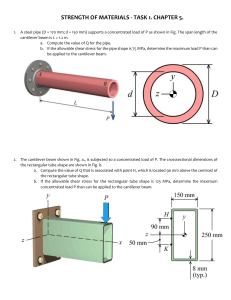

Analytical study and modelling of a MEMS based gas sensor for detection of gases by the frequency shift method Anik Mandal Centre for Nanoscience and Engineering, Indian Institute of Science, Bangalore Abstract— A gas sensor is a device which can detect a particular type of gas and its concentration in parts per million accurately. It finds applications in various fields like monitoring of air quality index in polluted areas, to analyze combustion gases at the exhaust of cars, to detect potential harm due to leakage of some toxic / combustible gas in industries, and in medical science. In the recent days, due to improvements in miniaturization science (which includes microfabrication and advanced lithography techniques) we have now access to MEMs based gas sensors which have several advantages over the conventional gas sensors. In the present work, we have attempted to design and derive a mathematical model of a MEMS based gas sensor which absorbs a certain gas at a cantilever tip and then the change in the resonant frequency gives an indication of the concentration of gases present . Keywords—MEMS, adsorption, frequency shift, cantilever, sensitivity. Several researchers[3] have suggested the use of unconventional fabrication processes for the fabrication of MEMS based gas sensors. II. MODELING If we consider a simple cantilever beam, we know that there is a deflection at the beam tip if we put a load on the tip. If we consider this deflection as δ , then the resonant frequency is giveb by Rayleigh’s formula as ω = (g/ δ)0.5 . However, things get a bit complicated when we deal with distributed loadings . In reality , there will be a deflection at the cantilever tip due to the self-weight of the cantilever as well . Standard MEMS based gas sensors detect gases by the phenomenon of adsorption. Adsorption is a surface phenomenon in which molecules of a gas or liquid forms a superficial monolayer on a surface. In order to simulate the adsorption effect, we can use multiple approaches. For example, we may consider an extremely thin layer of some insulating material being placed near the cantilever tip which acts as the monolayer of the adsorbed molecules and also superficially creates a mass loading effect. However, in this present work we have considered the cantilever beam as being made up of two parts – one part is the part from the base to near the tip and another small part is there near the tip which actually serves as the gas adsorbing part. It is important to consider the gas adsorption part at the tip only, because this pronounces the cantilever deflection which in turn serves the purpose of the resonant frequency shift which is actually the parameter which gives a measure of the gas concentration we are interested to measure. I. INTRODUCTION Primarily , mechanical (acoustic type) MEMS based gas sensors are of two types. One is the Surface Acoustic Wave type gas sensor and the other is a quartz crystal microbalance (QCM) gas sensor. The basic principle is same for both the two types of sensors where the signal comes from the mass loading effect of the gas molecules onto the sensitive layer which in turn produces a shift in the resonant frequency of the structure [1]. The physics of surface wave was studied extensively by Lord Rayleigh [2] . The basic principle in propagation of surface acoustic waves is that the waves die out in the out-of-plane direction and the dominant direction of the wave is along the surface. The SAW based gas sensors works on the principle of change in frequency at the receiving electrodes due to the mass loading effect at the sensing layer. Various types of SAW gas sensors are there some of which has the sensitive layer over the electrodes and some of which has the sensitive layer as a delay-line midway between the two sets of IDTs (interdigital transducers which are the two comb like structures). Fig. 1 : The two parts of the cantilever are as shown above . The left end is fixed while the right end (blue) is the tip where we consider the adsorption effects. In order to simulate the mass loading effect due to adsorption, we have considered that as if the density of the material at the tip part changes (increases). There might be some error in this estimation but since we are attempting to derive a simplified mathematical model, the above assumption might be reasonable. We have considered 5 runs, where the densities at the cantilever tip have been taken to be 3200 kg/m3, 3600 kg/m3, 3900 kg/m3, 4100 kg/m3, 4600 kg/m3. The modified version of the Rayleigh’s equation[4] is given as 𝑙 ω2 = 𝐸𝐼 ∫0 ( 2 𝑑2𝑦 ) 𝑑𝑥) 𝑑𝑥 2 𝑙 𝑚′ ∫0 𝑦12 𝑑𝑥 + ∆𝑚𝑦22 Fig. 3 : Second mode undamped natural frequency Where y is the deflection at any point, x is the distance between the point and the end tip of cantilever, y1 is the deflection caused by the homogenous cantilever mass, ∆𝑚 is the lumped mass caused due to the mass loading effect by the gas, & y2 is the deflection caused by this attached mass. The first five modes of natural frequency of an undamped cantilever can be derived from this equation. Numerically, they are given as : 𝐸𝐼 ω1 = 3.516√ 𝜌𝐴𝐿4 ω2 = 22.0345√ ω3 = 66.6792√ 𝐸𝐼 𝜌𝐴𝐿4 Fig. 4: Third mode undamped natural frequency 𝐸𝐼 𝜌𝐴𝐿4 ω4 = 120.0902√ ω5 = 199.8600√ 𝐸𝐼 𝜌𝐴𝐿4 𝐸𝐼 𝜌𝐴𝐿4 All the simulations has been done using Comsol Multiphysics© First , we have run the simulation for undamped conditions in order to validate and ensure that the solver provides corrects results . Fig. 5 : Fourth mode undamped natural frequency Fig. 6: Fifth mode undamped natural frequency Fig. 2 : First mode undamped natural frequency After simulating to get the undamped natural frequency modes , we have created the damping effect by intentionally modifying the density differently . The data obtained are as given below: ωn ω (3200 kgm3 ) ω (3600 kgm-3) ω (3900 ω ω (4600 kgm-3) (4100 kgm-3) kgm-3) 1st mode 33351 31171 30309 29708 29325 28430 2nd mode 208430 200220 197350 195450 194280 191680 3rd mode 300940 288340 2883030 279210 276730 270790 4th mode 320300 299900 291800 286140 282530 0 274080 5th mode 582280 567280 562270 559000 557000 552590 6th mode 921200 886850 873620 864530 858840 845760 Fig. 10: Fourth mode resonant frequency for density = 3200kg/m3 TABLE I. CONSIDERED DATA FOR THE PRESENT STUDY Fig. 11: Fifth mode resonant frequency for density = 3200kg/m3 Fig. 7: First mode resonant frequency for density = 3200kg/m3 Fig. 12: Sixth mode resonant frequency for density = 3200kg/m3 Fig. 8: Second mode resonant frequency for density = 3200kg/m3 Fig. 9: Third mode resonant frequency for density = 3200kg/m3 We have then plotted our obtained results to get the figure given below . : III. CONCLUSION As expected , the frequency decreases with increase in the damping effect . We have plotted the variation of shift in resonant frequency modes with increase in gas concentration( i.e, increase in density of tip material in our present case) . In reality , this cantilever might not be helpful in getting results as the adsorption phenomena is much more complicated and the loading effect varies with several other factors like temperature , etc . However, this is for the sake of a simple mathematical analysis only. REFERENCES Johnson et Al : Design and Analysis of SAW Based MEMS Gas Sensor for the Detection of Volatile Organic Gases(2014). [2] Rayleigh, L., "On waves propagated along the plane surface of an elastic solid". Proc. London Math. Soc, 1885. 1(1): p. 411. [3] Johnson et Al : Design and Analysis of SAW Based MEMS Gas Sensor for the Detection of Volatile Organic Gases(2014) [4] Zhang et Al : Modeling and Analysis of Multiple Attached Masses Tuning a Piezoelectric Cantilever Beam Resonant Frequency (2020) . [1]