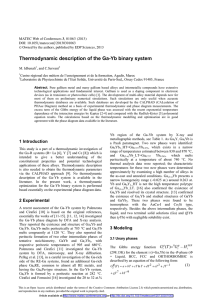

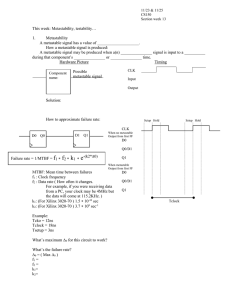

CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 Contents lists available at SciVerse ScienceDirect CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry journal homepage: www.elsevier.com/locate/calphad Thermodynamics of Ti–Ni shape memory alloys E. Povoden-Karadeniz a,n, D.C. Cirstea b, P. Lang c, T. Wojcik d, E. Kozeschnik a,d a Christian Doppler Laboratory for Early Stages of Precipitation, Institute of Materials Science and Technology, Vienna University of Technology, Favoritenstraße 9-11, 1040 Vienna, Austria b National Institute for Research and Development in Electrical Engineering INCDIE ICPE-CA, Advanced Materials Department, Splaiul Unirii, No. 313, Sector 3, Bucharest, Romania c Materials Center Leoben Forschung GmbH, Roseggerstraße 12, 8700 Leoben, Austria d Institute of Materials Science and Technology, Vienna University of Technology, Favoritenstraße 9-11, 1040 Vienna, Austria art ic l e i nf o a b s t r a c t Article history: Received 29 November 2012 Received in revised form 8 February 2013 Accepted 22 February 2013 Available online 23 March 2013 The thermodynamics of the Ti–Ni system are reviewed, and CALPHAD descriptions of metastable intermetallic phases are presented. These phases play an important role as precipitates in shape memory alloys. Metastable Ti3Ni4 and Ti2Ni3 are described as line compounds. Their thermodynamic model parameters are optimized with experimental solvus data and molar enthalpies at 0 K from new firstprinciples analysis. Best results are obtained, when the thermodynamic description of the D024-ordered TiNi3 phase is re-optimized with new thermodynamic data. This also requires adjustment of the other phase descriptions, including B2 austenite and B19′ martensite. The modifications have important consequences on the computed start temperature of the martensitic transformation, which is a crucial property for the shape memory effect. R-phase, a metastable intermediate martensite, is considered in the thermodynamic modeling. The following thermodynamic standard data for the metastable intermetallic phases are obtained at 298.15 K: ΔH1m(Ti3Ni4) ¼−34,714.5 J/mol, ΔH1m(Ti2Ni3) ¼−36,742 J/mol, ΔH1m(R-phase) ¼−35,649 J/mol, S1m(Ti3Ni4) ¼31.91 J/mol K, S1m(Ti2Ni3)¼ 29.76 J/mol K, S1m(R-phase) ¼ 27.87 J/mol K. & 2013 Elsevier Ltd. All rights reserved. Keywords: Ti3Ni4 Ti2Ni3 TiNi3 Metastable phases Shape memory 1. Introduction Ti–50Ni to Ti–55Ni (at%) can be termed as the pioneer of shape memory alloys (SMA) and a key system for studying phase transformations and precipitate evolution in shape memory alloys. Shape memory alloys are martensitic metals that “remember” the original shape of their parent modification under specific conditions of temperature and mechanical loading/unloading. The thermodynamics of the parent bcc-structured, ordered austenitic B2 phase and the monoclinic martensitic B19′ phase are well understood. In order to improve shape memory and mechanical properties, SMA are usually aged at temperatures where precipitation of second phases from the supersaturated B2-ordered matrix occurs. These phases are Ti3Ni4, Ti2Ni3 and the thermodynamically stable TiNi3 (η–) phase. In particular, Ti3Ni4 plays an important role for martensite formation. The martensite start temperature, Ms, is strongly influenced by changes of plastic deformation limits associated with precipitation hardening and the change of the matrix composition due to precipitation [1–8]. For instance, an n Corresponding author. Tel.: þ 43 6763352362. E-mail address: erwin.povoden-karadeniz@tuwien.ac.at (E. Povoden-Karadeniz). 0364-5916/$ - see front matter & 2013 Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.calphad.2013.02.004 increase of the martensite start temperature of approximately 30 K was reported due to aging of Ti–50.7 at% Ni [2]. Recently, the fatigue failure of Ti–Ni SMA was related to the occurrence of TiNi3 [9]. State-of-the-art precipitation simulation utilizes the thermodynamics of precipitates and matrix phase in the evolution equations [10]. In order to evaluate the effects of precipitation, thermodynamic descriptions of the precipitating phases are thus required. Whereas the equilibrium thermodynamics of the Ti–Ni system have been studied extensively [11–14], CALPHAD descriptions of the metastable intermetallic phases Ti3Ni4 and Ti2Ni3 are missing. Gibbs energy polynomials of metastable Ti3Ni4 and Ti2Ni3 have not been published yet. The only Gibbs energy data are available from Zhou et al. [15] and Guo et al. [16]. Both studies derived the Gibbs energy of Ti3Ni4 simply from tangent construction and did not compare their results with other thermodynamic and phase diagram data. Zhou et al. [15] did not consider temperature-dependence, and Guo et al. [16] neglected heat capacity in their formulation. In the present work, temperaturedependent Gibbs energy polynomials (in this paper, temperatures are consistently given in Kelvin) of Ti3Ni4 and Ti2Ni3 are assessed with first-principles thermodynamic data and metastable solvi information. Metastability of Ti3Ni4 and Ti2Ni3 from the solvus to room temperature is taken into account. E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 2. Nature, structures and thermodynamics of Ti3Ni4 and Ti2Ni3 2.1. Nature and phase compositions of metastable phases in Ti–Ni The discovery of metastable phases that occurred during aging of Ti–Ni SMA dates back to the early seventies of the last century, when Wasilewski et al. [17] identified Ti2Ni3 with X-ray diffraction and X-ray probe micro-analyzing. Koskimaki et al. [18] detected another intermetallic platelet phase in aged Ti–54.4 at% Ni, which they called “x-phase”, by using electron microscopy. During that time, the nature of phase relations among the new intermetallic phases was not clear. This situation was changed by the accurate experimental work of Nishida et al. [19]. These authors uncovered the composition of “x-phase”, being Ti3Ni4 with energy dispersive X-ray spectroscopy and found that Ti3Ni4 and Ti2Ni3 were essentially line compounds. Moreover, they understood that Ti3Ni4 and Ti2Ni3 would be intermediate phases in the B2-structured Ti–Nimatrix evolving towards the B2 þTiNi3 equilibrium. 