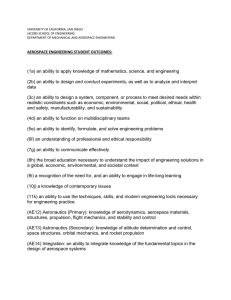

KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Revision 8, Dated May 26, 2016 HIGHLIGHTS To: Holders of the Component Maintenance Manual 26-10-76, Kidde Aerospace & Defense Model 3000 Open Area Smoke Detector, Part Number 474449-5 Shown below are the highlights of the significant changes and the effected pages contained in this revision. NOTE: The page numbers listed below do not indicate the precise location of where a change has occurred. The page numbers show where the affected sections begin. Manual users are encouraged to go directly to the affected section to view the changes (marked by change bars). If you have any questions about this revision, please contact Technical Publications by telephoning (252) 237-7004, fax: (252) 246-8415, or write to Kidde Aerospace & Defense, Technical Publications Department, 4200 Airport Drive NW, Wilson, NC 27896-8630 USA. Page Number Description of Change TITLE PAGE Page 1 Revised to reflect revision 8. LIST OF EFFECTIVE PAGES Page 1 Revised to reflect revision 8 changes. LED Bending-Block Page 9029 Corrected the Part Number and dimensions of Low Carbon Steel in Table 9011. HIGHLIGHTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page HL-1 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK HIGHLIGHTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page HL-2 May 26/16 CAGE: 61423 KIDDE AEROSPACE & DEFENSE 4200 Airport Drive NW Wilson, NC 27896-8630 USA Telephone: 252-237-7004 Fax: 252-246-8415 COMPONENT MAINTENANCE MANUAL WITH ILLUSTRATED PARTS LIST MODEL 3000 OPEN AREA SMOKE DETECTOR 474449-1 474449-5 ©2008, 2010, 2011, 2013, 2015, 2016 Kidde Technologies, Inc. PROPRIETARY COPYRIGHT © KIDDE TECHNOLOGIES, INC. THIS DOCUMENT IS THE PROPERTY OF KIDDE TECHNOLOGIES, INC. (KTI). YOU MAY NOT POSSESS, USE, COPY OR DISCLOSE THIS DOCUMENT OR ANY INFORMATION IN IT, FOR ANY PURPOSE, INCLUDING WITHOUT LIMITATION, TO DESIGN, MANUFACTURE OR REPAIR PARTS, OR OBTAIN ANY GOVERNMENT APPROVAL TO DO SO, WITHOUT KTI'S EXPRESS WRITTEN PERMISSION. NEITHER RECEIPT NOR POSSESSION OF THIS DOCUMENT ALONE, FROM ANY SOURCE, CONSTITUTES SUCH PERMISSION. POSSESSION, USE, COPYING OR DISCLOSURE BY ANYONE WITHOUT KTI'S EXPRESS WRITTEN PERMISSION IS NOT AUTHORIZED AND MAY RESULT IN CRIMINAL AND/OR CIVIL LIABILITY. INFORMATION SUBJECT TO EXPORT CONTROL LAWS U.S. Export Classification: EAR 9E991 The data in this document were developed only to maintain systems and/or parts manufactured by or for Kidde Technologies (KTI) or approved by KTI. The data may not be applicable to any other systems and/or parts, regardless of their apparent similarity to systems and/ or parts manufactured by or for KTI or approved by KTI. Do not rely in any way on data in this document to maintain or otherwise support systems and/or parts that were not manufactured by or for KTI or approved by KTI without evidence that the Federal Aviation Administration or other regulatory agency has determined that the data in this document is valid for such use. KTI assumes no liability whatsoever, whether contractual, warranty, tort or otherwise, for unauthorized alteration or alterations not performed in accordance with KTI approved procedures. Initial Issue: April 18, 2008 26-10-76 TITLE PAGE Page T-1 Revision 8: May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK TITLE PAGE UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page T-2 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SAFETY ADVISORY This manual has procedures that use chemicals, solvents, and other commercially available materials. Safety Data Sheets (SDSs) must be available to the operators for all chemicals used in these procedures per the Occupational Safety and Health Act (OSHA) (Reference 1910.1200, Appendix D). The manufacturers or suppliers of the materials can supply the SDSs. Follow the manufacturer's or supplier's procedures, warnings, and cautions to use, keep, and discard these materials safely. WARNING: OBEY ALL OF THE MANUFACTURER OR SUPPLIER INSTRUCTIONS WHEN YOU USE THE MATERIALS SPECIFIED IN THIS MANUAL. FAILURE TO OBEY THE MANUFACTURER'S OR SUPPLIER'S INSTRUCTIONS CAN CAUSE INJURY OR DISEASE. The materials used in this manual are given at the beginning of each section of this manual. The WARNINGS in this manual tell you about dangerous materials that can cause injury. They do not replace the manufacturer's instructions. The CAUTIONS in this manual tell you of possible conditions that can cause equipment damage. This Safety Advisory has all WARNINGS included in this manual. WARNING: BEFORE USING ANY OF THE MATERIALS SPECIFIED IN KIDDE AEROSPACE & DEFENSE MAINTENANCE PUBLICATIONS, BE AWARE OF ALL HANDLING, STORAGE, AND DISPOSAL PRECAUTIONS RECOMMENDED BY THE MANUFACTURER OR SUPPLIER. FAILURE TO COMPLY WITH MANUFACTURER'S OR SUPPLIER'S RECOMMENDATIONS MAY RESULT IN PERSONAL INJURY OR DISEASE. THE USER OF THIS PUBLICATION SHOULD OBTAIN THE SAFETY DATA SHEETS (OCCUPATIONAL SAFETY AND HEALTH ACT (OSHA) (REFERENCE 1910.1200, APPENDIX D OR EQUIVALENT) FROM THE MANUFACTURERS OR SUPPLIERS OF THE MATERIALS TO BE USED. THE USER MUST BECOME COMPLETELY FAMILIAR WITH THE MANUFACTURER OR SUPPLIER INFORMATION AND ADHERE TO THE PROCEDURES, RECOMMENDATIONS, WARNINGS, AND CAUTIONS OF THE MANUFACTURER OR SUPPLIER FOR THE SAFE USE, HANDLING, STORAGE, AND DISPOSAL OF THESE MATERIALS. WARNING: ELECTRIC SHOCK CAN OCCUR WHEN YOU USE A HIGH POTENTIAL TESTER. DO NOT TOUCH EXPOSED UNINSULATED CONNECTIONS, COMPONENTS BEING TESTED, OR THE TESTING SURFACE. PERSONNEL WORKING WITH ELECTRICITY SHALL HAVE ANOTHER PERSON SKILLED IN MODERN METHODS OF FIRST AID AND RESUSCITATION NEARBY. WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (207 KILOPASCALS). TO PREVENT INJURIES, DO NOT POINT THE AIR AT PERSONNEL. PUT ON GOGGLES OR A FACE SHIELD TO PREVENT EYE INJURY. IF YOU HAVE AN EYE INJURY, GET MEDICAL AID. SAFETY ADVISORY UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page SA-1 Mar 05/10 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 WARNING: USE ISOPROPYL ALCOHOL, ASTM D770, CORRECTLY. ISOPROPYL ALCOHOL IS FLAMMABLE, EXPLOSIVE, AND A MILD POISON. IT CAN HAVE A BAD EFFECT ON YOUR HEALTH OR SAFETY. BEFORE YOU USE THE ALCOHOL, GET THE SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. BEFORE YOU USE THE ALCOHOL, PUT ON CHEMICAL-SPLASH GOGGLES. MAKE SURE THAT YOU HAVE SUFFICIENT AIRFLOW TO KEEP THE ALCOHOL FUMES BELOW THE SAFETY DATA SHEET LIMIT. WARNING: ADHESIVE IS TOXIC. USE IN WELL VENTILATED AREA. PREVENT EYE AND SKIN CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT WASH WITH SOAP AND WATER. WARNING: PUT ON THERMALLY INSULATED GLOVES AND OTHER APPLICABLE PROTECTION TO PREVENT BURNS WHEN YOU USE THE HOT AIR SOURCE. LET THE EQUIPMENT AND UNIT BECOME COOL BEFORE YOU TOUCH THEM. WARNING: SILICONE SEALANT IS TOXIC. USE IN WELL VENTILATED AREA. PREVENT EYE AND SKIN CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT WASH WITH SOAP AND WATER. WARNING: USE SILICONE ADHESIVE/SEALANT, DOW CORNING 3145, CORRECTLY. KEEP THE SEALANT AWAY FROM WATER OR MOIST AIR. THE SEALANT CAN REACT WITH WATER OR MOIST AIR TO MAKE METHYL ALCOHOL GAS. METHYL ALCOHOL GAS IS VERY FLAMMABLE AND CAN BE EXPLOSIVE. DO NOT SWALLOW THE SEALANT. IT CAN MAKE METHYL ALCOHOL THAT CAN CAUSE DEATH OR BLINDNESS. BEFORE YOU USE THE SEALANT, GET THE SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. BEFORE YOU USE THE SEALANT, PUT ON SAFETY GLASSES. MAKE SURE THAT YOU HAVE SUFFICIENT AIRFLOW TO KEEP THE SEALANT FUMES BELOW THE SAFETY DATA SHEET LIMIT. WARNING: USE THE CONDUCTIVE COMPOUND, CHO-BOND 1075, CORRECTLY. PREVENT EYE CONTACT. DO NOT INGEST THE COMPOUND. THE COMPOUND MAY CAUSE MODERATE IRRITATION OF THE EYES, MUCOUS MEMBRANES, AND RESPIRATORY TRACT. PREVENT SKIN CONTACT; PROLONGED OR REPEATED CONTACT MAY CAUSE BLUE-GRAY DISCOLORATION OF THE SKIN. BEFORE YOU USE THE COMPOUND, GET THE MATERIAL SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. SAFETY ADVISORY UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page SA-2 Mar 05/10 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 RECORD OF REVISIONS REV NO. ISSUE DATE DATE INSERTED BY 1 Mar 5/10 Mar 5/10 KAD 2 Jun 30/10 Jun 30/10 KAD 3 Mar 11/11 Mar 11/11 KAD 4 Oct 02/13 Oct 02/13 KAD 5 Dec 16/13 Dec 16/13 KAD 6 Feb 09/15 Feb 09/15 KAD 7 Apr 30/15 Apr 30/15 KAD 8 May 26/16 May 26/16 KAD REV NO. ISSUE DATE DATE INSERTED BY RECORD OF REVISIONS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page RR-1 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK RECORD OF REVISIONS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page RR-2 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 RECORD OF TEMPORARY REVISIONS Temporary Revision Number Issue Date Date Inserted/ Inserted By Date removed/ Removed By Date Incorporated RECORD OF TEMPORARY REVISIONS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page RTR-1 Mar 05/10 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK RECORD OF TEMPORARY REVISIONS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page RTR-2 Mar 05/10 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SERVICE BULLETIN LIST The Service Bulletin List identifies the service bulletin number and revision number, if applicable, the date of the service bulletin, and the date the service bulletin was incorporated in the manual (manual revision date). Service Bulletin / Revision Number Issue Date Date Incorporated or No Effect Title SERVICE BULLETIN LIST UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page SBL-1 Mar 05/10 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK SERVICE BULLETIN LIST UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page SBL-2 Mar 05/10 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page Date HIGHLIGHTS HL-1 HL-2 May 26/16 May 26/16 TITLE PAGE T-1 T-2 May 26/16 May 26/16 SAFETY ADVISORY SA-1 SA-2 Mar 05/10 Mar 05/10 RECORD OF REVISIONS RR-1 RR-2 May 26/16 May 26/16 RECORD OF TEMPORARY REVISIONS RTR-1 RTR-2 Mar 05/10 Mar 05/10 SERVICE BULLETIN LIST SBL-1 SBL-2 Mar 05/10 Mar 05/10 LIST OF EFFECTIVE PAGES LEP-1 LEP-2 LEP-3 LEP-4 May 26/16 May 26/16 May 26/16 BLANK TABLE OF CONTENTS TOC-1 TOC-2 TOC-3 TOC-4 TOC-5 TOC-6 TOC-7 TOC-8 May 26/16 May 26/16 May 26/16 May 26/16 May 26/16 May 26/16 May 26/16 May 26/16 INTRODUCTION INTRO-1 Mar 11/11 INTRO-2 Mar 11/11 INTRO-3 Mar 11/11 INTRO-4 Mar 11/11 DESCRIPTION AND OPERATION 1 2 3 4 5 6 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 Subject Page TESTING AND FAULT ISOLATION Date 7 8 9 10 11 12 13 14 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 1001 1002 1003 1004 1005 1006 1007 1008 1009 1010 1011 1012 1013 1014 1015 1016 1017 1018 1019 1020 1021 1022 1023 1024 1025 1026 1027 1028 1029 1030 1031 1032 1033 1034 1035 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 Feb 09/15 LIST OF EFFECTIVE PAGES UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page LEP-1 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page Date 1036 Feb 09/15 SCHEMATICS AND WIRING DIAGRAMS 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 DISASSEMBLY 3001 3002 3003 3004 Oct 02/13 Oct 02/13 Oct 02/13 BLANK CLEANING 4001 4002 4003 4004 4005 4006 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 BLANK CHECK 5001 5002 5003 5004 5005 5006 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 BLANK REPAIR 6001 6002 6003 6004 6005 6006 6007 6008 6009 6010 6011 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Subject Page Date 6012 6013 6014 6015 6016 6017 6018 6019 6020 6021 6022 6023 6024 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 BLANK ASSEMBLY 7001 7002 7003 7004 Oct 02/13 Oct 02/13 Oct 02/13 Oct 02/13 FITS AND CLEARANCES 8001 8002 8003 8004 Jun 30/10 Jun 30/10 Jun 30/10 BLANK SPECIAL TOOLS, FIXTURES, AND EQUIPMENT 9001 9002 9003 9004 9005 9006 9007 9008 9009 9010 9011 9012 9013 9014 9015 9016 9017 9018 9019 9020 9021 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 LIST OF EFFECTIVE PAGES UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page LEP-2 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page Date 9022 9023 9024 9025 9026 9027 9028 9029 9030 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 Dec 16/13 BLANK ILLUSTRATED PARTS 10001 LIST 10002 10003 10004 10005 10006 10007 10008 10009 10010 10011 10012 10013 10014 10015 10016 10017 10018 10019 10020 10021 10022 10023 10024 10025 10026 10027 10028 10029 10030 10031 10032 10033 10034 10035 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Subject STORAGE (INCLUDING TRANSPORTATION) Page Date 10036 10037 10038 10039 10040 10041 10042 10043 10044 10045 10046 10047 10048 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 Apr 30/15 BLANK 15001 15002 15003 15004 Mar 05/10 Mar 05/10 Mar 05/10 Mar 05/10 LIST OF EFFECTIVE PAGES UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page LEP-3 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK LIST OF EFFECTIVE PAGES UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page LEP-4 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TABLE OF CONTENTS Subject Page INTRODUCTION.....................................................................................................................INTRO-1 TASK 26-10-76-990-812-A01 1. GENERAL INFORMATION......................................................................................INTRO-1 SUBTASK 26-10-76-99F-001-A01 A. General Information............................................................................................INTRO-1 SUBTASK 26-10-76-99F-003-A01 B. Statement of Verification.....................................................................................INTRO-1 SUBTASK 26-10-76-99F-005-A01 C. Abbreviations and Acronyms..............................................................................INTRO-1 DESCRIPTION AND OPERATION.....................................................................................................1 TASK 26-10-76-990-801-A01 1. GENERAL INFORMATION...................................................................................................1 SUBTASK 26-10-76-99F-011-A01 A. General Information........................................................................................................1 TASK 26-10-76-870-801-A01 2. DESCRIPTION AND OPERATION.......................................................................................3 SUBTASK 26-10-76-870-007-A01 A. Purpose...........................................................................................................................3 SUBTASK 26-10-76-870-002-A01 B. Physical Description........................................................................................................3 SUBTASK 26-10-76-870-003-A01 C. Connector Pin Assignments............................................................................................6 SUBTASK 26-10-76-870-006-A01 D. Leading Particulars.........................................................................................................6 SUBTASK 26-10-76-870-005-A01 E. Functional Description.....................................................................................................9 TASK 26-10-76-870-802-A01 3. OPERATION.......................................................................................................................11 SUBTASK 26-10-76-870-008-A01 A. Operation......................................................................................................................11 TABLE OF CONTENTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page TOC-1 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page TESTING AND FAULT ISOLATION..............................................................................................1001 TASK 26-10-76-990-802-A01 1. GENERAL INFORMATION.............................................................................................1001 SUBTASK 26-10-76-99F-002-A01 A. General Information..................................................................................................1001 SUBTASK 26-10-76-94A-005-A01 B. Consumable Materials..............................................................................................1001 SUBTASK 26-10-76-94B-001-A01 C. Special Tools and Equipment...................................................................................1002 TASK 26-10-76-490-801-A01 2. PREPARE FOR TEST....................................................................................................1005 SUBTASK 26-10-76-490-001-A01 A. Prepare the Personal Computer (PC).......................................................................1005 SUBTASK 26-10-76-490-002-A01 B. Prepare the M3000 Optical Smoke Box....................................................................1006 TASK 26-10-76-750-801-A01 3. RETURN-TO-SERVICE TEST........................................................................................1007 SUBTASK 26-10-76-750-002-A01 A. Ground Bonding Test................................................................................................1007 SUBTASK 26-10-76-750-003-A01 B. Dielectric and Insulation Resistance (IR) Test..........................................................1009 SUBTASK 26-10-76-750-006-A01 C. Functional Test..........................................................................................................1012 SUBTASK 26-10-76-750-005-A01 D. 50-Hour Burn-In Test................................................................................................1027 TASK 26-10-76-810-801-A01 4. FAULT ISOLATION.........................................................................................................1029 SUBTASK 26-10-76-810-001-A01 A. Fault Isolation............................................................................................................1029 TASK 26-10-76-990-803-A01 5. RETURN-TO-SERVICE-TEST DATASHEET.................................................................1033 TABLE OF CONTENTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page TOC-2 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page SUBTASK 26-10-76-99F-017-A01 A. Datasheet..................................................................................................................1033 SCHEMATICS AND WIRING DIAGRAMS....................................................................................2001 TASK 26-10-76-990-811-A01 1. GENERAL INFORMATION.............................................................................................2001 SUBTASK 26-10-76-99F-015-A01 A. General Information..................................................................................................2001 TASK 26-10-76-995-801-A01 2. SCHEMATIC...................................................................................................................2003 SUBTASK 26-10-76-995-001-A01 A. Schematic.................................................................................................................2003 DISASSEMBLY.............................................................................................................................3001 TASK 26-10-76-990-803-A01 1. GENERAL INFORMATION.............................................................................................3001 SUBTASK 26-10-76-99F-004-A01 A. General Information..................................................................................................3001 SUBTASK 26-10-76-94A-009-A01 B. Special Tools and Equipment...................................................................................3001 TASK 26-10-76-000-801-A01 2. DISASSEMBLY PROCEDURES....................................................................................3003 SUBTASK 26-10-76-010-001-A01 A. Disassembly Procedures..........................................................................................3003 CLEANING....................................................................................................................................4001 TASK 26-10-76-990-804-A01 1. GENERAL INFORMATION.............................................................................................4001 SUBTASK 26-10-76-99F-013-A01 A. General Information..................................................................................................4001 SUBTASK 26-10-76-94A-007-A01 B. Consumable Materials..............................................................................................4001 TASK 26-10-76-100-802-A01 2. PROCEDURES...............................................................................................................4003 TABLE OF CONTENTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page TOC-3 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page SUBTASK 26-10-76-100-001-A01 A. Non-Electrical Parts..................................................................................................4003 SUBTASK 26-10-76-100-002-A01 B. Electrical Parts..........................................................................................................4004 SUBTASK 26-10-76-100-003-A01 C. Clean The Labyrinth Assembly.................................................................................4004 CHECK..........................................................................................................................................5001 TASK 26-10-76-990-805-A01 1. GENERAL INFORMATION.............................................................................................5001 SUBTASK 26-10-76-99F-006-A01 A. General Information..................................................................................................5001 TASK 26-10-76-210-801-A01 2. CHECK PROCEDURES.................................................................................................5003 SUBTASK 26-10-76-210-001-A01 A. External Check..........................................................................................................5003 SUBTASK 26-10-76-210-002-A01 B. Internal Check...........................................................................................................5004 REPAIR.........................................................................................................................................6001 TASK 26-10-76-990-806-A01 1. GENERAL INFORMATION.............................................................................................6001 SUBTASK 26-10-76-99F-007-A01 A. General Information..................................................................................................6001 SUBTASK 26-10-76-94A-002-A01 B. Consumable Materials..............................................................................................6001 SUBTASK 26-10-76-94A-008-A01 C. Special Tools and Equipment...................................................................................6002 TASK 26-10-76-300-801-A01 2. REPAIR PROCEDURES................................................................................................6005 SUBTASK 26-10-76-350-001-A01 A. Wire Harness............................................................................................................6005 SUBTASK 26-10-76-350-002-A01 B. Circuit Card Assembly...............................................................................................6006 TABLE OF CONTENTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page TOC-4 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page SUBTASK 26-10-76-350-004-A01 C. Installation of the Labyrinth Internal Components.....................................................6007 SUBTASK 26-10-76-350-003-A01 D. Replacement of the Light Pipe..................................................................................6010 TASK 26-10-76-350-802-A01 3. SMOKE DETECTOR CALIBRATION.............................................................................6013 SUBTASK 26-10-76-99F-016-A01 A. General Information..................................................................................................6013 SUBTASK 26-10-76-350-006-A01 B. Calibration Setup.......................................................................................................6013 