DISCLAIMER

Portions of this document may be illegible

in electronic image products. Images are

produced from the best available original

document.

Experimental and Theoretical Study of Reflux Condensation

by

Knut Bakke

Thesis submitted in partial fulfillment of the requirements for the degree of

Doktor Ingenipr

Norwegian University of Science and Technology

Department of Refrigeration and Air Conditioning

November 1997

“Experience is the name everyone

gives to their mistakes.”

Oscar Wilde

Abstract

The objective of this work is to study separation of gas mixtures in a reflux condenser,

also called a dephlegmator. Reflux condensation is separation of a gas mixture, in

reflux flow with condensing liquid, under continuous heat removal. This thesis con­

tains theoretical and experimental work on the subject.

A numerical model of a dephlegmator for binary mixtures was developed. The model

may readily be extended to multi-component mixtures, as the solution method is

based on a matrix solver.

Separation of a binary mixture in a reflux condenser test rig is demonstrated. The

test facility contains a single-tube test section, and was designed and built during this

project. Test mixtures of propane and n-butane were used, and a total of 15 experi­

ments are reported. Limited degree of separation is obtained in the experiments, due

to limited heat transfer area and narrow boiling point range of the test mixture.

The numerical model reproduces the experiments, within reasonable accuracy. Devi­

ation, between measured and calculated properties, is less than 6% of the measured

temperature, and less than 5% of the measured flow rate. The model work is based

on mechanistic models of physical processes, and has not been calibrated or tuned to

fit the experimental data.

The numerical model is applied on a number of separation processes. These case

studies show that the required heat transfer area increases rapidly with increments

in top product composition (light component). Flooding limits the amount of reflux

liquid. The dephlegmator is, therefore, suitable for separation of feed mixtures that

are rich in light components. The gliding temperature in the dephlegmation process

enables utilisation of top product as refrigerant, with subsequent energy savings as a

result.

i

ii

Preface

This work was accomplished at Department of Refrigeration and Air Conditioning at

the Norwegian University of Science and Technology (NTNU). The study started in

September 1994, and ended in November 1997. The thesis is a contribution to the

research and development activity on process equipment for treatment of natural gas,

and was financed by the Research Council of Norway (NFR), through the research

program “GAVOT”, Gassforskning - varer og tjenester.

My supervisors have been Associate Professor Geir A. Owren, NTNU and Researcher

Bengt A. Neeraas, SINTER

During this time, I have been employed by the Foundation for Scientific- and Indus­

trial Research, SINTER.

Additional financial support provided by SINTER and NFR made it possible to per­

form experimental research, as a test facility was built in the laboratory. Research

manager David Lysne was very positive and helpful in the process of financing the

experimental activity.

I would like to express my thankfulness to Geir Owren for fruitful and interesting

discussions on all aspects of this work. It has truly been an experience.

Further, thanks are due to colleges at NTNU - SINTER for making this department

an interesting place to spend time. More specific, thanks are due to Arvid Almenning and Karl Gustav Gustavsen who gladly assisted me in the laboratory. Morten

Christian Svensson helped me with the data reconciliation method. Tove Stoeckert

and David Lysne volunteered to proofread the thesis. Without the positive attitude of

these people, this work would have been much harder than it turned out to be.

Finally, many thanks to friends and family, who put up with me through this chal­

lenging period.

Trondheim, November 1997

Knut Bakke

m

iv

Contents

Abstract

1

2

Preface

ili

Nomenclature

xi

Introduction

1

1.1

1.2

1.3

1.4

1

2

3

3

4

5

6

Background............................................................................................

Structure of the thesis............................................................................

Limitations............................................................................................

Definitions...............................................................................................

Literature review

2.1

2.2

2.3

3

i

5

Heat- and mass transfer models............................................................

Flooding point prediction......................................................................

Processes utilising dephlegmator technology......................................

5

8

13

Theory

17

3.1

3.2

3.3

17

19

20

Multicomponent heat-and mass transfer............................................

Flooding..................................................................

Pressure dependence and pressure drop ............................................

Numerical model

25

4.1

4.2

4.3

4.4

25

30

31

37

Model basis and assumptions...............................................................

Model implementation for an arbitrary heat exchanger ...................

Model implementation for PFHE.........................................................

Comparison with other models............................................................

Test facility

39

5.1

5.2

39

46

Design.....................................................................................................

Instrumentation......................................................................................

Experimental procedure

51

6.1

6.2

6.3

6.4

51

53

53

54

Selection of test fluid............................................................................

Operation...............................................................................................

Data collection and conversion............................................................

Parameter estimation............................................................................

v

7

8

9

Results

59

7.1

7.2

7.3

59

63

65

Experimental results ............................................................

Experimental results compared with numerical calculations.............

Discussion...............................................................................................

Case studies using the numerical model

73

8.1

8.2

8.3

8.4

8.5

73

74

84

86

88

General case study description .............................................................

De-methanizer. ......................................................................................

De-ethanizer............................................................................................

De-propanizer............................................

Alternative design of plate-fin layer ...................................................

Recommendations for future work

91

10 Conclusions

93

References

95

Appendices

101

A

Patents using dephlegmator technology

103

B

Matrix elements in model solution procedure

107

C

Gas chromatograph measurements

111

D Accuracy in Peng-Robinson and Soave-Redlich-Kwong cubic equations

of state for propane—n butane mixtures

115

E

Estimation and treatment of uncertainty in measurements

121

F

Data analysis of measurements

125

G Summary of measurements

129

H Specific recommendations for future work

163

vi

List of Tables

1.1

3.1

4.1

4.2

5.1

5.2

6.1

6.2

7.1

7.2

Definitions...............................................................................................

3

Data for pressure drop calculation (Measurement 1100697).............

23

Initial value input to numerical model................................................

29

Plate-fin dephlegmator design - parameter range................................

36

Accuracy of instrument Bopp & Reuther type OI 06Agl9 R7/A4

47

Calibration of instrument EG&G type FT2-8WFR2-PEH1 .............

49

Test rig fluid mixture composition......................................................

52

Control utilities on test rig...................................................................

53

Operating range of test rig . . .............................................................

59

Effect of heat- and mass transfer coefficient (Average deviation be­

tween measured- and calculated values in percent of measured value) 68

7.3 Estimated sub-cooling, due to difference in predicted and saturated

liquid composition, and difference in measured- and calculated tem­

perature ..................................................................................................

70

7.4 Effect of initial value, vapor flow rate (Average deviation between

measured- and calculated values in percent of measured value) ...

72

8.1 Base case input data for de-methanizer case......................................

75

8.2 Design of dephlegmator (De-methanizer case)...................................

76

8.3 Effect on design of parameter variation...............................................

77

8.4 Sensitivity of de-methanizer design to process pressure...................

79

8.5 Sensitivity of de-methanizer design to wall heat flux.........................

80

8.6 Sensitivity of de-methanizer design to top product composition (methane) 81

8.7 Distillation column design (Dephlegmator pre-separation, 15 trays).

82

8.8 Distillation column design (Without dephlegmator pre-separation, 10

trays) .....................................................................................................

83

8.9 Design of dephlegmator (De-ethanizer case with 50% capacity)...

85

8.10 Design of dephlegmator (De-propanizer case)...................................

87

C. 1 Gas chromatograph configuration......................................................... Ill

C. 2 Calibration data for GC measurements on Cg/n-C^ ......................... 113

D. 1 Comparison of thermodynamic data from experiments [57] and PengRobinson EOS ...................................................................................... 119

D. 2 Comparison of thermodynamic data from experiments [57] and SoaveRedlich-Kwong EOS............................................................................ 120

E. 1 Uncertainty in measurements (within a 95% confidence level for ran­

dom errors)............................................................................................ 124

E.2 Probability factors of the T distribution with v degrees of freedom [59] 124

vii

F. 1

F. 2

G. l

G.2

G.3

G.4

Summary of variables, measurements and equations in data analysis

Measurement points on test rig . . .......................................................

