like the problems in Chapters 4 to 6: given values of some process variables (feed and product stream temperatures, pressures, phases, amounts or flow rates, and component mole fractions), calculate values of other process variables. Starting in this chapter, you will also be asked to calculate the heat transferred to or from the process system (one additional variable), which will require writing and solving an energy balance (one additional equation). Here is the procedure to follow for the energy balance calculation. 1. Perform all required material balance calculations. 2. Write the appropriate form of the energy balance (closed or open system) and delete any of the terms that are either zero or negligible for the given process system. For a stationary closed system, drop ΔEk and ΔE p , and neglect W if the system volume is constant, there are no moving parts (such as a mixing impeller in a stirred tank), and no energy is transferred to or from the system by electricity or radiation. For an open system at steady state, drop ΔE_ p if there is no appreciable vertical separation between the inlet and outlet ports, and drop W_ s if there are no moving parts (such as a pump or turbine impeller) and no energy is transferred by electricity or radiation. In addition, if temperature changes of more than a few degrees, phase changes, or chemical reactions occur in the process, ΔE_ k usually is negligible compared to ΔU_ and ΔH_ and so may be deleted from the equation. 3. Choose a reference state—phase, temperature, and pressure—for each species involved in ^ or U^ for a species will be looked up in a table (such as the steam tables for the process. If H 8.1 Elements of Energy Balance Calculations 407 water), choose the reference state used to generate the table; otherwise, choose one of the inlet ^ or U ^ may be set equal or outlet states as the reference state for the species (so that at least one H to zero). 4. For a closed constant-volume system, construct a table with columns for initial and final amounts of each species (mi or ni) and specific internal energies relative to the chosen ^ i ).2 For an open system, construct a table with columns for inlet and reference states (U _ i or n_ i ) and specific enthalpies relative to the chosen outlet stream component flow rates (m ^ i ). Insert known values of the amounts or flow rates and the specific reference states (H internal energies and enthalpies, and insert labels for the entries that must be calculated (e.g., ^1; H ^ 2 , . . .). The next example illustrates the construction of such a table. H ^ i (or H ^ i ) and insert the values in the appropriate places in 5. Calculate all required values of U the table. To perform the calculation for a species in a particular state (inlet or outlet), choose ^ i ) as ΔU^ any convenient path from the reference state to the process state and determine U^ i (H ^ (ΔH) for that path. Sections 8.2–8.5 outline these calculations for different types of processes. 6. Calculate Closed System: ΔU X ^i ni U final Open System: ΔH_ X X ^i ni U or out X ^i n_ i H m_ i U^ i out initial ^i n_ i H X or X m_ i H^ i out in X m_ i U^ i in X ^i m_ i H in 7. Calculate any work, kinetic energy, or potential energy terms that you have not dropped from the energy balance. _ 8. Solve the energy balance for whichever variable is unknown (often Q or Q). Closed System: Open System: Q W ΔU ΔEk ΔE p _ Q W_ s ΔH_ ΔE_ k ΔE_ p The complete procedure for an open system is illustrated in the next example. We encourage you to take the time to follow each step, even though some parts may not be completely clear until you get to material that comes later in the chapter. The better you understand this example, the easier it will be for you to understand the rest of the chapter and to solve the end-of-chapter problems. Example 8.1-1 Equipment Encyclopedia condenser www.wiley.com/college/felder Energy Balance on a Condenser Acetone (denoted as Ac) is partially condensed out of a gas stream containing 66.9 mole% acetone vapor and the balance nitrogen. Process specifications and material balance calculations lead to the flowchart shown below. • Q(J/s) 100 mol/s 0.669 mol Ac(v)/mol 0.331 mol N2/mol 65°C, 1 atm 36.45 mol/s 0.092 mol Ac(v)/mol 0.908 mol N2/mol 20°C, 5 atm CONDENSER 63.55 mol Ac(l)/s 20°C, 5 atm The process operates at steady state. Calculate the required cooling rate. 2 ^ i instead of U ^ i for a closed constant-pressure system, since Q ΔH for such systems. Use H 408 C H AP T E R 8 Balances on Nonreactive Processes Solution We will follow the procedure given preceding this example. 1. Perform required material balance calculations. None are required in this example. 2. Write and simplify the energy balance. For this open steady-state system, Q_ W_ s ΔH_ ΔE_ k ΔE_ p . There are no moving parts in the system and no energy is transferred by electricity or radiation, so W_ s 0. No significant vertical distance separates the inlet and outlet ports, so ΔE_ p 0. Phase changes and nonnegligible _ The energy balance reduces to temperature changes occur, so ΔE_ k 0 (relative to ΔH). X X n_ i H^ i n_ i H^ i Q_ ΔH_ out in 3. Choose reference states for acetone and nitrogen. The reference states may be chosen for computational convenience, since the choice has no _ We will arbitrarily choose the inlet stream condition for effect on the calculated value of ΔH. nitrogen (65°C, 1 atm) as the reference state for this species and one of the two outlet stream conditions for acetone (l, 20°C, 5 atm) as the reference state for acetone, which will enable us to set ^ in the enthalpy table equal to zero instead of having to calculate them. the corresponding values for H 4. Construct an inlet—outlet enthalpy table. We first write the chosen reference states, then construct the table shown below: References: Ac(l, 20°C, 5 atm), N2(g, 65°C, 1 atm) Substance Ac(v) Ac(l) N2 n_ in (mol/s) Ĥ in (kJ/mol) n_ out (mol/s) Ĥ out (kJ/mol) 66.9 Ĥ 1 3.35 Ĥ 2 — — 63.55 33.1 0 33.1 0 Ĥ 3 Note the following points about the table: • Nitrogen has only one inlet state (gas, 65°C, 1 atm) and one outlet state (gas, 20°C, 5 atm), so we need only one row in the table for N2. Acetone has one inlet state (vapor, 65°C, 1 atm) but two outlet states (vapor and liquid, each at 20°C and 5 atm), so we need two rows for this species. • We mark out (using dashes) the two cells corresponding to n_ in and H^ in for liquid acetone, since no liquid acetone enters the system. • The n_ values are obtained from the flowchart. The flow rate of acetone vapor at the inlet, for example, is determined as (100 mol/s)[0.669 mol Ac(v)/mol] = 66.9 mol Ac(v)/s. • Since the nitrogen entering the system and the liquid acetone leaving the system area are at their reference states, we set their specific enthalpies equal to zero. • Three unknown specific enthalpies have been labeled and must be determined in Step 5. 5. Calculate all unknown specific enthalpies. To calculate the three unknown specific enthalpies in the table, we construct hypothetical ^ for process paths from the reference states to the states of the species in the process and evaluate ΔH each path. This is the part of the calculation you have not yet learned to do. We will show you the calculation of H^ 1 to illustrate the method, give the results of the other calculations, and go into detail about the required procedures in Sections 8.2–8.5. H^ 1 specific enthalpy of Ac v; 65°C; 1 atm relative to Ac l; 20°C; 5 atm ^ for Ac l; 20°C; 5 atm ! Ac v; 65°C; 1 atm ΔH ^ it helps to know that formulas and When choosing a process path for the determination of ΔH, data are given in this chapter for enthalpy changes corresponding to certain types of processes: ^ V^ ΔP for a change in pressure (ΔP) undergone by a liquid or • Section 8.2 gives the formula ΔH ^ The value of V^ for liquid acetone may be determined as solid with constant specific volume V. 0.0734 L/mol from the specific gravity (0.791) given in Table B.1. 8.1 Elements of Energy Balance Calculations 409 RT • Section 8.3 shows that ΔH^ T 12 Cp T dT for a change from T 1 to T 2 at constant P. Formulas for Cp T, the heat capacity at constant pressure, are given in Table B.2. The formulas for acetone liquid and vapor are as follows: kJ Ac l: C p 0:123 18:6 10 5 T mol°C kJ Ac v: Cp 0:07196 20:10 10 5 T 12:78 10 8 T 2 34:76 10 12 T 3 mol°C where T is in °C. A time-saving alternative for evaluating the integral by hand is to use the APEx function Enthalpy(“species”,T1,T2,[temp. units],[state]), beginning the cell entry with an equal sign. The function integrates the heat capacity formula in Table B.2 for the specified species from ^ in kJ/mol. If a temperature unit is not specified temperature T1 to temperature T2 and returns ΔH as “K,” “R,” or “F,” a unit of “C” is assumed. If the state of the species is not specified as “l,” “g,” or “c” (for solid), the first entry in Table B.2 is assumed. For example, the integrals of the heat capacity of acetone liquid and acetone vapor needed in this example would be calculated using the following formulas: Enthalpy “acetone”;20;56 Enthalpy “acetone”;56;65;;“g” Notice that internal arguments that go to their default values, like the temperature unit in the first formula, may be left blank but the commas around them must still be supplied. Default values of arguments at the end, such as the temperature unit and state in the second formula, may be omitted. ^ v T b as ΔH^ for a change from liquid to vapor at the • Section 8.4 defines the heat of vaporization ΔH normal boiling point, T b . Table B.1 lists T b for acetone as 56.0°C and ΔH^ v T b as 30.2 kJ/mol. Normal boiling points in °C and heats of vaporization at the normal boiling point in kJ/mol can also be retrieved using the APEx functions Tb(“species”) and Hv(“species”). The following process path from the reference state [Ac(l), 20°C, 5 atm] to the process state [Ac(v, 65°C, 1 atm)] enables us to use all this information in the determination of H^ 1 :3 ^1a ^1b ΔH ΔH Ac l; 20°C; 5 atm ! Ac l; 20°C; 1 atm ! Ac l; 56°C; 1 atm ^1c ^1d ΔH ΔH ! Ac v; 65°C; 1 atm w ! Ac v; 56°C; 1 atm w € ^ ^ path H 1 ΔH ^ 1a ΔH ^ 1b ΔH^ 1c ΔH^ 1d ΔH Z 65°C Z 56°C ^ v Ac C p Ac v dT C p Ac l dT ΔH V^ Ac l 1 atm 5 atm 56°C 20°C ^ v and the formulas for Cp T into the expression When we substitute the values of V^ Ac l and ΔH ^1 ^ 1 and carry out the necessary unit conversions and integrations, we obtain H for H 0:0297 4:68 30:2 0:753 kJ/mol 35:7 kJ/mol. ^ 2 and H^ 3 shown in the following Proceeding in a similar manner, we obtain the values for H revised enthalpy table: References: Ac(l, 20°C, 5 atm), N2(g, 65°C, 1 atm) Substance Ac(v) Ac(l) N2 n_ in (mol/s) Ĥ in (kJ/mol) n_ out (mol/s) Ĥ out (kJ/mol) 66.9 35.7 3.35 32.0 — — 63.55 0 33.1 0 33.1 1.26 3 To be completely accurate, we would include a step in which the acetone and nitrogen are mixed since the references are the pure species; however, enthalpy changes when gases are mixed are generally negligible (Section 8.5). 410 C H A PT ER 8 Balances on Nonreactive Processes _ 6. Calculate ΔH. X n_ i H^ i ΔH_ out X ^i n_ i H in 3:35 mol/s 32:0 kJ/mol 63:55 0 33:1 1:26 66:9 35:7 33:1 0 kJ/s 2320 kJ/s The factors in the last equation come directly from the inlet–outlet enthalpy table. 7. Calculate nonzero work, kinetic energy, and potential energy terms. Since there is no shaft work and we are neglecting kinetic and potential energy changes, there is nothing to do in this step. _ 8. Solve the energy balance for Q. Q_ ΔH_ 2320 kJ/s 2320 kW Heat must be transferred from the condenser at a rate of 2320 kW to achieve the required cooling and condensation. Before we leave this section, let us consider what we just did from a different perspective. The _ may be depicted as shown below: process for which we need to calculate ΔH_ Q 66:9 mol Ac v 33:1 mol N2 65°C; 1 atm ΔH_ ! 63:55 mol Ac l 3:35 mol Ac v 33:1 mol N2 20°C; 5 atm _ in effect we constructed the following process path: To calculate ΔH, 66.9 mol Ac(v) 33.1 mol N2 63.55 mol Ac(l) 3.35 mol Ac(v) 33.1 mol N2 ΔH 20°C, 5 atm 65°C, 1 atm ΔHa ΔHb Reference conditions 66.9 mol Ac(l), 20°C, 1 atm 33.1 mol N2, 65°C, 1 atm The total enthalpy change for the first step, ΔH_ a , is the negative of ΔH_ for the process in which acetone and nitrogen go from the reference conditions to the inlet conditions, or X ^i n_ i H ΔH_ a in Similarly, ΔH_ b is the enthalpy change for the process in which acetone and nitrogen go from the reference conditions to the outlet conditions, or X ΔH_ b n_ i H^ i out Since enthalpy is a state function, the overall enthalpy change for the process must be X X ^i n_ i H n_ i H^ i ΔH_ ΔH_ a ΔH_ b out in 8.2 Changes in Pressure at Constant Temperature 411 ^ for the different types of It remains for us to outline methods for calculating ΔU^ and ΔH processes we have discussed. The methods for the first four (change in P at constant T, change in T at constant P, change in phase at constant T and P, and mixing or dissolving at constant T and P) are outlined in Sections 8.2–8.5 of this chapter, and methods for chemical reactions at constant T and P are given in Chapter 9. 8.2 CHANGES IN PRESSURE AT CONSTANT TEMPERATURE It has been observed experimentally that internal energy is nearly independent of pressure for solids and liquids at a fixed temperature, as is specific volume. Therefore, if the pressure of a solid or liquid ^ ΔU ^ Δ PV ^ VΔP. ^ changes at constant temperature, you may write ΔU^ 0 and ΔH ^ in the formula just given may be calculated from the specific The specific molar volume V gravity and molecular weight of the solid or liquid species under consideration, but unit ^ conversions typically are needed to make the units of VΔP consistent with the more common units of terms in energy balances (e.g., kJ/mol). The table for the gas constant on the inside back cover of this text provides useful conversion factors. For example, if you know V^ in L/mol and ΔP ^ in atm, and you want VΔP in kJ/mol, look for two values of the gas constant with units of Latm and kJ and use their ratio as a conversion factor. The calculation would look like this: kJ 1L MW g/mol ΔP atm 8:314 J/ molK 1 kJ cm3 ^ VΔP 3 3 mol SG 1:00 g 10 cm 0:08206 Latm/ molK 103 J 1:013 10 4 MWΔP SG (8.2-1) Both the specific gravity (SG) and the molecular weight (MW) can be looked up in Table B.1 or retrieved by the APEx functions SG(“species”) and MW(“species”). Both U^ and H^ are independent of pressure for ideal gases. Consequently, you may generally ^ 0 for a gas undergoing an isothermal pressure change unless gases at assume ΔU^ 0 and ΔH ^ T; P or H ^ T; P are temperatures well below 0°C or well above 1 atm are involved. [If tables of U available for the gas, there is of course no need to make this assumption.] If gases are far from ideal or if they undergo large pressure changes, you must either use tables of thermodynamic properties (such as the steam tables for water) or thermodynamic correlations beyond the scope of this text to ^ A good source for such correlations is Chapter 5 of Poling, Prausnitz, and determine ΔU^ or ΔH. O’Connell.4 In summary, for changes in pressure at constant temperature: ΔU^ 0 0 ^ ΔH ideal gases gases close to ideal; solids and liquids 0 ideal gases 0 gases close to ideal ^ VΔP solids and liquids (8.2-2) (8.2-3) ^ In the last formula of Equation 8.2-3, VΔP can be calculated from tabulated specific gravities and molecular weights using Eq. 8.2-1, as long as variables are entered with the appropriate units. ^ and ΔH^ for gases far removed from ideal-gas conditions is beyond the scope Determination of ΔU of this text. 4 B. E. Poling, J. H. Prausnitz, and J. P. O’Connell, The Properties of Gases and Liquids, 5th Edition, McGraw-Hill, New York, 2001. 