Application Guide

Volume I

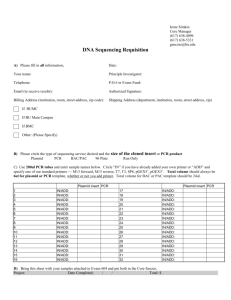

AG2015-12

Testing a Two-Terminal Application

of the SEL-411L in Test Mode

Ashwin Vashist and George Alexander

INTRODUCTION

The SEL-411L Advanced Line Differential Protection, Automation, and Control System has a

built-in test mode with flexible single-terminal and multiterminal testing options. This mode

allows you to perform acceptance, commissioning, and maintenance testing on a line differential

application that uses SEL-411L Relays in an easy and efficient manner. The TEST 87L

command makes it possible to test the differential element on an in-service line from only one

terminal or from all terminals at the same time (the latter requires the test sets to be satellitesynchronized).

Figure 1 shows a typical line differential protection arrangement where the exchange of local and

remote operating data between the relays in the scheme takes place over two channels. Bay 1

(Channel 1) uses a dedicated fiber direct connection between the two relays and a channel-based

data synchronization method (ping pong). Bay 2 uses multiplexers to create a hot standby

channel. This has the potential for channel asymmetry, so a time-based synchronization is used

for Channel 2. When external time-based synchronization is used, both SEL-411L Relays must be

connected to an external, high-precision, IEEE C37.118-compliant time source.

This application guide is a test guide for the scenario presented in Figure 1. The goal of this guide

is to provide the ability to test the characteristics of the differential elements in an SEL-411L and

to provide the tools to calculate the currents to be injected into the relay to validate the

differential scheme.

SEL-411L

Dedicated Fiber

Bay 1

Bay 2

Digital

Multiplexer

Hot Standby

Channel

Bay 1

SEL-411L

Bay 2

Digital

Multiplexer

Figure 1 Typical two-terminal SEL-411L application

Date Code 20150401

SEL Application Guide 2015-12

2

SEL-411L TEST MODE FEATURES

With the default settings, the {RELAY TEST MODE} front-panel pushbutton (Pushbutton 4, as

shown in Figure 2) allows you to test the protection functions of the relay by disabling the output

contacts of the relay that are used for tripping, closing, and pilot-scheme keying of the breakers in

the scheme.

RELAY

TEST

MODE

Figure 2 The {RELAY TEST MODE} pushbutton supervises the 87L test mode

The function of this pushbutton in the default settings of the SEL-411L is to supervise the

Access Level 2 TEST 87L command. The TEST 87L command allows for the testing of the

Alpha Plane or the relay differential operating characteristic. The TEST 87L command is

supervised by the SELOGIC® control equation 87TMSUP, which must be asserted to a logical 1 to

allow the use of the TEST 87L command. In the default logic, 87TMSUP asserts when the

{RELAY TEST MODE} pushbutton is used to place the SEL-411L in relay test mode, which

turns on the pushbutton LED.

DEFAULT PROGRAMMING AND TEST 87L MODE

The SEL-411L ships from the factory programmed with the following default equations, which

correspond to the activation, supervision of test mode, and LED indications in the relay.

PLT04S := PB4_PUL AND NOT PLT04 # ACTIVATE OR LATCH IN RELAY TEST MODE

PLT04R := PB4_PUL AND PLT04

87TMSUP = PLT04

# TEST MODE SUPERVISION

PB4_LED = PLT04

# LED RESPONSE

Note that pressing the {RELAY TEST MODE} pushbutton does not automatically initiate the

TEST 87L command. The TEST 87L command must be entered at Access Level 2 via terminal

emulation software.

With the default settings, if the RELAY TEST MODE LED is not on, then typing the

TEST 87L command returns the error message: 87 Test Mode Supervision is not asserted, test

aborted.