Summary of measurements (1)............................................................

Summary of measurements (2)............................................................

Summary of measurements (3)............................................................

Relative deviation between measured values and model calculations

(in percent of measured value).............................................................

Vlll

127

128

129

130

130

131

List of Figures

1.1

2.1

2.2

2.3

3.1

3.2

3.3

3.4

4.1

4.2

4.3

4.4

4.5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

6.1

6.2

6.3

7.1

7.2

7.3

7.4

7.5

7.6

The principle of reflux condensation...................................................

Pressure drop and superficial liquid velocity as a function of superfi­

cial vapor velocity..................................................................................

Calculated flooding velocity for water at 10 bar in a 20 mm (i.d.) tube

Calculated flooding velocity for methane at 10 in a 20 mm (i.d.) tube

Illustration of the condensing process in a T-x plot (Binary mixture,

constant pressure)..................................................................................

Mass transfer-diffusion vs. concentration gradient [14] ................

Total- and gravitational pressure drop in dephlegmator tube as a func­

tion of void fraction...............................................................................

Pressure drop due to acceleration and friction in dephlegmator tube

as a function of void fraction...............................................................

Control volume for reflux condensation model...................................

Fin geometry of a plate-fin heat exchanger.........................................

Sensitivity of PFHE heat transfer area to variation of fin geometry .

Sensitivity of PFHE flooding ratio to variation of fin geometry . . .

Comparison between model results and data from Di Cave et al. [21 ]

- condensation ratio and composition...................................................

Dephlegmator test rig [53]..................................................................

Connector sheet for power supply unit [54] ......................................

Details of test rig - test section............................................................

Details of test rig - boiler [53] ............................ ...............................

Details of test rig - heating cable layout in boiler [53]......................

Temperature reference connection......................................................

On-site check of reflux volume flow meter.........................................

Boiling-point vs. pressure diagram for light hydrocarbons C% —»Cs .

Flow of information in data analysis and model evaluation.............

Parameter estimation of measured data................................................

Experimental results: Variation of separation (propane) with wall heat

flux ........................................................................................................

Experimental results: Variation of reflux ratio with wall heat flux . .

Experimental results: Comparison between predicted and saturated

reflux liquid composition (propane) ...................................................

Statistical uncertainty of liquid volume flow measurements.............

Comparison between measured and calculated temperature.............

Comparison between measured and calculated feed flow rate ....

IX

2

8

9

10

18

20

24

24

25

31

34

35

38

40

42

43

44

45

47

48

52

54

57

60

60

61

62

64

64

7.7

7.8

7.9

7.10

7.11

7.12

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

C.l

D.l

D.2

D.3

F.l

Comparison between measured and calculated reflux flow rate ...

Temperature measurement points of vapor inlet and reflux liquid outlet

section

......................................................................................

Liquid- and vapor temperature deviation as function of Tv>meas Tl,meas ............................................................................... ..................

Saturated liquid composition dependency on temperature for propane/nbutane mixtures at 10 bar pressure . ...................................................

Illustration of sub-cooling in a T-x plot at constant pressure.............

Reduction of heat transfer area with void fraction in a circular tube .

Methane-ethane T-x diagram................

Methane - ethane composition profile ...............................................

Sensitivity of de-methanizer design to process pressure...................

Sensitivity of de-methanizer design to wall heat flux.........................

Sensitivity of de-methanizer design to top product composition ...

Process plant with dephlegmator and distillation column................

Partial refrigeration by top product in a dephlegmator......................

De-ethanizer composition profile.........................................................

De-propanizer composition profile......................................................

New design of PFHE dephlegmator internal geometry......................

Sample of gas chromatograph printout................................................

Tuning of PR interaction coefficient, 8^............................................

Tuning of SRK interaction coefficient,

.........................................

Experimental and calculated values using Peng-Robinson EOS with

tuned interaction coefficient, Sij = -0.0086 ......................... ...............

Conceptual sketch of test rig . . . ......................................................

x

65

66

67

69

70

71

74

77

78

79

80

82

84

86

88

89

112

117

117

118

125

Nomenclature

xi

Unit

kmole/s

inch

m2/s

kmole/s

kg/m2s (or Ib/h ft2)

kg/m2s

kmole/s

m

kmole/m2s

kg/m2s (or lb/h ft2)

m

kmole/s

kg

kg/kmole

kmole/m2s

kmole

Pa

J/kmole K

kmole/s

First introduced

4

4

F

2

2

3

2

4

6

4

2

3

4

2

4

3

2

3

H O n ^ -M o ^ o \w t> u a i

Roman letters

A

Area

A

Coefficient matrix

B

Bypass vapor stream

C

Constant in Equation 2.4

D

Tube inside diameter

D

Binary diffusion coefficient

F

Correction factors in equation 2.3

F

Feed flow rate

F()

Set of constraints

FR

Flooding ratio

G

Superficial vapor mass flux

G

Mass flow rate

G

Molar flow rate

Gr

Grashof number

H

Height of plate-fin core

J

Molar flux

L

Superficial liquid mass flux

L

Tube length

L

Reflux liquid stream

M

Mass

MW Molecular weight

N

Molar flux

N

Number of moles

Nu

Nusselt number

P

Pressure

Pr

Prandtl number

R

Residual vector

R

Response factor

R

Universal gas constant (8314.4)

R

Return liquid stream

Re

Reynolds number

Xll

s

s

T

V

w

z

a

b

b

c

cp

f

g

h

h

j

j

k

n

n

P

q

q

t

t

u

u

V

V

X

X

x,y,z

y

z

Perimeter length

Precision index of measurement

Temperature

Top product vapor stream

Width of plate-fin core

Vector of data values

Attraction parameter

Half fin height

Van der Waals covolume

Molar concentration

Molar heat capacity

Friction factor

Acceleration of the force of gravity

Enthalpy

Fin height

Dimensionless superficial velocity

Colburn factor

Mass transfer coefficient

Molar flux across interface

Number of fins per meter

Fin spacing

Heat flux

Duty

Probability multiplier

Thickness

Velocity

Velocity vector

Molar reflux ratio

Molar volume

Solution vector

Variable

Molar composition

Measured value

Coordinate direction

Experimental and Theoretical Study of Reflux Condensation

m

K

kmole/s

m

J/kmole

m

m3/kmole

kmole/m3

J/kmole K

m/s2

J/kmole

m

kmole/m2 s

kmole/m2 s

m-1

m

W/m2

W

m

m/s (or ft/s)

m

3

7

3

6

4

6

D

4

D

3

4

3

2

4

4

2

2

4

4

4

4

4

6

E

4

2

3

2

D

4

E

2,2,6

E

2

xiii

Greek letters

Deviation

Heat transfer coefficient

Relative volatility

Void fraction

a

6

e

e

8

6

Correction factor in PR and SRK

Interaction coefficient

Tube wall roughness

Error estimate

Tube taper angle (from horizontal)

