Shear Connection Design Fundamentals: AISC Webinar

advertisement

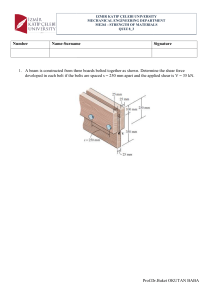

AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I AISC Live Webinars Today’s live webinar will begin shortly. Please stand by. AISC Live Webinars As a reminder, all lines have been muted. Please type any questions or comments through the chat feature on the left portion of your screen. Thank you for joining our live webinar today. We will begin shortly. Please standby. Thank you. Today’s audio will be broadcast through the internet. Alternatively, to hear the audio through the phone, dial: Need Help? Call ReadyTalk Support: 800.843.9166 (866)-519-2796 Passcode: 671831 Fundamentals of Connection Design Session 3: Shear Connections, Part I November 6, 2019 AISC Live Webinars Audio Options Today’s audio will be broadcast through the internet. Alternatively, to hear the audio through the phone, dial: (866)-519-2796 Passcode: 671831 •1 AISC Live Webinars AIA Credit AISC is a Registered Provider with The American Institute of Architects Continuing Education Systems (AIA/CES). Credit(s) earned on completion of this program will be reported to AIA/CES for AIA members. Certificates of Completion for both AIA members and non-AIA members are available upon request. This program is registered with AIA/CES for continuing professional education. As such, it does not include content that may be deemed or construed to be an approval or endorsement by the AIA of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. Questions related to specific materials, methods, and services will be addressed at the conclusion of this presentation. Copyright © 2019 American Institute of Steel Construction 1 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 AISC Live Webinars Fundamentals of Connection Design Session 3: Shear Connections, Part I AISC Live Webinars Copyright Materials Course Description This presentation is protected by US and International Copyright laws. Reproduction, distribution, display and use of the presentation without written permission of AISC is prohibited. Shear Connections, Part I November 6, 2019 © The American Institute of Steel Construction 2019 The information presented herein is based on recognized engineering principles and is for general information only. While it is believed to be accurate, this information should not be applied to any specific application without competent professional examination and verification by a licensed professional engineer. Anyone making use of this information assumes all liability arising from such use. This session will provide an overview of a variety of shear connection types, addressing the advantages and disadvantages of each. The limit states for block shear and flexural strength in coped beams will be presented. Shear end-plate and double-angle connection designs will also be discussed. Design examples will be presented to demonstrate the concepts. AISC Live Webinars Learning Objectives • Identify several types of shear connections. Fundamentals of Connection Design • Explain where the point of rotation is modeled for various shear connections. Session 3: Shear Connections, Part I November 6, 2019 • List the steps in designing shear end-plate connections. • List the steps in designing double-angle connections. Brad Davis, PhD, SE Associate Professor, University of Kentucky Owner, Davis Structural Engineering Copyright © 2019 American Institute of Steel Construction 2 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Schedule • • • • October 23, 2019 October 30, 2019 November 6, 2019 November 13, 2019 Fundamental Concepts Part I Fundamental Concepts Part II Shear Connections Part I Shear Connections Part II SHEAR CONNECTIONS PART I 9 10 Topics Connection Classification • Types of Shear Connections • Design Considerations • Additional Limit States for Shear Connections • Shear End-Plate Connections • Double-Angle Connections qs qs M MF q, M q, M MF MF 0.8qs 0.2MF q 11 qs Manual Figure 10-1 12 Copyright © 2019 American Institute of Steel Construction 3 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Types of Shear Connections • • • • • • • Design Considerations • Shear connection design assumes the connection is pinned. • Where is the pin? Shear End-Plate Double-Angle Single-Angle Single-Plate or Shear Tab Tee Shear Connections Unstiffened Seated Connections Stiffened Seated Connections 13 Design Considerations 14 Design Considerations • Where is the pin? Answer: At the most flexible side of the connection. • Where is the pin? 2 Angles 15 16 Copyright © 2019 American Institute of Steel Construction 4 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Design Considerations Design Considerations • Ductility Considerations • Beam Length Tolerance +/- 1/4 in. – Angle or end plate thickness < 5/8 in. +/- ¼ in. – Wide gage – Wide vertical weld spacing – Avoid welding along the top of angles or end plate Beam Length +/- ¼ in. • Stability Consideration Setbacks are usually 1/2 in. In calcs, end edge distances are taken as 1/4 in. less than detailed. – Depth of Connection > T / 2 (T is clear distance between fillets – Tabulated in Manual Table 1-1) 17 Design Considerations 18 Design Considerations • Beam Length Tolerance + 1/4 in. • Beam Length Tolerance + 1/4 in. Minus 1/4” in Design Calcs 1/2" setback 19 20 Copyright © 2019 American Institute of Steel Construction 5 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Design Considerations Add’l Limit States for Shear Connections • Effective Weld Length • Block Shear in Coped Beams When a weld terminates in the “air,” the dimensioned weld length is reduced by the weld size for calculations except for angles welded to a beam web. - Bolted at Web - Welded at Web • Coped Beam Flexural Strength Lw Leff = Lw – 2 w Shear End-Plate Double-Angle 21 Block Shear in Coped Beams 22 Block Shear in Coped Beams Specification Section J4.3 ϕ = 0.75 Rn = 0.6FuAnv + UbsFuAnt ≤ 0.6FyAgv +UbsFuAnt Equivalent to: Rn min min 23 Shear Rupture Shear Yielding 0.6 Fu Anv 0.6 Fy Agv Tensile Rupture U bs Fu Ant Ubs = 1.0 when tensile stress is uniform = 0.5 otherwise 24 Copyright © 2019 American Institute of Steel Construction 6 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Block Shear in Coped Beams Ubs = 1.0 Ubs = 1.0 Coped Beam Flexural Strength Ubs = 0.5 Single Cope More Examples in Commentary Figure C-J4.2 Evaluation Criterion Limit States Mu = Ru e < ϕbMn ϕb = 0.9 • Flexural Yielding (C or T) • Web Flexural Local Buckling (Single Cope) • Web LTB (Double Cope) 25 Coped Beam Flexural Strength Double Cope 26 Single Coped Beam Flexural Strength Single Coped Beam Flexural Strength Single Coped Beam Flexural Strength Manual Pages 9-6 through 9-9 λ ≤ λp Mn = Mp = FyZnet λp < λ ≤ 2λp Mn = Mp - (Mp-My)(λ/λp-1) λ > 2λp Mn = FcrSnet λ = web slenderness = ho/tw (Manual 9-6) (Manual 9-7) (Manual 9-8) p 0.475 k1E / Fy k1 max fk 1.61 1.65 h k 2.2 o c h k 2.2 o c where Fcr 0.903Ek1 / 2 Snet = net elastic section modulus at the cope, in.3 Znet = net plastic section modulus at the cope, in.3 27 Single Cope c 1.0 ho c if 1.0 ho if c 1.0 d f 1 c / d c min if 1.0 3.0 d 2 c d if 28 Copyright © 2019 American Institute of Steel Construction 7 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Double Coped Beam Flexural Strength Double Coped Beam Flexural Strength Web Lateral-Torsional Buckling Manual Page 9-9 and Specification Section F11 Web Lateral-Torsional Buckling, Manual Page 9-9 λ ≤ λp Mn = Mp = FyZ ≤ 1.6FyS λp < λ ≤ λr Mn = Cb[1.52-0.274λ(Fy/E)]My ≤ Mp λ > λr Mn = (1.9ECb/ λ)Sx ≤ Mp where Z twho2 / 4 Lb ho / tw2 If cb ≥ ct p 0.08E / Fy (Spec. F11-1) (Spec. F11-2) (Spec. F11-3) Note: First printing of the Manual Page 9-9 shows < . Should be > as shown here. 29 Single Cope Flexural Strength Example W14x30 1/2" 8" 3" d = 13.8 in. tw = 0.270 in. bf = 6.73 in. tf = 0.385 in. Vu = 40 kips W14x30 ho = 13.8 – 3.0 = 10.8 in. Snet = 8.37 in.3 from Manual Table 9-2 Znet = 15.1 in.3 from Companion to the AISC Steel Construction Manual, Volume 2, Table 9-A. 1/2" 8" 30 Coped Beam Flexural Strength Example Example: Evaluate coped beam flexural strength. Vu = 40 kips L d Cb 3 ln b 1 ct 1.84 d d c c Lb t b Otherwise 2 cb Lb dct Cb 3 ln 1 1.84 ct d d Note: When cb > ct flexural tensile yielding must be checked at the bottom cope. S twho2 / 6 r 1.9E / Fy Lb ct 3" W14x30 A992 Steel Note: The distance ho above ≠ ho that is tabulated in Manual Table 1-1 W-Shapes Dimensions. 31 32 Copyright © 2019 American Institute of Steel Construction 8 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Coped Beam Flexural Strength Example Coped Beam Flexural Strength Example 1/2" 8" Vu = 40 kips 1/2" 8" 3" Vu = 40 kips W14x30 Snet = 8.37 in.3 3" W14x30 Znet = 15.1 in.3 33 Coped Beam Flexural Strength Example 1/2" Local Web Flexural Strength 8" ho 10.8 in. 40 tw 0.270 in. Vu = 40 kips 3" Buckling Adjustment Factor, f: c 8 in. 0.580 1.0, so d 13.8 in. c f 2 2(0.580) 1.16 d W14x30 Limiting Slenderness for Yielding: p 0.475 k1E / Fy Need k1 = f k ≥ 1.61 Plate Buckling Coefficient, k: 1.65 k1 max 1.65 10.8 in. 2.2 8 in. 1/2" 8" Vu = 40 kips 3" W14x30 Modified Plate Bending Coefficient, k1: c 8 in. 1.0, so ho 10.8 in. h k 2.2 o c Coped Beam Flexural Strength Example Local Web Flexural Strength Slenderness: 34 fk (1.16)(3.61) 4.19 4.19 1.61 3.61 35 36 Copyright © 2019 American Institute of Steel Construction 9 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Coped Beam Flexural Strength Example Local Web Flexural Strength Coped Beam Flexural Strength Example Single Coped Beam Flexural Strength 1/2" p (0.475) k1E / Fy 8" 1/2" 3" 8" (0.475) (4.19)(29,000 / 50) 3" 23.4 p ( 40) 2 p I.B. Vu = 40 kips W14x30 Vu = 40 kips W14x30 M p Fy Znet (50)(15.1) 755 kip-in. M y Fy Snet (50)(8.37) 419 kip-in. Mn = Mp - (Mp-My)(λ/λp-1) = 755 – (755-419)(40/23.4 -1) = 517 kip-in. M n (0.9)(517 kip-in.) 465 kip-in. (Manual Eq. 9-7) M u (40 kips)(8.5 in.) 340 kip-in. M n , OK 37 Shear End-Plate Connections 38 Shear End-Plate Connections Advantages • Simple – Few Parts • No Holes in Beam Disadvantage • Requires Beam to be Cut to Exact Length 39 Manual Figure 10-6 40 Copyright © 2019 American Institute of Steel Construction 10 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Shear End-Plate Connection Limit States Beam Shear End-Plate Connection Limit States Plate 1. Shear Yielding 2. Coped Beam Flexural Strength 3. Web Base Metal Strength at Weld Weld 4. Weld Rupture Strength 3, 4 1 76 55 67 5. Shear Yielding 6. Shear Rupture 7. Block Shear 2 8 8. Shear Transfer Between Plate and Support Vu 7 7 6 55 6 41 Shear End-Plate Connection Example Shear End-Plate Connection Example Example: Determine the design strength, ϕVn. 1. Shear Yielding at Cope 8" 1 14" 2@3" 1 14" 3" Spec. J4-3: W14x30 A992 Vu PL 1/4 x 6 x 0'-8 1/2" A36 Girder: A992 steel tw = 0.5 in. 8" d = 13.8 in. dc = 3.0 in. 3/4 in. Gr. A325-N Bolts, E70XX Electrode 1 3 2" 42 3/16 W14x30 Fy = 50 ksi Fu = 65 ksi d = 13.8 in. tw = 0.27 in. 43 Vu 3" W14x30 A992 ϕVn = (0.6 Fy)(d-dc)tw = (1.0)(0.6)(50)(13.8-3.0)(0.27) = 87.5 kips 44 Copyright © 2019 American Institute of Steel Construction 11 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Shear End-Plate Connection Example Shear End-Plate Connection Example 2. Coped Beam Flexural Strength 3. Web Shear Rupture Strength at Weld From