2.2. Structure The structure of Ti3Ni4 was deciphered by Tadaki et al. [20]. The phase is rhombohedral and has the space group R-3. The suggested atomic positions were later refined by Tirry et al. [21] using least-squares optimization of diffracted beam intensities from transmission electron microscopy. The preference of the refined structure in terms of energy was confirmed by Density Functional Theory (DFT) calculations by the same authors and later by Wagner and Windl [22]. Ti2Ni3 is orthorhombic at low temperatures (Ti2Ni3_L) and tetragonal at high temperatures [23]. Hara et al. [24] analyzed X-ray diffractograms of aged Ti–52.0 at% Ni during heating from 298 K and 373 K and determined space group, lattice parameters and atomic coordinates. From the change of lattice parameters, a transition temperature near room temperature was proposed. In Table 1, structural properties of Ti3Ni4 and Ti2Ni3 are summarized. 2.3. Phase diagram data The thermodynamic stabilities of Ti3Ni4 and Ti2Ni3 are reflected by their metastable solvi. In a solution-treated and quenched Ti–Ni SMA, a metastable precipitate does not form above its metastable solvus temperature at any ageing time. In computational thermodynamics, the thermodynamic solvus of a metastable phase (here denoted as “metastable solvus”) is simply obtained by suppressing the stable phase. Then, the phase boundaries of the “next-stable” phase can be calculated, providing that its Gibbs energy is defined. In the real case of a continuous heating experiment after solution treatment and quenching of an alloy, phases will precipitate, grow and, eventually, disappear at the kinetic solvus. The kinetic solvus temperature of small particles in an alloy matrix is always lower than the metastable solvus temperature. This is due 129 to the increase of the Gibbs energy of precipitates by contributions of the interfacial energy, and, in the case of coherency, strain field around the particles. Keeping in mind this constraint, experimental solvus data help to define the thermodynamic stability of metastable phases. Nishida et al. [19] presented important experimental solvus data in terms of a time–temperature-transformation diagram of a Ti–52 at% Ni alloy. Concluding from his work, the kinetic solvi of Ti3Ni4 and Ti2Ni3 are situated at approximately 1023 K and 930 K, respectively. Pelton et al. [26] reported dissolution of Ti3Ni4 between 773 K and 873 K in Ti–50.8 at% Ni. Koskimaki's “x-phase”, representing Ti3Ni4, formed in Ti–54.4 at% Ni below 898 K. 2.4. Thermodynamic data Recently, Stott et al. [25] determined the enthalpy of formation of Ti3Ni4 at 0 K by first-principles analysis using the generalized gradient approximation (GGA) with projected augmented wave pseudo-potentials from Perdew, Burke and Ernzerhof (PAW-PBE) [27]. These authors obtain ΔH(Ti3Ni4), 0 K ¼ −37,629 J/mol (in the present study, energy values are consistently given for 1 mol of atoms). Hatcher [28] calculated the enthalpies of formation with full potential linearized augmented plane wave code (FLAPW) based on DFT and obtained ΔH (Ti3Ni4), 0 K ¼−45,900 J/mol. In the light of exactness of modern density functional theory-based calculations, this difference is considerably large. For Ti2Ni3, the FLAPW-derived value was the same as for Ti3Ni4. In the present study, a new dataset of molar enthalpies is produced with first-principles analysis using PAWPBE exchange correlation functional and GGA. The molar enthalpies at 0 K are compared with the results being available up to now. The analysis is also performed for the intermetallic equilibrium phases≥x(Ni) ¼0.5, in order to obtain an internally consistent comparison of the molar enthalpies of the important phases in Ti–Ni SMA. The first-principles analysis is documented in detail in the following section. First-principles analysis of Ti3Ni4 and Ti2Ni3 enthalpies. Firstprinciples calculations, based on DFT, require knowledge of the atomic species and crystal structure and yield quantities related to the electronic structure and total energy of a given structure. When the ground state electron density is known, all properties of a system are completely determined. By solving the Schrödinger equation for stoichiometric compounds and their respective constituents with given atomic structures, enthalpies of formation of compounds with respect to the constituting metals at 0 K are obtained. In the present study, the plane wave pseudo-potential method of the Vienna Ab initio Simulation Package (VASP, version 5.2) [29–32] with GGA PAW-PBE is used for the calculations. The crystal structures with their phase-specific atomic sites, as given in the Appendix of this paper, are used in the model. For all the structures investigated, energy and equivalent k-point meshes 20 20 20 are utilized to obtain the required energy Table 1 Crystal structures of Ti3Ni4 and Ti2Ni3. Phase Structure Space group Ti3Ni4 Rhombohedral Rhombohedral Rhombohedral Rhombohedral R-3 R-3 R-3 R-3 Ti2Ni3_L Orthorhombic Bbmm Ti2Ni3 Tetragonal I4/mmm Lattice parameters, nm Unit cell angles Method Reference a ¼0.6684 a ¼0.66697 a ¼0.6718 a ¼0.671 α ¼ 113.93 α ¼ 113.84 α ¼ 113.97 α ¼ 113.883 Exp. DFT DFT DFT Exp. Tadaki et al. [20] Stott et al. [25] Tirry et al. [21] Wagner andWindl [22] Khalil-Allafi et al. [3] a ¼0.43985, b ¼ 0.43705, c¼ 1.35442 Exp. Hara et al. [24] a ¼0.30954, c ¼ 1.35852 Exp. Hara et al. [24] 130 E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 convergences. This limits the uncertainty to 0.01 eV. The default energy cutoff (ENMAX) values for Ni and for Ti, as stored in the VASP-file POTCAR, are ENMAX(Ti) ¼222.338 eV and ENMAX(Ni) ¼ 367.945 eV. These are the recommended cutoff energies for d-elements, where semi-core p states are treated as valence states. In the VASP calculations, the maximum cutoff energy, ENMAX(Ni) ¼ 367.945 eV is used. Gaussian smearing with a smearing width of 0.1 eV was used. All calculations are fully relaxed with respect to volume and cell coordinates. For the evaluations of ΔHf of Ti3Ni4 and Ti2Ni3, the structural data listed in Table 1 are used. Positions of atoms in the Ti3Ni4 unit cell are taken from Tadaki et al. [20]. For Ti2Ni3, these are evaluated with the program VESTA [33], based on the structural data from Hara et al. [24]. Atomic positions are listed in the Appendix of this paper. The resulting unit cell geometry of Ti3Ni4 is visualized in Fig. 1. Fig. 2 shows the crystallographic unit cell for the high-temperature tetragonal modification of Ti2Ni3 and the low-temperature orthorhombic modification of Ti2Ni3_L, respectively. 