Second order error term

Correction factor in PR and SRK

Thermal conductivity

Dynamic viscosity

Kinematic viscosity

Density

Surface tension

Tensile stress

Standard deviation

Shear stress

Area factor

Acentric factor

k

A

jj,

V

p

a

a

a

T

4>

w

Subscripts

I

Interface

a

Light component in binary mixture

abs

Absolute value

acc

Acceleration

Heavy component in binary mixture

b

boil

Boiler

bot

Bottom

bypass Bypass vapor stream

c

Cross (perpendicular to flow direction)

c

Combined

Experimental and Theoretical Study of Reflux Condensation

W/m2K

4

3

3

3

Q Q

A

a

a

a

m

m

degrees

J/kmole

W/m2 K

Ns/m2 (or cp)

m2/s

kg/m3 (or lb/ft3)

N/m (or dyne/cm)

N/tn2

N/m2

3

E

2

4

D

4

2

3

2

2

4

6

3

4

D

2

3

G

3

3

6

8

F

4

E

xiv

calc

col

cond

deph

ext

feed

fin

fric

grav

h

i,j,k

in

I

lam

loss

meas

out

P

pred

r

rect

ref

reflux

strip

sub

sur

test

top

tot

turb

V

w

V

0

Calculated value from numerical model

Distillation column

Condenser

Dephlegmator

External refrigeration

Feed stream to separation unit

Fin (in PFHE)

Friction

Gravity

Hydraulic

Counting integers

Inlet

Liquid

Laminar flow

Heat loss on test rig

Measured values

Outlet

Plate (in PFHE)

Indirectly deteminded measurement value

Reduced temperature (=

Rectifier section of column

Reference value

Reflux liquid stream

Stripper section of column

Sub-cooling

Surroundings

Test section

Top product stream from separation unit

Total

Turbulent flow

Vapor

Wall

Degrees of freedom

Initial or reference value

Experimental and Theoretical Study of Reflux Condensation

7

8

6

8

8

4

4

3

3

2

4, C, E

2

2

3

6

7

2

4

7

D

8

4

8

8

7

F

5

4

3

3

2

3

E

4

XV

Superscripts

NOC

est

n

sat

Number of components

Estimate

Upper counting limit in summation

Saturated state

3

F

6

4

Miscellaneous symbols

d

d

Differential operator

Differential vector operator

Partial differential operator

2

3

4

Air Products & Chemicals Inc.

Hydrocarbons (methane,ethane,butane,etc)

Equation of state

Gas chromatograph

Heat Transfer and Fluid Flow Services

International Energy Agency

Liquid natural gas

Number of components

Natural gas liquids

The Norwegian University of Science and Technology

Plate-fin heat exchanger

Peng-Robinson EOS

Root mean square

Soave-Redlich-Kwong EOS

Tubular Exchanger Manufacturers Association

Vapor-liquid equilibrium

Volatile organic compounds

Inner diameter

2

6

D

5

2

1

2

3

2

Abbreviations

APCI

Ci,C2,C3,...,Cn

EOS

GC

HTFS

IEA

LNG

NOC

NGL

NTNU

PFHE

PR

RMS

SRK

TEMA

VLB

VOC

i d.

Experimental and Theoretical Study of Reflux Condensation

1

C

6

D

5

D

1

2

1

Introduction

1.1 Background

Norway is a major exporter of natural gas, and has increased its export volume sig­

nificantly during the past few years. The gigantic Troll field1 will, with supplements

from other fields, provide a vast export of gas for at least 50 years. In this context,

research and development of gas related technology is important for the Norwegian

petroleum industry.

The International Energy Agency (IEA) strategy plan 1995 - 2000 [1] states, quota­

tion: “Around 60% of all applications of heat exchangers involve multiphaseflow, in nearly

all cases with phase change (condensation, evaporation). The inadequacy of design methods

in this area still presents major problems, in extending the range of applications ...”

Reflux condensation is such an extension to this range of applications. The above

mentioned strategy plan also states that extension of plate-fin heat exchanger (PFHE)

applications to include simultaneous heat- and mass transfer should be pursued.

This thesis presents a separation unit, called a dephlegmator which is designed for

separating gas mixtures. The dephlegmator may, in principle, be used for separation

of any zeotropic gas mixture. A dephlegmator is essentially a separation process

inside a heat exchanger, and it can fully or partly replace conventional equipment,

like distillation columns and partial condensers.

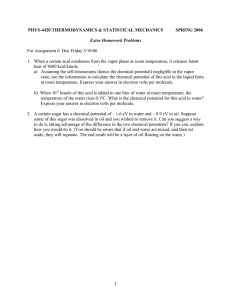

Reflux condensation works as displayed in Figure 1.1. A mixed vapor stream is

continuously stripped of heavy components in up-flow, and the reflux liquid flow is

enriched on these components. Continuous heat removal contribute to high thermal

efficiency. Small mass transfer driving forces reduce thermodynamic irreversibil­

ity compared to conventional distillation. Typical processes where dephlegmator

technology is potentially viable are petrochemical plants such as ethylene recovery,

de-methanizer, de-ethanizer, de-propanizer, pre-separation and retrofitting of existing

distillation processes. Other areas are re-liquefaction of boil-off gas from gas tanks

and VOC recovery.

Current design basis and operational experience are proprietary to the manufactur­

ers of equipment and processes. Improved understanding and open literature on

the subject, will reduce scepticism and enhance utilisation among the users of such

equipment, namely the process industries.

1 The Troll gas field was officially opened at the 19 June 1996, and gas exports started in October the

same year

1

2

1

INTRODUCTION

! t

Vapor

I I t

Vapor

Figure 1.1: The principle of reflux condensation

1.2

Structure of the thesis

The philosophy used when undertaking this work was to first identify a particular

physical phenomenon to examine in detail. Secondly, the identified phenomenon,

being reflux condensation, was examined with respect to the physics involved and

translated into a model. The model has subsequently been compared with experi­

mental data, to ascertain its validity. Finally, the model was used to study processes

viable for industrial use.

This thesis contains the following main parts:

• Theory: Literature review, theoretic basis and numerical model for dephlegmator simulation in Chapters 2, 3 and 4.

♦ Experimental work: Design, engineering and construction of the test facility in

Chapter 5. Measurement program and uncertainty analysis in Chapter 6.

• Results: Comparison between model and experiments. The results are presented

in Chapter 7.

♦ Case study: The numerical model is applied to design dephlegmators to different

processes in Chapter 8.

Experimental and Theoretical Study of Reflux Condensation

1.3

Limitations

3

• The thesis is completed with recommendations for further work in Chapter 9

and conclusions in Chapter 10.

1.3

Limitations

The chosen topic of this thesis is an extensive one, and must be subject to some

limitations due to the limited time spent on the work. This three year project includes

experimental and theoretical work.

Both the model and the experiments consider a single tube, and the work does not

reflect on “multi-tube items” such as flow distribution and instability. In Chapter 8, a

plate-fin heat exchanger is calculated on an “equivalent” single tube basis.

All model and experimental work have been performed on binary mixtures.

The terms dephlegmator and dephlegmation are used in connection with separation

using membranes and emergency cooling in nuclear power plants. These subjects are

not considered a part of this work, although flooding point prediction methods, de­

veloped in connection with emergency cooling in nuclear power plants, are reviewed.

