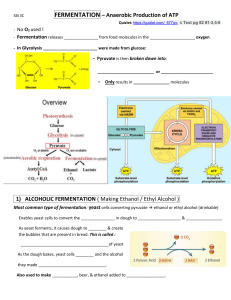

Appl Microbiol Biotechnol (1998) 49: 682±690 Ó Springer-Verlag 1998 ORIGINAL PAPER C. AÊkerberg á K. Hofvendahl á G. Zacchi B. Hahn-HaÈgerdal Modelling the in¯uence of pH, temperature, glucose and lactic acid concentrations on the kinetics of lactic acid production by Lactococcus lactis ssp. lactis ATCC 19435 in whole-wheat ¯our Received: 28 October 1997 / Received revision: 3 February 1998 / Accepted: 6 February 1998 Abstract A kinetic model of the fermentative production of lactic acid from glucose by Lactococcus lactis ssp. lactis ATCC 19435 in whole-wheat ¯our has been developed. The model consists of terms for substrate and product inhibition as well as for the in¯uence of pH and temperature. Experimental data from fermentation experiments under dierent physical conditions were used to ®t and verify the model. Temperatures above 30 °C and pH levels below 6 enhanced the formation of byproducts and D-lactic acid. By-products were formed in the presence of maltose only, whereas D-lactic acid was formed independently of the presence of maltose although the amount formed was greater when maltose was present. The lactic acid productivity was highest between 33 °C and 35 °C and at pH 6. In the concentration interval studied (up to 180 g l)1 glucose and 89 g l)1 lactic acid) simulations showed that both substances were inhibiting. Glucose inhibition was small compared with the inhibition due to lactic acid. Introduction Lactic acid is produced by fermentation of whey, for example, or synthetically from substrates such as lactonitrile (Vickroy 1985; Atkinson and Mavituna 1991). Its technical applications include use as a preservative in food, pharmaceuticals and cosmetics, and the production of polylactic acid, a biodegradable polyester used in C. AÊkerberg á G. Zacchi (&) Department of Chemical Engineering 1, Lund Institute of Technology/Lund University, P.O. Box 124, SE-221 00 Lund, Sweden Tel.: +46 46 2228297 Fax: +46 46 2224526 e-mail: Guido.Zacchi@kat.lth.se K. Hofvendahl á B. Hahn-HaÈgerdal Department of Applied Microbiology, Lund Institute of Technology/Lund University, P.O. Box 124, SE-221 00 Lund, Sweden medical sutures and clips for wound closure and selfdegradable prosthetic devices (Kharas et al. 1994). Lactic acid occurs naturally in two optical isomers and, since elevated levels of the D-()) form are harmful to humans (Expert Committee on Food Additives 1967), L-(+)-lactic acid is the preferred isomer. Polylactic acid with dierent properties can be produced, depending on the optical composition of the lactic acid used for polymerisation (Lipinsky and Sinclair 1986; Kharas et al. 1994). The synthetic production of lactic acid results in a racemic mixture of the two isomers, while fermentative production can yield either form alone or a racemate, depending on the organism, substrate and growth conditions used. The control of the optical composition and the reduction of by-product formation is essential for cost-eective fermentative production of L-lactic acid, since puri®cation constitutes a considerable fraction of the total production cost (Evangelista et al. 1994). Cheap raw materials, such as whey, molasses, starch waste and beet- and cane-sugar have been used for the fermentative production of lactic acid (Vickroy 1985; Atkinson and Mavituna 1991). Enzymatically hydrolysed whole-wheat ¯our, containing both gluten and bran, has been found to contain all the necessary nutrients for L. lactis 19435 (Hofvendahl and HahnHaÈgerdal 1997a). Hydrolysis is performed in two enzymatic steps, liquefaction and sacchari®cation, where fermentation could be integrated with sacchari®cation (simultaneous sacchari®cation and fermentation) and a kinetic model of the entire process is required to optimise the production of L-lactic acid. The model parameters for sacchari®cation and fermentation must be determined individually to evaluate whether the two steps should be performed simultaneously or separately. A number of kinetic models for the fermentation of glucose to lactic acid have been proposed (Luedeking and Piret 1959; Mercier et al. 1992; Parente et al. 1994). Models including terms for both substrate and product inhibition have been suggested (GoncËalves et al. 1991; Venkatesh et al. 1993), as well as a model considering only product inhibition (Yeh et al. 1991; Cachon and 683 DivieÁs 1994; Gadgil and Venkatesh 1997). The hydrolysis and fermentation steps have dierent pH and temperature optima, and models considering the pH and temperature dependence of the lactic acid production rate have been developed for Lactobacillus casei fermenting whey (Rincon et al. 1993). A number of models considering only the eect of pH on the production rate have been proposed for Lactococcus lactis ssp. lactis biovar diacetylactis (Cachon and DivieÁs 1994), Lactobacillus bulgaricus (Venkatesh et al. 1993; Gadgil and Venkatesh 1997) and Lactobacillus delbrueckii (Yeh et al. 1991) using lactose or glucose. In the present study, the kinetics were determined for fermentations at various pH and temperature values and initial glucose and lactic acid concentrations. Based on these data, an empirical model consisting of rate expressions for cell growth, product formation, starch degradation and substrate consumption was developed. For optimisation purposes, terms for