SUBTASK 26-10-76-350-007-A01 C. Smoke Calibration Procedure...................................................................................6014 SUBTASK 26-10-76-350-008-A01 D. Smoke Calibration Parameters Adjustment Guidelines............................................6017 TASK 26-10-76-350-803-A01 4. MICROCONTROLLER SOFTWARE INSTALLATION....................................................6019 SUBTASK 26-10-76-350-009-A01 A. General Information..................................................................................................6019 SUBTASK 26-10-76-350-011-A01 B. BBP Software Installation Procedure........................................................................6019 SUBTASK 26-10-76-350-010-A01 C. MEP Software Installation Procedure.......................................................................6021 ASSEMBLY...................................................................................................................................7001 TASK 26-10-76-990-807-A01 1. GENERAL INFORMATION.............................................................................................7001 SUBTASK 26-10-76-99F-008-A01 A. General Information..................................................................................................7001 SUBTASK 26-10-76-94A-003-A01 B. Consumable Materials..............................................................................................7001 SUBTASK 26-10-76-94A-010-A01 C. Special Tools and Equipment...................................................................................7002 TABLE OF CONTENTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page TOC-5 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page TASK 26-10-76-400-801-A01 2. ASSEMBLY PROCEDURES..........................................................................................7003 SUBTASK 26-10-76-410-003-A01 A. Assemble the Labyrinth Top to the Labyrinth Bottom...............................................7003 SUBTASK 26-10-76-410-001-A01 B. Assemble the CCA/Labyrinth Assembly to the Housing...........................................7003 SUBTASK 26-10-76-410-002-A01 C. Assemble the Lid to the Housing..............................................................................7004 FITS AND CLEARANCES.............................................................................................................8001 TASK 26-10-76-990-808-A01 1. GENERAL INFORMATION.............................................................................................8001 SUBTASK 26-10-76-99F-009-A01 A. General Information..................................................................................................8001 TASK 26-10-76-205-801-A01 2. TORQUE SPECIFICATIONS..........................................................................................8003 SUBTASK 26-10-76-205-001-A01 A. Torque Specifications................................................................................................8003 SPECIAL TOOLS, FIXTURES, AND EQUIPMENT......................................................................9001 TASK 26-10-76-990-810-A01 1. GENERAL INFORMATION.............................................................................................9001 SUBTASK 26-10-76-99F-010-A01 A. General Information..................................................................................................9001 TASK 26-10-76-94A-801-A01 2. CONSUMABLE MATERIALS..........................................................................................9003 SUBTASK 26-10-76-94A-006-A01 A. Consumable Materials..............................................................................................9003 TASK 26-10-76-940-802-A01 3. SPECIAL TOOLS, FIXTURES AND EQUIPMENT.........................................................9005 SUBTASK 26-10-76-94B-003-A01 A. Special Tools, Fixtures and Equipment.....................................................................9005 SUBTASK 26-10-76-94B-002-A01 B. Kidde Aerospace Software Information.....................................................................9009 TABLE OF CONTENTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page TOC-6 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page TASK 26-10-76-930-801-A01 4. LOCALLY-MADE-TEST-EQUIPMENT...........................................................................9011 SUBTASK 26-10-76-930-001-A01 A. M3000-Manual-Test-Set...........................................................................................9011 SUBTASK 26-10-76-930-002-A01 B. M3000-IR/Dielectric-Test-Cable-(CAN).....................................................................9020 SUBTASK 26-10-76-930-003-A01 C. M3000-Functional-Test-Cable...................................................................................9021 SUBTASK 26-10-76-930-004-A01 D. M3000-Programming-Test-Cable..............................................................................9023 SUBTASK 26-10-76-930-005-A01 E. Burn-In-Test Cable....................................................................................................9025 SUBTASK 26-10-76-930-006-A01 F. Bonding-Measurement Fixture..................................................................................9026 SUBTASK 26-10-76-930-007-A01 G. Light-Pipe Fixture......................................................................................................9028 SUBTASK 26-10-76-930-008-A01 H. LED Bending-Block...................................................................................................9029 ILLUSTRATED PARTS LIST.......................................................................................................10001 TASK 26-10-76-950-801-A01 1. INTRODUCTION...........................................................................................................10001 SUBTASK 26-10-76-99F-012-A01 A. General Information................................................................................................10001 STORAGE (INCLUDING TRANSPORTATION)..........................................................................15001 TASK 26-10-76-990-809-A01 1. GENERAL INFORMATION...........................................................................................15001 SUBTASK 26-10-76-99F-014-A01 A. General Information................................................................................................15001 SUBTASK 26-10-76-94A-004-A01 B. Consumable Materials............................................................................................15001 TASK 26-10-76-500-801-A01 2. STORAGE AND SHIPPING..........................................................................................15003 TABLE OF CONTENTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page TOC-7 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Subject Page SUBTASK 26-10-76-550-001-A01 A. Storage....................................................................................................................15003 SUBTASK 26-10-76-510-001-A01 B. Shipping..................................................................................................................15003 TABLE OF CONTENTS UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 Page TOC-8 May 26/16 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 INTRODUCTION TASK 26-10-76-990-812-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-001-A01 A. General Information (1) This manual provides component maintenance instructions for the assembly part number shown on the title page of this manual. SUBTASK 26-10-76-99F-003-A01 B. Statement of Verification Table 1 Verification Status Section Method Date Testing and Fault Isolation Performance Mar 4/2010 Disassembly Performance Mar 4/2010 Assembly Performance Mar 4/2010 Engineering Technical Review Completed Mar 3/2010 SUBTASK 26-10-76-99F-005-A01 C. Abbreviations and Acronyms (1) The definition list gives the abbreviations, acronyms, and symbols used in this manual. ABBREVIATION DEFINITIONS Baud A variable unit of data transmission speed (the number of signalling elements that occur each second) °C degrees Celsius °F degrees Fahrenheit A ampere AC alternating current ADC analog-to-digital converter AFT rearward ALT alternate AMPS amperes UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 INTRODUCTION Page INTRO-1 Mar 11/11 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 ABBREVIATION DEFINITIONS AR as required ASSY assembly BBP Boot Block Partition BIT built-in-test CAGE Commercial and Government Entity CAN Controller Area Network CCA circuit card assembly CMM Component Maintenance Manual DC direct current DMM digital multimeter EC explanation code EMI electromagnetic interference ESD electrostatic discharge ESDS electrostatic discharge sensitive FIG figure FWD forward GND ground HF hosted function Hz hertz ID identity IBIT initiated BIT I/O input/output IPL illustrated parts list IR infrared or insulation resistance LED light emitting diode mA milliampere MCU microcontroller or micro-control unit ms millisecond UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 INTRODUCTION Page INTRO-2 Mar 11/11 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 ABBREVIATION DEFINITIONS MEP Main Executive Partion NCC normally closed contact NHA next higher assembly NOC normally open contact No. or NO. number NP Non-provisioned: parts that are not available as spares NVM non-volatile memory Obscuration The amount of light blocked by smoke particles OPT optional PBIT periodic BIT PC personal computer PER ID Personality Identification P/N part number PWR power (from power supply) QTY quantity REPLD replaced REPLS replaces REV revision RF reference SB service bulletin SBIT start (power up) BIT SI Systeme International (International System) SPI serial peripheral interface SUPSD superseded SUPSDS supersedes TPN true part number UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 INTRODUCTION Page INTRO-3 Mar 11/11 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 ABBREVIATION DEFINITIONS USB universal serial bus UUT unit-under-test V ac volts, alternating current V dc volts, direct current UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 INTRODUCTION Page INTRO-4 Mar 11/11 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 DESCRIPTION AND OPERATION TASK 26-10-76-990-801-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-011-A01 A. General Information (1) This section gives the description and operation of the assembly shown on the title page of this manual. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 1 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 2 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-870-801-A01 2. DESCRIPTION AND OPERATION SUBTASK 26-10-76-870-007-A01 A. Purpose (1) The function of the Model-3000-Open-Area-Smoke-Detector is to sense combustiongenerated smoke. When the concentration of smoke is greater than a specified level, the smoke detector will give an alarm signal. SUBTASK 26-10-76-870-002-A01 B. Physical Description (1) The smoke detector (Refer to Figure 1) has: • A high-temperature plastic case (housing and lid) • A circuit card/labyrinth assembly (CCA/Labyrinth Assembly) • A labyrinth assembly • An electrical connector (J1) • A replaceable EMI gasket installed between J1 and the smoke detector housing. • A non-replaceable EMI gasket built into the lid. (2) The circuit card assembly (CCA), labyrinth assembly (labyrinth), and J1 are part of the CCA/Labyrinth Assembly. (3) The smoke detector housing has a raised section (to accommodate the labyrinth) that has slots for air and smoke to pass through. A dust screen, on the labyrinth, keeps unwanted materials out of the labyrinth. The electrical connector (J1), installed in the case, supplies the electrical interface to related equipment. The CCA attaches to four molded standoffs inside the case. The lid is attached to the housing with four screws. (4) The Labyrinth assembly is a specially made component that senses small changes in light reflection caused by smoke. The labyrinth assembly includes: • A photodiode • Mirror • Electromagnetic interference (EMI) shield • Two light-emitting diodes (LED) (one red, one blue) • A base • A top. (5) The two LED's and a mirror are installed at an angle to the photodiode. This is done so that light does not go directly into the photodiode during usual operation. The labyrinth is installed on the Labyrinth CCA and is held in place by three screws. The labyrinth design keeps external light away from the photodiode. (6) The CCA contains the electronic components to: • Operate the LED's UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 3 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • Monitor the photodiode • Do the built-in-test (BIT) • Communicate over a Controller Area Network (CAN) bus • Control the three-color (only red and green are used) status LED (DS1). It also has two thermal detectors to monitor air and LED temperatures. (7) The CCA also has a power circuit, high-voltage transient protection, and opposite input power protection. (8) The status LED can be seen through the light pipe on the top of the housing. The red status LED comes on when the internal voltage signal is too high or too low, or if there is a fault condition. The green status LED flashes when the smoke detector is functional. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 4 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector Figure 1 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 5 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-870-003-A01 C. Connector Pin Assignments Table 1 J1 Connector Pin Assignments Pin No. Signal Name Pin No. Signal Name 28VDC RTN 8 Internally Connected to 28VDC RTN 9 Internally Connected to 28VDC RTN 10 Internally Connected to 28VDC RTN 1 PER ID 1 2 PER ID 2 3 4 PER ID 3 11 CHASSIS GND 5 PER ID 4 12 CAN H 6 28VDC 13 CAN L 7 PARITY SUBTASK 26-10-76-870-006-A01 D. Leading Particulars (1) Leading Particulars for the smoke detector are given below (Refer to Table 2). Table 2 Leading Particulars Item or Function Data Input Voltage Requirements 18 to 32 Vdc at -40 °C (-40 °F) (+28 Vdc nominal) Input Current 45 mA (maximum) Polarity Protection Internal opposite input polarity protection Smoke Detection Settings (% of normal light transmission with cotton smoke): Alarm at: Ambient Temperature Detection Setting (minimum) >212 °F (100 °C) Mating Electrical Connector BACC63CT11M35SN or equivalent UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 95.0 ±0.5% DESCRIPTION AND OPERATION Page 6 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Item or Function Data Temperature Range for Operation -40 to +158 °F (-40 to +70 °C) Mounting Orientation All Angles Temperature Range for Storage -67 to +186 °F (-55 to +85.55 °C) Weight, Maximum 0.60 lb (0.27 Kg) Dimensions (Refer to Figure 2) Approvals Meets or exceeds requirements of FAATSO-C1d, Type II (SAE AS8036 and RTCA/ DO-160E) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 7 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Open-Area Smoke-Detector Dimensions Figure 2 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 8 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-870-005-A01 E. Functional Description (1) The smoke detector uses dual wavelength technology to discriminate true smoke events from false events. The labyrinth assembly monitors changes in reflected light caused by smoke particles. Other sensor circuits monitor the ambient temperature. If an alarm condition (smoke/overheat) is detected: • An alarm condition is transmitted over the CAN bus • The Status Indicator (DS1) changes from green (usual condition) to red (stable). (2) When smoke enters the labyrinth, the smoke particles increase the reflection of the light transmitted by the Blue LED and the Red LED. A mirror directs the reflected light onto a photodiode. As the scatter increases, the smoke detector changes from standby mode into the analysis mode. The analysis mode determines whether the increased scatter is by smoke or contamination. (3) The photodiode senses the scattered radiation and makes two analog signals. These analog signals are processed by an active band-pass-filter and converted into separate digital outputs by an A-to-D converter (ADC). The ADC output is processed by the micro-control unit (MCU). (4) The MCU calculates the ratio and magnitude of the red and blue signals. The fire or no-fire decision is based on the signal ratio, timing, data stored in non-volatile memory (NVM), and ambient temperature algorithms. The MCU also does calibration and contamination monitoring during operation. A maintenance signal is generated when contamination limits are exceeded. (5) Scheduled maintenance is not necessary. A maintenance message is transmitted and the red service LED (status indicator) will illuminate to show that maintenance is required. The maintenance indication will change to a fault indication if contamination prevents proper operation of the smoke detector (Refer to Table 3). Table 3 LED Status Indicator Color Indication Status Both Red & Green OFF Power fault, the detector is not operational. Green ON (Stable) None (except for circuit fault) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 9 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Color Red (6) Indication ON (Stable) Status 1. On power-up, changes to Green (flashing): Normal operation 2. On power-up, stays Red (stable): Unserviceable 3. Smoke/overheat condition detected (alarm condition) 4. Circuit fault condition Green Flashes Normal operation Red Flashes Maintenance required Background scatter levels will change as contamination collects within the labyrinth. The smoke detector automatically adjusts for the contamination level. To do this adjustment, the smoke detector monitors the background scatter level and stores the updated value in NVM. Adjustments to the stored value are made periodically, except under smoke or contamination conditions. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 10 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-870-802-A01 3. OPERATION SUBTASK 26-10-76-870-008-A01 A. Operation (1) The block diagram (Refer to Figure 3) shows the functional operations of the smoke detector. (2) The MCU operates the red and blue LEDs (inside the labyrinth) at different rates with a low duty cycle. This conserves power and extends the life of the LEDs. To keep a constant light output (brightness), the LED drive current (light intensity) is temperature compensated by the MCU based on a temperature sensor input. Serial bus communications are controlled, as necessary, to adjust the programmable gain amplifier, digital potentiometer and LED drive circuit flash rate. (3) The MCU reads the personality pins to make an address for the smoke detector. (4) The built-in-test (BIT) function is also controlled by the MCU. BIT circuits monitor bias current, LED drive current, photodiode preamplifier output, and temperature sensor outputs to determine the health of the smoke detector. A watchdog timer circuit will reset the MCU if software errors occur. BIT is done at start-up (SBIT), periodically (PBIT), and when initiated externally (IBIT) (Refer to Table 4). SBIT and PBIT are done automatically based upon internal time/event logic. IBIT is done when requested by the hosted function. Table 4 BIT Function Circuit/Function SBIT/IBIT PBIT Program Memory Yes Yes Random Access Memory Yes No Configuration Block Memory Yes Yes Watchdog Timer Test Yes No Smoke Sensors Circuit Yes Yes Temperature Sensors Yes Yes Analog-to-Digital Converter Yes Yes CAN Bus Controller Test Yes No Valid Address Test Yes No UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 11 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (5) The airflow-overheat-temperature sensor sends an alarm signal to the MCU on the serial-data-bus when the temperature is more than 100 °C (212 °F). The LED overheat-temperature-sensor (below the labyrinth) sends an alarm signal to the MCU on the bus when the temperature inside the labyrinth is more than 100 °C (212 °F). (6) During BIT, the air-temperature-sensor output is compared to the LED temperaturesensor output. If the difference between the two outputs is more than 25 °C (77 °F) for more than seven minutes, a temperature sensor failure is reported. (7) The programmable-gain-amplifier input is ac-coupled to the preamp output to block the offset voltage made by the photodiode dark-current and ambient light. The programmable-gain-amplifier gives a way to reduce the strength of the signal received by the ADC to prevent chopping. The digital trimming circuit is a solid-state volatile-digital-potentiometer. The signal voltage obtained at the output of the photodiode detector circuit is adjusted with a 256-step resistor array. The device also adjusts the gain amplifier and the LED drive circuits. (8) A first-order variable-gain band-pass-filter adjusts the programmable gain amplifier output to a calibrated signal voltage for input to the ADC. The ADC reads the photodiode detection and amplification circuit output. In standby mode, if the signal is too low, the MCU will give a fault message and illuminate the maintenance LED. (9) In the event-mode and/or alarm-mode, the input to the ADC can be more than the ADC input-voltage limit. The MCU lowers the amplifier gain as the analog voltage gets near the ADC maximum input/output limit. When an event is found, the MCU increases the LED's flash rate to improve detection. The MCU logic section executes detection logic code to determine if: • The detector is in alarm • The detector is in standby • The labyrinth needs to be cleaned • A failure condition has occurred. (10) If smoke is found, an alarm signal is given. When the ambient temperature gets near 100 °C (212 °F), the red and blue LEDs are disabled to reduce power consumption. Instead, the smoke detector uses the temperature sensors to find fires. (11) If the photodiode is exposed to bright light (such as sunlight), the photo-detection preamplifier can become saturated. A restoration circuit restores the photodetection preamplifier to normal operation after exposure to bright light. Usually, this will not occur when the labyrinth is fully assembled. The labyrinth is designed to keep external light away from the photodiode. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 12 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (12) The power supply circuit operates from 18 to 32.2 V dc (28 V dc nominal) to make +5 V dc for use by the MCU and the CAN transceiver. A low-noise supply is used to power the preamplifier, temperature sensors, and LED drivers. The power supply input is protected from transient voltages and input power reversal. All inputs and outputs are EMI filtered to prevent false alarms. The smoke detector uses linear regulators to reduce the input power to the levels necessary for operation. This is done to prevent any high-current-switching signals usually associated with switchingmode power supplies. (13) A switching-transformer circuit makes an isolated +5 V dc to energize the isolated CAN bus. This circuit operates at a low 180 kHz switching frequency and is put after the +12 V dc linear regulator to help remove noise from the input-power lines. (14) The photodiode detector circuitry includes a: • Photovoltaic mode curent-to-voltage converting preamplifier • Programmable gain amplifier • Digital trimming circuit • Band pass filter and • ADC. The preamplifier amplifies the photodiode current by approximately 3.7x108. This high gain is obtained by using a "T" network in the amplifier feedback path. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 13 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Open-Area-Smoke-Detector-Functional-Block-Diagram Figure 3 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. DESCRIPTION AND OPERATION Page 14 Oct 02/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TESTING AND FAULT ISOLATION TASK 26-10-76-990-802-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-002-A01 A. General Information (1) This section gives the tests to find the condition of the smoke detector. It also gives test equipment and instrumentation necessary to do the tests. (2) A data sheet is located at the end of this section to record test data. SUBTASK 26-10-76-94A-005-A01 B. Consumable Materials (1) The materials necessary to do tests of the smoke detector are given below (Refer to Table 1001). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 1001 Consumable Materials Material Wick, Cotton Twill Torch* Specification or Part Number 1115-S 0.125 inch (3.175 mm) diameter (approximately) Source or CAGE Code V7E009 *Keep at 113 °F (45 - 75 °C) and less than 10% humidity for 72 hours (minimum) before use. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1001 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-94B-001-A01 C. Special Tools and Equipment (1) The tools and equipment necessary to do the tests of the smoke detector are given below (Refer to Table 1002). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source Column. Make sure you have the correct revision of the Kidde Aerospace (CAGE code 61423) software (Refer to SUBTASK 26-10-76-94B-002-A01, Kidde Aerospace Software Information). NOTE: You can get the full address and other information regarding listed vendors or suppliers at http://www.logisticsinformationservice.dla.mil. Other CAGE Code sites are also available on the Internet. Table 1002 Special Tools and Equipment Name Specification or Part Number Source or CAGE Code AC/DC IR Hipot Tester 2945 V05611 Dwell Timer: 1 minute (minimum) Ramp Timer: 0 - 5 seconds Dielectric Output: 0-800 V dc, ±5%, 60 Hz, 2V/step, 2mA IR Output: 100 - 500 V dc, 10 V/step, ±5%, 1-40MΩ BBP Interface Utility Program 171007 V61423 Cable, Burn-in N/A Make locally (Refer to SUBTASK 26-10-76-930-005-A01, Burn-In-Test Cable) Cable, USB (2) Type A to Type B USB 2.0 Commercially available DC Power Supply 72-7295 0 - 36 V dc, 10A (for 200 msec), 1% regulation, Ripple/noise 100 mVrms V376C1 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1002 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Name Specification or Part Number Source or CAGE Code Digital Multimeter (DMM) Fluke 73 V89536 0 - 36 V dc, Min/Max function, 0 - 500 mA, 0 - 1 MΩ Heat Gun, Variable Temperature 8977-20 V40817 M3000 Test Monitor Software 170820 V61423 M3000 Manual Test Set N/A Make locally (Refer to SUBTASK 26-10-76-930-001-A01, M3000-Manual-Test-Set) M3000 Functional Test Cable N/A Make locally (Refer to SUBTASK 26-10-76-930-003-A01, M3000-Functional-TestCable) M3000 IR/Dielectric Test Cable (CAN) N/A Make locally (Refer to SUBTASK 26-10-76-930-002-A01, M3000-IR/Dielectric-TestCable-(CAN)) M3000 Optical Smoke Box 474610 ±0.1% obscuration V61423 MEP Program File (Flight) 404372.hex V61423 MEP Program File (Calibration) 404515.hex.hex V61423 Milliohmmeter 1880 1A, 0 to 20 mΩ, ±1% accuracy V0PK96 Fixture, Bonding Measurement Brass, 0.25 in. thick Make locally (Refer to SUBTASK 26-10-76-930-006-A01, Bonding-Measurement Fixture) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1003 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Name Specification or Part Number Source or CAGE Code Personal Computer 1GHz, Windows XP (or greater), VGA monitor with 1024 X 768 (or greater) resolution, 128 MB RAM, two USB ports Commercially available Temperature Probe Model 80PK-1 212 °F (100 °C) (Min.) V89536 Thermocouple Module Model 80TK V89536 ValueCan USB-to-CAN Adapter (w/NeoVI software) VCAN-DWCAN-2 V1YGN2 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1004 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-490-801-A01 2. PREPARE FOR TEST SUBTASK 26-10-76-490-001-A01 A. Prepare the Personal Computer (PC) (1) Copy the M3000 Test-Monitor Software (called Test Monitor Program), P/N 170820_Installer, and the BBP-Interface Utility-Program (called BBP Interface Program), P/N 171007 on the PC's hard drive. NOTE: The Test Monitor Program is used to do the CAN-Mode Functional Test during fault isolation. The BBP Interface Program is used to do the DiscreteMode Smoke Test (part of the Return-to-Service Test). (a) Run the 170820 "Setup.exe" file to install the Test Monitor Program. The installation process puts a 170820 shortcut on the PC's desktop. (b) Make a desktop shortcut for the BBP Interface Program. Name this shortcut 171007. (2) Make a directory named "C:\CBDS". This drive/directory must be as shown. (3) Make a directory named "C:\TEMP". This is where the M3000 Test Monitor software (Test Monitor Program) will store the collected data. (4) To install the ValueCan USB-to-CAN Adapter (called ValueCan), obey the instructions "Guide for Hardware Installation" contained on the ValueCan software CD: (a) Connect the ValueCan to a USB port. (b) Install the USB High Speed Converter drivers (if not installed before). (If the installation program does not automatically start, open the "DriverAutoInstall.exe" program.) (c) Install NeoVI Explorer (on the Software CD) onto your pc (if not installed before). (If the installation program does not automatically start, open the "neoVI/ neoex.exe" program.) (d) Open NeoVI Explorer to connect the ValueCan to a PC port. Make sure the "High Speed CAN Setup" baud rate is set to Standard (125 kHz). (e) The installation process automatically installs the ValueCan to the first available port. The Test Monitor Program communicates with the smoke detector through COM4 only. If COM4 is not selected: • Go to Windows Explorer and right-click on "My Computer" • Click on "Properties" to open the "System Properties" window • Select the "Hardware" tab, then click on "Device Manager" • From the "Device Manager" window, expand "Ports (COM & LPT)" • Select "USB Serial Port" (automatically selected during the installation process) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1005 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • Click on the "Advanced Settings" button • From the "Advanced Setting ..." window, click on the "COM Port Number" dropdown menu and select "COM4". (f) Disconnect the ValueCan from the PC. NOTE: The software and the ValueCan only need to be installed one time. If the ValueCan is later installed on a different computer, it must be installed on the test computer again. SUBTASK 26-10-76-490-002-A01 B. Prepare the M3000 Optical Smoke Box (1) Use a USB cable to connect the M3000-Optical-Smoke-Box (called Smoke Box) VALUECAN jack to a USB port on the PC (Refer to Figure 1006). NOTE: The smoke box has an internal ValueCan connected to the VALUECAN jack. (2) Do the procedure in paragraph 2.A.(4) to install the smoke box's internal ValueCan to the PC. (3) Disconnect the USB cable from the PC and smoke box. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1006 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-750-801-A01 3. RETURN-TO-SERVICE TEST SUBTASK 26-10-76-750-002-A01 A. Ground Bonding Test (1) Use a milliohmmeter to measure the resistance between connector J1-11 and the test points given below (Refer to Table 1003). CAUTION: THE LABYRINTH DUST SCREEN IS FRAGILE. USE CARE WHEN YOU MEASURE THE RESISTANCE AT THE DUST SCREEN. MEASURE AT A POINT WHERE A BAFFLE IS BEHIND THE SCREEN. THIS WILL GIVE SUPPORT TO THE SCREEN. Table 1003 Ground Bonding Resistance Test Points Test Points* From J1-11 To Results J1 body or flange 25 mΩ (maximum) Aft end of housing (use Bonding Measurement Fixture) 100 mΩ (maximum) Labyrinth dust screen (see Caution, above) 100 mΩ (maximum) Center of lid 100 mΩ (maximum) *See the illustration for the location of the test points (Refer to Figure 1001). (a) When you measure to the aft end of the housing, keep the bonding measurement fixture tightly against the housing. See the illustration for the correct position of the bonding probe (Refer to Figure 1002). UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1007 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Bonding Resistance Test Points Figure 1001 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1008 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Position of Bonding Measurement Fixture Figure 1002 SUBTASK 26-10-76-750-003-A01 B. Dielectric and Insulation Resistance (IR) Test WARNING: ELECTRIC SHOCK CAN OCCUR WHEN YOU USE A HIGH POTENTIAL TESTER. DO NOT TOUCH EXPOSED UNINSULATED CONNECTIONS, COMPONENTS BEING TESTED, OR THE TESTING SURFACE. PERSONNEL WORKING WITH ELECTRICITY SHALL HAVE ANOTHER PERSON SKILLED IN MODERN METHODS OF FIRST AID AND RESUSCITATION NEARBY. (1) Energize the hipot tester and set the controls to do a dielectric and IR test: (a) Dielectric Test Settings: • Output Test Voltage - 500 V ac (60 Hz) • Ramp Time - 5 seconds • Dwell Time - 1 minute • Current Limit - 2 mA. (b) IR Test Settings: UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1009 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • Output Test Voltage - 500 V dc • Dwell Time - 1 minute • Resistance Limit - 40 MΩ. (2) Connect the M3000 IR/Dielectric Test Cable (CAN) (called IR/Dielectric Test Cable) as follows (Refer to Figure 1003): • P1 to J1 of the smoke detector • J3 (GREEN, chassis ground) to the positive (+) hipot tester jack • J1 (BLACK, common), J2 (RED, 28V), and J4 (YELLOW, CAN) to the negative (-) hipot tester jack. Dielectric/IR Test Setup: Chassis Ground Isolation Figure 1003 (3) Do the dielectric test. (a) (4) Do the IR test. (a) (5) RESULT: Leakage current = 2 mA or less. Leakage current must be constant. RESULT: > 40 MΩ or PASS indication. Disconnect the IR/Dielectric Test Cable from the hipot tester. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1010 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (6) Connect the IR/Dielectric Test Cable as follows (Refer to Figure 1004): • P1 to J1 of the smoke detector • J4 (YELLOW, CAN) to the positive (+) hipot tester jack • J1 (BLACK, common), J2 (RED, 28V), and J3 (Green) to the negative (-) hipot tester jack. Dielectric/IR Test Setup: CAN Isolation Figure 1004 (7) Do the dielectric test. (a) (8) Do the IR test. (a) (9) RESULT: Leakage current = 2 mA or less. Leakage current must be constant. RESULT: > 40 MΩ or PASS indication. Disconnect the IR/Dielectric Test Cable from the hipot tester. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1011 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-750-006-A01 C. Functional Test (1) Prepare the test equipment (Refer to TASK 26-10-76-490-801-A01, PREPARE FOR TEST). (2) Set the switches on the M3000 Manual Test Set (Manual Test Set) as follows: • PWR - OFF • REVERSE/NORMAL VOLTAGE - NORMAL • AMMETER - OFF (ammeter not in circuit) • ID0 - ON • ID1 thru ID3 - OFF • ID4 thru ID6 - any position • PAR - OFF • TEST SELECT - any position • TEST - any position • SELF TEST - any position • HORN CANCEL - any position • EXT TEMP - any position • RELAY LOAD - any position • Rotary switch - any position. (3) Use the M3000 Functional Test Cable (Functional Test Cable) to connect J1 of the Manual Test Set to J1 of the smoke detector (Refer to Figure 1005). (4) Connect the ValueCan between a PC USB port and J3 of the Manual Test Set. (5) Make sure the power supply is set to OFF. (6) Connect the power supply positive (+) output to the 28VDC banana jack (J7) on the Manual Test Set. (7) Connect the power supply negative (-) output to the RTN banana jack (J8) of the Manual Test Set. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1012 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Functional Test Setup Figure 1005 (8) Connect the DMM (set to measure current) to the Manual Test Set's AMMETER NEG (J5) and POS (J6) banana jacks. (9) Set the AMMETER switch to ON (ammeter in circuit). (10) Set the power supply to ON and adjust the output as follows: • Voltage - +28 ±0.5 V dc • Current Limit - 105 mA (max). (11) Do the power-consumption test: (a) On the PC, double-click the 170820 icon to open the Test Monitor Program. (b) On the Manual Test Set, set the PWR switch to ON. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1013 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CAUTION: REMOVE POWER FROM THE SMOKE DETECTOR IF THE CURRENT IS MORE THAN 75 mA. DAMAGE TO THE UNIT CAN OCCUR. (c) Monitor the DMM for too much current. If the current is more than 75 mA, immediately set the power supply to OFF. During the power-consumption test, continue to monitor the input current. (d) Monitor the smoke detector Status Indicator (Refer to DESCRIPTION AND OPERATION, Table 3). 1 RESULT 1: Initially, the indicator is red (stable). After 10 seconds (minimum) (time for cold-start to complete), the indicator is green (flashes at 1 Hz rate) 2 RESULT 2: After cold-start, the normal current is 20 - 45 mA. (12) Do the input-power-reversal test: CAUTION: (a) Set and hold the REVERSE/NORMAL VOLTAGE switch to REVERSE. 1 (b) REMOVE POWER FROM THE SMOKE DETECTOR IF THE CURRENT IS MORE THAN 1 mA. DAMAGE TO THE UNIT CAN OCCUR. RESULT: The reverse current must be less than 1.0 mA. Release the REVERSE/NORMAL VOLTAGE switch to NORMAL (13) Retrieve the NVM data as follows: (a) Select the "Smoke Detector" tab. (b) Select the "MSG 4" tab. (c) Click on "TX" to read the NVM fault data from CAN bus Message 4. NOTE: Smoke detector fault data is contained in Message 4. Other information, such as aircraft tail number, phase of flight, and date and time are contained in Messages 5 and 6. (d) To save the NVM data, take a "screen-shot" of, or otherwise record, the "Data:" part of the CAN bus messages shown in the "SD CAN Payload 4" box. The data part of the messages look like this: "Data: 0A 00 00 00 00 00 00 00" (example). Make sure the messages have completed scrolling (download is completed) before you make a screen shot. (e) Do steps (b) thru (d) again, except use the "MSG 5" and "MSG 6" tabs, to save the Message 5 and Message 6 data. (f) On the PC, close the 170820 Test Monitor Program. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1014 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (14) Install the calibration MEP file as follows: (a) Set the switches on the Manual Test Set as follows: • PWR - OFF • ID0 thru ID3 - ON • PAR - ON. (b) Set the PWR switch to ON. (c) On the PC, double-click the 171007 icon to open the BBP Interface Utility Program (BBP Program). (d) 1 In the "LRU Type" box, click on "Smoke" 2 Click on the "Open neoVI" button. Make sure "Value CAN X SN XXXXX" shows below "VCAN Type" radio button. ("X" shows Value CAN number and serial number.) On the menu, select File>Open>MEP. 1 Select "C:\474449\MEP\404515.hex. 2 Click on "Open". (e) Make sure the Calibration MEP CRC text box contains the correct CRC data (Refer to REPAIR, Table 6011). If the CRC is not correct do step (d) again (f) Click on the "Load MEP CRC" button. (g) Click on the "Write MEP to Flash" button. Wait until the MEP download is completed. A progress bar shows the time that remains. When the program download is completed, "Download Complete" shows in the status bar. (h) Click on the "Read Configuration Data" button. (i) Click on the "Enable NVM Writes" button (j) Click on the "OK" button to write to the NVM. (k) Click on the "Clear NVM" button. Make sure address numbers scroll through the message text box. (l) Click on the "Read NVM Range" button. An NVM dialog box will appear. Look at the "Fault Record Summary" text box. If there are no faults, the "Count" will equal "0" for each Fault. If there are faults, do paragraph (k) again. If there are still faults, find and correct the malfunction. (m) On the Manual Test Set, set the PWR switch to OFF. (n) On the PC screen: • Close the NVM dialog box UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1015 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • Close the 171007 BBP Interface Utility program. (o) The MCU is now programmed with the Calibration MEP program (15) Do a test of CAN Bus Messages 4, 2, 3, 8, and 11, as follows: (a) Set the switches on the Manual Test Set as follows: • PWR - OFF • ID0 - ON • ID1 thru ID3 - OFF • PAR - OFF. (b) Set the PWR switch to ON. (c) On the PC, double-click the 170820 icon to open the Test Monitor Program.. (d) Select the "Smoke Detector" tab. (e) Select the "MSG 4" tab. (f) Click on "TX" to read the NVM fault data from CAN bus Message 4. (g) If CAN bus Message 4 shows no faults (Refer to Table 1006), continue to step (i) . (h) If CAN bus Message 4 shows faults (Refer to Table 1006), stop the functional test. Make the necessary repairs and do the Return-to-Service Test again. (i) Select the "MSG 3" tab. (j) Select "TX". 1 RESULT: Hardware P/N equals the "PNR" on the smoke detector's Nameplate. (k) Select the "MSG 8" tab. (l) Select "TX" to request the date-of-manufacture data contained in CAN bus Message 8. 1 RESULT: Manufacturing Date shows the date-of-manufacture (MM/DD/ YYYY). (The MFR DATE on the Nameplate shows only MM/YY.) (m) Select the "MSG 11" tab. (n) Select "TX". 1 (o) RESULT: Serial Number equals the "SER" on smoke detector's Nameplate. On the Manual Test Set, set the PWR switch to OFF and disconnect the smoke detector. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1016 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (p) On the PC, close the 170820 Test Monitor Program (optional). (q) Set the power supply to OFF. (16) Do the smoke test setup (Refer to Figure 1006): (a) Make sure the power supply is OFF. (b) Make sure the smoke box PWR switch is set to OFF. (c) Connect the smoke box to the power supply: • 28VDC jack to the power supply positive (+) output • RTN jack to the power supply negative (-) output. (d) Connect the smoke box to the PC: • DAC (digital-to-analog converter) output to a PC USB port • ValueCan output to a PC USB port. Make sure the ValueCan has been installed to the PC. (Refer to SUBTASK 26-10-76-490-002-A01, Prepare the M3000 Optical Smoke Box). (e) Connect the smoke detector to the cable inside the smoke box. Place the smoke detector on the mounting-block in the center of the smoke box. Make sure the face of the housing/screen assembly is up. There must be no blockage of the airflow through the labyrinth. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1017 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Smoke Test Setup Figure 1006 (17) Do the smoke test as follows: (a) Set the power supply to ON and adjust the output as follows: • Voltage - +28 ±0.5 V dc • Current Limit - 1A (max). (b) On the smoke box, set the PWR switch to ON. Make sure the fan operates. (c) Close and latch the smoke box door. (d) Close the smoke box exhaust valve. (e) On the PC, double-click the 170820 icon to open the Test Monitor Program. 1 Select the "Smoke Detector" tab. 2 Select the "MSG 0" tab. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1018 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 3 Wait 60 seconds (minimum). Make sure the Red and Blue smoke parameter values shown in the "Top" (Blue) and "Bottom" (Red) boxes are less than 0.200 V dc. 4 Click on the "Box Enable" button (enables the PC to calculate the smoke concentration in the smoke chamber). Wait until the "Concentration" window shows "-INF". 5 Select the "Reference Reading" button. RESULT 1: "Concentration" window display changes from "-INF" to "0" (±0.1) after 7 seconds. (f) Hold a flame to one end of the wick until the wick burns. Extinguish the fire. Put the end of the wick that gives off smoke through the hole in the side of the smoke chamber. Put the wick one inch inside the smoke chamber. (g) Monitor the "Concentration" and "Alarm Status" windows on the PC screen. When the concentration increases to near 5.0, remove the wick from the chamber. Put the wick, momentarily, into the smoke chamber (as many times as necessary) to slowly increase the concentration of smoke until the "Alarm High" indicator comes on. 1 RESULT: 1. Smoke parameter equals 6.0 to 8.0. 2. Smoke concentration equals 4.5 to 5.5% 3. The smoke detector status indicator is red (continuous). 4. The "Temperature Alarm" indicator does not come on. NOTE: The "Pre-Alarm", "Alarm Low", and "Alarm Mid" indicators will come on at lower smoke concentrations than the "Alarm High" indicator. (h) Open the smoke box exhaust valve to remove the smoke. Make sure all the alarm indicators are OFF when there is no smoke in the smoke chamber. (i) Open the smoke box door. (18) Do the Forward Voltage and Temperature test as follows: (a) On the PC: 1 Select the "MSG 1" tab. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1019 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 2 Select "TX" to request the LED forward voltage data (in hexadecimal) contained in CAN bus Message 1. A typical CAN bus message looks like this "ARB ID: 06100103, G/L: 0, Group ID:[Base: 03,Offset; 01], Msg ID: 00, Qual: 01, Func Status:03 Data 02 EC 02 E5 02 6B 00 EE". The data is contained in the eight bytes (0 thru 7) that follow "DATA:". Bytes 4 and 5 contain the Blue LED data. Bytes 6 and 7 contain the Red LED data. The table below shows an example of the data portion of the message (Refer to Table 1004). Bytes 4 and 5 show a Blue LED value of 26B. Bytes 6 and 7 show a Red LED value of EE. Table 1004 Example of Forward LED Voltage Data Data: 3 Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 02 EC 02 E5 02 6B 00 EE Look at the "SD CAN Payload 1" window and read CAN bus message 1. RESULT: • Value (Hex) in bytes 4 and 5 is in the range of 20F to 2E5. • Value (Hex) in bytes 6 and 7 is in the range of DC to F5. 4 Look at the "Temp 1" and "Temp 2" boxes. a RESULT: Temperature 1 is ±10 °F of Temperature 2, (b) Select the "MSG 9" tab. (c) Select "TX" to request the POT settings data (in hexadecimal) contained in CAN bus Message 9. These are the potentiometer settings from the last calibration. 1 RESULT: • POT 1 must be in the range of 1E - A0. • POT 2 must be in the range of 1E - A0. • POT 3 must be in the range of 37 - 6E. • POT 4 must be in the range of 19 - 64. (d) Select the "MSG 10" tab. (e) Select "TX" to request the last calibration data (in hexadecimal) contained in CAN bus Message 10. 1 RESULT: • IR Zero Cal = 80<Value>190 • Blue Zero Cal = 10<Value>90. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1020 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (19) Do the Temperature-Alarm test as follows: NOTE: The temperature-alarm test can be done in either the functional test configuration (Refer to Figure 1005) or the smoke test configuration (Refer to Figure 1006). Here, the test is done in the smoke test configuration. (a) On the PC, double-click the 170820 icon to open the Test Monitor Program. 1 Select the "Smoke Detector" tab. 2 Select the "MSG 0" tab. WARNING: PUT ON THERMALLY INSULATED GLOVES AND OTHER APPLICABLE PROTECTION TO PREVENT BURNS WHEN YOU USE THE HOT AIR SOURCE. LET THE EQUIPMENT AND UNIT BECOME COOL BEFORE YOU TOUCH THEM. CAUTION: KEEP THE HEAT SOURCE AT LEAST 1.00 IN. (2.54 CM) AWAY FROM THE SMOKE DETECTOR. TOO MUCH HEAT CAN CAUSE DAMAGE TO THE SMOKE DETECTOR HOUSING AND INTERNAL COMPONENTS. (b) Use the heat gun to blow hot air into the smoke detector. Point the heat gun so the air goes into the hole near the labyrinth. This hole is 180 degrees from the light pipe and directly above the airflow-overheat-temperature sensor (U4). Keep the tip of the heat gun at least four inches away from the smoke detector. (c) On the PC screen, monitor the "Temp" window (located at the upper left of the "TEMP CHART"). Record the temperature when the smoke detector alarms: 1 (d) RESULT: The temperature must be more than 212 °F (100 °C). Look at the PC screen "Alarm Status" window. 1 RESULT: • "Temperature Alarm" indicator is ON. • Smoke Alarm indicators (Pre, Low, Medium, and High) are OFF. (e) Use the heat gun, at the cool air setting, to blow cool air onto the smoke detector. On the PC, monitor the "Temp" window and the "Temperature Alarm" indicator. 1 RESULT: The "Temperature Alarm" goes OFF at less than 194 °F (90 °C). (f) On the smoke box, set the PWR switch to OFF. (g) Set the power supply to OFF. (h) Disconnect and remove the smoke detector from the smoke box. (i) Disconnect the smoke box from the PC. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1021 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (20) Install the flight MEP file as follows: (a) On the Manual Test Set, set the PWR switch to OFF. (b) On the PC, close the 170820 Test Monitor Program. (c) Set the switches on the Manual Test Set as follows: • PWR - OFF • REVERSE/NORMAL VOLTAGE - NORMAL • AMMETER - OFF (ammeter not in circuit) • ID0 thru ID3 - ON • ID4 thru ID6 - any position • PAR - ON • TEST SELECT - any position • TEST - any position • SELF TEST - any position • HORN CANCEL - any position • EXT TEMP - any position • RELAY LOAD - any position • Rotary switch - any position. (d) Use the Functional Test Cable to connect J1 of the Manual Test Set to J1 of the smoke detector (Refer to Figure 1006). (e) Connect the ValueCan between the PC and J3 of the Manual Test Set. (f) Set the power supply to ON and adjust the output voltage to +28 ±0.5 V dc. (g) On the Manual Test Set, set the PWR switch to ON. (h) On the PC, double-click the 171007 BBP Interface Utility program. (i) On the PC screen: (j) 1 In the "LRU Type" box, click on "Smoke" 2 Click on the "Open neoVI" button. Make sure "Value CAN X SN XXXXX" shows below "VCAN Type" radio button. On the menu, select File>Open>MEP. 1 Select "C:474449\MEP\404372.hex". 2 Click on "Open". (k) Make sure the Flight MEP CRC text box contains the correct CRC data (Refer to REPAIR, Table 6011). If the CRC is not correct do step (j) again (l) Click on the "Load MEP CRC" button. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1022 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (m) Click on the "Write MEP to Flash" button. Wait until the MEP download is completed. A progress bar shows the time that remains. When the program download is completed, "Download Complete" shows in the status bar. (n) Click on the "Read Configuration Data" button. (o) Click on the "Enable NVM Writes" button (p) Click on the "OK" button to write to the NVM. (q) Click on the "Clear NVM" button. Make sure address numbers scroll through the message text box. (r) Click on the "Read NVM Range" button. An NVM dialog box will appear. Look at the "Fault Record Summary" text box. If there are no faults, the "Count" will equal "0" for each Fault. If there are faults, do paragraph (q) again. If there are still faults, find and correct the malfunction. (s) On the PC screen, close the NVM dialog box. (t) Click on the "Extract CBDS from NVM" button. The CBDS will be written to C: \CBDS\CBDS.hex (this directory was created during the functional test). (u) Select File>Open>CBDS>CBDS.hex. (v) Click on the "Open" button. (w) Click on the "Load in NVM" button (to the right of the "CBDS CRC" text box). (x) On the Manual Test Set, set the PWR switch to OFF. (y) On the PC, close the 171007 BBP Interface Utility program. (z) The MCU is now programmed with the Flight MEP program. (21) Do the Pin-Programming Test as follows: NOTE: In this test, the ID switches are used to assign an identification number (0 thru 4) to the smoke detector. In the CAN bus message, the ID number is located in the first two digits that follow "Msg ID:". For example, "Msg ID: 00" shows that the smoke detector under test is programmed as smoke detector # 0. (a) Set the switches on the Manual Test Set as follows: • ID0 thru ID3 - OFF • PAR - OFF. (b) On the Manual Test Set, set the PWR switch to ON. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1023 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (c) On the PC, double-click the 170820 icon to open the Test Monitor Program. 1 Select the "Smoke Detector" tab. 2 Select the "MSG 0" tab. RESULT: No CAN bus communications (no messages in the "SD CAN Payload 0" window. (d) On the Manual Test Set: • Set the PWR switch to OFF • Set the ID0 switch to ON. Wait two seconds. • Set the PWR switch to ON. (e) Look at the "SD CAN Payload 0" window: 1 (f) RESULT: "MSG ID:00" On the Manual Test Set: • Set the PWR switch to OFF • Set the ID0 switch to OFF. • Set the ID1 switch to ON. Wait two seconds. • Set the PWR switch to ON. (g) Look at the "SD CAN Payload 0" window: 1 (h) RESULT: "MSG ID:01" On the Manual Test Set: • Set the PWR switch to OFF • Set the ID1 switch to OFF. • Set the ID2 switch to ON. Wait two seconds. • Set the PWR switch to ON. (i) Look at the "SD CAN Payload 0" window: 1 (j) RESULT: "MSG ID:02" On the Manual Test Set: • Set the PWR switch to OFF • Set the ID2 switch to OFF. • Set the ID3 switch to ON. Wait two seconds. • Set the PWR switch to ON. (k) Look at the "SD CAN Payload 0" window: 1 (l) RESULT: "MSG ID:03" On the Manual Test Set: UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1024 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • Set the PWR switch to OFF • Set the ID3 switch to OFF. • Set the PAR switch to ON. Wait two seconds. • Set the PWR switch to ON. (m) Look at the "SD CAN Payload 0" window: 1 (n) RESULT: "MSG ID:04" On the Manual Test Set: • Set the PWR switch to OFF • Set the PAR switch to OFF. (22) Make sure the MEP (Flight) CRC value is correct: (a) On the Manual Test Set: • Set the ID0 switch to ON • Make sure ID1 thru ID3 and PAR are set to OFF • Wait two seconds • Set the PWR switch to ON. (b) Select the "MSG 2" tab. (c) Select "TX" (select "TX" as many times as necessary, until the data is shown). 1 RESULT: BBP and MEP software part numbers are correct as shown in the Software Effectivity table (Refer to REPAIR, Table 6011). (d) On the PC, select "MSG 7" tab. (e) Select "TX" to request the CRC data contained in CAN bus Message 7. 1 RESULT: MEP CRC data = MEP (Flight) CRC value shown in the Software Effectivity table (Refer to REPAIR, Table 6011). If the CRC value is not correct, the flight MEP is not loaded in the MCU. (23) Do the IBIT Test as follows: (a) Adjust the power supply output voltage to 18 ±0.5 V dc. (b) On the PC, select the "MSG 0" tab. (c) Click the "TX" button (creates IBIT). For a successful boot-up, the results that follow must occur in 10 seconds (maximum): RESULT 1: • The Status Indicator is red (stable) • CAN messages do not scroll (CAN bus is not communicating) RESULT 2: • The Status Indicator is green (flashes) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1025 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • CAN messages scroll (CAN bus communicates) (d) Continue to monitor the Status Indicator and "SD CAN Payload 0" window for 10 more seconds. Make sure RESULT 2 from the step above continues. (e) Adjust the power supply output voltage to 32 ±0.5 V dc (f) Click the "TX" button (creates IBIT). For a successful boot-up, the results that follow must occur in 10 seconds (maximum): RESULT 1: • The Status Indicator is red (stable) • CAN messages do not scroll (CAN bus is not communicating) RESULT 2: • The Status Indicator is green (flashes) • CAN messages scroll (CAN bus communicates) (g) Continue to monitor the Status Indicator and "SD CAN Payload 0" window for 10 more seconds. Make sure RESULT 2 from the step above continues. (h) Adjust the power supply output voltage to 28 ±0.5 V dc (i) On the PC, close the 170820 Test Monitor Program. (24) Clear the NVM: (a) (b) On the Manual Test Set, make sure the PWR switch is set to OFF. 1 Set the ID0 thru ID3 switches to ON. 2 Set the PAR switch to ON. 3 Set the PWR switch to ON. On the PC, double-click the 171007 icon to open the BBP Program. 1 In the "LRU Type" box, click on "Smoke" 2 Click on the "Open neoVI" button. Make sure "Value CAN X SN XXXXX" shows below "VCAN Type" radio button. 3 Click on the "Read Configuration Data" button. 4 Click on the "Enable NVM Writes" button 5 Click on the "OK" button to write to the NVM. 6 Click on the "Clear NVM" button. A series of addresses will scroll across the "Messages" text window as the NVM is cleared. When the NVM is cleared, the addresses will stop scrolling. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1026 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (c) 7 Click on the "Read NVM Range" button. An NVM dialog box will appear. Look at the "Fault Record Summary" text box. The "Count" must equal "0" for each Fault. 8 If fault messages occur, do steps 6 and 7 again. If faults continue, find and correct the fault (Refer to TASK 26-10-76-810-801-A01, FAULT ISOLATION) and do the functional test again. 9 Close the NVM dialog box. Close the 171007 BBP Program. (25) On the Manual Test Set, set the PWR switch to OFF. (26) On the Manual Test Set, set the switches that follow: • ID0 - ON • ID1 thru ID3 - OFF • PAR - OFF. (a) On the Manual Test Set, set the PWR switch to ON. Wait a minimum of 10 seconds before you do the next step (time for cold-start to complete) (b) On the smoke detector, monitor the Status Indicator. RESULT: The indicator is green (flashes at 1 Hz rate) (normal state). (c) On the Manual Test Set, set the PWR switch to OFF. (27) Set the power supply to OFF. (28) Disconnect the smoke detector from the test equipment. SUBTASK 26-10-76-750-005-A01 D. 50-Hour Burn-In Test (1) This test energizes the smoke detector for 50-hours after the dielectric, IR, and functional test are completed. The purpose of this test is to let the smoke detector do at least one self-calibration. (2) Set the power supply to ON and adjust the output as follows: • Voltage - +28 ±0.5 V dc • Current Limit - 1A (max). (3) Set the power supply to OFF. (4) Use the Burn-in Test cable to connect the smoke detector to the power supply (Refer to Figure 1007): • P1 of the cable to J1 of the smoke detector • Pin 6 of the cable to the positive (+) output of the power supply • Pins 1, 2 8 of the cable to the negative (-) output of the power supply. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1027 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 50-Hour Burn-in Setup Figure 1007 (5) Set the power supply to ON. (6) Monitor the smoke detector Status Indicator (Refer to DESCRIPTION AND OPERATION, Table 3). RESULT: Initially, the indicator is red (stable). After 10 seconds (minimum) (time for cold-start to complete), the indicator is green (flashes at 1 Hz rate). (7) Keep the smoke detector energized for 50 hours continuously before you do the next step. If the power is removed from the smoke detector before 50 hours, the 50Hour Burn-in test must be done again. (8) Set the power supply to OFF. (9) Disconnect the smoke detector and Burn-in Test cable from the power supply. (10) Do the Functional Test (Refer to SUBTASK 26-10-76-750-006-A01, Functional Test), Retrieve NVM Data procedure, to find any MSG 4 faults. If there are no faults, the smoke detector has passed the return-to-service test. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1028 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-810-801-A01 4. FAULT ISOLATION SUBTASK 26-10-76-810-001-A01 A. Fault Isolation (1) Use the data below to find the cause of the malfunction (Refer to Table 1005). Table 1005 Fault Isolation Data Fault Probable Cause Correction Smoke detector fails the Defective chassis Ground Bonding Test ground connection Make sure the attaching hardware for the circuit card assembly is torqued correctly. Make sure there is no unwanted material (conformal coating, adhesive) on the area adjacent to the mounting holes. Lid is not attached correctly. Make sure the attaching hardware for the lid is torqued correctly. Defective EMI gasket in lid. Replace the lid. Bond between dust screen and labyrinth is defective Replace conductive adhesive. Smoke detector fails the Defective CCA/ Dielectric/IR test. Labyrinth assembly. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Use the smoke detector schematics and the IR/ Dielectric test cable schematic to troubleshoot the circuits. Repair or replace the CCA/ Labyrinth assembly. TESTING AND FAULT ISOLATION Page 1029 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Fault Probable Cause Smoke detector fails the Defective CCA/ Functional Test. Labyrinth assembly. Correction Refer to the fault messages in NVM to help find the malfunction [refer to paragraphs 4.A.(2) & (3)]. Repair or replace the CCA/Labyrinth assembly. Smoke detector fails the The labyrinth is too dirty Clean the labyrinth. smoke test. for the self-correcting circuits to compensate. Smoke calibration settings are incorrect. (2) Calibrate the smoke detector. During operation, smoke detector fault data is stored in NVM. This data can be read as messages contained in CAN bus Message 4. If the "DATA" part of any of the messages shows "DATA: 0x 00", there are no faults. If there is a fault message, the first bit will show the number of fault occurrences (up to 7). The second bit (shown by "x") shows the type of failure that has occurred. If the first bit shows any number other than "0", the smoke detector has a failure (Refer to Table 1006). There are 16 possible failures (0 thru Fhex). For example: "7F" shows there were seven temperature alarm events. Table 1006 NVM Failure Examples Pass Fail Data:00 Data:10 Data:01 Data:11 Data:02 Data:22 Data:03 Data:33 Data:04 Data:44 Data:05 Data:75 Data:06 Data:56 Data:07 Data:27 Data:08 Data:28 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1030 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Pass (3) Fail Data:09 Data:29 Data:0A Data:3A Data:0B Data:4B Data:0C Data:5C Data:0D Data:6D Data:0E Data:2E Data:0F Data:7F Faults and events are displayed in the CAN bus Message 0 screen in the "Alarm Status" or "Fault Status SD" windows (Refer to Table 1007). Table 1007 NVM Fault/Event Record Fault Number (Hex) Fault/Event Condition CAN Message 0: Alarm/Fault Status 0 Program Memory (FLASH) Memory test fails twice. No CAN transmission 1 Configuration Memory (EEPROM) Memory test fails twice. No CAN transmission Watchdog Timer Watchdog timer does not reset MCU. No CAN transmission CAN Bus Fails internal loopback test. No CAN transmission 4 IR LED LED failure Circuit Fault 5 Blue LED LED failure Circuit Fault 6 Photo-diode Photo-diode failure Circuit Fault 7 Programmable Gain Amplifier No detected gain change Circuit Fault Analog/Digital Converter At least 1 or 3 test Circuit Fault point measurements is out of tolerance. 2 3 8 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1031 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Fault Number (Hex) Fault/Event Condition CAN Message 0: Alarm/Fault Status Temperature Difference Sensor reading differs more than 10 C for more than 500 seconds. Temp Fault Air Temperature Sensor Circuit Fault A Cannot communicate correctly with sensor. Air and Labyrinth fault if temperature is different by more than 20 °C. Circuit Fault B Labyrinth Temperature Cannot communicate Sensor correctly with sensor. Air and Labyrinth fault if temperature is different by more than 20 °C. Valid Address Invalid address detected. No CAN transmission Cargo Alarm Alarm active depending on alarm sensitivity selected, Alarm Lo, Alarm Mid, or Alarm Hi. Alarm Low Alarm Mid/High Temperature Alarm Alarm active Temperature Alarm 9 C D Reserved E F UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1032 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-990-803-A01 5. RETURN-TO-SERVICE-TEST DATASHEET SUBTASK 26-10-76-99F-017-A01 A. Datasheet Return To Service Test Datasheet Part No. SHEET 1 of 4 474449-5 Serial No. Tested By/Date: Inspected By/Date: Para Test Description Expected Value Results • J1-11 to J1 Body ≤ 25 mΩ PASS / FAIL • J1-11 to Housing ≤ 100 mΩ PASS / FAIL • J1-11 to Dust Screen ≤ 100 mΩ PASS / FAIL • J1-11 to Lid ≤ 100 mΩ PASS / FAIL Ground Bonding 3.A.(1) Dielectric 3.B.(3) • CAN Bus ≤ 2 mA PASS / FAIL 3.B.(7) • Chassis Gnd ≤ 2 mA PASS / FAIL Insulation Resistance 3.B.(4) • CAN Bus > 40 MΩ PASS / FAIL 3.B.(8) • Chassis Gnd > 40 MΩ PASS / FAIL Power Consumption 3.C.(11)(d) • Status LED at start • Current (after cold-start) 3.C.(12)(a) Reverse current UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Initially Red (stable). After PASS / FAIL cold-start, Green (flashes). 20 - 45 mA PASS / FAIL < 1 mA PASS / FAIL TESTING AND FAULT ISOLATION Page 1033 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Return To Service Test Datasheet Para Test Description SHEET 2 of 4 Expected Value Results Part number is correct PASS / FAIL 3.C.(15)(n) • CAN Message 8 date of manufacture Date is correct PASS / FAIL 3.C.(15)(p) • CAN Message 11 serial number Serial number is correct PASS / FAIL 6.0 to 8.0 PASS / FAIL 4.5 to 5.5 %/ft PASS / FAIL Red (stable) PASS / FAIL OFF PASS / FAIL CAN bus communications 3.C.(15)(l) • CAN Message 3 Hardware PN Smoke Test 3.C.(17)(g) • Smoke parameter at Alarm High • Smoke concentration at Alarm High • Status Indicator • Temperature Alarm Indicator during smoke alarm. 3.C.(17)(h) • Alarm High clears as smoke concentration is reduced All alarms are off in clear air PASS / FAIL Forward Voltage and Temperature 3.C.(18)(a) • Blue LED Fwd voltage (bytes 4 & 5) • Red LED Fwd voltage (bytes 6 & 7) 20F to 2E5 PASS / FAIL DC to F5 PASS / FAIL • Temperature sensors test Temp 1 is ±10 °F of Temp 2 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. PASS / FAIL TESTING AND FAULT ISOLATION Page 1034 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Return To Service Test Datasheet Para SHEET 3 of 4 Test Description Expected Value Results POT 1 = 50 to A0 PASS / FAIL POT 2 = 50 to A0 PASS / FAIL POT 3 = 37 to 6E PASS / FAIL POT 4 = 19 to 64 PASS / FAIL IR Zero Cal = 80 to 190 PASS / FAIL Blue Zero Cal = 20 to 90 PASS / FAIL 3.C.(18)(c) • POT settings from last calibration 3.C.(18)(e) • Last zero calibration data (CAN Message 10) Temperature Alarm Threshold 3.C.(19)(c) • Temperature Alarm Alarm is ON @ > 212 °F (100 °C) PASS / FAIL 3.C.(19)(d) • Temperature Alarm indicator Temperature Alarm indicator is ON. PASS / FAIL • Smoke alarm indicators (Pre, Low, Medium, High) with Temperature Alarm Smoke alarms are OFF PASS / FAIL No CAN bus communications PASS / FAIL 3.C.(21)(e) • ID0 ON MSG ID = 00 PASS / FAIL 3.C.(21)(g) • ID1 ON MSG ID = 01 PASS / FAIL 3.C.(21)(i) •ID2 ON MSG ID = 02 PASS / FAIL 3.C.(21)(k) • ID3 ON MSG ID = 03 PASS / FAIL 3.C.(21) (m) MSG ID = 04 PASS / FAIL Pin-Programming 3.C.(21)(c) • All ID switches OFF • PAR ON UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. TESTING AND FAULT ISOLATION Page 1035 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Return To Service Test Datasheet Para Test Description SHEET 4 of 4 Expected Value 3.C.(22)(b) BBP software identification 40437104 MEP (flight) software identification 3.C.(22)(d) CAN Message 7 CRC 32bit data 40437213 Results PASS / FAIL PASS / FAIL MEP (flight) CRC = 7D21A509 PASS / FAIL 3.C.(23)(d) • IBIT at 18 V dc Detector boots up correctly. PASS / FAIL 3.C.(23)(g) • IBIT at 32 V dc Detector boots up correctly. PASS / FAIL IBIT 3.C.(24)(b) • Clear NVM • On power-up, detector boots up correctly. 3.D.(10) 50-hour burn-in UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Zero faults PASS / FAIL LED is green (flashes @ 1 PASS / FAIL Hz) Zero faults PASS / FAIL TESTING AND FAULT ISOLATION Page 1036 Feb 09/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SCHEMATICS AND WIRING DIAGRAMS TASK 26-10-76-990-811-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-015-A01 A. General Information (1) This section gives the schematic applicable to the smoke detector. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2001 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2002 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-995-801-A01 2. SCHEMATIC SUBTASK 26-10-76-995-001-A01 A. Schematic (1) The schematic applicable to the smoke detector is given below (Refer to Figure 2001). UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2003 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 1 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2004 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 2 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2005 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 3 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2006 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 4 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2007 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 5 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2008 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 6 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2009 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 7 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2010 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 8 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2011 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model-3000-Open-Area-Smoke-Detector-Schematic Figure 2001 (Sheet 9 of 9) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SCHEMATICS AND WIRING DIAGRAMS Page 2012 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 DISASSEMBLY TASK 26-10-76-990-803-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-004-A01 A. General Information (1) This section contains disassembly procedures for the smoke detector. Item numbers in the procedures are the same as those in the Illustrated Parts List (IPL). (2) Disassemble the smoke detector only as much as necessary to do troubleshooting or to make repairs. SUBTASK 26-10-76-94A-009-A01 B. Special Tools and Equipment (1) The special tools and equipment necessary to repair the smoke detector are given below (Refer to Table 3001). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can get the full address and other information regarding listed vendors or suppliers at http://www.logisticsinformationservice.dla.mil. Other CAGE Code sites are also available on the Internet. Table 3001 Special Tools and Equipment Name Socket, Thin Wall UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Specification or Part Number Socket Size:1/4-in Drive Size; 1/4-in Socket Points: 6 Outside Wall Diameter: 0.305 in (maximum) Source or CAGE Code Make or get Locally 26-10-76 DISASSEMBLY Page 3001 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 DISASSEMBLY Page 3002 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-000-801-A01 2. DISASSEMBLY PROCEDURES SUBTASK 26-10-76-010-001-A01 A. Disassembly Procedures CAUTION: (1) To remove the lid ( IPL Figure 1, 5), remove the four screws (10A), (15A), and flat washers (25). CAUTION: (2) THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. THE CIRCUIT CARD ASSEMBLY (CCA) CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL) NOMENCLATURE AREA. OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE CCA OR DAMAGE CAN OCCUR. To remove the CCA/labyrinth assembly (IPL Figure 1, 30): • Remove the four screws (35A), and flat washers (45) • Remove the four screws (50), flat washers (55), and the nutplate (60) • Move the wires through the slot in the housing (75) and remove the CCA/ Labyrinth Assembly (30) from the housing. (3) To remove the gasket (IPL Figure 1, 62), pull the gasket over the flange of the connector (J1). (4) If it is necessary to remove the light pipe (IPL Figure 1, 80), refer to REPAIR. CAUTION: (5) DO NOT USE A STANDARD 0.25 INCH SOCKET WHEN YOU REMOVE OR INSTALL THE HEX NUTS. YOU CAN DAMAGE TRANSISTOR Q1 ON THE CCA. USE A 0.25 INCH SOCKET WITH A MAXIMUM OUTSIDE DIAMETER OF 0.305 INCHES. To remove the labyrinth top (IPL Figure 2, 5): • Remove the conductive compound that forms a seal between the dust screen (25) and the top. • Remove the three fasteners (20), flat washers (15), and hex nuts (10). • Lift and straighten the three tabs of the dust screen (25). • Lift the labyrinth top (5) off the labyrinth assembly. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 DISASSEMBLY Page 3003 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 DISASSEMBLY Page 3004 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CLEANING TASK 26-10-76-990-804-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-013-A01 A. General Information (1) This section has the procedures necessary to clean the smoke detector. SUBTASK 26-10-76-94A-007-A01 B. Consumable Materials (1) The materials necessary to clean the smoke detector are given below (Refer to Table 4001). NOTE: You can use equivalent alternatives for the items given in the table. Table 4001 Consumable Materials Material Specification or Part Number Source or CAGE Code Alcohol, Isopropyl ASTM D770 Commercially Available Brush, Soft Bristle None Commercially Available Cloth, Low Lint Absorbent A-A-59323 Commercially Available Soap, Liquid None Commercially Available Swabs, Cotton None Commercially Available UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CLEANING Page 4001 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CLEANING Page 4002 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-100-802-A01 2. PROCEDURES CAUTION: DO NOT CLEAN INSIDE THE LABYRINTH UNLESS DIRECTED TO DO SO. THE SMOKE DETECTOR AUTOMATICALLY ADJUSTS THE LABYRINTH CALIBRATION TO CORRECT FOR UNWANTED MATERIALS INSIDE THE LABYRINTH. IF YOU CLEAN THE LABYRINTH, THE SMOKE DETECTOR MAY NOT OPERATE CORRECTLY. SUBTASK 26-10-76-100-001-A01 A. Non-Electrical Parts CAUTION: (1) THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. Clean all non-electrical parts as follows: WARNING: USE ISOPROPYL ALCOHOL, ASTM D770, CORRECTLY. ISOPROPYL ALCOHOL IS FLAMMABLE, EXPLOSIVE, AND A MILD POISON. IT CAN HAVE A BAD EFFECT ON YOUR HEALTH OR SAFETY. BEFORE YOU USE THE ALCOHOL, GET THE SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. BEFORE YOU USE THE ALCOHOL, PUT ON CHEMICAL-SPLASH GOGGLES. MAKE SURE THAT YOU HAVE SUFFICIENT AIRFLOW TO KEEP THE ALCOHOL FUMES BELOW THE SAFETY DATA SHEET LIMIT. (a) Clean the external surfaces with a low-lint cloth moist with isopropyl alcohol. (b) Dry the surfaces with a dry low-lint cloth. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CLEANING Page 4003 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-100-002-A01 B. Electrical Parts (1) Clean connectors and other electrical components as follows: WARNING: USE ISOPROPYL ALCOHOL, ASTM D770, CORRECTLY. ISOPROPYL ALCOHOL IS FLAMMABLE, EXPLOSIVE, AND A MILD POISON. IT CAN HAVE A BAD EFFECT ON YOUR HEALTH OR SAFETY. BEFORE YOU USE THE ALCOHOL, GET THE SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. BEFORE YOU USE THE ALCOHOL, PUT ON CHEMICAL-SPLASH GOGGLES. MAKE SURE THAT YOU HAVE SUFFICIENT AIRFLOW TO KEEP THE ALCOHOL FUMES BELOW THE SAFETY DATA SHEET LIMIT. (a) Clean the circuit card and connectors with a soft-bristled brush and isopropyl alcohol. WARNING: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (207 KILOPASCALS). TO PREVENT INJURIES, DO NOT POINT THE AIR AT PERSONNEL. PUT ON GOGGLES OR A FACE SHIELD TO PREVENT EYE INJURY. IF YOU HAVE AN EYE INJURY, GET MEDICAL AID. CAUTION: WHEN YOU USE COMPRESSED AIR TO CLEAN OR DRY PARTS, MAKE SURE THAT THE PRESSURE IS NOT MORE THAN 30 POUNDS PER SQUARE INCH (207 KILOPASCALS). TOO MUCH PRESSURE CAN CAUSE DAMAGE TO EQUIPMENT. CAUTION: DO NOT BLOW AIR INTO THE LABYRINTH. THE SMOKE DETECTOR AUTOMATICALLY ADJUSTS THE LABYRINTH CALIBRATION TO CORRECT FOR UNWANTED MATERIALS INSIDE THE LABYRINTH. IF YOU CLEAN THE LABYRINTH, THE SMOKE DETECTOR MAY NOT OPERATE CORRECTLY. (b) Dry the parts with compressed air at a maximum pressure of 30 psig (207 kPa). SUBTASK 26-10-76-100-003-A01 C. Clean The Labyrinth Assembly CAUTION: DO NOT CLEAN INSIDE THE LABYRINTH UNLESS DIRECTED TO DO SO. THE SMOKE DETECTOR AUTOMATICALLY ADJUSTS THE LABYRINTH CALIBRATION TO CORRECT FOR UNWANTED MATERIALS INSIDE THE LABYRINTH. IF YOU CLEAN THE LABYRINTH, THE SMOKE DETECTOR MAY NOT OPERATE CORRECTLY. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CLEANING Page 4004 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CAUTION: THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. CAUTION: DO NOT USE ALCOHOL TO CLEAN THE INNER SURFACES OF THE LABYRINTH BECAUSE IT MAY REMOVE THE PAINT. THE SMOKE DETECTOR MAY NOT OPERATE CORRECTLY IF ANY OF THE PAINT IS REMOVED. (1) Remove the CCA/labyrinth assembly (IPL Figure 1, 30) (refer to DISASSEMBLY). (2) Remove the labyrinth top (IPL Figure 2, 5) (refer to DISASSEMBLY). (3) Make a solution of soap and water with one part liquid soap and twenty parts water. CAUTION: (4) USE THE SOAP AND WATER SOLUTION IN SMALL QUANTITIES. KEEP AWAY FROM WIRES AND ELECTRICAL COMPONENTS. DO NOT PUT THE LABYRINTH FULLY IN THE SOAP AND WATER SOLUTION, OR SOAK THE LED OR PHOTO DIODE AREA, OR DAMAGE CAN OCCUR. Clean unwanted material from the inner area of the labyrinth with a soft bristle brush and clean, dry air. You can also use the soap and water solution. Remove the soap and water solution with clean water. CAUTION: MAKE SURE NO MATERIAL FROM THE COTTON SWAB STAYS IN THE LABYRINTH, OR THE SMOKE DETECTOR WILL NOT OPERATE CORRECTLY. CAUTION: MAKE SURE NO OILS FROM YOUR FINGERS OR OTHER UNWANTED MATERIALS STAY ON THE PHOTODIODE AND LED LENSES. THE SMOKE DETECTOR MAY NOT OPERATE CORRECTLY IF THE LENSES ARE NOT CLEAN. (5) Clean the inner area of the labyrinth with a clean cotton swab, moist with the soap and water solution. Dry the lenses with a clean, dry swab. Remove any remaining soap or contamination from the lenses. (6) Make sure the labyrinth assembly is fully dry before you assemble the smoke detector (refer to ASSEMBLY). UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CLEANING Page 4005 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CLEANING Page 4006 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CHECK TASK 26-10-76-990-805-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-006-A01 A. General Information (1) This section has the procedures necessary to examine the smoke detector for damage. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CHECK Page 5001 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CHECK Page 5002 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-210-801-A01 2. CHECK PROCEDURES SUBTASK 26-10-76-210-001-A01 A. External Check CAUTION: THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. (1) Look for loose, damaged, or missing parts, correct installation, and correct hardware size. Repair or replace as necessary. (2) Examine the connector (IPL Figure 2, 60) for unwanted materials and bent or broken pins. Repair or replace as necessary. (3) Make sure the connector's (60) master keyway is at the six o'clock position [points down toward the lid (5)] (Refer to Figure 5001). (4) Make sure the EMI gasket (IPL Figure 1, 62) is installed between the connector flange and the housing. (5) Examine the dust screen (IPL Figure 2, 25) for unwanted materials and damage. Clean, or replace, as necessary (refer to CLEANING or REPAIR). (6) Examine the nameplate and labels. Make sure you can read the data on the nameplate and labels and that they have the correct data. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CHECK Page 5003 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Master Keyway Position Figure 5001 SUBTASK 26-10-76-210-002-A01 B. Internal Check CAUTION: THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. (1) Look for loose, damaged, or missing parts, correct installation, and correct hardware size. Repair or replace as necessary. (2) Examine the wire harness: • Make sure the connector (IPL Figure 2, 60) is connected correctly and the wires are not damaged. • Make sure the terminal lug (IPL Figure 2, 70) is installed between the connector (60) flange and the nutplate (IPL Figure 1, 60). NOTE: The terminal lug can be installed at any of the four screw locations. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CHECK Page 5004 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (3) Examine the form-in-place EMI gasket in the lid (IPL Figure 1, 5). The gasket must be continuous, with no gaps (except at the tab at the front of the lid). The gasket material must be lower than the rib in the lid. If the gasket is damaged, replace the lid. (4) Examine the labyrinth assembly dust screen (IPL Figure 2, 25) for unwanted materials and damage. Clean, or replace as necessary (refer to CLEANING or REPAIR). (5) Examine the circuit card for cracks, indications of too much heat or burned components, and for defective solder connections. Replace as necessary. (6) Make sure that replacement parts have correct part numbers and are installed in the correct locations. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CHECK Page 5005 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 CHECK Page 5006 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 REPAIR TASK 26-10-76-990-806-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-007-A01 A. General Information (1) This section has the procedures necessary to repair the smoke detector components. Replace all parts that are not satisfactory after repair. Item numbers in the procedures are the same as those in the Illustrated Parts List (IPL). (2) Do all repairs to the ANSI/IPC-A-610 standard. (3) Remove all silicone coating from the repair area. If necessary, use the silicone coating stripper to remove the silicone coating. (4) Unless specified differently, install all components as close to the surface of the circuit card as possible. (5) Do the return-to-service test after any repairs are done (refer to TESTING AND FAULT ISOLATION). SUBTASK 26-10-76-94A-002-A01 B. Consumable Materials (1) The materials necessary to repair the smoke detector are given below (Refer to Table 6001). Replace all parts that are not satisfactory after repair. Item numbers in the procedures are the same as those in the Illustrated Parts List (IPL). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: Unless specified differently, you can use equivalent alternatives for the items given in the table. Table 6001 Consumable Materials Material Specification or Part Number Source or CAGE Code Adhesive Permabond 910 (Methyl-2-Cyanoacrylate) V3R2V1 Adhesive, Epoxy (5-Minute Epoxy) Devcon 5-Minute Epoxy #14250 (Bisphenol A Diglycidyl Ether Resin) V16059 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6001 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Material Specification or Part Number Source or CAGE Code Adhesive, Structural Dymax 955-Rev A (Urethane Oligomer/ (Meth) Acrylate Monomer Blends) V46733 Coating, Silicone 1C49 MIL-I-46058, Type SR IPC-CC-830 V99109 Compound, Conductive Cho-Bond 1075* V57003 Solder SN63PB37* QQ-S-571 Commercially Available Stripper, Silicone Coating 1090 V99109 Wire, 22AWG, Type E NEMA HP3-EXDE (Color as necessary) V1VYS1 * No alternative permitted SUBTASK 26-10-76-94A-008-A01 C. Special Tools and Equipment (1) The special tools and equipment necessary to repair the smoke detector are given below (Refer to Table 6002). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. Make sure you have the correct revision of the Kidde Aerospace (CAGE code 61423) software (Refer to SUBTASK 26-10-76-94B-002-A01, Kidde Aerospace Software Information). NOTE: You can use equivalent alternatives for the items given in the table. Table 6002 Special Tools and Equipment Name Specification or Part Number Source or CAGE Code BBP Interface Utility Program 171007 V61423 BBP Program File 404371.hex V61423 Block, LED Bending None Make locally (Refer to SUBTASK 26-10-76-930-008-A01, LED Bending-Block) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6002 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Name Specification or Part Number Source or CAGE Code Cable, M3000 Programming Test (use with MPLAB ICD2 Module) None Make locally (Refer to SUBTASK 26-10-76-930-004-A01, M3000-ProgrammingTest-Cable) Cable, USB (2 each) Type A to Type B USB 2.0 Commercially Available Configuration File 404516.mch V61423 DC Power Supply 72-7295 0 - 36 V dc, 10A (for 200 msec), 1% regulation, Ripple/noise 100 mVrms V376C1 Fixture, Light Pipe None Make locally (Refer to SUBTASK 26-10-76-930-007-A01, Light-Pipe Fixture) M3000 Optical Smoke Box 474610 ±0.1% obscuration V61423 M3000 Test Monitor Software 170820 (Installed by 170820_Installer) V61423 MEP Program File (Flight) 404372.hex V61423 MEP Program File (Calibration) 404515.hex.hex V61423 MPLAB ICD 2 Module DV164005 (No alternative is permitted) V60991 MPLAB IDE Software Version 7.3 (Part of DV164005) SW007002 (No alternative is permitted) V60991 Personal Computer 1GHz, Windows XP (or greater), VGA monitor with 1024 X 768 (or greater) resolution, 128 MB RAM, two USB ports Commercially Available UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6003 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Name Specification or Part Number Source or CAGE Code ValueCAN USB-to-CAN Adapter (w/NeoVI software) VCAN-DWCAN-2 or VCAN-DW3 V1YGN2 Block, LED Bending None Make locally (Refer to SUBTASK 26-10-76-930-008-A01, LED Bending-Block) Socket, Thin Wall Socket Size:1/4-in Drive Size; 1/4-in Socket Points: 6 Outside Wall Diameter: 0.305 in Make or get Locally UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6004 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-300-801-A01 2. REPAIR PROCEDURES SUBTASK 26-10-76-350-001-A01 A. Wire Harness CAUTION: (1) THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. Use the data in the table to do repairs to the wire harness. Table 6003 Wiring Table From To Color Length J1-1 CCA XJ1 Black 2.00 in. (5.08 cm) J1-2 CCA XJ2 Brown 2.00 in. (5.08 cm) J1-3 CCA XJ3 Orange 2.00 in. (5.08 cm) J1-4 CCA XJ4 Yellow 2.00 in. (5.08 cm) J1-5 CCA XJ5 Green 2.00 in. (5.08 cm) J1-6 CCA XJ6 Red 2.00 in. (5.08 cm) J1-7 CCA XJ7 Blue 2.00 in. (5.08 cm) J1-8 CCA XJ8 Violet 2.00 in. (5.08 cm) J1-9 CCA XJ9 White/Black 2.00 in. (5.08 cm) J1-10 CCA XJ10 White/Blue 2.00 in. (5.08 cm) J1-11 E1 Gray 3.00 in. (7.62 cm) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6005 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 From To Color Length E1 CCA XJ 11 Gray 2.00 in. (5.08 cm) J1-12 CCA XJ 12 White 2.00 in. (5.08 cm) J1-13 CCA XJ 13 Gray/Red 2.00 in. (5.08 cm) (2) Use ANSI/NEMA-HP3, Type E wire. (3) Remove the insulation 0.25 inches (6.35 mm) on ends of wires at the connector J1 (IPL Figure 2, 60) and terminal lug (70). (4) Remove the insulation 0.180 inches (4.572 mm) on ends of wires at the CCA (75A). (5) Tin the ends of the wires at the CCA (75A). (6) Do not tin the ends of the wire at the connector (60) or terminal lug (70A). (7) Crimp the wires onto the contacts (65) and terminal lug E1 (70A) (Refer to Table 6003). SUBTASK 26-10-76-350-002-A01 B. Circuit Card Assembly CAUTION: THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. WARNING: SILICONE SEALANT IS TOXIC. USE IN WELL VENTILATED AREA. PREVENT EYE AND SKIN CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT WASH WITH SOAP AND WATER. (1) Apply three coats of silicone coating to the repaired areas and component bodies. Let each coat cure before you apply the next coat. Do not apply silicone coating to the locations and component bodies that follow: • The three labyrinth mounting locations • The four CCA (IPL Figure 2, 75A) mounting locations UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6006 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • U4 (245) and U5 (245). (2) If the microcontroller (MCU) (U1) (300) is replaced, do the procedures that follow, in the sequence shown: (a) 1. Install the Boot Block Partition (BBP) software (Refer to SUBTASK 26-10-76-350-011-A01, BBP Software Installation Procedure). 2. Install the calibration Main Executive Program (MEP) software (Refer to SUBTASK 26-10-76-350-010-A01, MEP Software Installation Procedure). 3. Calibrate the smoke detector (Refer to TASK 26-10-76-350-802-A01, SMOKE DETECTOR CALIBRATION). 4. Do the smoke test (Refer to SUBTASK 26-10-76-750-005-A01, 50-Hour Burn-In Test). 5. Install the flight MEP Software (Refer to SUBTASK 26-10-76-350-010A01, MEP Software Installation Procedure). 6. Do the return-to-service test (Refer to TASK 26-10-76-750-801-A01, RETURN-TO-SERVICE TEST). SUBTASK 26-10-76-350-004-A01 C. Installation of the Labyrinth Internal Components CAUTION: (1) THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. Use the LED bending block to form the leads for the red and blue LEDs (IPL Figure 2, 45) (50) (Refer to Figure 6001): • Align the LED cathode (flat side with shorter lead) with the corner of the tool • Make sure both leads rest on, and extend over, the tool's long wall • Hold the LED fully in place while you bend both leads downward against the face of the tool • The LED leads must be bent at a 90° angle. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6007 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 LED Bending Block Figure 6001 (2) Assemble the photodiode (40) to the labyrinth base (55). WARNING: ADHESIVE IS TOXIC. USE IN WELL VENTILATED AREA. PREVENT EYE AND SKIN CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT WASH WITH SOAP AND WATER. (3) Hold the photodiode in place while you fill the molded pocket (where the leads are) in the labyrinth base's bottom with the structural adhesive (Dymax 955). Make sure the adhesive does not flow past the photodiode leads and onto the photodiode face. (4) Let the structural adhesive cure before you complete the assembly. (5) Assemble the LEDs (45), (50) to the labyrinth base (55). Make sure the cathode (flat side, shorter lead) of the red LED (45) is pointed toward the photodiode (40). Make sure the cathode (flat side, shorter lead) of the blue LED (50) is pointed away from the photodiode. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6008 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 WARNING: ADHESIVE IS TOXIC. USE IN WELL VENTILATED AREA. PREVENT EYE AND SKIN CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT WASH WITH SOAP AND WATER. (6) Apply one to two drops of the Permabond 910 adhesive to the inner rear surface of the photodiode-shield-can (35). Assemble the photodiode-shield-can over the photodiode (40). Make sure no adhesive gets onto the photodiode. (7) The mirror (30) has a long tab on one end and a short tab on the other end. Engage the long tab in the slot in the labyrinth base. Make sure the mirror's curved (concave) surface is pointed to the inside of the labyrinth. (8) Install the dust screen (25) around the baffles of the labyrinth bottom (55). The ends of the dust screen insert into the screen post (slotted post behind the photodiode) on the labyrinth bottom. Make sure the three tabs are straight, not bent, or the labyrinth top (5) will not install correctly. (9) Install the labyrinth top (5) onto the labyrinth base (55). Make sure the baffle locator posts (on labyrinth base) are aligned with the six holes in the labyrinth top. Make sure the short tab on the top of the mirror is engaged with the slot in the labyrinth top. (10) Bend the three tabs of the dust screen (25) over the labyrinth top (5). Make sure the tabs are aligned with the mounting holes in the cover (5). (11) Hold the labyrinth top onto the base while you install the labyrinth assembly onto the CCA (75). Make sure the component leads are inserted into the correct vias on the CCA. CAUTION: DO NOT USE A STANDARD 0.25 INCH SOCKET WHEN YOU REMOVE OR INSTALL THE HEX NUTS. YOU CAN DAMAGE TRANSISTOR Q1 ON THE CCA. USE A 0.25 INCH SOCKET WITH A MAXIMUM OUTSIDE DIAMETER OF 0.305 INCHES. (12) Use the three fasteners (20), flat washers (15), and hex nuts (10) to attach the labyrinth assembly to the CCA. Torque the hex nuts (10) to 4 to 5 lbf-in. (0.46 to 0.56 N•m). (13) Solder the leads of the components that follow: • Red LED (45) • Blue LED (50) • Photodiode (40) • Photodiode-shield-can (35). UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6009 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 WARNING: USE THE CONDUCTIVE COMPOUND, CHO-BOND 1075, CORRECTLY. PREVENT EYE CONTACT. DO NOT INGEST THE COMPOUND. THE COMPOUND MAY CAUSE MODERATE IRRITATION OF THE EYES, MUCOUS MEMBRANES, AND RESPIRATORY TRACT. PREVENT SKIN CONTACT; PROLONGED OR REPEATED CONTACT MAY CAUSE BLUEGRAY DISCOLORATION OF THE SKIN. BEFORE YOU USE THE COMPOUND, GET THE MATERIAL SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. (14) Apply a continuous bead (maximum diameter of 0.09 in. [2.28 mm]) of the conductive compound to bond the screen to: • The labyrinth top • The labyrinth bottom • Both sides of the screen post (part of the labyrinth bottom). WARNING: SILICONE SEALANT IS TOXIC. USE IN WELL VENTILATED AREA. PREVENT EYE AND SKIN CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT WASH WITH SOAP AND WATER. (15) Apply silicone coating to the solder connections and to the leads exposed between the labyrinth base and the CCA. SUBTASK 26-10-76-350-003-A01 D. Replacement of the Light Pipe (1) If it is necessary to replace the light pipe (IPL Figure 1, 80), use the 5-minute epoxy to keep the light pipe in the housing (75). (a) All components must be removed from the housing (75) to do this procedure. (b) Use the light-pipe fixture (Refer to Figure 6002) to make sure the light pipe is installed correctly. The top of the light pipe must extend 0.060 - 0.080 inches (1.542 - 2.032 mm) from the housing. WARNING: ADHESIVE IS TOXIC. USE IN WELL VENTILATED AREA. PREVENT EYE AND SKIN CONTACT AND DO NOT BREATHE VAPORS. IN CASE OF EYE CONTACT, FLUSH WITH WATER FOR 15 MINUTES AND SEEK MEDICAL ATTENTION. IN CASE OF SKIN CONTACT WASH WITH SOAP AND WATER. (c) Put the light-pipe fixture through the openings in the housing (75) and around the light-pipe shaft. The fixture will hold the light pipe in place while the epoxy cures. • Turn the housing topside down. • Apply a small bead of 5-minute epoxy around the mid section of the light pipe. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6010 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • Fully install the light pipe in the tapered hole of the light-pipe shaft. The lightpipe fixture will prevent the light pipe from extending too far beyond the top of the housing. • Keep the housing in the topside down position until the epoxy has cured. Light-Pipe-Fixture Installed On Cover Figure 6002 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6011 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6012 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-350-802-A01 3. SMOKE DETECTOR CALIBRATION SUBTASK 26-10-76-99F-016-A01 A. General Information (1) This section contains the information and procedures to calibrate the smoke sensitivity of the smoke detector. (2) The 404372.hex MEP (flight) software file must be removed from the MCU (IPL Figure 2, 425), and the 404516.hex MEP (calibration) file installed before the smoke detector can be calibrated (Refer to SUBTASK 26-10-76-350-010-A01, MEP Software Installation Procedure). (3) After the smoke detector calibration is completed, do the smoke test (Refer to SUBTASK 26-10-76-750-005-A01, 50-Hour Burn-In Test). (4) After the smoke test is completed satisfactorily, reinstall the 404372.hex MEP file in the MCU (Refer to SUBTASK 26-10-76-350-010-A01, MEP Software Installation Procedure). (5) Do the return-to-service test (Refer to TASK 26-10-76-750-801-A01, RETURN-TOSERVICE TEST). SUBTASK 26-10-76-350-006-A01 B. Calibration Setup (1) The smoke detector must be fully assembled before you do the calibration procedure (Refer to ASSEMBLY). (2) Do the calibration setup as follows (Refer to TESTING AND FAULT ISOLATION, Figure 1006): (a) Make sure the power supply is OFF. (b) Make sure the smoke box PWR switch is set to OFF. (c) Connect the smoke box to the power supply: • 28VDC jack to the power supply positive (+) output • RTN jack to the power supply negative (-) output. (d) Connect the smoke box to the PC: • DAC (digital-to-analog converter) output to a PC USB port • ValueCan output to a PC USB port. (Refer to SUBTASK 26-10-76-490-002-A01, Prepare the M3000 Optical Smoke Box). UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6013 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (e) Connect the smoke detector to the cable inside the smoke box. Put the smoke detector on the mounting-block in the center of the smoke box's smoke chamber. Make sure the face of the housing/screen assembly is up. There must be no blockage of the airflow through the labyrinth. (f) Set the power supply to ON and adjust the output as follows: • Voltage - +28 ±0.5 V dc • Current Limit - 1A (max). (g) On the smoke box, set the PWR switch to ON. Make sure the fan operates. (h) Make sure no object causes a blockage of the smoke box internal sensor path (i) Close and latch the smoke box door. (j) Close the smoke box exhaust valve. Let the smoke box stabilize for 10 minutes (minimum). (k) On the PC, double-click on the 170820 icon to open the Test Monitor Program. (l) Click on the "Smoke Detector" tab and then the "Msg 0" tab. (m) Make sure the Test Monitor Program can speak with the smoke detector. Look at the "SD CAN Payload 0" window. If messages continuously scroll up the window, the program and smoke detector are connected correctly. (n) On the PC, click on the "Box Enable" button. ("Box Enable" enables the PC to calculate the smoke concentration in the smoke chamber). (o) Select the "Reference Reading" button. 