SiGe BiCMOS Technology and Circuits for Active Safety Systems

INVITED

Franz Dielacher, Marc Tiebout, Rudolf Lachner*), Herbert Knapp*), Klaus Aufinger*) Willy Sansen**),

Infineon Technologies Austria AG, Siemensstrasse 2, 9500 Villach Austria

Infineon Technologies AG, Am Campeon 1-12, 85579 Neubiberg, Germany

**)

KU Leuven, &*3%"*("$$($54 61<99: +,$1"+#

*)

ABSTRACT

This paper provides an overview of the features and capabilities of

state-of-the-art SiGe devices and BiCMOS technology for

applications such as high-data-rate communications and pro-active

safety systems like car-radar, identification and e-safety.

The capabilities offered by SiGe-BiCMOS and microwave packaging

enable the integration of complete transceivers on a chip or in a

package even including the antenna. The criteria and trade-off’s for

the technology selection and system partitioning are described in the

introduction. In addition to the electrical components performance,

major criteria are addressed such as high reliability, long lifetime and

high yield fabrication. Advanced packaging technologies are

addressed as well, including embedded passive components and

package co-design.

Existing circuit design examples and future solutions for 77 GHz

automotive radar are presented, followed by a multichannel receiver

and a multichannel transmitter for mm-wave people scanners for

airport security.

Keywords – Silicon-Germanium (SiGe), BiCMOS, Heterojunction

Bipolar Transistor (HBT), Automotive Radar, mm-Wave Security

Scanner, mm-Wave Imaging

ratio of gm over IC (gm over IDS in CMOS) of the SiGe bipolar

transistor is essential to save current.

The mm-wave bandwidth covers a frequency range from 30 GHz to

300 GHz. However the interest for application development is

concentrated in selected bands for worldwide communication. The

allocation of the ISM band around 60 GHz and the 70 GHz and 80

GHz bands are released worldwide mainly for wireless high-data-rate

communication and car-radar applications, with an operating range

that is limited to a few meters for indoor communications at 60 GHz,

whereas it is up to around 1 km for the outdoor applications. The

operating range has a direct impact on the transmitted power, which

is between 0 and 10 dBm within indoor networks, whereas it needs to

be much higher in the case of outdoor applications. A rough

estimation gives an output power level of around 15 dBm to

guarantee reliable 1-to-2-km link for data transmission in all weather

conditions or to achieve a distance of >200m for long-range

automotive radar [9].

As circuit design examples, a multichannel 77GHz automotive radar

transmitter a multichannel receiver and a multichannel transmitter for

mm-wave people scanners in the 70 to 80 GHz frequency band will

be presented.

INTRODUCTION

RF/microwave circuits are designed in advanced CMOS, SiGeBiCMOS, GaAs and InP technologies as shown in Figure 1. In terms

of RF performance InP is the best but other criteria like integration

complexity and cost have to be taken into consideration. As a general

rule we can say that “what can be done in silicon will be done in

silicon” and “what can be done in CMOS will be done in CMOS” [2].

Today almost all the designs up to about 10GHz are in CMOS

because of the multi-million volumes and SoC integration

requirements. For the frequency range from 10GHz to about 100GHz

where the volumes are still moderate, SiGe-BiCMOS is most

attractive because of the excellent performance and overall cost

trade-off. Beyond 100 GHz InP is needed but here we are talking

about volumes below one k pieces and therefore the high technology

cost is not an issue.

In the SiGe bipolar and BiCMOS process development good

progress was made [1,2,9]. Today technologies with fmax>400GHz

and fT >250GHz are available as shown in table 1. This excellent RF

performance is achieved with a 130nm process lithography.

Extended temperature range, high reliability and long process

lifetime are other important features of the SiGe technologies.

According to the ITRS roadmap the next SiGe-based bipolar

transistor generation will even achieve 700 GHz in a 65nm (or 90nm)

technology [4].

Other SiGe-bipolar features as a 4 times higher breakdown voltage

compared to CMOS (for identical fmax) are most useful for circuits

like power-amplifiers and to achieve a very low phase-noise in

VCO’s. For practical applications the collector base breakdown

voltage (BVCBo or BVCEs) is most relevant and is about 5V in a SiGe

bipolar transistor with fmax >400GHz. Further the four times better

FIGURE 1. TECHNOLOGY CHOICE

TABLE 1. SIGE PROCESS FOUNDRIES

978-1-4799-2217-8/14/$31.00 ©2014 IEEE

Authorized licensed use limited to: Indraprastha Institute of Information Technology. Downloaded on June 30,2022 at 09:27:21 UTC from IEEE Xplore. Restrictions apply.