pH and temperature in¯uence were also included in the model. Materials and methods Inoculum preparation and microorganism used For the propagation of the inoculum, a ¯our-free, reference medium (Hofvendahl and Hahn-HaÈgerdal 1997b) was used. For plates, 20 g l)1 agar (Merck) was added. Lactococcus lactis ssp. lactis ATCC 19435 (L. lactis 19435) (American Type Culture Collection, Rockville, Md., USA) stored at )80 °C was plated on an agar plate and incubated at 30 °C for 48±72 h. A single colony was transferred to another plate and incubated for another 24 h. A single colony was then transferred to 5 ml liquid medium and incubated in a Gallenkamp INR-200 orbital incubator (Leicester, UK) for 12±24 h at 140 rpm. The cells were harvested by centrifugation (8000 g, 2 min, 4 °C), resuspended in 100 ml fresh medium and incubated in the same way for another 6±12 h. The bacteria were harvested by centrifugation (9000 g, 10 min, 4 °C; Beckman J2-21, Beckman Instruments Inc., Fullerton, Calif., USA) and resuspended in 100 ml NaCl 9 g l)1 (Across Organics, N.J., USA), corresponding to 5% of the total working volume of the fermentor. This suspension was used to inoculate the fermentor. Media composition Two dierent fermentation media were used, both containing whole-wheat ¯our suspended in water. The hydrolysed ¯our medium contained ¯our at a concentration of 120 g l)1 or 240 g l)1, which was completely hydrolysed to glucose by the sequential action of the enzymes Termamyl 120 L (Novo Nordisk, Bagsvaerd, Denmark) at 95 °C for 30 min and SAN Super 240 L (Novo Nordisk) at 55 °C for 16±20 h (Hofvendahl and Hahn-HaÈgerdal 1997a). This resulted in glucose concentrations of 89 g l)1 and about 170 g l)1 respectively. The supplemented ¯our medium contained glucose added to a 240 g l)1 ¯our suspension to act as a substrate at concentrations around 45 g l)1 (Hofvendahl and Hahn-HaÈgerdal 1997b). In some fermentation experiments the ¯our-free medium used for inoculum preparation was used. Fermentation Cultivation was carried out in a 3-l Chemoferm FLC-B-3 fermentor (HaÈgersten, Sweden), coupled to a Chemoferm LMS 500 control unit, controlling the temperature and rate of stirring. The working volume was 2 l. The pH was measured with a pH electrode (Schott GeraÈte H63, Germany) and was kept constant at 4.0, 5.0 or 6.0 by a pH meter and titrator (pHM61 and TTT80, Radiometer, Copenhagen, Denmark) with the addition of 200 g l)1 NaOH (Akzo Nobel, Eka Nobel, Bohus, Sweden). The stirring rate was 350 rpm, and the temperature 30 °C, 33.5 °C, 37 °C, or 40 °C. To ensure anaerobic conditions, N2 was bubbled through the fermentor at a rate of 150 ml min)1 or 500 ml min)1, controlled by a rotameter (Sho-Rate, Brooks, Instrument N. V. Veenendaal, The Netherlands). A sterile anti-foaming agent (Silicone antifoam, Kebo Lab, SpaÊnga, Sweden) was added with a sterile syringe, via a septum, as required. In two fermentation experiments lactic acid (sodium salt solution, ICN Biomedicals Inc., Aurora, Ohio, USA) was added, either 80 g l)1 at the time of inoculation or 35 g l)1 12 h after inoculation. Analysis Double measurements of the cell mass of the inoculum as dry weight were performed. The samples were ®ltered through 0.2-lm membrane ®lters (Supor-200, Gelman Science, Ann Arbor, Mich., USA) and dried in a microwave oven at low power (420 W) for 15 min. Owing to the high particle content of the ¯our, dry-weight analyses of the cell mass during fermentation could not be carried out. The amount of carbon dioxide in the outgoing gas was measured by photoacoustic spectroscopy (BruÈel & Kjñr type 1308; BruÈel & Kjñr, Nñrum, Denmark). Sterile samples were collected regularly, and analysed with HPLC as described previously (Hofvendahl and Hahn-HaÈgerdal 1997b). D- and L-lactic acid concentrations were measured enzymatically as described (Hofvendahl and Hahn-HaÈgerdal 1997a). Modelling The rates of cell growth, product formation and substrate consumption were expressed by an unstructured model for batch fermentation. The parameters in the model were ®tted to experimental data, obtained from the fermentation experiments, by non-linear least-squares ®tting. Cell growth For fermentation with L. delbrueckii, it has been observed that both substrate and product inhibition is of importance (GoncËalves et al. 1991). In the present study, the cell growth rate, rx (g l)1 h)1), was described by Monod kinetics, including terms for both types of inhibition. rx lmax Sg X Sg Ks Sg 2 Ki 1 ÿ Kp P n 1 where X, Sg and P represent the cell, substrate and product concentrations (g l)1) respectively, lmax is the maximum speci®c growth rate (h)1), Ks the saturation parameter (g l)1), Ki the substrate inhibition parameter (g l)1), Kp the parameter representing the pH dependence of product inhibition (l g)1) and n the parameter used to describe product inhibition. The cells are inhibited by the glucose and lactic acid concentrations prevailing in the fermentor, and thus concentrations not adjusted for dilution due to NaOH addition (marked*) were used when calculating the glucose and lactic acid inhibition. Product formation The lactic acid formation rate, rp, (g l)1 h)1) was modelled using the Luedeking-Piret expression (Luedeking and Piret 1959): rp a rx b X 2 where a is a growth-associated constant for product production and b is the non-growth-associated