1.4 Definitions

To avoid any potential confusion with respect to the terms used throughout this thesis,

the following definitions are given:

Term

Dephlegmation

Dephlegmator

Reflux condensation

Reflux condenser

Definition

Separation of a gas mixture in reflux flow with condensing

liquid under continuous heat removal

An apparatus in which dephlegmation occurs

Dephlegmation

Dephlegmator

Table 1.1: Definitions

Experimental and Theoretical Study of Reflux Condensation

4

Experimental and Theoretical Study of ReOux Condensation

1

INTRODUCTION

2

Literature review

The literature on dephlegmation, or reflux condensation, is concerned with three

different areas; heat- and mass transfer, flooding and process integration. Theoretical

and experimental development, or a combination of both, are reported. The following

sections reviews the open literature. Literature surveys were made both in the database

of Heat Transfer and Fluid Flow Services (H ITS), Harwell, UK and other major

databases through the Technical University Library of Norway. Some 100 references

were found with dephlegmation or dephlegmator as subject, of which 41 are patents.

A summary of known patents are listed in Appendix A. Work from countries such

as the former USSR, Poland, Romania and China is unfortunately inaccessible due

to lack of translations. These are, therefore, only reviewed on basis of abstracts from

the databases [2,3].

References of direct relevance to the topics discussed in this thesis are cited where

appropriate.

2.1 Heat- and mass transfer models

Numerous authors have studied heat- and mass transfer of multicomponent (mainly

binary) mixtures. Colburn & Hougen [4] wrote the first significant paper on mul­

ticomponent condensation. This along with other important work [5-12] forms the

basis for the specific work on condensation of mixtures. The subject is also described

in various books, where the works by Collier & Thome [13] and Taylor & Krishna [14]

are detailed and well described.

Articles which particularly deal with heat- and mass transfer in reflux condensation

of mixtures are scarce. Kirschbaum [15] presents some early work (1930) on reflux

condensation of binary mixtures. This work, along with the work of Kirschbaum &

Lipphardt [16] and Kirschbaum & Troster [17] investigates mass transfer in partial

condensation. Kirschbaum [15] claims that the rectification is solely dependent on

the reflux ratio (v). However, Equation 2.1 is valid only at thermodynamic equilib­

rium, and denotes an upper separation limit. A rather large deviation between the

theoretical limit and experimental data is shown [17]. This deviation increases with

vapor velocity and reflux ratio.

(2.1)

5

2

6

LITERATURE REVIEW

The experiments of Kirschbaum et al. were performed on the outside of a single tube,

contrary to the common practice of reflux condensation inside tubes.

Bell [18] presents an algorithm for design and rating of reflux condensers, but it is

neither implemented nor verified experimentally. The author points out the lack of

understanding of the processes involved and experimental basis for further develop­

ment.

Two articles by Davis, Tung and Mah [19,20] study condensation and evaporation

in reflux flow. In Reference 19, an experimental scheme with a binary mixture of

n-hexane - toluene with heat input/removal through a wetted-wall is studied. A math­

ematical model based on differential conservation equations is presented and verified

against experiments. The model includes heat- and mass transfer in both liquid and

vapor phase, and performs top-down calculation. Davis et al. assumes uniform liquid

composition in the liquid phase. The experimental rectangular column consists of

one wetted wall with three adjacent adiabatic, dry walls (0.152mx0.00953m). The

model predictions are in good agreement with experiments, but few of the experi­

mental runs are presented. In Reference 20, the wetted wall column is replaced by

plate-fin channels. Again, the authors report acceptable agreement between theory

and experiments.

Di Cave, Mazzarotta and Sebastani [21] present a model based on the Colburn &

Drew [5] approach. The model is supported by experiments on a 18 mm i.d. 920 mm

long tube. The authors point out sensitivity of the model with respect to heat- and

mass transfer coefficients. The model is developed for a single tube, and it is argued

that this is sufficient to describe a complete tube bundle. No comments are made on

multi-tube challenges such as fluid distribution, instability or flooding limits.

Fox, Peterson and Hijikata [22] present a time dependent hydrodynamic model for

steam-air mixtures in the condensing section of a thermosyphon. The oscillating

nature of the reflux flow phenomenon at various Reynolds1 (Re) and Grashof2 (Gr)

numbers are studied. Unstable flow patterns were found, as expected, at increasing

Re and Gr numbers. The impact from flow patterns on heat transfer was found to be

significant.

Heat- and mass transfer coefficients in reflux condensation of mixed vapors are treated

by Onda, Sada and Takahashi [23]. An experimental apparatus with 20 mm column

i.d. and lengths 330, 830,1330 and 1830 mm is presented. Test fluid is a binary mix­

1 Reynolds number denotes the ratio of inertia and viscous forces

2Grashof number denotes the ratio of buoyancy and viscous forces

Experimental and Theoretical Study of Reflux Condensation

2.1

Heat- and mass transfer models

7

ture of methanol and water, No information on temperature or pressure is reported,

although an illustration of the experimental apparatus indicates atmospheric condi­

tions. The apparently good agreement between experiments and theory is, therefore,

of limited value to the reader.

Rohm [24] treats unsteady state behavior in dephlegmation of binary vapor mixtures.

A literature survey by the same author [25], based on several references, states that

three known methods for multi-component mass transfer give similar and acceptable

results. These methods are the linear theory3 by Toor [7,8] and Stewart & Prober [9]

and the matrix method of Krishna & Standart [11]. The models are compared for

steady state simulation of the dephlegmation process on a ternary mixture (methanol,

ethanol and water). The matrix method of Krishna & Standart [11] produces more

accurate results, the penalty is more computing time.

Dixit, Gaitonde and Sharma [26] present a model for computation of rectification

in dephlegmators for an aqua-ammonia (binary mixture) refrigeration system. The

method is extracted from a general model for distillation columns, and modified for

dephlegmation. The authors discuss, rather briefly, the results of computations on a

qualitative basis. Verification of these are not reported.

Fiolitakis [27] presents a model for binary mixtures. The model consists of conser­

vation equations for species, mass and energy. At the inlet of the dephlegmator, the

author assumes thermodynamic equilibrium (i.e. both temperature and concentration

gradients are zero) between liquid and vapor.

Urban, Nishio, Matsuo, Ishikawa, Natori, Akamatsu, Sonoi and Onaka [28] present

a recent paper about a dephlegmator for an ethylene plant. The authors report a nu­

merical model and experiments on a pilot plant, with a plate-fin heat exchanger used

as a dephlegmator. The described model is detailed, and even distinguish between

primary surface (parting sheets) and fin surface. The rationale for this is, quotation:

"The separation effect was only slightly better in the case ofserratedfins despite much

higher value ofjo factor. This indicates that condensation of low volatility compo­

nents with simultaneous vaporization of high volatility components (which results in

high separation effect) occurs only at the parting sheet surface. At the fins surface

all components are condensing in a “one way” manner. Next, the liquid condensed

on the fins moves under surface tension forces towards the parting sheet (primary)

surface.” This conclusion is not strongly supported by the reported observations,

and the difference in separation may originate from other sources, such as coolant

3The linear theory of multicomponent mass transfer were developed independently by the authors

Experimental and Theoretical Study of Reflux Condensation

2

8

LITERATURE REVIEW

conditions and over design of area. The authors report agreement between model and

pilot plant test, although no numbers are presented to quantify this agreement. The

paper also discuss flow distribution an distributor design.

H ITS in the UK works both with theory and laboratory activities on dephlegmators.

This work is not commonly available to the public and, thus, not reported in this

thesis.

2.2 Flooding point prediction

- dP/dz

(

(-------)

Figure 2.1: Pressure drop and superficial liquid velocity as a function of superficial

vapor velocity

Flooding is recognized as an important constraint in vertical reflux flow. Much of

the work on this subject has been dedicated to emergency heat removal in nuclear

reactors.