3. Thermodynamic modeling and optimization 3.1. Modifications of previous thermodynamic descriptions Experimental phase equilibria [17,34–47], calorimetric studies [48–53] and activity measurements [54–56] delivered a sufficient number of data for the CALPHAD assessment of thermodynamic model parameters of the Gibbs energy polynomials of stable phases. Phase diagram data of Ti2Ni, TiNi-B2 and TiNi3 are well reproduced by the thermodynamic assessments [11–14]. Nevertheless, in the present study, the parameters of the thermodynamic description of D024-ordered TiNi3 are re-optimized. In particular, it is found that with previous assessments the agreement between CALPHAD-optimized and DFT (density functional theory)-based molar enthalpies is not sufficiently close in the light of modern first-principles data accuracy, the difference being as high as 10 kJ/mol. All optimizations of thermodynamic parameters in this study were performed using the PARROT module of the ThermoCalc [57] software, version S. PARROT minimizes the sum of squared errors between thermodynamic input data and Fig. 2. Unit cell geometry normal to crystallographic b of tetragonal Ti2Ni3 (a) and orthorhombic Ti2Ni3_L (b) based on evaluated positions of atoms. -30 Hf, kJ/mol of atoms -35 De Keyzer09 [14] Bellen96 [11] Matsumoto05 [12] -40 this w -45 1st-princ. -50 [25] GGA [78] LMTO-ASA [78] FP-LMTO this work, GGA -55 -60 0 Fig. 1. Unit cell [111]-direction. geometry of Ti3Ni4, shown along the crystallographic ork 500 [58] direct synth. cal. [58] heat content [59] solution cal. [49] cal. [51] direct synth. cal. 1000 1500 Temperature, K 2000 Fig. 3. Re-assessed enthalpy of formation of TiNi3 compared with experimental data, first-principles results and previous assessments. LMTO-ASA¼ linear-muffintin-orbital-atomic sphere approximation. FP ¼full-potential. E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 assessment results. The assessment procedure includes the possibility of weighing input data for the optimization. If one tries a better fit of the first-principles results, i.e. strong weight of these data in the optimization, the metastable phases will become stable at low temperatures. This, however, is in disagreement with the experimental observations. As we prefer the newest experimental enthalpies of formation (Fig. 3) from direct synthesis calorimetry [58] and solution calorimetry [59] for the parameter optimization of TiNi3 and experimental heat capacity data (Fig. 4) from Onderka et al. [60], TiNi3 is stabilized at low temperatures. As a consequence, the optimized thermodynamics of Ti3Ni4 and Ti2Ni3 are closer to our first-principles data, while they remain metastable. Moreover, after the re-optimization, the molar enthalpy of TiNi3 is in better agreement with first-principles results [25]. The modification of a single phase description, in fact, necessitates manipulations of all other model parameters as well, while keeping the same sublattice descriptions as used in the assessment by De Keyzer et al. [14], and by Tang et al. [13] for the martensite phase. These manipulations lead to slight deviations of transition temperatures from earlier descriptions, which are listed in Table 2. Further differences concern the liquidus and solidus and the martensite phase: In the present study, the course of liquidus and solidus is adjusted to recent experimental results [63], which are close to the early experimental work by Poole and Hume-Rothary [35], as shown in Fig. 5. This adjustment is obtained by reassessment of interaction parameters of the liquid phase and the fcc-phase. The new parameters are compared with previous assessments in Table 3. With the re-assessed descriptions of the fcc phase and the liquid phase the activities and the enthalpy of mixing remain inside the experimental scatter [50,53,54,56]. For the re-optimization of the martensite phase, recent enthalpy of formation at 0 K [64–67], the experimental decomposition temperature during slow cooling of TiNi-B2 [17] and vibrational entropy data derived from low-temperature calorimetry and inelastic neutron-scattering [68,69] are taken into account. As shown in the insert to the re-assessed equilibrium phase diagram of the Ti–Ni system, Fig. 6, the composition of the B19′ 131 phase does not depart from the composition of TiNi-B2 inside the experimental detection limits. In addition to B19′, the existence of intermediate martensite phase modifications, orthorhombic B19 [1,64] and rhombohedral R-phase [1,70], have been reported. These intermediate transformation stages are normally induced by additional alloying of third elements [71,72]. Interestingly, R-phase has also been observed in pure precipitation-hardened Ti–Ni SMA [73–77]. The intermediate martensite modifications are included in the thermodynamic Ti– Ni SMA database presented. Among the first-principles-results on their relative stabilities [65–68,78] listed in Table 4, we prefer the data from Hatcher et al. [66], who included R-Phase in the analysis of molar enthalpies. Further, reported formation temperature around 315 K during slow cooling of aged Ti–Ni SMA [77] is accounted for in the parameterization of R-phase. We obtain the following thermodynamic standard data of R-phase at 298.15 K: ΔH1m(R-phase) ¼ −35,722 J/mol, S1m(R-phase)¼ 27.6 J/mol K. Khalil-Allafi et al. [2] clearly demonstrated that R-phase formation is controlled by kinetics, involving delicate interplay between supersaturation of the Ti–Ni B2 matrix, precipitate sizes and distribution and stress fields. B19 is not found in pure Ti–Ni SMA at any temperatures. In Table 2 Assessed transition temperatures in the Ti–Ni equilibrium phase diagram. Phase transition liq o –4bcc þ Ti2Ni bcc o –4hcp þ Ti2Ni liq þTiNi-B2 o –4Ti2Ni liq o –4TiNi-B2 liq o –4TiNi-B2 þ TiNi3 liq o –4TiNi3 liq o –4TiNi3 þfcc TiNi-B2 o –4 B19' Transition temperatures (K) This work Bellen et al. [11] Matsumoto et al. [12] Tang et al. [13] 1221 1045 1250 1583 1419 1648 1559 353 1215 1040 1258 1584 1393 1653 1573 1215 1040 1258 1585 1393 1650 1576 1205 1040 1275 1580 1450 1660 1560 366 1750 45 35 u Ne 30 ma this -K nn op p’s 1700 work Temperature, K Heat capacity, J/molK atoms 40 25 20 1650 1600 15 10 5 1550 0 500 1000 1500 2000 Temperature, K Fig. 4. Calculated heat capacity of TiNi3 compared with experimental data [60-62,80] (symbols) and Neumann–Kopp's rule. 0 5 10 15 Mass percent ofTi Fig. 5. Calculated liquidus and solidus in the Ni-corner. TL and Ts denote experimental liquidus and solidus data, respectively. 