previous example ϕMn = 465 kip-in. Plate L = 8.5 in. tweld = 3/16 in. Beam Web tw = 0.270 in. With e = cope length + plate thickness = 8.0 + 0.25 = 8.25 in. 8" 3" W14x30 A992 Vu Spec. Table J2.5 and Eq. J4-4: 3/16 ϕVn = (0.6Fu)(L - 2tweld)tw = 0.75(0.6)(65)[8.5 – (2)(3/16)] (0.270) = 64.2 kips ϕVn = 465 / 8.25 = 56.4 kips 45 Shear End-Plate Connection Example 46 Shear End-Plate Connection Example 4. Weld Rupture Strength Plate Limit States 8" From Manual Table J2.4, the minimum weld size is 1/8 in. 3/16 in. weld OK so far. Vu tp = 1/4 in. 3" W14x30 A992 A36 Steel: Fy = 36 ksi Fu = 58 ksi 3 2" 1 14 " 2@3" 1 14" 6" 5. Shear Yielding 3/16 ϕVn = (1.392)(D)(L - 2tweld) = (1.392)(3)[8.5 – (2)(3/16)](2 welds) = 67.9 kips ϕVn = (0.6Fy)(2 L tp) (Spec. J4-3) = 1.0 (0.6 x 36) (2 x 8.5 x 1/4) = 91.8 kips 47 48 Copyright © 2019 American Institute of Steel Construction 12 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Shear End-Plate Connection Example 3 2" 6. Shear Rupture d h 3 / 4 1 / 16 1 / 16 7 / 8 in. Anv (1/ 4) 8.5 3(7 / 8) (2) 2.94 in.2 Shear End-Plate Connection Example PL 1/4 x 6 x 0’-8 1/2” ϕ = 0.75 1 14 " 2@3" 1 14" 1 14" 7. Block Shear Strength 3" 3" Shear Rupture Rn min Tensile Rupture Shear Yielding 6" Vn 0.6 Fu Anv (0.75)(0.6)(58)(2.94) min 76.7 kips 0.6 Fu Anv 0.6 Fy Agv U bs Fu Ant (Spec. J4-5) 49 Shear End-Plate Connection Example 50 Shear End-Plate Connection Example 7. Plate Block Shear 7. Plate Block Shear - Shear Rupture 0.6FuAnv = (0.6)(58)(1/4)[7.25 – (2.5)(7/8)](2) = 88.1 kips 1 14" - Shear Yielding 0.6FyAgv = (0.6)(36)(1/4)(7.25)(2) 3" = 78.3 kips 3" Tensile Rupture FuAnt = 58(1/4)[1.25 – (0.5)(7/8)](2) = 23.6 kips 1 14" Rn min min min Shear Rupture Shear Yielding 0.6 Fu Anv 0.6 Fy Agv Tensile Rupture 1 14" 3" 3" U bs Fu Ant 88.1 kips 78.3 kips 1 14" (1.0)(23.6 kips) 102 kips 1 14" Vn = (0.75)(102) = 76.4 kips 51 52 Copyright © 2019 American Institute of Steel Construction 13 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Shear End-Plate Connection Example Shear End-Plate Connection Example 8. Shear Transfer Between Plate and Girder 8. Shear Transfer Between Plate and Girder A992 girder with tw = 0.5 in. 1-1/4" A36 plate with t = 0.25 in. 3" Therefore, the plate won’t will control. 3" A B C Vu Bearing: rn = 26.1 kips with d = 3/4 in. Bolt Shear Rupture rn = 23.9 kips A 3" 3" 1-1/4" Bolt Rupture rn min Plate Bearing B C Vu Plate Tearout 23.9 kips Tearout with dh = 13/16 in. At A: rn = 14.7 kips At B and C: rn = 38.1 kips rnA min 26.1 kips 23.9 kips rnB rnC min 26.1 kips 14.7 kips 53 38.1 kips Rn (0.75) (14.7)(2) (23.9)(4) 93.8 kips 54 Shear End-Plate Connection Example Double-Angle Connections Connection Design Strength 8" 1 3 2" 3" 1 14 " 2@3" 1 14" W14x30 A992 Vu PL 1/4 x 6 x 0'-8 1/2" A36 Welded/Bolted 3/16 Bolted/Bolted Bolted/Welded Coped Beam Flexural Strength Controls ϕVn = 56.4 kips 55 56 Copyright © 2019 American Institute of Steel Construction 14 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Double-Angle Connections Solution of Erection Safety Issue Advantages • Beam length can vary. • Weld or bolt to beam. • Strong Disadvantage • For double-sided connections at a column or girder web, shared bolts cause an erection safety issue. 2 Angles Double-Sided Connection into Column Web 57 Welded/Bolted Double-Angle Connections 58 Welded/Bolted Double-Angle Connections Horizontal short slots may be used in angles 2 Angles Pin is at face of supporting element Manual Figure 10-4(b) Beam web weld is subjected to eccentric shear. 