SIGE TECHNOLOGY OVERVIEW

Modern SiGe and deep sub-µm CMOS processes both provide

transistors with fT/fmax well above 200/250 GHz, thus making mmwave transceivers feasible in either technology as is widely

documented in the literature. Usually the choice of the fabrication

process will be strictly linked to the final application specifications

and to technical implementation trade-offs such as the desired level

of integration, frequency bandwidth and distance operating ranges. In

addition to the required fT/fmax capability this relates to output signal

power, quality of on-chip passive components, noise issues,

robustness to process and temperature variations, antenna cointegration, and so on.

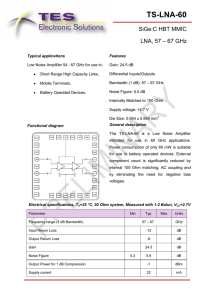

Current state of the art SiGe bipolar/BiCMOS technologies are

shown in table 1. The B7HF200 process from Infineon is a bipolar

SiGe HBT process featuring cut-off frequencies of 200 GHz (fT) and

250 GHz (fmax) and the next generation B11HFC achieves 250 GHz

(fT) and 435 GHz (fmax) with scaled HBT geometries as shown in

table 2 [1,2,3,4]. Beside the SiGe HBT key devices, both processes

offer poly-silicon and metal film resistors, MIM capacitors, a hyper

abrupt pn varactor diode and laser fuses. The SiGe HBT uses a

classical DPSA emitter/base structure (double-poly-silicon selfaligned structure, although one of the two poly-silicon contacts – the

emitter - actually is now made of mono crystalline Silicon) and a

selective epitaxially grown (SEG) Silicon Germanium base layer.

Shallow and deep trench isolation minimize internal parasitic

capacitances and allow for dense device packing. A cross-section of

the B7HF200 and the B11HFC fmax=435 GHz HBT device is shown

in figure 2 in a comparison. Measured fmax and fT characteristics as a

function of collector current IC for B11HFC are shown in figure 3.

The metallization system of B7HF200 consists of 4 copper layers

and one aluminum layer and a gold pad. The new B11HFC process is

using 6 copper and one aluminum layer and it incorporates 130nm

CMOS devices.

Currently the B7HF200 process is extensively used for products like

car-radars, mm-wave transceivers for data-links and airport security

scanners. Volume production started in 2007 and B7HF200 is

automotive qualified and fulfills all the extended reliability and

operating conditions requirements like extended temperature range.

In the future the new B11HFC BiCMOS with the improved HBT

performance and the additional CMOS devices will be used.

FIGURE 3: fmax AND fT VERSUS IC FOR B11HFC

%!&*)%#&*,$)),$%(&&"*%$)/%$),("

:990*($*"/"+$+(%&$ &(% *7=8

*(*)*($)*('+$/#.%93?03),"%&#$*)

$" / ()), )"$ % "*(" $ ,(*" ,

#$)%$) *%*( -* $- %$&*) %( (+ *($))*%(

&()*)3

$)+##(/# %(,$*)%*%#&(*%$#

(2

4

high amplification in the RF/mm-wave front-end

4

more than 10 dBm output power at mm-wave frequencies

4

passive devices with good high-frequency behaviour,

including top thick metal layers and a thick oxide from this

metal towards the substrate

4

the oxide thickness of SiGe processes is usually around

twice the oxide thickness of CMOS

4

both modern SiGe and CMOS transistors offer good noise

performance behaviour in the mm-wave range, but SiGe

devices are still superior and

4

technology reliability in terms of process and temperature

PACKAGING OF MM-WAVE ICS

TABLE 2. DEVICE PARAMETERS OF SIGE HBTS

FIGURE 2: SIGE HBT CROSS SECTION

To simplify the fabrication of microwave systems and to reduce

production costs, the development of surface mountable devices

(SMD) was very important. A fan-out embedded wafer level ball grid

array package technology (eWLB) proved to be suited and most

useful [7]. Like shown in figure 3, the significant advantage

compared to the standard BGA-wirebond and BGA flip-chip

packages are the significantly reduced parasitic. A cross section of a

packaged device is shown in figure 4. eWLB is suited for)/)*#%$

& 5%6 $*(*%$ $ )/)*# $ &! 56 $*(*%$

"! ) / ) $ )*!$ % ,)3 However for the eWLB

package, not just accurate electrical modeling and package cosimulation but also thermal modeling and simulation is very

important because all the generated heat has to be transported

through the balls. % (#%, *1 %$ )%"+*%$ ) *% %$$*

*%$" *(#" "")1 33 * %* )&%*)1 ** ""%- (#%," %

* *% * %(3 +)1 $ *%$ ")% * (#%," (%# *

%(#*('+(3

Authorized licensed use limited to: Indraprastha Institute of Information Technology. Downloaded on June 30,2022 at 09:27:21 UTC from IEEE Xplore. Restrictions apply.