The following is an example of entering the 87L test mode, as shown on the screen of a terminal

emulation program:

Level 2

=>>TEST 87L

Entering 87L Test Mode

Select Test: Characteristic or Loopback (C,L)

SEL Application Guide 2015-12

? |

Date Code 20150401

3

Note that when not in test mode, the relay differential element is supervised by both local and

remote disturbance detectors. An operation of the differential element that occurs without

assertion of the disturbance detection logic (sometimes due to channel asymmetry or unaligned

ramping of local or remote currents during testing) can cause a watchdog error. Two counters are

started when these spurious assertions take place, and their outputs are represented by the

targetable Relay Word bits 87ERR1 and 87ERR2. If these Relay Word bits are asserted at any

time, the relay is disabled, 87L function is inhibited, the 87L ALM and 87L LOST LEDs

illuminate on the front panel (assuming default LED programming), and you can no longer

continue testing. The command to reset this watchdog error is COM 87L WD C, issued from

Access Level 2 on the terminal as follows:

Level 2

=>>COM 87L WD C

Clear 87L watchdog counters?

Are you sure (Y/N) ?Y

87L watchdog counters cleared

=>>|

The test mode also allows you to bypass the watchdog timer logic in the SEL-411L and gives you

the ability to ramp local and remote currents into the relay in an independently adjustable manner.

This provides additional flexibility to find acceptable test points without needing to worry about

inhibiting 87L function.

Note: For applications that use SEL-411L Relays with firmware older than version R108, the

watchdog counters cannot be cleared from Access Level 2. You must log in to the

calibration level of the relay and clear the counters with the same command (i.e.,

COM 87L WD C).

For more information on the watchdog timer logic, please see the SEL-411L Instruction Manual

or contact SEL for further assistance.

PRELIMINARY CHECK

Changes may need to be made to the relay settings and test procedure, depending on the

application and protection scheme configuration.

Before entering test mode, ensure that the relays are communicating remote and local data with

each other by targeting the status of Relay Word bit 87CH1OK. This bit is a snapshot of the

channel health. To monitor this bit, use the command TAR 87CH1OK.

You should also use the Sequential Events Recorder (SER) in the SEL-411L to monitor Relay

Word bit 87CH1OK over a larger time frame to make sure the bit does not de-assert due to an

excess number of lost packets. Doing so verifies that the channel is healthy.

If the channel-addressing settings in the relay (87TADR, 87R1ADR, 87R2ADR) are configured

correctly, and the direct fiber and multiplexer arrangements are physically sound, the expected

result of the target command should be as follows:

=>>TAR 87CH10K

87MTR

1

Date Code 20150401

87SLV

0

87LST

0 |

87CH10K 87CH20K 87CH30K 87SYNH

1

1

0

1

87SYNL

0

SEL Application Guide 2015-12

4

In addition, you can use the target command to monitor the status of Relay Word bits such as

87BLKL, 87BLK, and 87LST to troubleshoot issues, like the watchdog error, that inhibit 87L

function in the SEL-411L.

Note: Noticing whether the red and green transmit and receive lights are illuminated on the

back of the SEL-411L is one way to verify that the fiber connections on the channel ports

on the back of the SEL-411L are correct.

87L CHARACTERISTIC TEST METHODS

There are two methods to test the 87L characteristics, depending on the availability of personnel

and equipment and the choice of testing philosophy:

•

Single-terminal characteristic testing: Use a single test set to inject current at one

terminal. The channels do not have to be in use, and local and remote currents are

simulated locally by the test set.

•

Multiterminal characteristic testing: Use multiple test sets at multiple terminals. Test sets

are satellite-synchronized, channels are in use, and currents can be ramped at all

terminals.

SINGLE-TERMINAL AND MULTITERMINAL CHARACTERISTIC TESTS

In the single-terminal mode, you can apply both local and remote currents to one SEL-411L. This

allows for the simulation of independently adjustable local and remote currents without the need

to apply any current to the remote relay(s). Figure 3 depicts a single-terminal 87L characteristic

test.

Test Set

V, I

87L

87L

Figure 3 Single test set connection to a single relay

Figure 4 shows a multiterminal 87L characteristic test.