412 C H A PT ER 8 Balances on Nonreactive Processes Test Yourself (Answers, p. 658) 1. Which of the following assumptions appears reasonable for each of the isothermal processes ^ 0, ΔH^ 0; (ii) ΔU ^ 0, ΔH ^ ≠ 0; (iii) neither (i) or (ii). to be described below? (i) ΔU (a) H2 O l; 1 atm ! H2 O l; 1200 atm; T 25°C (b) N2 g; 1 atm ! N2 g; 1:2 atm; T 25°C (c) N2 g; 1 atm ! N2 g; 200 atm; T 25°C 2. Consider the process C2 H6 g; 25°C; 1 atm ! C2 H6 g; 25°C; 30 atm How would you use the compressibility charts to determine whether it is reasonable to ^ for this process? neglect ΔH 8.3 CHANGES IN TEMPERATURE 8.3a Sensible Heat and Heat Capacities The term sensible heat signifies heat that must be transferred to raise or lower the temperature of a substance or mixture of substances. The quantity of heat required to produce a temperature change in a system can be determined from the appropriate form of the first law of thermodynamics: Q ΔU closed system (8.3-1) Q_ ΔH_ open system (8.3-2) (We have neglected kinetic and potential energy changes and work.) To determine the sensible heat requirement for a heating or cooling process, you must therefore be able to determine ΔU or ΔH_ for the specified temperature change. The specific internal energy of a substance depends strongly on temperature. If the temperature is raised or lowered in such a way that the system volume remains constant, the specific internal energy might vary as shown in the following plot: Û(J/kg) V = constant ΔÛ ΔT T1 T1 + ΔT T (°C) ^ in specific internal energy. As ΔT ! 0, A temperature change ΔT from T 1 leads to a change ΔU ^ the ratio ΔU=ΔT approaches a limiting value (i.e., the slope of the curve at T 1 ), which is by definition the heat capacity at constant volume of the substance, denoted by Cv . ^ ΔU @ U^ C v T lim (8.3-3) ΔT!0 ΔT @T V ^ versus T is not generally a straight line, C v (the slope of the curve) is a function Since the plot of U of temperature. The change in U^ for a temperature rise from T to T dT at constant volume is from Equation 8.3-3 ^ Cv T dT dU (8.3-4) 8.3 Changes in Temperature ^U ^2 and the change ΔU volume is, accordingly, 413 ^ 1 associated with a temperature change from T 1 to T 2 at constant U ΔU^ Z T2 Cv T dT (8.3-5) T1 ^ Now, suppose both the temperature and the volume of a substance change. To calculate ΔU, ^ you may break the process into two steps—a change in V at constant T followed by a change in ^ T at constant V. ˆ ΔU1 A(T1, Vˆ 1) A(T1, Vˆ 2) ΔUˆ 2 A(T2, Vˆ 2) ↓ ↑ ΔUˆ ^ is a state property, ΔU^ (the desired quantity) equals ΔU ^ 1 ΔU ^ 2 . But for ideal gases and Since U ^ depends only on T, so that since T is constant in (to a good approximation) liquids and solids, U step 1, ΔU 1 0 for any substance but a nonideal gas. Moreover, since the second step is a change ^ 2 is given by Equation 8.3-5. In summary, then, for a in temperature at constant volume, ΔU temperature change from T 1 to T 2 ^ ΔU Example 8.3-1 Z Ideal gas: exact Solid or liquid: good approximation Nonideal gas: valid only if V is constant T2 Cv T dT T1 (8.3-6) Evaluation of an Internal Energy Change from Tabulated Heat Capacity Calculate the heat required to raise 200 kg of nitrous oxide from 20°C to 150°C in a constant-volume vessel. The constant-volume heat capacity of N2O in this temperature range is given by the equation Cv kJ/kg°C 0:855 9:42 10 4 T where T is in °C. Solution From Equation 8.3-6, ΔU^ kJ/kg Z 150°C 20°C 0:855 9:42 10 4 T kJ dT kg°C 150°C 9:42 10 4 T 2 2 20°C 111 10:4 kJ/kg 121 kJ/kg 150°C 0:855T20°C The energy balance for this closed system neglecting ΔE k , ΔEp , and W is ^ kJ/kg 200 kg 121 kJ/kg 24;200 kJ Q ΔU m kg ΔU Next, let us suppose that we heat a substance at constant pressure and consider the resulting ^ is the change in enthalpy. Like internal energy, enthalpy depends strongly on temperature. If ΔH change in specific enthalpy resulting from a temperature increase at constant pressure from T to ^ T ΔT, then as ΔT approaches zero the ratio ΔH=ΔT approaches a limiting value, defined as the heat capacity at constant pressure and denoted by Cp . ^ ^ ΔH @H (8.3-7) C p T lim ΔT!0 ΔT @T P 414 CHAPTER 8 Balances on Nonreactive Processes Proceeding as before, we observe that the change in H^ for a temperature change at constant pressure from T to T dT is ^ C p T dT dH and so for a change from T 1 to T 2 at constant pressure Z T2 ΔH^ Cp T dT (8.3-8) T1 For a process A T 1 ; P1 ! A T 2 ; P2 , we may construct a two-step process path A(T1, P1) ↓ ΔHˆ 1 A(T1, P2) ΔHˆ 2 A(T2, P2) ↑ ΔĤ The first step is a change in pressure at constant temperature, the type of process described in Section 8.2. We saw in that section that ^ 1 0 ideal gas ΔH ^ VΔP solid or liquid (8.3-9) ^ 2 is given by The second step is a change in temperature at constant pressure, so that ΔH ^ 2 (why?), we obtain ^ 1 ΔH Equation 8.3-8. Finally, since ΔH^ ΔH ^ ΔH Z T2 C p T dT T1 ^ VΔP ^ ΔH Z Ideal gas: exact Nearly ideal gas: approximate for variable P Nonideal gas: exact only if P is constant T2 Solid or liquid C p T dT (8.3-10a) (8.3-10b) T1 For all but large pressure changes and small temperature changes, the first term of Eq. 8.3-10b is usually negligible relative to the second term. ^ for a nonideal gas undergoing a temperature and pressure change is best done Evaluating ΔH ^ with using tabulated enthalpies. If none are available, a thermodynamic relation for variations of H P must be combined with Equation 8.3-8 to determine the enthalpy change; such relations are given by Poling, Prausnitz, and O’Connell (see Footnote 4). Test Yourself (Answers, p. 658) 1. By definition, what are Cv and C p ? 2. Suppose the formula ^ ΔH Z T2 Cp T dT T1 is used to calculate the specific enthalpy change for a change in temperature and pressure undergone by (a) an ideal gas, (b) a highly nonideal gas, and (c) a liquid. For which of these is the formula exact, and for which is it most likely to lead to significant error? 3. If C p for an ideal gas is 0.5 cal/(g°C) (i.e., a constant), what is the enthalpy change in calories corresponding to a change from 10°C to 30°C undergone by five grams of the gas? 8.3 Changes in Temperature 415 CREATIVITY EXERCISE Your task this time is to estimate the heat capacity of an unknown liquid. You have available a laboratory balance, a very well-insulated container, a sensitive thermometer that can measure liquid temperatures, and a thermocouple that can measure temperatures of solids. The container is a very poor conductor of heat, so that virtually all heat transferred to or from its contents goes entirely into changing the temperature of those contents. If you need anything else (within reason), you can get it. Devise as many ways as you can to estimate Cv , which you may assume is independent of temperature. [Example: Mix in the insulated flask a known mass, m1 , of your liquid at temperature T 1 , and a known mass, m2 , of hot water at temperature T 2 , and measure the final temperature T f . Since you can calculate the heat lost by water, Q m2 CvH2 O T 2 T f , and you know Q must also equal the heat gained by the other liquid, m1 C v T f T 1 , you can solve for Cv .] 8.3b Heat Capacity Formulas The heat capacities C v and C p are physical properties of materials and are tabulated in standard references such as Perry’s Chemical Engineers’ Handbook.5 They may be expressed in any units of energy per unit species amount (mass or moles) per unit temperature interval—for example, J/(molK), or Btu/(lbm °F). The term specific heat is also used for this physical property. Heat capacities are functions of temperature and are frequently expressed in polynomial form (C p a bT cT 2 dT 3 ). Values of the coefficients a; b; c; and d are given in Table B.2 of Appendix B for a number of species at 1 atm, and listings for additional substances are given on pp. 2-156 to 2-180 of Perry’s Chemical Engineers’ Handbook. Heat capacities of solutions and various other substances are given on pp. 2-183 to 2-185. When reading the coefficients of a heat capacity formula from Table B.2, do not mistake their orders of magnitude: if a value of 72.4 is read from the column labeled b105 , then the value of b must be five orders of magnitude less than 72.4, or b 72:4 10 5 . Simple relationships exist between Cp and C v in two cases: Liquids and Solids: C p C v (8.3-11a) Ideal Gases: Cp Cv R (8.3-11b) where R is the gas constant. (Try to prove the second relation.) The relationship between C p and C v for nonideal gases is complex and will not be discussed in this text. ^ using Equations 8.2-2, 8.3-10, and 8.3-11 for the heating or You can estimate ΔH^ or ΔU cooling of any solid, liquid, or gas (except a gas far from ideal-gas conditions), whether or not the pressure changes. Heat capacity formulas given in Table B.2 may be integrated in these equations, or APEx functions can be used to avoid the integration. The mathematical and APEx formulas are as follows (convince yourself): Gases: ^ ΔH ^ ΔU kJ mol kJ mol Z Z T2 Cp T dT Enthalpy “Species”;T1;T2;“T unit”;“g” T2 T1 (8.3-12a) T1 C v T dT Z T2 Cp T dT R T2 T1 Enthalpy “Species”;T1;T2;“T unit”;“g” T 1 R 8:314 10 8:314e-3* T2-T1 3 kJ molK (8.3-12b) 5 R. H. Perry and D. W. Green, Eds., Perry’s Chemical Engineers’ Handbook, 8th Edition, McGraw-Hill, New York, 2008. 416 C H AP T E R 8 Balances on Nonreactive Processes Liquids and Solids: ^ ΔH ^ ΔU kJ mol kJ mol ^ VΔP Z T2 C p T dT T1 (8.3-12c) 1:013e-4* MW “species”* P2 P1/SG “species” Enthalpy “Species”;T1;T2;“T unit”;“state” Z T2 C v T dT T1 Z T2 C p T dT (8.3-12d) T1 Enthalpy “Species”;T1;T2;“T unit”;“state” The APEx formula in Equation 8.3-12c presumes a pressure difference in atmospheres. If pressures are in other units, a pressure conversion factor should be added. Example 8.3-2 Cooling of an Ideal Gas Assuming ideal-gas behavior, calculate the heat that must be transferred in each of the following cases. 1. A stream of nitrogen flowing at a rate of 100 mol/min is heated from 20°C to 100°C. 2. Nitrogen contained in a 5-liter flask at an initial pressure of 3 bar is cooled from 90°C to 30°C. Solution Neglecting kinetic energy changes, the energy balance for the open system of Part 1 is Q ΔH, and that for the closed system of Part 2 is Q ΔU. (Show it.) The problem is therefore to evaluate ΔH and ΔU for the two specified processes. 1. From Table B.2, Appendix B, the heat capacity of N2 at a constant pressure of 1 atm is C p kJ/ mol°C 0:02900 0:2199 10 5 T 0:5723 10 8 T 2 12 3 2:871 10 T where T is in °C. Since we are assuming ideal-gas behavior, the enthalpy change for the gas is independent of any pressure change that may occur, and hence, from Equation 8.3-10a, ^ ΔH w w € Z 100°C 20°C C p T dT ΔH^ kJ/mol 0:02900T 100°C 0:2199 10 20°C T4 2:871 10 12 4 5 T2 2 100°C 0:5723 10 8 20°C T3 3 100°C 20°C 100°C 20°C 2:320 0:0106 1:9 10 3 7 10 5 kJ/mol 2:332 kJ/mol If you were using APEx to perform the preceding calculation, you would simply enter the formula of Equation 8.3-12a Enthalpy “nitrogen”; 20;100 or Enthalpy “nitrogen”; 20;100;“C”; “g” in a spreadsheet cell, and the value 2.332 (in kJ/mol) would be returned. Finally, _ H^ Q_ ΔH_ nΔ mol 2:332 kJ 100 233 kJ/min min mol 417 8.3 Changes in Temperature 2. To evaluate ΔU, we need the number of moles n, which may be calculated using the ideal-gas ^ which we calculate from Equation 8.3-12b, equation of state, and ΔU, ΔU^ Z 30°C 90°C Cp N2 dT R 30°C 90°C Substituting the formula from Table B.2 for the heat capacity and integrating as in Part (1) or entering the APEx formula =Enthalpy(“nitrogen”,90,30) for the integral, and substituting 8:314 10 3 kJ/ molK for R, yields ΔU^ 1:250 kJ/mol. Calculate n: At the initial condition (the only point at which we know P, V, and T) n PV=RT 3:00 bar 5:00 L 0:497 mol 0:08314 Lbar/ molK 363 K Calculate Q: ^ Q ΔU nΔU 0:621 kJ 0:497 mol 1:250 kJ/mol When enthalpies must be calculated frequently for a species, it is convenient to prepare a table ^ T for the species (as was done for water in the steam tables) to avoid having to integrate the of H formula for C p T again and again. Tables B.8 and B.9 in Appendix B list specific enthalpies of species involved in combustion reactions—air, O2, N2, H2 (a fuel), CO, CO2, and H2O(v). The values in these tables were generated by integrating Cp T from the specified reference state (25°C for Table B.8, 77°F for Table B.9) to the listed temperatures. The next example illustrates the use of these tables. Example 8.3-3 Evaluation of ΔH_ Using Heat Capacities and Tabulated Enthalpies Fifteen kmol/min of air is cooled from 430°C to 100°C. Calculate the required heat removal rate using (1) heat capacity formulas from Table B.2, (2) specific enthalpies from Table B.8, and (3) the Enthalpy function of APEx. air g; 430°C ! air g; 100°C Solution With ΔE_ k , ΔE_ p , and W_ s deleted, the energy balance is Q_ ΔH_ n_ air H^ air;out n_ air H^ air;in n_ air ΔH^ ^ Assume ideal-gas behavior, so that pressure changes (if there are any) do not affect ΔH. 1. The hard way. Integrate the heat capacity formula in Table B.2. Z 100°C kJ Cp T dT ΔH^ mol 430°C Z 100°C 0:02894 0:4147 10 5 T 0:3191 10 8 T 2 430°C 0:02894 100 430 0:4147 10 2 5 1002 1:965 10 12 3 4302 0:3191 10 8 1:965 10 12 3 3 4 4 100 100 430 430 kJ/mol 3 4 9:5502 0:3627 0:0835 0:0167 kJ/mol 9:98 kJ/mol T dT 418 C H A PT ER 8 Balances on Nonreactive Processes 2. The easy way. Use tabulated enthalpies from Table B.8. H^ for air at 100°C can be read directly from Table B.8 and H^ at 430°C can be estimated by linear interpolation from the values at 400°C (11.24 kJ/mol) and 500°C (14.37 kJ/mol). H^ 100°C 2:19 kJ/mol H^ 430°C 11:24 0:30 14:37 w w € ^ 2:19 ΔH 11:24 kJ/mol 12:17 kJ/mol 12:17 kJ/mol 9:98 kJ/mol 3. The easiest way. In a spreadsheet cell, insert =Enthalpy(“air”,430,100). The value 9.98 (in kJ/mol) will be returned. In using the spreadsheet, it is absolutely essential to keep track of units by adding explicit notation where appropriate; otherwise the probability of getting units wrong increases substantially. Whichever way ΔH^ is determined 15:0 kmol _ H^ Q_ ΔH_ nΔ min 103 mol 1 kmol 9:98 kJ mol 1 min 60 s 1 kW 1 kJ/s 2500 kW Reminder: The enthalpies listed in Tables B.8 and B.9 (and for that matter, the heat capacity formulas of Table B.2 and the Enthalpy function of APEx) apply strictly to heating and cooling at a constant pressure of 1 atm. The tabulated enthalpies and heat capacities may also be used for nonisobaric heating and cooling of ideal or nearly ideal gases; however, at pressures high enough (or temperatures low enough) for the gases to be far from ideal, enthalpy tables or more accurate heat capacity formulas should be used. Test Yourself (Answers, p. 658) 1. The heat capacity of a species is 28.5 J/(molK). Remembering that the temperature unit in the denominator refers to a temperature interval, what is the heat capacity of this species in J/(mol°C)? 