Definition of the flooding point varies from author to author. Figure 2.1 shows both

liquid superficial velocity and pressure drop plotted qualitatively against superficial

vapor velocity in a vertical tube. Some authors define the flooding point based on

entrainment level, some on liquid bridging of the flow channel, and others on no

liquid reflux. The latter two criteria are recognized in the figure. No liquid reflux

occurs in the vicinity of the maximum pressure drop, while bridging occurs when

the pressure drop curve starts to increase rapidly towards the peak with increasing

superficial vapor velocity.

Experimental and Theoretical Study of Reflux Condensation

2.2 Flooding point prediction

9

Many attempts have been made to predict the flooding point, most of them are based

on empiricism. There are several reviews on the flooding literature [29-32], where the

review by Bankoff & Lee [32] considers most aspects of flooding. All of the reviews

point out that vapor velocity and entrance/exit geometry are significant parameters

that determine the onset of flooding. Another point commented is the wide variation

in flooding point predictions between different authors. There is no common agree­

ment on what parameters that are most important to the flooding phenomenon. The

difference in experimental setup explains some of the variation. Most experiments

are done with air-water or steam-water, different fluids properties may, therefore,

influence flooding predictions.

Further, it is unclear whether or not the adiabatic and condensing situation differs

significantly with respect to the flooding point.

Correlations for flooding point prediction are either empirical, semi-empirical or

analytical. Ragland [31] states that the statistical nature of this phenomenon may

obstruct purely analytical solutions. Many correlations for flooding point prediction

exist [29-35], only four are presented here to show the qualitative differences among

them. The equations are plotted in Figures 2.2 and 2.3, for a methane and a water

system, respectively, at 10 bar in a 20 mm (inner diameter) tube. The differences in

predicted flooding velocity are evident.

Flooding velocity (Water (liquid - vapor), 10 bar)

20

i

i

i

i

0.2

0.3

0.4

_i_

0.5

I »

i

i

i

_i_

0.6

0.7

0.8

English et al.

Diehl and Koppany

Wallis (C=1.0)

Wallis (C=0.7)

Pushkina and Sorokin

I

g. io

0

0.1

0.9

1

(L/G) Ratio of superficial liquid to vapor mass flow rates

Figure 2.2: Calculated flooding velocity for water at 10 bar in a 20 mm (i.d.) tube

Experimental and Theoretical Study of Reflux Condensation

2

10

LITERATURE REVIEW

Flooding velocity (Methane (liquid - vapor), 10 bar)

5

I

I

i

i

i

0.1

0.2

0.3

r

i

4

i

i

i

English et al.

Diehl and Koppany

Wallis (C=1.0)

Wallis (C=0.7)

Pushkina and Sorokin

i

----------------...........

...........

--------

3

a

2

73

I

a

1

0

J____I___ I____I____L

0

0.4

0.5

0.6

0.7

0.8

0.9

1

(L/G) Ratio of superficial liquid to vapor mass flow rates

Figure 2.3: Calculated flooding velocity for methane at 10 in a 20 mm (i.d.) tube

English, Jones, Spillers and Orr [34] present an empirical correlation, Equation 2.2.

The correlation predicts a maximum superficial vapor mass flow rate (G) at the bottom

of the condenser. They state that this mass flow rate depends on tube diameter (D),

liquid and vapor density (pv, pi), surface tension (a), liquid viscosity (pi), tube-taper

angle ($) and the ratio of liquid and vapor superficial mass flow rates (L/G). This cor­

relation is based on 56 flooding experiments done by the authors on water, n-propyl

alcohol, n-heptane and carbon tetrachloride. The flooding point is taken as the top

point of the pressure drop curve in Figure 2.1.

£)0.3p0.46a0.09p0.5

G

G, z;

D

Pli Pv

<7

Pi

e

1550

tf-14{cose)°-32(L/G)0-07

Superficial vapor and liquid mass flow rate - lb/h ft2

Tube inner diameter - in.

Liquid and vapor density - lb/ft3

Surface tension - dyne/cm

Liquid viscosity - cp

Tube taper angle (from horizontal) - degrees

Experimental and Theoretical Study of Reflux Condensation

(2.2)

11

2.2 Flooding point prediction

Diehl & Koppany [33] also present an empirical correlation for prediction of the

superficial flooding velocity (u„). The authors report that flooding is dependent on

a critical diameter determined only by surface tension (a). In addition, the flooding

velocity depends on tube diameter (D), vapor density (pv) and the ratio of liquid and

vapor superficial mass flow rates (L/G). This correlation is based both on experiments

by the authors (hydrogen-diesel oil, water, and steam-air-water) and on measurements

done by others. The flooding point is defined (unclearly): “ The flooding point was

determined in the tests by noting the velocity at which a large increase of entrain­

ment occurred and by checking the pressure drop increase as the vapor velocity was

increased.”

F\F2

Fi

Fx

1.0

(2.3)

D '

< 1.0

<7/80,

' D

> 1.0

.<7/80

F2

uv

fi, #

o

Superficial flooding velocity of vapor - ft/s

Correction factors

Surface tension - dyne/cm

Pv

Vapor density - lb/ft3

D

Tube inner diameter - in.

Z, G

Superficial liquid and vapor mass flow rate - lb/h ft2

The correlation given by Wallis [35], Equation 2.4, is probably the most commonly

used for prediction of the flooding point. This equation is referred to as semiempirical. The flooding point predictions are made on the basis of water-air experi­

ments. The sum of the square root of the liquid and vapor dimensionless velocities

(p,j„) is predicted to be constant at the flooding point. The equation is valid for tubes

and packed columns. The constant (C) varies with geometry of the tube or column.

Experimental and Theoretical Study of Reflux Condensation

2

12

# +;7

=

jv

—

31

=

Jv

31

C

G.vjini It u

Pvt Pi

9

Dh

LITERATURE REVIEW

c

(2.4)

Gy,in

VPv (Pi ~ Pv) 9 Dh

Gj7in

y/Pi (pi ~ Pv) 9 Dh

Dimensionless superficial vapor velocity

Dimensionless superficial liquid velocity

Constant (0.7 - 1.0)

Superficial vapor and liquid mass flux at inlet - kg/m2 s

Vapor and liquid density - kg/m3

Acceleration due to gravity - m/s2

Hydraulic diameter - m

Pushkina and Sorokin [36] found that tube diameter is invariant in the interval between

6 and 309 mm. They recommend the Kutadeladze correlation, Equation 2.5, which

is based on water-air experiments. Flooding is predicted as the vapor velocity (uy)

where flow reversal occurs and is claimed to depend on surface tension (a), vapor and

liquid density (pv,pi) and the acceleration of gravity (g).

0.25

uv

gv{pi - Pv)

3.2

P v2

Viy

Flooding velocity of vapor - m/s

9

a

Acceleration due to gravity - m/s2

Ph Pv

Liquid and vapor density - kg/m3

(2.5)

Surface tension - N/m

Both Equation 2.2 and 2.3 are dimensional, and take English engineering units as in­

put in the listed form. The equations must therefore be carefully converted to comply

Experimental and Theoretical Study of Reflux Condensation

2.3

Processes utilising dephlegmator technology

13

with SI units. This was done when comparing the different equations.

Girard & Chang [37] have recently developed an elaborate system of equations that

treats wave stability in order to solve the flooding problem. Even with a set of eight

simplifying assumptions, their model is rather complex. The model is verified by

experimental data obtained in 4.8 m long Pyrex tubes of 2.06,1.59 and 0.95 cm i.d.

The work is done with focus on water cooling of fuel rods in nuclear power plants,

and does not consider mixtures.

