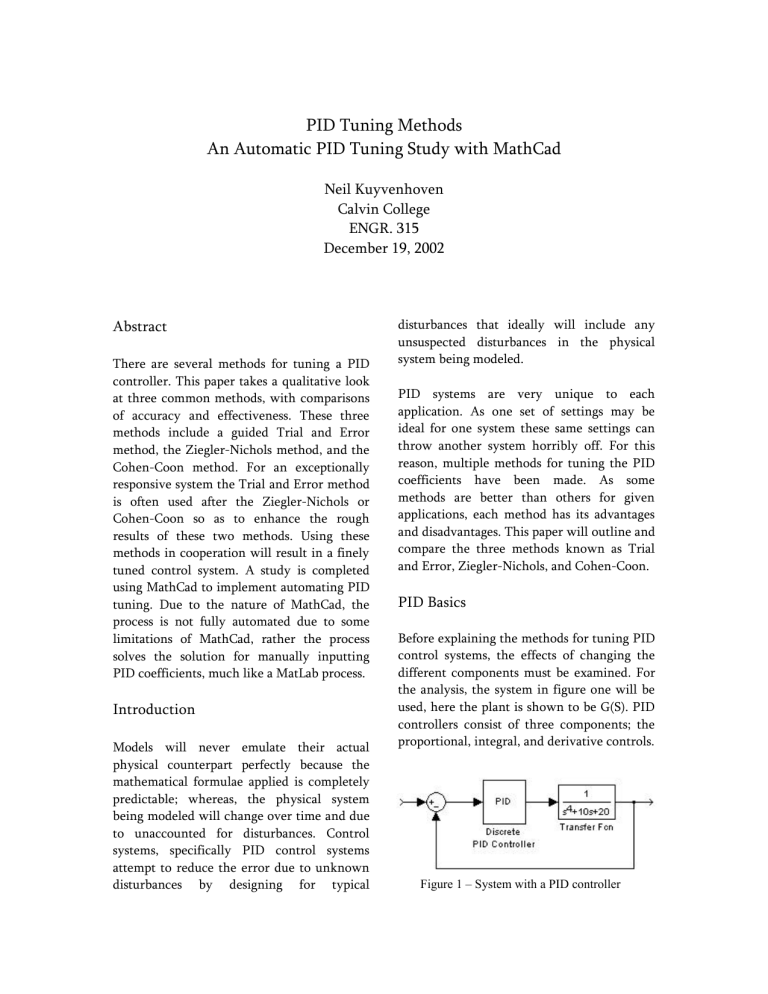

PID Tuning Methods An Automatic PID Tuning Study with MathCad Neil Kuyvenhoven Calvin College ENGR. 315 December 19, 2002 Abstract There are several methods for tuning a PID controller. This paper takes a qualitative look at three common methods, with comparisons of accuracy and effectiveness. These three methods include a guided Trial and Error method, the Ziegler-Nichols method, and the Cohen-Coon method. For an exceptionally responsive system the Trial and Error method is often used after the Ziegler-Nichols or Cohen-Coon so as to enhance the rough results of these two methods. Using these methods in cooperation will result in a finely tuned control system. A study is completed using MathCad to implement automating PID tuning. Due to the nature of MathCad, the process is not fully automated due to some limitations of MathCad, rather the process solves the solution for manually inputting PID coefficients, much like a MatLab process. Introduction Models will never emulate their actual physical counterpart perfectly because the mathematical formulae applied is completely predictable; whereas, the physical system being modeled will change over time and due to unaccounted for disturbances. Control systems, specifically PID control systems attempt to reduce the error due to unknown disturbances by designing for typical disturbances that ideally will include any unsuspected disturbances in the physical system being modeled. PID systems are very unique to each application. As one set of settings may be ideal for one system these same settings can throw another system horribly off. For this reason, multiple methods for tuning the PID coefficients have been made. As some methods are better than others for given applications, each method has its advantages and disadvantages. This paper will outline and compare the three methods known as Trial and Error, Ziegler-Nichols, and Cohen-Coon. PID Basics Before explaining the methods for tuning PID control systems, the effects of changing the different components must be examined. For the analysis, the system in figure one will be used, here the plant is shown to be G(S). PID controllers consist of three components; the proportional, integral, and derivative controls. Figure 1 – System with a PID controller Each of these components has very distinct effects on the system. Table one outlines the effects of the PID components on a particular system. Though there is no set standard for the way a PID controller is set up, there is however three main types. These include the ideal, parallel and series controllers. These types can be seen in figure 1.5 along with there corresponding frequency domain equations as equations one, two and three. controller will result in drastically different effects on the the different types of controllers. This difference is most significant on the derivative control in the series and parallel controllers. With the series controller, the derivative control is operating on the partially fixed error as it has already gone through the proportional and integral control. The is juxtaposed by the parallel controller where the parameters are order independent. The effect of the derivative control is not amplified by proportional control which results in a less fine tuned system. The series system begins by amplifying the error which promotes a faster response from the integral and derivative control. The ideal system creates a sensitive response in the proportional control as small changes have big effects on the integral and derivative portions separately. This is different from the series model due to the lack of direct interaction between the integral and series control. This paper uses the parallel PID control model for analysis. Figure 2 – Ideal, series, and parallel PID configurations Eq. 1 Eq. 2 To increase the rise time of the system, the proportional, integral, and derivative