constant for product produc- 684 tion (h )1). The lactic acid concentration in the model represents the total lactic acid concentration, and thus no distinction was made between the D and L isomers. At temperatures higher than 30 °C the formation of the by-products acetic acid, formic acid and ethanol increased. Acetic acid was the major by-product, and its formation rate, rpa (g l)1 h)1), was modelled as a measure of the total by-product formation. rpa aa rx ba X 3 where aa is the growth-associated constant for by-product production and ba the non-growth associated constant for by-product production (h)1) In the hydrolysed ¯our medium, no by-products were found, and rpa was set to zero. A limited amount of glucose was produced by unintentional hydrolysis of the supplemented ¯our medium. This degradation, rst (g l)1 h)1) was expressed as: rst ÿkst Sst 4 )1 where Sst is the concentration of starch (g l ), de®ned as the sum of non-soluble polysaccharides and soluble oligosaccharides larger than glucose, and kst is an empirical parameter for starch degradation (h)1). The hydrolysed ¯our medium contained no residual starch. Substrate consumption The substrate consumption rate, rsg (g l)1 h)1), was described using the expression 1 1 1 rp ÿ rpa ÿ rx ÿ rst ÿ m X Yp Ypa Yx 5 describing the glucose consumption during fermentation, resulting in cell mass, lactic acid and by-product formation, and the glucose formation from the unintentional starch degradation. A certain amount of glucose is also used for maintenance energy, described with the m áX term. Yp and Yx are the stoichiometric parameters (g/g substrate) describing the theoretical yield of lactic acid and cell mass respectively, i.e. Yp 1 g lactic acid/g glucose and Yx 0.79 g cell mass/g glucose, using an experimentally determined cell mass composition of CH1.52O0.45N0.22; Ypa is the byproduct yield coecient. Ypa is the by-product yield coecient (g by-product/g substrate) and m is the maintenance energy parameter (g substrate/g cell mass á h). pH dependence The parameters for maximum speci®c growth rate, lmax, and product inhibition, Kp in Eq. 1 are dependent on pH. The pH dependence of lmax and Kp was expressed according to Sinclair (1989): lm lmax 6 1 kl1 =H kl2 H Kp Kpm 1 kp1 =H kp2 H ÿE1 7 where [H+] 10)pH, and lm, kl, Kpm and kp are kinetic parameters describing the eect of pH on lmax and Kp. Temperature dependence There are a number of temperature-dependent parameters in the kinetic model: a, b, aa, ba and kst, and it was assumed that the ÿE2 parameter A1 e RT ÿ A2 e RT 8 )1 where E1 and E2 have the dimensions J mol and R is the universal gas constant (J mole)1 K)1). The model was evaluated in the temperature interval 30±37 °C. The temperature was raised above the standard conditions of 30 °C since the optimal temperature for the enzymatic hydrolysis of wheat starch is 55 °C. The upper limit was chosen to be 37 °C because, at 40 °C, the unstructured model could not account for all by-products formed. The high by-product formation also renders this temperature cost-ineective. Since the temperature interval is relatively small, the temperature parameter T, in Eq. 8, was expressed as: T T1 ÿ Tref Starch consumption rsg ÿ temperature dependence of the parameters can be described with the following expression: K where T1 is the temperature (K) under investigation. The reference temperature, Tref, was chosen as 300 K to increase the eect of temperature in Eq. 8. Results The kinetic parameters in Eqs. 1, 2, 4 and 5 were determined by minimising the objective function X X Q1 Xcalc ÿ Xexp 2 Pcalc ÿ Pexp 2 X 9 Sg;calc ÿ Sg;exp 2 using experimental data from fermentation experiments in the ¯our-free medium with initial glucose concentrations between 40 g l)1 and 130 g l)1 (Table 1) exp and calc represent experimental and simulated data, respectively. The ¯our-free medium was used to determine the cell mass, which could not be determined in the wholewheat ¯our medium because of the particle content. Experimental and simulated data from one fermentation are presented in Fig. 1. A relationship between lactic acid concentration and dry weight of cells has previously been observed in a medium free from particles (Hofvendahl and Hahn-HaÈgerdal 1997b). Assuming that the bacteria produced the same amount of lactic acid per cell mass in whole-wheat ¯our medium as in ¯our-free medium, the parameters a and b in Eq. 2, describing the Table 1 Parameter values in the fermentation model under standard conditions (pH 6.0 and 30 °C) for fermentation in a particlefree medium. lmax maximum speci®c growth rate, Ks saturation parameter in Monod expression, Ki substrate inhibition parameter, Kp parameter representing pH dependence of the product inhibition, n parameter describing product inhibition, a growth-associated constant for product production, b non-growth-associated constant for product production, m maintenance energy parameter (g substrate/(g cell mass á h)). Parameter )1 lmax (h ) Ks (g l)1) Ki (g l)1) Kp (l g)1) n a b (h)1) m (g g)1 h)1) Value 0.403 0.790 164 1.60 ´ 10)2 2.06 13.2 6.45 ´ 10)2 3.70 ´ 10)3 685 conditions and the corresponding results are summarised in Table 2. In all fermentation experiments the molar amount of carbon dioxide produced was two to three orders of magnitude lower than the amounts of the other by-products measured (data not shown). The data used for modelling were adjusted for dilution caused by NaOH addition required to maintain a stable pH. However, all concentrations given in text and tables are the concentrations prevailing in the fermentor. Fig. 1 Experimental and simulated data for a fermentation in ¯ourfree medium at pH 6, 30 °C. Experimental data for lactic acid (m), glucose (j) and cell mass (d), and simulated results for lactic acid, glucose and cell mass (б). The experimental data have been adjusted for dilution due to NaOH addition In¯uence of glucose inhibition, lactic acid inhibition and pH on the kinetics relationship between the growth rate and the product formation rate, were set to the same values for fermentation experiments in a whole-wheat ¯our medium as those in the ¯our-free medium. In all subsequent fermentation experiments one of the whole-wheat ¯our media, hydrolysed ¯our or supplemented ¯our, was used. Fermentation experiments were carried out under dierent physical conditions in supplemented ¯our medium. To control the sugar concentration, dierent amounts of glucose were added, and the whole-wheat ¯our contributed nutrients. However, a sudden change in glucose consumption and lactic acid production rates was observed in all fermentation experiments. Therefore, some of the fermentation experiments were repeated in hydrolysed ¯our, since previous observations have indicated that nutrients were released during the enzymatic hydrolysis of whole-wheat ¯our (Hofvendahl and Hahn-HaÈgerdal 1997a, b). The experimental data were used to determine the parameters in the kinetic model. Unless otherwise stated, the pH was 6.0 and the temperature 30 °C (standard conditions). The physical The eect of glucose and lactic acid inhibition was investigated by varying the initial glucose concentration between 44 g l)1 and 182 g l)1 resulting in lactic acid concentrations up to 86 g l)1 (Fig. 2). In one fermentation in supplemented ¯our medium, 35 g l)1 lactic acid was added 12 h after inoculation (Fig. 2A). The in¯uence of pH was investigated in fermentation experiments at pH 6.0, 5.0 and 4.0 in hydrolysed ¯our medium (Fig. 2B±D) and in supplemented ¯our medium (data not shown). The maximal volumetric lactic acid productivity increased with decreasing initial glucose concentration and was considerably inhibited at lower pH values (Table 2). However, the productivities of lactic acid and by-products decreased throughout the whole fermentation process. When 35 g l)1 lactic acid was added 12 h after inoculation (Fig. 2A), the lactic acid productivity decreased from 2.1 g l)1 h)1 to 0.40 g l)1 h)1. No glucose consumption or lactic acid production was observed when 80 g l)1 lactic acid was present from the start of the fermentation (data not shown). The lactic acid concentration at the end of the exponential phase decreased with decreasing pH, but increasing the initial glucose concentration from about 80 g l)1 to about 170 g l)1 did not result in signi®cantly higher lactic acid concentrations at the end of the exponential phase (Table 2). Table 2 Results of fermentation experiments in whole-wheat ¯our media. Std standard conditions, Glc glucose, Temp temperature, LA lactic acid, LA add 35 g/l LA added after 12 h, Hydr hydrolysed ¯our medium, Suppl supplemented ¯our medium, LA prod LA produced, end expon at the end of the exponential phase, Q maximal volumetric LA productivity Variable Medium pH Temp (°C) Glucose initial (g l)1) Cell mass initial (mg l)1) LA prod (end expon) (g l)1) L-LA (end expon) (% of total LA) Q (g l)1 h)1) Std Glc Glc, pH Hydr Hydr Hydr Hydr Hydr Suppl Suppl Suppl Suppl Suppl Suppl 6.0 6.0 5.0 5.0 4.0 6.0 6.0 6.0 6.0 6.0 6.0 30 30 30 30 30 30 30 33.5 37 40 30 182 79 174 85 170 47 72 44 40 43 44 11 6 12 3 3 20 10 15 17 20 13 86 70 20 21 7 39 49 50 31 32 42 99 99 99 96 97 99 98 90 96 82 99a 2.9 4.0 0.42 0.83 0.23 2.2 2.1 2.8 2.3 1.5 2.1 pH Std Glc Temp LA add a Before lactic acid addition 686 Table 3 Parameter values in the fermentation model under standard conditions (pH 6.0 and 30 °C) for fermentation experiments in hydrolysed ¯our and supplemented ¯our media parameters as in Table 1 Parameter Value )1 Ks (g l ) Ki (g l)1) n a b (h)1) m (g g)1 h)1) 0.790 164 2.36 13.2 6.45 ´ 10)2 6.78 ´ 10)3 Experimental data from Fig. 2B±D were used to determine the parameters for growth, glucose and lactic acid inhibition, and to determine how these parameters were in¯uenced by pH. Thus, Ks, Ki, n, m, lm, kl1, kl2, Kpm, kp1 and kp2 were determined by minimising the objective function X X Q2 Pcalc ÿ Pexp 2 Sg;calc ÿ Sg;exp 2 10 using the values of a and b in Table 1 exp and calc represent experimental and simulated data, respectively. The parameter values are summarised in Tables 3 and 4. In¯uence of temperature on the kinetics Fig. 2A±D Experimental and simulated data for fermentation experiments at 30 °C, performed in supplemented ¯our medium (A) and hydrolysed ¯our medium (B±D); pH 6 with and without 40 g l)1 lactic acid added after 12 h (A), pH 6 in high and low concentrations of ¯our (B), pH 5 in high and low concentrations of ¯our (C) and pH 4 (D). The experimental data are for lactic acid (m, n) and glucose (j, h). Simulated results are represented by lines. j±j, m±m No lactic acid added (A) and high concentrations of ¯our (B±D); h- - -h, n- - -n lactic acid added (A) and low