FIGURE 3: PACKAGE PARASITICS

FIGURE 5: THREE CHANNEL TRANSMITTER

FIGURE

4: eWLB PACKAGE

CROSS SECTION

DESIGN

EXAMPLE

: AUTOMOTIVE

RADAR

AUTOMOTIVE RADAR TRANSMITTER

The market for driver assistance systems based on millimeter-wave

radar sensor technology is gaining momentum. Radar is robust

against environmental influences and therefore has been identified as

the most promising technology for many driver assistance functions

for active comfort and active safety. For the radar transceivers

performance, integration, power consumption and cost are key

factors. Chip sets and MMICs in GaAs technology are used in the

2nd generation of radars but for the 3rd generation highly integrated

SiGe transceivers are the favorites.

Figure 5 shows the block diagram of a three-channel 77 GHz radar

transmitter [5]. The circuit is manufactured in Infineon’s B7HF200

SiGe process and mounted in a eWLB package.

The transmitter contains a push-push VCO for the 76 – 77 GHz radar

band with a phase noise of -76 dBc/Hz. Three independent output

channels are available. The output power of each channel can be

controlled over a wide range via a digital interface.

In order to simplify the implementation of frequency control schemes,

the circuit contains a versatile frequency divider block which can be

configured to provide output signals in the range from 19 GHz to 50

kHz. An additional low-noise 18 GHz VCO allows the

implementation of offset PLLs.

Figure 6 shows a photograph of the transmitter chip in the eWLB

package. The package size is 6x6 mm2 with a ball pitch of 0.5 mm.

With additional balls for thermal management a thermal resistance

from chip to board of less than 10 K/W was achieved.

The circuit operates from a single supply voltage of 3,3 V and

consumes between 205 mA and 710 mA, depending on the

configuration. Measured performance data is shown in table 3.

FIGURE 6: CHIP/PACKAGE PHOTOGRAPH

TABLE 3: TRANSMITTER PERFORMANCE SUMMARY

WIDEBAND CHIPSET FOR MM-WAVE IMAGING

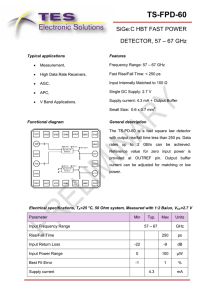

In this section a four channel receiver and transmitter chipset for high

resolution real-time imaging systems for people screening

applications operating near the W-band will be described [6, 10]. The

center frequency of operation is 78GHz with a 3-dB bandwidth of at

Authorized licensed use limited to: Indraprastha Institute of Information Technology. Downloaded on June 30,2022 at 09:27:21 UTC from IEEE Xplore. Restrictions apply.

least 7GHz for optimal image resolution and depth of focus.

Specifications are listed in Table 4.

CONCLUSION

It can be concluded that the potential of SiGe bipolar and BiCMOS

technology is excellent to push emerging mm-wave applications to

broader acceptance and market penetration. SiGe is an optimal

technology choice for „medium“ volume RFIC applications like carradar, mm-wave security scanners and high data-rate transceivers.

The strive for higher fT/fmax is driven by power saving needs and

new applications at even higher frequencies. New SiGe BiCMOS

with fmax > 400 GHz will be in volume production soon and research

projects with the goal to achieve fmax= 700 GHz have been initiated.

REFERENCES

[1]

TABLE 4: CHIPSET SPECIFICATIONS

Figure 7 shows the block diagram of the four-channel receiver, Fig. 8

the block diagram of the four channel transmitter. The circuits are

manufactured in Infineon’s B7HF200 SiGe process, die size is

2x2.2mm².

The frequency generation consists of a frequency quaddrupler

consisting of 2 cascaded active Gilbert mixers. The receiver RFIC

contains 4 channels including LO generation and distribution. The

measured receiver conversion gain is 23dB with a SSB NF below

10dB over a wide frequency range from 70GHz up to 82GHz.