components are tweaked so as to improve the rise time, steady state error, and overshoot respectively. Despite the fact that changing one component effects all the characteristics as seen in table one, the system can still be brought to stability with the three components together; although sometimes fewer than all three are needed. Table 1 – Effects of PID Eq. 3 The difference between these types of PID controllers is only seen when attempting to tune them. The outcome can be made similar with different values, but as is realized from the equations, one set of parameters for the Rise Time Steady State Proportional Decrease Decrease Integral Decrease Eliminate Derivative None None Overshoot Increase Increase Decrease Method 1: Trial and Error Method 2: Ziegler-Nichols The Trail and Error method requires a closed loop system, it steps through the system from proportional to integral to derivative. This method is a divide and conquer approach, first it puts the system into a rough solution from which small tweaks are performed to perfect the response. To begin, each coefficient of the PID controller is set to zero. The proportional component is now considered by increasing its value until a steady oscillation is obtained as in figure two. Scaling the current proportional value down by a factor of two will give the resulting proportional value. Applying this proportional value will dismiss the steady oscillations. Next the integral coefficient is increased until steady oscillations are again obtained. The present value of the integral coefficient is scaled up by a factor of three and applied to the integral as the final value. This once again sets oscillations off, which brings up the derivative control, this value is increased until for a final time the oscillations are at a constant period and amplitude. The coefficient of the derivative is then scaled down by a factor of three and applied as the final value for the derivative control. The resulting output may still have some noise associated with it, this must now be tuned by hand with small educated tweak of the different coefficients. The Ziegler Nichols method takes two approaches depending on the system at hand. First, with the closed method or begins in much the same way as the Trial and Error method as a steady oscillation is desired with only a proportional influence present. The proportional value at which the oscillations become constant is coined the term 'ultimate gain'. The period of oscillations at the ultimate gain is termed 'ultimate period'. The ultimate gain can be found in an simpler way with the root locus of the open loop transfer function. The ultimate gain and ultimate period as noted in figure 2, are applied to the Ziegler-Nichols formulae as noted in table 2. This method works provided the closed loop transfer function is known and there is an ultimate gain, the point where the root locus value has zero for the real portion. Table 2 – Tuning parameters for Ziegler Nichols closed loop ultimate gain method KP KI KD P 0.5*Ku PI 0.45*Ku 1.2/Tu PID 0.6*Ku 2/Tu Tu/8 The second Ziegler-Nichols method applies to the open loop transfer function. It is simpler to calculate because the guess work is taken out as opposed to the closed loop method where the accuracy of 'steady oscillations' becomes an estimation at best. The tuning parameters for the Ziegler-Nichols open loop method is shown in table three. Table 3 – Tuning parameters for ZieglerNichols open loop ultimate gain method Figure 2 – Steady oscillation illustrating the ultimate period KP P 1/(RL) PI 0.9/(RL) PID 1.2/(RL) TI TD 3L 2L 0.5L as seen in figure three and applied to the Ziegler-Nichols open loop formulae as found in table three. The outcome of the two Ziegler-Nichols method is a system with a fairly clean response, work still must be done tweaking the system as the Ziegler-Nichols method will only give rough estimates. Cohen-Coon The Cohen-Coon