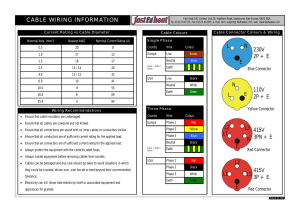

Wiring systems WIRING SYSTEMS The choice of wiring system is affected by many factors such as the type of building, temperature, safety, cost, etc. The electrician needs to be able to decide upon the most suitable type of cable or wiring for a given situation. A wiring system consists of the conductor, its insulation, its mechanical protection, and the various accessories, such as joint boxes, etc. The systems are named mainly in terms of the mechanical protection used. Factors affecting the choice of wiring system 1. Type of building construction – to decide the routing, fixing and terminations 2. Flexibility of the system – change of location of equipment such as in machine shops and temporary buildings. 3. Installation conditions – protection against mechanical damage requirements and working heights. 4. Ambient temperatures – to be withstood, that is, in boiler houses, and heat treatment installations. 5. Appearance of the finished installation – can it be run on the surface or concealed? 6. Durability – life of the installation. 7. Economics – cost of the installation and money available. 8. Safely aspect CABLES A cable is a length of single conductors having one or several wires stranded together, or two or more such conductors, each provided with its own insulation and lay up together. These insulated conductors may or may not be further covered with an overall protective sheath to prevent mechanical damage and to minimize risk of fire and shock. The insulated conductors are referred as the cores of the cable. They comprise very wide range of sizes and types. The necessary requirements of a cable are that it should conduct electricity efficiently, cheaply and safely. Cables consist of essential parts: The conductor to carry the current The insulation (dielectric) to provide the means to prevent the leakage of current, and External overall protection against mechanical damage, chemical attack, fire or other external damaging factors to the cable. When cables are to be drawn in or enclosed in metal conduits or trunking, they are to be chosen with the above temperature. The above temperatures also apply to flexible type cables supplying heating appliances or high temperature light fittings. All fixed wiring systems must be suitably protected against mechanical damage by heat, fire or explosion and against damp and corrosive elements, which may be present on the installation. Detailed information on the types of wiring systems and the regulations which apply to them is given in the I.E.E. Regulations. A number of points must be considered for the wiring system:1. Neatness of the finished job; 2. The durability of the installation; Electrical Installation Systems 1 Wiring systems 3. 4. 5. 6. 7. Future extensions and alterations; The time required to do the work; Damage to the fabric of the building by cutting away; Special conditions to be withstood, such as fumes, dampness; and the total cost of the job. The basic requirement for the installation of conductors and wiring systems are listed below. 1. All conductors and cables should be sufficient in size and power rating for the purpose for which they are to be used. 2. All live conductors should be effectively insulated or so positioned and protected as to avoid danger. 3. Every circuit should be protected against excess current and earth leakage. 4. Any metalwork associated with current carrying conductors should be connected to earth or c.p.c. (Circuit Protective Conductor) 5. Special precautions must be taken where conductors and wiring systems are exposed to inflammable surroundings, or in wet or damp situations. Conductor materials Copper and aluminium are the materials used as conductors in power and lighting cables. Copper has lower resistivity and higher conductivity than aluminium. This means that copper conductors have smaller crosssectional area and take up less space than aluminium for the same current capacity. Aluminium has about onethird the weight of copper and will have an advantage in some circumstances. Copper conductors may be annealed or hard-drawn. Annealed copper conductors are comparatively soft and flexible and are most suitable for indoor and outdoor wires and cables laid or fixed in position. Hard-drawn copper conductors, which have a very high tensile strength, are used as overhead wires mainly in the form. The great majority of cables in use are of copper. With some insulation materials, but not all, copper conductors need to be tinned. Aluminium conductors are made in all standard sizes but at present only in the larger sizes. I.E.E. Regulation B1 lays down that all cable conductors of cross-sectional area 10mm² or smaller shall be of copper. The respective resistivities of copper and aluminium are given in Table 2 as 17.24μΩ mm and 28.2μΩ mm. Stranding. To ensure flexibility and ease of handling, conductors are stranded: a number of small wires twisted