concentrations of ¯our (B±C). The experimental data are adjusted for dilution due to NaOH addition The initial glucose concentration did not in¯uence which isomer of lactic acid that was produced at pH 6 (Table 2). However, at pH 5 a lower initial glucose concentration resulted in increased D-lactic acid formation. At initial glucose concentrations of around 40, 80 or 180 g l)1, a lower pH increased D-lactic acid formation. In supplemented ¯our medium, where maltose was present, the D-lactic acid content, 42% and 10% of total amount of lactic acid, at pH 4 and 5, was higher than in hydrolysed ¯our medium (Table 2). By-product formation was not observed in the hydrolysed ¯our medium (Fig. 2B±D), whereas in the supplemented ¯our medium (Fig. 2A) a slight increase in acetic acid and ethanol, and in some cases formic acid, was observed. The by-product formation increased with decreasing pH (data not shown). The in¯uence of temperature on product formation was investigated between 30 °C and 40 °C in fermentation experiments in supplemented ¯our medium (Fig. 3, 4). The maximal volumetric lactic acid productivity was highest at 33.5 °C: 2.8 g l)1 h)1. At 33.5 °C and above, lactic acid formation decreased and the formation of equimolar amounts of acetic acid and ethanol increased (Fig. 4). In addition, a number of unidenti®ed compounds were detected in the chromatograms. Formic acid production, on the other hand, decreased with increasing temperature, and diminished as the fermentation continued. At higher temperatures, more of the lactic acid produced was in the D form (Table 2). When 20 g l)1 glucose was consumed, the rates of glucose consumption and lactic acid production decreased suddenly, e.g. Fig. 3A at 10 h. At this point, the maltose liberated by starch degradation diminished, and the maltose concentration remained constant at around 10 g l)1. Maltose was consumed when the glucose concentration became suciently low: 5 g l)1; see, for example, Fig. 3A at 27 h. Maltose was not modelled Table 4 Parameter values in the expression for the pH dependence of lmax and Kp in hydrolysed ¯our medium (Eqs. 6, 7) lmax lm (h)1) kl1 (M) kl2 (M)1) Kp 1.10 9.42 ´ 10)7 1.27 ´ 105 Kpm (l g)1) kp1 (M) kp2 (M)1) 0.154 1.02 ´ 10)5 3.82 ´ 104 687 Fig. 3A±D Experimental data and simulations of fermentation experiments at pH 6, performed at 30 °C (A), 33.5 °C (B), 37 °C (C), and 40 °C (D). Symbols as in Fig. 1; experimental data for maltose (r) and simulated results using two (±±) and one ( ) value of lmax. The experimental data have been adjusted for dilution due to NaOH addition because, in an industrial process, the whole-wheat ¯our is either totally hydrolysed to glucose prior to fermentation (hydrolysed ¯our medium), or sacchari®cation and fermentation are performed simultaneously, resulting in the continuous production of glucose by starch hydrolysis. Thus, only experimental data obtained at glucose concentrations higher than 5 g l)1 were used to ®t the model for fermentaiton in supplemented ¯our medium. The objective function Q2 was minimised using the experimental data shown in Fig. 3A±C and 4A±C, and assuming that Ks, Ki, Kpm, kp1, kp2, n and m had the same values as when modelled for fermentation under standard conditions (Tables 3, 4). The parameter Ypa, as well as the temperature dependence of a, b, aa, ba and kst, was determined and A1, A2, E1 and E2 are presented in Table 5. No stoichiometric value was used for Ypa since it accounts for all by-products formed, and not only the acetic acid. To account for the sudden change in productivity after 20 g l)1 glucose had been consumed, dierent values of lmax were determined before and after the drop (Table 5). Fig. 4A±D Production of acetic acid, ethanol and formic acid. A±D as in Fig. 3. Experimental data for acetic acid (´), ethanol (s) formic acid (+) and simulated results for acetic acid (Ð). The experimental data have been adjusted for dilution due to NaOH addition Table 5 Parameter values in the expression for the temperature dependence of the parameters a, b, aa, ba and kst and values of the parameters Ypa, lmax, before and lmax, after in supplemented ¯our medium. aa growth-associated constant for by-product formation, ba non-growth-associated constant for by-product formation, kst empirical starch degradation parameter, Ypa by-product yield coecient (g by-product/g substrate), before/after before or after drop in product formation rate. Parameters as in Table 1 Parameter A1 A2 E1 E2 a b (h)1) aa ba (h)1) kst (h)1) Ypa (g g)1) lmax, before (h)1) lmax, after (h)1) 287 1.77 2.88 2.97 ´ 10±2 7.52 ´ 10±2 0.169 0.525 0.216 8.88 ´ 103 76.9 82.4 53.9 543 151 376 0.590 343 Comparison of simulation and experimental data Parameter values for Ks, Ki, n and m (Table 3) and all parameter values summarised in Tables 4 and 5 were used for simulations. The resulting curves are shown in Fig. 2±4, together with the experimental data. To illustrate the dierence between using one or two values of 688 lmax in supplemented ¯our medium, simulations were also performed using only lmax, before (Table 5), shown in Fig. 3A±C. The model was veri®ed by simulating data from fermentation experiments not used for model parameter determination, e.g. those in Fig. 2A. The model showed that both substrate and product inhibition are present, the latter being dominant. The simulated