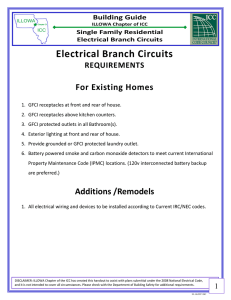

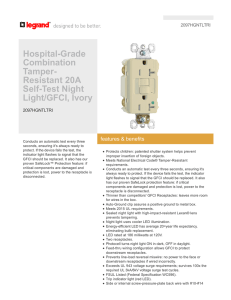

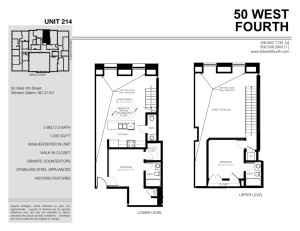

ELECTRICAL SPECIFICATION ELECTRICAL SYMBOLS EXIT LIGHTING FIXTURE ON EMERGENCY CIRCUITRY ARROWS AS B. C. D. E. 4. F. G. H. GENERAL 1. THE ENTIRE ELECTRICAL INSTALLATION SHALL CONFORM TO THE LATEST EDITION OF THE NATIONAL ELECTRICAL CODE AND LOCAL JURISDICTION REQUIREMENTS. K. SHOP DRAWINGS 1. PROVIDE SHOP DRAWINGS FOR THE FOLLOWING ITEMS: LIGHTING FIXTURES, OCCUPANCY SENSORS , RECEPTACLES AND FIRE ALARM DEVICES EQUIPMENT AND DEFINITIONS 1. ALL ELECTRICAL EQUIPMENT SHALL BEAR THE UNDERWRITER’S LABORATORIES LABEL. 2. UNLESS SPECIFICALLY NOTED ON THE PLANS ALL CIRCUITRY, EQUIPMENT, DEVICES, ETC., NOT NOTED EXISTING TO REMAIN OR TO BE RELOCATED SHALL BE NEW. L. JUNCTION BOXES LABELING REQUIREMENTS 1. ALL JUNCTION BOXES FOR BRANCH CIRCUITRY SHALL BE CLEARLY LABELED WITH PANEL DESIGNATION AND CIRCUIT NUMBERS. PANELBOARDS 1. PROVIDE A TYPED CIRCUIT DIRECTORY FOR THE ENTIRE PANELBOARD REVISED UNDER THIS CONTRACT. 2. CONTRACTOR SHALL PHASE BALANCE ALL PANELBOARDS AS NECESSARY. 3. THE BRANCH CIRCUITS SHOWN FOR ITEMS SERVED AS INDICATED. CONTRACTOR SHALL FIELD COORDINATE ALL BRANCH CIRCUITS ACCORDINGLY. BRANCH CIRCUITRY SHOWN ON FLOOR PLAN CONNECTED TO A DESIGNATED CIRCUIT EXACT POSITION OF CIRCUIT BREAKER SHALL BE AFTER REMOVAL OF OUTLETS UNDER DEMOLITION. CONTRACTOR SHALL UTILIZE ALL C/B’S BECOMING SPARE CIRCUIT BREAKERS 1. ALL NEW CIRCUIT BREAKERS TO BE INSTALLED IN NEW PANELS SHALL BE BOLT-ON TYPE. SWITCHES, RECEPTACLES, TELEPHONE OUTLETS AND DATA OUTLETS 1. WHERE TWO OR MORE DEVICES OF THE SAME VOLTAGE ARE SHOWN M. TOGETHER ON THE PLANS, A GANGED PLATE SHALL BE USED. DEVICES OF DIFFERENT VOLTAGES SHALL BE SEPARATED HORIZONTALLY BY 6” BUT SHALL BE HORIZONTALLY OR VERTICALLY ALIGNED. 2. ALL RECEPTACLES, TELEPHONE, AND DATA OUTLETS SHOWN ON A WALL BACK TO BACK SHALL BE OFFSET A MINIMUM OF 6" HORIZONTALLY. LIGHTING FIXTURES 1. COORDINATE ALL LIGHTING FIXTURES WITH SPRINKLERS, MECHANICAL N. EQUIPMENT AND ARCHITECTURAL CEILING PLAN TO AVOID CONFLICT. GRID LAYOUT ON PLANS IS APPROXIMATE, ADJUST AND COORDINATE LIGHTING FIXTURES IN FIELD PER ARCHITECTS REFLECTED CEILING PLAN. 2. PROVIDE FINISHED FRAMES FOR ALL RECESSED LIGHTING FIXTURES, TYPE TO BE COORDINATE ALL FIXTURE TYPES WITH CEILING SYSTEM BEFORE ORDERING FIXTURES. PROVIDE ALL MOUNTING ATTACHMENTS FOR A O. COMPLETE INSTALLATION. LIGHTING FIXTURES SHALL BE SUPPORTED PER LOCAL CODE REQUIREMENTS. 3. ALL NEW LIGHTING FIXTURES SHALL BE INSTALLED COMPLETE WITH P. LAMPS. SEE LIGHTING FIXTURE SCHEDULE FOR LAMPS AND TYPE OF BALLASTS REQUIREMENTS AND/OR PLANS. 4. COLOR OF LIGHTING FIXTURES SHALL BE AS SELECTED BY THE ARCHITECT. I. BRANCH CIRCUITRY AND FEEDER 1. ALL CONDUCTORS SHALL BE COPPER. 2. ALL BRANCH CIRCUITRY AND FEEDER SHALL COMPLY WITH THE UTEST NATIONAL ELECTRICAL CODE (N.E.C.) LOCAL JURISDICTION AND LOCAL STATE CODE REQUIREMENTS. THE FOLLOWING ARE SOME ACCEPTABLE WIRING METHOD REQUIREMENTS. J. INDOOR USE BRANCH CIRCUITRY 1. METAL CLAD CABLE (MC CABLE) IS PERMITTED TO SERVE RECEPTACLES/LIGHTING AND OTHER EQUIPMENT LOAD. METAL CLAD CABLE MC IS PERMITTED TO RUN CONCEALED AREA SUCH AS CEILING SPACE AND FINISHED WALL AREA ONLY. CONTRACTOR SHALL FOLLOW ELECTRICAL SYMBOLS LIST ALL HOMERUN BRANCH CIRCUITRY FOR THE INDOOR EQUIPMENT SHALL BE INSTALLED IN EMT GENERAL NOTES IN REGARDS TO BRANCH CIRCUITRY AND FEEDER 1. USE OF ALUMINUM CONDUIT SHALL NOT BE PERMITTED. 2. ALL BRANCH CIRCUITRY AND FEEDERS SHALL BE RUN CONCEALED. 3. ALL CIRCUITRY RUNS ARE DIAGRAMMATIC. THE CONTRACTOR SHALL DETERMINE IN FIELD THE MOST SUITABLE ROUTES. 4. MINIMUM SIZE EMT OR CONDUIT SHALL BE 3/4’’. UNLESS MULTIPLE HOMERUN CIRCUITS REQUIRES URGER SIZE CONDUIT. 5. NO NONMETALLIC CONDUIT SHALL BE USED FOR BRANCH CIRCUIT WORK ABOVE GRADE WIRE AND CABLE 1. FEEDERS: FEEDER SHALL BE ALUMINUM . INSULATION SHALL BE THW OR THHN/THWN. 2. COLOR CODE: ALL WIRING SHALL BE COLOR CODED THROUGHOUT AS PER N.E.C. REQUIREMENTS. 3. ALL CONDUCTORS SHALL BE COPPER, MINIMUM #2 AWG. 4. ALL RECEPTACLES, LIGHTING FIXTURES, MOTORS, ETC.. SHALL BE GROUNDED PER N.E.C. ALL RECEPTACLE CIRCUITS SHALL CONTAIN A #12 INSULATED GROUND CONDUCTORS 5. RUN MULTIPLE HOMERUNS TO ALTERNATELY NUMBERED PANELBOARD CIRCUITS (I.E., 1,3,5) SERVING LIGHTING, GENERAL RECEPTACLES, AND MOTORS. ANY CIRCUITS SERVING, ISOLATED GROUND RECEPTACLES OR RECEPTACLES SERVING COMPUTER EQUIPMENT, WHEN THE CONTRACTOR RUN CIRCUITRY IN MULTIPLE HOMERUNS. CONTRACTOR SHALL OVERSIZE THE NEUTRAL CONDUCTOR TO A MINIMUM 200% OF THE CAPACITY OF PHASE CONDUCTORS SIZE THE EMT/CONDUIT ACCORDINGLY WHERE NECESSARY. 6. ALL EMPTY RACEWAYS SHALL CONTAIN A DRAG WIRE. EMPTY RACEWAYS 2” OR LARGER IN SIZE SHALL HAVE A MAXIMUM OR 2 - 90 DEGREES BENDS PER RUN. WHERE REQUIRED, PROVIDE PULL BOXES PER N.E.C. REQUIREMENTS. 7. FINAL CONNECTION TO ALL MOTORS OR VIBRATING EQUIPMENT SHALL BE WITH FLEXIBLE CONDUIT OR LIQUID-TIGHT FLEXIBLE CONDUIT FOR OUTDOOR. 8. ALL 120 VOLT CIRCUIT HOMERUNS WHICH ARE OVER 100 LINEAR FEET SHALL BE A MINIMUM OF #10 CONDUCTORS OR AS SHOWN ON THE PLANS. 9. EXPOSED AND CONCEALED CIRCUITRY SHALL BE RUN TIGHT TO CEILING SLAB IN A NEAT WORKMANLIKE MANNER. ALL RUNS SHALL BE PARALLEL OR PERPENDICULAR TO BUILDING WALL. GROUNDING 1. PROVIDE GROUND TO ALL DEVICES PER N.E.C. REQUIREMENTS. 2. PROVIDE SERVICE GROUND CONDUCTORS SIZE PER NEC REQUIREMENTS. 3. PROVIDE EQUIPMENT GROUND CONDUCTORS SIZE PER NEC REQUIREMENTS. FIRE SEALANT MATERIALS 1. ANY PENETRATION TO THE FIRE WALLS. CONTRACTOR SHALL PROVIDE FIRE SEALANT MATERIALS AT EVERY POINT WHERE OCCURRED. FIRE SEALANT MATERIALS MANUFACTURER SHALL BE SUBMITTED TO THE ARCHITECT FOR APPROVAL PRIOR TO APPLICATION. REQUIREMENTS - SEE SCHEDULE PANELBOARD - SEE SCHEDULE. MOUNTING HEIGHT TO CENTERLINE ST ABOVE FINISHED FLOOR 6' - 0 " TO TOP. GROUNDED (HUBBELL #5362). COLOR OF DEVICE AND FACE PLATE IF NO NOTED. SHALL BE AS SELECTED BY THE ARCHITECT. MOUNTING HEIGHT TO DISCONNECT SWITCH - SEE DRAWING FOR VOLTAGE, POLES AND CENTERLINE ABOVE FINISHED FLOOR 18” UON. AMPERAGE RATING. WALL MOUNTED DOUBLE DUPLEX RECEPTACLE - 2P, 3W, 20A, HOMERUN TO PANELBOARD. NUMBER OF ARROWHEADS INDICATE A-1 125V, NUMBER OF GROUNDED (HUBBELL #5362). COLOR OF DEVICE AND FACE PLATE CIRCUITS. NUMERALS AND LETTERS ADJACENT TO ARROWHEADS SHALL BE AS SELECTED BY THE ARCHITECT. MOUNTING HEIGHT INDICATE TO CENTERLINE ABOVE FINISHED FLOOR 18” UON. ASSIGNED PANEL AND CIRCUIT NUMBERS. SEE PANEL SCHEDULE FOR AMPERAGE 2-HEAD BATTERY LIGHTING UNIT RATING OF EACH CIRCUIT BREAKER AND CONDUCTOR SIZES CIRCUITRY INSTALLED CONCEALED IN WALL OR ABOVE CEILING. J J NUMBER OF TICKS INDICATE NUMBER OF CONDUCTORS. IF NO TICKS MARK INDICATE 2 MOTOR RATED SWITCH WITH THERMAL OVERLOAD WALL MOUNTED DUPLEX RECEPTACLE - 2P, 3W, 20A, 125V, MOTOR CONNECTION - HORSEPOWER AS INDICATED, FRACTIONAL JUNCTION BOX - CEILING OR WALL MOUNTED SINGLE POLE SWITCH - ARROW HART #1991. COLOR OF S (TWO) CONDUCTORS IN RACEWAY. SEE PANEL SCHEDULE FOR DEVICE AND FACE PLATE SHALL BE WHITE. MOUNTING HEIGHT TO CENTERLINE ABOVE FINISHED FLOOR 4' - 0". CONDUCTOR SIZES. THREE WAY SWITCH . COLOR OF DEVICE AND FACE SHALL BE SM OCCUPANCY SENSOR FOR THE SMALL INDIVIDUAL OFFICE, +48” SET @ LESS THAN 15 MINUTES WATTSTOPPER CAT# DW-100 COLOR TO BE SELECTED BY THE ARCHITECT. OC S3 A.F.F. MOTION SENSOR SHALL BE AS MANUF. BY WATTSTOPPER WITH TIME DELAY SHALL BE WORK SCHEDULE 1. COORDINATE WITH ARCHITECT AND/OR OWNER’S REPRESENTATIVE FOR WORK SCHEDULE REQUIREMENTS FINAL TESTING 1. AT THE TIME OF FINAL INSPECTION AND TEST, ALL CONNECTIONS AND TERMINATIONS AT PANELBOARDS, DEVICES, EQUIPMENT, AS WELL ALL SPLICES MUST BE ALL COMPLETED. EACH BRANCH CIRCUIT AND ITS RESPECTIVE CONNECTED EQUIPMENT MUST TEST FREE OF SHORT CIRCUIT COMPLETION OF THE WORK, CLEAN AND POLISH ALL EXPOSED SURFACES IN ACCORDANCE WITH THE MANUFACTURER’S RECOMMENDATIONS. INDICATED. FIXTURES TO COMPLY WITH LOCAL JURISDICTION ELECTRICAL SYMBOLS OCCUPANCY SENSOR, CEILING MOUNTED AS MANUF. BY WATTSTOPPER. SD WHITE MOUNTING HEIGHT TO CENTERLINE ABOVE FINISHED FLOOR 4' - 0" SMOKE DETECTOR 3985 GEORGIA ST, SAN DIEGO, CA 92103 A. SPECIAL OUTLET. COORDINATE EXACT NEMA CONFIGURATIONS OF OUTLET WITH OWNER’S REPRESENTATIVE AND EXACT MOUNTING HEIGHT PRIOR TO ROUGH-IN. SWITCH BANK DL DAYLIGHT SENSOR ABBREVIATIONS A AMPERE AFF ABOVE FINISHED FLOOR AIC AMPERES INTERRUPTING CAPACITY C CONDUIT/EMT C/B CIRCUIT BREAKER EC EMPTY CONDUIT/EMT. PROVIDE PULL WIRE EMT ELECTRICAL METALLIC TUBING G HP GROUND HORSEPOWER MCB MAIN CIRCUIT BREAKER MTD MOUNTED NIC NOT IN CONTRACT KW KILOWATTS P PNL POLE PANEL R RECESSED LF LINEAR FEET S UON SURFACE UNLESS OTHERWISE NOTED V VOLT W WIRE MTD DATE DESCRIPTION ISSUE: PROJECT NO: CAD FILE: DATE: MOUNTED OC ON CEILING EG EQUIPMENT GROUND IG ISOLATED GROUND FACP MARK FIRE ALARM CONTROL PANEL DRAWN BY: Sal Sham CHECKED BY: COPYRIGHT: SHEET TITLE: ELECTRICAL NOTES DRAWING SHEET NO: E000 NOTES: A- 6 WP A- 6 D A- 6 A-6 WP PANEL A WP A- 6 A-6 C - 15,17 A-6 1. NEWLY INSTALLED, REPLACED, OR RELOCATED RECEPTACLES SHALL BE TAMPER-RESISTANT (TR). ALL RECEPTACLES SHALL BE GFCI PROTECTED AND TAMPER-RESISTANT (TR). IF ANY NEW/ADDITIONAL OUTLETS ARE INSTALLED, THE BATHROOM SHALL HAVE A DEDICATED 20-AMP CIRCUIT. 