method is a more complex version of the Ziegler-Nichols method. Using the same process to come up with the input values from figure three. The difference comes with the fact that the rise time is required. This method is more sensitive than the Ziegler-Nichols as it is limited to one type of open loop response. Table four displays the formulae for the Cohen-Coon method. By the formulae given in table four, it is obvious that this system is designed with different objectives than Ziegler-Nichols Table 4 – Tuning parameters for Cohen-Coon method Figure 3 – Two possible outputs for the Ziegler-Nichols open loop analsys. To apply the Ziegler-Nichol open loop method, the output is monitored as a sharp step is applied to the input. The response is monitored for a response similar to that of figure three, which gives two of the three possible responses for an open loop system. The third being an oscillatory system; which requires the closed approach method rather than the open loop approach of the ZieglerNichols methods. For this reason it is not included in the figure. The second diagram in figure two illustrates a stable system which as the name suggests, settles to a given steady state. The last plot in the figure is an unstable system which approaches infinity due to a step applied to the input. With the response captured, values are found Method Comparison The methods described thus far are by no means the only way to tune a PID controller, though, the specific methods described above are well known and accepted for their simplicity and ease of use even though they will not work with every system. Every method has its advantages and disadvantages;. depending on the system at hand, one method may be preferable over another but by no means is it the only option. The Trial and Error method is very common not only in educational settings due to the intuition and clarity it provides with what the PID components are doing. Often after using a method such as the Ziegler-Nichols or Cohen-Coon some manual tweaking is favourable to get the system tuned specifically for the system at hand, whether it be more robust to handle large disturbances or keenly sensitive to respond instantaneously to small annoyances introduced to the system. The Ziegler-Nichols and Cohen-Coon method are systems keyed towards speed rather than robustness as they are both design with a 25% damping factor meaning the oscillations will decrease by a factor of four every period. The settling time from these systems can vary depending on the initial overshoot. The Ziegler-Nichols method is designed around the point of critical damping, where the root locus gives a purely imaginary pole. This system works best with 2nd order systems, beyond this the oscillations could give more than on solution for the ultimate gain. Methods such as Integral of Time Weighted Absolute Error (ITAE) or Internal Model Control (IMC). Can be found to do a more precise job. The standard for PID has not been set, as the western world welcomes fuzzy logic more and more systems are leaning this way. MathCad Study The methods thus far have only provided solutions that are classified as satisfactory depending on the system. The intent of the MathCad study was initially to develop a program that would automatically find a set of results that meet the overshoot, rise time, settling time, and steady state error criteria which is set by the user. The user would input the plant function and the set point disturbance in the frequency domain and have MathCad find a best fit solution with these inputs. The theory behind the application is simple, calculate the transfer function of the system with the input plant and disturbance and plot the output from the time domain. Using the time domain function, the overshoot, rise time settling time, and steady state error are calculated. These values are compared against the users inputs depending on the outcome, the