together spirally forming a core equivalent to a single of the required size. The numbers of strands used are 1, 7, 19, 37, 61 and 127. The sizes of conductors range from 1.0 mm² (1/1.13 mm) to 630mm² (127/2.52mm). The latter conductor, for example, consists of 127 strands of circular conductor each strand of 2.52mm diameter, with a total cross-sectional area of 630mm². Insulation The function of insulation is to confine the electricity to the conductor. The insulation itself must have a very high resistance. For normal work the insulation is arranged to surround the conductor throughout its length. For overhead wires it is normally sufficient to provide insulation (e.g., a porcelain insulator) at the point of suspension of the wire. The remainder of the cable is insulated by the air surrounding it. Electrical Installation Systems 2 Wiring systems Voltage ratings for cable are given as Eo/E, where Eo is the system voltage to earth, E is the voltage between lines, e.g. 600/1000 V. Large cables may be single-core, twin-core, triple-core or multi-core, in which form the cores are separately insulated and laid side by side with a slight continuous ‘lay’, packed with wormings and further insulated overall to form a circular shape. They may also be made as twin concentric or triple concentric. Smaller cables for lighting and power are laid up in flat form to give neatness of installation. The types of insulating material commonly used are: Polyvinyl Chloride (P.V.C.) Cheap & resistance to corrosion. Use in temperature not exceeding 65° Rubber: - Vulcanized rubber (v.i.r.) - Butyl rubber (b.r.) - Ethylene-propylene (e.p.) - Silicone rubber (s.r.) Very cheap, perishes. Use in temperature not exceeding 65°. Impenetrable to water, flexible, high resistivity. Use in materials not exceeding 80°. Same as butyl rubber used in flexible cords in lighting fittings. Use in temperature not exceeding 145°. All of the above are made up according to requirements as textile-braided and compounded, glass-braided and compounded or with various qualities of heat-resistance, oil-resistance and flame-resistance sheathing. Impregnated paper Mineral Insulated Enamel Nominal Cross Section Area (mm²) 1.0 1.5 2.5 4 6 10 mainly for underground laying 600V/1000V to 19KV/33KV. All cable ends are sealed by special oil-filled or compound-filled sealing boxes. Use in temperature not exceeding 75°. copper-aluminium conductor with compressed powdered mineral insulation enclosed in a copper of aluminium sheath (MICS). Ambient temperature up to 150°. For light duty 600V, heavy duty 1000V. Only a very thin coat required Wire Diameter (mm) 1.13 1.38 1.78 7 / 0.85 7 / 1.04 7 / 1.35 Single-strand Wire Use single strand wire where rigid wire is required. Multi-Strand Wire Use multi-strand wire where a flexible wire required. Note: Both single and multi-strand conductors are classified and the nominal cross sectional area in mm. Electrical Installation Systems 3 Wiring systems Mechanical Protection The larger cables, used for underground work and for large interior power installation, may be mechanically protected in various ways. Unarmoured cables may be run without further protection than the lead sheathing. A further protection is one or two layers of compounded jute or hessian tape yarn lay over the lead sheath. Aluminium is used as an alternative to lead for sheathing cables. Armoured cables include single-wire armouring (a single layer of galvanized iron wire laid spirally upon a bedding of jute or Hessian), double-wire armouring (two layers of armouring), and double steel tape armouring (two layers of steel tape laid spirally over the bedding with an overall finish of jute and hessian). Aluminium strip armouring is sometimes used as an alternative to wire armouring. For underground cables, wire armouring is used where the ground is liable to subsidence, to prevent the cable from breaking, whereas steel tape armouring is needed where physical damage from stones or workmen’s tools may be expected. Cable types The range of types of cables used in electrical work is very wide: from heavy lead-sheathed and armoured paperinsulated cables to the domestic flexible cable. Lead, tough-rubber, PVC and other types of sheathed cables used for domestic and industrial wiring are generally placed under the heading of power cables. Flexible cords and cables Flexible cords is defined as a flexible cable in which the cross sectional area of each conductor does not exceed 4 mm² (56/0.30) which varying from 0.5mm² (16/0.20) to 4 mm² (56/0.30). The most common types of flexible cords are used in domestic and light installation work. The diameter of each strand or wires varies from 0.21 to 0.31 mm. In general they must not be used for fixed wiring. Flexible cords come in many sizes and types; for convenience they are grouped as follows:Vulcanized rubber-insulated Braided, twisted twin Braided, circular twin and 3-core, ordinary and unsinkable. Rubber