2. EXHAUST FANS WITH A MINIMUM VENTILATION RATE OF 50 CFM ARE REQUIRED IN ALL BATHROOMS, EVEN IF AN OPERABLE WINDOW IS INSTALLED. EXHAUST FANS AND LIGHTING SHALL HAVE SEPARATE CONTROL SWITCHES (EVEN IF A COMBINATION UNIT IS INSTALLED). THE EXHAUST FAN MAY NEED TO BE SUPPLIED BY A GFCI PROTECTED CIRCUIT BASED ON THE MANUFACTURER’S REQUIREMENTS. 3. LIGHTING FIXTURES LOCATED WITHIN 3 FEET HORIZONTALLY AND 8 FEET VERTICALLY OF THE BATHTUB RIM OR SHOWER STALL THRESHOLD SHALL BE LISTED FOR A DAMP LOCATION, OR LISTED FOR WET LOCATIONS WHERE SUBJECT TO SHOWER SPRAY. 4. EACH BATHROOM SHALL HAVE ONE LIGHT FIXTURE CONTROLLED BY A VACANCY SENSOR SWITCH THAT REQUIRES A MANUAL ON ACTIVATION (DOES NOT AUTOMATICALLY TURN ON) AND AUTOMATICALLY TURNS OFF WITHIN 30 MINUTES AFTER THE ROOM IS VACATED. ALL OTHER LIGHT FIXTURES SHALL BE CONTROLLED BY A VACANCY SENSOR OR DIMMER 5. GFCI PROTECTION SHALL BE PROVIDED FOR ALL COUNTERTOP RECEPTACLES, RECEPTACLES WITHIN 6 FEET OF A SINK (INCLUDING BELOW COUNTER AND BEHIND AN APPLIANCE), AND FOR RECEPTACLES SUPPLYING DISHWASHERS. THE RESET BUTTON FOR GFCI RECEPTACLES SHALL BE INSTALLED IN AN ACCESSIBLE LOCATION (I.E. NOT BEHIND AN APPLIANCE). 6. COUNTERTOP RECEPTACLES SHALL BE LOCATED SO THAT NO POINT ALONG THE WALL IS MORE THAN 24 INCHES FROM A RECEPTACLE. 7. COUNTERTOP RECEPTACLES SHALL BE LOCATED NO MORE THAN 20 INCHES ABOVE THE COUNTERTOP. 8. ISLANDS/PENINSULAS SHALL HAVE AT LEAST ONE RECEPTACLE MOUNTED NOT MORE THAN 12 INCHES BELOW THE COUNTERTOP AND WHERE THE COUNTERTOP DOES NOT EXTEND MORE THAN 6 INCHES BEYOND ITS BASE. 9. ELECTRIC STOVES AND OVENS SHALL BE SUPPLIED WITH A 40- OR 50- AMP BRANCH CIRCUIT. 10. COUNTERTOP RECEPTACLES SHALL BE SUPPLIED BY A MINIMUM OF TWO 20-AMP BRANCH CIRCUITS. 11. A DEDICATED CIRCUIT IS REQUIRED FOR CORD AND PLUG CONNECTED RANGE EXHAUST HOODS. SEPARATE CIRCUITS MAY BE REQUIRED FOR THE GARBAGE DISPOSAL, DISHWASHER, AND BUILT-IN MICROWAVE BASED ON THE MANUFACTURER’S REQUIREMENTS AND THE MOTOR RATING. 12. DINING AREA, BREAKFAST ROOM, PANTRY, OR SIMILAR AREA SHALL BE SUPPLIED BY A 20-AMP CIRCUIT, THE COUNTERTOP CIRCUITS MAY BE USED TO SUPPLY THESE AREAS. 13.ALL LIGHTING FIXTURES SHALL BE CONTROLLED BY EITHER A DIMMER SWITCH OR BY A VACANCY SENSOR SWITCH THAT REQUIRES A MANUAL ON ACTIVATION (DOES NOT AUTOMATICALLY TURN ON) AND AUTOMATICALLY TURNS OFF WITHIN 30 MINUTES AFTER THE ROOM IS VACATED. 14. ALL LIGHT FIXTURES SHALL CONTAIN BULBS THAT ARE LABELED AS JA8-2016 (JA8-2016-E FOR SEALED LENS OR RECESSED FIXTURE). SCREW BASE BULBS ARE PERMITTED, EXCEPT IN RECESSED LIGHTING FIXTURES. 15. RECESSED LIGHTING SHALL BE LISTED AS IC (ZERO CLEARANCE TO INSULATION) AND AT (AIR TIGHT), BE SEALED/CAULKED BETWEEN THE FIXTURE HOUSING AND CEILING, SHALL NOT CONTAIN A SCREW BASE SOCKET, AND CONTAIN BULBS MARKED WITH JA8-2016-E EFFICIENCY LABEL. 16. ALL OUTDOOR LIGHTING SHALL BE CONTROLLED BY A MANUAL ON AND OFF SWITCH AND BE CONTROLLED BY PHOTOCELL AND MOTION SENSOR A-6 UTILIT A- 6 A- 6 D - 15,17 GFCI GFCI GFCI GFCI D- 13 C- 13 B- 13 A- 17 3985 GEORGIA ST, SAN DIEGO, CA 92103 B - 15,17 GROUND FLOOR POWER PLAN 1/4" = 1'-0" GROUND BAR B- 18 NEUTRAL BAR WP GFCI B- 7 B- 8 B- 7 TV B- 6 B- 6 CLOSET BATH B- 8 BEDROOM CONNECT AS REQUIRED GFCI BY CODE LIVING B- 18 FLOOR CONCRETE SLAB WP B- 7 #3/0 GROUNDING CONDUCTOR B- 7 TV WP B- 6 GROUNDING B- 18 B- 6 BONDING JUMPER CLAMPS MAIN DISTRIBUTION PANEL B- 6 PANEL B WATER PIPE DINING GFCI B- 7 B- 8 BATH #3/0 GROUNDING CONDUCTOR TV B- 8 B- 2 KITCHEN B- 3 B- 6 B- 7 B- 7 CLOSET GROUNDING ROD PROJECT NO: B- 6 DESCRIPTION CAD FILE: DATE: DRAWN BY: B- 5 Sal Sham CHECKED BY: REF. B- 1 GFCI COPYRIGHT: 6'-0" OR SHEET TITLE: MORE GROUND & 1ST FLOOR POWER PLANS 1ST FLOOR POWER PLAN 1/4" = 1'-0" DATE ISSUE: B- 4 B- 12 MARK GROUNDING CLAMP TV B- 7 GFCI GFCIGFCI GFCI DW BEDROOM GFCI GFCI WP B- 18 GROUNDING DETAIL NOT TO SCALE DRAWING SHEET NO: E001 A - 19 D CEILING FAN WITH LAMP C- 16 A- 10 A- 5 WP A- 5 LED SURFACE MNT. DISC LIGHT (2.7K-5K 16 W) (WET LISTED AT SHOWERS) D- 16 EXTERIOR LISTED LED WALL SCONCE (WAC LIGHTING RUBIX WALL LIGHT) B- 16 EXHAUSTER FAN WP A- 5 SECURITY CAMERA A- 10 UTILIT 3985 GEORGIA ST, SAN DIEGO, CA 92103 GROUND FLOOR LIGHTING PLAN 1/4" = 1'-0" B- 9 B- 9 BEDROOM BATH CLOSET B- 9 B- 9 B- 9 WALL FRAMING LIVING B- 9 B- 11 B- 11 B- 9 SD CO STAPLE EVERY 4.5 FEET B- 14 B- 11 B- 14 CO B- 14 SD STAPLE NOT REQUIRED WHERE CABLE RUN THROUGH HOLES IN FRAMING MEMBERS STAPLE WITHIN 12 INCHES OF ELECTRICAL BOX B- 11 DINING B- 11 STAPLE WHERE CABLE CHANGED DIRECTION B- 10 B- 10 B- 10 SD B- 10 BATH MARK CO BEDROOM DATE DESCRIPTION ISSUE: B- 10 B- 11 B- 10 PROJECT NO: CAD FILE: KITCHEN ELECTRICAL BOX ATTACHED TO STUD DATE: DRAWN BY: B- 10 CABLE SUPPORT INSIDE WALL REF. 1/2" = 1'-0" Sal Sham CHECKED BY: COPYRIGHT: SHEET TITLE: GROUND & 1ST FLOOR LIGHTING PLANS 1ST FLOOR LIGHTING PLAN 1/4" = 1'-0" DRAWING SHEET NO: E002 NOTES: 1. NEWLY INSTALLED, REPLACED, OR RELOCATED RECEPTACLES SHALL BE TAMPER-RESISTANT (TR). ALL RECEPTACLES SHALL BE GFCI PROTECTED AND TAMPER-RESISTANT (TR). IF ANY NEW/ADDITIONAL OUTLETS ARE INSTALLED, THE BATHROOM SHALL HAVE A DEDICATED 20-AMP CIRCUIT. 2. EXHAUST FANS WITH A MINIMUM VENTILATION RATE OF 50 CFM ARE REQUIRED IN ALL BATHROOMS, EVEN IF AN OPERABLE WINDOW IS INSTALLED. EXHAUST FANS AND LIGHTING SHALL HAVE SEPARATE CONTROL SWITCHES (EVEN IF A COMBINATION UNIT IS INSTALLED). THE EXHAUST FAN MAY NEED TO BE SUPPLIED BY A GFCI PROTECTED CIRCUIT BASED ON THE MANUFACTURER’S REQUIREMENTS. 3. LIGHTING FIXTURES LOCATED WITHIN 3 FEET HORIZONTALLY AND 8 FEET VERTICALLY OF THE BATHTUB RIM OR SHOWER STALL THRESHOLD SHALL BE LISTED FOR A DAMP LOCATION, OR LISTED FOR WET LOCATIONS WHERE SUBJECT TO SHOWER SPRAY. 4. EACH BATHROOM SHALL HAVE ONE LIGHT FIXTURE CONTROLLED BY A VACANCY SENSOR SWITCH THAT REQUIRES A MANUAL ON ACTIVATION (DOES NOT AUTOMATICALLY TURN ON) AND AUTOMATICALLY TURNS OFF WITHIN 30 MINUTES AFTER THE ROOM IS VACATED. ALL OTHER LIGHT FIXTURES SHALL BE CONTROLLED BY A VACANCY SENSOR OR DIMMER 5. GFCI PROTECTION SHALL BE PROVIDED FOR ALL COUNTERTOP RECEPTACLES, RECEPTACLES WITHIN 6 FEET OF A SINK (INCLUDING BELOW COUNTER AND BEHIND AN APPLIANCE), AND FOR RECEPTACLES SUPPLYING DISHWASHERS. THE RESET BUTTON FOR GFCI RECEPTACLES SHALL BE INSTALLED IN AN ACCESSIBLE LOCATION (I.E. NOT BEHIND AN APPLIANCE). 6. COUNTERTOP RECEPTACLES SHALL BE LOCATED SO THAT NO POINT ALONG THE WALL IS MORE THAN 24 INCHES FROM A RECEPTACLE. 7. COUNTERTOP RECEPTACLES SHALL BE LOCATED NO MORE THAN 20 INCHES ABOVE THE COUNTERTOP. 8. ISLANDS/PENINSULAS SHALL HAVE AT LEAST ONE RECEPTACLE MOUNTED NOT MORE THAN 12 INCHES BELOW THE COUNTERTOP AND WHERE THE COUNTERTOP DOES NOT EXTEND MORE THAN 6 INCHES BEYOND ITS BASE. 9. ELECTRIC STOVES AND OVENS SHALL BE SUPPLIED WITH A 40- OR 50- AMP BRANCH CIRCUIT. 10. COUNTERTOP RECEPTACLES SHALL BE SUPPLIED BY A MINIMUM OF TWO 20-AMP BRANCH CIRCUITS. 11. A DEDICATED CIRCUIT IS REQUIRED FOR CORD AND PLUG CONNECTED RANGE EXHAUST HOODS. SEPARATE CIRCUITS MAY BE REQUIRED FOR THE GARBAGE DISPOSAL, DISHWASHER, AND BUILT-IN MICROWAVE BASED ON THE MANUFACTURER’S REQUIREMENTS AND THE MOTOR RATING. 