For tube bundles some authors recommend a reduction in velocity of between 30%

and 50% of the flooding correlations [18,29],

The discrepancies in existing theory and experimental work do not lead to any strong

conclusions. The flooding correlations have generally been developed for circular

tubes with large diameters (typically 3/4 inch). The geometry of the actual equipment

should always be checked against the experimental setup that was used to develop the

different correlations.

Limb & Czamecki [38] have tested different flooding correlations in plate-fin chan­

nels. The authors state: “These data confirm that most of the existing correlations

are suspect for equivalent diameters below 3/4 in., with the possible exception of the

Wallis correlation.’’

The present work focuses both on rectangular plate-fin channels and circular tubes.

The Wallis correlation is, supported by the above statements, used throughout this

thesis.

2.3 Processes utilising dephlegmator technology

The literature on process integration with dephlegmator technology is dominated by

articles and patents from Air Products & Chemicals Inc. (APCI). Ethylene recovery

has been their main concern, but various combinations of gas separation are suggested

and patented [2,3,39,40], The literature from APCI includes several patents (listed

in Appendix A). Connected processes such as recovery from synthesis gas, COg, N2,

He, HgS and H2 recovery are also presented [38-41]. Some industrial experience

with dephlegmator technology is reported, and examples are reproduced below.

Absorption refrigeration cycles with H2O-NH3 or Li-Br refrigerant is a field where

dephlegmator technology gains some attention [2,3].

Various older patents, mainly from the 1920s and 1930s, describe distillation and

Experimental and Theoretical Study of Reflux Condensation

14

2

LITERATURE REVIEW

cracking of valuable gases from coal shales, solids and oils [2,3]. Utilization of these

processes are believed to have been hampered by development of other more suitable

processes.

Recovery of hydrocarbons from fluid catalytic cracker off-gas using dephlegmator

technology is a feasible process [41]. The introduction of dephlegmators in the cryo­

genic section reduces refrigeration duty significantly. Expanded top product from the

dephlegmators may be sufficient to cover the condensing duty. Brahn [41] reports

satisfactory economy for such plants, i.e. significant cost reduction and pay-back

time less than two years.

A similar process for recovery of NGL from natural and associated gases is reported

by Limb & Czamecki [38,42] with several alleged advantages. By replacing a turbo­

expander process with a high pressure process (with dephlegmators), better turn-down

capability and power savings of 40% are reported. An installation at the Kincora gas

terminal in Australia is reported to work better than design (95% propane recov­

ery). The authors briefly present some new applications for the process, of which

one is hydrocarbon dew point control. The reflux heat exchanger will separate out

heavy components at higher temperatures and save about half the refrigeration duty

according to the authors. Limb & Czamecki also indicate applications such as ethane

recovery, dual mode plant4, supercritical feed and LNG production.

A thermodynamic analysis of separation in refineries and natural gas handling is given

by Rojey [43]. Distillation with heat exchange is given attention, and a process is

presented where the rectifier of a distillation column is replaced by a dephlegma­

tor. Optimization is done with focus on reducing necessary equipment, temperature

difference and entropy production. This leads to reduction in both investments and op­

erational costs. For propane-butane separation, 99% recovery of propane is achieved

with increased refrigeration temperature from -85°C to -60°C. A 30% reduction in

refrigeration duty is reported.

IMI Marston, a manufacturer of plate-fin heat exchangers, identifies a number of

processes in which PFHE dephlegmators are suitable. These are: extracting helium

from natural gas, condensing argon, hydrogen purification, COg purification, ethylene

recovery, ammonia purge gas separation, etc [44]. ALTEC, another PFHE manufac­

turer, also promotes reflux condensers for applications such as air separation, refinery

& petrochemical recoveries, natural gas processing and refrigeration systems [45].

4The suggested dual mode plant handles both ethane and propane recovery

Experimental and Theoretical Study of Reflux Condensation

2.3

Processes utilising dephlegmator technology

15

The term dephlegmation is used in membrane separation technology [46] for adia­

batic separation in membranes. This technology is not considered to be a part of the

subjects covered by this work.

Experimental and Theoretical Study of Reflux Condensation

16

Experimental and Theoretical Study of Reflux Condensation

2

LITERATURE REVIEW

3

Theory

Reflux condensation in dephlegmators offers, in principle, some intriguing advantages

to both conventional distillation processes and partial condensers. Heat removal at a

gliding temperature range is one feature that may improve thermodynamic efficiency.

In a conventional distillation column, all heat is removed at the lowest temperature in

the condenser. The temperature difference between the condenser and the surround­

ings may be substantial (cryogenic temperature).

The driving forces for mass transfer in a conventional distillation column are often

large, especially around the feed point. In a dephlegmator, the driving forces are

small, and the irreversible loss due to mass transfer is significantly reduced. The rea­

son for this is that the reflux flow of liquid enhances stripping of the light component

from the liquid phase. Liquid in down-flow is continuously exposed to vapor at a

higher temperature, enabling the light component to re-evaporate.

In order to fully understand the possibilities and limitations of this technology, the

different factors that govern the utilisation of dephlegmators must be investigated. It

is important to obtain knowledge about the physical basis of the dephlegmation pro­

cess, and to identify the more important parameters. This applies to both design and

operation of such equipment. In this chapter, the following subjects are discussed:

• Heat- and mass transfer

• Flooding

• Pressure dependence and pressure drop

3.1

Multicomponent heat- and mass transfer

A thermal process device, such as a dephlegmator, which is designed to separate

liquid and vapor fractions with binary or multicomponent mixtures, is constrained by

the physics of heat- and mass transfer. The significance of the different contributions

varies with temperature, pressure, fluid properties, flow rates, geometry and heat flux.

Heat transfer

A temperature difference always leads to heat transfer from the high- to the low tem­

perature. The rate at which the heat transfer takes place depends on the temperature

difference, thermal properties and geometry of the materials involved. Determination

17

3

18

THEORY

of heat- and mass transfer coefficients is recognized as a challenge in modeling. The

heat transfer coefficient, a, is commonly assumed to vary with flow rate, geometry,

mass transfer and properties of the actual fluid mixture. Correlations for these coeffi­

cients are mainly empirical, and may contain substantial uncertainty. This is indeed

true for complex geometries and multi-phase flow. The heat transfer coefficients

needed in this text are obtained from open literature and cited where used.

Condensation of a multicomponent mixture is a process where both composition1

and temperature of the liquid and vapor phase change. This is illustrated in Figure

3.1 for a binary mixture. Super-heated vapor is cooled to the dew point (1). Further

cooling splits the feed vapor into a two-phase mixture of vapor and liquid. The first

condensed liquid (2) is rich in heavy components. Both vapor phase and liquid phase

are enriched with light components throughout the two-phase region. This means

that both the dew point temperature (1—»3—>5) and the boiling point temperature

(2—»4—»6) of the mixture decrease. Total condensation is accomplished in point 6.

Liquid-vapor

Composition (increasing light

)

100%

Figure 3.1: Illustration of the condensing process in a T-x plot (Binary mixture,

constant pressure)

‘Composition of a binary mixture refers to the lighter component, if not differently specified,

throughout this thesis

Experimental and Theoretical Study of Reflux Condensation

19

3.2 Flooding

Mass transfer

In a gas or liquid mixture with a concentration gradient, mass transport by diffusion

may occur. The condensation process illustrated in Figure 3.1 serves as an example

of a process where mass transfer develops. When the heavy component is transferred

into the liquid phase, the concentration in the vapor is lowered in the vicinity of the

vapor-liquid interface. The concentration gradient between the bulk and the interface

initiates mass transfer by diffusion. Similarly, the light component diffuses from the

interface towards the bulk of the vapor. Pick’s law describes this transport in a binary

mixture, Equation 3.2, and states that mass transport by diffusion in a binary mixture

is proportional to the concentration gradient.