2. The gas constant R is approximately equal to 2 cal/(molK). If C p for a vapor is 7 cal/(mol°C), estimate C v for the vapor. If Cp for a liquid is 7 cal/(mol°C), estimate Cv for the liquid. 3. Use Table B.8 or B.9 to calculate the following quantities: (a) The specific enthalpy (kJ/mol) of N2 at 1000°C relative to N2 at 300°C. ^ (b) ΔH(kJ/mol) for the process CO2(g, 800°C, 1 atm) → CO2(g, 300°C, 1 atm). _ (c) ΔH(Btu/h) for 100 lb-mole O2/h being cooled from 500°F and 1.5 atm to 200°F and 0.75 atm. 8.3c Estimation of Heat Capacities The polynomial expressions for C p in Table B.2 are based on experimental data for the listed compounds and provide a basis for reasonably accurate estimations of enthalpy changes. Several rougher approximate methods follow for estimating heat capacities in the absence of tabulated formulas. Kopp’s rule is a simple empirical method for estimating the heat capacity of a solid or liquid at or near 20°C. According to this rule, C p for a molecular compound is the sum of contributions (given in Table B.10) for each element in the compound. For example, the heat capacity of solid calcium hydroxide, Ca(OH)2, would be estimated from Kopp’s rule as C p Ca OH2 C pa Ca 2 Cpa O 2 Cpa H 26 2 17 2 9:6 J/ mol°C 79 J/ mol°C [The true value is 89.5 J/(mol°C).] 8.3 Changes in Temperature 419 More accurate heat capacity estimation formulas for various types of gases and liquids are given in Chapter 5 of Poling, Prausnitz, and O’Connell (see Footnote 4), and several correlations are presented by Gold and Ogle.6 Suppose you wish to calculate the enthalpy change associated with a change in temperature undergone by a mixture of substances. Enthalpies and heat capacities of certain mixtures are tabulated in standard references (e.g., pp. 2-183 and 2-184 of Perry’s Chemical Engineers’ Handbook, Footnote 5). Lacking such data, you may use the following approximation: Rule 1. For a mixture of gases or liquids, calculate the total enthalpy change as the sum of the enthalpy changes for the pure mixture components. You are in effect neglecting enthalpy changes associated with the mixing of the components, which is an excellent approximation for mixtures of gases and for mixtures of similar liquids such as pentane and hexane but a poor one for dissimilar liquids such as nitric acid and water. Enthalpies of mixing for systems of the latter type are discussed in detail in Section 8.5. Rule 2. For highly dilute solutions of solids or gases in liquids, neglect the enthalpy change of the solute. The more dilute the solution, the better this approximation. The calculation of enthalpy changes for the heating or cooling of a mixture of known composition may often be simplified by calculating a heat capacity for the mixture in the following manner: X yi C pi T (8.3-13) C p mix T all mixture components where (Cp)mix = heat capacity of the mixture yi = mass or mole fraction of the ith component Cpi = heat capacity of the ith component If C pi and Cp mix are expressed in molar units, then yi must be the mole fraction of the ith component, and if the heat capacities are expressed in mass units, then yi must be the mass fraction ^ for a change in temperature from T 1 to T 2 may of the ith component. Once Cp mix is known, ΔH be calculated as Z T2 Cp mix T dT (8.3-14) ΔH^ T1 Equation 8.3-14 is valid to the extent that enthalpies of mixing may be neglected. Example 8.3-4 Heat Capacity of a Mixture Calculate the heat required to bring 150 mol/h of a stream containing 60% C2H6 and 40% C3H8 by volume from 0°C to 400°C. Determine a heat capacity for the mixture as part of the problem solution. Solution Neglecting changes in potential and kinetic energy and recognizing that there is no R shaft work involved ^ 400°C C p in the process, the energy balance becomes Q_ ΔH_ nΔ _ H^ where ΔH dT. The 0°C mix polynomial expressions for the heat capacity of ethane and propane given in Table B.2 are substituted into Equation 8.3-13 to yield 6 P. I. Gold and G. J. Ogle, “Estimating Thermochemical Properties of Liquids, Part 7—Heat Capacity,” Chem. Eng., Apr. 7, 1969, p. 130. 420 C H AP T E R 8 Balances on Nonreactive Processes C p mix kJ/ mol°C 0:600 0:04937 13:92 10 5 T 5:816 10 8 T 2 7:280 10 5 0:400 0:06803 22:59 10 T 8 2 12 3 13:11 10 T 31:71 10 0:05683 17:39 10 5 T 8:734 10 8 T 2 17:05 10 Z 400°C ^ Cp mix dT 34:89 kJ/mol ΔH T 12 3 T 12 3 T 0°C If potential and kinetic energy changes and shaft work are neglected, it follows that ^ 150 mol _ H Q_ ΔH_ nΔ h 34:89 kJ mol 5230 kJ h As usual, we have assumed that the gases are sufficiently close to ideal for the formulas for C p at 1 atm to be valid. Test Yourself (Answers, p. 658) 1. Estimate the heat capacity of solid calcium carbonate (CaCO3) using Kopp’s rule and Table B.10. 2. Two kilograms of liquid n-hexane Cp 2:5 kJ/ kg°C and 1 kg of liquid cyclohexane C p 1:8 kJ/ kg°C are mixed and heated from 20°C to 30°C. Use the rule for liquid mixtures (Rule 1) given in this section to show that ΔH 68 kJ for this process. What is ^ ΔH(kJ/kg mixture)? 3. A 0.100 wt% aqueous solution of sodium chloride is heated from 25°C to 50°C. Use the rule ^ for solutions (Rule 2) given in this section to estimate ΔH(cal/g) for this process. C p for water is 1 cal/(g°C). 4. The heat capacity of liquid water is 1 cal/(g°C), and that of ethanol is 0.54 cal/(g°C). Estimate the heat capacity of a mixture containing 50% ethanol and 50% water by mass. 8.3d Energy Balances on Single-Phase Systems We are now in a position to perform energy balances on any processes that do not involve phase changes, mixing steps for which enthalpy changes cannot be neglected, or chemical reactions. If a process only involves heating or cooling a single species from T 1 to T 2 , the procedure is straightforward: R RT ^ T 2 Cp dT, correcting for pressure changes if necessary. 1. Evaluate, ΔU^ T 12 Cv dT or ΔH T1 ^ (where n is the amount of the 2. For a closed system at constant volume, calculate ΔU nΔU ^ species being heated or cooled). For a closed system at constant pressure, calculate ΔH nΔH. ^ where n_ is the species flow rate. _ H, For an open system, calculate ΔH_ nΔ 3. Substitute for ΔU, ΔH, or ΔH_ in the appropriate energy balance equation to determine the _ (See Example 8.3-2.) required heat transfer, Q, or heat transfer rate, Q. If more than one species is involved or if there are several input or output streams instead of just one of each, the procedure given in Section 8.1 should be followed: choose reference states for each species, prepare and fill in a table of amounts and specific internal energies (closed system) or species flow rates and specific enthalpies (open system), and substitute the calculated values into the energy balance. The next example illustrates the procedure for a continuous heating process. Example 8.3-5 Energy Balance on a Gas Preheater A stream containing 10% CH4 and 90% air by volume is to be heated from 20°C to 300°C. Calculate the required rate of heat input in kilowatts if the flow rate of the gas is 2:00 103 liters (STP)/min. 8.3 Changes in Temperature Solution 421 Basis: Given Flow Rate Assume ideal-gas behavior. 2000 L (STP)/min, 20°C HEATER • • n(mol/min), 300°C 0.100 mol CH4/mol 0.900 mol air/mol n(mol/min) 0.100 mol CH4/mol 0.900 mol air/mol • Q(kW) Recall that specifying the flow rate in liters (STP)/min does not imply that the feed gas is at standard temperature and pressure; it is simply an alternative way of giving the molar flow rate. n_ 2000 L STP min 1 mol 22:4 L STP 89:3 mol/min _ The The energy balance with kinetic and potential energy changes and shaft work omitted is Q_ ΔH. P P ^ i . Since each species has only one inlet condition and one outlet ^i n_ i H task is to evaluate ΔH_ n_ i H out in condition in the process, two rows are sufficient for the enthalpy table. References: CH4(g, 20°C, 1 atm), air(g, 25°C, 1 atm) Substance n_ in (mol/min) CH4 8.93 Air 80.4 Ĥ in (kJ/mol) 0 Ĥ 2 n_ out (mol/min) 8.93 80.4 Ĥ out (kJ/mol) Ĥ 1 Ĥ 3 ^ in could be set equal to zero, and that for air was The reference condition for methane was chosen so that H ^ out could be determined directly from Table B.8. chosen so that H^ in and H The next step is to evaluate all of the unknown specific enthalpies in the table. H^ 1 , for example, is the specific enthalpy of methane in the outlet gas mixture at 300°C relative to pure methane at its reference temperature of 20°C. In other words, it is the specific enthalpy change for the process CH4 g; 20°C; 1 atm ! CH4 g; 300°C; P in outlet mixture We neglect the effect of pressure on enthalpy (i.e., we assume ideal-gas behavior) and we always neglect heats of mixing of gases, so that the enthalpy change is calculated for the heating of pure methane at 1 atm: ^1 H Z 300°C Z 300°C C p CH4 dT w 20°C w € Substitute for C p from Table B:2 20°C 0:03431 5:469 10 5 T 0:3661 10 8 T 2 11:0 10 12 3 T dT 12:07 kJ/mol Alternatively, in APEx enter the formula =Enthalpy(“CH4”,20,300) into a spreadsheet cell, and the value 12.07 (in kJ/mol) will be returned. The enthalpies of air at the inlet and outlet conditions relative to air at the ^ 2 and H^ 3 , respectively) are determined from Table B.8 as reference state (H ^ 2 0:15 kJ/mol; H The energy balance now yields ^ 3 8:17 kJ/mol H 422 C H AP T E R 8 Balances on Nonreactive Processes Q_ ΔH_ X ^i n_ i H out X n_ i H^ i in w 8:93 mol/min 12:09 kJ/mol 80:4 8:17 w € 776 kJ Q_ min 1 min 60 s 1 kW 1 kJ/s 8:93 0 80:4 0:15 kJ/min 12:9 kW In the last example the temperatures of all input and output streams were specified, and the only unknown in the energy balance equation was the heat transfer rate required to achieve the specified conditions. You will also encounter problems in which the heat input is known but the temperature of an output stream is not. For these problems, you must evaluate the outlet stream component enthalpies in terms of the unknown T, substitute the resulting expressions in the energy balance equation, and solve for T. Example 8.3-6 illustrates this procedure. Example 8.3-6 ENVIRONMENTAL Equipment Encyclopedia boiler www.wiley.com/college/felder Energy Balance on a Waste-Heat Boiler Eliminating discharges of hot streams to the environment has two beneficial effects: the temperature of the receiving entity (e.g., a lake, a river, or the atmosphere) is not raised, which can avoid violating an EPA regulation, and the energy contained in the discharged stream is not wasted by being dissipated in the environment. For example, a gas stream at 500°C containing 8.0 mol% CO and 92.0% CO2 that was originally going to be sent up a stack is instead sent to a heat exchanger and flows across tubes through which water is flowing. The water enters at 25°C and is fed at a ratio of 0.200 mol water/mol hot gas, is heated to its boiling point, and forms saturated steam at 5.0 bar. The steam may be used for heating or power generation in the plant or as the feed to another process unit. The heat exchanger can be assumed to operate adiabatically—that is, all heat transferred from the hot gas goes to heat the water, as opposed to some of it leaking through the heat exchanger walls to the environment. The flowchart for an assumed basis of 1.00 mol feed gas is shown below. Calculate the temperature of the gas leaving the heat exchanger (a) using data from Tables B.1 and B.2 but not using APEx; (b) using APEx. 1.00 mol gas, 500°C 8.0% CO, 92.0% CO2 0.200 mol 0.200 mol H2O (l, 25°C, 5.0 bar) H2O (v, 5.0 bar, sat'd) 1.00 mol gas, T (°C) To flare 8.0% CO, 92.0% CO2 Solution Since no material balances are required in this problem, we may proceed directly to the energy balance, which for this adiabatic unit reduces to X X ΔH ni H^ i ni H^ i 0 out in Note that we do not write ΔH_ and n_ i since a quantity (1 mol feed gas) and not a flow rate has been assumed as a basis of calculation. (Exercise: What assumptions have been made in writing the energy balance?) References: CO(g, 500°C, 1 atm), CO2(g, 500°C, 1 atm), H2O(l, triple point) Substance nin Ĥ in nout Ĥ out CO 0.080 mol 0 kJ/mol 0.080 mol CO2 0.920 mol 0 kJ/mol 0.920 mol Ĥ 1 (kJ/mol) Ĥ 2 (kJ/mol) H2 O 0.00360 kg Ĥ 3 (kJ/kg) 0.00360 kg Ĥ 4 (kJ/kg) 8.3 Changes in Temperature 423 ^ 2 T by integrating the heat capacity formulas of Table B.2 The solution strategy will be to calculate H^ 1 T and H ^ 4 in the steam tables, ^ 3 and H from the reference temperature (500°C) to the unknown T at the gas outlet, look up H ^ 1 through H^ 4 in the energy balance, and solve the resulting equation for T using a spreadsheet. substitute for H Note the following points about the enthalpy table: • We chose the reference states for CO and CO2 as the gas inlet temperature and 1 atm. We assume ideal-gas behavior so that deviations of the pressure from 1 atm have no effect on enthalpies, and accordingly set the inlet enthalpies of the gas species equal to zero. • We will find the enthalpies of the feedwater and product steam in the steam tables. Knowing this, we chose the reference state for the steam tables (liquid water at the triple point) as our reference for water, and knowing that the enthalpies in the steam tables are in kJ/kg, we list the quantity of water in kg (m 0:200 mol H2 O 0:0180 kg/mol 0:00360 kg). • We will integrate the heat capacity formulas of Table B.2 for CO and CO2 even though enthalpies for those species are listed in Table B.8, since we do not know the temperature at which to look them up. (a) The specific enthalpies are Z T C p CO dT H^ 1 500°C T H^ 2 Z 500°C Z T 500°C T Z 500°C 0:02895 0:4110 10 5 T 0:3548 10 8 T 2 2:220 10 12 3 T dT C p CO2 dT 0:03611 4:223 10 5 T 2:887 10 8 T 2 7:464 10 12 3 T dT ^ 2 O l; 25°C; 5 bar 105 kJ/kg Table B:5: neglect effect of pressure on H ^ H^ 3 HH ^ ^ H 4 HH2 O v; 5 bar; sat’d 2747:5 kJ/kg Table B:6 ^ 1 and H ^ 2 and substituting the resulting expressions and the Integrating the expressions for H ^ 3 and H^ 4 into the energy balance (ΔH 0) yields the following equation: values of H 1:672 10 12 4 T 0:8759 10 8 T 3 1:959 10 5 T 2 0:03554T 12:16 0 The problem is to find the value of T(°C) that satisfies this equation. The equation can be solved by trial-and-error using any mathematical software program, or using Excel’s Solver or Goal Seek. The solution is T 299°C . The heat transferred from the specified quantity of gas as it cools from 500°C to 299°C goes to convert the specified amount of feed water into steam. (b) Following is a portion of an Excel spreadsheet with the APEx add-on activated. The n values in Columns C and E and the 0s (zeroes) in Column D are entered as numbers, and the T value in Cell C8 is an initial guess at the temperature of the outlet gas. The other values in Columns C through H result from entering the formulas shown on the next page. We strongly recommend that you attempt to replicate the spreadsheet for yourself. A B C D E F G H H(out) nH(in) nH(out) 1 Solution to Example 8.3-6b 2 Substance n(in) H(in) n(out) 3 CO 0.08 0 0.08 12.1852 0 0.97482 4 CO2 0.92 0 0.92 18.4467 0 16.971 5 H2O 0.0036 6 7 8 T(gas out) 100 9 Delta H 8.4321 104.8 0.0036 2547.3 0.37728 9.891 Sum-> 0.37728 8.05482 424 C H AP T E R 8 Balances on Nonreactive Processes Cell Entries [D5] = SteamSatT(25, “T”, “H”, “L”) [Enthalpy of saturated H2O(l) at T = 25°C]; “T” is the first argument, “H” is the quantity to be provided by the spreadsheet (i.e., enthalpy), “L” is the phase of the water. [F3] = Enthalpy(“CO”, 500, C$8) [Integral of (Cp)CO from 500°C to T in Cell C8] [F4] = Enthalpy(“CO2”, 500, C$8) [As above for CO2] [F5] = SteamSatP(5,“P”, “H”, “V”) [Enthalpy of saturated H2O(v) at P = 5 bar] [H3] = E3∗ F3 [G3] = C3∗ D3 [G4] = C4∗ D4 [H4] = E4∗ F4 [G5] = C5∗ D5 [H5] = E5∗ F5 [G6] = SUM(G3:G5) [H6] = SUM(H3:H5) [C9] = H6–G6 [ΔH, which must equal zero when the correct temperature is found] Once all of the formulas have been entered, open Solver; set the target cell to C9 (or $C$9), check “Value of ” and enter 0, insert C8 as the cell to be changed, and then click on “Solve.” Cell C8 should then contain the solution T 299°C . 