maximum speci®c growth rate, lmax, was highest at pH 6.0: 0.53 h)1, in agreement with the observed lactic acid productivity in the hydrolysed ¯our medium (Table 2). Simulating the temperature dependence of a, b, aa and ba con®rmed that maximum lactic acid productivity occurred 33.5 °C (Table 2) and the increase in acetic acid formation at higher temperatures (Fig. 4). In addition, the simulations showed that glucose formation due to starch degradation was highest at 35 °C. Discussion The model developed in the present study describes statisfactorily the kinetics of lactic acid fermentation in whole-wheat ¯our medium with L. lactis 19435. The model was veri®ed by simulating data from fermentation experiments not used for model parameter determination (e.g. Fig. 2A). It could be observed that simulated data ®t experimental data satisfactorily except after lactic acid addition. This could be due to the fact that lactic acid added to the fermentation and lactic acid produced from the bacteria do not inhibit the cell growth to the same extent. The values of the model parameters are speci®c for this bacterial strain. This model considers the eect of both product and substrate inhibition on the kinetics, while models presented previously often consider the eect of product inhibition only (Yeh et al. 1991; Cachon and DivieÁs 1994; Gadgil and Venkatesh 1997). A number of models have been presented that include the in¯uence of pH (Yeh et al. 1991; Venkatesh et al. 1993; Cachon and DivieÁs 1994; Gadgil and Venkatesh 1997). Few models consider the eect of temperature on the kinetics (Rincon et al. 1993), whereas the model developed in this study includes both pH and temperature. In addition, the acetate formation rate was included as a measure of the total formation of by-products. Similar expressions for by-product formation have not been presented before. The value of the parameter a in Eq. 2 was found to be much higher than b (13.2 compared with 0.064 h)1) indicating that the production of lactic acid was growthassociated. The parameter m, in Eq. 5, representing the maintenance energy, was higher for the ¯our media than for the ¯our-free medium containing, among other things, yeast extract and tryptone. Thus, in the ¯our media more glucose was used for products besides cell mass, lactic and acetic acid, than was used in the ¯ourfree medium. The model is not valid when all substrate has been consumed. Because of the non-growth-associated term in Eq. 2 (báX) the simulation results in an increase of the product concentration, although the substrate concentration, and thus the cell growth rate, is zero. The sudden change in product formation rate observed in supplemented ¯our medium did not occur in the fermentation of hydrolysed ¯our medium. The drop in product formation rate in the supplemented ¯our medium may be due to nutrient limitation, and indicates that nutrients are released from the ¯our during enzymatic hydrolysis, in accordance with previous studies (Hofvendahl and Hahn-HaÈgerdal 1997a, b), as well as with work in progress. The value of lmax for fermentation in hydrolysed ¯our medium was the same (0.53 h)1) as for the supplemented ¯our medium before the drop in product formation rate. It could be observed that simulations in supplemented ¯our medium using only this value of lmax did not ®t experimental data well, and therefore two values of lmax were used (Fig. 3A±C). For L. delbrueckii, susbtrate inhibition is of major importance (GoncËalves et al. 1991), and both experimental data and simulations of L. lactis 19435 showed that substrate inhibition is of importance in the glucose concentration interval investigated: 40±82 g l)1. For example, at an initial glucose concentration of 100 g l)1 the cell growth rate decreased by 37% compared with fermentation without substrate inhibition. Lactic acid concentrations above 70 g l)1 and 110 g l)1 inhibited the growth of Streptococcus cremoris (Bibal et al. 1988) and Lactobacillus plantarum (Giraud et al. 1991). Simulations showed that the growth of L. lactis 19435 was totally inhibited by 74, 16 and 32 g l)1 lactic acid in hydrolysed ¯our medium at pH 6, 5 and 4 respectively. When modelling, it was observed that this inhibition could not be related to the concentration of the undissociated acid alone. Neither could the inhibition be accounted for by the total concentration of lactic acid. Thus, it was concluded that both the undissociated and the dissociated forms of lactic acid contributed to the inhibition. This has also been reported for L. bulgaricus and L. rhamnosus growing on lactose and glucose, respectively (Venkatesh et al. 1993; GoncËalves et al. 1997). Growth of lactic acid bacteria is notably slower below a certain pH: pH 5 for Lactococci (Nannen and Hutkins 1991; Cachon and DivieÁs 1994) and pH 3.4 for L. plantarum (Giraud et al. 1991). The present study showed that the maximum speci®c growth rate, lmax, of L. lactis 19435 in hydrolysed ¯our medium was only slightly higher at pH 6 than at pH 5: 0.53 and 0.47 h)1 respectively. However, since the eect of product inhibition was much greater at pH 5 than at pH 6: Kp 0.064 l g)1 and 0.014 l g)1 respectively, the product formation rate was substantially lower at pH 5. At pH 4, lmax was much lower, 0.080 h)1, than at the higher pH values, causing the lowest product formation rate. Simulations showed that 32 g l)1 lactic acid inhibited cell growth completely at pH 4. However, since this concentration was never reached and total inhibition of cell growth was not observed in fermentation at pH 4 in this study, this value is dicult to verify. 