59 60 Copyright © 2019 American Institute of Steel Construction 15 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Welded/Bolted Double-Angle Connections Limit States Beam Shear Yielding Coped Beam Flexural Strength Block Shear Web Base Metal Strength at Weld Weld Rupture of Eccentrically Loaded Weld Group Welded/Bolted Double-Angle Connections Angles Base Metal Strength at Weld Shear Yielding Shear Rupture Block Shear Shear Transfer Angle Bearing / Tearout Bolt Shear Rupture Supporting Element Bearing / Tearout 61 62 Welded/Bolted Double-Angle Example Welded/Bolted Double-Angle Example Example: Determine Rn for 1. Beam Web Block Shear 2. Weld Rupture due to Eccentric Shear 3. Beam Web Strength at Weld 1. Beam Web Block Shear 1/4" Ru 3/16 W14x30 A992 tw = 0.270” 1/4" W14x30 A992 tw = 0.270" Shear Area Tensile Area Ru 2L3x3x5/16 x 0'-8 1/2" Rn 0.6 Fy Agv U bs Fu Ant Setback (0.6)(50)(0.270)(8.5 1 / 4) (1.0)(65)(0.270)(3 1 / 2 1 / 4) 110 kips Beam E70XX 2L 3 x 3 x 5/16 x 0'-8 1/2” 0.6 Fy Agv U bs Fu Ant • Anv = Agv (no holes) • 0.6FuAnv > 0.6FyAgv • Shear yielding controls 2" 1/2" 1-1/4" 3" 3" 1-1/4" Rn min 0.6 Fu Anv 1/2" 63 Rn (0.75)(110) 82.8 kips Length Tolerance 64 Copyright © 2019 American Institute of Steel Construction 16 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Welded/Bolted Double-Angle Example Welded/Bolted Double-Angle Example 2. Weld Rupture Due to Eccentric Shear ex = al 1/2" Ru Weld Group Ru + k x x a k&aC l xl kl 2L3x3x5/16 x 0'-8 1/2" Rn = CC1Dl Instantaneous Center of Rotation Method Design Aid: Table 8-8 Rn = CC1Dl ϕ = 0.75 C1 from Table 8-3. C1 = 1.00 for 70 ksi 65 Welded/Bolted Double-Angle Example 66 Welded/Bolted Double-Angle Example Determine C from Table 8-8: ex = al 1/2" Ru Weld Group 2L3x3x5/16 x 0'-8 1/2" Ru l = 8.5 in. + xl kl = 3 – 1/2 – 1/4 = 2.25 in. k = 2.25 / 8.5 = 0.265 67 k = 0.265 x = 0.0465 68 Copyright © 2019 American Institute of Steel Construction 17 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Welded/Bolted Double-Angle Example Welded/Bolted Double-Angle Example Determine C from Table 8-8: ex = al 1/2" Ru Ru Weld Group + l = 8.5 in. xl = (0.0465)(8.5) = 0.395 in. 2L3x3x5/16 x 0'-8 1/2" k = 0.265 a = 0.307 k & a C = 2.62 ex = 3 - 0.395 = 2.61 in. a = 2.61 / 8.5 = 0.307 69 70 Welded/Bolted Double-Angle Example Welded/Bolted Double-Angle Example C = 2.62 3/16 in. welds D = 3 E70XX C1 = 1.0 3. 1/2" Beam Web Strength at Weld Proposed Rational Approach 8-1/2" R u Strength of eccentrically loaded weld group: Rn = CC1Dl = (0.75)(2.62)(1.0)(3)(8.5)(2) = 100 kips Web Shear Rupture Strength / in. Weld Rupture Strength / in. 0.6Futw (1.0 in.) = Rn Weld (1.392)(D)(1.0 in.)(2 welds) (0.75)(0.6)(65)(0.270)(1.0) (100) (1.392)(3)(1.0)(2) 94.6 kips Rn Rn Weld 3/16 2L3x3x5/16 x 0'-8 1/2” 71 72 Copyright © 2019 American Institute of Steel Construction 18 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Bolted/Bolted Double-Angle Connections Bolted/Bolted Double-Angle Connections Bolt eccentricity ignored in bolted/bolted doubleangle connections. Shear transfer between angles and beam web and angles and supporting element as previous: Min of Bearing, Tearout & Bolt Shear Rupture at each hole/bolt. Beam to Girder Beam to Column Flange No Additional Limit States 73 Bolted/Welded Double-Angle Connections 74 Double-Angle Knife Connections 2 Angles Return @ Top Weld returns per Specification Section J2.2b User Note. Bolted/Welded to Column Flange Bolted/Welded Double-Angle Knife Connection 75 76 Copyright © 2019 American Institute of Steel Construction 19 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Bolted/Welded Double-Angle Bolted/Welded Double-Angle Bolted to Beam / Welded to Column Flange Coped Beam Web Strength at Tension Flange • Referred to as a “Knife” Connection • Bottom Cope to Permit Erection b = 0.9 Vn = Mn / e where Additional Limit States M n min Vu M p Fy Znet e 1.6M y 1.6Fy Snet Snet = elastic section modulus from Manual Table 9-2 Znet = plastic section modulus from AISC Companion to the AISC Steel Construction Manual Table 9-A. • Coped Beam Web Strength at Tension Flange • Weld Strength on Outstanding Legs (OSLs) – angle-to-column flange connection. 