8.3e Numerical Integration of Tabulated Heat Capacities You have now seen two ways to evaluate an expression of the type Z T2 C p T dT T1 If a functional relation for Cp T is available, such as one of the polynomials of Table B.2, the integration can be carried out analytically; and if tabulated specific enthalpies are available for the substance being heated or cooled, a simple subtraction replaces the integration. Suppose, however, that the only information you have about Cp is its value at a series of temperatures that span the range from T 1 to T 2 . The question is how to estimate the value of the integral from these data. One way would of course be to plot C p versus T, draw a curve by visual inspection through the points at which C p is known, and estimate the integral graphically as the area under the curve from T 1 to T 2 . This is a cumbersome procedure, however, even if you have access to a planimeter, a device that can calculate the area under a traced-out curve. A better solution is to use one of the many existing quadrature formulas—algebraic expressions that provide estimates of the integrals of tabulated data. Several such formulas are presented and illustrated in Appendix A.3; the use of one of them, Simpson’s rule, is required for the integration of heat capacity data in several problems at the end of this chapter. 8.4 PHASE-CHANGE OPERATIONS Consider liquid water and water vapor, each at 100°C and 1 atm. Which would you expect to be ^ vapor ? (Recall that U ^ is related among other things to the energy of motion of the greater, U^ liquid or U individual molecules at the specified condition.) If you said U^ vapor , you would be correct. One way to think of it is that the molecules of a vapor, which can move around relatively freely, are much more energetic than the densely packed molecules of a liquid at the same T and P. Also think about the fact that liquid molecules are held in close proximity to each other by attractive forces between the molecules. The energy required to overcome these forces when a liquid is vaporized is reflected in the higher internal energy of the vapor molecules. 8.4 Phase-Change Operations 425 ^ liquid and U ^ vapor can be. Inspection of Table B.5 reveals how dramatic the difference between U ^ ^ For water at 100°C and 1 atm, U l 419 kJ/kg and U v 2507 kJ/kg. The difference in specific ^ is even greater, owing to the much greater specific volume of the vapor: at enthalpy ( U^ PV) ^ v 2676 kJ/kg. ^ l 419:1 kJ/kg and H the same temperature and pressure, H Phase changes such as melting and evaporation are usually accompanied by large changes in internal energy and enthalpy, as in the example just given. Heat transfer requirements in phasechange operations consequently tend to be substantial, since Q ΔU (closed constant-volume system) or Q_ ΔH_ (open system). The paragraphs that follow outline procedures for setting up and solving energy balances on such operations. The discussion will be limited to phase changes between liquid and vapor (evaporation, condensation) and solid and liquid (melting, freezing); however, the methods may be extended directly to other phase changes, such as sublimation (conversion from solid to vapor) and conversion from one solid phase to another (e.g., amorphous to crystalline). 8.4a Latent Heats The specific enthalpy change associated with the transition of a substance from one phase to another at constant temperature and pressure is known as the latent heat of the phase change (as distinguished from sensible heat, which is associated with temperature changes for a single-phase ^ for the transition of liquid water to steam system). For example, the specific enthalpy change ΔH at 100°C and 1 atm, which equals 40.6 kJ/mol, is by definition the latent heat of vaporization (or simply the heat of vaporization) of water at this temperature and pressure. Since condensation is the reverse of vaporization and enthalpy is a state property, the heat of condensation must be the negative of the heat of vaporization. Thus, the heat of condensation of water at 100°C and 1 atm must be 40.6 kJ/mol. Similarly, the heat of solidification is the negative of the heat of fusion at the same temperature and pressure. Latent heats for the two most commonly encountered phase changes are defined as follows: ^ m T; P is the specific enthalpy difference between the 1. Heat of fusion (or heat of melting). ΔH solid and liquid forms of a species at T and P.7 ^ v T; P is the specific enthalpy difference between the liquid and 2. Heat of vaporization. ΔH vapor forms of a species at T and P. Tabulated values of these two latent heats, such as those in Table B.1 and on pp. 2-144 through 2-155 of Perry’s Chemical Engineers’ Handbook, (see Footnote 5) usually apply to a substance at its normal melting or boiling point—that is, at a pressure of 1 atm. These quantities are referred to as standard heats of fusion and vaporization. The standard heats of fusion and vaporization in Table B.1 may be accessed in APEx with the following functions: ^ m species T m ; 1 atm: Hm “Species”; ΔH ^ v species T b ; 1 atm: Hv “Species” ΔH For example, if you enter = Hv(“Acetic acid”) in the cell of a spreadsheet with APEx activated, the value 24.39 (in kJ/mol) will be returned, corresponding to the value listed in Table B.1 of the standard heat of vaporization of acetic acid at its normal boiling point of 118°C. The latent heat of a phase change may vary considerably with the temperature at which the change occurs but hardly varies at all with the pressure at the transition point. For example, the heat of vaporization of water at 25°C is 2442.5 J/g at P 23:78 mm Hg and 2442.3 J/g at P 760 mm Hg.8 When using a tabulated latent heat, you must therefore be sure that the phase 7 8 ^ m rather than ΔH ^ f because the latter symbol is used for the heat of formation, a quantity defined in Chapter 9. We call it ΔH In a system containing only pure water at 25°C, evaporation can only occur at P p∗w 25°C 23:78 mm Hg, but if the system contains several species, evaporation can occur over a range of pressures. 426 CHAPTER 8 Balances on Nonreactive Processes change in question takes place at the temperature for which the tabulated value is reported, but you may ignore moderate variations in pressure. Example 8.4-1 Heat of Vaporization At what rate in kilowatts must heat be transferred to a liquid stream of methanol at its normal boiling point to generate 1500 g/min of saturated methanol vapor? Solution From Table B.1 or using APEx functions Tb and Hv, ΔH^ v 35:3 kJ/mol at T b 64:7°C. The energy balance with potential and kinetic energy changes neglected is _ H^ v Q_ ΔH_ nΔ w w € 1500 g CH3 OH Q_ min 1 mol 35:3 kJ 32:0 g CH3 OH mol 1 min 60 s 1 kW 1 kJ/s 27:6 kW Phase changes often occur at temperatures other than the temperature for which the latent heat is tabulated. When faced with this situation, you must select a hypothetical process path that permits the available data to be used. Suppose, for example, that a substance is to be vaporized isothermally at 130°C, but the only available value of the heat of vaporization is at 80°C. A process path from the liquid at 130°C to the vapor at the same temperature must then be chosen that includes an isothermal vaporization step at 80°C: specifically, cool the liquid from 130°C to 80°C, vaporize the liquid at 80°C, and then heat the vapor back to 130°C. Summing the changes in enthalpy for each of these steps yields the change in enthalpy for the given process. (By definition, the calculated value is the latent heat of vaporization at 130°C.) Example 8.4-2 Vaporization and Heating One hundred g-moles per hour of liquid n-hexane at 25°C and 7 bar is vaporized and heated to 300°C at constant pressure. Neglecting the effect of pressure on enthalpy, estimate the rate at which heat must be supplied. Solution An energy balance yields Q_ ΔH_ W_ s ΔE_ p 0; ΔE_ k 0 _ Therefore an evaluation of ΔH_ will yield the desired value of Q. From the Antoine equation (Table B.4) or the APEx function AntoineT (“n-hexane,” 5250), the temperature at which the vapor pressure of n-hexane is 7 bar (5250 mm Hg) is 146°C, and this is therefore the temperature at which the vaporization actually occurs. However, Table B.1 lists a value of ΔH^ v at the normal boiling point of n-hexane, ^ v 28:85 kJ/mol at 69°C ΔH We must therefore find a path that takes hexane from a liquid to a vapor at 69°C, rather than at the true vaporization temperature of 146°C. As noted previously, the change in enthalpy associated with a process may be determined from any convenient path as long as the initial and final points of the chosen path correspond to those of the process. The diagram shown on the following page illustrates several possible paths from liquid hexane at 25°C to hexane vapor at 300°C. 8.4 Phase-Change Operations State 1 n–C6H14(l) 25°C, 7 bar State 4 n–C6H14(v) 25°C, 7 bar C 427 State 7 n–C6H14(v) 300°C, 7 bar F G A State 2 n–C6H14(l) 69°C, 1 atm D State 5 n–C6H14(v) 69°C, 1 atm E State 6 n–C6H14(v) 146°C, 7 bar H B State 3 n–C6H14(l) 146°C, 7 bar ^ for the If we knew ΔH^ v at 146°C, we would follow path ABEH (the true process path) to evaluate the overall ΔH process, or if we knew ΔH^ v at 25°C, we would follow path CF, which would require only two calculations. ^ v at 69°C, we must follow path ADG, which includes vaporization at that temperature. Since we have ΔH n-C6 H14 l; 25°C; 7 bar ^A ΔH ! n-C6 H14 l; 69°C; 1 atm w w ^ €ΔH D n-C6 H14 v; 69°C; 1 atm ^ A VΔP ^ ΔH Z 69°C ^G ΔH from Equation 8:3-10b Cp C6 H14 l dT 1:013 1L w w € w w w w € € 25°C w w Table B:1 SG 0:659 ρ 0:659 kg/L w w C p 0:2163 kJ/ mol°C w Table B:2 w € 1 atm 1:013 bar ^A ΔH 7:0 bar 0:659 kg 0:2163 kJ ! n-C6 H14 v; 300°C; 7 bar 86:17 kg 0:008314 kJ/ molK 1000 mol 69 25°C mol°C 0:08314 Lbar/ molK 0:0782 9:517 kJ/mol 9:44 kJ/mol ^ D ΔH^ v C H 69°C; 1 atm 28:85 kJ/mol ΔH 6 14 Z 300°C ^G ΔH C p C6 H 14 v dT from Equation 8:3-10a 69°C w w €Cp kJ/ mol°C 0:13744 40:85 10 5 T 23:92 10 8 T 2 57:66 10 12 3 T ^ G 47:1 kJ/mol ΔH For the overall process Q_ ΔH_ n_ mol/hΔH^ kJ/mol w w ^ ^ A ΔH^ D ΔH^ G 85:5 kJ/mol €ΔH ΔH 100 mol Q_ h 85:5 kJ mol 1h 1 kW 3600 s 1 kJ/s 2:38 kW ^ Notice that the pressure change term in the first step (VΔP 0:0782 kJ/mol) accounts for less than 0.1% of the overall process enthalpy change. We will generally neglect the effects of pressure changes on ΔH^ unless ΔP is on the order of 50 atm or more. ^ Δ PV ^ for If a phase change takes place in a closed system, you must evaluate ΔU^ ΔH the phase change to substitute into the energy balance equation. For phase changes such as fusion, which involve only liquids and solids, changes in PV^ are generally negligible compared to 428 C H AP T E R 8 Balances on Nonreactive Processes ^ so that changes in H, ^ m ΔH^ m ΔU (8.4-1) For vaporization, PV^ for the vapor (which equals RT if ideal-gas behavior may be assumed) is normally orders of magnitude greater than PV^ for the liquid, so that Δ PV RT, and ^ v ΔH ^v ΔU Test Yourself (Answers, p. 658) RT (8.4-2) 1. If you are given a value of a heat of vaporization at 100°C and 1 atm, would you be confident about using it to estimate the enthalpy change for a vaporization at 100°C and 2 atm? What about 200°C and 1 atm? 2. The enthalpies of a pure liquid and its vapor at 75°C and 1 atm are 100 J/mol and 1000 J/mol, respectively, both measured relative to the liquid at 0°C. (a) What is the enthalpy of the liquid at 0°C? (b) What is the heat of vaporization at 75°C? (c) Suppose you have heat capacity data for both the liquid and its vapor. What path would you follow to calculate the enthalpy change associated with 100 mol of the vapor at 400°C being cooled and condensed to form a liquid at 25°C? 3. The heat of fusion of zinc chloride at 556 K is ΔH^ m 5500 cal/mol, and the heat of ^ v 28;710 cal/mol. Estimate ΔU^ m (556 K) vaporization of this substance at 1000 K is ΔH ^ v (1000 K) for ZnCl2. [Say R 2 cal/ molK.] and ΔU 8.4b Estimation and Correlation of Latent Heats Poling, Prausnitz, and O’Connell (see Footnote 4) review procedures for estimating latent heats of vaporization, fusion, and sublimation. Several of the methods given in this reference are summarized below. A simple formula for estimating a standard heat of vaporization (ΔH^ v at the normal boiling point) is Trouton’s rule: ΔH^ v kJ/mol 0:088T b K nonpolar liquids 0:109T b K water; low molecular weight alcohols (8.4-3) ^v where T b is the normal boiling point of the liquid. Trouton’s rule provides an estimate of ΔH accurate to within 30%. Another formula that provides roughly 2% accuracy is Chen’s equation: ^ v kJ/mol ΔH T b 0:0331 T b =T c 0:0327 0:0297 log10 Pc 1:07 T b =T c (8.4-4) where T b and T c are the normal boiling point and critical temperature in kelvin and Pc is the critical pressure in atmospheres. A formula for approximating a standard heat of fusion is 0:0092T m K ^ m kJ/mol 0:0025T m K ΔH 0:050T m K metallic elements inorganic compounds organic compounds (8.4-5) Latent heats of vaporization may be estimated from vapor pressure data by using the Clausius–Clapeyron equation, which was discussed in Section 6.1b. ln p* ΔH^ v B RT (8.4-6) 8.4 Phase-Change Operations 429 ^ v is constant over the range of temperatures encompassed by the vapor pressure Provided that ΔH data, the latent heat of vaporization may be determined from a plot of ln p* versus 1=T. (See Example 6.1-1.) In many cases the latent heat of vaporization varies considerably with temperature, invalidating Equation 8.4-6. It is then necessary to use the Clapeyron equation, from which Equation 8.4-6 was derived. From Equation 6.1-2, ^v d ln p* ΔH (8.4-7) R d 1=T The heat of vaporization at a temperature T may be estimated from vapor pressure data by plotting ln p* versus 1=T, determining d ln p* =d 1=T at the temperature of interest as the slope of the ^ v . The slope may be determined graphically tangent to the curve, and solving Equation 8.4-7 for ΔH or by any of several numerical differentiation techniques outlined in texts on numerical analysis. A procedure for calculating the latent heat of vaporization at one temperature from a known value at any other temperature was presented in Section 8.4a. The technique outlined is rigorous but time-consuming, and it requires heat capacity data that might not be available for the substance of interest. A useful approximation for estimating ΔH^ v at T 2 from a known value at T 1 is Watson’s correlation: T c T 2 0:38 ^ ^ (8.4-8) ΔH v T 2 ΔH v T 1 Tc T1 where T c is the critical temperature of the substance. Example 8.4-3 Estimation of a Heat of Vaporization The normal boiling point of methanol is 337.9 K and its critical temperature and pressure are 513.2 K and 78.5 atm. The heat of vaporization at the normal boiling point is 35.3 kJ/mol. (a) Estimate the heat of vaporization at 337.9 K using Trouton’s rule and Chen’s equation, and determine the percent error for each estimate. (b) Using the Watson’s correlation estimate: the value of the heat of vaporization of methanol at 200°C using the measured and estimated values at the normal boiling point. Determine the percent error for each estimate if the measured value is 19.8 kJ/mol. Solution (a) Trouton’s Rule: ΔH^ v 337:9 K 0:109 337:9 36:8 kJ/mol The error associated with this value is +4.4%. Chen’s Equation: ΔH^ v 337:9 K 337:9 0:0331 337:9=513:2 0:0327 0:0297 log10 78:5 37:2 kJ/mol 1:07 337:9=513:2 for a +5.6% error. (b) Using the Watson’s correlation estimate: ΔH^ v 473 K 36:8 kJ 513:2 473 0:38 21:0 kJ/mol mol 513:2 337:9 for a +6.3% error. Using the actual value of the heat of vaporization at the normal boiling point: kJ 513:2 473 0:38 ^ ΔH v 473 K 35:3 20:2 kJ/mol mol 513:2 337:9 for a +1.8% error. 