(3.1)

(3.2)

(3.3)

The interaction effects in a ternary mixture is treated by Taylor & Krishna [14]. The

“three-way” interaction renders a possibility of diffusive transport with no gradient,

known as osmotic diffusion and transport against gradients, reverse diffusion. These

phenomena, illustrated in Figure 3.2, occur because transport is dependent on the

gradients of the other compounds in the mixture.

In a system with macroscopic flow, mass transfer by bulk transport is also present.

The total transport of one component is:

Na

= Ja +

Nt/a

(3.4)

For mixtures containing multiple components, the challenge of describing mass trans­

port becomes complex, and will not be elaborated here.

3.2 Flooding

Flooding in counter-current vertical flow is obtained when a rapid increase in pressure

drop is observed with increasing flow rates. An illustration of this is given in Figure

2.1. Vapor friction on the liquid film increases with increasing flow rate, and waves

form on the liquid surface. Further increase of vapor flow rate leads to liquid bridging

Experimental and Theoretical Study of Reflux Condensation

20

3

THEORY

Ternary diffusion

Binary diffusion

J1

J1

Osmotic

diffusion

Diffusion \

o

dxl

Normal

diffusion

behaviour

Normal

diffusion

behaviour

dxl

Reverse

diffusion

Figure 3.2: Mass transfer - diffusion vs. concentration gradient [14]

of the flow channel. The flow regimes resulting from further increase in flow rate

(especially vapor rate) are complex, and highly statistical in nature, until a reversal to

co-current annular flow is obtained at yet higher vapor flow rates. The mechanisms

of flooding are treated in detail elsewhere, as reported in Section 2.2, and will not be

discussed here.

3.3 Pressure dependence and pressure drop

The pressure has a significant influence on a separation process. At high pressure,

the two-phase region in Figure 3.1 shrinks. The boiling- and the dew point line shifts

upwards, and the temperature difference between them decreases. This is shown

in a temperature-composition diagram for methane and ethane in Figure 8.1. At

elevated pressure, the temperature needed to liquefy gas increases, while the volatility

decreases. High relative volatility eases the separation of gases. The relative volatility

of two gases is defined as (component a being the more volatile of the two):

(3.5)

If the relative volatility is greater than unity, separation is possible. aab is temperature

and pressure dependent. The above mentioned pressure dependence indicates an

optimization task on design of separation equipment, with volatility and separation

Experimental and Theoretical Study of Reflux Condensation

3.3

Pressure dependence and pressure drop

21

efficiency on one side, and refrigeration and compressor duty on the other. The

pressure dependency is studied in some detail in Chapter 8, as a part of the case

studies with the numerical model.

Pressure drop in reflux flow is generally low due the limited flow rates, restricted by

flooding, as discussed in Section 3.2. This is supported by the example reported in

Figures 3.3 and 3.4 below.

The equation for conservation of momentum in two-phase flow [47] is given by

Equation 3.6. By assuming a vertical tube2, separate flow of vapor and liquid phase,

uniform density in each phase and constant shear stress, the momentum equation is

integrated to Equation 3.7. a is the void fraction of vapor phase.

+g[apv

+ (1 - Oi)pi]

(3.7)

The total pressure drop in a two-phase flow may now be classified into three terms

due to friction, gravity and acceleration, Equation 3.8. These separate terms are

recognized on the right hand side of Equation 3.7.

The frictional pressure drop, Equation 3.9, has two terms, one due to friction between

wall and liquid, and one due to friction between liquid and vapor. By using friction

factors from White [48] for both wall and liquid-vapor interface, the frictional pressure

drop is given by Equations 3.9, 3.12, 3.13 and 3.14. Reynolds number and friction

factor are calculated for liquid and vapor, respectively, for wall and interface.

Pressure drop due to gravity is given by Equation 3.10, and due to acceleration by

^Positive z direction is upwards

Experimental and Theoretical Study of Reflux Condensation

22

3

THEORY

Equation 3.11.

)

_W

^

\ jz V

tot

\^

(3.8)

dz J acc

grav

+ 5/7"/)

{SWTW

(3.9)

fric

g[apv + (1 - o;)pi]

(3.10)

grav

^ acc

— [o.Gvuv + (1 — a)Giui]

d

dz

&G2 + (1 - ol)G2

pv

pi

(Gl_G±\^ , 2<*GvdGv

Pi ) dz

\Pv

pv

dz

I o(l ~ a)Gi dGi _ aG2 dpv

pi

dz

pi dz

(1 — a)Gj dpi

Pi

dz

(3.11)

fG2

(3.12)

8P

flam

fturb

Re

64

Ee

f— 1.8 log 6.9

Ri +

(3.13)

(3.14)

uD

The different terms of the pressure drop correlation is evaluated below, based on

process data from the test rig described in Chapters 5 to 7. The data in Table 3.1 are

taken from one of the measurements, named tl00697, in Appendix G. This is the

measurement with the highest wall heat flux, separation and reflux ratio. The void

fraction is assumed to be 1.0 at the top, and to vary linearly from top to bottom of the

tube. The pressure drop, and the single terms in Equation 3.8, are plotted in Figures

3.3 and 3.4 as a function of void fraction. Hewitt [47] reports data for vertical upwards

flow with void fractions between 0.9 and 1. This interval is used in the figures.

Pressure drop in the tube is in the order of 2 to 5 mbar/m in a dephlegmator tube

Experimental and Theoretical Study of Reflux Condensation

3.3

Pressure dependence and pressure drop

23

(with properties as listed in Table 3.1), at void fractions varying form 0.9 to 1 at the

inlet of the tube. The dominating contribution to the overall pressure drop is due to

gravity. The relatively low pressure drop validates a constant pressure assumption in

the remaining theoretical work in this thesis.

Gi

Gv

Pi

Pv

dGi

A

dz

dpi

dpv

da

L

D

p

e

Top Bottom

0.00

-17.20

13.40

26.50

499.80

501.53

23.43

23.56

8.62

-6.56

-0.87

-0.07

0.15

2.00

21.4

10.87e5

0.0015

Unit

kg/m2s

kg/m2s

kg/m3

kg/m3

kg/m3s

kg/m3s

kg/m4

kg/m4

m_1

m

mm

Pa

mm

Table 3.1: Data for pressure drop calculation (Measurement 1100697)

Experimental and Theoretical Study of Reflux Condensation

24

3

THEORY

Total

Gravity

Inlet void fraction (-)

Figure 3.3: Total- and gravitational pressure drop in dephlegmator tube as a function

of void fraction

Acceleration

Friction (wall)

Friction (interface)

60 -

40

20

-

-20

-40 0.9

0.92

0.94

0.96

0.98

Inlet void fraction (-)

Figure 3.4: Pressure drop due to acceleration and friction in dephlegmator tube as a

function of void fraction

Experimental and Theoretical Study of Reflux Condensation

4

Numerical model

Several models of reflux condensation are reviewed in Section 2.1. These are based

on conservation of species, mass, momentum and energy, in addition to equilibrium

at the interface between liquid and vapor. The models tend to involve a large amount

of equations to be solved. Insufficient physical models for prediction of properties

and heat- and mass transfer coefficients, reduce accuracy. Such a model is dependent

on initial values and require iterative solution schemes. Numerical difficulties with

complex models have been reported [19]. The various physical effects of a large

number of unknown properties are difficult to judge, and the quality of such models

as design tools, and the results produced, may be doubtful.