Test Set

V, I

87L

87L

V, I

Test Set

Satellite

Time

Figure 4 Test set connections to the relays at multiple terminals

The following are examples of entering the test mode for single-terminal and multiterminal tests,

respectively:

=>>TEST 87L

Entering 87L Test Mode

Select Test: Characteristic or Loopback (C,L)

Test Mode: Single, Multi Terminal, or Disabled (S,M,D)

87L Element: (A,B,C,Q,G)

SEL Application Guide 2015-12

? c

? s

? |

Date Code 20150401

5

=>>TEST 87L

Entering 87L Test Mode

Select Test: Characteristic or Loopback (C,L)

Test Mode: Single, Multi Terminal, or Disabled (S,M,D)

87L Element: (A,B,C,Q,G)

? c

? m

? a

Select one of the 87L differential elements for testing. In the 87L test mode, the normal 87L

elements (i.e., 87LA, 87LB, 87LC, 87LQ, and 87LG) are blocked from operating. Their bits are

replaced with 87TOUT. Only the differential element selected is active. If 87LA is selected,

87LQ and 87LG will not cause 87TOUT to assert, even though their pickups may be more

sensitive.

Note that once one of the 87L elements has been selected, it cannot be changed until you exit and

re-enter the 87L test mode. The 87L test mode permits testing of both the normal and securemode 87L elements.

The following shows the application of the TEST 87L command in a terminal emulation

program:

=>>TEST 87L

Entering 87L Test Mode

Select Test: Characteristic or Loopback (C,L)

Test Mode: Single, Multi Terminal, or Disabled (S,M,D)

87L Element: (A,B,C,Q,G)

Alpha Plane Security: Normal or Secure (N,S)

Ensure that relay outputs are isolated or supervised.

Are you sure (Y/N)? y

Testing is enabled

Warning!

Ctrl X does not exit test mode

Type “TEST 87L OFF” to exit

?

?

?

?

c

s

a

n

When testing is complete, exit the 87L test mode by using the command TEST 87L OFF, as

follows:

=>>TEST 87L OFF

Exiting 87L Test Mode

=>>|

Note: When exiting the 87L test mode, there is no warning message requiring a second user

input as there is when entering 87L test mode.

Be sure to restore line currents to the relay prior to terminating the 87L test mode.

As soon as you exit the 87L test mode, the differential protection is enabled. If the correct

line currents are not present at all terminals, the differential protection may operate. This

could trip the line when the relay is taken out of test mode.

Note also that it is also necessary to restore the line currents and terminate the 87L test

mode when switching between characteristic tests of the various elements (87LA, 87LB,

87LC, 87LQ, and 87LG). You must re-enter the 87L test mode, disconnect the line

currents, and reconnect the test set currents before testing the next 87L element.

Date Code 20150401

SEL Application Guide 2015-12

6

SINGLE-TERMINAL 87L TEST CURRENT SOURCES

When using the single-terminal test mode, the local and remote currents are injected into different

phase current inputs of the SEL-411L being tested. The currents used are determined by the

element under test. Table 1 shows the analog substitutions to test the phase, ground, and negativesequence fault quantities. A pictorial representation of Table 1 is shown in Figure 5.

Table 1 Single-terminal test analog substitutions

87LA

87LB

87LC

87LQ

87LG

IA

IA

IB

IB

IA

Local IA

IB

Local IB

IC

Local IC

IB

Remote IA

IC

Remote IB

IA

Remote IC

Single-Terminal

87LA Element Test

Single-Terminal

87LB Element Test

87TOUT

Local

Current

IA

Remote

Current

IB

87L

A

87TOUT

Local

Current

IB

Remote

Current

IC

Single-Terminal

87LQ Element Test

87L

B

IA

Remote

Current

IB

87L

Q

87TOUT

Local

Current

IC

Remote

Current

IA

87L

C

Single-Terminal

87LG Element Test

87TOUT

Local

Current

Single-Terminal

87LC Element Test

87TOUT

Local

Current

IA

Remote

Current

IB

87L

G

Figure 5 Diagrams of single-terminal test analog substitutions

87LA, 87LQ, and 87LG Testing

The local current is injected into the IA current input. The remote current is injected into the

IB current input.

87LB Testing

The local current is injected into the IB current input. The remote current is injected into the

IC current input.

87LC Testing

The local current is injected into the IC current input. The remote current is injected into the

IA current input.

SEL Application Guide 2015-12

Date Code 20150401

7

SINGLE-TERMINAL AND MULTITERMINAL TEST PROCEDURE

Current injection for these tests is based on the differential element selected in the 87L test mode,

as described in the previous section. This procedure checks the pickup, radius, and angle settings.

The following is a list of the settings that are used and tested in this application guide:

•

87LPP, 87LQP, and 87LGP are the differential pickups for phase, negative-sequence, and

ground elements.

