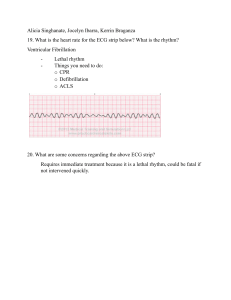

MINISTRY OF EDUCATION AND SCIENCE OF THE RUSSIAN FEDERATION _______________ Saint Petersburg Electrotechnical University “LETI” Faculty of Information Measurement and Biotechnical Systems (FIBS) ____________________________________________________ ESSAY Final Part I For the course “Maintenance and Repair of Modern Medical Equipment” Title: MAINTENANCE AND REPAIR PROCEDURES OF A CP 150 12-LEADS RESTING ELECTROCARDIOGRAPH Student - Group: 7500 HARUMUKIZA Jean Domitien Teacher Mochalin Dmitry Nikolaevich Saint Petersburg ETU “LETI” 2022 1 MAINTENANCE AND REPAIR PROCEDURES OF A CP 150 12-LEADS RESTING ELECTROCARDIOGRAPH 1. Description of the device 1.1 Main function of the ECG device An electrocardiogram (ECG) is one of the simplest and fastest tests used to evaluate the heart. Electrodes are placed at certain spots on the chest, arms, and legs. The electrical activity of the heart is then measured, interpreted, and printed out. Figure 1- The CP150 12-Leads resting ECG The printed view of these recordings requires only 12 electrode leads. The interpretation learns about the heart rate and rhythm as well as blood flow to the ventricles : Rate refers to how fast the heart beats and Rhythm strip showing a normal 12-lead ECG(figure 2). Heart rhythms can include: Normal sinus rhythm, Sinus tachycardia, Sinus bradycardia, Atrial fibrillation, Atrial flutter, Ventricular tachycardia, Ventricular fibrillation. Figure 2- ECG of a heart in normal sinus rhythm 2 1.2 Structure and design of the CP150 12-Leads resting ECG The main board is the heart of the instrument. It consists of bottom board and core board (CPU board), it implements a series of tasks including CPU system, display processing, printing control, keyboard signal processing. CPU system receives also signals from button board to finish the button board signal process, moreover, signals of lead-fall, paper detecting, battery management are all processed by main board CPU. The main board also process print task, CPU system receives order and data from print control system, generate control signals for stepping motor and printer head to implements waveforms and other information’s print. CPU system also sends order and data to display waveforms and other(figure 3). Figure 3- Structure of the CP150 12-Leads resting ECG. The interconnection diagram (figure 4) shows the connection between the Main board(Microprocessor) , the ECG board, the Recorder , the inverter, the peripheral circuit like LCD panel, Button board, the battery, the transformer, the USB interface , the Communication interface and the external like USB devices, the current input, the connection with the 12 electrodes and patient and as well as the user with the keyboard. 3 Figure 4- Interconnect diagram of the CP150 12-Leads resting ECG 1.3 Technical and organizational means and methods of ensuring safe operation The equipment is marker by the following symbols: Protective earth Nonionizing electromagnetic radiation Equipotential terminal Defibrillation-proof Type CF applied parts That shows that it in the first class and provide a higher degree of protection against electrical shock especially leakage currents. I additions, it must have electromagnetic compatibility (EMC) information that is the ability of electrical equipment and systems to function acceptably in their electromagnetic environment. 4 1.4 Legal regulations of ECG device usage in BURUNDI a. Decontamination and cleaning requirements Electrocardiogram device must undergo decontamination before transport for service, repair, inspection, or disposal. Cleaning is an essential prerequisite for effective disinfection or decontamination. b. Electrical Safety for medical devices The international standards for perform arc flash analysis for electrical hazardous from 0.208 kV to 15 kV in accordance with IEEE 1584-2018 “IEEE Guide: short-circuit, protective device coordination, and arc-flash, Earthing Types, integrated with load flow, short circuit, and protective device coordination modules, electric shock requirement assessment, loop impedance and current calculation, resistance to ground, touch voltage calculation and evaluation. Basic electrical safety tests include: visual inspection of cables, plugs and connectors, measurement of ground wire resistance, chassis and patient lead/contact isolation Requirements for safety are the types of premises, protection classes E / O, patient circuit protection types and grounding systems: IT, TT. c. Local or international standards and documents regulate the electrical safety system in Burundi International Guidelines of the Electricity Sector, Specific international and national energy-sector guidelines also apply in Burundi. These include: the International Commission on the Non-Ionizing Radiation Protection (ICNIRP) Guidelines for limiting exposure to time-varying electric, magnetic and electromagnetic fields (up to 300 GHz); and Guidelines for Large Electric Systems on minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (electromagnetic fields) within the meaning of Article 16(1) of Directive 89/391/EEC. Furthermore, Burundi is signatorie to several international conventions on environmental and electrical safety. 5