1 RESULT: "Concentration" window display changes from "-INF" to "0" (±0.1) after 7 seconds. SUBTASK 26-10-76-350-007-A01 C. Smoke Calibration Procedure (1) Do the Calibration Setup (Refer to SUBTASK 26-10-76-350-006-A01, Calibration Setup). (2) If not already open, open the Test Monitor Program 170820. (3) Click on the "Msg 0" tab. (4) Click on the "Box Enable" button. (5) Click on the "Reference Reading" button. (6) If necessary, click on the "Clear Data" button to clear the Smoke and Concentration parameter table (located above the "Clear Data" button). UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6014 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (7) Hold a flame to one end of the wick until the wick burns. Extinguish the fire so the end of the wick gives off smoke only. Put the end of the wick one inch into the hole in the side of the smoke chamber. (8) Leave the wick in the smoke chamber until the "Alarm High" indicator (in the "Msg 0" "Alarm Status" window) comes ON. (9) Remove the wick from the smoke chamber and open the exhaust valve to remove the smoke. (10) When the "Msg 0" "Concentration" window reads 0.5 or less, open the door to the smoke chamber. Make sure all smoke is removed from the smoke detector labyrinth. (11) Look at the Smoke Parameter and Concentration table in the "Msg 0" screen. (a) If the "Alarm High" smoke parameter and concentration levels agree with the parameters in the table below (Refer to Table 6004), the smoke detector is calibrated. Go to step (24). Table 6004 Correct Smoke Calibration Criteria Column Headings on Msg 0 Screen (b) Alarm Value Smoke P(arameter) Alarm High 7.0 ±1.0 Concen(tration) Alarm High 5.0 ±0.5 If the smoke parameter and concentration level do not agree with the parameters in the table, continue the calibration procedure. Go to step (10). (12) The Smoke Calibration Parameters Adjustment Guidelines (Refer to SUBTASK 26-10-76-350-008-A01, Smoke Calibration Parameters Adjustment Guidelines) describe the effect POT adjustments have on the smoke and concentration parameters. It is recommended that you become familiar with these guidelines before you adjust the POT settings. (13) On the PC, select the "Msg 9" tab and click "TX". Record the current values for POT 1 thru POT 4. You will need this data to calibrate the smoke detector. (a) Refer to TESTING AND FAULT ISOLATION/Return-to-Service test/Functional Test/Forward Voltage and Temperature test for the POT limits. NOTE: In TESTING AND FAULT ISOLATION, POT 0 thru POT 3 are shown as POT 1 thru POT 4. (14) Select the "HFT" tab. (In this menu, the pots are called POT 1 thru POT 4.) (15) Select the "TX" tab (not the "TX" button). UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6015 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (16) To adjust the POT settings, enter the data from the table that follows (Refer to Table 6005) into the "Alt Message to TX" cells. "XX" shows the new POT settings (selected by you) and the current settings [recorded from Message 9 in step (11)]. For example: to adjust POT 3, enter the new value (selected by you) in the POT 3 cell. Enter the current settings (from Message 9) in the other POT cells. You may adjust more than one POT at a time. Table 6005 Store New POT Values to Memory 13 0E XX POT 0 XX POT 1 XX POT 2 XX 00 00 POT 3 (17) Click on "TX" one time to write the new values into memory. (18) Click on "Clear all text displays" to clear the cells. (19) Enter the same data as before, except for the last two cells (Refer to Table 6006). Table 6006 Remove Old Offset Values From Memory 13 0E XX XX XX XX 01 01 (20) Click on "TX" two times to remove the old offset values from memory. (21) On the PC, select Smoke Detector>Msg 0 tab. (a) Make sure the "Bottom" LED value is less than 1.90 V. 1 If the value is 1.90 V, or more, troubleshoot the LED drive circuits. 2 If the value is less than 1.90 V, continue to the next step. (22) On the PC, select HFT>TX tabs. (23) Enter the same data as before, except for the last two cells, (Refer to Table 6007) into the "Alt Message to TX" cells. Table 6007 Store New Offset Values To Memory 13 0E XX XX XX XX 00 01 (24) Click on "TX" one time to write the new offset values into memory. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6016 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (25) Do the Smoke Detector Calibration procedure again (Refer to SUBTASK 26-10-76-350-007-A01, Smoke Calibration Procedure) until the "Alarm High" smoke parameter and concentration levels agree with the parameters in the Correct Smoke Calibration Criteria table (Refer to Table 6004). (26) The calibration procedure is complete. Remove the smoke detector from the smoke box. SUBTASK 26-10-76-350-008-A01 D. Smoke Calibration Parameters Adjustment Guidelines (1) To change the smoke calibration parameters, the POT (potentiometer) settings must be adjusted. Use the information that follows as guidelines to adjust the POT settings. NOTE: These guidelines may vary slightly for each smoke detector. (a) (2) 1. Adjust the "Smoke P" parameter before you adjust the "Concen" (concentration) parameter. 2. Adjustments to POT 3 have a greater effect on parameter changes than do POT 2 adjustments. 3. An adjustment to the POT 3 value by ±3 will change the "Smoke P" parameter by ±1.0 and the concentration parameter by ±0.3. 4. An adjustment to the POT 2 value by ±6 will change the "Smoke P" parameter by ±1.0. The Case tables that follow describe the effects of POT changes on the parameters. From the tables, determine the case that most agrees with the smoke calibration parameters (Refer to Table 6004). Use the tables below and the guidelines above to make adjustments to the POT values. Table 6008 Case 1 - Both Parameters Incorrect Condition Effect Smoke P(aramater) Concen(tration) POT Action Smoke P Concen Too High Too High 2 Increase ↓ No Effect Too Low Too High 3 Increase ↑ ↓ Too High Too Low 3 Decrease ↓ ↑ Too Low Too Low 2 Decrease ↑ No Effect UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6017 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Table 6009 Case 2 - Smoke Parameter Incorrect Condition Smoke P(aramater) Concen(tration) Too High Correct Too Low Effect POT Action 2 Increase 3 Decrease 2 Decrease 3 Increase Smoke P ↓ ↑ Correct Table 6010 Case 3 - Concentration Parameter Incorrect POT Action Effect Concen(tration 0&1 Increase ↓ 0&1 Decrease ↑ Keep POT 0 and POT 1 values equal when you make an adjustment UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6018 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-350-803-A01 4. MICROCONTROLLER SOFTWARE INSTALLATION SUBTASK 26-10-76-350-009-A01 A. General Information (1) This section contains the procedures to install the BBP and MEP software in the MCU (U6). (2) The Effectivity Table below gives the software files and revision levels necessary to install software in the MCU. Table 6011 Software Effectivity Table For P/N 474449-5 Program File Rev. Level Part Number or Version Number 404371.hex E 40437104 BBP 7191 286D5C6F 404372.hex T 40437213 MEP (Flight) N/A 7D21A509 404515.hex A 40451500 MEP (Calibration) N/A F44CCDBA 404516.mch A 40451600 Configuration N/A N/A Software Description Checksum CRC SUBTASK 26-10-76-350-011-A01 B. BBP Software Installation Procedure NOTE: It is possible that some or all of the software/hardware was installed before. They only need to be installed one time. (1) On the PC's hard drive make a directory for the software files. The drive and name of the directory are optional. For the procedures in this manual, C:\474449\ is used. (2) Follow the instructions supplied with the MPLAB ICD2 Module to install the MPLAB IDE software (Refer to Table 6002). (3) In the procedures that follow, make sure you have the correct software files (Refer to Table 6011). (4) Copy the 404516.mch file into the C:\474449 directory. (5) On the PC's hard drive, make a directory for the BBP file. The drive and name of the directory are optional. For the procedures in this manual, C:\474449\BBP is used. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6019 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (6) Copy the 404371.hex file into the C:\474449\BBP directory. (7) Copy the 404372.hex and 404515.hex files to the C:\474449\MEP directory. (8) Do TESTING AND FAULT ISOLATION, paragraph 2.A., "Prepare the Personal Computer" (Refer to SUBTASK 26-10-76-490-001-A01, Prepare the Personal Computer (PC)). CAUTION: (9) THE CIRCUIT CARD ASSEMBLY (CCA) CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL) NOMENCLATURE AREA. OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE CCA OR DAMAGE CAN OCCUR. Disassemble the smoke detector, as necessary, to get access to the P2 connector (IPL Figure 2, 420) (Refer to SUBTASK 26-10-76-010-001-A01, Disassembly Procedures). (10) Remove the conformal coating from P2. (11) Set the switches on the Manual Test Set as follows: • PWR - OFF • REVERSE/NORMAL VOLTAGE - NORMAL • AMMETER - OFF (ammeter not in circuit) • ID0 - ON • ID1 thru ID3 - OFF • ID4 thru ID6 - any position • PAR - OFF • TEST SELECT - any position • TEST - any position • SELF TEST - any position • HORN CANCEL - any position • EXT TEMP - any position • RELAY LOAD - any position • Rotary switch - any position. (12) Use the Functional Test Cable to connect J2 of the smoke detector to J1 of the test set. (13) Connect the MPLAB ICD 2 Module to a USB port on the PC. (14) Use the M3000 Programming Test Cable (programming cable) to connect the MPLAB ICD 2 Module to the smoke detector P2 connector. Make sure the tab on the Programming Cable connector faces toward the center of the CCA. (15) Set the power supply to ON and adjust the output voltage to +28 ±0.5 V dc. (16) On the test set, set the PWR switch to ON. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6020 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (17) On the PC, open the MPLAB.exe file (installed with the MPLAB IDE software). (18) From the menu, select: • Configure>Device>OK (make sure the device is PIC18F4680) • PROGRAMMER>Select Programmer>MPLAB ICD 2 • PROGRAMMER> Connect (if AutoConnect is not enabled). (19) Make sure "Running ICD Self Test ...Passed. MPLAB IDC 2 Ready" shows on the output screen. (20) From the menu, select File>Import>Directory (C:\474449\BBP) >404371.hex>Open (21) Look at the tool bar on the PC screen. Make sure the MPLAB checksum (404371.hex file) is correct (Refer to Table 6011). (22) From the menu, select View>EEPROM. (23) Select Address at position row 0000, Column 00. Right click and select "Import Table". (24) Select directory (if required, directory may already be selected) C: \474449\404516.mch>Open. (25) From the menu, select PROGRAMMER>Program>OK. Wait for the MCU EEPROM Configuration to program. (26) Make sure the "Verify Succeeded." message shows on the screen. (27) On the test set, set the PWR switch to OFF. (28) On the PC, from the menu, select File>Exit. (29) The MCU is now programmed with the BBP program. (30) Disconnect the MPLAB ICD 2 Module from P2 of the smoke detector. SUBTASK 26-10-76-350-010-A01 C. MEP Software Installation Procedure (1) If the BBP program is not installed, install it now (Refer to SUBTASK 26-10-76-350-011-A01, BBP Software Installation Procedure). (2) Set the switches on the Manual Test Set as follows: • PWR - OFF • REVERSE/NORMAL VOLTAGE - NORMAL • AMMETER - OFF (ammeter not in circuit) • ID0 thru ID3 - ON • ID4 thru ID6 - any position • PAR - ON • TEST SELECT - any position UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6021 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 • TEST - any position • SELF TEST - any position • HORN CANCEL - any position • EXT TEMP - any position • RELAY LOAD - any position • Rotary switch - any position. (3) Make sure the ValueCan adapter is installed to the PC USB port and to the test set's CAN connector (J3). (4) Set the power supply to ON and adjust the output voltage to +28 ±0.5 V dc. (5) On the test set, set the PWR switch to ON. (6) On the PC, open the 171007 BBP Interface Utility program. (7) On the PC screen: • In the "LRU Type" box, select "Smoke" • Click on the "Open neoVI" button. Make sure "Value CAN X SN XXXXX" shows below "VCAN Type" radio button. (8) From the menu, select File>Open>BBP>C:\474449\BBP\404371.hex>Open. (9) Make sure the "BBP CRC" text box contains the correct CRC data (Refer to Table 6011). (10) Click the "Load BBP CRC" button. (11) On the menu, select File>Open>MEP: • To install the calibration MEP, select "C:\474449\MEP\404515.hex" • To install the flight MEP, select "C:\474449\MEP\404372.hex • Click on "Open". NOTE: The calibration MEP must be installed to do the smoke detector calibration. The flight code MEP must be installed before you do the final return-toservice test. (12) Make sure the MEP CRC text box contains the correct CRC data (Refer to Table 6011). If the CRC is not correct, do paragraphs (8) thru (11) again. (13) Click on the "Load MEP CRC" button. (14) Click on the "Write MEP to Flash" button. Wait until the MEP download is completed. A progress bar shows the time remaining. When the program download is completed, "Download complete" shows in the status bar. (15) Click on the "Read Configuration Data" button. (16) Click on the "Enable NVM Writes" button. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6022 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (17) Click on the "OK" button to write to the NVM. (18) Look at the number to the right of the "Load HW PN" button. Make sure the 8-digit hardware part number is "47444905". If correct, go to step (20). If necessary, enter the part number in the text box to the left of the "Load HW PN" button. (19) Click on the "Load HW PN" button. (20) Look at the number to the right of the "Load HW SN" button. Make sure the 7-digit serial number agrees with the SN on the Nameplate. If correct, go to step (22). If necessary, enter the serial number in the text box to the left of the "Load HW SN" button. (21) Click on the "Load HW SN" button. (22) Look at the date to the right of the "Load Man Date" button. Make sure the date (mm/ yy) agrees with the MFG DATE on the Nameplate. If correct, go to step (24). if necessary, enter the date in the text box to the left of the "Load Man Date" button. (23) Click on the "Load Man Date" button. (24) Click on the "Read Configuration Data" button. Make sure that the hardware part number is "47444905". Make sure the serial number and date agree with the data on the Nameplate. (25) Click on the "Clear NVM" button. Make sure the address numbers scroll through the "Messages" text box. (26) Click on the "Read NVM Range" button. An NVM dialog box will appear. Look at the "Fault Record Summary" text box. The count must equal "0" for each fault. If there are faults, do paragraph (25) again. If there are still faults, find and correct the malfunction. (27) Close the NVM dialog box. (28) If the flight MEP was selected in paragraph (11), go to paragraph (29). If the calibration MEP was selected, go to paragraph (33). (29) Click on the "Extract CBDS from NVM" button. The CBDS will be written to C:\CBDS \CBDS.hex (this directory was created during the functional test). (30) Select File>Open>CBDS>CBDS.hex. (31) Click on the "Open" button. (32) Click on the "Load in NVM" button (to the right of the "CBDS CRC" text box). (33) Set the test set PWR switch to OFF. (34) On the PC, close the 171007 BBP Interface Utility program. (35) The MCU is now programmed with the MEP program. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6023 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 REPAIR Page 6024 Apr 30/15 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 ASSEMBLY TASK 26-10-76-990-807-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-008-A01 A. General Information (1) This section has the procedures necessary to assemble the smoke detector. Item numbers in the procedures are the same as those in the Illustrated Parts List (IPL). (2) After the smoke detector is assembled, do the return-to-service test (refer to TESTING AND FAULT ISOLATION). SUBTASK 26-10-76-94A-003-A01 B. Consumable Materials (1) The materials necessary to assemble the smoke detector are given below (Refer to Table 7001). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 7001 Consumable Materials Material Cap, Protective Conductive UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Specification or Part Number CEC-12 Source or CAGE Code V99017 26-10-76 ASSEMBLY Page 7001 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-94A-010-A01 C. Special Tools and Equipment (1) The special tools and equipment necessary to repair the smoke detector are given below (Refer to Table 7002). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column.. NOTE: You can use equivalent alternatives for the items given in the table. Table 7002 Special Tools and Equipment Name Socket, Thin Wall UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Specification or Part Number Socket Size:1/4-in Drive Size; 1/4-in Socket Points: 6 Outside Wall Diameter: 0.305 in (maximum) Source or CAGE Code Make or get Locally 26-10-76 ASSEMBLY Page 7002 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-400-801-A01 2. ASSEMBLY PROCEDURES SUBTASK 26-10-76-410-003-A01 A. Assemble the Labyrinth Top to the Labyrinth Bottom CAUTION: THE CIRCUIT CARD ASSEMBLY (CCA) CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL) NOMENCLATURE AREA. OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE CCA OR DAMAGE CAN OCCUR. (1) Make sure the three tabs of the dust screen (IPL Figure 2, 25) are straight, not bent, or the labyrinth top (5) will not install correctly. (2) Install the labyrinth top (5) onto the labyrinth base (55). Make sure the baffle locator posts (on labyrinth base) are aligned with the six holes in the labyrinth top. Make sure the short tab on the top of the mirror is engaged with the slot in the labyrinth top. (3) Bend the three tabs of the dust screen (25) over the labyrinth top (5). Make sure the tabs are aligned with the mounting holes in the cover (5). CAUTION: (4) DO NOT USE A STANDARD 0.25 INCH SOCKET WHEN YOU REMOVE OR INSTALL THE HEX NUTS. YOU CAN DAMAGE TRANSISTOR Q1 ON THE CCA. USE A 0.25 INCH SOCKET WITH A MAXIMUM OUTSIDE DIAMETER OF 0.305 INCHES. Use the three fasteners (20), flat washers (15), and hex nuts (10) to attach the labyrinth assembly to the CCA. Torque the hex nuts (10) to 4 to 5 lbf-in. (0.46 to 0.56 N•m). WARNING: USE THE CONDUCTIVE COMPOUND, CHO-BOND 1075, CORRECTLY. PREVENT EYE CONTACT. DO NOT INGEST THE COMPOUND. THE COMPOUND MAY CAUSE MODERATE IRRITATION OF THE EYES, MUCOUS MEMBRANES, AND RESPIRATORY TRACT. PREVENT SKIN CONTACT; PROLONGED OR REPEATED CONTACT MAY CAUSE BLUEGRAY DISCOLORATION OF THE SKIN. BEFORE YOU USE THE COMPOUND, GET THE MATERIAL SAFETY DATA SHEET FROM THE MANUFACTURER OR SUPPLIER OF THE MATERIAL AND READ IT CAREFULLY. (5) Apply a continuous bead of the conductive compound to bond the screen to the labyrinth top. The bead must be a maximum of 0.09 in. (2.28 mm). SUBTASK 26-10-76-410-001-A01 B. Assemble the CCA/Labyrinth Assembly to the Housing UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 ASSEMBLY Page 7003 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CAUTION: THE CIRCUIT CARD ASSEMBLY (CCA) CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL) NOMENCLATURE AREA. OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE CCA OR DAMAGE CAN OCCUR. (1) Put the EMI gasket (IPL Figure 1, 62) over the connector (J1) so the gasket is behind the connector flange. (2) Put the wires of the wire harness through the housing (75) slot. (3) Align the circuit card assembly on the housing's (75) built-in standoffs. (4) Attach the CCA to the housing (75) with the four screws (35A), and flat washers (45). (5) Torque the screws (35A) to 8 to 9 lbf in. (0.91 to 1.01 N•m). (6) Make sure the EMI gasket (62) is between the connector (J1) flange and the outer surface of the housing (75). (7) Use three of the four screws (50) and flat washers (55), and the nutplate (60), to loosely install the connector (J1) to the housing (75). Make sure the nutplate (60) is turned as shown in IPL Figure 1. Make sure the master keyway of J1 is at the six o'clock position [points down toward the lid (5)].(Refer to CHECK, Figure 5001) (5). (8) Use the fourth screw (50) and flat washer (55) to install the wire-harness-terminallug (IPL Figure 2, 70A). Install the terminal lug between the nutplate (IPL Figure 1, 60) and inner surface of the housing (75). Bend the terminal lug as necessary. NOTE: The terminal lug may be installed at any of the four screw locations. (9) Torque the screws (50) to 5 to 6 lbf-in. (0.57 to 0.67 N•m). SUBTASK 26-10-76-410-002-A01 C. Assemble the Lid to the Housing (1) Align the lid (IPL Figure 1, 5) on the built-in-standoffs in the housing (75). (2) Attach the lid to the housing with the four screws (10A), (15A) and flat washers (25). (3) Torque the screws (10A), (15A) to 8 to 9 lbf-in. (0.91 to 1.01 N•m). UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 26-10-76 ASSEMBLY Page 7004 Oct 02/13 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FITS AND CLEARANCES TASK 26-10-76-990-808-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-009-A01 A. General Information (1) This section has the necessary torque values for the smoke detector. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. FITS AND CLEARANCES Page 8001 Jun 30/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. FITS AND CLEARANCES Page 8002 Jun 30/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-205-801-A01 2. TORQUE SPECIFICATIONS SUBTASK 26-10-76-205-001-A01 A. Torque Specifications (1) The torque specifications necessary for the assembly of the smoke detector are given below (Refer to Table 8001). Table 8001 Torque Specifications Torque Value IPL Figure-Item Number Name Lbf In. N•m 1-35A Screw 8 to 9 0.91 to 1.01 1-50 Screw 5 to 6 0.57 to 0.67 1-10A Screw 8 to 9 0.91 to 1.01 1-15A Screw 8 to 9 0.91 to 1.01 2-10 Nut, Hex 4 to 5 0.46 to 0.58 2-20 Screw 4 to 5 0.46 to 0.58 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. FITS AND CLEARANCES Page 8003 Jun 30/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. FITS AND CLEARANCES Page 8004 Jun 30/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SPECIAL TOOLS, FIXTURES, AND EQUIPMENT TASK 26-10-76-990-810-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-010-A01 A. General Information (1) This section gives the consumable materials and the special tools, fixtures and equipment used in this manual. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9001 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9002 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-94A-801-A01 2. CONSUMABLE MATERIALS SUBTASK 26-10-76-94A-006-A01 A. Consumable Materials (1) The consumable materials used in this manual are given below (Refer to Table 9001). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: Unless specified differently, you can use equivalent alternatives for the items given in the table. Table 9001 Consumable Materials Material Specification or Part Number Source or CAGE Code Use Adhesive Permabond 910 (Methyl-2Cyanoacrylate) V3R2V1 Repair Adhesive, Epoxy Devcon 5-Minute Epoxy #14250 (Bisphenol A Diglycidyl Ether Resin) V16059 Assembly Adhesive, Structural Dymax 955-Rev A (Urethane Oligomer/[Meth] Acrylate Monomer Blends) V46733 Repair Alcohol, Isopropyl ASTM D770 Commercially Available Cleaning Brush, Soft Bristle N/A Commercially Available Cleaning Cap, Protective CEC-12 (Conductive) V99017 Assembly Storage Cloth, Low Lint Absorbent A-A-59323 Commercially Available Cleaning Coating, Silicone 1C49 MIL-I-46058, Type SR IPC-CC-830 V99109 Repair UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9003 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Material Specification or Part Number Source or CAGE Code Use Compound, Conductive* Cho-Bond 1075 V57003 Repair Soap, Liquid N/A Commercially Available Cleaning Solder SN63PB37* QQ-S-571 Commercially Available Repair Stripper, Silicone Coating 1090 V99109 Repair Swabs, Cotton N/A Commercially Available Cleaning Wick, Cotton Twill Torch** 1115-S 0.125 inch (3.175 mm) diameter (approximately) V7E009 Smoke Test Wire, 22AWG, Type E NEMA HP3EXDFE Commercially Available Locally Made Test Equipment *No alternative permitted. **Keep at 113 °F (45 °C) and less than 10% humidity for 72 hours (minimum) before use. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9004 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-940-802-A01 3. SPECIAL TOOLS, FIXTURES AND EQUIPMENT SUBTASK 26-10-76-94B-003-A01 A. Special Tools, Fixtures and Equipment (1) The special tools, fixtures and equipment used in this manual are given below (Refer to Table 9002). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: Unless specified differently, you can use equivalent alternatives for the items given in the table. Table 9002 Special Tools, Fixtures and Equipment Material Specification or Part Number Source or CAGE Code Use AC/DC IR Hipot Tester 2945 V05611 Dwell Timer: 1 minute (minimum) Ramp Timer: 0 to 5 seconds Dielectric Output: 0 to 800 V dc, ±5%, 60 Hz, 2V/ setp, 2mA IR Output: 100 to 500 V dc, 10 V/ step, ±5%,1-40MΩ Dielectric and Insulation Resistance (IR) Test Cable, M3000 IR/ Dielectric Test (CAN) N/A Make locally (Refer to SUBTASK 26-10-76-930-002A01, M3000-IR/ Dielectric-TestCable-(CAN)) Dielectric and Insulation Resistance (IR) Test BBP Program File 404371.hex V61423 Repair (Refer to SUBTASK 26-10-76-94B-002A01, Kidde Aerospace Software Information) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9005 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Material Specification or Part Number Source or CAGE Code Use BBP Interface Utility Program 171007 V61423 Functional Test (Refer to Repair SUBTASK 26-10-76-94B-002A01, Kidde Aerospace Software Information) Cable, USB (2 each) Type A to Type B USB 2.0 Commercially available Cable, M3000 Functional Test N/A Make locally Functional Test (Refer to SUBTASK 26-10-76-930-003A01, M3000Functional-TestCable) Cable, M3000 Programming Test (Use with MPLAB ICD 2 Module) N/A Make locally Repair (Refer to SUBTASK 26-10-76-930-004A01, M3000ProgrammingTest-Cable) Configuration File 404516.mch V61423 Repair (Refer to SUBTASK 26-10-76-94B-002A01, Kidde Aerospace Software Information) Digital Multimeter (DMM) Fluke 73 0 - 36 V dc, Min/ Max function, 0 500 mA, 0 - 1 MΩ V89536 Functional Test Fault Isolation DC Power Supply 72-7295 V376C1 0 - 36 V dc, 10A (for 200 msec), 1% regulation Functional Test Repair UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Test Repair SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9006 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Material Specification or Part Number Source or CAGE Code Use Heat Gun, Variable Temperature Milwaukee 8977-20 V40817 M3000 Manual Test Set N/A Make locally Functional Test (Refer to SUBTASK 26-10-76-930-001A01, M3000Manual-Test-Set) M3000 Optical Smoke Box 474610 V61423 M3000 Test Monitor Software 170820 V61423 (Refer to SUBTASK 26-10-76-94B-002A01, Kidde Aerospace Software Information) Milliohmmeter 1880 1A, 0 to 20 mΩ, ±1% accuracy V0PK96 MEP Program File (Flight) 404372.hex V61423 Repair (Refer to SUBTASK 26-10-76-94B-002A01, Kidde Aerospace Software Information) MEP Program File (Calibration) 404515.hex V61423 Repair (Refer to SUBTASK 26-10-76-94B-002A01, Kidde Aerospace Software Information) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Functional Test Functional Test Repair Ground Bonding Test SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9007 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Material MPLAB ICD 2 Module Specification or Part Number Source or CAGE Code Use DV164005 (No alternative is permitted) V60991 Repair MPLAB IDE SW007002 Software (No alternative is Version 7.3 permitted) (Part of DV164005) V60991 Repair Personal Computer 1GHz, Windows Comercially XP (or greater), Available VGA monitor with 1024 X 768 (or greater) resolution, 128 MB RAM, two USB ports Functional Test Repair Temperature Probe Model 80PK-1 212 °F (100 °C) (Min.) V89536 Functional Test Thermocouple Module Model 80TK V89536 Functional Test ValueCAN USB-to- VCAN-DWCAN-2 CAN Adapter or (w/NeoVI software) VCAN-DW3 V1YGN2 Functional Test Repair Cable, Burn-in None Make locally 50-Hour Burn-in (Refer to Test SUBTASK 26-10-76-930-005A01, Burn-In-Test Cable) Fixture, Light Pipe None Make locally Repair (Refer to SUBTASK 26-10-76-930-007A01, Light-Pipe Fixture) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9008 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Material Specification or Part Number Source or CAGE Code Use Fixture, Bonding Measurement None Make locally Bonding Test (Refer to SUBTASK 26-10-76-930-006A01, BondingMeasurement Fixture) Block, LED Bending None Make locally Repair (Refer to SUBTASK 26-10-76-930-008A01, LED BendingBlock) Socket, Thin-wall Socket Size:1/4-in Make or get locally Assembly Drive Size; 1/4-in Disassembly Socket Points: 6 Repair Outside Wall Diameter: 0.305 in. (maximum) SUBTASK 26-10-76-94B-002-A01 B. Kidde Aerospace Software Information (1) To get the Kidde Aerospace software specified in this manual, contact: Kidde Aerospace & Defense 4200 Airport Dr NW Wilson, NC 27896-8630 USA Attention: Technical Services Department Telephone: 252-237-7004. Table 9003 Kidde Aerospace Software Information Software PN Revision Media 171007 N CD-ROM 170820_Installer E CD-ROM 404371.hex E CD-ROM 404372.hex T CD-ROM UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9009 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Software PN Revision Media 404516.mch A CD-ROM 404515.hex A CD-ROM UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9010 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-930-801-A01 4. LOCALLY-MADE-TEST-EQUIPMENT SUBTASK 26-10-76-930-001-A01 A. M3000-Manual-Test-Set (1) Use the parts given below (Refer to Table 9004), and the illustrations (Refer to Figure 9001) (Refer to Figure 9002), to make the M3000-Manual-Test-Set. Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 9004 M3000-Manual-Test-Set-Parts-List Description Specification or Part Number Reference Designator Qty Source or CAGE Code Box, Utility, 10x6x3 in. CU-3286 1 None V71218 Banana Jack, Red 861-R 3 J5, J6, J7 V63590 Banana Jack, Black 861-B 1 J8 V63590 Banana Jack, Yellow 861-Y 2 J9, J11 V63590 Banana Jack, White 861-W 2 J10, J12 V63590 Capacitor, 0.1µF, Tantalum M39003/01-2818 1 C1 V96906 Capacitor 1.0µF, Tantalum M39003/01-2836 2 C2 V96906 Connector, DB9F SD9S 1 J3 V43321 Connector, DB15F SD15S 1 J2 V43321 Connector DB25F SD25S 1 J1 V43321 Diode JAN1N5618 1 CR1 V14552 Diode, Zener 3.3V, 3W 1N5913B 3 CR2-CR4 V1MQ07 Knob (Use with S12) EH710F2B 1 None V23480 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9011 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Qty LED, Red SSI-LXH312ID-150 6 DS2, DS3, DS5, DS7, DS9, DS12 V1EM90 LED, Green SSILXH312GD-150 1 DS1 V1EM90 LED, Yellow SSILXH312YD-150 5 DS4, DS6, DS8, DS10, DS11 V1EM90 Proto Board 8015 1 None V82893 Regulator Voltage Fixed, +12 V dc LM78M12C 1 VR1 V57962 Resistor 1.8KΩ, 1 W PRO1000101801J 14 R1, R11-R17, R25, R26, R29, R30, R34, R35 V56699 Resistor 820Ω, 3W RWR89S8200FS 7 R23, R24, R27, R28, R31-R33 V96906 Resistor 15Ω, 70W TEH70P15R0JE 8 R4-R10, R22 V44655 Resistor 10Ω, 3W RWR89S10R0FS 1 R2 V96906 Resistor 120Ω, 0.25W RLR07C1200FS 1 R3 V96906 Spacer, 1/4 Hex, Female-Female, No. 6-32 x 1.0 in. (attaching part for circuit board 8220-SS-0632 4 None V1YGB8 Screw, Machine, No.6-32 x 0.375 in. (attaching part for circuit board) MS24693-C26 8 None V96906 Switch, Toggle 34ADP31B1M1QT DPDT ON-OFF-ON 1 S10 V81073 Switch, Toggle SPDT 13 S1, S2, S4-S9, S13- V81073 S16, S18 Description UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 34ASP11B1M1QT Reference Designator Source or CAGE Code Specification or Part Number SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9012 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Qty Switch, Toggle DPDT ON-NONEON 34ADP11B1M1QT 1 S19 V81073 Switch, Toggle DPDT ON-(ON) 34ADP21B1M1QT 1 S3 V81073 Switch, Rotary A11215RNZQ 1 S12 V09353 Terminal, Press Mount 571-4182-03-01-19 12 TP1-TP12 VK3105 Wire, 22AWG, Type E NEMA HP3-EXDFE (Wire color is optional) AR None V1VYS1 Description UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Reference Designator Source or CAGE Code Specification or Part Number SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9013 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Manual-Test-Schematic Figure 9001 (Sheet 1 of 4) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9014 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Manual-Test-Schematic Figure 9001 (Sheet 2 of 4) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9015 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Manual-Test-Schematic Figure 9001 (Sheet 3 of 4) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9016 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Manual-Test-Schematic Figure 9001 (Sheet 4 of 4) (2) The illustrations below show a suggested configuration for the M3000 Manual Test Set switches and indicators. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9017 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Manual-Test Set-Views Figure 9002 (Sheet 1 of 2) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9018 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Manual-Test Set-Views Figure 9002 (Sheet 2 of 2) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9019 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-930-002-A01 B. M3000-IR/Dielectric-Test-Cable-(CAN) (1) Use the parts given below (Refer to Table 9005), and the illustration (Refer to Figure 9003), to make the M3000-IR/Dielectric-Test-Cable-(CAN). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 9005 M3000-IR/Dielectric-Test-Cable-(CAN)-Parts-List Description Specification or Part Number Reference Designator Qty Source or CAGE Code Connector D38999/26MB35SN 1 P1 V81349 Banana Jack, Black 861-B 1 J1 V63590 Banana Jack, Red 861-R 1 J2 V63590 Banana Jack, Green 861-GR 1 J3 V63590 Banana Jack, Yellow 861-Y 1 J4 V63590 Wire, 22AWG, Type E NEMA HP3-EXDFE AR (Wire color is optional) None V1VYS1 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9020 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-IR/Dielectric-Test-Cable-(CAN)-Schematic Figure 9003 SUBTASK 26-10-76-930-003-A01 C. M3000-Functional-Test-Cable (1) Use the parts given below (Refer to Table 9006) and the illustration (Refer to Figure 9004) to make the M3000-Functional-Test-Cable. Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 9006 M3000 Functional-Test-Cable Parts-List Description Specification or Part Number Reference Designator Qty Source or CAGE Code Connector D38999/26MB35SN 1 P2 V81349 Connector DBM25S 1 P1 V63590 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9021 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Description Specification or Part Number Reference Designator Qty Resistor 120 Ω, 0.25W RLR07C1200FS 1 Wire, 22AWG, Type E NEMA HP3-EXDFE AR (Wire color is optional) Source or CAGE Code R1 V96906 None V1VYS1 M3000-Functional-Test-Cable-Schematic Figure 9004 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9022 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-930-004-A01 D. M3000-Programming-Test-Cable (1) Use the parts given below (Refer to Table 9007) and the illustration (Refer to Figure 9005) to make the M3000-Programming-Test-Cable. Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 9007 M3000-Programming-Test-Cable-Parts-List Description Specification or Part Number Qty Source Reference or CAGE Designator Code Modular Surface Jack 8588-0071 1 None V63590 RJ12 Modular Plug (6-contacts) 30566EZ 2 None V07QN7 1 None V55322 Ribbon Cable Assembly FFSD-05-S-06.00-01-N UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9023 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 M3000-Programming-Test-Cable Schematic Figure 9005 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9024 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-930-005-A01 E. Burn-In-Test Cable (1) Use the parts given below (Refer to Table 9008) and the illustration (Refer to Figure 9006) to make the Burn-In-Test Cable. Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 9008 Burn-In-Test Cable Parts List Description Specification or Part Number Qty Source Reference or CAGE Designator Code Connector D38999/26MB35SN 1 P1 V81349 Plug, Banana (Red) 108-0302-001 1 None V1VY65 Plug, Banana (Black) 108-0303-001 1 None V1VY65 Wire, 22AWG, Type E NEMA HP3-EXDFE (Wire color is optional) AR None V1VYS1 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9025 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Burn-in-Test-Cable Schematic Figure 9006 SUBTASK 26-10-76-930-006-A01 F. Bonding-Measurement Fixture (1) Use the parts given below (Refer to Table 9009) and the illustration (Refer to TESTING AND FAULT ISOLATION, Table 1006) to make the BondingMeasurement Fixture. Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 9009 Bonding-Measurement-Fixture Parts List Description Specification or Part Number Brass, Ultra-Machinable 8954K273 (Alloy 360) 0.625 Thick X 1.50 W X 12 In L UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Qty 1 Source Reference or CAGE Designator Code None V39428 SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9026 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Bonding-Measurement-Fixture Specifications Figure 9007 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9027 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-930-007-A01 G. Light-Pipe Fixture (1) Use the parts given below (Refer to Table 9010) and the illustration (Refer to Figure 9008) to make the Light-Pipe Fixture. Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 9010 Light-Pipe-Fixture Parts List Description Cast Nylon Specification or Part Number 8687K71 1.50 Thick X 4.0 W X 12 In L Qty 1 Source Reference or CAGE Designator Code None V39428 Light-Pipe-Fixture Specifications Figure 9008 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9028 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 SUBTASK 26-10-76-930-008-A01 H. LED Bending-Block (1) Use the parts given below (Refer to Table 9011) and the illustration (Refer to Figure 9009) to make the LED Bending-Block. Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 9011 LED-Bending-Block Parts List Description Specification or Part Number Low-Carbon Steel 9143K21 1.00 Thick X 1.00 W X 6 In L ASTM A108 Qty 1 Source Reference or CAGE Designator Code None V39428 LED-Bending-Block Specifications Figure 9009 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9029 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. SPECIAL TOOLS, FIXTURES, AND EQUIPMENT Page 9030 Dec 16/13 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 ILLUSTRATED PARTS LIST TASK 26-10-76-950-801-A01 1. INTRODUCTION SUBTASK 26-10-76-99F-012-A01 A. General Information (1) (2) General (a) This Illustrated Parts List (IPL) gives illustrations and a breakdown, in disassembly sequence, of all assemblies that can be disassembled, repaired or replaced, and reassembled. The illustrations and detailed parts list can use a grid layout to show the component locations. (b) When equipment designators are used in schematics and wiring diagrams for electrical and electronic parts, they are shown in the illustrations and the detailed parts list. They are also included in an Equipment Designator Index. (c) When the detailed parts list is more than five pages, a Numerical Index is included in this section. (d) Supplier (vendor) information includes the name and CAGE code for each supplier. Explanation and Usage (a) The "FIG ITEM" column shows the figure and item number for each part. The figure number is shown one time in the header row. Each part is identified by an item number. A part that is not illustrated will have a dash (-) before the item number. (b) Alpha variants, letters A through Z (but not I and O), are used with an item number to show: Configuration differences Alternative parts Optional parts. (c) (d) The PART NUMBER column shows the part number for each part. The true part number will be given in the NOMENCLATURE column when: 1 The part number contains characters that are not permitted by ATA 2000 Specification: for example, a slash (/). 2 The part number has more than 15 characters. 3 The part number contains a dash (-) between a number and a letter. The AIRLINE PART NO. column is a blank column. The airline customer can use this space to record their stock numbers. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10001 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (e) The NOMENCLATURE column gives this type of information about the part: 1 The indenture level shows how the part is related to the next-higher assembly (NHA). For example: 1234567 Assembly • Detail Parts for Assembly • Subassembly • Attaching Parts for Subassembly • • Detail Parts for the Subassembly • • Sub-subassembly • • Attaching Parts for Sub-subassembly • • Detail Parts for Sub-subassembly 2 The true part number if not given in the part number column. 3 ESDS designation, if the electronic part is electrostatic discharge sensitive. 4 The values and tolerances permitted for electrical and electronic parts, such as resistors and capacitors. 5 The CAGE code for parts made by other vendors. 6 Applicable service bulletins; PRE SB XXXX shows the initial configuration and post SB XXXX identifies assemblies and parts after the service bulletin has been completed. If a service bulletin is related to an Airworthiness Directive (AD), then the AD number is identified as AD XXXX. 7 Interchangeability data (how the parts relate to each other). A list of the terms, abbreviations, and definitions is shown in Paragraph (3). 8 Figures or CMMs are referenced to show that more breakdown information is available. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10002 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 (3) (f) The EFF CODE column is used to show limited interchangeability only. It identifies different configurations in each figure and shows how parts relate to Item 1 (or an alpha variant of Item 1) in that figure only. A code letter A through Z (but not I and O) identifies each configuration. The same code is used in this figure to show all parts for a specified configuration. A blank space shows that the part is used on all configurations in that figure. (g) The UNITS PER ASSY column gives the quantity of the specified item number used on one next-higher assembly, subassembly, or sub-subassembly. The letters AR (as necessary) are for bulk items, and RF indicates that the item is shown for reference only. Interchangeability Terms, Abbreviations, Definitions (a) Term: (Abbreviation) Definition Alternate: (ALT) The part agrees with all functional and structural specifications, but the external dimensions, connection installation, and/or mounting provisions are different. Rework or possible changes can be necessary. Optional: (OPT) The part is fully interchangeable in form, fit, and function with other item numbers shown. Replaced By: (REPLD BY) The part is replaced and is two-way interchangeable with the item number shown (old part number can replace either old or new part number when removed). Replaces: (REPLS) The part replaces and is two-way interchangeable with the item number shown (new part number is acceptable replacement for old or new part number). Superseded By: (SUPSD BY) The part is superseded by and is one-way interchangeable with the item number shown (old part number can used as replacement only where old part was installed). Supersedes: (SUPSDS) The part supersedes and is one-way interchangeable with the item number shown (new part number is acceptable replacement for old or new part number). Service Bulletins: (PRE SB) Identifies when a Service Bulletin (SB) has an effect on a part. PRE shows the condition of the part before the work in the service bulletin is done. Service Bulletins: (POST SB) Identifies when a Service Bulletin (SB) has an effect on a part. POST shows the condition after the work is done. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10003 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10004 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR INDEX EQUIPMENT DESIGNATOR A1 FIGURE - ITEM 1-30 2-75A C1 2-175 C10 2-175 C100 2-145 C101 2-315 C102 2-130 C103 2-80A C104 2-80A C105 2-90 C106 2-80A C107 2-130 C108 2-115 C109 2-115 C11 2-115 C110 2-190A 2-190 C115 2-90 C116 2-385 C117 2-175 C118 2-90 C12 2-90 C13 2-200 C14 2-130 C15 2-130 C16 2-265 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10005 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM C17 2-265 C18 2-135 C19 2-115 C2 2-115 C20 2-115 C21 2-135 C22 2-115 C23 2-80A C24 2-115 C25 2-115 C26 2-115 C27 2-115 C28 2-115 C29 2-130 C3 2-190 C3-C4 2-190A C30 2-115 C31 2-115 C32 2-135 C33 2-145 C34 2-200 C35 2-200 C36 2-90 C37 2-115 C38 2-130 C39 2-345 C4 2-190 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10006 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM C40 2-135 C41 2-115 C42 2-315 C43 2-130 C44 2-135 C45 2-135 C46 2-115 C47 2-350 C48 2-90 C49 2-265 C5 2-130 C50 2-135 C51 2-145 C56 2-165 C6 2-130 C63 2-165 C66 2-165 C7 2-115 C71 2-115 C72 2-165 C73 2-115 C74 2-145 C75 2-135 C76 2-115 C77 2-115 C78 2-115 C79 2-115 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10007 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM C8 2-290 C80 2-115 C81 2-115 C82 2-115 C83 2-115 C84 2-115 C85 2-115 C86-C87 2-90 C88 2-135 C89 2-115 C9 2-175 C90 2-135 C91 2-130 C92 2-130 C93 2-115 C94 2-130 C95 2-115 C96 2-115 C97 2-130 C98 2-145 C99 2-145 CR1 2-170 CR10 2-325 2-325A CR11 2-40 CR13 2-310A 2-310 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10008 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM CR2 2-95 CR25 2-105 CR3 2-185 CR33 2-125 2-125A CR34 2-125 2-125A CR36 2-250 CR4 2-250 CR40 2-105 CR41 2-105 CR42 2-105 CR43 2-105 CR44 2-105 CR45 2-105 CR46 2-105 CR7 2-45 CR8 2-325A 2-325 CR9 2-50 DS1 2-140 E1 2-70A J1 2-60 L1 2-390 L10 2-400 L2 2-375 L3 2-100 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10009 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM L4 2-100 L5 2-380 L6 2-100 L7 2-100 P2 2-280 Q1 2-340 Q4 2-150A 2-150 Q5 2-340 R1 2-180 R10 2-220 R101 2-110 R105 2-110 R106 2-110 R107 2-110 R108 2-110 R109 2-110 R11 2-205 R110 2-110 R111 2-110 R112 2-110 R113 2-235 R114 2-235 R115 2-235 R116 2-235 R118 2-195 R119 2-235 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10010 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM R120 2-235 R121 2-205 R122 2-155 R123 2-195 R124 2-110 R125 2-210 R126 2-210 R127 2-195 R13 2-220 R130 2-210 R131 2-85 R15 2-210 R16 2-210 R17 2-210 R18 2-180 R19 2-235 R2 2-205 R20 2-210 R21 2-210 R22 2-235 R23 2-210 R24 2-210 R25 2-210 R26 2-210 R27 2-210 R28 2-210 R29 2-195 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10011 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM R3 2-220 R30-R33 2-255 R34 2-220 R35 2-110 R36 2-195 R37 2-195 R38 2-85 R39 2-235 R4 2-195 R40 2-235 R41 2-235 R43 2-225 R44 2-195 R45 2-240 R46 2-225 R47 2-240 R48 2-210 R49 2-110 R50 2-235 R51 2-225 R52 2-195 R53 2-240 R54 2-235 R55 2-195 R56 2-330 R57 2-195 R58 2-225 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10012 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM R59 2-110 R6 2-215 R60 2-270 R61 2-240 R62 2-220 R63 2-195 R64 2-230 R65 2-235 R66 2-195 R67 2-235 R68 2-225 R69 2-230 R7 2-195 R70 2-110 R71 2-240 R72 2-270 R73 2-210 R74 2-240 R75 2-240 R78 2-195 R83 2-195 R84 2-195 R9 2-260 R90 2-235 T1 2-410A 2-410 U1 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. 