•

87LPR, 87LQR, and 87LGR are the Alpha Plane radius settings for phase, negativesequence, and ground elements.

•

87LPA, 87LQA, and 87LGA are the Alpha Plane blocking angle settings for phase,

negative-sequence, and ground elements.

As mentioned previously, 87TOUT is the Relay Word bit that is targeted to look for differential

element operation in test mode. Use the TAR 87TOUT 1000 command to see the differential

element assert (Relay Word bit changes from 0 to 1) or drop out (Relay Word bit changes from

1 to 0) as the test currents are applied.

Use the MET DIF command while injecting currents to look at measured quantities, the validity

of the test set injected quantities, and the position of the operating point on the Alpha Plane. The

following shows an example MET DIF command output capture for a sample single-terminal

characteristic test:

=>>MET DIF

Relay 1

Station R

Date: 05/11/2012 Time: 10:42:35.698

Serial Number: 1111240304

87L Communication: Master

87L Function: Available

Stub Bus:

Disabled

MAG (pu)

ANG (DEG)

THROUGH (pu)

IA

1.634

0.00

1.634

IB

0.000

37.44

0.000

Local Terminal

IC

0.000

37.44

0.000

I1

0.545

0.00

3I2

1.634

0.00

0.000

3I0

1.634

0.00

0.000

MAG (pu)

ANG (DEG)

THROUGH (pu)

IA

6.535

79.97

6.534

IB

0.000

37.44

0.000

Remote Terminal 1

IC

0.000

37.44

0.000

I1

2.178

79.97

3I2

6.535

79.97

0.000

3I0

6.535

79.97

0.000

MAG (pu)

ANG (DEG)

IA

7.007

66.70

IB

0.000

37.44

Differential

IC

0.000

37.44

3I2

7.007

66.70

3I0

7.007

66.70

k

alpha (DEG)

87LA

0.250

79.94

87LB

1.000

180.00

Alpha Plane

87LC

1.000

180.00

87LQ

0.000

0.00

87LG

0.000

0.00

Date Code 20150401

SEL Application Guide 2015-12

8

SINGLE-TERMINAL TESTS

Pickup Setting Check

Step 1.

Connect the proper local current source. Start with no current applied.

Step 2.

Slowly increase the applied local current until Relay Word bit 87TOUT asserts.

The pickup value should be within ±5 percent of the value calculated by (1):

I PICKUP = 87LTAPn • 87LkP

(1)

where:

87LTAPn is 87LTAPW or 87LTAPX, depending on which input is under test.

87LkP is 87LPP for an 87LA, 87LB, or 87LC test; 87LQP for an 87LQ test;

and 87LGP for an 87LG test.

Radius Setting Check

Step 1.

Connect the proper local and remote current sources suggested in Table 1.

Step 2.

Set the magnitudes of the local and remote currents equal to each other and greater

than the pickup value calculated in (1). Set the local current angle at 0 degrees and

the remote current angle at 180 degrees.

Step 3.

Confirm that 87TOUT is deasserted.

Step 4.

Slowly increase the local current until 87TOUT asserts. The pickup value should

be within ±5 percent of the value calculated by (2):

I PICKUP = [magnitude of the remote current] • 87LkR

(2)

where:

87LkR is 87LPR for an 87LA, 87LB, or 87LC test; 87LQR for an 87LQ test;

and 87LGR for an 87LG test.

Block Angle Setting Check

Step 1.

Connect the proper local and remote current sources suggested in Table 1.

Step 2.

Set the magnitudes of local and remote currents equal to each other and greater

than the pickup value calculated in (1). Set the local current angle at 0 degrees and

the remote current angle at 180 degrees.

Step 3.

Confirm that 87TOUT is deasserted.

Step 4.

Rotate the angle of the local current in the counter-clockwise direction until

87TOUT asserts. Record this angle as ANG1.

Step 5.

Reset the angle of the local current to 0 degrees.

Step 6.

Rotate the angle of the local current in the clockwise direction until 87TOUT

asserts. Record this angle as ANG2.

SEL Application Guide 2015-12

Date Code 20150401

9

Step 7.