This chapter presents a simpler and different approach, in which all simplifications

are discussed and the effects of these are surveyable.

4.1 Model basis and assumptions

Figure 4.1 displays a control volume of the current model, where the different param­

eters are named. The system is assumed to be isobaric, an assumption which reduces

the number of equations, as the momentum equations are neglected. Pressure drop in

a dephlegmator was discussed in Section 3.3.

I

f

-—

9w

T,

X

Liquid

c

h naj nb

|X,

:yi

qv

Interface

°4

Tv

y

(j

Vapor

-G-t

Figure 4.1: Control volume for reflux condensation model

The conservation equations for mass, species and energy in liquid and vapor phase

are listed in Equations 4.1 to 4.8. Diffusion of mass and heat in the axial (flow)

direction is neglected in this system. The non-linear differential algebraic system

25

4

26

NUMERICAL MODEL

consists of 6+2NOC independent equations and 8+4NOC variables. In order to solve

the equations, a set of assumptions and closure laws must be added.

dGv NOC

ni Si

dz

i=i

dGi

dz +

-

dz

= 0

(4.1)

E ni^1 - 0

(4.2)

NOC

2=1

Gvyi ) - ni Si

=

0

(4.3)

Gi Xi) + rii Si

=

0

(4.4)

—

0

(4.5)

qw )

—

0

(4.6)

E y* -1

=

0

(4.7)

=

0

(4.8)

NOC

E

— y — Gvhvj —Si(qv+ ^2 nihv,i)

2=1

NOC

dz

Gi hi j -f- Si (c[v

^ ] fiihv i

i=1

NOC

2=1

NOC

E Xi - 1

2= 1

The system could be solved, simultaneously for the whole dephlegmator, by a dif­

ferential algebraic equations solver. The main disadvantage of using such a strategy,

and the rationale for not using it here, is loss of control with the different variables

during the calculations.

Proceeding from the conservation equations, the aim was to develop an analytical

solution to the problem of reflux condensation.

The system is reduced to a binary mixture. This constraint is not strictly necessary,

but the binary case is more surveyable than cases with multiple components. An ex­

tension of the model to handle multicomponent mixtures postponed until a thorough

understanding of the binary case is obtained. This assumption reduces the number of

conservation equations to eight, four in each phase.

A linear interpretation of the remaining differential algebraic equations is needed to

Experimental and Theoretical Study of Reflux Condensation

4.1

Model basis and assumptions

27

obtain an analytical solution. The composition sums and the heat- and mass transfer

Equations (4.9 - 4.11) are substituted. The system is reduced to six independent

equations.

nb

= ^[(1 + y)na +k (yj-y)]

qv

- av{Tv — Tj)

(4.10)

qw

= ai(Ti-Tw)

(4.11)

(4.9)

To close the system of equations and variables, an assumption is made with respect to

the liquid phase composition, as the liquid phase is assumed to be saturated. In mass

transfer modeling [14], it is common to make a choice between a completely mixedor an unmixed liquid phase. The effect of the two optional choices is significant at low

heat flux. Here, the assumption is made that the liquid phase is well mixed without

sub-cooling. This assumption must be kept in mind, and the model should be used

with care at low heat flux, and in the presence of non-condensible components.

The interface perimeter, 57, is set equal to the tube perimeter in the model.

Interface conditions are defined to be saturated at the liquid temperature. This defini­

tion is formulated in Equations 4.12 - 4.14.

Ti

VI

XI

=

=

Ti

%(T,,Tr*

(4.12)

=

c(T;,T)"*

(4.14)

(4.13)

The effect of the assumptions are discussed in Section 7.3.

A set of linear thermodynamic relations are substituted into the equations. These

are necessary in order to obtain a linear system of equally numbered variables and

equations. A first order Taylor series expansion of the thermodynamic relations is

used. As an example, first order Taylor series expansion of enthalpy in the vicinity of

a known point, h(To, To, A7,o)> is shown in Equation 4.15. The second order term,

9 (AT2, AT2, AN?), contains the deviation between the real and the approximated

value. By reducing the step length, the alteration in the thermodynamic properties

are small. The method is consistent with small steps, as the error in the Taylor

Experimental and Theoretical Study of Reflux Condensation

28

4

NUMERICAL MODEL

approximation is reduced in the second order error term1.

(4.15)

The thermodynamic Equations, 4.16 - 4.22, are listed below. When substituting these

into the conservation equations, a set of six equations with six unknowns is obtained.

The unknowns are: na, £ Gv, ^ Gu £ y, j-z Tv and £ 2).

(4.16)

hi

—

hliref

(4.19)

(4.20)

(4.21)

(4.22)

The solution method is more compact when the variables and equations are denoted

as matrices, Equation 4.23. The conservation equations, with substituted linear

thermodynamic functions, are shown as matrix elements in Appendix B. The analytic

solution is obtained in Equation 4.24. The solution vector, x, was not as simple as

desired, as the matrix elements contain multiple terms. The rationale for obtaining

an analytical set of equation, is to examine the different parameters effect on the

solution. This analysis demands an overview of each variable, which was lost due to

'The error term reduces proportional to the square of the step in each direction (T,P,Ni)

Experimental and Theoretical Study of Reflux Condensation

4.1

Model basis and assumptions

29

the complexity of the analytical solution.

Ax

=

R

(4.23)

x

=

A-1 R

(4.24)

A

-

Coefficient matrix (6 by 6)

x

—

Solution vector (6 by 1)

R

-

Residual vector (6 by 1)

The model need initial values for at the start of the calculations. The required initial

values are listed in Table 4.1.

A numerical solution procedure was chosen, where the equations are solved by a

matrix solver using Gauss elimination.

The numerical integration is done by a fourth order Runge-Kutta method with variable

step size [49]. The model can advance either upwards or downwards, dependent on

the specified initial data. The thermodynamic properties are calculated from the initial

values, along with heat- and mass transfer coefficients.

Initial value

y

Gy

G,

Ty

T,

P

q«?

kmole/kmole

kmole/s

kmole/s

K

K

Pa

W/m2

Description

Light composition of vapor phase

Molar flow rate of vapor

Molar flow rate of liquid

Vapor phase temperature

Liquid phase temperature

Pressure

Wall heat flux (May also be specified as

wall temperature)

Table 4.1: Initial value input to numerical model

Experimental and Theoretical Study of Reflux Condensation

4

30

4.2

NUMERICAL MODEL

Model implementation for an arbitrary heat exchanger

The model is programmed in C, and takes input as specified in Table 4.1 at one end of

the dephlegmator. In addition, a criterion is set, at the opposite end, to determine when

to stop the numerical integration. This criterion may be chosen between composition,

flow rate, length of dephlegmator or flooding point.

Thermodynamic properties are calculated using an in-house thermodynamic library,

where the Peng-Robinson equation of state [50] is used. Appendix D describes the

equation and mixing rules, used on the test mixture of propane and n-butane in the

laboratory test rig (Chapters 5 and 6).

Flooding is monitored by calculating the Wallis flooding coefficient (Equation 2.4).

In a multi-tube heat exchanger, some authors recommend a reduction in flooding

factor [18,29]. In this program, the flooding coefficient is printed to the output file,

and can be evaluated according to the comments made in Section 2.2.

The vapor phase heat transfer coefficient is calculated by Equations 4.25 or 4.26,

taken from Kays & Crawford [51]. Nusselt (Nu) number denotes a dimensionless

temperature gradient at the surface, and the Prandtl (Pr) number denotes the ratio of

the momentum and thermal diffiisivity. There are several equations for pure gas flow