12. DINING AREA, BREAKFAST ROOM, PANTRY, OR SIMILAR AREA SHALL BE SUPPLIED BY A 20-AMP CIRCUIT, THE COUNTERTOP CIRCUITS MAY BE USED TO SUPPLY THESE AREAS. 13.ALL LIGHTING FIXTURES SHALL BE CONTROLLED BY EITHER A DIMMER SWITCH OR BY A VACANCY SENSOR SWITCH THAT REQUIRES A MANUAL ON ACTIVATION (DOES NOT AUTOMATICALLY TURN ON) AND AUTOMATICALLY TURNS OFF WITHIN 30 MINUTES AFTER THE ROOM IS VACATED. 14. ALL LIGHT FIXTURES SHALL CONTAIN BULBS THAT ARE LABELED AS JA8-2016 (JA8-2016-E FOR SEALED LENS OR RECESSED FIXTURE). SCREW BASE BULBS ARE PERMITTED, EXCEPT IN RECESSED LIGHTING FIXTURES. 15. RECESSED LIGHTING SHALL BE LISTED AS IC (ZERO CLEARANCE TO INSULATION) AND AT (AIR TIGHT), BE SEALED/CAULKED BETWEEN THE FIXTURE HOUSING AND CEILING, SHALL NOT CONTAIN A SCREW BASE SOCKET, AND CONTAIN BULBS MARKED WITH JA8-2016-E EFFICIENCY LABEL. 16. ALL OUTDOOR LIGHTING SHALL BE CONTROLLED BY A MANUAL ON AND OFF SWITCH AND BE CONTROLLED BY PHOTOCELL AND MOTION SENSOR C- 18 WP GFCI C- 7 C- 7 TV C- 6 C- 8 C- 6 CLOSET BATH C- 8 BEDROOM GFCI LIVING WP C- 18 C- 7 C- 7 C- 6 TV WP C- 6 C- 18 C- 6 C- 6 PANEL C GFCI DINING C- 7 C- 8 BATH KITCHEN C- 6 C- 6 TV C- 4 C- 5 C- 12 REF. C- 1 GFCI 3985 GEORGIA ST, SAN DIEGO, CA 92103 GFCI GFCI GFCI CLOSET C- 7 DW C- 7 GFCI C- 3 C- 7 BEDROOM C- 8 GFCI TV C- 2 GFCI WP C- 18 2ND FLOOR POWER PLAN 1/4" = 1'-0" D- 18 WP GFCI D- 7 D- 8 D- 7 TV D- 6 WP D- 6 A - 19 A- 8 A- 8 WP CLOSET BATH D- 8 WP BEDROOM WP GFCI A- 15 A- 8 LIVING A - 19 D- 18 WP D- 7 D- 7 D- 6 TV WP D- 6 D- 18 D- 6 D- 6 PANEL D A- 16 GFCI WP A- 18 DINING D- 7 D- 8 WP BATH MARK D- 18 BEDROOM D- 8 GFCI GFCI D- 7 D- 2 DW TV GFCI WP D- 7 DATE ISSUE: KITCHEN D- 6 D- 6 PROJECT NO: A- 12,14 D- 3 A- 11,13 WP TV WP CAD FILE: DATE: GFCI D- 4 DRAWN BY: D- 5 CLOSET GFCI GFCI D- 7 D - 12 DESCRIPTION REF.D- 1 GFCI 2' HEIGHT A- 8 A- 8 WP WP Sal Sham CHECKED BY: COPYRIGHT: SHEET TITLE: 3RD FLOOR POWER PLAN ROOF POWER & LIGHTING PLAN 1/4" = 1'-0" 1/4" = 1'-0" 2ND & 3RD FLOOR POWER PLANS DRAWING SHEET NO: E003 SOLAR SYSTEM AND RV 6.2 KW A - 19 C- 9 INVERTER 5 5 TV BEDROOM 5 3 5 C- 9 4 CLOSET 7 M 7 M M 7 M BATH 2 9 6 8 8 8 EXISTING PANEL PANEL A PANEL B PANEL C PANEL D C- 9 C- 9 C- 9 C- 9 C- 11 C- 11 LIVING C- 9 CO SD TV 1 C- 14 GROUND FLOOR C- 11 C- 14 CO C- 14 SD ELECTRICAL RISER DIAGRAM NOT TO SCALE C- 11 C- 11 FEEDER AND EQUIPMENT NOTES C- 10 C- 10 DINING C- 10 C- 10 BATH SD BEDROOM 1. INCOMING ELECTRICAL FROM POWER CO. 2. (N) MAIN SWITCH 800A 1PH. 3. COPPER FEEDERS 3 2-600 + 1 1/0 GND IN 2-3 1/2" CONDUIT. 4. (N) SOCKET METER 800A, 120/240V, 1PH. 5. COPPER FEEDERS 3 3/0 + 1 #6 GND IN 2" CONDUIT. 6. PANEL A 800A, 120/240 V, 1PH, 3 W - SEE PANEL SCHEDULE 7. (N) SOCKET METER 800A, 120/240V, 1PH. 8. PANEL B,C,D 100A, 120/240 V, 1PH, 3 W - SEE PANEL SCHEDULE 9. EXISTING PANEL IN THE OLD BUILDING CO C- 10 C- 11 C- 10 TV A - 19 KITCHEN TV C- 10 THE FEEDER FROM PROPOSED BUILDING TO THE EXISTING BUILDING WILL BE PASSING THROUGH A CONDUIT IN THE GROUND WITH 5" DIAMETER REF. CLOSET 3985 GEORGIA ST, SAN DIEGO, CA 92103 WE HAVE TO MAKE A NEW PANEL FOR ADDITIONAL PV AND CONNECT IT TI THE INVERTER, THE CONDUTE WILL BE USED FOR THIS CONNECTION 2ND FLOOR LIGHTING PLAN 1/4" = 1'-0" D- 9 TV BEDROOM D- 9 CLOSET BATH D- 9 D- 9 D- 9 D- 9 D- 11 D- 11 D- 9 SD PANEL TAG PANEL LOCATION VOLTAGE PHASE LIVING CIRCUIT TV D- 11 D- 14 D- 14 SD CO D- 11 D- 11 D- 10 D- 10 BATH 1 3 5 7 9 11 13 15 17 19 21 23 DESCRIPTION AIC 25K MOUNTING Recessed NEW/ EXIST. PANEL B -UTIL LIGHTING PANEL D -SPA -FIRE PIT TABLE WH SECURITY CAMERA'S LOAD BREAKER TYPE SIZE HVAC; ... 100 A --L 20 A HVAC; ... 100 A --R 50 A --R 20 A R 20 A Lighting 20 A POLES Wire Size A 2 -1 2 -2 -1 1 1 2-#1, 1-#1, 1-#8 -1-#12, 1-#12, 1-#12 2-#1, 1-#1, 1-#8 -2-#6, 1-#6, 1-#10 -1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 13.0 DINING D- 10 D- 10 WIRE 3 RATED AMPS 800 A MCB 800 A CO D- 14 A TENANT STORAGE 128 120/240 Single 1 SD BEDROOM CONNECTED LOAD CONNECTED AMPS CO D- 10 A B 13.2 9.1 0.5 9.1 1.8 13.1 9.1 0.9 0.6 3.5 1.8 3.5 1.8 0.2 1.0 0.0 0.2 0.0 A 42.8 356.6 B 39.4 328.1 TOTAL 82.2 342.3 A Wire Size POLES 2-#1, 1-#1, 1-#8 -1-#10, 1-#10, 1-#10 1-#10, 1-#10, 1-#10 1-#12, 1-#12, 1-#12 2-#6, 1-#6, 1-#10 -1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 2 -1 1 1 2 -1 1 BREAKER LOAD NEW/ SIZE TYPE EXIST. 100 A HVAC; ... --20 A R 20 A R 20 A L 50 A R --20 A L 20 A R DESCRIPTION PANEL C -GROUND LL RECEPTACLES ROOF RECEPTACLES OUTDOOR LIGHTING SPA -ROOF LIGHTING HOT TUB RECEPTACLE CIRCUIT 2 4 6 8 10 12 14 16 18 20 22 24 MARK DATE DESCRIPTION ISSUE: D- 11 DEMAND LOAD CALCULATION D- 10 FACTOR CONNECTE D LOAD DEMAND LOAD CONTINUOUS LOADS (C) NON CONTINUOUS LOAD (NC) TV KITCHEN TV D- 10 REF. CLOSET 3RD FLOOR LIGHTING PLAN 1/4" = 1'-0" B LIGHTING (L) RECEPTACLES (R) - UNDER / OVER 10kVA MOTOR LOADS (M) KITCHEN (K) WATER HEATER (WH) SUB PANEL (SP) DEMAND LOAD DEMAND AMPS PROJECT NO: CAD FILE: 125% 59.05% 100% 7.3 55.2 0.6 9.1 32.6 0.6 DATE: DRAWN BY: Sal Sham CHECKED BY: COPYRIGHT: 61.3 255.6 A SHEET TITLE: 2ND & 3RD FLOOR LIGHTING PLANS DRAWING SHEET NO: E004 PANEL TAG PANEL LOCATION VOLTAGE PHASE B BEDROOM 107 120/240 Single 1 WIRE 3 RATED AMPS 100 A MCB 100 A CIRCUIT 1 3 5 7 9 11 13 15 17 19 21 23 DESCRIPTION AIC 25K MOUNTING Recessed NEW/ EXIST. REFRIGERATOR DISPOSAL OVEN BEDROOMS RECEPTACLES BEDROOM & BATH LIGHTNG KITCHEN/DINING LIGHTING WH CU-1 -- DEMAND LOAD CALCULATION LOAD TYPE R R R R L; M L R HVAC -- BREAKER SIZE 20 A 20 A 30 A 20 A 20 A 20 A 20 A 30 A -- POLES Wire Size A 1 1 1 1 1 1 1 2 -- 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#10, 1-#10, 1-#10 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 2-#10, 1-#10, 1-#10 -- 0.8 3.2 CONNECTED LOAD A 13.0 B 9.1 TOTAL 22.1 CONNECTED AMPS 108.2 75.8 92.0 A POLES Wire Size A B 1 1 1 1 1 1 1 2 -- 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#10, 1-#10, 1-#10 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 2-#10, 1-#10, 1-#10 -- 0.8 3.2 CONNECTED LOAD CONNECTED AMPS A 13.2 109.7 B 9.1 75.8 POLES Wire Size A B 1 1 1 1 1 1 1 2 -- 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#10, 1-#10, 1-#10 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 2-#10, 1-#10, 1-#10 -- 0.8 3.2 CONNECTED LOAD A 13.1 B 9.1 TOTAL 22.2 CONNECTED AMPS 108.8 75.8 92.3 A FACTOR CONNECTE D LOAD DEMAND LOAD 125% 87.31% 100% 2.1 13.4 0.2 2.6 11.7 0.2 B A B 1.2 1.0 3.5 1.0 1.3 1.4 0.6 0.7 0.6 0.7 1.0 1.0 0.4 3.2 0.1 0.5 Wire Size POLES 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1 1 1 1 1 1 1 1 1 Wire Size POLES 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1 1 1 1 1 1 1 1 1 Wire Size POLES 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1-#12, 1-#12, 1-#12 1 1 1 1 1 1 1 1 1 BREAKER SIZE 20 A 20 A 20 A 20 A 20 A 20 A 20 A 20 A 20 A LOAD TYPE R R R R L; M R L L R NEW/ EXIST. BREAKER SIZE 20 A 20 A 20 A 20 A 20 A 20 A 20 A 20 A 20 A LOAD TYPE R R R R L; M R L L R NEW/ EXIST. BREAKER SIZE 20 A 20 A 20 A 20 A 20 A 20 A 20 A 20 A 20 A LOAD TYPE R R R R L; M R L L R NEW/ EXIST. DESCRIPTION CIRCUIT DISHWASHER RANGE KITCHEN/DINING RECEPTACLES BATH RECEPTACLES BEDROOM & BATH LIGHTING MICROWAVE OUTDOOR LIGHTING TENANT STORAGE LIGHTING OUTDOOR RECEPTACLES 2 4 6 8 10 12 14 16 18 20 22 24 DESCRIPTION CIRCUIT DISHWASHER RANGE KITCHEN/DINING RECEPTACLES BATH RECEPTACLES BEDROOM & BATH LIGHTING MICROWAVE OUTDOOR LIGHTING TENANT STORAGE LIGHTING OUTDOOR RECEPTACLES 2 4 6 8 10 12 14 16 18 20 22 24 DESCRIPTION CIRCUIT DISHWASHER RANGE KITCHEN/DINING RECEPTACLES BATH RECEPTACLES BEDROOM & BATH LIGHTING MICROWAVE OUTDOOR LIGHTING TENANT STORAGE LIGHTING OUTDOOR RECEPTACLES 2 4 6 8 10 12 14 16 18 20 22 24 CONTINUOUS LOADS (C) NON CONTINUOUS LOAD (NC) DEMAND LOAD DEMAND AMPS PANEL TAG PANEL LOCATION VOLTAGE PHASE RATED AMPS MCB CIRCUIT 1 3 5 7 9 11 13 15 17 19 21 23 20.9 87.1 A C BEDROOM 140 120/240 Single 1 100 A 100 A DESCRIPTION WIRE 3 AIC 25K MOUNTING Recessed NEW/ EXIST. REFRIGERATOR DISPOSAL OVEN BEDROOMS RECEPTACLES BEDROOM & BATH LIGHTNG KITCHEN/DINING LIGHTING WH CU-2 -- DEMAND LOAD CALCULATION LOAD TYPE R R R R L; M L R HVAC -- BREAKER SIZE 20 A 20 A 30 A 20 A 20 A 20 A 20 A 30 A -- FACTOR CONNECTE D LOAD DEMAND LOAD 125% 86.82% 100% 2.1 13.6 0.2 2.6 11.8 0.2 A B 1.2 1.0 3.5 