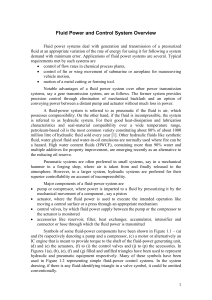

Navarro, Dan FIRE SAFE VALVE Methodology The methodology used in this study begins with the identification of characteristics (geometrical elements) by taking photos of the six section views. This view is also known as the inner view, front view, back view, side view, top view, and bottom view. Figure 3 showed those perspectives. Next, several characteristics such as holes, threaded holes, and pins were seen from those perspectives. Therefore, there are three basic features: the base feature (in this example, the valve's main body as the location for further features to be attached), the feature that ensures the valve's proper operation (controlling fluid flow), and the mated features (connected to other feature in different part of valve body). Following the process, the features' dimensions (size, form, orientation, and placement) are measured using a 3D scanner. The goal of feature identification is to streamline the 3D scanner measurement procedure (started from the base feature and so on). The front view is scanned first, and the bottom view is scanned last. The 3D Scanner's shortcoming is that it can only capture surface features. The next stage is to split the product in half in order to get around that restriction. The inside features are then photographed using the scanner's internal perspective. Figure 4 displays the body scanning of a fire safe valve. The interior characteristics are the most practical because this is where fluid moves and is controlled. Then, a point cloud is produced from each view. These point clouds were then combined to form the body of a fire-safe valve.