Transmitter output power is 5dBm over a 3dB bandwidth ranging

from 72GHz to 84GHz. The chip is supplied from a single 3,3V

supply voltage and the power consumption per channel is below

180mW/channel for the receiver and below 145mw/channel for the

transmitter.

The analog front ends are built of custom made four-channel receiver

and transmitter chips, which are connected to aperture-coupled patch

excited horn antennas. Those elements are embedded in a RF

multilayer PCB. The chips are mounted in multilevel cavities, as the

antenna’s differential feed lines run on an inner layer of the PCB, and

for RF performance reasons, vias and longer bond wires have been

avoided.

FIGURE 7: RECEIVER BLOCK DIAGRAM

Lachner, R., "Industrialization of mmWave SiGe technologies:

Status, future requirements and challenges," SiRF, 2013 IEEE

13th Topical Meeting on , vol., no., pp.105,107, 21-23 Jan.

2013

[2] Lachner, R. “SiGe-Technology: State-of-the-Art and Road

Map for Future Applications”, Workshop Proceedings,

European Microwave Week, Oct. 2013

[3] http://www.dotfive.eu

[4] http://www.dotseven.eu

[5] Knapp, H.; Treml, M.; Schinko, A.; Kolmhofer, E.; Matzinger,

S.; Strasser, G.; Lachner, R.; Maurer, L.; Minichshofer, J.,

"Three-channel 77 GHz automotive radar transmitter in plastic

package," Radio Frequency Integrated Circuits Symposium

(RFIC), 2012 IEEE , vol., no., pp.119,122, 17-19 June 2012

[6] Tiebout, M.; Wohlmuth, H.-D.; Knapp, H.; Salerno, R.; Druml,

M.; Rest, M.; Kaeferboeck, J.; Wuertele, J.; Ahmed, S.S.;

Schiessl, A.; Juenemann, R.; Zielska, A., "Low Power

Wideband Receiver and Transmitter Chipset for mm-Wave

Imaging in SiGe Bipolar Technology," Solid-State Circuits,

IEEE Journal of , vol.47, no.5, pp.1175,1184, May 2012

[7] Wojnowski, M.; Lachner, R.; Bock, J.; Wagner, C.; Starzer, F.;

Sommer, G.; Pressel, K.; Weigel, R., "Embedded wafer level

ball grid array (eWLB) technology for millimeter-wave

applications," Electronics Packaging Technology Conference

(EPTC), 2011 IEEE 13th , vol., no., pp.423,429, 7-9 Dec.

2011

[8] Camillo-Castillo, R.A.; Liu, Q.Z.; Adkisson, J.W.; Khater,

M.H.; Gray, P.B.; Jain, V.; Leidy, R.K.; Pekarik, J.J.;

Gambino, J.P.; Zetterlund, B.; Willets, C.; Parrish, C.;

Engelmann, S.U.; Pyzyna, A.M.; Cheng, P.; Hamare, D.L.,

"SiGe HBTs in 90nm BiCMOS technology demonstarating

300GHz/420GHz fT/fmax through reduced RB and CCB

parasitic," IEEE BCTM 13.2, 978-1-4799-0129-6/13/$31.00

©2013 IEEE

[9] Hasch, J.; Topak, E.; Schnabel, R.; Zwick, T.; Weigel, R.;

Walschmidt,

C.,

"Millimeter-Wave

Technologyfor

Automotive Radar Sensors in the 77 GHz Frequency Band",

1 3>91 3<1 ;9:;

[10] Sherif-Sayed, A.; Schiessl, A.; Gumbmann, F.; Tiebout, M.;

Methfessel, S.; Schmidt, L.P., “Advanced Microwave

Imaging”,

IEEE

Microwave

Magazine,

10.1109/MMM.2012.2205772, 13 Sept. 2012

[11] Böck, J.; Schäfer, H.; Aufinger, K.; Stengl, R.; Boguth, S.;

Schreiter, R.; Rest, M.; Knapp, H.; Wurzer, M.; Perndl, W.;

Bottner, T.; Meister, T.F., "SiGe bipolar technology for

automotive radar applications," Bipolar/BiCMOS Circuits and

Technology, 2004. Proceedings of the 2004 Meeting , vol., no.,

pp.84,87, 13-14 Sept. 2004

FIGURE 8: TRANSMITTER BLOCK DIAGRAM

Authorized licensed use limited to: Indraprastha Institute of Information Technology. Downloaded on June 30,2022 at 09:27:21 UTC from IEEE Xplore. Restrictions apply.