1.0 1.4 1.4 0.6 0.7 0.6 0.7 1.0 1.0 0.4 3.2 0.1 0.5 3985 GEORGIA ST, SAN DIEGO, CA 92103 LIGHTING (L) RECEPTACLES (R) - UNDER / OVER 10kVA MOTOR LOADS (M) KITCHEN (K) WATER HEATER (WH) SUB PANEL (SP) TOTAL 22.3 92.8 A CONTINUOUS LOADS (C) NON CONTINUOUS LOAD (NC) LIGHTING (L) RECEPTACLES (R) - UNDER / OVER 10kVA MOTOR LOADS (M) KITCHEN (K) WATER HEATER (WH) SUB PANEL (SP) DEMAND LOAD DEMAND AMPS PANEL TAG PANEL LOCATION VOLTAGE PHASE 21.0 87.4 A D BEDROOM 149 120/240 Single 1 WIRE 3 RATED AMPS 100 A MCB 100 A CIRCUIT 1 3 5 7 9 11 13 15 17 19 21 23 DESCRIPTION AIC 25K MOUNTING Recessed NEW/ EXIST. REFRIGERATOR DISPOSAL OVEN BEDROOMS RECEPTACLES BEDROOM & BATH LIGHTNG KITCHEN/DINING LIGHTING WH CU-3 -- DEMAND LOAD CALCULATION FACTOR LOAD TYPE R R R R L; M L R HVAC -- BREAKER SIZE 20 A 20 A 30 A 20 A 20 A 20 A 20 A 30 A -- CONNECTE D LOAD DEMAND LOAD DEMAND LOAD DEMAND AMPS B 1.2 1.0 3.5 1.0 1.4 1.4 0.6 0.7 0.5 0.7 1.0 1.0 0.4 3.2 0.1 0.5 MARK DATE DESCRIPTION ISSUE: PROJECT NO: CAD FILE: DATE: DRAWN BY: Sal Sham CHECKED BY: CONTINUOUS LOADS (C) NON CONTINUOUS LOAD (NC) LIGHTING (L) RECEPTACLES (R) - UNDER / OVER 10kVA MOTOR LOADS (M) KITCHEN (K) WATER HEATER (WH) SUB PANEL (SP) A COPYRIGHT: 125% 86.82% 100% 2.0 13.6 0.2 2.5 11.8 0.2 SHEET TITLE: SCHEDULES 20.9 86.9 A DRAWING SHEET NO: E005 MECHANICAL GENERAL NOTES 1. GENERAL 1.1 THE MECHANICAL WORK SHALL CONFORM TO APPLICABLE STATE AND LOCAL CODES AND THE REQUIREMENTS OF THE AUTHORITIES HAVING JURISDICTION. 1.2 THE CONTRACTOR SHALL MAKE ALL NECESSARY ARRANGEMENTS AND PAY FOR ALL PERMITS, FEES, CHARGES AND INSPECTIONS REQUIRED, AS WELL AS HAULING, RIGGING AND TRANSPORTATION CHARGES APPLICABLE TO HIS WORK. 1.3 THE PROJECT SHALL BE BID ON THE BASIS OF SPECIFIED PRODUCT(S) WHICH ESTABLISH MINIMUM QUALITY REQUIREMENTS. WHERE MORE THAN ONE PRODUCT NAME IS INDICATED, BIDS SHALL BE BASED ON ONE OF THE NAMED PRODUCTS. ALL MECHANICAL EQUIPMENT SHOWN ON CONTRACT DOCUMENTS SHALL BE NEW, SHALL BE ALL LISTED AND SHALL BE PROVIDED BY THE MECHANICAL CONTRACTOR UNLESS OTHERWISE NOTED. A). WHERE USE OF AN ’ACCEPTABLE EQUAL' PRODUCT REQUIRES CHANGES TO THE BASE DESIGN IN ORDER TO INCORPORATE THE PRODUCT INTO THE PROJECT, THE CONTRACTOR SHALL SUBMIT A LAYOUT SHOWING ALL CHANGES TO ARCHITECTURAL. STRUCTURAL, ELECTRICAL, PLUMBING AND MECHANICAL REQUIREMENTS. CHANGES DUE TO USE OF ’ACCEPTABLE EQUAL’ PRODUCTS SHALL BE PROVIDED AT NO ADDITIONAL COST TO THE OWNER AND THE COST OF CHANCES SHALL BE THE RESPONSIBILITY OF THE CONTRACTOR LAYOUT SHALL ACCOMPANY PRODUCT SUBMITTAL DATA. SYMBOLS 4.3 ALL NECESSARY ALLOWANCES AND PROVISIONS SHALL BE MADE BY CONTRACTOR FOR BEAMS. COLUMNS OR OTHER OBSTRUCTIONS OF THE BUILDING OR THE WORK OF OTHER CONTRACTORS. WHETHER OR NOT SAME IS INDICATED. WHERE NECESSARY TO AVOID OBSTRUCTIONS. THE DUCTS SHALL BE TRANSFORMED, DIVIDED OFFSET, RAISED OR LOWERED WITH THE REQUIRED FREE AREA BEING MAINTAINED IN ACCORDANCE WITH SMACNA STANDARDS. 12X10 AHU 1 UNIT TAG TYPE UNIT DESIGNATED NUMBER AIR INTO REGISTER/GRILLE 4.7 PROVIDE FIRE DAMPERS IN HVAC AIR DISTRIBUTION SYSTEMS THAT PENETRATE FIRE RATED ASSEMBLIES IN ACCORDANCE WITH THE INTERNATIONAL BUILDING AND MECHANICAL CODES. FIRE DAMPERS SHALL BE TYPE B IN ALL DUCTWORK, IN ADDITION TO SECONDARY FIRE DAMPERS FOR CEILING, WALL AND FLOOR MOUNTED AIR DEVICES. AIR OUT OF REGISTER/GRILLE 4.8 COORDINATE SPECIFIC FIRE RESISTIVE CONSTRUCTION REQUIREMENTS WITH THE FIRE RATED ASSEMBLIES INDICATED ON ARCHITECTURAL DRAWINGS. THROUGH PENETRATIONS FIRESTOP SYSTEMS SHALL CONFORM TO UL LISTED FIRE RESISTANCE DIRECTORY OR OTHER METHODS ACCEPTABLE TO LOCAL GOVERNING CODE AUTHORITIES. 4.10 PROVIDE ACCESS DOORS IN DUCTWORK TO PROVIDE ACCESS FOR ALL SMOKE DETECTORS, FIRE DAMPERS. SMOKE DAMPERS, VOLUME DAMPERS, COILS, AND OTHER ITEMS LOCATED IN THE DUCTWORK WHICH REQUIRE SERVICE AND/ OR INSPECTION. LABEL ACCESS WITH 1/2" LETTERING. CEILING MOUNTED EXHAUST FAN RECTANGULAR/SQUARE DUCT TO ROUND DUCT SIZE Transition 4.6 DUCTWORK SHALL BE SEALED WITH AN APPROVED DUCT MASTIC OR LIQUID SEALANT AS MANUFACTURED BY UNITED MCGILL CORP., OR APPROVED EQUAL. DUCT SYSTEM LEAKAGE SHALL CONFORM TO SMACNA "HVAC DUCT LEAKAGE TEST MANUAL" FOR CLASS 2’ W.C. SEAL CLASS A, LEAKAGE CLASS 24 FOR RECTANGULAR DUCTS AND CLASS 12 FOR ROUND DUCTWORK. C). WHERE ’OR EQUAL’ PRODUCTS ARE INDICATED. THE CONTRACTOR SHALL SUBMIT A LIST OF PROPOSED EQUAL SUBSTITUTE PRODUCTS WITH THE BID. THE LIST SHALL INCLUDE ADEQUATE SUPPORTING INFORMATION AS PROOF OF EQUALITY IN ORDER TO BE CONSIDERED ACCEPTABLE. NO LATER SUBSTITUTES WILL BE CONSIDERED. DOUBLE LINE DUCT W/ SIZE IN INCHES DUCT SIZE TRANSITION 4.5 DUCTWORK SIZES SHOWN ARE NET CLEAR INSIDE DIMENSIONS. FOR INTERNALLY LINED DUCTS, FABRICATE SHEET METAL TO ALLOW FOR THICKNESS OF INSULATION AND MAINTAIN NET CLEAR DIMENSIONS. 4.9 PROVIDE FLEXIBLE CONNECTIONS IN ALL DUCTWORK SYSTEMS (SUPPLY, RETURN AND EXHAUST) CONNECTED TO AIR HANDLING UNITS, FANS AND OTHER EQUIPMENT WHICH REQUIRE VIBRATION ISOLATION. FLEXIBLE CONNECTIONS SHALL BE PROVIDED AT THE POINT OF CONNECTION TO THE EQUIPMENT UNLESS OTHERWISE INDICATED. EXISTING TO NEW CONNECTION 12X8 4.4 ALL RECTANGULAR DUCTWORK ELBOWS 30 DEGREE OR GREATER SHALL BE PROVIDED WITH DOUBLE THICKNESS RADIUS TURNING VANES. B). SUBSTITUTIONS FOR ’ACCEPTABLE EQUAL’ PRODUCTS NOT SPECIFIED WILL BE CONSIDERED WHEN INCLUDED WITH SUBMISSION OF THE BID AND SHALL BE SUBJECT TO ACCEPTANCE BY THE ENGINEER. PROPOSALS FOR SUBSTITUTIONS SHALL INCLUDE, BUT NOT BE LIMITED TO: (1) ANY ADDED CREDIT OR COST. (2) PRODUCT IDENTIFICATION. (3) CODE COMPLIANCE. (4) REFERENCED STANDARD COMPLIANCE. (5) DESCRIPTION OF ALL CHANGES INCLUDING ARCHITECTURAL, STRUCTURAL, ELECTRICAL, PLUMBING AND MECHANICAL, REQUIRED TO INCORPORATE SUBSTITUTED PRODUCT INTO THE PROJECT. THE OWNER/ENGINEER RESERVES THE RIGHT TO REJECT PROPOSED SUBSTITUTIONS. NEW DUCT (1ST DIMENSION INDICATES SIDE SHOWN, INSIDE CLEAR DIMENSIONS) FLEXIBLE DUCT CONNECTOR T THERMOSTAT S SWITCH SD DUCT SMOKE DETECTOR U DOOR UNDERCUT 2’X2‘ SUPPLY DIFFUSER MANUAL VOLUME DAMPER 2’X2' RETURN GRILLE BACKDRAFT DAMPER 5. INSULATION 1.4 THE CONTRACTOR SHALL VERIFY FIELD CONDITIONS FOR POINTS OF CONNECTIONS, CAPACITIES, AND LOCATIONS OF SYSTEMS. IN ALL AREAS AFFECTED BY THE PROJECT, CUT, PATCH, REPAIR, AND/OR REPLACE ALL MATERIALS DAMAGED AS A RESULT OF WORK. ALL REPAIRED FINISHES SHALL MATCH APPROPRIATE ADJACENT FINISHES. FILL VOIDS AROUND DUCTWORK PENETRATING WALLS WITH FIRE STOPPING MATERIAL. 5.1 INSULATION MATERIALS SHALL BE CERTAIN-TEED OR APPROVED EQUAL INSULATION MATERIALS SHALL HAVE A FLAME SPREAD RATING NOT MORE THAN 25 AND A SMOKE DEVELOPED RATING OF NOT MORE THAN 50. PROVIDE IN ACCORDANCE WITH MANUFACTURER'S RECOMMENDATIONS AND AS FOLLOWS: 1.6 THE DRAWINGS ARE DIAGRAMMATIC AND INDICATE THE GENERAL ARRANGEMENT OF WORK INCLUDED IN THE PROJECT. DO NOT SCALE THE DRAWING. THE CONTRACTOR SHALL ESTABLISH FINAL DIMENSIONS FROM FIELD MEASUREMENTS, PRIOR TO STARTING WORK. 1.7 MECHANICAL WORK SHALL BE COORDINATED WITH THE WORK OF ALL OTHER TRADES PRIOR TO INSTALLATION, TO AVOID CONFLICTS AND ALLOCATE SPACE REQUIREMENTS. 1.8 MATERIALS SHALL BE RATES FOR THE OPERATING TEMPERATURE AND PRESSURE OF THE HYDRONIC SYSTEM. MATERIALS SHALL BE SUITABLE FOR THE TYPE OF FLUID IN THE HYDRONIC SYSTEM. 1.9 PROJECT PREMISES SHALL BE THOROUGHLY CLEANED AND READY FOR OCCUPANCY INCLUDING ALL FINISHES OF EQUIPMENT PROVIDED AS PART OF THE CONTRACTOR'S WORK. PROVIDE ONE NEW SET OF CLEAN AIR FILTERS FOR ALL AIR MOVING EQUIPMENT AT PROJECT CLOSEOUT. 