or PCP-sheathed, single-core, twin, 3-core and 4-core. PVC-insulated (other than heat-resisting) Single-core twisted twin and parallel twin. PVC-sheathed, single-core, twin, 3-core and 4-core. PVC-insulated (heat-resisting) Single-core, twin, 3-core and 4-core. Butyl-rubber or ethylene-propylene rubber-insulated Single-core, twin, 3-core and 4-core, sheathed with either PVC compound (heat resisting) or H.O.F.R. compound. Silicone rubber-insulated Single-core, twisted twin, circular twin and 3-core, all glass fibre braided. Electrical Installation Systems 4 Wiring systems Varnished glass fibre braided Single-core, twisted twin, circular twin and 3-core. These flexible cords are manufacture in 300/300 V and 300/500 V ranges according to types. Flexible cables Flexible cable is a cable specially designed to afford flexibility. The cable conductor therefore consists of a number of fines wires. These cables are made with stranded conductors, the diameters varying from 6 mm² (84/0.30) to 630 mm² (2257/0.60). These are made in the 600/1000V range and include single-core, two-core, three-core, circular twin and multi-core cables. The conductors are of tinned annealed copper and the insulation consists of vulcanized rubber, butyl rubber or EP rubber. Length of cables The smaller cables, as used for house lighting and power are supplied in lengths of 100 m on drums or in coils, whilst flexible cords are supplied in lengths of 50m. Current carrying capacity of cables When a cable carries electric current there are inevitable power losses in the cable, which may be calculated from the formula, P = I²R, where R is the resistance of the cable in Ohms and I is the current in amperes. This wasted power is used in heating the cable, causing temperature of the cable to rise. If the cable is overloaded the temperature may rise sufficiently to damage or even destroy the insulation. Heat is lost from the cable by conduction, radiation and convection of air currents; the rate at which it is lost depends upon various factors, the surface area of the copper, the material and thickness of the insulation, and upon the difference in temperature between the copper and the surrounding atmosphere. The current ratings are to be modified by factors in respect of: Ambient temperature Class of excess-current protection Grouping Disposition Type of sheath Voltage Drop The cable conductor has resistance and whin it is carrying current, a drop in voltage will occur along its length of run. Voltage drop = conductor current (A) conductor resistance (Ω) Because of this voltage drop, the voltage of the load is less than the incoming supply. The I.E.E. Regulations states that conductor sizes must be such that the voltage at any point on an installation does not drop by more than 4% of the incoming voltage at the consumer’s terminals. For an installation where the incoming voltage is 240V, the maximum allowable voltage drop is; 4 x 240 = 9.6V. 100 Electrical Installation Systems 5 Wiring systems Calculation of voltage drop in a cable, using Ohm’s Law By considering the formula, V = R x I it will be seen that the voltage drop in the conductors of a cables is the product of the current in the conductors and the resistance of the conductors. This applies to direct current circuits, and to those alternating circuits where the effect of the inductance and the capacitance of the cable can be neglected. The resistance of a conductor is calculated from the formula, R pl , a where R is the resistance of the conductor in ohms, p is the reisitivity of the conductor material in mircrohm millimeters (μΩ), l is the length of the conductor in millimeters (m) and a is the cross-sectional area of the conductor in square millimeters (mm²) When calculating the voltage drop in a 2 core cable, the lengths of the both lead and return conductors are taken into account, and the value for l is twice the cable length. Electrical Installation Systems 6 Wiring systems CABLE COLOUR CODE BS7671:2008 IEE Wiring Regulations 17th Edition FUNCTION SYMBOL Protective conductor Functional earthing conductor AC Power Circuit Single Phase Circuit - Phase - Neutral OLD COLOUR CODE NEW COLOUR CODE GREEN-YELLOW CREAM GREEN-YELLOW CREAM RED BLACK BROWN BLUE Three Phase Circuit - Phase 1 - Phase 2 - Phase 3 - Neutral L1 L2 L3 N RED YELLOW BLUE BLACK BROWN BLACK GREY BLUE DC Two-Wire Unearthed Circuit - Positive - Negative L+ L- RED BLACK BROWN GREY DCTwo-Wire Earthed Circuit - Positive (of negative earth) - Negative (of negative earth) L+ M RED BLACK BROWN GREY Positive (of Positive earth) Negative (of Positive earth) M L- BLACK BLUE BLUE GREY DC Three-Wire Circuit - Positive - Mid-wire (may be earthed) - Negative L+ M L- RED BLACK BLUE BROWN BLUE GREY - From 1st April 2006 onwards the electrical installations on site are to comply with Section 514 and , as appropriate, cores are to be identified with the harmonized colours. Electrical Installation Systems 7