430 CHAPTER 8 Balances on Nonreactive Processes Test Yourself (Answers, p. 659) ^ v for a pure hydrocarbon at its normal boiling point under each of the How would you estimate ΔH following conditions? 1. You know only the normal boiling point. 2. You know the normal boiling point and the critical constants. 3. You have vapor pressure data over a range that encompasses p* 1 atm, and a semilog plot of p* versus 1=T is a straight line. 4. Repeat 3, only suppose the plot is curved. ^ v at a temperature other than T b and do not know the heat capacities of the 5. You know ΔH substance in its gaseous and liquid forms. 6. Repeat 5, only suppose that you have the heat capacity data. 8.4c Energy Balances on Processes Involving Phase Changes When writing an energy balance on a process in which a component exists in two phases, you must choose a reference state for that component by specifying both a phase and a temperature and calculate the specific enthalpy of the component in all process streams relative to this state. If the ^ may be calculated as substance is a liquid at its reference state and a vapor in a process stream, H outlined in Section 8.4a: that is, bring the liquid from the reference temperature to a point at which ^ v is known, vaporize the liquid, bring the vapor to the process stream temperature, and sum the ΔH individual enthalpy changes for the three steps. Example 8.4-4 Partial Vaporization of a Mixture An equimolar liquid mixture of benzene (B) and toluene (T) at 10°C is fed continuously to a vessel in which the mixture is heated to 50°C. The liquid product is 40.0 mole% B, and the vapor product is 68.4 mole% B. How much heat must be transferred to the mixture per g-mole of feed? Solution Basis: 1 mol Feed Equipment Encyclopedia evaporator EVAPORATOR nV(mol), 50°C 0.684 mol B/mol 0.316 mol T/mol www.wiley.com/college/felder Q(J) 1 mol, 10°C 0.500 mol B/mol 0.500 mol T/mol nL(mol), 50°C 0.400 mol B/mol 0.600 mol T/mol We start with a degree-of-freedom analysis: 3 unknown variables nV ; nL ; Q 2 material balances 1 energy balance 0 degrees of freedom We could count each specific enthalpy to be determined as an unknown variable, but then we would also count the equations for each of them in terms of heat capacities and latent heats, leaving the number of degrees of freedom unchanged. 8.4 Phase-Change Operations 431 0:500 mol 0:684 nV 0:400 nL Benzene Balance: w w € We next determine nV and nL from material balances, and then Q from an energy balance. nV 0:352 mol Total Mass Balance: 1:00 mol nV nL nL 0:648 mol The energy balance for this process has the form Q ΔH. An enthalpy table for the process appears as follows: References: B(l, 10°C, 1 atm), T(l, 10°C, 1 atm) nin mol ^ in H (kJ/mol) nout (mol) ^ out H (kJ/mol) B(l) 0.500 0 0.259 T(l) 0.500 0 0.389 Ĥ 1 Ĥ 2 B(v) — — 0.241 T(v) — — 0.111 Substance Ĥ 3 Ĥ 4 The values of nout were determined from the known mole fractions of benzene and toluene in the outlet streams and the calculated values of nV and nL . We do not know the feed-stream pressure and so we assume that ΔH for the change from 1 atm to Pfeed is negligible, and since the process is not running at an unusually ^1 low temperature or high pressure, we neglect the effects of pressure on enthalpy in the calculations of H through H^ 4 . (The pressure can be estimated from the Antoine equation and Raoult’s law to be 164 mm Hg.) The heat capacity and latent heat data needed to calculate the outlet enthalpies are obtained from Tables B.1 and B.2. The formulas (including the APEx formulas) and values of the unknown specific enthalpies are given ^ for the transitions from the reference states to the below. Convince yourself that the formulas represent ΔH process states. Z 50°C ^1 H C p C6 H6 l dT Enthalpy “benzene”;10;50;“C”;“l” 5:341 kJ/mol ^2 H ^3 H 10°C 50°C Z 10°C Z 80:1°C 10°C C p C7 H8 l dT Enthalpy “toluene”;10;50;“C”;“l” 6:341 kJ/mol ^ v C H 80:1°C Cp C6 H6 l dT ΔH 6 6 Z 50°C 80:1°C C p C6 H6 v dT Enthalpy “benzene”;10;80:1;“C”;“l” Hv “benzene” ^4 H Z Enthalpy “benzene”;80:1;50;“C”;“g” 37:53 kJ/mol Z 50°C C p C7 H8 l dT ΔH^ v C7 H8 110:62°C Cp C7 H8 v dT 110:62°C 10°C 110:62°C Enthalpy “toluene”;10;110:62;“C”;“l” Hv “toluene” Enthalpy “toluene”;110:62;50;“C”;“g” 42:94 kJ/mol The energy balance is X out ni H^ i X ni H^ i Q 17:7 kJ w w € Q ΔH in CREATIVITY EXERCISE A gas emerges from a stack at 1200°C. Rather than being released directly to the atmosphere, it can be passed through one or several heat exchangers, and the heat it loses can be put to use in a variety of ways. Think of as many uses of this heat as you can. (Example: During the winter, pass the gas through a series of radiators, thereby getting free heating.) 432 CHAPTER 8 Balances on Nonreactive Processes 8.4d Psychrometric Charts On a psychrometric chart (or humidity chart) several properties of a gas–vapor mixture are cross-plotted, providing a concise compilation of a large quantity of physical-property data. The most common of these charts—that for the air-water system at 1 atm—is used extensively in the analysis of humidification, drying, and air-conditioning processes. A psychrometric chart in SI units for the air–water system at 1 atm is shown in Figure 8.4-1, and a second chart in U.S. customary units is shown in Figure 8.4-2. Charts that cover wider temperature ranges in several formats are given on pp. 12-7 through 12-12 of Perry’s Chemical Engineers’ Handbook (see Footnote 5). The following paragraphs define and describe the different properties of humid air at 1 atm that appear on the psychrometric chart. Once you know the values of any two of these properties, you can use the chart to determine the values of the others. We will use the abbreviation DA for dry air. • Dry-bulb temperature, T—the abscissa of the chart. This is the air temperature as measured by a thermometer, thermocouple, or other conventional temperature-measuring instrument. • Absolute humidity, ha [kg H2O(v)/kg DA] (called moisture content on Figure 8.4-1)—the ordinate of the chart. This ratio can easily be calculated from or converted to the mass fraction of water. If, for example, the absolute humidity is 0.0150 kg H2O/kg DA, then for every kilogram of dry air there is 0.015 kg of water vapor, for a total of 1.015 kg. The mass fraction of water is (0.0150 kg H2O)/(1.015 kg humid air) = 0.0148 kg H2O/kg. • Relative humidity, hr 100 pH2 O =p*H2 O T. Curves on the psychrometric chart correspond to specified values of hr (100%, 90%, 80%, etc.). The curve that forms the left boundary of the chart corresponds to 100% relative humidity and is known as the saturation curve. • Dew point, T dp —the temperature at which humid air becomes saturated if it is cooled at constant pressure. The dew point of humid air at a given point on the psychrometric chart can easily be determined. For example, locate the point on Figure 8.4-1 corresponding to air at 29°C and 20% relative humidity. Cooling this air at constant pressure ( 1 atm) corresponds to moving horizontally (at constant absolute humidity) to the saturation curve. T dp is the temperature at the intersection, or 4°C. (Verify this statement.) • Humid volume, V^ H (m3/kg DA). The humid volume is the volume occupied by 1 kg of dry air plus the water vapor that accompanies it. Lines of constant humid volume on the psychrometric chart are steep and have negative slopes. On Figure 8.4-1, humid-volume lines are shown corresponding to 0.75, 0.80, 0.85, and 0.90 m3/kg dry air. To determine the volume of a given mass of wet air using the psychrometric chart, you must first determine the corresponding mass of dry air from the absolute humidity, then multiply this mass by V^ H . Suppose, for example, you wish to know the volume occupied by 150 kg of humid air at T 30°C and hr 30%. From Figure 8.4-1, ha 0:0080 kg H2O(v)/kg DA and V^ H 0:87 m3 /kg DA. The volume may then be calculated as V 150 kg humid air 1:00 kg DA 1:008 kg humid air 0:87 m3 kg DA 129 m3 (In this calculation, we used the fact that if the absolute humidity is 0.008 kg H2O/kg DA, then 1 kg DA is accompanied by 0.008 kg water for a total of 1.008 kg humid air.) 115 120 125 130 135 45 40 140 50 145 55 110 35 105 0.032 0.031 0.029 0.028 30 95 90% 100 0.030 y ation kJ/k gD dit mi 85 50 % 25 Enthalpy De vi Re lat ive 60 % Hu 80 Air 75 ry gD 70 J/k n, k 65 tio % 0.019 0.018 0.017 40 ura 60 Sat 0.020 55 0.016 0.015 20 lpy At 0.021 0.95 50 % En 0.014 0.011 % 20 °C 0.010 0.009 0.008 0.007 0.006 10% 0.005 0.004 0.003 0 0.002 0.001 +1.0 5 Moisture Content, kg/kg Dry Air 0.012 –1.2 –0.6 –0.4 2 –0. .1 –0 .05 –0 –1.0 0.013 –0.8 tha 0.022 30 15 40 0.023 25 –10 –5 0.00 10 0.80 Below 0°C Properties and Enthalpy Deviation Lines Are For Ice FIGURE 8.4-1 0.024 +0.2 +0.4 +0.6 +0.8 0.75 0.025 15 10 10 5 0 –5 –5 –10 ry Air 0.026 70% 90 80% 0.027 45 40 35 30 25 20 e, tur era 10 p m Te tion a r u Sat 5 b or Bul t e W 0 0.033 15 20 25 Dry Bulb Temperature, °C 30 0.85 35 40 45 50 55 0.90 Humid Volume, m3/kg Dry Air Psychrometric chart—SI units. Reference states: H2O (liquid, 0°C, 1 atm), dry air (0°C, 1 atm). (Data obtained from Carrier Corporation.) 433 Grains of moisture per pound of dry air 47 48 49 Enthalpy at saturation, Btu per pound of dry air 90 95 100 105 180 46 85 Pounds of moisture per pound of dry air 45 .025 170 43 44 .024 .023 42 80 160 41 .022 40 150 39 .021 .020 .019 y 75 37 38 140 mi 36 dit 130 .017 .015 70 % 65 tu tu –.0 6B –.0 22 4B tu –. 23 02 % 8B 40 –.0 50 16 19 .006 .005 .004 Btu Btu air .001 65 70 Dry Bulb Temperature, °F 75 80 85 90 95 cu ft 60 14.0 55 ft 50 cu 13.5 45 Btu cu ft cu 12.5 ft +0.5 0 100 105 110 0 ry of d .002 10 Btu ound per p Btu +0.4 40 .003 20 10% .3 +0 13.0 .2 +0 35 .007 40 13 12 .008 50 . cu ft 15 14 12 11 10 9 8 .1 +0 80% 30 .009 60 30 20% 25 .010 20% 40% 20 .011 70 35 7 Dry Bulb .012 30% 40 60% Wet Bulb, Dew Point or Saturation Temperature .013 14.5 17 20 18 21 55 % 50 .014 80 Enthalpy deviation Btu per Bt u 60 24 25 27 % 60 100 90 pound of dry 28 26 29 30 air –0.3 B tu 80 % 31 32 110 45 30 25 .016 70 33 90 % Re 34 lat ive 35 hu .018 120 Humid Volume, ft3/lbm Dry Air FIGURE 8.4-2 434 Psychrometric chart—U.S. customary units. Reference states: H2O (liquid, 32°F, 1 atm), dry air (0°F, 1 atm). (Data obtained from Carrier Corporation.) 8.4 Phase-Change Operations Equipment Encyclopedia thermometer www.wiley.com/college/felder 435 • Wet-bulb temperature, T wb . This quantity is best defined in terms of how it is measured. A porous material such as cloth or cotton is soaked in water and wrapped around the bulb of a thermometer to form a wick, and the thermometer is placed in a stream of flowing air, as in the figure shown below.9 Evaporation of water from the wick into the flowing air is accompanied by a transfer of heat from the bulb, which in turn causes a drop in the bulb temperature and hence in the thermometer reading.10 Provided that the wick remains moist, the bulb temperature falls to a certain value and remains there. The final temperature reading is the wet-bulb temperature of the air flowing past the wick. Thermometer Thermometer bulb wrapped with moist wick Humid air The wet-bulb temperature of humid air depends on both the dry-bulb temperature and the moisture content of the air. If the air is saturated (100% relative humidity), no water evaporates from the wick, and the wet-bulb and dry-bulb temperatures are the same. The lower the humidity, the greater the difference between the two temperatures. The humid air conditions that correspond to a given wet-bulb temperature fall on a straight line on the psychrometric chart, called a constant wet-bulb temperature line. The constant wet-bulb temperature lines for air–water at 1 atm appear on Figures 8.4-1 and 8.4-2 as lines with negative slopes extending beyond the saturation curve that are less steep than the lines of constant humid volume. The value of T wb corresponding to a given line can be read at the intersection of the line with the saturation curve. For example, suppose you wish to determine the wet-bulb temperature of air at 30°C (dry bulb) with a relative humidity of 30%. Locate the point on Figure 8.4-1 at the intersection of the vertical line corresponding to T 30°C and the curve corresponding to hr 30%. The diagonal line through the point is the constant wet-bulb temperature line for air at the given condition. Follow that line upward to the left until you reach the saturation curve. The temperature value you read on the curve (or vertically down from it on the abscissa) is the wet-bulb temperature of the air. You should get a value of 18°C. This means that if you wrap a wet wick around a thermometer bulb and blow air with T 30°C and hr 30% past the bulb, the thermometer reading will drop and eventually stabilize at 18°C. • Specific enthalpy of saturated air The diagonal scale above the saturation curve on the psychrometric chart shows the enthalpy of a unit mass (1 kg or 1 lbm) of dry air plus the water vapor it contains at saturation. The reference states are liquid water at 1 atm and 0°C (32°F) and dry air at 1 atm and 0°C (Figure 8.4-1) or 0°F (Figure 8.4-2). To determine the enthalpy from the chart, follow the constant wet-bulb temperature line from the saturation curve at the desired temperature up to the enthalpy scale. 