2-300 ILLUSTRATED PARTS LIST Page 10013 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 EQUIPMENT DESIGNATOR FIGURE - ITEM U10 2-320 U11 2-360 U18 2-415 U2 2-365 U20 2-305 U206 2-160 U207 2-405 U3 2-275 U4 2-245 U5 2-245 U6 2-355A 2-355 U7 2-335 2-335A U8 2-320 U9 2-420 VR1 2-295 VR2 2-285 VR3 2-295 VR4 2-295 Y1 2-370 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10014 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 NUMERICAL INDEX PART NUMBER AIRLINE PART NO. FIGURE-ITEM TTL REQ. ADUM1201AR 2-160 1 AD8403ARU100 2-420 1 AT283-12 1-60 1 BC846BPDW1T1 2-340 2 BLM31PG601SN1L 2-100 4 CDR31BP151BJUS 2-145 6 CDR31BP680BJUS 2-315 2 CDR32BP102BKSR 2-90 8 CRCW06031002F 2-110 14 CRCW06031003F 2-205 3 CRCW06031005F 2-330 1 CRCW0603137KFK 2-180 2 CRCW060315K8FK 2-220 5 CRCW06031501F 2-235 16 CRCW06031504F 2-270 2 CRCW06031823F 2-240 7 CRCW0603243KFK 2-260 1 CRCW060333R2FK 2-210 16 CRCW06034991F 2-230 2 CRCW06038253F 2-225 5 CRCW06303012F 2-195 17 CRCW12061002F 2-155 1 CRCW12064990F 2-255 4 CRCW121022R6F 2-85 2 C0805C330K1GAC 2-265 3 C1206C103K1RAC 2-200 3 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10015 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 PART NUMBER AIRLINE PART NO. FIGURE-ITEM TTL REQ. C1206C104K3RAC 2-115 34 C1206C104K5RAT 2-385 1 C1206C105K3RAC 2-135 10 C1206C106K4RAC 2-130 13 C1206C223K1RAC 2-350 1 C1206C225K4RAC 2-345 1 C1210C102KDGAC 2-165 4 2-80 C1812C102K5RAC 2-290 1 C1812C472K5RAC 2-175 4 DLW5BSN102SQ2 2-380 1 DS2003TM 2-305 1 DT1608C233 2-375 1 DT3316P224 2-390 1 D38999-20MB35PN 2-60 1 1-65 FTS105-01LDVP 2-280 1 GRM32QR73A103KW 2-80A 4 HLMPCB11UVB00 2-50 1 HSMFA341A00J1 2-140 1 LD274-3 2-45 1 LM3595LD 2-320 2 LT17161S5 2-365 1 LT3010EMS8E 2-295 3 LT3023EMSE 2-285 1 MAX809MEURT 2-275 1 MCP23S08ESS 2-415 1 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10016 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 PART NUMBER AIRLINE PART NO. FIGURE-ITEM TTL REQ. MCP2551ESN 2-405 1 MCP6S91EMS 2-360 1 MMBD1504AA14 2-250 2 MMBD701LT 2-125 2 MMBD701LT1G 2-125A 2 MMSZ4689T1 2-105 8 MMSZ4699T1 2-325 2 MMSZ4699T1G 2-325A 2 MMSZ5258BT1 2-310 1 MMSZ5258BT1G 2-310A 1 MS15795-803 2-15 3 1-55 4 1-45 4 1-25 4 MS25036-101 2-70A 1 MS25036-148 2-70 MS15795-805 1-90 MS35338-136 1-20 1-40 MS35649-244 2-10 3 MS51957-122 1-10 2 MS51957-17 1-50 4 MS51957-27 1-35 4 MS51957-31 1-15 2 MURS360T3 2-170 1 M39029-58-360 2-65 13 1-70 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10017 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 PART NUMBER AIRLINE PART NO. FIGURE-ITEM TTL REQ. PE68386 2-410 1 PE68386NLT 2-410A 1 PIC18F4680EPT 2-300 1 PM2JM10-000MHZ 2-370 1 SFH206K 2-40 1 SMBJ33A 2-185 1 SMLJ40A 2-95 1 TC7750MCTTR 2-245 2 TX8111NLT 2-400 1 T491X107K020AT 2-190A 3 T91X107K020AS 2-190 3 WSC1-15-1 2-215 1 0 2-0 2-0 0PA348AIDBVT 2-335A 1 0PA348A1 2-335 1 0PA4348AIPWT 2-355A 1 0PA4348A1PW 2-355 1 171039 1-85 188194 1-85A 1 2N7002L 2-150 1 2N7002LT1G 2-150A 1 325802-2 2-20 3 326264 2-25 1 326343 2-35 1 326668-1 1-35A 4 326668-2 1-15A 2 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10018 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 PART NUMBER AIRLINE PART NO. FIGURE-ITEM TTL REQ. 326668-5 1-10A 2 347821 2-30 1 347888 1-80 1 347895 1-5 1 348550-15 1-87A 1 348550-2 1-87 1 348598-15 1-85B 1 372590 2-55 1 372591 2-5 1 372623 1-75 1 404414 2-75A 1 404415 2-75 474432 1-30 1 2-1 RF 474449-1 1-1 474449-5 1-1A RF 8516-0151-56 1-62 1 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10019 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10020 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Vendor (Supplier) Codes NOTE: You can get the full address and other information regarding listed vendors or suppliers at http://www.logisticsinformationservice.dla.mil. Other CAGE Code sites are also available on the Internet. Vendor (Supplier) Codes used in this manual are listed below: CAGE CODE MANUFACTURER NAME VK3105 Wearnes Cambion Ltd V4V1Y1 Tyco Corp. V0A554 Abbotec, Inc. V0PK96 Quadtech, Inc. V02111 Vishay Spectrol Electronics V02113 Coilcraft, Inc. V04713 Motorola, Inc. V05611 STS Instruments, Inc. V06090 Tyco Electronics/Raychem V07QN7 Bomar Interconnect Products, Inc. V09353 C and K Components, Inc. V1BWU2 Kemet Technologies Corp. V1EM90 Lumex Opto/Components Inc. V1ES66 Maxim Integrated Products, Inc. V1MQ07 ON Semiconductor V1MY97 Agilent Technolgoies, Inc. V1NKH7 Texas Instruments V1VY65 Emerson Electronic Connector and Component Company V1YGN2 Intrepid Control Systems, Inc. V1VYS1 Texwire, Ltd. V1YGB8 Amatom Electronic Hardware V14552 Microsemi Corp. V16059 Devcon Corp. V18612 Vishay Intertechnology, Inc. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10021 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CAGE CODE MANUFACTURER NAME V19061 Pulse Engineering, Inc. V23480 Electronic Hardware Corp. V23875 M-Tron Industries, Inc. V24355 Analog Devices, Inc. V27014 National Semiconductor Corp. V3A9H3 Osram Opto Semiconductors, Inc. V3EH09 Murata Electronics North America, Inc. V3R2V1 Permabond LLC V30817 Laird Technologies, Inc. V31433 Kemet Electronics Corp. V376C1 Tenma Test Equipment V39428 McMaster-Carr Supply Co. V4L975 S A S Industries, Inc. V40817 Milwaukee Electric Tool Corp. V44655 Heico Ohmite LLC V46733 Dymax Corp. V50434 Avago Technologies, Inc. V51406 Murata Erie North America, Inc. V55322 Samtech, Inc. V56699 BC Components V57003 Chomerico Inc. Shielding Technology, Inc. V57962 ST Microelectronics, Inc. V60991 Microchip Technology, Inc. V61423 Kidde Aerospace & Defense V63590 SPC Technology V64155 Linear Technology Corp. V7E009 Pepperell Braiding Co. V71218 Bud Industries, Inc. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10022 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CAGE CODE MANUFACTURER NAME V81073 Grayhill, Inc. V81349 Military Specifications promulgated by Military Departments/ Agencies under authority of Defense Standardization Manual 4120 3-M V82893 Vector Electronics and Technology, Inc. V89536 Fluke Corp. V91637 Vishay Dale Electronics, Inc. V96906 Military Standards promulgated by Military Departments under authority of Defense Standardization Manual 4120 3-M V99017 Mokon Div. Caplugs V99109 Chase Corp. Humiseal Div. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10023 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 Model 3000 Open Area Smoke Detector IPL Figure 1 UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10024 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER EFF NOMENCLATURE CODE 1234567 UNITS PER ASSY 1 -1 474449-1 DELETED (DETECTOR, SMOKE, MODEL 3000 OPEN AREA) -1A 474449-5 DETECTOR, SMOKE, MODEL 3000 OPEN AREA (ESDS) RF 5 347895 . LID, SMOKE DETECTOR 1 ATTACHING PARTS -10 MS51957-122 . SCREW, MACHINE, NO. 6-32 X 1.375 (V96906) (KIDDE PN: 6075-0622) (SUPSD BY ITEM 10A) 2 10A 326668-5 . SCREW, PAN HEAD SELF-LOCKING, 0.138-32 X 1.375 (SUPSDS ITEM 10) 2 -15 MS51957-31 . SCREW, MACHINE, PAN HEAD, NO. 6-32 X 0.625 (V96906) (KIDDE PN: 6075-0610) (SUPSD BY ITEM 15A) 2 15A 326668-2 . SCREW, PAN HEAD SELF-LOCKING, 0.138-32 X 0.625 (SUPSDS ITEM 15) 2 -20 MS35338-136 DELETED (WASHER, LOCK, NO. 6) 25 MS15795-805 . WASHER, FLAT, NO. 6 (V96906) (KIDDE PN: 1159-9246) ---*--- 4 30 474432 . ASSEMBLY, CCA/LABYRINTH (ESDS) (FOR DETAILS SEE FIG. 2) (A1) 1 ATTACHING PARTS -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10025 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER EFF NOMENCLATURE CODE 1234567 UNITS PER ASSY -35 MS51957-27 . SCREW, MACHINE, PAN HEAD, NO. 6-32 X 0.31 IN. LG., PHILLIPS (V96906) (KIDDE PN: 6075-0605) (FENWAL PN: 06-250087-025) (SUPSD BY ITEM 35A) 4 35A 326668-1 . SCREW, PAN HEAD SELF-LOCKING, 0.138-32 X 0.312 (SUPSDS ITEM 35) 4 -40 MS35338-136 DELETED (WASHER, LOCK, NO. 6) 45 MS15795-805 . WASHER, FLAT, NO. 6 (V96906) (KIDDE PN: 1159-9246) 4 50 MS51957-17 . SCREW, PAN HD, NO. 4-40 X 0.500 LG (V96906) (KIDDE PN: 6075-0408) (FENWAL PN: 06-250087-084) 4 55 MS15795-803 . WASHER, FLAT, NO. 4 (V96906) (KIDDE PN: 1159-9940) 4 60 AT283-12 . NUTPLATE, SHELL SIZE 12 (V0A554) (KIDDE PN: 7063-0012) ---*--- 1 62 8516-0151-56 . GASKET (V30817) (KIDDE PN: 326631) 1 -65 D38999-20MB35PN DELETED (CONNECTOR, 13 PIN) -70 M39029-58-360 DELETED (PIN, CONTACT) 75 372623 . HOUSING, SMOKE DETECTOR 1 80 347888 . PIPE, LIGHT 1 -85 171039 DELETED (NAMEPLATE) 85A 188194 . NAMEPLATE (PROVIDE SW PNR, SERIAL NUMBER, MFG. DATE WITH ORDER.) (SUPSD BY ITEM 85B) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10026 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY -85B 348598-15 . NAMEPLATE, BLANK (REFER TO REPAIR FOR DATA REQUIRED WITH ORDER) (SUPSDS ITEM 85A) 1 87 348550-2 . FILM, POLYESTER OVERLAMINATING (SUPSD BY ITEM 87A) 1 -87A 348550-15 . FILM, POLYESTER OVERLAMINATING (SUPSDS ITEM 87) 1 -90 MS25036-148 DELETED (LUG, TERMINAL, #6) -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10027 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CCA/Labyrinth Assembly IPL Figure 2 (Sheet 1 of 7) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10028 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CCA/Labyrinth Assembly IPL Figure 2 (Sheet 2 of 7) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10029 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CCA/Labyrinth Assembly IPL Figure 2 (Sheet 3 of 7) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10030 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CCA/Labyrinth Assembly IPL Figure 2 (Sheet 4 of 7) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10031 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CCA/Labyrinth Assembly IPL Figure 2 (Sheet 5 of 7) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10032 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CCA/Labyrinth Assembly IPL Figure 2 (Sheet 6 of 7) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10033 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 CCA/Labyrinth Assembly IPL Figure 2 (Sheet 7 of 7) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10034 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER EFF NOMENCLATURE CODE 1234567 UNITS PER ASSY 2 0 0 INITIALIZATION RECORD 0 0 INITIALIZATION RECORD -1 474432 ASSEMBLY, CCA/LABYRINTH (ESDS) RF 5 372591 . TOP, LABYRINTH 1 10 MS35649-244 . NUT, HEX, CRES NO. 4-40 (V96906) (KIDDE PN: 5796-0400) 3 15 MS15795-803 . WASHER, FLAT, NO. 4 (V96906) (KIDDE PN: 1159-9940) 3 20 325802-2 . FASTENER, SELF-LOCKING, NO. 4-40 X 1.25 3 25 326264 . SCREEN, DUST 1 30 347821 . MIRROR 1 35 326343 . CAN, SHIELD, PHOTODIODE 1 40 SFH206K . PHOTODIODE, 400-1100 NM (V3A9H3) (ESDS) (KIDDE PN: 304871) (CR11) 1 45 LD274-3 . LED, RED, 950 NM (V3A9H3) (ESDS) (KIDDE PN: 304869) (CR7) 1 50 HLMPCB11UVB00 . LED, BLUE, 470 NM (V50434) (ESDS) (KIDDE PN: 304870) (CR9) 1 55 372590 . LABYRINTH, BOTTOM 1 60 D38999-20MB35PN . CONNECTOR, 13 PIN (V81349) (TRUE PN: D38999/20MB35PN) (J1) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10035 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY -65 M39029-58-360 . . PIN, CONTACT (V81349) (TRUE PN: M39029/58-360) 13 -70 MS25036-148 DELETED (LUG, TERMINAL, #6) 70A MS25036-101 . LUG, TERMINAL, NO. 6 (KIDDE PN: 5607-0001) (E1) -75 404415 DELETED (ASSEMBLY, CIRCUIT CARD) 75A 404414 . ASSEMBLY, CIRCUIT CARD (ESDS) (A1) -80 C1210C102KDGAC DELETED (CAPACITOR, 1000 PF, 10%, 1000V) 80A GRM32QR73A103KW . . CAPACITOR, 10000 PF, 10%, 1000V (OVERLENGTH P/N GRM32QR73A103KW01) (V3EH09) (ESDS) (KIDDE PN: 304853) (C23, C103, C104, C106) 4 85 CRCW121022R6F . . RESISTOR, 22.6 OHM, 1%, 0.250W (V18612) (ESDS) (KIDDE PN: 7081-22R6) (R38, R131) 2 90 CDR32BP102BKSR . . CAPACITOR, 0.001 uF, ±10%, 100V (V81349) (ESDS) (C12, C36, C48, C86-C87, C105, C115, C118) 8 95 SMLJ40A . . DIODE, ZENER, TRANSIENT ABSORPTION, 40V, 5%, 3000W (V14552) (ESDS) (KIDDE PN: 06-250447-103) (CR2) 1 1 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10036 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 100 BLM31PG601SN1L . . BEAD, FERRITE, 600 OHM (V51406) (ESDS) (KIDDE PN: 304801-1) (L3, L4, L6, L7) 4 105 MMSZ4689T1 . . DIODE, 5.1V ZENER, SILICON (V1MQ07) (ESDS) (KIDDE PN: 304617) (CR25, CR40, CR41, CR42, CR43, CR44, CR45, CR46) 8 110 CRCW06031002F . . RESISTOR, 10K, 1%, 0.0625W (V18612) (KIDDE PN: 7085-1002) (R35, R49, R59, R70, R101, R105, R106, R107, R108, R109, R110, R111, R112, R124) 14 115 C1206C104K3RAC . . CAPACITOR, 0.1 MICROFARAD, 10%, 25V (V31433) (ESDS) (KIDDE PN: 7083-0033) (C2, C7, C11, C19, C20, C22, C24, C25, C26, C27, C28, C30, C31, C37, C41, C46, C71, C73, C76, C77, C78, C79, C80, C81, C82, C83, C84, C85, C89, C93, C95, C96, C108, C109) 34 125 MMBD701LT . . DIODE, SCHOTTKY, 70V (V1MQ07) (ESDS) (KIDDE PN: 304691) (CR33, CR34) (SUPSD BY ITEM 125A) 2 -125A MMBD701LT1G . . DIODE, SCHOTTKY, 70V (V5V1P1) (ESDS) (KIDDE PN: 304691) (SUPSDS ITEM 125) (CR33, CR34) 2 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10037 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 130 C1206C106K4RAC . . CAPACITOR, 10 MICROFARAD, 10%, 16V (V31433) (ESDS) (KIDDE PN: 7082-0135) (C5, C6, C14, C15, C29, C38, C43, C91, C92, C94, C97, C102, C107) 13 135 C1206C105K3RAC . . CAPACITOR, 1.0 uF, ±10%, 25V (V31433) (ESDS) (KIDDE PN: 7083-0078) (C18, C21, C32, C40, C44, C45, C50, C75, C88, C90) 10 140 HSMFA341A00J1 . . LED, RGB, 80/100/25 MCD, 120 DEG (V1MY97) (ESDS) (KIDDE PN: 304898) (DS1) 1 145 CDR31BP151BJUS . . CAPACITOR, 150 PF, 5%, 100V (ESDS) (C33, C51, C74, C98, C99, C100) 6 150 2N7002L . . MOSFET, N-CHANNEL (V1MQ07) (ESDS) (KIDDE PN: 324871) (Q4) (SUPSD BY ITEM 150A) 1 -150A 2N7002LT1G . . TRANSISTOR, SEMICONDUCTOR DEVICE, SMALL SIGNAL MOSFET, 60V, 115mA, N-CHANNEL SOT-23 (V1MQ07) (ESDS) (KIDDE PN: 324871) (Q4) (SUPSDS ITEM 150) 1 155 CRCW12061002F . . RESISTOR, 10K OHM, ±1%, 0.125W (V18612) (ESDS) (KIDDE PN: 7023-1002) (R122) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10038 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 160 ADUM1201AR . . MICROCIRCUIT, ISOLATOR, DIGITAL, DUAL-CHANNEL (V24355) (ESDS) (KIDDE PN: 304907) (U206) 1 165 C1210C102KDGAC . . CAPACITOR, 1000 PF, 10%, 1000V (V1BWU2) (ESDS) (KIDDE PN: 304963) (C56, C63, C66, C72) 4 170 MURS360T3 . . RECTIFIER, POWER, ULTRAFAST, 3A, 600V (V1MQ07) (ESDS) (KIDDE PN: 304931) (CR1) 1 175 C1812C472K5RAC . . CAPACITOR, 4.7 MICROFARAD, 10%, 50V (V31433) (ESDS) (KIDDE PN: 7026-0168) (C1, C9, C10, C117) 4 180 CRCW0603137KFK . . RESISTOR, 137K OHM, 1%, 0.0625W (V02111) (ESDS) (KIDDE PN: 7085-1373) (R1, R18) 2 185 SMBJ33A . . DIODE, ZENER, 33V (V14552) (ESDS) (KIDDE PN: 06-115900-296) (CR3) 1 190 T91X107K020AS . . CAPACITOR, 100 MICROFARAD, 10%, 20V (V31433) (KIDDE PN: 7047-0144) (C3, C4, C110) (SUPSD BY ITEM 190A) 3 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10039 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY -190A T491X107K020AT . . CAPACITOR, TANTALUM, 100 MICROFARAD, 10%, 20V (V31433) (ESDS) (KIDDE PN: 7047-0144) (C3-C4, C110) (SUPSDS ITEM 190) 3 195 CRCW06303012F . . RESISTOR, 30.1K, 1%, 0.0625W (V18612) (KIDDE PN: 7085-3012) (R4, R7, R29, R36, R37, R44, R52, R55, R57, R63, R66, R78, R83, R84, R118, R123, R127) 17 200 C1206C103K1RAC . . CAPACITOR, 0.01 uF, ±10%, 100V (V31433) (ESDS) (KIDDE PN: 7027-0044) (C13, C34, C35) 3 205 CRCW06031003F . . RESISTOR, 100K, 1%, 0.0625W (V18612) (ESDS) (KIDDE PN: 7085-1003) (R2, R11, R121) 3 210 CRCW060333R2FK . . RESISTOR, 33.2 OHM, 1%, 0.0625W (V02111) (ESDS) (KIDDE PN: 7085-33R2) (R15, R16, R17, R20, R21, R23, R24, R25, R26, R27, R28, R48, R73, R125, R126, R130) 16 215 WSC1-15-1 . . RESISTOR, WIREWOUND, 15 OHM, 1%, 1W (V91637) (ESDS) (KIDDE PN: 7058-15R0) (R6) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10040 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 220 CRCW060315K8FK . . RESISTOR, 15.8K OHM, 1%, 0.0625W (V02111) (ESDS) (KIDDE PN: 7085-1582) (R3, R10, R13, R34, R62) 5 225 CRCW06038253F . . RESISTOR, 825K, 1%, 0.0625W (V18612) (ESDS) (KIDDE PN: 7085-8253) (R43, R46, R51, R58, R68) 5 230 CRCW06034991F . . RESISTOR, 4.99K OHM, 1%, 0.0625W (V18612) (ESDS) (KIDDE PN: 7085-4991) (R64, R69) 2 235 CRCW06031501F . . RESISTOR, 1.5K, 1%, 0.0625W (V18612) (ESDS) (KIDDE PN: 7085-1501) (R19, R22, R39, R40, R41, R50, R54, R65, R67, R90, R113, R114, R115, R116, R119, R120) 16 240 CRCW06031823F . . RESISTOR, 182K, 1%, 0.0625W (V18612) (ESDS) (KIDDE PN: 7085-1823) (R45, R47, R53, R61, R71, R74, R75) 7 245 TC7750MCTTR . . SENSOR, THERMAL (V60991) (ESDS) (TRUE PN: TC77-5.0MCTTR) (KIDDE PN: 304867) (U4, U5) 2 250 MMBD1504AA14 . . DIODE, LOW LEAKAGE, DUAL, 180V (V27014) (ESDS) (TRUE PN: MMBD1504A A14) (KIDDE PN: 325679) (CR4, CR36) 2 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10041 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 255 CRCW12064990F . . RESISTOR, 499 OHM, 1%, 0.125W (V18612) (ESDS) (KIDDE PN: 7023-4990) (R30-R33) 4 260 CRCW0603243KFK . . RESISTOR, 243K OHM, 1%, 0.0625W (V02111) (ESDS) (KIDDE PN: 7085-2433) (R9) 1 265 C0805C330K1GAC . . CAPACITOR, 33 pF, ±10%, 100V (V31433) (ESDS) (KIDDE PN: 7035-0019) (C16, C17, C49) 3 270 CRCW06031504F . . RESISTOR, 1.5M, 1%, 0.0625W (V18612) (KIDDE PN: 7085-1504) (R60, R72) 2 275 MAX809MEURT . . MICROCIRCUIT, RESET, MICROPROCESSOR (V1ES66) (ESDS) (TRUE PN: MAX809MEUR-T) (KIDDE PN: 325700) (U3) 1 280 FTS105-01LDVP . . CONNECTOR, 10-PIN TERMINAL STRIP (V55322) (TRUE PN: FTS-105-01-L-DV-P) (KIDDE PN: 304905) (P2) 1 285 LT3023EMSE . . MICROCIRCUIT, REGULATOR, DUAL (V64155) (ESDS) (KIDDE PN: 304862) (VR2) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10042 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 290 C1812C102K5RAC . . CAPACITOR, 1 MICROFARAD, 10%, 50V (V31433) (ESDS) (KIDDE PN: 7026-0162) (C8) 1 295 LT3010EMS8E . . REGULATOR, MICROPOWER, LINEAR (V64155) (ESDS) (KIDDE PN: 304861) (VR1, VR3, VR4) 3 300 PIC18F4680EPT . . MICROCONTROLLER, 8-BIT CMOS FLASH (V60991) (ESDS) (KIDDE PN: 304868) (U1) 1 305 DS2003TM . . MICROCIRCUIT, VOLTAGE DRIVER (V1NKH7) (ESDS) (KIDDE PN: 325640) (U20) 1 310 MMSZ5258BT1 . . DIODE, ZENER, 36V, ±5%, 0.5W (V04713) (ESDS) (KIDDE PN: 325760) (CR13) (SUPSD BY ITEM 310A) 1 -310A MMSZ5258BT1G . . DIODE, ZENER, 36V, ±5%, 0.5W (V5V1P1) (ESDS) (KIDDE PN: 325760) (CR13) (SUPSDS ITEM 310) 1 315 CDR31BP680BJUS . . CAPACITOR, 68 PF, 10%, 100V (ESDS) (C42, C101) 2 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10043 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER EFF NOMENCLATURE CODE 1234567 UNITS PER ASSY 320 LM3595LD . . PARALLEL CONSTANT CURRENT DRIVER, 25 MILLI AMP (V27014) (ESDS) (KIDDE PN: 304860) (U8, U10) 2 325 MMSZ4699T1 . . DIODE, ZENER, 12V (V1MQ07) (ESDS) (KIDDE PN: 325681) (CR8, CR10) (SUPSD BY ITEM 325A) 2 -325A MMSZ4699T1G . . DIODE, ZENER, 12V (V5V1P1) (ESDS) (KIDDE PN: 325681) (SUPSDS ITEM 325) (CR8, CR10) 2 330 CRCW06031005F . . RESISTOR, 10M, 1%, 0.0625W (V18612) (ESDS) (KIDDE PN: 7085-1005) (R56) 1 335 0PA348A1 . . MICROCIRCUIT, AMPLIFIER, OPERATIONAL (V13919) (ESDS) (KIDDE PN: 304863) (U7) (SUPSD BY ITEM 335A) 1 -335A 0PA348AIDBVT . . MICROCIRCUIT, AMPLIFIER, OPERATIONAL (V1NKH7) (ESDS) (KIDDE PN: 304863) (TRUE PN: OPA348AIDBV (T)) (U7) (SUPSDS ITEM 335) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10044 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 340 BC846BPDW1T1 . . TRANSISTOR, DUAL, NPN/PNP (V1MQ07) (ESDS) (KIDDE PN: 304709) (Q1, Q5) 2 345 C1206C225K4RAC . . CAPACITOR, 2.2 MICROFARAD, 10%, 16V (V31433) (ESDS) (KIDDE PN: 7082-0086) (C39) 1 350 C1206C223K1RAC . . CAPACITOR, 0.022 MICROFARAD 10%, 100V (V31433) (ESDS) (KIDDE PN: 7027-0048) (C47) 1 355 0PA4348A1PW . . MICROCIRCUIT, OP AMP, CMOS (V13919) (ESDS) (KIDDE PN: 304864) (U6) (SUPSD BY ITEM 355A) 1 -355A 0PA4348AIPWT . . MICROCIRCUIT, RAIL-TO-RAIL OP AMP, LOW POWER, QUAD (V1NKH7) (ESDS) (KIDDE PN: 304864) (TRUE PN: OPA4348AIPW(T)) (U6) (SUPSDS ITEM 355) 1 360 MCP6S91EMS . . MICROCIRCUIT, SINGLE-ENDED, RAILTO-RAIL LOW GAIN PGA (V60991) (ESDS) (KIDDE PN: 304865) (U11) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10045 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 365 LT17161S5 . . MICROCIRCUIT, COMPARATOR (V64155) (ESDS) (KIDDE PN: 304806) (U2) 1 370 PM2JM10-000MHZ . . CRYSTAL, QUARTZ, 10.000 MHZ (V23875) (ESDS) (TRUE PN: PM-2JM10.000MHZ) (KIDDE PN: 304866) (Y1) 1 375 DT1608C233 . . INDUCTOR, 22 MICRO HENRIES (V02113) (KIDDE PN: 06-115904-028) (L2) 1 380 DLW5BSN102SQ2 . . FILTER, EMI SUPPRESSION, COMMON MODE CHOKE COIL, 1.5A, 50V, 10M OHM (V51406) (ESDS) (KIDDE PN: 304798) (L5) 1 385 C1206C104K5RAT . . CAPACITOR, 0.1 MICROFARAD, ±10%, 50V (V31433) (KIDDE PN: 9-1072) (C116) 1 390 DT3316P224 . . INDUCTOR, 220 MICROHENRIES, 0.5A, 0.39 OHM (V02113) (ESDS) (TRUE PN: DT3316P-224) (KIDDE PN: 06-115904-037) (L1) 1 400 TX8111NLT . . COMMON MODE CHOKE, CAN BUS 51 MICRO HENRIES (V01961) (ESDS) (KIDDE PN: 304965) (L10) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10046 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 FIG. ITEM PART NUMBER AIRLINE PART NUMBER 1234567 EFF NOMENCLATURE CODE UNITS PER ASSY 405 MCP2551ESN . . MICROCIRCUIT, CAN DRIVER/ RECEIVER (V60991) (ESDS) (TRUE PN: MCP2551-E/SN) (KIDDE PN: 304821) (U207) 1 410 PE68386 . . TRANSFORMER, GATE DRIVE (VSV170) (ESDS) (KIDDE PN: 304908) (T1) (SUPSDS ITEM 410) 1 -410A PE68386NLT . . TRANSFORMER, GATE DRIVE (VSV170) (ESDS) (TRUE PN: PE-68386NLT) (T1) (SUPSDS ITEM 410) 1 415 MCP23S08ESS . . MICROCIRCUIT, I/O EXPANDER, 8-BIT (V60991) (ESDS) (TRUE PN: MCP23S08-E/SS) (KIDDE PN: 304897) (U18) 1 420 AD8403ARU100 . . POTENTIOMETER, DIGITAL, 100K (V24355) (ESDS) (KIDDE PN: 304858) (U9) 1 -ITEM NOT ILLUSTRATED UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10047 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. ILLUSTRATED PARTS LIST Page 10048 Apr 30/15 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 STORAGE (INCLUDING TRANSPORTATION) TASK 26-10-76-990-809-A01 1. GENERAL INFORMATION SUBTASK 26-10-76-99F-014-A01 A. General Information (1) This section has the procedures necessary to store and transport the smoke detector. SUBTASK 26-10-76-94A-004-A01 B. Consumable Materials (1) The consumable materials necessary to store the smoke detector are given below (Refer to Table 15001). Refer to the Vendor (Supplier) Codes paragraph in the IPL for the names of the suppliers shown in the Source column. NOTE: You can use equivalent alternatives for the items given in the table. Table 15001 Consumable Materials Name Cap, Protective Black (Conductive) UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. Specification or Part Number CEC-12 Source or CAGE Code V99017 STORAGE (INCLUDING TRANSPORTATION) Page 15001 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. STORAGE (INCLUDING TRANSPORTATION) Page 15002 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 TASK 26-10-76-500-801-A01 2. STORAGE AND SHIPPING SUBTASK 26-10-76-550-001-A01 A. Storage CAUTION: THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. (1) Make sure the protective cap is installed on the J1 connector. (2) Keep the smoke detector in materials to protect it from ESD. (3) Keep the smoke detector in an applicable container that will prevent damage. (4) Keep the container in a cool, dry, place. (5) Use sufficient material to prevent damage during transportation. SUBTASK 26-10-76-510-001-A01 B. Shipping CAUTION: THE UNIT CONTAINS ELECTROSTATIC DISCHARGE SENSITIVE (ESDS) COMPONENTS. THESE COMPONENTS ARE IDENTIFIED BY THE LETTERS (ESDS) IN THE ITEM DESCRIPTION CONTAINED IN THE ILLUSTRATED PARTS LIST (IPL). OBEY ESDS PRECAUTIONS WHEN YOU TOUCH THE UNIT OR DAMAGE CAN OCCUR. (1) Make sure the protective cap is installed on the J1 connector. (2) Ship the smoke detector in an applicable container that will prevent damage. (3) Use sufficient material to prevent damage during transportation. UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. STORAGE (INCLUDING TRANSPORTATION) Page 15003 Mar 05/10 26-10-76 KIDDE AEROSPACE & DEFENSE COMPONENT MAINTENANCE MANUAL PART NUMBER 474449 THIS PAGE INTENTIONALLY LEFT BLANK UTC AEROSPACE SYSTEMS PROPRIETARY Subject to the EAR. See the title page for more information. STORAGE (INCLUDING TRANSPORTATION) Page 15004 Mar 05/10 26-10-76