Fabrication Process Technology: Thin Film & CMOS Integration

advertisement

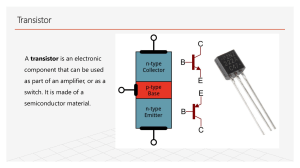

Fabrication Process Technology Gong Xiao Email: elegong@nus.edu.sg Office: E4-05-31 Main Content: Thin Film Deposition and Growth Dopant Introduction – Diffusion & Ion Implantation Pattern Transfer – Lithography Pattern Transfer – Plasma Etching Back-End Technology CMOS Process Flow Integration A Look Inside Apple’s iPhone: A Modern Electronic System with Multiple IC Chips Si-based chips Source: www.ifixit.com Transistor Faster Device Operation Lower Power Consumption Higher Device Density III-V-based Devices History of Transistor Scaling Number of transistors in CPU ~$2800 4 First transistor in 1950’ 10 2016: Intel 14 nm Xeon E5 -2600 16-24 CPU cores (456 mm2) 7.2 Billion Transistors! Cost/transistor = 2-5μ cents ~$1000 2 10 1971: Intel 4004 (12 mm2) 2300 Transistors Cost/transistor = 50 cents 50 billion Transistors? 0 10 60' 65' 70' 75' 80' 2016 2022 Moore’s Law: the number of transistors on a microchip doubles about every two years, though the cost of computers is halved. Recent Transistor Scaling Year 2005 Tech node 65 nm 2009 2011 32 nm 22 nm 14 nm 10 nm Sub-5 nm, beyond Si CMOS 2013 2017 2019 and Beyond Nanosheet Nanowire III-V Ge TFET Strained Si High-k Metal Gate FinFET MoS2 Strained Silicon High-k/Metal Gate FinFET GeSn BP Overview of Integrated Circuits • Currently more than hundreds of device structures exist, Si CMOS is the dominant technology! • For example: Microprocessor (many levels of Interconnects and high density of very small transistors) Intel’s 22 nm Tri-gate Fabrication Process There are two major stages in the production process of semiconductor. One is called front-end of the line process where the transistors are formed on the silicon substrate (wafer), and the other is called backend of the line process where devices are connected by layers of metal lines. EE4436 Course Outline 1. Thin Film Deposition and Growth 2. Dopant Introduction 3. Lithography 4. Plasma Etching 5. Interconnects 6. CMOS Integration What to Learn Thin Film Deposition and Growth Dopant Introduction –Diffusion & Ion Implantation Pattern Transfer –Lithography Pattern Transfer –Plasma Etching Transistor Back-End Technology CMOS Process Flow Integration Assessment: 40% CA + 60% (Final Exam) Simulation Project (20%) Literature Review Report (20%) Assignment 1 Assignment 2