9 Alternatively, the thermometer may be mounted in a sling psychrometer and whirled around in stationary air. 10 Think about what happens when you step out of a shower or swimming pool. Water evaporates, your skin temperature drops, and you feel cold, even if you felt perfectly comfortable when you were dry. 436 CHAPTER 8 Balances on Nonreactive Processes For example, saturated air at 25°C and 1 atm—which has an absolute humidity ha 0:0202 kg H2O/kg DA—has a specific enthalpy of 76.5 kJ/kg DA. (Verify these values of both ha and H^ on Figure 8.4-1.) The enthalpy is the sum of the enthalpy changes for 1.00 kg dry air and 0.0202 kg water going from their reference conditions to 25°C. The following calculation uses heat capacity data from Table B.2 for air and data from the steam tables (Table B.5) for water. 1:00 kg DA 0°C ! 1 kg DA 25°C w w € Z 25 1 kmol kJ 25:1 kJ C p;air TdT ΔH air 1:00 kg DA 29:0 kg kmol 0 0:0202 kg H2 O l; 0°C ! 0:0202 kg H2 O v; 25°C w w € kJ ^ ^ 51:4 kJ ΔH water 0:0202 kg H H2 O v;25°C H H2 O l;0°C kg ΔH air ΔH water kJ 25:1 51:4 kJ 76:5 kJ/kg DA H^ 1:00 kg DA 1:00 kg DA • Enthalpy deviation The remaining curves on the psychrometric chart are almost vertical and convex to the left, with labeled values (on Figure 8.4-1) of 0.05, 0.1, 0.2, and so on. (The units of these numbers are kJ/kg DA). These curves are used to determine the enthalpy of humid air that is not saturated. The procedure is as follows: (a) locate the point on the chart corresponding to air at its specified condition; (b) interpolate to estimate the enthalpy deviation at this point; (c) follow the constant wet-bulb temperature line to the enthalpy scale above the saturation curve, read the value on that scale, and add the enthalpy deviation to it. For example, air at 35°C and 10% relative humidity has an enthalpy deviation of about 0.52 kJ/kg DA. The specific enthalpy of saturated air at the same wet-bulb temperature is 45.0 kJ/kg DA. (Verify both of these numbers.) The specific enthalpy of the humid air at the given condition is therefore (45.0 0.52) kJ/kg DA 44:5 kJ/kg DA. The basis for the construction of the psychrometric chart is the Gibbs phase rule (Section 6.3a), which states that specifying a certain number of the intensive variables (temperature, pressure, specific volume, specific enthalpy, component mass or mole fractions, etc.) of a system automatically fixes the value of the remaining intensive variables. Humid air contains one phase and two components,11 so that from Equation 6.2-1 the number of degrees of freedom is F 22 13 Specifying three intensive variables therefore fixes all other system properties. If the system pressure is fixed at 1 atm, then all other properties may be plotted on a two-dimensional plot, such as those shown in Figures 8.4-1 and 8.4-2. Example 8.4-5 The Psychrometric Chart Use the psychrometric chart to estimate (1) the absolute humidity, wet-bulb temperature, humid volume, dew point, and specific enthalpy of humid air at 41°C and 10% relative humidity, and (2) the amount of water in 150 m3 of air at these conditions. 11 Since the components of dry air do not condense and are present in fixed proportion, dry air may be considered a single species (designated DA) in humidity calculations. 8.4 Phase-Change Operations Solution 437 Following is a sketch of the psychrometric chart (Figure 8.4-1) showing the given state of the air: 54.2 kJ/kg DA 10% hr Twb = 19°C ha(kg H2O/kg DA) Saturation curve 0.005 0.004 3°C Tdp 19°C Twb 41°C Tdb Enthalpy deviation curves (–0.8 kJ/kg DA) (–0.6 kJ/kg DA) 1. Reading from the chart, ha 0:0048 kg H2 O/kg DA T wb 19°C V^ m3 /kg DA 0:897 curve not shown The dew point is the temperature at which the air with the given water content would be saturated at the same total pressure (1 atm) and is therefore located at the intersection of the horizontal constant absolute humidity line (ha 0:0048) and the saturation curve, or T dp 3°C The specific enthalpy of saturated air at T wb 19°C is 54.2 kJ/kg DA. Since the point corresponding to 41°C and 10% relative humidity falls roughly midway between the enthalpy ^ as deviation curves corresponding to 0.6 kJ/kg and 0.8 kJ/kg, we may calculate H H^ w 54:2 w € 0:7 kJ/kg DA ^ 53:5 kJ/kg DA H 2. Moles of humid air. From Figure 8.4-1, the humid volume of the air is 0.897 m3/kg DA. We therefore calculate 150 m3 1:00 kg DA 0:897 m 3 0:0048 kg H2 O 1:00 kg DA 0:803 kg H2 O The psychrometric chart can be used to simplify the solution of material and energy balance problems for constant-pressure air–water systems, at the expense of some precision. Note the following points: 1. Heating or cooling humid air at temperatures above the dew point corresponds to horizontal movement on the psychrometric chart. The ordinate on the chart is the ratio kg H2O/kg dry air, which does not change as long as no condensation occurs. 2. If superheated humid air is cooled at 1 atm, the system follows a horizontal path to the left on the chart until the saturation curve (dew point) is reached; thereafter, the gas phase follows the saturation curve. 438 CHAPTER 8 Balances on Nonreactive Processes 3. Since the psychrometric chart plots the mass ratio kg H2O/kg dry air rather than the mass fraction of water, it is usually convenient to assume a quantity of dry air in a feed or product stream as a basis of calculation if the chart is to be used in the solution. www.wiley.com/college/felder Solution Air at 80°F and 80% relative humidity is cooled to 51°F at a constant pressure of 1 atm. Use the psychrometric chart to calculate the fraction of the water that condenses and the rate at which heat must be removed to deliver 1000 ft3/min of humid air at the final condition. Basis: 1 lbm Dry Air12 A flowchart for the process is shown below. By convention we show heat transfer (Q) into the process unit, but since the air is being cooled we know that Q will be negative. 1 lbm DA, 51°F m2(lbm H2O(v)) Ĥ2(Btu/lbm DA) AIR COOLER 1 lbm DA m1(lbm H2O(v)) 80°F, hr = 80% Ĥ1(Btu/lbm DA) m3(lbm H2O(l)), 51°F Ĥ3(Btu/lbm) Q (Btu) Note: In labeling the outlet gas stream, we have implicitly written a balance on dry air. Degree-of-Freedom Analysis: Point 1: 7 unknowns m1 ; m2 ; m3 ; H^ 1 ; H^ 2 ; H^ 3 ; Q 1 material balance H2 O dry air is already balanced on the chart 2 absolute humidities from psychrometric chart for inlet and outlet air 2 enthalpies from psychrometric chart for inlet and outlet air 1 enthalpy of condensate from known heat capacity of liquid water 1 energy balance 0 degrees of freedom Figure 8:4-2 80°F ha 0:018 lbm H2 O/lbm DA 80% RH H^ 1 38:8 Btu/lbm DA w w w w € Equipment Encyclopedia heat exchanger Material and Energy Balances on an Air Conditioner m1 Point 2: 1:0 lbm DA lbm DA 51°F Saturated m2 Balance on H2 O: 0:018 lbm H2 O Figure 8:4-2 0:018 lbm H2 O ha 0:0079 lbm H2 O/lbm DA ^ 2 20:9 Btu/lbm DA H w w w w € Example 8.4-6 1:0 lbm DA 0:0079 lbm H2 O m1 m2 m3 lbm DA 0:0079 lbm H2 O w w m1 0:018 lbm w € m 0:0079 lb 2 m m3 0:010 lbm H2 O condensed Fraction H2 O Condensed: 12 0:010 lbm condensed 0:555 0:018 lbm fed In assuming this basis, we are temporarily ignoring the specification of the volumetric flow rate at the outlet. After the process is balanced for the assumed basis, we will scale up to an outlet flow rate of 1000 ft3/min. 8.4 Phase-Change Operations 439 Enthalpy of Condensate: Since the reference condition for water on Figure 8.4-2 is liquid water at 32°F, we must use the same condition to calculate H^ 3 . H2 O l; 32°F ! H2 O l; 51°F ^ 3 1:0 Btu 51°F ΔH^ H lbm °F 32°F 19:0 Btu/lbm H2 O Energy Balance: The open-system energy balance with W s , ΔE k , and ΔEp set equal to zero is Q ΔH X ^i mi H out X ^i mi H in (There are no dots over the extensive variables in this equation because the basis of calculation is an amount, ^ i ) of the humid not a flow rate.) The enthalpy table for the process is shown below. Since (1) the enthalpies (H air streams are obtained from the psychrometric chart in Btu/lbm dry air, and (2) the mass units of mi and H^ i must cancel when the two are multiplied in the energy balance, the tabulated values of mi for these streams must be in lbm dry air. References: Dry air (DA) (g, 0°F, 1 atm), H2O (l, 32°F, 1 atm) Substance min Ĥ in mout Ĥ out Humid air 1.0 lbm DA 38.8 Btu/lbm DA 1.0 lbm DA 20.9 Btu/lbm DA — — 0.010 lbm 19 Btu/lbm H2O(l) The references were of necessity chosen to be the ones used to generate the psychrometric chart. Substituting the values in the table into the energy balance yields Q ΔH 1:0 lbm DA 20:9 Btu lbm DA 0:010 lbm H2 O l 19 Btu 1:0 lbm DA lbm H2 O 38:8 Btu lbm DA 17:7 Btu To calculate the cooling requirement for 1000 ft3/min of delivered air, we must first determine the volume of delivered air corresponding to our assumed basis and scale the calculated value of Q by the ratio (1000 ft3/min)=(V basis ). From the psychrometric chart, for humid air saturated at 51°F V^ H 13:0 ft3 /lbm DA w w € V basis w w € Q_ Test Yourself (Answers, p. 659) 1:0 lbm DA 13:0 ft3 lbm DA 17:7 Btu 13:0 ft3 1000 ft3 /min 13:0 ft3 1360 Btu/min Air at 25°C and 1 atm has a relative humidity of 20%. Use the psychrometric chart to estimate the absolute humidity, wet-bulb temperature, dew point, humid volume, and specific enthalpy of the air. 440 C H AP T E R 8 Balances on Nonreactive Processes CREATIVITY EXERCISE In home air-conditioning systems, the controlling thermostat is set to the desired room temperature T 1 , and the AC unit typically cools air passing through it to a temperature T 2 significantly lower than T 1 . Give at least two reasons why. 8.4e Adiabatic Cooling www.wiley.com/college/felder In adiabatic cooling, a warm gas is brought into contact with a cold liquid, causing the gas to cool and some of the liquid to evaporate. Heat is transferred from the gas to the liquid but no heat is transferred between the gas–liquid system and its surroundings (hence “adiabatic” cooling). Some common processes of this type are described below. • Spray cooling, spray humidification. Liquid water is sprayed into a relatively dry warm stream of air. Some of the water evaporates, and the temperature of the air and of the unevaporated liquid both decrease. If the object is to cool the water or the air, the operation is called spray cooling; if the point is to increase the moisture content of the air, the operation is spray humidification.13 • Spray dehumidification. Warm humid air is dehumidified by spraying cold water into it. Provided that the liquid temperature is low enough, the air is cooled below its dew point, causing some of the water vapor in it to condense. • Drying. Hot air is blown over wet solids—for example, over a wet cake deposited in a filter or centrifuge. The water evaporates, leaving a dry solid product. Drying is the last step in the production of most crystalline products and powders, including many pharmaceuticals and food products. • Spray drying. A suspension of small solid particles in water is sprayed as a fine mist into a stream of hot air. The water evaporates, larger solid particles settle out of the air and are removed by a conveyor, and fine suspended particles are separated from the air by a bag filter or cyclone separator. Dried milk is produced in this manner. Writing material and energy balances on an adiabatic cooling operation is a straightforward but cumbersome procedure. It can be shown, however, that if certain well-justified assumptions are made (we will state them later), air undergoing adiabatic cooling through contact with liquid water moves along a constant wet-bulb temperature line on the psychrometric chart from its initial condition to the 100% relative humidity curve. Further cooling of the air below its saturation temperature leads to condensation and hence dehumidification. hr = 100% ha(kg H2O/kg DA) Equipment Encyclopedia humidifier, dryer, spray dryer Constant wet-bulb temperature line Inlet air Twb T1 This result (which is not at all obvious) allows us to perform adiabatic cooling calculations with relative ease using the psychrometric chart. First locate the initial state of the air on the 13 Spraying the water into the air rather than simply blowing air over a water surface provides a large liquid surface-tovolume ratio, greatly increasing the evaporation rate. 8.4 Phase-Change Operations 441 chart; then locate the final state on the constant wet-bulb temperature line that passes through the initial state (or on the 100% humidity curve if cooling below the adiabatic saturation temperature (Tas) takes place); and finally perform whatever material and energy balance calculations are required. Example 8.4-7 illustrates such a calculation for an adiabatic humidification operation. Example 8.4-7 Equipment Encyclopedia humidifer—water spray Adiabatic Humidification A stream of air at 30°C and 10% relative humidity is humidified in an adiabatic spray tower operating at P 1 atm. The emerging air is to have a relative humidity of 40%. www.wiley.com/college/felder Humidified air hr = 40% H2O (l) SPRAY TOWER Air, 30°C, hr = 10% H2O (l) 1. Determine the absolute humidity and the adiabatic saturation temperature of the entering air. 2. Use the psychrometric chart to calculate (i) the rate at which water must be added to humidify 1000 kg/h of the entering air, and (ii) the temperature of the exiting air. Solution We assume that the heat required to raise the temperature of the liquid in the spray tower is negligible compared with the heat of vaporization of water, so that the air follows an adiabatic saturation curve (constant wet-bulb temperature line) on the psychrometric chart. 1. Air at 30°C, 10% relative humidity w w €Figure 8:4-1 ha 0:0026 kg H2 O/kg DA T wb T as 13:2°C 2. The state of the outlet air must lie on the T wb 13:2°C line. From the intersection of this line with the curve for hr 40%, the absolute humidity of the exit gas is determined to be 0.0063 kg H2O/kg DA. The inlet (and outlet) flow rate of dry air, m_ DA , is m_ DA 1000 kg air/h 1 kg DA=1:0026 kg air 997:4 kg DA/h The amount of water that must be evaporated, m_ H2 O , may be calculated as the difference between the outlet and inlet water flow rates in the air stream. m_ H2 O 997:4 kg DA/h 0:0063 0:0026 3:7 kg H2 O/h From Figure 8.4-1 the temperature of the exiting air is 21:2°C . kg H2 O kg DA 442 C H AP T E R 8 Balances on Nonreactive Processes A complete justification of the procedure given above is beyond the scope of this text,14 but we can at least offer a partial explanation. A flowchart of an adiabatic cooling operation is shown below. A stream of warm air and either a stream of liquid water (spray cooling or spray humidification), a wet solid (drying), or a solid suspension (spray drying) are brought into contact. The air enters at T 1 and leaves at T 3 , the water and any solids enter at T 2 and leave at T 4 , and entering liquid water evaporates at a rate m_ we kg/s. Air, T3(°C) Air, T1(°C) • ma (kg dry air/s) mw1 (kg H2O(v)/s) H2O(l) (+ solids) SPRAY TOWER T2(°C) ma (kg dry air/s) (mw1 + mwe) (kg H2O(v)/s) H2O(l) (+ solids) T4(°C) We assume: ^ v H O are independent of temperature at the process conditions. 1. Cp air , C p H2 O , and ΔH 2 2. The enthalpy changes undergone by the unevaporated liquid water and the solid (if there is one) in going from T 2 to T 4 are negligible compared to the changes undergone by the entering wet air and the evaporated water. 