1.10 THE WORD ’PROVIDE’ AS USED IN THE PROJECT SHALL BE DEFINED AS ’"FURNISH AND INSTALL" 1. SUPPLY/RETURN AIR DUCTWORK (CONCEALED): INSULATE WITH NOMINAL 1-INCH THICK TYPE 75 STANDARD DUCTWRAP WITH FSK FACING VAPOR BARRIER. MINIMUM 3/4-INCH INSTALLED THICKNESS WITH A 5.6 R VALUE. SUPPLY DUCT TO DROP DOWN 2. SUPPLY/RETURN AIR DUCTWORK (INTERIOR EXPOSED WHERE INDICATED): INSULATE WITH 1-INCH THICK TYPE 200 ULTRA-LITE ACOUSTICAL DUCT LINER WITH 100 PERCENT ADHESIVE COVERAGE AND MECHANICAL FASTENERS. MINIMUM INSTALLED R VALUE OF 3.1. RETURN DUCT TO RISE UP 3. SUPPLY/RETURN AIR DUCTS (CONCEALED IN ATTIC/CRAWL/ROOF CEILING SPACE): INSULATE WITH NOMINAL 3-INCH THICK TYPE 75 STANDARD DUCTWRAP WITH FSK FACING, VAPOR BARRIER. MINIMUM 2-1/4-INCH INSTALLED THICKNESS WITH 8.5 R VALUE. RETURN DUCT TO DROP DOWN 4. SUPPLY/RETURN/EXHAUST/OUTSIDE AIR DUCTS (OA DUCTWORK & DUCTWORK EXPOSED TO WEATHER CONDITIONS): INSULATE DUCTWORK EXTERIOR WITH SEMI-RIGID FIBERGLASS BOARD INSULATION, TYPE 1B300, 3.0 LBS/CU. FT. DENSITY, MINIMUM 2-INCH INSTALLED THICKNESS WITH 8.5 R VALUE. PROVIDE WEATHERPROOF FINISH AS MANUFACTURED BY FOSTERS MONOLAR 60 -95 COATINGS (MINIMUM OF 3 COATS) OR APPROVED EQUAL. ELBOW WITH TURNING VANES 5. PROVIDE ALL NECESSARY FOUNDATIONS, SUPPORTS, PADS AND BASES AS REQUIRED FOR MECHANICAL EQUIPMENT, PIPING, AND DUCTWORK AS PER INTERNATIONAL BUILDING AND MECHANICAL CODES. INSTALL EQUIPMENT, PIPING, AND DUCTWORK SO AS TO BE FREE FROM OBJECTIONABLE NOISE AND VIBRATIONS. CONTRACTOR SHALL COORDINATE WORK WITH STRUCTURAL AND ARCHITECTURAL DRAWINGS PRIOR TO ACTUAL WORK. SUPPLY AIR DEVICE RETURN OR EXHAUST AIR DEVICE 7. ELECTRICAL WORK 2.2 MATERIALS SHALL BE RATED FOR THE OPERATING TEMPERATURE AND PRESSURE OF DOMESTIC SYSTEM. MATERIALS SHALL BE SUITABLE FOR THE TYPE OF FLUID IN THE DOMESTIC SYSTEM. 2.3 PIPE SUPPORTS SHALL BE SELECTED AND INSTALLED IN ACCORDANCE WITH THE MSS SP-69 OR LOCAL CODES, WHICHEVER IS MORE STRINGENT. UTILIZE TRAPEZE HANGERS FOR PARALLEL RUNS OR PIPING, OTHER THAN SPRINKLER AND WASTE PIPING. COPPER PIPING SYSTEMS SHALL BE SUPPORTED ON COPPER OR COPPER-PLATED SUPPORTS. HANG PIPE FROM SUBSTANTIAL BUILDING STRUCTURE. PIPING SHALL NOT BE HUNG FROM OTHER PIPING, ALL RIGID HANGERS SHALL PROVIDED A MEANS OF VERTICAL ADJUSTMENT AFTER ERECTION. SHIELD SHALL BE PROVIDED BETWEEN HANGERS AND INSULATION. 2.4 WELDING SHALL CONFORM TO CURRENT STANDARDS AND RECOMMENDATIONS OF THE NATIONAL CERTIFIED PIPE WELDING BUREAU, NFPA 51B, STANDARD FOR FIRE PROTECTION; AND NFPA 241,STANDARD FOR SAFEGUARDING CONSTRUCTION, ALTERATION, AND DEMOLITION OPERATIONS. 3. EQUIPMENT 3.1 ALL MECHANICAL EQUIPMENT SHOWN ON CONTRACT DOCUMENTS SHALL BE NEW, AND SHALL BE PROVIDED BY THE MECHANICAL CONTRACTOR UNLESS OTHERWISE NOTED. 3.2 EQUIPMENT AND PRODUCT MANUFACTURER'S RECOMMENDATIONS AND INSTRUCTIONS FOR INSTALLATION AND OPERATION SHALL BE FOLLOWED IN PERFORMING MECHANICAL WORK, UNLESS OTHERWISE INDICATED OR DIRECTED. MATERIALS AND METHODS USED IN THE WORK SHALL BE COMPATIBLE WITH BUILDING CONDITIONS AND COMPLY WITH THE BUILDING CODE REQUIREMENTS, WHICH SHALL BE THE BASIS FOR MINIMUM PRODUCT QUALITY. ALL WORK SHALL BE PERFORMED IN A NEAT AND WORKMANLIKE MANNER BY SKILLED WORKMEN EXPERIENCED IN THEIR TRADE. THE WORK SHALL BE SUBJECT TO THE ACCEPTANCE OF THE OWNER OR THE DULY AUTHORIZED REPRESENTATIVE. 4. DUCTWORK 4.1 DUCTWORK SHALL BE FABRICATED OF GALVANIZED SHEET METAL WITH CONSTRUCTION AND INSTALLATION IN ACCORDANCE WITH SMACNA STANDARDS AND SYSTEM REQUIREMENTS. SHEET METAL GAUGES SHALL CONFORM TO THE INTERNATIONAL MECHANICAL CODE (IMC), ASHRAE STANDARDS, AND UL LISTED FIRE RESISTANCE DIRECTORY REQUIREMENTS AS APPLICABLE. 4.2 DUCT COVERINGS, DUCT LININGS, TAPES, AND CORE MATERIAL SHALL HAVE A FLAME SPREAD RATING NOT OVER 25, AND SMOKE DEVELOPMENT NOT OVER 50. 7.1 ELECTRIC MOTORS FOR MECHANICAL EQUIPMENT SHALL BE PROVIDED UNDER THE MECHANICAL WORK UNLESS OTHERWISE NOTED. ALL MOTORS SHALL BE NEMA STANDARD DESIGN FOR QUIET OPERATION AND SIZED TO PROPERLY OPERATE EQUIPMENT AT RATED LOAD. MOTORS WITH BELT DRIVES SHALL BE PROVIDED WITH ADJUSTABLE PULLEYS AND SHAFTS. ELECTRICAL POWER CONNECTIONS FOR MECHANICAL EQUIPMENT SHALL BE PROVIDED UNDER THE ELECTRICAL WORK. 7.2 MOTOR STARTERS, RELAYS, AND CONTACTORS SHALL BE FURNISHED UNDER THE MECHANICAL WORK AND INSTALLED AND POWERED UNDER THE ELECTRICAL WORK. STARTERS, RELAYS. AND CONTACTORS SHALL BE COMPUTE WITH LUGS SIZED FOR SPECIFIED CONDUCTORS AND INCLUDE REQUIRED ACCESSORIES (I.E. START-STOP PUSH BUTTON, PILOT LIGHTS, H.O.A. SWITCH, AUXILIARY CONTACTS AND OVERLOAD PROTECTION), GENERAL PURPOSE NEMA TYPE 1 ENCLOSURES INDOORS, NEMA TYPE 3R ENCLOSURES OUTDOORS. SINGLE PHASE MOTOR STARTERS SHALL BE MANUAL TYPE WITH OVERLOAD PROTECTION, UNLESS OTHERWISE NOTED. THREE PHASE STARTERS SHALL BE MAGNETIC FULL VOLTAGE, NON-REVERSING, UNLESS OTHERWISE NOTED. STARTERS FOR MECHANICAL SYSTEMS SHALL BE AS MANUFACTURED BY SQUARE-D, GENERAL ELECTRIC, OR CUTLER HAMMER. STARTERS SHALL CONFORM TO NEMA STANDARDS AND NATIONAL ELECTRICAL CODE (NEC) REQUIREMENTS. STARTER CONTROL AND INTERLOCK WIRING SHALL BE PROVIDED UNDER THE MECHANICAL WORK. ALL EQUIPMENT SHALL BE FURNISHED W/ MANUFACTURER PROVIDED DISCONNECT SWITCH. 7.3 DUCT SMOKE DETECTORS SHALL BE INSTALLED IN ALL AIR DISTRIBUTION SYSTEMS WITH A DESIGN CAPACITY OF 2000 CFM OR GREATER IN ACCORDANCE WITH THE INTERNATIONAL MECHANICAL CODE SECTION 606 AND NATIONAL FIRE PREVENTION CODE NFPA 72 AND 90A. DUCT SMOKE DETECTORS SHALL BE "DUAL CONTAC"’ TYPE (FOR TIE-IN TO FIRE ALARM SYSTEM AND FOR FAN SHUTDOWN). COMPLETE WITH SAMPLING TUBE, REMOTE RESET, REMOTE PILOT INDICATOR (FOR CONCEALED APPLICATIONS), UL LISTED FOR INTENDED USE AND COMPLETELY COMPATIBLE WITH FIRE ALARM SYSTEM. DUCT SMOKE DETECTORS SHALL BE FURNISHED AND INSTALLED UNDER THE MECHANICAL WORK AND WIRED AND POWERED UNDER THE ELECTRICAL WORK. 8 CONTROLS 8.1 PROVIDE AUTOMATIC TEMPERATURE CONTROL SYSTEM(S) FOR HVAC EQUIPMENT UNDER MECHANICAL WORK. CONTROL DEVICES SHALL BE PROVIDED BY UNIT MANUFACTURER, UNLESS OTHERWISE NOTED. HVAC EQUIPMENT NOT PROVIDED WITH CONTROL DEVICES SHALL BE PROVIDED WITH DEVICES AS MANUFACTURED TO MATCH BASE BUILDING CONTROLS OR APPROVED EQUAL AIR HANDLER SHALL HAVE NIGHT SET BACK CONTROLLED BY A PROGRAMMABLE THERMOSTAT. DEVICE(S) SHALL BE FULLY COMPATIBLE AND SUITABLE FOR INTENDED USE. CONTROL WIRING SHALL BE PROVIDED IN ACCORDANCE WITH THE NEC FOR 24-VOLT CONTROL SYSTEM(S). WIRING SHALL BE A MINIMUM 22 AWG, COLOR CODED AND INSTALLED IN CONDUIT WHERE SUBJECT TO PHYSICAL DAMAGE OR WHERE REQUIRED TO AVOID PLENUM SPACES. EXTEND ALL LOW VOLTAGE WIRING UNBROKEN BETWEEN EACH CONTROL DEVICE AND EQUIPMENT TERMINAL STRIP. INSTALLATION OF CONTROL SYSTEM(S), WRING. AND DEVICES SHALL BE BY A CERTIFIED CONTROLS CONTRACTOR WITH A MINIMUM OF FIVE (5) YEARS EXPERIENCE IN THE INSTALLATION AND SERVICING OF CONTROLS. 8.2 UNLESS OTHERWISE INDICATED, ALL THERMOSTATS SHALL BE MOUNTED IN ACCORDANCE WITH ADA REQUIREMENTS. GRILLE TAG TYPE AIR CFM (CUBIC FEET PER MINUTE) SUPPLY DUCT TO RISE UP 2. PIPING 2.1 PIPING SHOWN IS SCHEMATIC AND DOES NOT INDICATE EVERY OFFSET, ELBOW, UNION, VALVE, TRAP, ACCESS PANEL, ETC., THAT IS REQUIRED FOR A COMPUTE WORKING SYSTEM. PROVIDE ITEMS AND FITTINGS THAT ARE REQUIRED TO INSTALL THE PIPING SYSTEM WITHIN THE SPACE PROVIDED AND THAT ARE REQUIRED FOR A COMPUTE SYSTEM. PIPING SHALL BE PROPERLY SECURED IN ACCORDANCE WITH MSS STANDARD SP-69. R1 100 FIRE DAMPER 6. DUCT INSULATION 1.5 MECHANICAL EQUIPMENT AND PRODUCTS SHALL BE LISTED AND/OR LABELED BY AN APPROVED TESTING OR INSPECTION AGENCY IN ACCORDANCE WITH LOCAL AND GOVERNING CODE REQUIREMENTS. DIFFUSER TAG TYPE AIR CFM (CUBIC FEET PER MINUTE) 3985 GEORGIA ST, SAN DIEGO, CA 92103 D). SUBSTITUTIONS SHALL PROVIDE THE SAME GUARANTEE AS SPECIFIED FOR BASE BID PRODUCTS. AUTOMATIC (MOTORIZED) VOLUME DAMPER/ SMOKE DAMPER S1 100 DUCT WITH DUCT BRANCH DUCT WITH ROUND DUCT TAKE-OFF DUCT WITH CAPPED END ABBREVIATIONS AF AFF ACU AHU APD ARCH AIR FILTER ABOVE FINISHED FLOOR AIR CONDITIONING UNIT AIR HANDLING UNIT AIR PRESSURE DROP ARCHITECTURAL BHP BLDG BLW BTUH BRAKE HORSEPOWER BUILDING BELOW BRITISH THERMAL UNIT PER HOUR CC CFM CLG CU CW DB DDC DlA DI DN DO DO DPS DWG DX (E) EA EAT EF CUBIC FEET PER MINUTE CEILING CONDENSING UNIT COLD WATER DRY BULB DIRECT DIGITAL CONTROL DIAMETER DIGITAL INPUT DOWN DAMPER OPERATOR DIGITAL OUTPUT DIFFERENTIAL PRESSURE SWITCH DRAWING DIRECT EXPANSION EXISTING EACH ENTERING AIR TEMPERATURE EXHAUST FAN EQUIP ESP EXT EQUIPMENT EXTERNAL STATIC PRESSURE EXTERNAL NO NOM No. NORMALLY OPEN NOMINAL NUMBER F FD FL FPM FT DEGREE FAHRENHEIT FIRE DAMPER FLOOR FEET PER MINUTE FEET O.A. OAT OED PD PS PSI RA RAT REFRIG RLA RPM OUTSIDE AIR OUTSIDE AIR TEMPERATURE OPEN END DUCT PRESSURE DROP PRESSURE SENSOR POUND PER SQUARE INCH RETURN AIR RETURN AIR TEMPERATURE REFRIGERANT RUNNING LOAD AMPERE REVOLUTION PER MINUTE SA SAT