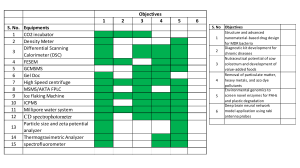

APPLICATION NOTE Process Analyzers for Stable, Long-Term Measurement of High-temperature, Dust-laden Gases Industry: Cement Product: Gas Analyzers Introduction Cement is made by heating calcareous and argillaceous materials to a temperature between 1100 and 1500 °C. As this process uses massive amounts of energy, various energy saving measures are taken, including the measurement of oxygen concentrations in exhaust gases to control combustion. To protect the environment, electrostatic precipitators (ESPs) reduce dust emissions and analyzers measure concentrations of nitrogen oxides (NOx), sulfur dioxide (SO2), and other pollutants. Analyzers installed for this purpose are expected to provide stable, long-term performance even under harsh process conditions. Yokogawa process analyzers can be used to measure O2 and CO at the upper end of a kiln or at the outlet of a flash furnace, where high-temperature, dust-laden gases flow. They can also be installed at the outlet of an ESP to monitor dust concentrations and optimize efficiency, and in a smoke stack to measure NOx, SO2, and O2. Expected Benefits – Measures gas concentrations and dust concentrations in cement plants – Reduces operating costs Sample Conditions at Measurement Points Measuring Point 1: Upper End 2: Precalciner of Kiln Condition Outlet 3: Suspension 4: ESP Outlet 5: Stack Inlet Flash furnace Outlet Measured Components O2+CO+CO2 O2+CO+CO2 (O2)+CO+CO2 Dust Gas Temperature (°C) 1050 to 1200 600 to 850 350 to 400 100 to 130 (MAX.200) 100 to 130 (MAX.200) Amount of Dust (g/Nm3) 200 100 to 200 60 or less 0.1 or less 0.1 or less Pressure (kPa) -0.2 to 0.5 -3 to -2 -0.2 to 0.5 -5 to -3 1 to 2 2 to 4 2 to 4 3 to 5 3 to 5 3 to 5 0.2 or less 0.2 or less 0.2 or less 0.2 or less 0.2 or less 23 to 26 9 to 11 23 to 30 9 to 11 23 to 30 9 to 11 23 to 30 10 to 15 23 to 30 10 to 15 Remaining 0.1 or less 0.01 or less Remaining 0.1 or less 0.01 or less Remaining 0.01 or less 0.01 or less Remaining 0.01 or less 0.01 or less Remaining 0.01 or less 0.01 or less Water-washing/ cooling probe water ejector type sampling system Water-washing (*1) probe water ejector type sampling system Water-washing probe water ejector type sampling system Model DT450 dust Model SG750 monitor (refer to stack gas analyzer AN 10K02H01-01E) NOX+SO2+O2 Gas Component (vol%) O2 CO CO2 H 2O N2 SO2 NOX Main measurement system configuration Model IR200 Model IR200 Model IR200 Infrared gas analyzer Infrared gas analyzer Infrared gas analyzer (*1) Water-washing/cooling probe is recommended, when sample gas temperature ≥ 800°C. NOTE: 1 to 5 represent the measuring points in the summarized process overview for a Cement Plant. http://www.yokogawa.com/an/index.htm AN 10Y02H01-01E All Rights Reserved, Copyright © 2006, Yokogawa Electric Corporation APPLICATION NOTE Process Overview Exhaust Clay 3 4 2 Limestone Exhaust : Material flow : Gas flow ESP 5 Cyclone Limestone dryer 4 Burner ESP Flash furnace r Clay drye Cooler exhaust Water Stack Stabilizer Rotary kiln Bucket elevator Mill Burner 1 Clinker cooler Clinker Cement Manufacturing Process: Raw materials such as calcareous and argillaceous materials are dried, blended, and pulverized in a mill to create powdered material. The powdered material is preheated and decarbonated in a suspension preheater and flash furnace, and calcinated in a kiln to produce clinker. The clinker is cooled, mixed with gypsum and ground in a finish mill to produce cement. 1 O2-CO Measurement System at the Upper End of a Kiln Years of experience in high-temperature dust laden gas application Probe should be installed so that 2 (Wet suction method for high-temperature dust laden gases) Probe Selection the probe head points upward at Cooling 1 3 water outle an angle of 5 to 15° to the horizontal. : Water-washing/ t Coolin g Wa Rc 2 ter in 1/2 Washing Water Out cooling probe Probe (see right figure) Contact Output Purging Status Low Level of Cooling Water Power Supply 100V AC, 50/60Hz Solenoid Valve P Cooling Water Return Sample Gas Out Sample Gas Vent Water In Drain Out To Analyzer Panel Mounting fla nge Manifold Details of part A Drain Pot Flow Switch Sampling System with Air Blowback Function (Separate analyzer panel type) Can be used for sample containing dust of up to 1 kg/Nm3. Water In Drain Out Dehumidifier O2 Analyzer Bubbler 3 : Water-washing probe Heter B Power Supply Sample Gas in Output (O2 Analyzer) Output (CO Analyzer) CO Analyzer Air Purge Support pipe Rc1/2 Mounting flange Details of part B ZERO Wash water inlet Rc1/8 Gas drain outlet Sample Gas in SPAN Washing water Sample gas + Wash water + Dust SPAN Inst Air In Wash head 5 : SG750 stack gas analyzer Increased stability and reliability achieved in combination with a sampling system with excellent maintainability Scale For positioning the wash head Sample Gas In Thermostat Wash water in Rc1/2 Rc1/8 Sample gas + Wash wa (+ Dust) ou ter t (to Ejector) Wash water diffuser Sample Gas Out positioning Cooling water return Cooling water intake Wash water intake Sample gas + Wash water + Dust Jet wash Piping distance: 15 m maximum a Note: When measuring only O2 concentration at point 3 , ZR22G/ZR402G zirconia oxygen analyzer can be used. Sample gas in (+ dust) Inst. Air In T a Scale For wash he ad A Cooling Water Out Sample Gas In Probe Teflon Tube, Φ10/Φ8 Switch Box Air Inlet e or rm ˚o 15 *1 Sampling Module 3-Way Solenoid Valve Pump Sample Gas Inlet, Rc 3/8 Needle Valve Gas Conditioner Flow Checker NO2/NO Converter 30 kPa 0.5L/min Atmospheric Air *1 Sampling System 2-Way Solenoid Valve Membrane Filter Electric gas cooler Solenoid Valve Infrared Analyzer CO, CO2 Membrane Filter Infrared Analyzer NO, SO2 ZERO NO SO2 CO2 CO O2 Pressure Regulator Zirconia O2 Analyzer Air NO /N2 Drain Filter Regulator 30 kPa Instrument Air Inlet http://www.yokogawa.com/an/index.htm AN 10Y02H01-01E All Rights Reserved, Copyright © 2006, Yokogawa Electric Corporation 4th Ed: Jan.2011 (YK) SO2 /N2 CO2 /N2 CO /N2 O2 /N2 Standard Gas Outlet