3. The heat required to raise liquid water from T 2 to T 3 is negligible compared to the heat of vaporization of water. If the energy balance equation ΔH_ 0 is written for this process and these three assumptions are made, the simplified equation becomes m_ a C p air T 3 w w € T 1 m_ w1 C p H2 O v T 3 1 m_ we m_ a ΔH^ v H2 O Cp air ^ v H O 0 T 1 m_ we ΔH 2 m_ w1 Cp H2 O v T 1 m_ a T 3 (8.4-9) Suppose now that the temperature T 1 and absolute humidity m_ w1 =m_ a of the inlet air are specified, so that the state of the inlet air is fixed on the psychrometric chart. If we specify in addition the outlet air temperature T 3 < T 1 , then m_ we =m_ a may be calculated from Equation 8.4-9, and it may in turn be used to calculate the absolute humidity of the outlet air, m_ we m_ w1 =m_ a . The outlet temperature and humidity determined in this manner are represented by a point on the psychrometric chart. If a lower value of T 3 is assumed, a higher outlet humidity would be calculated, yielding another point on the chart. The set of all such points for a specified T 1 and m_ w1 =m_ a defines a curve on the chart, known as the adiabatic saturation curve. If the three stated assumptions are valid, the final state of air undergoing an adiabatic humidification must lie on the adiabatic saturation curve that passes through the inlet state on the psychrometric chart. If the outlet temperature T 3 is low enough, the air leaves saturated with water. The temperature corresponding to this condition is the adiabatic saturation temperature and is found at the intersection of the adiabatic saturation curve with the 100% relative humidity curve. 14 One can be found in W. L. McCabe, J. C. Smith, and P. Harriott, Unit Operations of Chemical Engineering, 7th Edition, McGraw-Hill, New York, 2004, Chap. 19. 8.5 Mixing and Solution 443 The psychrometric chart for most gas–liquid systems would show a family of adiabatic saturation curves in addition to the families of curves shown on Figures 8.4-1 and 8.4-2. However, for the air–water system at 1 atm, the adiabatic saturation curve through a given state coincides with the constant wet-bulb temperature line through that state, so that T as T wb . The simple material and energy balance procedure for adiabatic cooling outlined in this section is possible only because of this coincidence. Test Yourself (Answers, p. 659) 8.5 1. (a) Under what conditions do the temperature and humidity of a gas undergoing adiabatic cooling follow a unique curve on the psychrometric chart, regardless of the entering liquid temperature? (b) Does this curve coincide with a constant wet-bulb temperature line if the gas is air and the liquid is water? (c) What if they were nitrogen and acetone? 2. Air at 26°C with a relative humidity of 10% undergoes an adiabatic humidification. Use Figure 8.4-1 to estimate the adiabatic saturation temperature of the air. If the exiting air has a dry-bulb temperature of 14°C, determine its absolute humidity, relative humidity, and specific enthalpy. MIXING AND SOLUTION You may have carried out an experiment in a chemistry laboratory in which you mixed two liquids (such as concentrated sulfuric acid and water) or dissolved a solid in a liquid (such as sodium hydroxide in water) and observed that the mixture or solution became quite hot. The question is: Why? When two different liquids are mixed or when a gas or solid is dissolved in a liquid, bonds are broken between neighboring molecules—and possibly between atoms—of the feed materials, and new bonds are formed between neighboring molecules or ions in the product solution. If less energy is required to break the bonds in the feed materials than is released when the solution bonds form, a net release of energy results. Unless this energy is transferred from the solution to its surroundings as heat, it goes into raising the solution temperature, which is what happened in the experiments described in the first paragraph. Suppose you mix 1 mol of pure liquid sulfuric acid with water at a specified temperature and pressure and then cool the mixture at constant pressure to bring it back to the initial temperature. The energy balance for this constant-pressure process is Q ΔH H H2 SO4 aq H H2 SO4 l H H2 O where ΔH—the difference between the enthalpy of the solution at the specified temperature and pressure and the total enthalpy of the pure solute and solvent at the same T and P—is the heat of solution at that temperature and pressure. For the sulfuric acid dilution, we know Q < 0 (the container must be cooled to keep the solution temperature from rising) and so it follows that ΔH—the heat of solution—is negative for this process. An ideal P mixture is one for which the heat of mixing or solution is negligible and so ^ i , where ni is the amount of mixture component i and H^ i is the specific enthalpy ni H H mixture of the pure component at the temperature and pressure of the mixture. Up to now in this text, we have assumed ideal-mixture behavior for all mixtures and solutions. This assumption works well for nearly all gas mixtures and for liquid mixtures of similar compounds (such as mixtures of paraffins or of aromatics), but for other mixtures and solutions—such as aqueous solutions of strong acids or bases or certain gases (such as hydrogen chloride) or solids (such as sodium hydroxide)—heats of solution should be included in energy balance calculations. This section outlines the required procedures. 444 C H AP T ER 8 Balances on Nonreactive Processes 8.5a Heats of Solution and Mixing ^ s T; r is defined as the change in enthalpy for a process in which 1 mole The heat of solution ΔH of a solute (gas or solid) is dissolved in r moles of a liquid solvent at a constant temperature T. As r ^ s approaches a limiting value known as the heat of solution at infinite becomes large, ΔH dilution. The heat of mixing has the same meaning as the heat of solution when the process involves mixing two fluids rather than dissolving a gas or solid in a liquid. Perry’s Chemical Engineers’ Handbook (see Footnote 5) on pp. 2-203 through 2-206 gives heats of solution of various substances in water at either 18°C or “room temperature,” which is roughly 25°C. Caution: The values given in the Handbook are evolved heats and thus negatives of ^ s . the heats of solution ΔH As an illustration of how to use these data, suppose you wish to calculate ΔH for a process in which 2 mol of potassium cyanide (KCN) is dissolved in 400 mol of water at 18°C. First, calculate the moles of solvent per mole of solute: r 400=2 200 mol H2 O/mol KCN The value of ΔH s (18°C, r 200) is listed as dissolved). The total enthalpy change is therefore 2:0 mol KCN ΔH nΔH^ s 3.0 kcal/mol (meaning per mol of KCN 3:0 kcal mol KCN 6:0 kcal Table B.11 lists values of the heats of solution at 25°C of HCl(g) and NaOH(s) in water, and the heat of mixing at 25°C of H2SO4(l) and water. Heats of solution such as those given in Table B.11 may be used to determine directly the specific enthalpies of solutions at 25°C relative to the pure solute and solvent at this temperature. Another common choice of reference conditions, however, is the pure solvent and an infinitely dilute solution at 25°C. Consider, for example, a hydrochloric acid solution for which r 10 moles H2O/mole HCl. From Table B.11, the specific enthalpy of this solution relative to pure HCl(g) and H2O(l) at 25°C is ΔH^ s r 10 69:49 kJ/mol HCl. Now, the enthalpy of the solution relative to H2O(l) and a highly dilute solution of HCl (say, r 106 moles H2O/mole HCl) is the enthalpy change for the isothermal process 1 mol HCl 25°C 1 mol HCl 106 10 mol H2 O l ! 106 mol H2 O 10 mol H2 O We may evaluate this enthalpy change using any convenient reference state—in particular, taking ^ for the (106 10) pure HCl(g) and H2O(l) at 25°C as references. In view of the latter choice, H moles of pure water equals zero, and the enthalpy change for the process is therefore ^ s r 10 ΔH^ ΔH ΔH^ s r 1 69:49 75:14 kJ/mol HCl 5:65 kJ/mol HCl In general, the enthalpy of a solution containing r moles H2O/mole solute is for reference states of pure solute and solvent at 25°C and 1 atm ^ ΔH ^ s r H (8.5-1) and for reference states of pure solvent and an infinitely dilute solution at 25°C and 1 atm H^ ΔH^ s r ^ s 1 ΔH (8.5-2) Note again that these enthalpies are expressed per mole of solute, not per mole of solution. 8.5 Mixing and Solution Test Yourself (Answers, p. 659) 445 The heat of solution of a solute A in water at 25°C is 40 kJ/mol A for r 10 mol H2O/mol A and 60 kJ/mol A for infinite dilution. 1. What is the specific enthalpy (kJ/mol A) of an aqueous solution of A for which r 10 mol H2O/mol A relative to (a) pure H2O and A at 25°C? (b) pure H2O and an infinitely dilute aqueous solution of A? 2. If 5 mol of A is dissolved in 50 mol of H2O at 25°C, how much heat is evolved or absorbed? (State which, observing that Q ΔH for this process.) 3. How much heat is evolved or absorbed if the solution prepared in question 2 is poured into a large tank of water at 25°C? 8.5b Balances on Dissolution and Mixing Processes When setting up an energy balance on a process that involves forming, concentrating, or diluting a solution for which the heat of solution or mixing cannot be neglected, prepare an inlet–outlet enthalpy table considering the solution as a single substance and the pure components at 25°C as reference states. To calculate the enthalpy of the solution at a temperature T ≠ 25°C, first calculate its enthalpy at 25°C from tabulated heat of solution data, then add the enthalpy change for the heating or cooling of the solution from 25°C to T. The enthalpy change for the latter step should be calculated from tabulated solution heat capacities if they are available [e.g., if they are listed on pp. 2-183 and 2-184 of Perry’s Chemical Engineers’ Handbook (see Footnote 5)]; otherwise, use the average heat capacity determined using Equation 8.3-13 for liquid mixtures or the heat capacity of the pure solvent for dilute solutions. Example 8.5-1 Equipment Encyclopedia absorber Production of Hydrochloric Acid Hydrochloric acid is produced by absorbing gaseous HCl (hydrogen chloride) in water. Calculate the heat that must be transferred to or from an absorption unit if HCl(g) at 100°C and H2O(l) at 25°C are fed to produce 1000 kg/h of 20.0 wt% HCl(aq) at 40°C. www.wiley.com/college/felder Solution It is advisable to determine the molar amounts or flow rates of the components of all feed and product solutions before drawing and labeling the flowchart. In this case n_ HCl n_ H2 O 1000 kg/h of 20:0 wt% HCl aq w w € 1000 kg 0:200 kg HCl 103 mol h kg 36:5 kg HCl 1000 kg 0:800 kg H2 O 103 mol h kg 18:0 kg H2 O 5480 mol HCl/h 44;400 mol H2 O/h 5480 mol HCl(g)/h 100°C ABSORBER 1000 kg/h, 20 wt% HCl(aq), 40°C 5480 mol HCl/h 44,400 mol H2O/h 44,400 mol H2O(l)/h 25°C • Q(kJ/h) The enthalpy table for the process is shown below. As usual, physical property data valid at P 1 atm are used and the effects on enthalpy of any pressure differences that may occur in the process are neglected. Balances on Nonreactive Processes Note that the value of n_ for the product solution is the molar flow rate of the solute (HCl) rather than the solution, since the enthalpy will be determined in kJ/mol solute. References: HCl(g), H2O(l) at 25°C and 1 atm Substance n_ in Ĥ in n_ out Ĥ out Ĥ 1 (kJ/mol HCl) HCl(g) 5480 mol HCl — — H2O(l) 44,400 mol H2O 0 — HCl(aq) — — 5480 mol HCl — ̂ H 2 (kJ/mol HCl) ^ 1 and H ^2: Calculate H HCl g; 25°C ! HCl g; 100°C Z 100°C ^ 1 ΔH^ C p dT H w 25°C w €Cp for HCl g from Table B:2 ^ 1 2:178 kJ/mol H For the product solution, r 44;400 mol H2 O= 5480 mol HCl 8:10 HCl g; 25°C 8:10 H2 O 1; 25°C ^ a ΔH^ s 25°C; r 8:1 ΔH ^a ΔH ! HCl aq; 25°C Table B:11 ^b ΔH ! HCl aq; 40°C 67:4 kJ/mol HCl w w w w € 446 CHAPTER 8 The heat capacities of aqueous hydrochloric acid solutions are listed on p. 2-183 of Perry’s Chemical Engineers’ Handbook (see Footnote 5) as a function of the mole fraction of HCl in the solution, which in our problem is Cp 5480 mol HCl/h 0:110 mol HCl/mol 5480 44;400 mol/h w w € 0:73 kcal kg°C 1000 kg solution 4:184 kJ 0:557 5480 mol HCl kcal Z 40°C ^b Cp dT 8:36 kJ/mol HCl ΔH w25°C w € ^ 2 ΔH^ a ΔH^ b H kJ mol HCl°C 67:4 8:36 kJ/mol HCl 59:0 kJ/mol HCl Energy Balance: Q_ ΔH_ X n_ i H^ i out X n_ i H^ i in 5480 mol HCl/h 59:0 kJ/mol HCl 5480 mol HCl/h 2:178 kJ/mol HCl 3:35 105 kJ/h Heat must be transferred out of the absorber at a rate of 335,000 kJ/h to keep the product temperature from rising above 40°C. 8.5 Mixing and Solution 447 8.5c Enthalpy–Concentration Charts—Single Liquid Phase Energy balance calculations on liquid-phase systems involving mixtures can be cumbersome when heats of mixing are significant. The calculations can be simplified for binary (twocomponent) systems by using an enthalpy–concentration chart, a plot of specific enthalpy versus mole fraction (or mole percent) or mass fraction (or weight percent) of one component. An ^ chart for aqueous solutions of sulfuric acid at several temperatures is shown in Figure 8.5-1. H-x The reference conditions for the plotted enthalpies are pure liquid H2SO4 at 77°F and liquid water at 32°F. The points on the isotherms of Figure 8.5-1 were determined using the procedure outlined in the last section. Suppose, for example, you wish to calculate the specific enthalpy (Btu/lbm) of a 40 wt% sulfuric acid solution at 120°F. If you know the heat of mixing of sulfuric acid at 77°F, the process path you would follow would be to bring pure liquid water from its reference temperature of 32°F to 77°F (the sulfuric acid starts at 77°F and so does not require this step), mix the two liquids at 77°F, bring the product solution to 120°F, and calculate and add the enthalpy changes for each of these steps. 140 120 100 80 60 Ĥ(Btu/lbm solution) 40 20 0 –20 –40 20 0° F 18 0 16 14 0 0 12 10 0 0 –60 –80 60 77 80 ezi 40 Fre °F 32 –120 ng l ine –100 –140 0 0.10 0.20 0.30 0.40 0.50 0.60 0.70 Mass fraction of H2SO4 0.80 0.90 1.00 FIGURE 8.5-1 Enthalpy–concentration chart for H2SO4-H2O. (Redrawn from the data of W. D. Ross, Chem. Eng. Progr., 43:314, 1952.) 448 C H AP T E R 8 Balances on Nonreactive Processes 0:40 lbm H2 SO4 4:08 10 w w € Basis: 1 lbm solution ( 10 2 lb-mole) 3 lb-mole, 0:60 lbm H2 O 3:33 • 0.60 lbm H2O(l, 32°F) → 0.60 lbm H2O (l,77°F) ΔH 1 Btu 0:60 lbm H2 O Z 77°F 32°F Btu C p H2 O dT lbm The heat capacity of liquid water is approximately 1 Btu/(lbm °F). • 0.40 lbm H2 SO4 77°F 0:60 lbm H2 O 77°F ! 1:0 lbm H2 SO4 solution (aq, 77°F) Btu ^ s 77°F; r 8:2 lb-mole H2 O ΔH 2 Btu 0:40 lbm H2 SO4 ΔH lb-mole H2 SO4 lbm H2 SO4 The heat of mixing can be determined from the data in Table B.11 to be 279 Btu/lbm H2SO4. • 1.0 lbm H2SO4 solution (aq, 77°F) → 1.0 lbm H2SO4 solution (aq, 120°F) Z 120°F C p 40% H2 SO4 aq dT ΔH 3 Btu 1:0 lbm 77°F The heat capacity of the 40% sulfuric acid solution is roughly 0.67 Btu/(lbm °F).15 ΔH 1 ΔH 2 ΔH 3 Btu • H^ 40% H2 SO4 ; 120°F 1:0 lbm solution (Verify that this is the value shown in Figure 8.5-1.) 