program will increment one of the PID coefficients and recalculate the worksheet. This iterative process would ideally give the values of the PID components to satisfy the criteria outlined by the user if the solution exists. The objectives of the MathCad program have been altered due to the capabilities of MathCad. Using the programming tools with functions such as H(s) gives multiple errors as these functions cannot be assigned as is required with the programming tools. The result is a worksheet acts much in the same way as MatLab Simulink. After inputing the plant function, the user is required to alter the controller parameters manually as the worksheet updates the new values on the fly. This worksheet along with a root locus or Nyquist plot will allow the user to easily tune a PID control system with the methods described in this paper. MathCad Code The MathCad code for the worksheet is shown below, the end result makes only the plant and the input visible along with the output plot with the characteristics. Parallel PID Control Factored numerator without any scalar z User Input i i 1 H( s) := 2 Input disturbance Num( s , Kp , Ki , Kd ) scaleNumF( s) := partialNumFr( s) 1 s Factored numerator Begin Calculations NumF( s) := scaleNumF( s) ⋅ partialNumF( s) PID Controller 2 G( s , Kp , Ki , Kd ) := Kp⋅ s + Kd ⋅ s + Ki 1 + G( s , Kp , Ki , Kd ) ⋅ H( s ) Num( s , Kp , Ki , Kd ) := numer( T( s , Kp , Ki , Kd ) ) Denominator of Closed loop Den( s , Kp , Ki , Kd ) := denom( T( s , Kp , Ki , Kd ) ) Zeros of closed loop Z := solve( Num( s , Kp , Ki , Kd ) , s ) Poles of closed loop P := ( solve( Den( s , Kp , Ki , Kd ) , s) ) Size of Pole and Zero matricies z := rows( Z) − 1 p partialDen F( s) := (s − P ) ∏ = i i F( s) G( s , Kp , Ki , Kd ) ⋅ H( s) Numerator of Closed loop p := rows( P) − 1 Factored denominator without any scalar s Closed Loop Transfer function T( s , Kp , Ki , Kd ) := 0 Numerator's scalar s + 10⋅ s + 20 F( s ) := (s − Z ) ∏ = partialNumF( s) := Plant 0 Denominator's scalar scaleDenF( s ) := Den( s , Kp , Ki , Kd ) partialDen F( s) Factored denominator ( DenF( s) := scaleDenF( s) ⋅ partialDen F( s) ) Factored Transfer function TFactor( s) := NumF( s) DenF( s) Time domain transfer funciton ( ) h( t) := invlaplace TFactor( s) , s , t float , 4 complex SETTLING TIME @ 90% SS := 1 Given Given x ( q) − SS < SS⋅ .02 x ( q) = SS⋅ .9 x ( q) − SS > −SS⋅ .02 x ( q) > 0 T90% := Find( q) Ts := Find( q) Tr := T90% − T10% RISE TIME Time for response to go from 10% of steady state to 90% of steady state PERCENT OVERSHOOT X ( t) := d dt x ( t) Given @ 10% X ( q) = 0 q>0 Given x ( q) = SS⋅ .1 Tovershoot := Find( q) x ( q) > 0 T10% := Find( q) PO := . ( ) x Tovershoot − SS SS References • Control Tutorials for Matlab. University of Michigan, 1996. <http://www.krellinst.org/UCES/archive/cl asses/control/PID/PID.html> • Dorf, Richard, Bishop, Robert. Modern Control Systems, Prentice Hall, 2000. • Examining the Fundamentals of PID Control, <http://www.geocities.com/chemforum/pi dcontrol.htm> • Example Problem of PID, <www.phys.ntnu.no/brukdef/undervisning/si f4037/Lecturenotes/Example%20Problem%2 0of%20PID.doc> • Hubertus, Dr. Comparison of PID Control Algorithms (all Controllers are not Created Equal),Expertune Inc. 1999. <http://www.expertune.com/artCE87.h tml> • Lee, Jay. PID Controller Tunning, Part II – Reaction Curve Method, Georgia Inst. Technology. 2001. <http://dot.che.gatech.edu/Information/res earch/issicl/che4400/files/lecturenote/lectu re6b_2.pdf> • Lelic, Muhiden, PID Controllers in the Nineties, Corning Inc. 1999. <http://www.ece.rutgers.edu/~gajic/IEEET alk.pdf> • Park, S. PID Controller Tuning to Obtain Desired Closed-Loop Responses for Single Input, Single Output Systems, Advanced Institute of Science and Technology. <http://www.cwru.edu/cse/eche/people/fac ulty/brosilow/papers/pidcontrol.pdf> • Smith, L. C. Fundamentals of Control Theory, Chemical Engineering,1979.