ME18 FINAL-PAPER rev15

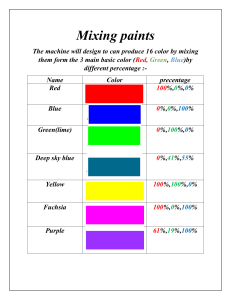

advertisement