132 E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 the kinetic solvi are taken into account. The resulting values of A and B are the result of a balanced weight of these input data. Model parameters C–F are governed by the temperaturedependence of excess heat capacity. The heat capacities of these metastable phases are not known. In such cases, normally Neumann–Kopp's rule is applied, and the heat capacity is equal to the weighted sum of these parameters of the metals that constitute the modeling, this is reflected when the same formation entropy as in B19′ is assumed. The re-optimized model parameters of the intermetallic equilibrium phases of the Ti–Ni system and are listed in Table 5. Table 6 summarizes experimental [49,58–60,62,80], firstprinciples [32,33,64–67,78,81–83], previously assessed [11,12,14] and re-assessed thermodynamic standard data of the intermetallic equilibrium phases of the Ti–Ni system. The experimental enthalpies of formation of TiNi3 presented in Table 6 show a considerable spread among different studies [49,58] using the same technique. The Guo and Kleppa´s value [58] was reproduced recently by solution calorimetry [59] and lies closer to first principles analysis. It is thus given a high weight in the thermodynamic parameter optimization. Accuracy of first-principles analysis increased over the last years with the improvement of pseudopotentials by Perdew, Burke and Ernzerhof (PBE) [27]. FLAPW results seem to have the same quality as first principle data with PBE. This was also observed by Herper in a thorough study in Al–Cu–Zn [84].In contrast, calculations with muffin-tin orbitals (MTO) and atomic sphere approximations (ASA) are a compromise between accuracy and computation efficiency. In the present case, LDA-results for TiNi-B2 are closer to the clalorimetric data than GGA-results. However, since TiNi-B2 is the only phase with both LDA and GGA data available, general judgment of the accuracy of GGA versus LDA data cannot be made. Table 4 First-principles results of enthalpies of formation of martensite modifications at 0 K from the literature and assessed values at 298.15 K referred to B2. 298.15 K Method Reference −1700 −1800 −7815 −4728 −4052 −4438 −5347 LMTO-ASAa FP-LMTOb DFT-GGA USPP-LDAc USPP-GGA LDA FLAPW Pasturel et al. [78] Pasturel et al. [78] Vishnu and Strachan [67] Huang et al. [64] Huang et al. [64] Ye et al. [65] Hatcher et al. [66] CALPHAD assessed This work LMTO-ASA FP-LMTO DFT-GGA USPP-LDA USPP-GGA LDA FLAPW Pasturel et al. [78] Pasturel et al. [78] Vishnu and Strachan [67] Huang et al. [64] Huang et al. [64] Ye et al. [65] Hatcher et al. [66] CALPHAD assessed This work TiNi B19' −3001 TiNi B19 þ 3600 þ 6800 −5114 −3859 −2895 −3281 −3911 3.2. Modeling of metastable phases As there are no indications for off-stoichiometry of Ti3Ni4 and Ti2Ni3, we model them as line compounds. Their Gibbs energy polynomials read −1564.3 R-Phase GTixNiy −x1H hcpðTiÞ −y1H fmccðNiÞ ¼ A þ BT þ CTlnðTÞ þ DT 2 þET 3 þ FT ð−1Þ m m f ccðNiÞ þ x1GhcpðTiÞ þ y1Gm m 0K −3275 −928.6 ð1Þ a The adjustable parameter A is optimized with molar enthalpies of formation. Simultaneously, the constraint of metastability and b c FLAPW Hatcher et al. [66] CALPHAD assessed This work LMTO-ASA¼ linear-muffin-tin-orbital-atomic sphere approximation. FP ¼ full-potential. USPP-LDA ¼ ultrasoft pseudopotentials-local-density approximation. Table 3 Assessed interaction parameters (J/mol) of the fcc-phase and the liquid phase. Order of interaction This work Bellen et al. [11] Matsumoto et al. [12] De Keyzer et al. [14] 0 −111400þ 5.66T −52046 −160000 þ38T −80000þ 18T −5000−8T þ3000 −99290.4 þ 6.21142T −59449.5 Ref. [12] Ref. [12] Ref. [12] Ref. [12] −130333.64 þ20.22423T −46714.31 −153707þ34.8594T −81824.8þ 25.8099T −10.0779T 0 −97427þ 12.112T −32315 Ref. [12] Ref. [12] Ref. [12] Ref. [12] L(fcc) L(fcc) 0 L(liquid) 1 L(liquid) 2 L(liquid) 3 L(liquid) 1 2000 1800 1648 1583 liquid 1559 1400 fcc 1200 354.0 B2 1419 TiNi3 1250 1221 bcc 1045 TiNi3+B2 B2+Ti2Ni TiNi3+B19' B19'+Ti2Ni 1000 353.0 800 Ti2Ni+hcp 600 400 353 200 0 0.2 0.4 B19' Temperature, K 1600 0.6 0.8 1.0 352.0 0.4995 0.5000 Mole fractionTi Fig. 6. Calculated equilibrium phase diagram of the Ti–Ni system. 0.5005 Table 5 Assessed model parameters of the intermetallic equilibrium phases. Matsumoto et al. [12] De Keyzer et al. [14] This work Tang et al. [13] Sublattice description Model type (Ni,Ti)0.5(Ni,Ti)0.5 (Ni,Va)0.5 (Ni,Ti)0.5 Ref. [11] (Ni,Ti)0.5(Ni,Ti)0.5 bcc-based split Solid solution Ref. [11] bcc-based split Ni:Ni Ni:Ti 0 −33193.7 þ10.284T Ref. [11] Ref. [11] 0 −31000þ 11T Ti:Ni Ti:Ti Va:Ni −33193.7 þ10.284T 0 – Ref. [11] Ref. [11] – −31000þ 11T 0 – −50100þ30T 0 – Va:Ti Va:Va Ni:Va Ti:Va 0 L Ni,Ti:Ni 0 L Ni:Ni,Ti 1 L Ni,Ti:Ni 1 L Ni:Ni,Ti 2 L Ni,Ti:Ni 2 L Ni:Ni,Ti 0 L Ti:Ni,Ti 0 L Ni,Ti:Ti 1 L Ti:Ni,Ti 1 L Ni,Ti:Ti 0 L Va:Ni,Ti 1 L Va:Ni,Ti 0 L Ni,Va:Ni 0 L Ni,Va:Ti 0 L Ti:Ni,Va 0 L Va:Ni,Ti 1 L Va:Ni,Ti – – – – þ 55288.8 þ 25.4416T þ 55288.8 þ 25.4416T – – þ 6010.11þ 3.95974T þ 6010.11þ 3.95974T þ 60723.7−15.4024T þ 60723.7−15.4024T – – – – – – – – – GNIBCCb 0.5GTIBCC þ 0.5GNIBCC þ 81198.65 −13.702875T – – þ0.5GNIBCC þ 81198.65 −13.702875T þ0.5GTIBCC þ 39351.22−8.296145T – – – – −72295.24 þ23.47071T – −24442.75 – – – – – – −72295.24 þ23.47071T −24442.75 −32012.19 þ13.247095T −32012.19 þ13.247095T – −72295.24 þ23.47071T −24442.75 (Ni,Ti,Va)0.5 (Ni,Ti,Va)0.5 bcc-based split 0 −50100þ30T – – – – Ref. Ref. – – Ref. Ref. Ref. Ref. – – – – – – – – – – – – – −56500þ 23T −56500þ 23T þ 13500−8T þ 13500−8T þ 37300−14T þ 37300−14T þ 70000−13T þ 70000−13T −10000þ 8T −10000þ 8T – – – – – – – 0 0 0 0 −108297þ 60T −108297þ 60T −7258 −7258 þ15347 þ15347 þ56480 þ56480 – – – – – þ22666−41T þ22666−41T – – Ti3Ni Sublattice description Ni:Ni Ni:Ti Bellen et al. [11] (Ni,Ti)(Ni,Ti)3c Matsumoto et al. [12] (Ni,Ti)(Ni,Ti)3 De Keyzer et al. [14] (Ni,Ti)(Ni,Ti)3 This work (Ni,Ti)(Ni,Ti)3 þ 4GNIHCP þ 3GNIHCP þ GHSERTI157744þ 18.6544T þ GNIHCP þ 3GHSERTI þ157744 −18.6544T – þ 224163.6−166.7884T þ 224788.4−152.9008T þ 240000 þ 80000 þ4GNIHCP þ3GHSERNI þ GHSERTI-165687.84 þ29.43472T þ3GHSERTI þGHSERNI−22753.08 þ4GHSERTI þ73099−64.85152T – þ200000 þ200000 þ 2GNIHCP þ 2GHSERNI þ 1.5GNIHCP þ 1.5GHSERNI þ 0.5GHSERTI þ0.5GTIFCC −157744þ 18.6544T þ 0.5GNIHCP þ 0.5GHSERNI þ 1.5GHSERTI þ1.5GTIFCCþ 157,744−18.6544T – þ 143216−101.776T þ 109156−66.448T þ 240000 þ 80000 þ 2GNIHCP þ 2GHSERNI þ 1.5GNIHCP þ 1.5GHSERNI þ 0.5GHSERTI þ0.5GTIFCC −181000þ19T þ Gexd þ 0.5GNIHCP þ 0.5GHSERNI þ 1.5GHSERTI þ1.5GTIFCCþ 181,000−19Tþ Gexd) þ 2GTIFCC þ2GHSERTI þ 143216−101.776T þ 109156−66.448T þ 50000 þ 50000 Bellen et al. [11] (Ni)(Ti)2 Matsumoto et al. [12] Ref. [11] De Keyzer et al. [14] (Ni,Ti)(Ni,Ti)2 This work (Ni,Ti)(Ni,Ti)2 þ 2GHSERTI þ GHSERNI −82542 þ 8.56035T – – – Ref. [11] Ref. [11] þ 2GHSERTI þ GHSERNI−83342 þ 8.56035T þGexe – – – GHSERNI−GHSERTI þ 127542.7−8.560357T þ 60000 þ 60000 Ref. [14] Ref. [14] Ref. [14] Ti:Ni Ti:Ti 0 L Ni:Ni,Ti 1 L Ni:Ni,Ti 0 L Ni,Ti:Ti 0 L Ti:Ni,Ti Ti2Ni Sublattice description Ni:Ti Ti:Ni 0 L Ni,Ti:Ni 0 L Ni:Ni,Ti a [11] [11] [11] [11] [11] [11] 133 Bellen et al. [11] E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 TiNi-B2 E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 