SD SF STRUC SUPPLY AIR SUPPLY AIR TEMPERATURE SMOKE DETECTOR SUPPLY FAN STRUCTURAL DRAWN BY: TD TS TYP TRANSFER DUCT TEMPERATURE SENSOR TYPICAL SHEET TITLE: UNO UNLESS NOTED OTHERWISE W WB WC WMC WPD WATT WET BULB WATER COLUMN WIRE MESH SCREEN WATER PRESSURE DROP GALV HC HP HW GALVANIZED HEATING COIL HEAT PUMP HOT WATER IN IN. WG. KW INCH INCH WATER GAUGE KILOWATT LAT LB LF LEAVING AIR TEMPERATURE POUNDS LINEAR FEET MAX MBH MECH MER MIN MOT MAXIMUM 1000 BTUH MECHANICAL MECHANICAL EQUIPMENT ROOM MINIMUM MOTORIZED NC NC NIC NOISE CRITERIA NORMALLY CLOSED NOT IN CONTRACT MARK DATE DESCRIPTION ISSUE: PROJECT NO: CAD FILE: DATE: Sal Sham CHECKED BY: COPYRIGHT: MECHANICAL NOTES DRAWING SHEET NO: M000 3' - 0" 36" MIN. 6"ø BEDROOM EF 1 6"ø CLOSET S1 6"ø AC 1.2 BATH 8"ø S1 100 CFM 8"ø 100 CFM S1 100 CFM BEDROOM R1 300 CFM LIVING DINING 8"ø R1 300 CFM DW AC 1.1 BATH 8"ø S1 100 CFM S1 S1 100 CFM 100 CFM KITCHEN BEDROOM 8"ø 6"ø 6"ø 6"ø EF 1 3' - 0" 6"ø 36" MIN. 3985 GEORGIA ST, SAN DIEGO, CA 92103 REF. CLOSET 1ST FLOOR MECHANICAL PLAN 1/4" = 1'-0" AIR DEVICE SCHEDULE TYPE SERVICE CFM RANGE S1 R1 Supply Air Return Air 100 CFM 300 CFM MAX MAX SP NC 0.1 0.1 30 30 TYPE LOCATION 10" Face 3" Neck 10" Face 3" Neck CEILING CEILING MODEL NOTES ALL-WEATHER VENT CAP PROVIDE 3' DUCT HEIGHT PROVIDE ROOF FLASHING COMPATIBLE WITH EXISTING ROOF TYPE. UNIT NO. LOCATION SERVICE COUNTS CFM ESP WATTS EF -1 CEILING BATHROOM 6 75 CFM 0.5 50 W DESCRIPTION PROJECT NO: ROOF DECK ELECTRICAL DATA VOLTS PHASE CYCLE 120 1 60 DATE ISSUE: STORM COLLAR FAN SCHEDULE MARK CAD FILE: ROOFING METHOD OF CONTROL DATE: NOTES DRAWN BY: SWITCH ROOF STRUCTURE Sal Sham CHECKED BY: COPYRIGHT: SPLIT TYPE UNIT SCHEDULE COOLING INDOOR UNIT NUMBER SERVES TYPE MAX CFM OA CFM SHEET TITLE: COMPRESSOR DATA EAT °F LAT °F MFCR AND MODEL TOTAL BTUH DB WB DB WB OUTDOOR UNIT NUMBER MOUNTING COOLING BTUH IEER CONDENSER FAN DATA NOTES: POWER SUPPLY CIRCUIT QTY QTY RLA HP RPM FLA LRA MCA MOCP VOLTS PHASE CYCLE UNIT WEIGHT, POUNDS LRA 1) MFCR AND MODEL REMARKS LOCATE ROOF PENETRATION A MINIMUM OF 10'-0" FROM ANY OUTSIDE AIR INTAKES. 2) PROVIDE ROOF ACCESSORIES THAT ARE COMPATIBLE WITH EXISTING ROOFING MATERIALS. AC-1.1 KITCHEN/DINING/BEDROOM CASETTE 300 9000 80 67 55 54 AC-1.2 LIVING/BEDROOM CASETTE 300 9000 80 67 55 54 CU-1 DECK 36000 21.5 35 50 240 1 60 255 EXHAUST ROOF PENETRATION DETAIL 1 3 NOT TO SCALE GR. & 1ST LL MECHANICAL PLANS DRAWING SHEET NO: M001 3' - 0" 3' - 0" 36" MIN. 36" MIN. EF 1 S1 CLOSET 100 CFM 6"ø TV S1 S1 100 CFM 100 CFM BEDROOM EF 1 S1 CLOSET 100 CFM 8"ø BATH BATH8"ø AC 2.2 LIVING AC 2.2 6"ø R1 R1 300 CFM TV S1 S1 100 CFM LIVING 300 CFM BEDROOM TV 100 CFM 8"ø 6"ø 6"ø 6"ø 6"ø TV 8"ø 8"ø R1 300 CFM DINING 300 CFM BATH AC 2.1 BATH R1 DINING AC 3.1 100 CFM 100 CFM S1 100 CFMBEDROOM 8"ø TV 36" MIN. 6"ø 3' - 0" 6"ø S1 100 CFM 100 CFM TV 6"ø 36" MIN. REF. CLOSET S1 REF. 2ND FLOOR MECHANICAL PLAN 3RD FLOOR MECHANICAL PLAN 1/4" = 1'-0" 1/4" = 1'-0" 3985 GEORGIA ST, SAN DIEGO, CA 92103 3' - 0" 6"ø EF 1 6"ø 6"ø 6"ø TV DW S1 BEDROOM 8"ø EF 1 S1 6"ø 8"ø TV 100 CFM KITCHEN 8"ø DW KITCHEN S1 ALL-WEATHER VENT CAP MARK DATE DESCRIPTION PROVIDE 3' DUCT HEIGHT ISSUE: STORM COLLAR PROJECT NO: PROVIDE ROOF FLASHING COMPATIBLE WITH EXISTING ROOF TYPE. CAD FILE: ROOF DECK ROOFING DATE: DRAWN BY: SPLIT TYPE UNIT SCHEDULE COOLING INDOOR UNIT NUMBER SERVES TYPE MAX CFM OA CFM CHECKED BY: ROOF STRUCTURE COMPRESSOR DATA EAT °F LAT °F MFCR AND MODEL TOTAL BTUH DB WB DB WB 80 67 55 54 OUTDOOR UNIT NUMBER MOUNTING COOLING BTUH SEER CONDENSER FAN DATA POWER SUPPLY CIRCUIT QTY QTY RLA HP RPM FLA LRA MCA MOCP VOLTS PHASE CYCLE UNIT WEIGHT, POUNDS MFCR AND MODEL NOTES: LRA KITCHEN/DINING/BEDROOM CASETTE 300 9000 CU-2 AC-2.2 LIVING/BEDROOM CASETTE 300 9000 80 67 55 54 AC-3.1 KITCHEN/DINING/BEDROOM CASETTE 300 9000 80 67 55 54 AC-3.2 LIVING/BEDROOM CASETTE 300 9000 80 67 55 54 DECK 36000 22 10 35 50 240 1 60 255 COPYRIGHT: SHEET TITLE: REMARKS 1) LOCATE ROOF PENETRATION A MINIMUM OF 10'-0" AC-2.1 Sal Sham FROM ANY OUTSIDE AIR INTAKES. 2) PROVIDE ROOF ACCESSORIES THAT ARE COMPATIBLE 2ND & 3RD LL MECHANICAL PLANS WITH EXISTING ROOFING MATERIALS. CU-3 DECK 36000 22 10 35 50 240 1 60 255 EXHAUST ROOF PENETRATION DETAIL 2 3 NOT TO SCALE DRAWING SHEET NO: M002 CONTRACTOR SHALL BE RESPONSIBLE FOR VISITING THE SITE AND VERIFYING ALL EXISTING FIELD CONDITIONS PRIOR TO SUBMISSION OF BlD. 2. CONTRACTOR IS RESPONSIBLE FOR COORDINATING WORK WITH THE WORK OF ALL OTHER TRADES AND MAKING ANY NECESSARY MODIFICATIONS TO WORK AT NO ADDITIONAL COST, INCLUDING ALL OFFSETS. 3. CONTRACTOR SHALL BE RESPONSIBLE FOR RELOCATION OF ANY EXISTING MINOR INTERFERENCE'S. INCLUDING CONDUIT, HANGERS, ETC., AT NO ADDITIONAL COST. 25. CONTRACTOR SHALL REMOVE EXISTING EQUIPMENT AND MATERIALS PERTAINING TO CONTRACT AS SPECIFIED OR AS REQUIRED WHETHER SHOWN ON THE DRAWINGS OR NOT. TO PREPARE FOR THE NEW WORK. 26. 4. 5. 24. ALL WORK AND MATERIALS SHALL BE IN ACCORDANCE WITH LOCAL CODES. THESE CODES SHALL BE FOLLOWED AS MINIMUM PROVIDING HIGHER GRADES OF MATERIAL AND WORKMANSHIP WHERE REQUIRED BY THESE DOCUMENTS. PROVIDE ALL TESTS REQUIRED BY LOCAL CODES. 27. 6. 7. 8. ALL PERMITS. FEES. LICENSES. APPROVALS AND OTHER ARRANGEMENTS FOR WORK SHALL BE OBTAINED BY THE CONTRACTOR AT HIS OWN EXPENSE. SUBMIT ASSEMBLED PRINTED INSTRUCTIONS FOR THE OPERATION AND MAINTENANCE OF EACH ITEM INSTALLED ALONG WITH EQUIPMENT CUTS AND CONTROL WIRING DIAGRAMS. SUBMIT COORDINATED SHOP DRAWINGS FOR REVIEW. THE SHOP DRAWINGS SHALL INDICATE WORK OF OTHER TRADES AND MUST BE SUBMITTED PRIOR TO FABRICATION AND INSTALLATION. 9. SUBMIT EQUIPMENT SPECIFICATIONS FOR REVIEW BEFORE PURCHASE. 10. CONTRACTOR SHALL GUARANTEE ALL WORK AND MATERIAL FOR ONE YEAR AFTER COMPLETION AGAINST ALL DEFECTS OF MATERIAL, EQUIPMENT AND WORKMANSHIP. 11. PROVIDE COMPETENT OPERATING TECHNICIAN TO INSTRUCT THE OWNER IN THE OPERATION AND MAINTENANCE OF THE INSTALLED EQUIPMENT. 12. PROVIDE ACCESS PANELS FOR ALL VALVES OR ANY PIECE OF EQUIPMENT WHEN NECESSARY TO LOCATE ABOVE NON-ACCESSIBLE CEILINGS. PROVIDE SUBMITTAL DRAWINGS FOR APPROVAL OF THE ARCHITECT. NO EQUIPMENT SHALL BE LOCATED DIRECTLY ABOVE WALLS. 13. PROVIDE ALL HOLES, SLEEVES AND CAULKING FOR INSTALLATION OF THIS WORK. CAULKING TO CONFORM TO FIRE RATING OF WALLS. 14. PIPING SHALL BE ABOVE CEILING AND CLEAR ANY EXISTING PIPING, LIGHTING FIXTURES, DUCTS, ETC. 15. RUN NEW WASTE PIPES AS CLOSE AS POSSIBLE TO UNDERSIDE OF FLOOR SLAB AND VENT PIPING AS CLOSE AS POSSIBLE TO SLAB ABOVE. 16. RUN ALL PIPING OCTAGONAL & PARALLEL TO CLOSEST WALL OR PRIMARY STRUCTURAL ELEMENTS. 17. CONTRACTOR SHALL SUBMIT SKETCH TO THE STRUCTURAL ENGINEER FOR APPROVAL, PRIOR TO MAKING REQUIRED BEAM PENETRATIONS. 18. PIPING SHOWN IS SCHEMATIC AND DOES NOT INDICATE EVERY OFFSET. ELBOW, UNION, VALVE, TRAP. ACCESS PANEL. ETC., THAT IS REQUIRED FOR A COMPLETE WORKING SYSTEM. PROVIDE ITEMS AND FITTINGS THAT ARE REQUIRED TO INSTALL THE PIPING SYSTEM WITHIN THE SPACE PROVIDED AND THAT ARE REQUIRED FOR A COMPLETE SYSTEM. PIPING SHALL BE PROPERLY SECURED IN ACCORDANCE WITH MSS STANDARD SP-69. 29. ACCESS PANEL BFP BACKFLOW PREVENTER C.O.P CLEAN OUT PLUG CW COLD WATER PLUMBING FIXTURES: DW DISHWASHER MACHINE A. EX. EXISTING HW HOT WATER LAV LAVATORY OSD OPEN SITE DRAIN TPV TRAP PRIMER VALVE TV TEMPERING VALVE S.A. SHOCK ABSORBER (WATER HAMMER) SK SINK V VENT VTR VENT THROUGH ROOF W WASTE WC WATER CLOSET PIPE SUPPORTS SHALL BE SELECTED AND INSTALLED IN ACCORDANCE WITH THE MSS SP-69 OR LOCAL CODES, WHICHEVER IS MORE STRINGENT. UTILIZE TRAPEZE HANGERS FOR PARALLEL RUNS OR PIPING. OTHER THAN SPRINKLER AND WASTE PIPING. COPPER PIPING SYSTEMS SHALL BE SUPPORTED ON COPPER OR COPPER-PLATED SUPPORTS. HANG PIPE FROM SUBSTANTIAL BUILDING STRUCTURE, PIPING SHALL NOT BE HUNG FROM OTHER PIPING. ALL RIGID HANGERS SHALL PROVIDE A MEANS OF VERTICAL ADJUSTMENT AFTER ERECTION. SHIELD SHALL BE PROVIDED BETWEEN HANGERS AND INSULATION. FURNISH AND INSTALL PLUMBING FIXTURES INDICATED. FIXTURES TO BE FIRST QUALITY, CONNECTED, CLEANED AND READY FOR USE. PIPING TO BE PROPERLY SECURED TO WALLS AND STUDS. PROVIDE TRAPS AND SUPPLIES WITH STOPS. MAKE ALL FINAL CONNECTION TO EACH FIXTURE. HANGERS: A. PIPE HANGERS ON HOT PIPING TO BE ON INSIDE OF INSULATION. PROVIDE WITH SADDLES AND/OR SHIELDS AS REQUIRED. B. PIPE HANGERS ON COLD PIPING TO BE ON OUTSIDE OF INSULATION. PROVIDE WITH AND/OR SHIELDS AS REQUIRED. SADDLES PROVIDE ANY AND ALL ITEMS NECESSARY TO COMPLETE THE PLUMBING SYSTEM. THE PLUMBING DRAWINGS ARE DIAGRAMMATIC AND DO NOT NECESSARILY SHOW ALL VALVES, FITTINGS, TRAPS, CONTROL DEVICE METHODS. 