689 L. lactis switches from homolactic to mixed-acid fermentation when grown under glucose-limited conditions (Fordyce et al. 1984; SjoÈberg et al. 1995) or when grown on galactose or lactose (Thomas et al. 1980; Garrigues et al. 1997), or maltose (Lohmeier-Vogel et al. 1986; Qian et al. 1994; Hofvendahl and Hahn-HaÈgerdal 1997b). In mixed-acid fermentation, pyruvate is metabolised into lactic acid, ethanol, acetic acid and either formic acid or carbon dioxide (Fordyce et al. 1984). In the present study, maltose was only present in the supplemented ¯our medium and consumption only started when the glucose concentration had decreased to 5 g l)1, in accordance with previous observations (Qian et al. 1997; Hofvendahl and Hahn-HaÈgerdal 1997b). This resulted in mixed-acid fermentation, with lactic acid being the major product, and formic acid, acetic acid and ethanol being by-products. The present study showed that temperatures above 30 °C and pH levels below 6 also enhanced by-product formation in supplemented ¯our medium. When the temperature was increased, only acetic acid and ethanol formation increased in equimolar amounts, whereas the amount of formic acid decreased with increasing fermentation time. Carbon dioxide formation was two to three orders of magnitude lower than acetic acid and ethanol formation, con®rming that carbon dioxide is only produced under aerobic conditions (Cocaign-Bousquet et al. 1996). Pyruvate may still be metabolised to formic acid, acetic acid and ethanol, but the detection of formic acid may be masked by compounds produced in higher concentrations at higher temperatures. A change from the formation of almost exclusively Llactic acid to a higher proportion of D-lactic acid was seen at pH 4 and 5, as well as at 33.5±40 °C, resulting in 3%±42% of the lactic acid being in the D-form. Similar observations were made when L. lactis 19345 was grown without pH control (Hofvendahl and Hahn-HaÈgerdal 1997a) and for L. casei (HjoÈrleifsdottir et al. 1990) and L. plantatrum (Bobillo and Marshall 1992), when grown under starvation conditions or at acidic pH. It has been suggested that this is because the enzymes D- and L-lactate dehydrogenase have dierent pH optima (Mou et al. 1972; Gordon and Doelle 1975; Bobillo and Marshall 1992), or that L-lactate dehydrogenase exclusively is activated by fructose 1,6-bisphosphate (Mou et al. 1972). However, the latter would imply that the mixed-acid formation observed under carbon limitation should also result in enhanced D-lactic acid formation, and this has so far not been observed. In Escherichia coli, for example, D-lactic acid can be formed from dihydroxyacetone phosphate via methylglyoxal (Cooper 1984), and this pathway might be present in L. lactis as well. The in¯uence of temperature on lactic acid production has not been widely investigated. Earlier studies on L. lactis have mainly been concerned with the in¯uence of temperature on proteolytic activity and diacetyl formation (de Giori et al. 1985, 1986). The experimental data obtained and the model developed in the present study showed that lactic acid productivity was optimal between 33 °C and 35 °C. However, D-lactic acid and by-product formation increased at temperatures above 30 °C, which would increase the cost of puri®cation. To simulate the simultaneous sacchari®cation of starch to glucose and further fermentation to lactic acid, the model developed in this study will be combined with a kinetic model for the enzymatic sacchari®cation of wheat starch. The model will be used to determine optimal operating conditions and to determine whether sacchari®cation and fermentation should be performed simultaneously or separately. Acknowledgements We wish to thank Prof. A. H. Stouthamer for his advice, and Elahe Behtoye and Daniel Kronhall for technical assistance. This work was supported by the Swedish National Board for Industrial and Technical Development. References Atkinson B, Mavituna F (1991) Industrial microbial processes. In: Atkinson B, Mavituna F (eds) Biochemical engineering and biotechnology handbook, 2nd edn. Macmillan, New York, pp 1181±1183 Bibal B, Goma G, Vassier Y, Pareilleux A (1988) In¯uence of pH, lactose and lactic acid on the growth of Streptococcus cremoris: a kinetic study. Appl Microbiol Biotechnol 28: 340±344 Bobillo M, Marshall VM (1992) Eect of acidic pH and salt on acid end-products by Lactobacillus plantarum in aerated, glucoselimited continous culture. J Appl Bacteriol 73: 67±70 Cachon R, DivieÁs C (1994) Generalized model of the eect of pH on lactate fermentation and citrate bioconversion in Lactococcus lactis ssp. lactis biovar. diacetylactis. Appl Microbiol Biotechnol 41: 694±699 Cocaign-Bousquet M, Garrigues C, Loubiere P, Lindley ND (1996) Physiology of pyruvate metabolism in Lactococcus lactis. Antonie Van Leeuwenhoek 70: 253±267 Cooper RA (1984) Metabolism of methylglyoxal in microorganisms. Annu Rev Microbiol 38: 49±68 Evangelista RL, Mangold AJ, Nikolov ZL (1994) Recovery of lactic acid by sorption: Resin evaluation. Appl Biochem Biotechnol 45/46: 131±144 Expert Committee on