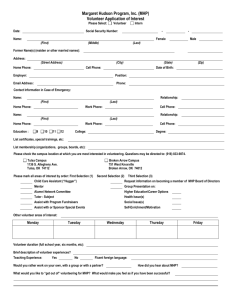

14 May 2013 14 May 2013 Construction of MHP System 1 MHP Project Development Process Feasibility Study Handing over to users Operation Maintenance Warranty Completion Tendering/ Ordering Site verification Manufacturing Installation Testing & Commissioning Power verification MHP Project Construction Technical feasibility Financial Viability Social Acceptability Environment friendly Design Study Design Sizing of Civil Components Design sizing of Mechanical Component Design sizing of Electrical Component 2 Financial Appraisal 1 14 May 2013 14 May 2013 Construction Phase The Construction of MHP is the practical aspect of putting the DPR into action (paper work applied in practical field). How well a project is designed, it has no use unless it is practically made / installed meeting the designed criteria and quality standards. 3 Construction Phase A MHP installer team should comprise of trained skill man power (Preferably comprising of Civil, Electrical and Mechanical team). A design engineers should closely supervise and monitor the project work during construction and installation of the project to ensure quality and timely completion of work. 4 2 14 May 2013 14 May 2013 Construction of MHP Involves • Construction of all Civil Components (Intake, Headrace, Forebay, Powerhouse, Tailrace etc.) 5 Construction of MHP involves • Fabrication of Electromechanical components (Turbine, Base frame, Penstock pipe, Control Panel etc.) 6 3 14 May 2013 14 May 2013 Construction of MHP involves • Supply and delivery and installation of of Electromechanical components to the site (Turbine, Generator, Penstock etc.) 7 Construction of MHP Involves • Erection of Transmission and Distribution System (Pole erection, stretching transmission/ distribution cables etc.) 8 4