30. INSTALL ALL ADA FIXTURES IN AN ADA COMPLIANT MANNER. 31. INSTALL SKAL + GARD #SC-100B ON SINKS SUPPLIES AND TRAPS FOR HANDICAPPED USE. GENERAL NOTES: THE DRAWINGS PREPARED FOR THIS PROJECT ARE AN OUTLINE TO SHOW WHERE PIPES, DUCTS AND APPARATUSES MUST GO IN ORDER TO HARMONIZE WITH THE BUILDING AND INSTALLATION OF THE VARIOUS TRADES. WORK MUST BE INSTALLED IN ACCORDANCE WITH THE DRAWINGS AS MUCH AS POSSIBLE. DRAWINGS SHALL BE CAREFULLY CHECKED DURING THE COURSE OF BIDDING AND CONSTRUCTION. IF DISCREPANCIES, ERRORS OR OMISSIONS ARE DISCOVERED PRIOR TO OR DURING CONSTRUCTION PHASE, NOTIFY THE ENGINEER IMMEDIATELY FOR INTERPRETATION OR CORRECTION. TAKE NECESSARY MEASUREMENTS AND RESPONSIBLE FOR SAME, INCLUDING CLEARANCES FOR EQUIPMENT THAT ARE TO BE FURNISHED. THE ARCHITECT /ENGINEER RESERVE THE RIGHT TO MAKE MINOR LOCATION CHANGES OF PIPING AND EQUIPMENT WHERE SUCH ADJUSTMENTS ARE DEEMED DESIRABLE FROM AN APPEARANCE OR OPERATIONAL STANDPOINT. SUCH CHANGES WILL BE ANTICIPATED SUFFICIENTLY IN ADVANCE OR AVOID EXTRA WORK OR DELAY THE PROGRESS OF THE PROJECT. DISRUPTION OF ANY EXISTING SERVICE SHALL BE COORDINATED WITH THE OWNER AND SHALL BE PERFORMED AT A TIME AND MANNER SO AS TO CAUSE THE OWNER A MINIMUM OF INCONVENIENCE. FOR EXACT LOCATION OF PLUMBING FIXTURES, REFER TO ARCHITECTURAL PLANS AND ELEVATIONS. EXAMINATION OF EXISTING CONDITIONS: 20. R3 PIPE INSULATION: DOMESTIC HOT AND COLD WATER PIPING SHALL BE INSULATED WITH 1’’ THICK 4# DENSITY, GLASS FIBER PRE-FORMED, ALL PURPOSE FLAME RETARDANT JACKET WITH BUILT-IN VAPOR BARRIER. PROVIDE INSULATION PIPE HANGERS WHEN NECESSARY, ARMACELL, ARMAFIX IPH 32. MATERIALS SHALL BE RATED FOR THE OPERATING TEMPERATURE AND PRESSURE OF THE HYDRONIC SYSTEM. MATERIALS SHALL BE SUITABLE FOR THE TYPE OF FLUID IN THE HYDRONIC SYSTEM. 33. 22. TRAP SEAL PRIMER VALVE AP 19. 21. GATE VALVE MATERIALS SHALL BE RATED FOR THE OPERATING TEMPERATURE AND PRESSURE OF DOMESTIC SYSTEM. MATERIALS SHALL BE SUITABLE FOR THE TYPE OF FLUID IN THE DOMESTIC SYSTEM. B. 28. PLUMBING SYMBOL LIST PROJECT PREMISES SHALL BE THOROUGHLY CLEANED AND READY FOR OCCUPANCY INCLUDING ALL FINISHES OF EQUIPMENT PROVIDED AS PART OF THE CONTRACTOR'S WORK. VISIT AND CAREFULLY EXAMINE THOSE PORTIONS OF THE SHE AND/OR PRESENT BUILDINGS AFFECTED BY THIS WORK SO AS TO BECOME FAMILIAR WITH EXISTING CONDITIONS AND DIFFICULTIES THAT WILL ATTEND THE EXECUTION Of THE WORK BEFORE SUBMITTING PROPOSALS. SUBMISSION OF A PROPOSAL WILL BE CONSTRUCTED AS EVIDENCE THAT SUCH EXAMINATION HAS BEEN MADE AND LATER CLAIMS FOR LABOR, EQUIPMENT OR MATERIALS REQUIRED BECAUSE DIFFICULTIES ENCOUNTERED. WHICH COULD HAVE BEEN FORESEEN HAD SUCH AN EXAMINATION HAD BEEN MADE, WILL NOT BE RECOGNIZED. PONT OF CONNECTION OF NEW WORK TO EXISTING WORK END OF DEMOLITION CROSS HATCH DEMOLITION THE CONTRACTOR SHALL GUARANTEE ALL MATERIALS AND WORKMANSHIP FOR A PERIOD OF ONE (1) YEAR FROM THE DATE OF ACCEPTANCE BY THE OWNER AND SHALL REPAIR OR REPLACE AT NO ADDITIONAL COST TO THE OWNER ANY PART THEREOF WHICH MAY BECOME DEFECTIVE DURING THE PERIOD OF GUARANTEE, ORDINARY WEAR AND TEAR EXCEPTED. THE CONTRACTOR SHALL BE RESPONSIBLE FOR AND PAY FOR ANY DAMAGES RESULTING FROM OR CAUSED BY DEFECTS IN HIS/HER WORK. 34. 35. DEMOLITION KEYED NOTES 27 NEW WORK EQUIPMENT/FIXTURE TAG NUMBER W 2 REFERENCE WATER RISER TAG NUMBER 4'' CO 7 CLEANOUT NEW WORK KEYED NOTES FCO FLOOR CLEANOUT FCO FLOOR DRAIN WH 1 CONNECTIONS TO EXISTING WORK: 23. 2 PLAN INSTALLATION OF NEW WORK AND CONNECTIONS TO EXISTING WORK TO INSURE MINIMUM INTERFERENCE WITH REGULAR OPERATION OF EXISTING FACILITIES. 3985 GEORGIA ST, SAN DIEGO, CA 92103 1. EQUIPMENT NUMBER NEW VENT NEW SANITARY PROJECT PREMISES SHALL BE THOROUGHLY CLEANED AND READY FOR OCCUPANCY INCLUDING ALL FINISHES OF EQUIPMENT PROVIDED AS PART OF THE CONTRACTOR'S WORK AT PROJECT CLOSEOUT. NEW GRAY WATER SANITARY NEW HOT WATER PIPE MATERIAL SCHEDULE SANITARY STORM VENT WATER NEW COLD WATER 3" AND SMALLER SERVICE WT. C l. NO-HUB PIPE AND FITTINGS. 4" STORM AND LARGER SERVICE WT. C.L HUB AND SPIGOT PIPE AND FITTINGS. V BLACK/GRAY WATER VALUE 3’ AND SMALLER SCH. 40 GAL PIPE AND SCREWED FITTINGS OR TYPE M COPPER PIPE AND SOLDER DRAINAGE FITTINGS. REMOTE MANUAL PULL STATION 4" AND LARGER SCH. 40 GAL PIPE AND SCREWED FITTINGS. PEX TYPE B AND SOLDER FITTINGS. DISREGARD SYMBOLS WHICH ARE NOT APPLICABLE TO THIS PROJECT GAS BLACK STEEL ASTM A53 SCHEDULE 40. FITTINGS, ASME B16.3, MALLEABLE IRON, 150 PSIG. JOINTS;THREADED FOR PIPE 2 INCH AND SMALLER, WELDED FOR PIPE 2 1/2" AND LARGER MARK DATE DESCRIPTION ISSUE: TANK LESS WATER HEATER SCHEDULE CAD FILE: ELECTRICAL CONNECTION UNIT NO. SERVED MOUNTING WH-1 HOT WATER WALL PHASE CYCLE 1ST HOUR DELIVERY (GPH 100F RISE) 1 60 80 GAS, MBH WATTS VOLTS 150 1200 120 PROJECT NO: DATE: DRAWN BY: Sal Sham CHECKED BY: COPYRIGHT: SHEET TITLE: PLUMBING NOTES DRAWING SHEET NO: P000 1/2"ø HW 1/2"ø HW 1/2"ø HW 1/2"ø CW HOSE BIB 1/2"ø CW D 1/2"ø CW BEDROOM BATH 1/2"ø HW 3/4"ø CW CLOSET LIVING 1/2"ø HW 1/2"ø HW 3/4"ø CW 1/2"ø HW 1/2"ø CW 3/4"ø CW HOSE BIB 1/2"ø HW DINING 3/4"ø CW WH 1 WH 1 WH 1 WH 1 1/2"ø HW 3/4"ø CW 1/2"ø CW 3/4" DOWN TO GR. FLOOR 3/4" DOWN TO GR. & UP TO 2ND FLOOR REF. 3/4" DOWN TO GR. & UP TO 3RD FLOOR CLOSET 1/2"ø HW HOSE BIB 3/4" DOWN TO GR. & UP TO ROOF 3/4"ø CW GR. FLOOR WATER SUPPLY PLAN 1ST FLOOR WATER SUPPLY PLAN 1/4" = 1'-0" 1/4" = 1'-0" 1/2"ø HW 1/2"ø CW 1/2"ø HW BEDROOM 1/2"ø HW 3/4"ø CW BATH 1/2"ø HW 3/4"ø CW 1/2"ø CW CLOSET CLOSET BEDROOM 1/2"ø HW 3/4"ø CW 1/2"ø HW BATH LIVING LIVING 1/2"ø HW 1/2"ø HW 3/4"ø CW 1/2"ø HW 3/4"ø CW 1/2"ø HW 1/2"ø HW 1/2"ø HW 3/4"ø CW 3/4"ø CW 1/2"ø HW BATH DINING BEDROOM 1/2"ø HW KITCHEN BEDROOM 1/2"ø HW 3/4"ø HW 3/4" DOWN TO 1ST FLOOR REF. 3/4" DOWN TO 1ST FLOOR UP TO 3RD FLOOR 1/2"ø HW CLOSET 1/2"ø HW MARK 3/4"ø CW 1/2"ø HW 1/2"ø CW 3/4"ø CW 1/2"ø CW DW KITCHEN 1/2"ø CW DW 1/2"ø HW 3/4"ø CW BATH 3/4"ø CW DINING 1/2"ø HW 3/4"ø CW 3/4"ø CW 1/2"ø CW 3985 GEORGIA ST, SAN DIEGO, CA 92103 3/4"ø HW 3/4"ø HW 3/4" UP TO 1ST FLOOR 1"ø CW KITCHEN BEDROOM 3/4"ø CW 1" PIPE CW INPUT 3/4"ø CW 1"ø CW DOUBLE CHECK VALVE 3/4"ø CW 3/4"ø CW 1 1/4" WATER METER BATH DW 1/2"ø CW 1/2"ø HW UTILIT DATE DESCRIPTION ISSUE: CLOSET 1/2"ø HW REF. 3/4" UP TO ROOF 3/4"ø HW PROJECT NO: CAD FILE: 3/4"ø CW GENERAL NOTES 3/4"ø CW 3/4" DOWN TO 1ST FLOOR UP TO ROOF 3/4"ø CW 3/4"ø CW 3/4" DOWN TO 2ND FLOOR 2ND FLOOR WATER SUPPLY PLAN 3RD FLOOR WATER SUPPLY PLAN 1/4" = 1'-0" 1/4" = 1'-0" DATE: DRAWN BY: Sal Sham CHECKED BY: COPYRIGHT: 1. 2. 3. 4. 5. 6. 7. 8. 9. FOR DOMESTIC WATER PIPE SIZES, REFER TO DOMESTIC WATER RISER DIAGRAM. ALL WATER LINES ARE LOCATED ABOVE THE CEILING UNLESS OTHERWISE NOTED IF THE WATER PRESSURE EXCEEDS 80 PSI, AND EXPANSION TANK AND AN APPROVED PRESSURE REGULATOR SHALL BE INSTALLED. THAT NON-REMOVABLE BACKFLOW PREVENTER OR BIBB-TYPE VACUUM BREAKER WILL BE INSTALLED ON ALL EXTERIOR HOSE BIBS. ALL PLUMBING VENTS SHALL TERMINATE NOT LESS THAN 6” ABOVE THE ROOF NOR LESS THAN 1’ FROM ANY VERTICAL SURFACE. VENTS SHALL TERMINATE NOT LESS THAN 10” FROM OR 3’ ABOVE ANY WINDOW, DOOR, OPENING, AIR INTAKE, OR VENT SHAFT NOR 3’ FROM LOT LINE. NEW OR RECONFIGURED SHOWER STALLS SHALL BE A MINIMUM FINISHED INTERIOR OF 1,024 SQUARE INCHES, BE CAPABLE OF ENCOMPASSING A 30 INCH DIAMETER CIRCLE. ANY DOORS SHALL SWING OUT OF THE ENCLOSURE HAVE A CLEAR OPENING OF 22 INCHES MINIMUM. SHOWER STALLS AND BATHTUBS WITH SHOWER HEADS INSTALLED, SHALL HAVE WALLS FINISHED WITH A NONABSORBENT SURFACE FOR A MINIMUM OF 6 FEET ABOVE THE FLOOR. HYDRO-MASSAGE TUBS (I.E. JACUZZI TUBS) SHALL HAVE ACCESS TO THE MOTOR, BE SUPPLIED BY A GFCI PROTECTED DEDICATED CIRCUIT, AND BE LISTED BY A RECOGNIZED TESTING AGENCY (I.E. UL). ALL METAL CABLES, FITTINGS, PIPING, OR OTHER METAL SURFACES, WITHIN 5 FEET OF THE INSIDE WALL OF THE HYDRO-MASSAGE TUB SHALL BE PROPERLY