Food Additives (1967) Lactic acid. WHO Food Addit Ser 29: 144-148 Fordyce AM, Crow VL, Thomas TD (1984) Regulation of product formation during glucose or lactose limitation in nongrowing cells of Streptococcus lactis. Appl Environ Microbiol 48: 332±337 Gadgil CJ, Venkatesh KV (1997) Structured model for batch culture growth of Lactobacillus bulgaricus. J Chem Technol Biotechnol 68: 89±93 Garrigues C, Loubiere P, Lindley ND, Cocaign-Bousquet M (1997) Control of shift from homolactic acid to mixed-acid fermentation in Lactococcus lactis: predominant role of the NADH/ NAD+ ratio. J Bacteriol 179: 5282±5287 Giori GS de, Valdez GF de, Ruiz Holgado AP de, Oliver G (1985) Eect of pH and temperature on the proteolytic activity of lactic acid bacteria. J Dairy Sci 68: 2160±2164 Giori GS de, Valdes GF de, Ruiz Holgado AP de, Oliver G (1986) Eect of pH and temperature on diacetyl production by lactic acid bacteria. Milchwissenschaft 41: 80±81 Giraud E, Lelong B, Raimbault M (1991) In¯uence of pH and initial lactate concentration on the growth of Lactobacillus plantarum. Appl Microbiol Biotechnol 36: 96±99 GoncËalves LMD, Xavier AMRB, Almieda JS, Carrondo MJT (1991) Concomitant substrate and product inhibition kinetics in lactic acid production. Enzyme Microb Technol 13: 314±319 GoncËalves LMD, Ramos A, Almeida JS, Xavier AMRB, Carrondo MJT (1997) Elucidation of the mechanism of lactic acid growth 690 inhibition and production in batch cultures of Lactobacillus rhamnosus. Appl Microbiol Biotechnol 48: 346±350 Gordon GL, Doelle HW (1975) Production of racemic lactic acid in Pediococcus cerevisae cultures by two lactate dehydrogenases. J Bacteriol 121: 600±607 HjoÈrleifsdottir S, Seevaratnam S, Holst O, Mattiasson B (1990) Eects of complete cell recycling on product formation by Lactobacillus casei ssp. rhamnosus in continuous cultures. Curr Microbiol 20: 287±292 Hofvendahl K, Hahn-HaÈgerdal B (1997a) L-lactic acid production from whole wheat ¯our hydrolysate using strains of Lactobacilli and Lactococci. Enzyme Microb Technol 20: 301±307 Hofvendahl K, Hahn-HaÈgerdal B (1997b) The eect of nutrients and a-amylase inactivation on the fermentative lactic acid production in whole wheat ¯our hydrolysate by Lactococcus lactis ssp. lactis ATCC 19435. In: Campbell GM, Webb C, McKee SL (eds) Cereals: novel uses and processes. Plenum, New York, NY, pp 219±227 Kharas GB, Sanchez-Riera F, Severson DK (1994) Polymers of lactic acid. In: Mobley DP (ed) Plastics from microbes: microbial synthesis of polymers and polymer precursors. Hanser, Munich, pp 93±137 Lipinsky ES, Sinclair RG (1986) Is lactic acid a commodity chemical? Chem Eng Progr 82: 26±32 Lohmeier-Vogel EM, Hahn-HaÈgerdal B, Vogel HJ (1986) Phosphorus-31 NMR studies of maltose and glucose metabolism in Streptococcus lactis. Appl Microbiol Biotechnol 25: 43±51 Luedeking R, Piret EL (1959) Transient and steady state in continuous fermentation. Theory and experiment. J Biochem Microbiol Technol Eng 1: 431±450 Mercier P, Yerushalmi L, Rouleau D, Dochain D (1992) Kinetics of lactic acid fermentation on glucose and corn by Lactobacillus amylophilus. J Chem Technol Biotechnol 55: 111±121 Mou L, Mulvena DP, Jonas HA, Jago GR (1972) Puri®cation and properties of nicotinamide adenine dinucleotide-dependent Dand L-lactate dehydrogenases in a group N Streptococcus. J Bacteriol 111: 392±396 Nannen NN, Hutkins RW (1991) Intracellular pH eects in lactic acid bacteria. J Dairy Sci 74: 741±746 Parente E, Ricciardi A, Addario G (1994) In¯uence of pH on growth and bacteriocin production by Lactococcus lactis subsp. lactis 140NWC during batch fermentation. Appl Microbiol Biotechnol 41: 388±394 Qian N, Stanley GA, Hahn-HaÈgerdal B, RaÊdstroÈm P (1994) Puri®cation and characterisation of two phosphoglucomutases from Lactococcus lactis subsp. lactis and their regulation in maltoseand glucose-utilizing cells. J Bacteriol 176: 5304±5311 Qian N, Stanley GA, Bunte A, RaÊdstroÈm P (1997) Product formation and phosphoglucomutase activities in Lactococcus lactis: cloning and characterization of a novel phospoglucomutase gene. Microbiology 143: 855±865 Rincon J, Fuertes J, Moya A, Monteagudo JM, Rodriguez L (1993) Optimization of the fermentation of whey by Lactobacillus casei. Acta Biotechnol 13: 323±331 Sinclair CG (1989) Microbial process kinetics. In: Bu'Lock J, Kristiansen B (eds) Basic biotechnology. Academic Press, London, pp 102±103 SjoÈberg A, Persson I, Quednau M, Hahn-HaÈgerdal B (1995) The in¯uence of limiting and non-limiting growth conditions on glucose and maltose metabolism in Lactococcus lactis ssp. lactis strains. Appl Microbiol Biotechnol 42: 931±938 Thomas TD, Turner KW, Crow VL (1980) Galactose fermentation by Streptococcus cremoris: pathways, products, and regulation. J Bacteriol 144: 672±682 Venkatesh KV, Okos MR, Wankat PC (1993) Kinetic model of growth and lactic acid production from lactose by Lactobacillus bulgaricus. Process Biochem 28: 231±241 Vickroy TB (1985) Lactic acid. In: Blanch HW, Drew S, Wang DIC (eds) The practice of biotechnology: commodity products, vol 3, Pergamon Press, Elmsford, NY, pp 761±776 Yeh PL-H, Bajpai RK, Iannotti EL (1991) An improved kinetic model for lactic acid fermentation. J Ferment Bioeng 71: 75±77 Note added in proof: Further investigations showed that the Dlactic acid formation observed was not produced by L. Lactis 19435