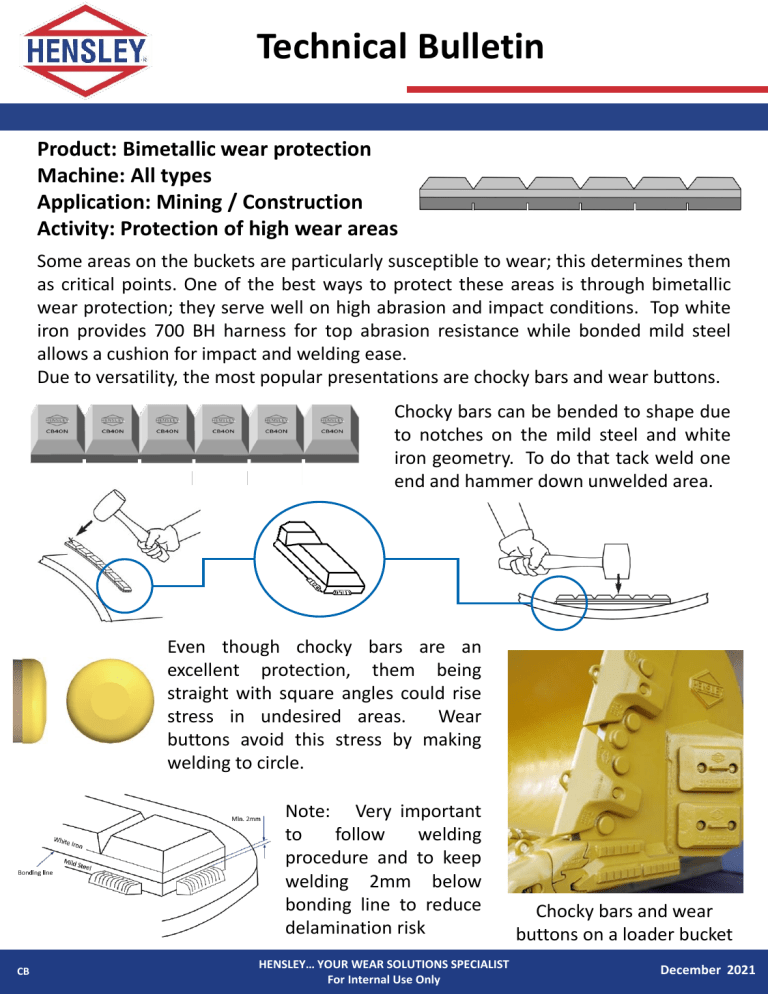

Technical Bulletin Product: Bimetallic wear protection Machine: All types Application: Mining / Construction Activity: Protection of high wear areas Some areas on the buckets are particularly susceptible to wear; this determines them as critical points. One of the best ways to protect these areas is through bimetallic wear protection; they serve well on high abrasion and impact conditions. Top white iron provides 700 BH harness for top abrasion resistance while bonded mild steel allows a cushion for impact and welding ease. Due to versatility, the most popular presentations are chocky bars and wear buttons. Chocky bars can be bended to shape due to notches on the mild steel and white iron geometry. To do that tack weld one end and hammer down unwelded area. Even though chocky bars are an excellent protection, them being straight with square angles could rise stress in undesired areas. Wear buttons avoid this stress by making welding to circle. Note: Very important to follow welding procedure and to keep welding 2mm below bonding line to reduce delamination risk CB HENSLEY… YOUR WEAR SOLUTIONS SPECIALIST For Internal Use Only Chocky bars and wear buttons on a loader bucket December 2021