BONDED. HYDRO-MASSAGE TUBS SHALL BE BONDED WITH A MINIMUM #8 AWG BARE COPPER WIRE AND THE BONDING SHALL BE ACCESSIBLE. WHERE THE WATER CLOSET (OR OTHER PLUMBING FIXTURE) COMES INTO CONTACT WITH THE WALL OR FLOOR, THE JOINT SHALL BE CAULKED AND SEALED TO BE WATERTIGHT. SHEET TITLE: FLOOR WATER SUPPLY PLANS DRAWING SHEET NO: P001 3" SANITARY UP TO 1ST FLOOR 3"ø 1 1/2"ø CONTINUES TO ALLEY VENT UP TO 1ST FLOORD 4"ø 4"ø 3" SANITARY DOWN TO GR. & UP TO 2ND FLOOR VENT UP TO 2ND FLOOR 4"ø 1 1/2"ø (E) 4" SANITARY LINE 3"ø CLOSET 4"ø 1 1/2"ø 1 1/2"ø 1 1/2"ø 3"ø BEDROOM LIVING 1 1/2"ø 1 1/2"ø KITCHEN 1 1/2"ø 1 1/2"ø 3" SANITARY UP TO 1ST FLOOR 1 1/2"ø DW 1 1/2"ø 1 1/2"ø 1 1/2"ø DINING BATH UTILIT 1 1/2"ø 3"ø 3"ø BEDROOM VENT UP TO 2ND FLOOR 3" SANITARY DOWN TO GR. & UP TO 2ND FLOOR 3"ø 3"ø 1 1/2"ø REF. CLOSET GR. FLOOR POWER SANITARY PLAN 1ST FLOOR SANITARY PLAN 1/4" = 1'-0" 1/4" = 1'-0" 3"ø 3" SANITARY DOWN TO 1ST & UP TO 3RD FLOOR 3"ø 3"ø 3"ø 3" SANITARY DOWN TO 2ND FLOOR VENT DOWN TO 2ND FLOOR BATH 1 1/2"ø 1 1/2"ø VENT DOWN TO 1ST & UP TO 3RD FLOOR CLOSET 3985 GEORGIA ST, SAN DIEGO, CA 92103 3"ø CLOSET BATH 1 1/2"ø 1 1/2"ø 1 1/2"ø BEDROOM BEDROOM 1 1/2"ø LIVING 1 1/2"ø LIVING VENT AT ROOF 1 1/2"ø DATE DESCRIPTION 1 1/2"ø ISSUE: 1 1/2"ø PROJECT NO: BEDROOM VENT AT ROOF KITCHEN CAD FILE: DATE: 1 1/2"ø 1 1/2"ø 1 1/2"ø KITCHEN 1 1/2"ø DW 1 1/2"ø BEDROOM BATH 1 1/2"ø DW 1 1/2"ø BATH MARK 1 1/2"ø 1 1/2"ø 1 1/2"ø 1 1/2"ø DINING DINING 1 1/2"ø DRAWN BY: Sal Sham CHECKED BY: 1 1/2"ø 1 1/2"ø 3"ø VENT DOWN TO 1ST & UP TO 3RD FLOOR 3"ø 3"ø 3" SANITARY DOWN TO 1ST & UP TO 3RD FLOOR CLOSET VENT DOWN TO 2ND FLOOR 3" SANITARY DOWN TO 2ND FLOOR 3"ø 1 1/2"ø 1 1/2"ø SHEET TITLE: CLOSET REF. 3"ø COPYRIGHT: REF. FLOOR SANITARY PLANS 3"ø 2ND FLOOR SANITARY PLAN 3RD FLOOR SANITARY PLAN 1/4" = 1'-0" 1/4" = 1'-0" DRAWING SHEET NO: P002 1/2" HW 1/2" CW SANITARY VENT VACUUM BREAKER RECESSED OUTLET BOX WITH 3/4" HOSE BIBB CONNECTIONS, WATER HAMMER ARRESTORS AND 2" DRAIN INLET AUTOMATIC CLOTHES WASHER 2" STANDPIPE DRAIN 2" TRAP DRAIN HOSE 1/2"ø CW HOSE BIB HOSE BIB 1/2"ø CW 3/4"ø CW 1/2"ø CW 1/2"ø CW 3/4" DOWN TO GR. FLOOR 3 ROOF WATER SUPPLY PLAN 1/4" = 1'-0" 2 ROOF SANITARY PLAN 1/4" = 1'-0" 3985 GEORGIA ST, SAN DIEGO, CA 92103 1 CLOTHES WASHER DETAILS NOT TO SCALE GALV. WROT-IRON OR STEEL PIPE HOT DIPPED GALVANIZED SEALING AND ANCHORING COMPOUND WELD MEMBRANE FLASHING AS REQUIRED GALV. MAL. IRON (IPS) FLASHING FITTING FRESH AIR INLET SEAL SLEEVE WITH TIGHTLY PACKED OAKUM AND POURED LEAD IF COPPER; ALSO PROVIDE & INSTALL ISOLATION FELT 4" 2'-0" ABOVE HVAC VENT OPENING CONCRETE FLOOR DRAIN WITH ADJUSTABLE COLLAR / STRAINER ASSEMBLY FLOOR LINE CO U NTERFLASHIN G: 6L BPER SQ U ARE FO O T SH EET LEA D O R16OZ. COO PER FINISHED FLOOR FINISHED GRADE SOLDER JOINT (PLMB. CONT'R) CENTER PIPE IN SLEEVE MEMBRANE ANCHOR FLANCE HOUSE TRAP W/ C.O. PLUGS 6" ALL AROUND MARK ROOF FINISH STRUCTURAL SLAB C.O. HOT DIPPED GALVANIZED STANDARD WEIGHT STEEL PIPE POURED IN PLACE "P" TRAP DESCRIPTION ISSUE: CONNECT TO COMBINED SYSTEM COAT EXTERIOR SURFACES WITH TAR CONPOUND DATE FLA SH IN G U N DER G EN ERA L CO N ST. PROJECT NO: ROOF CONSTRUCTION CAD FILE: SANITARY FROM SYSTEM UPPER HALF MASTIC CAULKING COMPOUND STEEL PIPE SLEEVE ESCUTCHEON (WHETHER OR NOT IN FIN.AREAS) DATE: DRAWN BY: Sal Sham CHECKED BY: LOWER HALF PICKED OAKUM PACKED GALV. WROT-IRON OR STEEL PIPE COPYRIGHT: SHEET TITLE: ROOF WATER SUPPLY & SANITARY PLANS 4 FLOOR DRAIN DETAIL NOT TO SCALE 5 PIPE THRU FOOTING PENETRATION NOT TO SCALE 6 SANITARY HOUSE TRAP DETAIL NOT TO SCALE 7 VENT STACK DETAIL NOT TO SCALE DRAWING SHEET NO: P003 W øC 3/4 " 3/4 " øC W " 1/2 ø 3/4 " BATH 1/2 " LAV WC 1/2 " HW "ø 2 / 1 1/2 " WC 1/2 " LAV ø H W øC W W 3/4 " ø H W øC W 3/4 "ø CW CW 3/4 " HW "ø 1/2 DOUBLE CHECK VALVE øC W "ø 1/2 WC 1/2 " øC W ø H W 1"ø CW 1"ø 1/2 " " 1/2 BT HW 1 11 /2" ø /2" 1 11 1/2 " ø /2" 11 1 ø "ø 1/2 ø SK BATH HW "ø 1/2 W øC CW "ø 4 / 3 1/2 "ø CW 1/2 "ø "ø 1/2 1 1 1/2"ø LAV 11 /2" "ø 1/2 11 /2" WC 11 /2" HW LAV HW "ø 1/2 CW "ø 2 / 1 1 ø ø 11 /2" WC ø CW LAV ø H W "ø 1/2 " 1/2 HW "ø 2 / 1 W ø H BATH CW 1 "ø 1/2 SLO PE 1/4 " FD LAV 1"ø 3"ø CW CONTINUES TO ALLEY HOSE BIB LAV 1' PER /2" 11 ø ø /2" 11 WC ø BT SK "ø 1/2 11 /2" ø 11 /2" ø /2" 11 ø 3"ø PE SLO 1' ER P " 1/4 3"ø LAV ø /2" 11 ø 11 /2" ø /2" 11 WC BT ø LAV PER 1' 3"ø ø /2" 11 WC /2" 11 LAV SLO PE 1/4 " ø H W 1" PIPE CW INPUT BT ø WC 11 /2" LAV BT W C "ø 3/4 HW "ø 2 / 1/2 1 "ø HW 1/2"ø CW ø /4" E1 P O SL 11 /2" BATH 11 /2" 11 /2" ø LAV 3"ø WC W øC " 4 / 3/4 3 "ø CW 1" WATER METER øC W 1/2 "ø HW ø H W ø H W W 3"ø PER 1' PE SLO 3"ø 4"ø 11 /2" ø 1' ER P " 1/4 3"ø ø 3"ø 1 4"ø WATER SUPPLY RISER DIAGRAM SLO PE 1/4 " 2 PER 1' 4"ø SANITARY RISER DIAGRAM (E) 4" SANITARY LINE MARK PLUMBING FIXTURE SCHEDULE 7' - 0" WH 1 DOMESTIC HOT WATER CONDENSATE DOMESTIC HOT WATER RETURN DOMESTIC COLD WATER RP 1 2' - 8" 4 1/2" 1/2 " 1/2 " 3/4 " CW "ø 3/4 HOSE BIB øC W øC W ø HW "ø 2 / 1 øC W LAV 1/2 " " 3/4 HW "ø 1/2 CW "ø 3/4 HW "ø 1/2 BATH CW "ø 2 / 1 SK CW "ø 3/4 ø H W 3/4 " 3/4 " CW "ø 3/4 ø H W WC øC W ø H W HW 1/2 " 3"ø 1' PER " 1/4 PE O ø L S /2" 11 3985 GEORGIA ST, SAN DIEGO, CA 92103 ø H W 1/2 " ø H W 1/2 " HW "ø 1/2 CW "ø 3/4 HW "ø 1/2 HW CW 3"ø "ø 1/2 CW "ø 4 / 3 øC W 3/4 " WCW ø4"Hø / " 3 2 1/ ø 3"ø 1/2 " 3/4 " SK CW "ø 1/2 3"ø WC "ø 3/4 ø H W 1 1/2"ø LAV 11 /2" HOSE BIB øC W CW "ø 4 / 3 ø H W SK 3"ø 1/2 " VENT AT ROOF BT 3/4"ø CW BATH 1/2 " 3/4"ø CW 3/4"ø CW 3/4 " HW "ø 1/2 ø H W HW "ø 1/2 HW ø CW øC W 3/4"ø CW 3/4"ø CW 1/2 " "ø 1/2 /2" 11 3"ø 3/4 " 3/4 " CW 3/4"ø CW "ø 3/4 CW 1 1/2"ø SK CW "ø 3/4 "ø 1/2 1/2 "ø øC W 3/4 "ø HW 3"ø HOSE BIB øC W 1 1/2"ø 1/2 " 3/4"ø CW " 3/4 3 TUB / SHOWER PLUMBING 3/4" = 1'-0" MARK SS LAV WC BT HB DW WS F WH-1 DESCRIPTION SERVICE SINK LAVATORY WATER CLOSET BATHTUB HOSE BIBB DISHWASHER WASHER/DRYER FRIDGE WATER HEATER WASTE 1 1/2" 1 1/4" 3" 1 1/2" VENT 1 1/2" 1 1/2" 1 1/2" 1 1/2" 2" 2" 1 1/2" 1 1/2" 1/2" MATERIAL PVC PVC PVC PVC PVC PVC PVC PVC PVC NOTES: 1. PROVIDE WITH THERMOSTATIC MIXING VALVE, SET 100°F 2. PROVIDE WITH BACKFLOW PREVENTION 3. PROVIDE WITH INDIRECT AND INDEPENDENT HARD PLUMBING (COPPER/PVC) TO A FLOOR DRAIN 4. PROVIDE WITH WATER HAMMER ARRESTOR 4 WATER HEATER DETAIL NOT TO SCALE CW 1/2" 1/2" 1/2" 1/2" 1/2" 1/2" 1/2" 1/2" 1" DATE DESCRIPTION ISSUE: HW 1/2" 1/2" GAS FLOW NOTES PROJECT NO: NOTE 1 CAD FILE: DATE: 1/2" NOTE 1 1/2" 1/2" NOTE 2, 4 NOTE 2, 4 DRAWN BY: Sal Sham CHECKED BY: COPYRIGHT: SHEET TITLE: 1" NOTE 3 NOTE 3 RISER DIAGRAMS DRAWING SHEET NO: P004 CLOSET CLOSET BATH BATH BEDROOM BEDROOM LIVING LIVING DINING DINING BATH KITCHEN DW DW BATH KITCHEN BEDROOM REF. CLOSET CLOSET 1ST FLOOR GAS PLAN 1/4" = 1'-0" 2 REF. 2ND FLOOR GAS PLAN 1/4" = 1'-0" 3985 GEORGIA ST, SAN DIEGO, CA 92103 1 GAS GAS BEDROOM CLOSET BATH BEDROOM LIVING DINING BATH DW MARK DATE DESCRIPTION KITCHEN ISSUE: BEDROOM PROJECT NO: CAD FILE: GAS DATE: CLOSET DRAWN BY: REF. Sal Sham CHECKED BY: COPYRIGHT: SHEET TITLE: 3 3RD FLOOR GAS PLAN 1/4" = 1'-0" FLOOR GAS PLANS DRAWING SHEET NO: P005 1"ø 1"ø GAS 117' (167 MBH) GAS 1"ø 2 1/2"ø GAS EQUIPMENT SCHEDULE GR D MBH EACH TOTAL GRILL 1 102 102 WATER HEATER 4 150 600 4 BURNER RANGE 3 90 270 FIRE PIT 1 65 65 DREYER 1 65 65 1"ø 3' (102 MBH) 1 1/4"ø QTY 97' (257 MBH) 144' (65 MBH) 6' (90 MBH) "ø 1/2 1 1/4"ø GAS EQUIP # GAS SIZING IS BASED ON A TOTAL GAS LOAD OF 1102 MBH IN STEEL PIPE AT 0.5 PSI ΔP, WITH LONGEST RUN NOT TO EXCEED 150 FEET. 97' (347 MBH) 6' (90 MBH) ø 1 1/2"ø GAS " 1/2 UTILIT 62' (887 MBH) 60' (1037 MBH) 6' (90 MBH) 2"ø GAS 87' (437 MBH) 64' (737 MBH) WH GAS WH WH WH 21 /2" WH /2" 21 ø WH 66' (587 MBH) " 1/2 ø WH ø 21 /2" UP TO ROOF WH 2"ø ø 2"ø GAS GR. FLOOR GAS PLAN 1/4" = 1'-0" 18' (1102 MBH) 21 /2" ø DR 21 /2" ø GAS PIPE INPUT 4 GAS RISER DIAGRAM 1"ø GAS GAS LINE GAS SHUTOFF VALVE 90° ELBOW POINTING DOWN MARK DATE DESCRIPTION TEE FLEX GAS HOSE AND QUICK DISCONNECT ISSUE: 3" (MIN) PROJECT NO: GAS CAD FILE: DIRT LEG (SEDIMENT TRAP), 2" MINIMUM ABOVE FINISHED FLOOR DATE: DRAWN BY: Sal Sham 1"ø CHECKED BY: GAS COPYRIGHT: 1"ø 1 3985 GEORGIA ST, SAN DIEGO, CA 92103 2"ø SHEET TITLE: DOWN TO GROUND FLOOR GAS FLOOR GAS PLANS GAS 1 1/4"ø GAS CONNECTION NOT TO SCALE DRAWING SHEET NO: ROOF GAS PLAN 2 1/4" = 1'-0" P006