Assuming that the angles are measured as 0 to +180 degrees and 0 to –180 degrees,

respectively, check that the block angle is set within ±5 percent of the angle

determined by (3):

87LkA

= ANG1 + ANG2

(3)

where:

87LkA is 87LPA for an 87LA, 87LB, or 87LC test; 87LQA for an 87LQ test;

and 87LGA for an 87LG test.

Repeat the preceding steps for each of the differential elements.

Note: You can also test the extended security differential settings of the relay by choosing the

87TESTS = S option in test mode, which switches the normal radius and angle settings

to secure mode settings.

MULTITERMINAL TESTS

Pickup Setting Check

Step 1.

Connect the proper local current source. Do not apply current at any remote

terminal. Start with no current applied.

Step 2.

Slowly increase the applied local current until Relay Word bit 87TOUT asserts.

The pickup value should be within ±5 percent of the value calculated by (4):

I PICKUP = 87LTAPn • 87LkP

(4)

where:

87LTAPn is 87LTAPW or 87LTAPX, depending on which input is under test.

87LkP is 87LPP for an 87LA, 87LB, or 87LC test; 87LQP for an 87LQ test;

and 87LGP for an 87LG test.

Radius Setting Check

Step 1.

Connect the proper local and remote current sources.

Step 2.

Set the magnitude of the local current greater than the pickup value calculated

in (4). Set the local current angle at 0 degrees.

Step 3.

Set the magnitude of the remote current, as determined by (5), at 180 degrees.

I REMOTE = [magnitude of the local current] •

87LTAPn REMOTE

87LTAPn LOCAL

(5)

where:

87LTAPn is 87LTAPW or 87LTAPX, depending on which input is under test.

Step 4.

Date Code 20150401

Confirm that 87TOUT is deasserted.

SEL Application Guide 2015-12

10

Step 5.

Slowly increase the local current until 87TOUT asserts. The pickup value should

be within ±5 percent of the value calculated by (6):

I PICKUP = [magnitude of the local current] • 87LkR

(6)

where:

87LkR is 87LPR for an 87LA, 87LB, or 87LC test; 87LQR for an 87LQ test;

and 87LGR for an 87LG test.

Block Angle Setting Check

Step 1.

Connect the proper local and remote current sources.

Step 2.

Set the magnitudes and angles of local and remote currents as determined in Step 2

and Step 3 in the previous subsection (Radius Setting Check).

Step 3.

Confirm that 87TOUT is deasserted.

Step 4.

Rotate the angle of the local current in the counter-clockwise direction until

87TOUT asserts. Record this angle as ANG1.

Step 5.

Reset the angle of the local current to 0 degrees.

Step 6.

Rotate the angle of the local current in the clockwise direction until 87TOUT

asserts. Record this angle as ANG2.

Step 7.

Assuming that the angles are measured as 0 to +180 degrees and 0 to –180 degrees,

respectively, check that the block angle is set within ±5 percent of the angle

determined by (7):

= ANG1 + ANG2

87LkA

(7)

where:

87LkA is 87LPA for an 87LA, 87LB, or 87LC test; 87LQA for an 87LQ test;

and 87LGA for an 87LG test.

Repeat the preceding steps for each of the differential elements.

Note: You can also test the extended security differential settings of the relay by choosing the

87TESTS = S option in test mode, which switches the normal radius and angle settings

to secure mode settings.

CONCLUSION

This application guide provides the tools to test the characteristics of the differential elements of

the SEL-411L relay in test mode.

SEL Application Guide 2015-12

Date Code 20150401

11

FACTORY ASSISTANCE

We appreciate your interest in SEL products and services. If you have questions or comments,

please contact us at:

Schweitzer Engineering Laboratories, Inc.

2350 NE Hopkins Court

Pullman, WA 99163-5603 USA

Telephone: +1.509.332.1890

Fax: +1.509.332.7990

www.selinc.com • info@selinc.com

Date Code 20150401

SEL Application Guide 2015-12

12

© 2015 by Schweitzer Engineering Laboratories, Inc.

All rights reserved.

All brand or product names appearing in this document are

the trademark or registered trademark of their respective

holders. No SEL trademarks may be used without written

permission.

SEL products appearing in this document may be covered by

U.S. and Foreign patents.

SEL Application Guide 2015-12

*AG2015-12*

Date Code 20150401