56 Btu/lbm If any reference temperature but 77°F had been chosen for sulfuric acid, another step would have been included in which H2SO4 was brought from T ref to 77°F prior to mixing. Once someone has gone to the trouble of preparing an enthalpy-concentration chart like that of Figure 8.5-1, energy balance calculations become relatively simple, as shown in Example 8.5-2. Example 8.5-2 Concentration of an Aqueous H2SO4 Solution A 5.0 wt% H2SO4 solution at 60°F is to be concentrated to 40.0 wt% by evaporation of water. The concentrated solution and water vapor emerge from the evaporator at 180°F and 1 atm. Calculate the rate at which heat must be transferred to the evaporator to process 1000 lbm/h of the feed solution. Solution Basis: Given Feed Rate of 5% • m1[lbm H2O(v)/h] @ 180°F, 1 atm Equipment Encyclopedia evaporator EVAPORATOR ĤV(Btu/lbm) 1000 lbm/h @ 60°F www.wiley.com/college/felder • Q(Btu/h) 0.050 lbm H2SO4/lbm 0.95 lbm H2O/lbm ĤF(Btu/lbm) Total Mass Balance: 1000 lbm /h m_ 1 m_ 2 Reference States for Energy Balance: 15 m_ 2 125 lbm /h w w € 0:050 1000 lbm /h 0:400m_ 2 0.400 lbm H2SO4/lbm 0.600 lbm H2O/lbm ĤL(Btu/lbm) m_ 2 125 lbm /h m_ 1 875 lbm /h w w w w € H2 SO4 Balance: • m2(lbm/h) @ 180°F, 1 atm H2 O l; 32°F; H2 SO4 l; 77°F R. H. Perry and D. W. Green, Eds., Perry’s Chemical Engineers’ Handbook, 8th Edition, McGraw-Hill, New York, 2008, p. 2-184. 8.5 Mixing and Solution 449 From Figure 8.5-1: ^ F 10 Btu/lbm H ^ L 17 Btu/lbm H 5% H2 SO4 at 60°F 40% H2 SO4 at 180°F The enthalpy of water vapor at 180°F and 1 atm relative to liquid water at 32°F may be obtained from the steam tables in Perry’s Chemical Engineers’ Handbook (see Footnote 5) as ^ V 1138 Btu/lbm H ^ V m_ 2 H ^L Q_ ΔH_ m_ 1 H Energy Balance: ^F 1000 lbm /hH 875 1138 125 17 1000 10 Btu/h 984;000 Btu/h Compare the ease of this computation with that of Example 8.5-1. Having the enthalpy–concentration chart eliminates the need for all of the hypothetical heating, cooling, and isothermal mixing steps that would normally be required to evaluate the total enthalpy change for the process. ^ chart is Processes involving adiabatic mixing are particularly simple to analyze when an H-x available. Suppose xA is the mass fraction of A in a mixture of two species, A and B, and that a ^ 2 ). We mass m1 of Solution 1 (xA1 ; H^ 1 ) is mixed adiabatically with a mass m2 of Solution 2 (xA2 ; H ^ ^ will show that the condition of the product mixture, (xA3 ; H 3 ), is on a straight line on the H-x chart between the points corresponding to the feed stream conditions. m1(lbm) xA1(lbm A/lbm) Ĥ2 m3(lbm) Ĥ1(Btu/lbm) Ĥ3 xA3(lbm A/lbm) m2(lbm) Ĥ3(Btu/lbm) xA2(lbm A/lbm) Ĥ1 Ĥ2(Btu/lbm) xA1 xA3 xA3 = xA2 m1xA1 + m2xA2 m1 + m2 To prove this result, we write a total mass balance, a material balance on species A, and an energy balance (ΔH 0 for this constant-pressure batch process): m1 m2 m3 Total Mass Balance: A Balance: m1 xA1 m2 xA2 m3 xA3 m1 xA3 Energy Balance: a xA1 m2 xA2 ^3 ΔH m3 H ^3 m1 H b w w €Substitute for m3 from a; rearrange ^1 m1 H xA3 ^2 0 m2 H w w €Substitute for m3 from a; rearrange ^ 1 m2 H^ 2 H c H^ 3 d Dividing (d) by (c) yields H^ 3 xA3 H^ 2 H^ 1 xA1 xA2 ^3 H xA3 e ^ 1 ) to (xA3 , H ^ 3 ) (the left-hand side of this equation) Since the slope of the line segment from (xA1 , H ^ ^ equals the slope of the segment from (xA3 , H 3 ) to (xA2 , H 2 ) (the right-hand side) and the segments 450 C H AP T E R 8 Balances on Nonreactive Processes have a point in common, the three points must lie on a straight line. The value of xA3 can be calculated from Equations a and b: xA3 m1 xA1 m2 xA2 m1 m2 (8.5-3) It follows that if two feed solutions of known masses and compositions (mi , xi , i 1, 2) are mixed ^ chart, you may (i) calculate x3 for the product mixture from adiabatically and you have an H-x Equation 8.5-3, (ii) draw a line connecting the points on the chart corresponding to the two feeds, and (iii) read the enthalpy and temperature of the product mixture from the point on the connecting line for which x x3 . Example 8.5-3 Adiabatic Mixing Pure water at 60°F is mixed with 100 g of an aqueous 80 wt% H2SO4 solution, also at 60°F. The mixing vessel is insulated well enough to be considered adiabatic. 1. If 250 g H2O is mixed with the acid, what will the final solution temperature be? 2. What is the maximum attainable solution temperature and how much water must be added to achieve it? Solution 1. From Equation 8.5-3, the mass fraction of H2SO4 in the product solution is xp 100 0:80 250 0 g H2 SO4 0:23 g H2 SO4 /g 100 250 g A straight line on Figure 8.5-1 between points at (x 0, T 60°F) and (x 0:80, T 60°F) goes through the point (x 0:23, T 100°F ). (Verify this result.) 2. The line between (x 0, T 60°F) and (x 0:80, T 60°F) passes through a temperature maximum at roughly (x 0:58, T 150°F ). (Verify.) From Equation 8.5-3, 100 0:80 g mw 0 100 g mw mw 38 g H2 O w w € 0:58 The graphical construction of these solutions is illustrated below. 100°F Ĥ(Btu/lbm solution) 150°F 60°F 0 Test Yourself (Answers, p. 659) 23 58 wt% H2SO4 80 Use Figure 8.5-1 to answer the following questions. 1. What is the specific enthalpy of 80 wt% H2SO4(aq, 110°F) relative to pure H2SO4 at 77°F and pure water at 32°F? 2. The 100 wt% intercepts of the isotherms on Figure 8.5-1 are difficult to read. Which isotherm must have an intercept of 0 Btu/lbm? (Your answer should be a temperature.) 8.5 Mixing and Solution 451 3. Pure water at 32°F is used to dilute a 90 wt% H2SO4 solution (aq, 32°F). Estimate the maximum temperature the product solution can achieve and the concentration of sulfuric acid (wt%) in this solution. 4. Estimate (a) the specific enthalpy of a 30 wt% H2SO4 solution (aq, 77°F) and (b) the specific enthalpy of a 30 wt% solution obtained by mixing pure water at 77°F and pure sulfuric acid at 77°F adiabatically. What is the physical significance of the difference between these two enthalpies? 8.5d Using Enthalpy–Concentration Charts for Vapor–Liquid Equilibrium Calculations Enthalpy–concentration charts are particularly useful for two-component systems in which vapor and liquid phases are in equilibrium. The Gibbs phase rule (Equation 6.2-1) specifies that such a system has 2 2 2 2 degrees of freedom. If as before we fix the system pressure, then specifying only one more intensive variable—the system temperature, or the mass or mole fraction of either component in either phase—fixes the values of all other intensive variables in both ^ diagram for the ammonia–water system at 1 atm is shown in Figure 8.5-2. The phases. An H-x specific enthalpies of aqueous solutions and gaseous mixtures of ammonia and water in equilibrium with each other are shown on the two curves on this figure. Each phase is said to be saturated. Suppose the mass fraction of ammonia in a saturated liquid solution of NH3 and H2O at 1 atm is specified to be 0.25. According to the phase rule, the system temperature and the mass fraction of NH3 in the vapor phase are uniquely determined by these specifications. (Verify.) A tie line may therefore be drawn on the enthalpy–concentration chart from x 0:25 on the liquid-phase curve to the corresponding point on the vapor-phase curve, which experimental data have shown to be at 1300 1200 Reference states: Water: liquid at 32°F NH3: liquid at –40°F 1100 1000 °F 16 0° F 600 500 14 0° F 700 C 180 800 Vapor phase 200°F Specific enthalpy Ĥ(Btu/lbm) 900 F 0° 12 A 400 F 0° 10 300 40 B –100 –200 0.0 20 0 °F 100 6 °F 0°F 80 °F 200 Liquid phase 0.1 0.2 0.3 0.4 0.5 0.6 0.7 x (mass fraction NH3) 0.8 0.9 1.0 Enthalpy–concentration diagram for the ammonia–water system at 1 atm. (From G. G. Brown et al., Unit Operations, 1950, Figure 551. Reprinted by permission of John Wiley & Sons.) FIGURE 8.5-2 452 C H AP T E R 8 Balances on Nonreactive Processes y 0:95; the tie line may be labeled with the corresponding temperature, 100°F. Several tie lines constructed in this manner are shown in Figure 8.5-2; once drawn, the lines may be used to determine the equilibrium composition and the specific enthalpy of each phase at a specified temperature. Example 8.5-4 Use of the Enthalpy–Concentration Chart for a Two-Phase System An aqueous ammonia solution is in equilibrium with a vapor phase in a closed system at 160°F and 1 atm. The liquid phase accounts for 95% of the total mass of the system contents. Use Figure 8.5-2 to determine the weight percent of NH3 in each phase and the enthalpy of the system per unit mass of the system contents. The mass fractions of ammonia and specific enthalpies of each phase may be read from the intersections of the 160°F tie line with the vapor and liquid equilibrium curves on Figure 8.5-2. Liquid Phase: 8% NH3 ; 92% H2 O ^ L 110 Btu/lbm H Vapor Phase: 64% NH3 ; 36% H2 O H^ V 855 Btu/lbm 1 lbm total mass Basis: 0:95 lbm liquid; 0:05 lbm vapor w w € Solution 0:95 lbm liquid H^ Btu/lbm lbm 110 Btu lbm 0:05 lbm vapor 855 Btu lbm lbm 147 Btu/lbm If the overall composition of a two-phase two-component system at a given temperature and pressure is known, the fraction of the system that is liquid or vapor may easily be determined from the enthalpy–concentration chart. Suppose, for example, that a mixture of ammonia and water that is 40% NH3 by mass is contained in a closed vessel at 140°F and 1 atm. Point A on Figure 8.5-2 corresponds to this condition. Since this point lies between the vapor and liquid equilibrium curves, the mixture separates into two phases whose compositions are found at the extremities of the 140°F tie line (points B and C). In general, if F, L, and V are the total mass of the mixture, the mass of the liquid phase and the mass of the vapor phase, respectively, and xF , xL , and xV are the corresponding mass fractions of NH3, then F LV Total balance: NH 3 balance: (8.5-4) xF F xL L xV V (8.5-5) Substituting the expression of Equation 8.5-4 for F into Equation 8.5-5 and rearranging the result yields L xV V xF xF xL (8.5-6) The tie line in question appears as shown below: C A B xL xF xV 8.5 Mixing and Solution 453 From the properties of similar triangles, the right side of Equation 8.5-6 equals the ratio of distances AC=AB. We have thus proved the following general rule: if A, B, and C are the points on a tie line corresponding to the total mixture, the liquid phase, and the vapor phase, respectively, and if F, L, and V are the corresponding masses, then the liquid-to-vapor mass ratio is L xV V xF xF AC xL AB (8.5-7) This is the lever rule. It is also not difficult to prove that the mass fractions of the liquid and vapor phases are L xV F xV xF AC xL BC (8.5-8) V xF F xV xL AB xL BC (8.5-9) Once you have located the total mixture on the chart from a specified set of feed conditions, it becomes a simple matter to determine the compositions, enthalpies, and relative proportions of each phase, calculations that would take much more time in the absence of the chart. Example 8.5-5 Equilibrium Flash Vaporization A 30 wt% NH3 solution at 100 psia is fed at a rate of 100 lbm/h to a tank in which the pressure is 1 atm. The enthalpy of the feed solution relative to the reference conditions used to construct Figure 8.5-2 is 100 Btu/lbm. The vapor composition is to be 89 wt% NH3. Determine the temperature of the stream leaving the tank, the mass fraction of NH3 in the liquid product, the flow rates of the liquid and vapor product streams, and the rate at which heat must be transferred to the vaporizer. Solution Basis: 100 lbm/h Feed • mV (lbm/h) FLASH TANK 0.89 lbm NH3/lbm 0.11 lbm H2O/lbm ĤV (Btu/lbm) 100 lbm/h • Q(Btu/h) 0.3 lbm NH3/lbm ĤF = 100 Btu/lbm • mL(lbm/h) xL(lbm NH3/lbm) (1 – xL)(lbm H2O/lbm) ĤL(Btu/lbm) From Figure 8.5-2, xV 0:89 lbm NH3 /lbm T 120°F xL 0:185 lbm NH3 /lbm ^ V 728 Btu/lbm H ^ L 45 Btu/lbm H 454 C H AP T ER 8 Balances on Nonreactive Processes From Equation 8.5-8 m_ L xV 100 lbm /h xV w w € xF xL m_ L 100 lbm /h m_ V 100 Energy Balance: 0:89 0:30 84 lbm /h liquid product 0:89 0:185 84 lbm /h 16 lbm /h vapor product ^ V m_ L H^ L Q_ ΔH_ m_ V H 100H^ F 16 728 84 45 Test Yourself Use Figure 8.5-2 for the following calculations. 1. Estimate (a) the temperature at which the mass fraction of NH3 in the vapor phase of a twophase system equals 0.85, and (b) the corresponding liquid-phase NH3 mass fraction. 2. What is the heat of vaporization of NH3 at its normal boiling point? 3. If an NH3–H2O mixture whose overall composition is 50% NH3–50% H2O is in equilibrium at 120°F, what fraction of the mixture is a vapor? (Answers, p. 659) 8.6 100 100 Btu/h 5400 Btu/h SUMMARY An integral energy balance (the first law of thermodynamics) for a closed constant-volume system with no kinetic or potential energy changes (ΔEk 0, ΔE p 0) and no energy transferred in or out as work (W 0) is X X ^i ni U^ i ni U Q ΔU final initial For a closed system expanding or contracting against a constant external pressure, the balance is X X ni H^ i ni H^ i Q ΔH final initial For an open system at steady state with negligible kinetic and potential energy changes from inlet to outlet and no energy transfer as shaft work, the balance is X X ^i ^i n_ i H n_ i H Q_ ΔH_ outlet inlet In these equations n is the amount (mass or moles) of a species in one of its initial or final states in the process, n_ is the flow rate (mass or molar) of a species in a continuous stream entering or ^ and H ^ are respectively the specific leaving the process, and U internal energy and specific enthalpy of a species in a process state relative to a specified reference state for the same species. This chapter presents formulas and methods for evaluating U^ ^ (and hence ΔU, ΔH, and ΔH) _ when tables of internal and H energies and enthalpies are not readily available. Here is the general procedure: 1. Choose a reference state (phase, temperature, and pressure) for each species involved in a process. 2. Choose a path from the reference state to each initial and final (or inlet and outlet) process state for each species, and evaluate ^ for the transition from the reference U^ i (or H^ i ) as ΔU^ (or ΔH) state to the process state. 3. Once all of the U^ i (or all H^ i ) values are determined in this manner and all of the ni (or all n_ i ) values are determined from material balances, densities or equations of state, and phase equilibrium relations, calculate ΔU, ΔH, or ΔH_ and substitute the result in the energy balance to determine whichever variable is unknown _ (usually the heat, Q, or heat transfer rate, Q). Following are points regarding the implementation of this procedure for various types of processes. Each step can be conveniently carried out on a spreadsheet. • Energy balance calculations for a system (a process unit or combination of units) are conveniently organized through the construction of an inlet–outlet internal energy table (or enthalpy ^ for each species at _ and U^ (or H) table). The table lists n (or n) each state (phase, temperature, pressure) in which the species is found in process streams. Once all of these variable values have been determined and inserted in the table, the subsequent evaluation of ΔU, ΔH, or ΔH_ is straightforward. • The fact that internal energy and enthalpy are state properties means that any convenient process path from a reference state to a process state may be chosen, even if the actual process