the intermetallic phases, thus C ¼D ¼E ¼F¼ 0. However, Ti3Ni4 and Ti2Ni3 are intermediate compounds to the equilibrium phase, TiNi3, and the same deviation from Neumann–Kopp' rule as in TiNi3 is assumed for their heat capacities, parameterizing C–F, accordingly. In Table 7, optimized model parameters A–F of Ti3Ni4 and Ti2Ni3 are summarized. Table 8 represents a comparison of the CALPHAD values of molar enthalpies referred to the molar enthalpy of TiNi3 with the results from DFT-calculated data. It is seen that the results of Ti2Ni3_L and Ti2Ni3 lie inside the accuracy limits of the first principles analysis of 0.01 eV. Hence, Ti2Ni3_L is not described separately in the modeling. The metastable phase diagrams of the Ti–Ni system presented in Figs. 7 and 8 complete this section. For the validation of the modeled metastable solvi, experimental metastable subsolvus data [17–19,26,85] are included as symbols in the figures. For the evaluation of the thermodynamic metastability of Ti2Ni3 in Fig. 5, the equilibrium TiNi3 phase was suppressed. Accordingly, in Fig. 8, Ti2Ni3 was also suppressed and the nextstable phase, Ti3Ni4 appears in the metastable equilibrium with TiNi-B2. The optimized thermodynamic database for Ti–Ni SMA alloys, mc_SMA_v1.000.tdb is attached as supplement to this paper. Ref. [14] Ref. [14] This work Tang et al. [13] 134 Disordered parameters of Ti–Ni bcc_a2 were given in published assessments [11,12,14]. All G-functions of unary metals are taken from Dinsdale [79]. c Some original sublattice formulas are transformed to obtain unified descriptions for direct comparisons. d Excess terms optimized with experimental heat capacity data [60] read þ 0.0072T2−5 10−8T3 þ 450525T(−1). e Excess terms optimized with experimental heat capacity data [80] read þ5.5 10−3T2−2.78T·ln(T)−1.87 10-7T3 þ33285T(−1). f Excess terms optimized with experimental heat capacity data [62] read −0.002T2 þ50000T(−1). b a þGNIBCC þ0.5GNIBCC þ 0.5GTIBCC −43394 þ12.069T þ0.5GNIBCC þ50000 þ0.5GTIBCC þ22500 −6000þ 16T −24255 þ8T þ GNIBCC þ 0.5GNIBCC þ0.5GTIBCC −46750 þ 16.3T þ Gexf [13] [13] þ 8000 −18000þ 8T Va:Ni Va:Ti 0 L Ni:Ni,Ti 0 L Ni,Va:Ti Tang et al. [13] (Ni,Va)0.5(Ni,Ti)0.5 This work (Ni,Va)0.5(Ni,Ti)0.5 TiNi B19' Sublattice description Ni:Ni Ni:Ti þ60000 þ60000 L Ti:Ni,Ti L Ni,Ti:Ti 0 – – – – 0 Table 5 (continued ) Matsumoto et al. [12] Bellen et al. [11] TiNi-B2 De Keyzer et al. [14] 4. Discussion 4.1. Thermodynamics of TiNi3 Previously in this paper, it was mentioned that the quality of the descriptions of metastable phases are improved by the re-optimization of the TiNi3 phase. The re-assessed thermodynamics of TiNi3 require some discussion. When assessing the set of experimental and first-principles data for the TiNi3 phase, it became clear that it would not be possible to obtain a description, which is consistent with the available set of data. The discrepancies among different research groups [11,12,14,54– 56,86–89] are obvious when comparing the different Gibbs energies of formation of TiNi3 as a function of temperature, as shown in Fig. 9. In fact, it is not easy to judge, which values should be given a high weight in the optimization. In the early assessment work by Bellen et al. [11], it was decided not to use any of the Gibbs energies based on electro-magnetic force (EMF) experiments in the optimization, but to focus on the approximation of modeled and experimental enthalpies of formation. Agreement of both sets of experimental data would lead to an unrealistic formation entropy close to 0 J/mol K. This argumentation needs reconsideration in the light of new experimental heat capacities. Indeed, it is important to take care of physically realistic entropy values in the modeling, and, in the case of TiNi3, the strong exothermic character of formation of TiNi3 should be coupled with a considerably negative entropy of formation. Smith et al. [62] derived a ΔSf(TiNi3) ¼ −14.9 J/mol K at 1653 K, close to the melting point. Preferring experimental heat capacities over Neumann–Kopp's rule, applied in all previous assessments, now both groups of experimental thermodynamic data, part of calorimetric experiments as well as experimental activities are approximated by the modeling, while the entropy of formation remains highly negative, ΔSf ¼ −10.3 J/mol K at 1653 K. The least squares of errors between modeling and experimental data are obtained, when the enthalpies of formation from Moser et al. [59] and Guo and Kleppa [58], as well as EMF data from Kubaschewski [86] and chrono-potentiometry results from Barner et al. [87] is given a high weight in the optimization. E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 135 The interfacial energy contributes to the nucleation barrier to the third power. This means that precipitation is very sensitive to changes of interfacial energy. Therefore, in the thermokinetic simulation also lower (10 mJ/m2) and higher (100 mJ/m2) 4.2. Thermodynamics of metastable phases Different types of data have been used for the thermodynamic descriptions of Ti3Ni4 and Ti2Ni3. Among these, the first-principles results are regarded as the most exact data, whereas the kinetic solvi are to be taken with care due to typical experimental insecurities such as the quantitative quenching rates of solutiontreated alloy. The difference between the kinetic solvus of a small particle in Ti–Ni-Matrix and the metastable equilibrium solvus is governed by properties, which are not directly determined by experiments. The most important property in this context is the interfacial energy. This means that by adopting the enthalpies of formation from first-principles analysis in the modeling and considering metastability from high to low temperature, still considerable uncertainty remains for the entropic contribution to the Gibbs energy. In the present study, we circumvent this dilemma by iterative test runs of thermo-kinetic precipitation simulations with MatCalc, version 5.51, release 0.0019, using assessed mobility diffusion data [90]. A published interfacial energy of 50 mJ/m2 for Ti3Ni4 [15] was used, and the same interfacial energy was assumed for Ti2Ni3. For each simulation, the T-dependent B parameters of the descriptions of Ti3Ni4 and Ti2Ni3 were modified stepwise, until the best reproduction of simulated and experimental precipitation [27] was obtained. Table 7 Optimized model parameters of Ti3Ni4 and Ti2Ni3. Phase A B C D E F Ti3Ni4 Ti2Ni3 −265000 −200000 −6 þ11 0 0 0.0175 0.0086 −3.00E−07 −2.00E−07 þ 609713 þ 589836 Table 8 CALPHAD and DFT-calculated molar enthalpies of metastable phases referred to Ti3Ni in the form ΔHm−ΔHm(Ti3Ni). Phase 