77 78 Bolted/Welded Double-Angle Weld Strength on OSLs Bolted/Welded Double-Angle e = Leg Width Vu / 2 Vertical Weld Force fv l Return at Top Web contact pressure Vu / 2 l l fv Vu / 2 Max Horizontal Weld Force e fv and fh in kips/in. Vu / 2 Elastic Vector Method • Uniform vertical weld force. • Linearly varying horizontal weld force. • Neglect returns. M 0 f h 1.8 l 79 Vu e l2 (5/6)l fh 80 Copyright © 2019 American Institute of Steel Construction 20 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Bolted/Welded Double-Angle Maximum Weld Force as a function of Vu V fu f h2 f v2 u2 l 2 12.96e 2 2l Design Weld Force (kips/in.) with q = 0○ Bolted/Welded Double-Angle Example (kips/in.) Example: Calculate the weld design rupture strength at OSLs, ϕVn. 2L3x3x5/16 x 0'-8 1/2" f n 1.392 D W14x30 8-1/2" Weld Group Design Shear Strength, Vn Vn 2 l 12.96e 2 2 2l 2(1.392 Dl ) Vn 1 12.96e 2 / l 2 f n 4" (Manual 10-1a) E70XX e = 3 in. and l = 8.5 in. 81 Bolted/Welded Double-Angle Example 1/4 82 End of Session 3 Weld design rupture strength at OSLs Vn 2(1.392 Dl ) Thank You for Attending 1 12.96e 2 / l 2 (2)(1.392)(4)(8.5) 1 12.96(32 ) / (8.52 ) Next Up 58.5 kips 83 84 Copyright © 2019 American Institute of Steel Construction 21 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I Next Session • November 13, 2019 Shear Connections Part II TOPICS • • • • Single-Angle Connections Single-Plate (Shear Tab) Connections Unstiffened Seated Connections Stiffened Seated Connections 85 AISC | Questions? Single-Session Registrants Single-Session Registrants CEU / PDH Certificates CEU / PDH Certificates • You will receive an email on how to report attendance from: registration@aisc.org. • Reporting site (URL will be provided in the forthcoming email). • Username: Same as AISC website username. • Be on the lookout: Check your spam filter! Check your junk folder! • Password: Same as AISC website password. • Completely fill out online form. Don’t forget to check the boxes next to each attendee’s name! Copyright © 2019 American Institute of Steel Construction 22 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I 4-Session Registrants 4-Session Registrants CEU / PDH Certificates Attendance and PDH Certificates One certificate will be issued at the conclusion of the course. • You have two options to receive credit for a given session. • Option 1: Watch the live session. Credit for live attendance will be displayed on the Course Resources table within two days of the session. • Option 2: Watch the recording and pass the associated quiz. Videos and Quizzes • For each session, find access by the end of the day, Friday, after the live air date. (An email will be sent from webinars@aisc.org.) • Each video recording and quiz will be available for four weeks. • Quiz scores are displayed in the Course Resources table. Distribution of Certificates All certificates will be issued after the course is completed (the week of December 16). Only the registrant will receive a certificate for the course. 4-Session Registrants 4-Session Registrants Course Resources Course Resources Find all your handouts, quizzes and quiz scores, recording access, and attendance information in one place! Go to www.aisc.org and sign in. Copyright © 2019 American Institute of Steel Construction 23 AISC Live Webinar Series November 6, 2019 Revised: Nov 8, 2019 Fundamentals of Connection Design Session 3: Shear Connections, Part I 4-Session Registrants 4-Session Registrants Course Resources Course Resources Go to www.aisc.org and sign in. 4-Session Registrants Course Resources AISC | Thank you. Copyright © 2019 American Institute of Steel Construction 24