0 K, FLAPW [28] þ6000 Ti3Ni4 Ti2Ni3_L Ti2Ni3 þ6000 0 K, PAWPBE [25] 0 K, PAW-PBE, this work 298.15 K, CALPHAD, this work þ8683.8 þ 8759 þ 5799 þ 5549 þ7418 þ5390 Table 6 Thermodynamic data of intermetallic equilibrium phases in Ti–Ni. Hm (J/mol), 298.15 K Hm (J/mol), 0 K TiNi3 −42,132 −36,871 −40,043 −36,978 −43,800±1600 −42,200±1200 −34,700 Sm (J/mol K), 298.15 K Cp (J/mol K), 298.15 K Method Reference 27.44 27.01 25.09 27.01 21.42 25.02 25.02 25.02 Calphad assessment Calphad assessment Calphad assessment Calphad assessment Solution calorimetry Direct synthesis calorimetry Direct synthesis calorimetry calorimetry Calorimetry 1st-princ., GGA 1st-princ. (LMTO-ASA) 1st-princ. (FP-LMTO) 1st-princ. (PBE GGA) This work Bellen et al. [11] Matsumoto et al. [12] De Keyzer et al. [14] Moser et al. [59] Guo and Kleppa [58] Kubaschewski [49] Onderka et al. [60] Smith et al. [62] This work Pasturel et al. [78] Pasturel et al. [78] Stott et al. [25] Calphad assessment Calphad assessment Direct synthesis calorimetry Calorimetry Calorimetry 1st-princ. (LMTO-ASA) 1st-princ. (FP-LMTO) This work Bellen et al. [11] Kubaschewski [49] Zabdyr et al. [80] Smith et al. [62] Pasturel et al. [78] Pasturel et al. [78] 21.79 23.4 −45,928 −47,100 −47,600 −46,313 Ti2Ni −26,977 −26,901 −26,800 29.22 28.63 24.71 25.09 23.4 24.6 −33,700 −28,200 TiNi-B2 −34,721 −34,052 −33,339 −33,900 30.82 31.19 31.47 25.52 25.52 25.58 Calphad assessment Calphad assessment Calphad assessment direct synthesis calorimetry 1st-princ., GGA 1st-princ. (LMTO-ASA) 1st-princ. (FP-LMTO) 1st-princ. (FP-LMTO) 1st-princ. (FLAPW) 1st-princ. (PW/PBE) 1st-princ. (EMTO/GGA) 1st-princ. (PW/LDA) This work Bellen et al. [11] Matsumoto et al. [12] Kubaschewski [49] This work Pasturel et al. [78] Pasturel et al. [78] Sanati et al. [81] Hatcher et al. [66] Stott et al. [25] Lu et al. [82] Huang et al. [83] 22.31 25.54 24.2 Calphad assessment Calorimetry 1st-princ. (LMTO-ASA) 1st-princ. (FP-LMTO) 1st-princ. (FLAPW) This work Smith et al. [62] Pasturel et al. [78] Pasturel et al. [78] Hatcher et al. [66] −32,784 −38,100 −36,000 −38,000 −34,100 −31,840 −36,665 −33,770 TiNi B19' −37,721 −39,800 −37,800 −39,500 136 E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 1600 Sf, J/mol K Wasilewski1971 [17] Nishida1986 [19] Pelton2000 [26] Zheng2008 [5] Paryab2010 [6] 1500 1400 3 Ti3Ni4 1 liquid 1200 1100 1000 Ti2Ni+ TiNi-B2 800 700 0.45 TiNi-R TiNi3 -7 TiNi-B19' 0.50 0.55 0.60 0.65 0.70 0.75 -9 Fig. 7. Metastable phase diagram of the Ti–Ni system. The TiNi3 phase is suspended from the calculation. Symbols denote conditions of experimentally observed TiNi-B2þTi2Ni3. 1600 400 1400 1300 350 300 Temperature,K 1500 liquid 1200 fcc 250 200 150 700 0.45 Ti3Ni4 0.50 0.55 50 0.60 0.65 0.70 0.75 10-3 Fig. 8. Metastable phase diagram of the Ti–Ni system. TiNi3 and Ti2Ni3 are suspended from the calculation. Symbols denote conditions of experimentally observed TiNi-B2 þ Ti3Ni4. -20 Gf,kJ/mol -25 -30 -35 -40 -45 -50 1300 1500 (th is wo rk wo ) rk ) T0, exp.: Tang99 [13] 1700 Mole fraction of Ni Fig. 11. Calculated T0 and Ms of B19′ martensite (lines) compared with experiments (symbols). -15 1100 s 0 480 485 490 495 500 505 510 515 520 Mole fraction of Ni 900 (th is 9] 800 M Ms[ Ti2Ni+ TiNi-B2 0 Otsuka2005 [1] Khalil-Allafi2006 [3] Wasilewski71 [17] Nishida86 [19] Bogdanoff2001 [69] Miyazaki86 [93] Hanlon71 [94] Melton81 [95] Tang2000 [96] Kornilov71 [97] Smith91 [98] Saburi82 [99] ] [9 100 900 T M s, exp.: T0 TiNi-B2 Temperature, K Fig. 10. ΔHf versus ΔSf of Ti–Ni phases at 298.15 K. Nishida [19] Zheng2008 [5] Pelton [26] Cao2012 [7] Khalil-Allafi2002 [4] Koskimaki1969 [18] Otsuka2002 [84] Zheng2008 [5] 1000 -45 -40 -5 Mole fraction of Ni 1100 -35 Ti2Ni3 Ti2Ni -3 Ti2Ni3 900 -30 -1 fcc Hf, kJ/mol TiNi-B2 0 TiNi-B2 Temperature, K 1300 1900 Temperature, K Fig. 9. Gibbs energy of formation of TiNi3 from various sources. E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 -43 Gm, kJ/mol -44 Rph B1 as e 9' -45 T0 -46 Tc hand, the re-assessed data agree with experimental data from Refs. [1,3,17,19,94–99]. As seen in Fig. 11, the kink of T0-course and derived Ms-temperatures above x(Ni) ¼ 0.5, using the same assumptions as Tang et al. [13] for the calculation of Ms, is less pronounced than proposed by these authors. The slope of T0 is resulting from optimized 1st and 2nd order interaction parameters 0 for the ordering of TiNi-B2, as well as0 LB19 Ni:Ni,Ti . The thermodynamic relations between B19′ and R-phase are shown in Fig. 12. The critical temperature of equal Gm is calculated at 388 K, which is above the thermodynamic equilibrium transformation to TiNi-B2. This result is quite reasonable, as slow cooling of stress- and precipitate-free Ti–Ni SMA results in B19′ martensite only, indicating the metastable nature of R-phase. This means that the cross-over between Gm(B19′) and Gm(R-phase) must be kept above the B2-formation temperature. B2 -47 137 260 300 340 380 Temperature, K Fig. 12. Molar Gibbs energies of B19′ and R-phase as a function of temperature. T0 is calculated at 353 K. Gm(B19′) ¼ Gm(R-phase) at Tc ¼388 K. interfacial energy values were tested. Those lead to worse overall reproduction of available data, and for the time being, the suggested interfacial energy [15] is adopted. In Fig. 10, the thermodynamic standard data of equilibrium and metastable phases resulting from the present assessment are shown. A ΔHf versus ΔSf plot chosen reveals a typical dependence for the phases, which form precipitates in Ti–Ni SMA (black diamonds in Fig. 10). ΔSf decreases with increasing phase stabilities. Ti3Ni4, the least-stable precipitate, has high positive entropy of formation, whereas the equilibrium phase TiNi3 has a strongly negative entropy of formation. Similar trends were shown in other systems with metastable precipitates, e.g. Refs. [91,92]. An even stronger tendency of decreasing ΔSf is calculated from TiNi-B2 austenite via intermediate martensitic TiNi-R-phase, to TiNi-B19′ martensite. This is a result of stability considerations explained in the next section. 4.3. Martensitic transformation The present re-assessment of the Ti–Ni system has also strong influence on the martensitic transformation as follows. With the present model parameters, the two-phase region of TiNiB2 þmartensite becomes smaller compared to the work of Tang et al. [13]. This is more realistic, since the physical meaning of two transformations involving TiNi-B2 and martensite is in question in the light of first-order martensitic transformation. For the model parameterization of B19′, enthalpies from first principles were given a high weight due to their consistency among different groups (see Tables 4 and 6). This requires a high negative entropy of formation of B19′ relative to TiNi-B2 (see Fig. 10), ΔSf ¼−8.5J/ mol K for the reproduction of T0-temperatures. The entropy data available [68,69] from low-T calorimetry and inelastic neutron scattering is significantly lower, ΔSf ¼ −3.9±0.75 J/mol K. However, adopting of this value would lead to a large difference between assessed and first principles enthalpies or T0-temperatures. The re-assessed T0-temperatures for the martensitic transformation, where the parent phase TiNi-B2 and the B19′ phase have the same Gibbs free energy, lead to higher Ms-temperatures compared to Tang et al. [13] and experiments from Refs. [93–95]. On the other 5. Conclusions The thermodynamic assessment of metastable Ti3Ni4 and Ti2Ni3 phases, based on new first-principles results and metastable solvi, is coupled with necessary re-considerations of the thermodynamic equilibrium descriptions. New experimental heat capacities were given high weight in the re-optimization of TiNi3. These data deviate significantly from Neumann–Kopp's rule, and former constraints for the modeling were loosened. New calorimetric enthalpies of formation and enthalpy increments, ΔTHf−Δ298.15 KHf, are preferred, and activity measurements are included in the parameter optimization of TiNi3. The re-calculated enthalpy of formation shows a pronounced temperature dependence. A systematic dependence of ΔSf of the thermodynamic stability of the intermetallic phases precipitating in SMA is identified. Ti3Ni4 has the highest entropy and enthalpy of formation, followed by Ti2Ni3 and TiNi3. The presented thermodynamic descriptions of metastable phases in Ti–Ni are essential prerequisites for the evaluation of the changing martensite start temperature in Ti–Ni SMA associated with precipitation during ageing. Acknowledgment The contribution of the Vienna Computational Materials Laboratory (VICOM) is acknowledged in allocating computational capacities, maintenance and technical support. Financial support by the Christian Doppler Forschungsgesellschaft (CDG), and by the Austrian Federal Government (in particular from the Bundesministerium für Verkehr, Innovation und Technologie and the Bundesministerium für Wirtschaft, Familie und Jugend) and the Styrian Provincial Government, represented by Österreichische Forschungsförderungsgesellschaft mbH and by Steirische Wirtschafts-förderungsgesellschaft mbH, within the research activities of the K2 Competence Centre on “Integrated Research in Materials, Processing and Product Engineering”, operated by the Materials Center Leoben Forschung GmbH in the framework of the Austrian COMET Competence Centre Programme, is gratefully acknowledged. Appendix A See appendix Table A1. 138 E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 Table A1 Positions of atoms, as used in the first-principles analysis. Ni3Ti DFT structure x y z Occupancy Ni1 Ni2 Ni3 Ni4 Ni5 Ni6 Ni7 Ni8 Ni9 Ni10 Ni11 Ni12 Ti1 Ti2 Ti3 Ti4 0.5000 0.5000 0.0000 0.5000 0.5000 0.0000 0.1645 0.8355 0.3289 0.6711 0.1645 0.8355 0.0000 0.0000 0.6667 0.3333 0.5000 0.5000 0.5000 0.0000 0.0000 0.5000 0.8355 0.1645 0.1645 0.8355 0.3289 0.6711 0.0000 0.0000 0.3333 0.6667 0 0.5 0 0 0.5 0.5 0.25 0.75 0.75 0.25 0.25 0.75 0 0.5 0.25 0.75 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 b 0.5101 c 0.8307 α 901 β 901 γ 1201 Ni1 Ni2 Ni3 Ni4 Ni5 Ni6 Ni7 Ni8 Ti1 Ti2 Ti3 Ti4 Ti5 Ti6 Lattice parameters: a¼ b¼ c ¼0.672 nm; α ¼β ¼ γ¼ 113.971 0 0.5 0.0605 0.7574 0.5931 0.5931 0.0605 0.7574 0.4989 0.2513 0.1125 0.1125 0.4989 0.2513 0 0.5 0.5931 0.0605 0.7574 0.0605 0.7574 0.5931 0.1125 0.4989 0.2513 0.4989 0.2513 0.1125 0 0.5 0.7574 0.5931 0.0605 0.7574 0.5931 0.0605 0.2513 0.1125 0.4989 0.2513 0.1125 0.4989 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Ti2Ni3 Ni1 Ni2 Ni3 Ni4 Ni5 Ni6 Ti1 Ti2 Ti3 Ti4 0 0 0.5 0.5 0 0.5 0 0 0.5 0.5 0 0 0.5 0.5 0 0.5 0 0 0.5 0.5 0.196 0.804 0.696 0.304 0 0.5 0.391 0.609 0.891 0.109 1 1 1 1 1 1 1 1 1 1 b 0.3095 c 1.3585 α 901 β 901 γ 901 Ni1 Ni2 Ni3 Ni4 Ni5 Ni6 Ni7 Ni8 Ni9 Ni10 Ni11 Ni12 Ti1 Ti2 Ti3 Ti4 Ti5 Ti6 Ti7 Ti8 0.725 0.275 0.225 0.775 0.232 0.768 0.232 0.768 0.732 0.268 0.732 0.268 0.227 0.773 0.227 0.773 0.727 0.273 0.727 0.273 0.25 0.75 0.25 0.75 0.25 0.75 0.25 0.75 0.25 0.75 0.25 0.75 0.25 0.75 0.25 0.75 0.25 0.75 0.25 0.75 0 0 0.5 0.5 0.3 0.7 0.7 0.3 0.8 0.2 0.2 0.8 0.106 0.894 0.894 0.106 0.606 0.394 0.394 0.606 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 b 0.437 c 1.3544 α 901 β 901 γ 901 Lattice parameters (nm) a 0.5101 Ti3Ni4 Lattice parameters (nm) a 0.3095 Ti2Ni3_L Lattice parameters (nm) a 0.4398 E. Povoden-Karadeniz et al. / CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry 41 (2013) 128–139 Appendix A. Supporting information Supplementary data associated with this article can be found in the online version at http://dx.doi.org/10.1016/j.calphad.2013.02. 004. References [1] K. Otsuka, X. Ren, Prog. Mater. Sci. 50 (2005) 511–678. [2] J. Khalil-Allafi, X. Ren, G. Eggeler, Acta Mater. 50 (2002) 793–803. [3] J. Khalil-Allafi, G. Eggeler, W.W. Schmahl, D. Sheptyakov, Mater. Sci. Eng. A 438–440 (2006) 593–596. [4] J. Khalil-Allafi, A. Dloughy, G. Eggerer, Acta Mater. 50 (2002) 4255–4274. [5] Y. Zheng, F. Jiang, L. Li, H. Yang, Y. Liu, Acta Mater. 56 (2008) 736–745. [6] M. Paryab, A. Nasr, O. Bayat, V. Abouei, A. Eshraghi, MJoM 16 (2010) 123–131. [7] S. Cao, S. Pourbabak, D. Schryvers, Scr. Mater. 66 (2012) 650–653. [8] E. Akin, Doctoral Thesis, Texas A&M University, 2010. [9] O.W. Bertacchini, Doctoral Thesis, College Station: Texas A&M University, 2009. [10] MatCalc. Solid state and precipitation kinetics simulation software. ⟨http:// www.matcalc.tuwien.ac.at⟩. E. Kozeschnik. Last access: 2012-10-25. [11] P. Bellen, K.C. Hari Umar, P. Wollants, Z. Metallkd. 87 (1996) 972–978. [12] S. Matsumoto, T. Tokunaga, H. Ohtani, M. Hasebe, Mater. Trans. 46 (2005) 2920–2930. [13] W. Tang, B. Sundman, R. Sandström, C. Qiu, Acta Mater. 12 (1999) 3457–3468. [14] J. De Keyzer, G. Cacciamani, N. Dupin, P. Wollants, CALPHAD 33 (2009) 109–123. [15] N. Zhou, C. Shen, M.F.-X. Wagner, G. Eggeler, M.J. Mills, Y. Wang, Acta Mater. 58 (2010) 6685–6694. [16] W Guo, I. Steinbach, C. Somsen, G. Eggeler, Acta Mater. 59 (2011) 3287–3296. [17] R.J. Wasilewski, S.R. Butler, J.E. Hanlon, D. Worden, Metall. Trans. 2 (1971) 229–238. [18] D. Koskimaki, M.J. Marcinkowski, A.S. Sastri, Trans. AIME 245 (1969) 1883. [19] M. Nishida, C.M. Wayman, T. Honma, Metall. Trans. A 17 (1986) 1505–1515. [20] T. Tadaki, Y. Nakata, K. Shimizu, K. Otsuka, JIM 27 (1986) 731–740. [21] W. Tirry, D. Schryvers, K. Jorissen, D. Lamoen, Acta Cryst. B 62 (2006) 966–971. [22] M.F.-X. Wagner, W. Windl, Acta Mater. 60 (2009) 207–210. [23] M. Nishida, C.M. Wayman, T. Honma, Metall. Trans. 17A (1986) 1505–1515. [24] T. Hara, T. Ohba, K. Otsuka, M. Nishida, Mater. Trans. JIM 38 (1997) 277–284. [25] A.C. Stott, J.I. Brauer, A. Garg, S.V. Pepper, P.B. Abel, C. DellaCorte, R.D. Noebe, et al., J. Phys. Chem. C 114 (2010) 19704–19713. [26] A.R. Pelton, J. DiCello, S. Miyazaki, Proceedings of the international conference on shape memory and superelastic technologies, SMST-2000. S. Russell, A. Pelton (Eds.), 2000. pp. 361–374. [27] J.P. Perdew, K. Burke, M. Ernzerhof, Generalized gradient approximation made simple, Phys. Rev. Lett. 77 (1996) 3865–3868. [28] N.B. Hatcher, Doctoral Thesis,. Northwestern University, 2010. [29] G. Kresse, J. Hafner, Phys. Rev. B 47 (1993) 558–561. [30] G. Kresse, J. Hafner, Phys. Rev. B 48 (1993) 13115–13118. [31] G. Kresse, G.J. Furthmüller, Comput. Mater. Sci. 6 (1996) 15–50. [32] G. Kresse, G.J. Furthmüller, Phys. Rev. B 54 (1996) 11169–11186. [33] http://jp-minerals.org/vesta/, VESTA 3D visualization program for structural models, K. Momma, 2012. [access 27.11.12]. [34] A. Taylor, R.W. Floyd, J. Inst. Met. 80 (1951) 577–587. [35] D.M. Poole, W. Hume-Rothary, J. Inst. Met. 83 (1954) 473–480. [36] Y.A. Bagariatskii, Y.D. Tiapkin, Soc. Phys. Crystallogr. 2 (1957) 414–421. [37] C.C. Jia, K. Ishida, T. Nishizawa, Partitioning of alloying elements between μ (A1) and γ(SO24) phases in the Ni–Ti base systems, in: J.E. Morral, R. S. Shiffman, S.M. Merchant (Eds.), Experimental Methods of Phase Diagram Determination, Pub. TMS, Pittsburgh, PA, 1993pp. 31–38. [38] A.D. McQuillan, J. Inst. Met. 80 (1951) 363–368. [39] H. Margolin, E. Ence, J.P. Nielsen, Trans. AIME 197 (1953) 243–247. [40] A.D. McQuillan, J. Inst. Met. 82 (1954) 47–48. [41] G.F. Bastin, G.D. Rieck, Metall. Trans. 5 (1974) 1817–1826. [42] G.R. Purdy, J.G. Parr, Trans. AIME 221 (1961) 636–639. [43] R. Vogel, H.S. Wallbaum, Arch. Eisenhüttenwes 12 (1938) 299–304. [44] R. Vogel, H.S. Wallbaum, Z. Metall. 87 (1996) 972–978. [45] J.C. Schuster, Z. Pan, S. Liu, F. Weitzer, Y. Du, Intermetallics 15 (2007) 1257–1267. 139 [46] R.J. Wasilewski, S.R. Butler, J.E. Hanlon, Trans. AIME 239 (1967) 1323. [47] C.M. Jackson, H.J. Wagner, R.J. Wasilewski, NASA Report, SP 5110, (1972). [48] J.L. Murray, Ni–Ti (nickel–titanium), in: P. Nash (Ed.), Phase Diagrams of Binary Nickel Alloys, ASM International, 1991pp. 342–355. [49] O. Kubaschewski, Trans. Faraday Soc. 54 (1958) 814–820. [50] Y.O. Esin, M.G. Valishev, A.F. Ermakov, O.V. Gel’d, M.S. Petrushevskii, Russ. J. Phys. Chem. 55 (1981) 421–422. [51] J.C. Gachon, M. Notin, J. Hertz, Thermochim. Acta 48 (1981) 155–164. [52] P.A. Gomozov, Yu.V. Zasypalov, B.M. Mogumov, Russ. J. Phys. Chem. 60 (1986) 1122–1124. [53] R. Lück, I. Arpshofen, B. Predel, J.F. Smith, Thermochim. Acta 131 (1988) 171–181. [54] R.M. German, G.R. St. Pierre, Metall. Trans. 3 (1972) 2819–2823. [55] G.A. Levshin, V.I. Alekseev, Russ. J. Phys. Chem. 53 (1979) 437–439. [56] G. Chattopadhyay, H. Kleykamp, Z. Metallkd. 74 (1983) 182–197. [57] B. Sundman, B. Jansson, J.-O. Andersson, CALPHAD 9 (1985) 153–190. [58] Guo, Kleppa, J. Alloys Cmpd. 269 (1998) 181–186. [59] Z. Moser, W. Gasior, K. Rzyman, A. Debski, Arch. Metal. Mater. 51 (2006) 605–608. [60] B. Onderka, A. Sypien, A. Wierzbicka-Miernik, T. Czeppe, L.A. Zabdyr, Arch. Metal. Mater. 55 (2010) 435–439. [61] O. Knacke, O. Kubaschewski, K. Hesselmann, Thermochemical Properties of Inorganic Substances, 2nd ed., Springer, Berlin, Verlag, 1991, Stahleisen m. b. Düsseldorf. [62] J.F. Smith, R. Lück, O. Jiang, B. Predel, J. Phase Equilibria 14 (1993) 494–500. [63] K. Kajikawa, K. Oikawa, F. Takahashi, H. Yamada, K. Anzai, Mater. Trans. 51 (2010) 781–786. [64] X. Huang, G.J. Ackland, K.M. Rabe, Nature Mater. 2 (2003) 307–311. [65] Y.Y. Ye, C.T. Chan, K.M. Ho, Phys. Rev. B 56 (1997) 3678–3689. [66] N. Hatcher, O.Yu. Kontsevoi, A.J. Freeman, Phys. Rev. B 80 (2009) 144203-1–15. [67] K.G. Vishnu, A. Strachan, Acta Mater. 58 (2010) 745–752. [68] P.D. Bogdanoff, 2002, Dissertation, California Institute of Technology, 2002. [69] P.D. Bogdanoff, B. Fultz, Phil. Mag. B 81 (2001) 299–311. [70] G.D. Sandrock, A.J. Perkins, R.F. Hehemann, Metall. Trans. 2 (1971) 2769–2781. [71] T. Hara, T. Ohba, E. Okunishi, K. Otsuka, Mater. Trans. JIM 38 (1997) 11–17. [72] V.N. Khachin, V.G. Pushin, V.V. Kondratyev, Titanium nickelide: structure and properties, Moscow (1992) 178, in Russian. [73] V.G. Pushin, V.V. Kondratyev, V.N. Khachin, Pretransformation phenomena and martensitic transformations, Ekaterinburg (1998) 368, in Russian. [74] G. Fan, W. Chen, S. Yang, et al., Acta Mater. 52 (2004) 4351–4362. [75] L. Bataillard, J.-E. Bidaux, R. Gotthardt, Philos. Mag. A 78 (1998) 327–344. [76] J. Michutta, Ch. Somsen, A. Yawny, et al., Acta Mater. 54 (2006) 3525–3542. [77] M.C. Carroll, Ch. Somsen, G. Eggeler, Scr. Mater. 50 (2004) 187–192. [78] A. Pasturel, C. Colinet, D.N. Manh, A.T. Paxton, M. van Schilfgaarde, Phys. Rev. B 52 (1995) 15176–15190. [79] A.T. Dinsdale, CALPHAD 15 (1991) 317–425. [80] L. Zabdyr, A. Sypien, A. Wierzbicka-Miernik, unpublished result. [81] M. Sanati, R.C. Albers, F.J. Pinski, Phys. Rev. B 58 (1998) 13590–13593. [82] J.M. Lu, Q.M. Hu, L Wang, Y.J. Li, D.S. Xu, R. Yang, Phys. Rev. B 75 (2007) 094108. [83] X. Huang, C. Bungaro, V. Godlevsky, K.M. Rabe, Phys. Rev. B 65 (2002) 014108. [84] H.C. Herper, Doctoral Thesis. University of Duisburg, 2000. [85] K. Otsuka, T. Kakeshita, MRS Bull. 27 (2002) 91–100. [86] O. Kubaschewski, H. Villa, W.A. Dench, Trans. Faraday Soc. 52 (1956) 214–222. [87] J.H. von Barner, P. Noye, A. Barhoun, F. Lantelme, J. Electrochem. Soc. 152 (2005) C20–C26. [88] J. Kapala, D. Kath, A. Hilpert, Metal. Mater. Trans. A 27 (1996) 2673–2677. [89] I. Barin, Thermochemical Data of Pure Substances, Parts I and II, Wiley-VCH, 1993. [90] E. Povoden-Karadeniz, E. Kozeschnik, unpublished results. [91] C. Ravi, C. Wolverton, V. Ozoliņš, Europhys. Lett. 73 (2006) 719–725. [92] E. Povoden-Karadeniz, P. Lang, P. Warczok, A. Falahati, W. Jun, E. Kozeschnik, unpublished results. [93] S. Miyazaki, K. Otsuka, Metall. Trans. 17 A (1986) 53–63. [94] J.E. Hanlon, S.R. Butler, R.J. Wasilewski, Trans. AIME 239 (1967) 1323–1327. [95] K.N. Melton, O. Mercier, Acta Met. 29 (1981) 393–398. [96] W. Tang, R. Sandström, Y.G. Wei, S. Miyazaki, Metal. Mater. Trans. A 31 (2000) 2423–2430. [97] I.I. Kornilov, Ye.V. Kachur, O.K. Belousov, Fiz. Metall 32 (1971) 420–422. [98] J.F. Smith, Q. Jiang, R. Luck, B. Predel, Mater. Sci. Eng. A 149 (1991) 111–120. [99] T. Saburi, T. Tatsumi, S. Nemo, J. Phys. 43 (1982) C4-261-266.