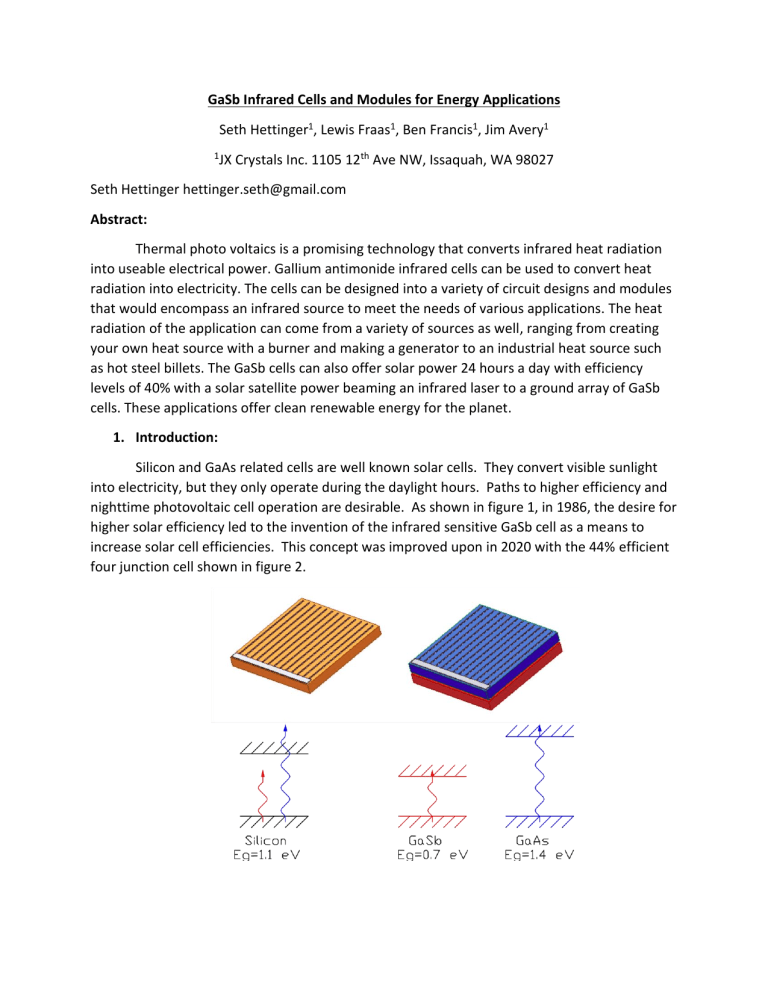

GaSb Infrared Cells and Modules for Energy Applications Seth Hettinger1, Lewis Fraas1, Ben Francis1, Jim Avery1 1JX Crystals Inc. 1105 12th Ave NW, Issaquah, WA 98027 Seth Hettinger hettinger.seth@gmail.com Abstract: Thermal photo voltaics is a promising technology that converts infrared heat radiation into useable electrical power. Gallium antimonide infrared cells can be used to convert heat radiation into electricity. The cells can be designed into a variety of circuit designs and modules that would encompass an infrared source to meet the needs of various applications. The heat radiation of the application can come from a variety of sources as well, ranging from creating your own heat source with a burner and making a generator to an industrial heat source such as hot steel billets. The GaSb cells can also offer solar power 24 hours a day with efficiency levels of 40% with a solar satellite power beaming an infrared laser to a ground array of GaSb cells. These applications offer clean renewable energy for the planet. 1. Introduction: Silicon and GaAs related cells are well known solar cells. They convert visible sunlight into electricity, but they only operate during the daylight hours. Paths to higher efficiency and nighttime photovoltaic cell operation are desirable. As shown in figure 1, in 1986, the desire for higher solar efficiency led to the invention of the infrared sensitive GaSb cell as a means to increase solar cell efficiencies. This concept was improved upon in 2020 with the 44% efficient four junction cell shown in figure 2. Figure 1: GaAs/GaSb Stacked Cell for Higher Efficiency (1986) Figure 2: 2020: 44% Efficient 4 Junction Solar Cell Predan, Dimroth, et al PVSC 2020 Combines Fraas 1978 3J GaInP/GaAs/GaInAs Cell with Fraas 1989 2J GaAs/GaSb Stack Cell to make GaInP/GaAs/GaInAs/GaSb 44% 4J Solar Cell [2] The new GaSb cell then enabled various Thermal PhotoVoltaic (TPV) systems which can operate at night and for 24 hours per day if needed. TPV is the concept of converting infrared radiation, commonly known as heat, into electrical energy. Using TPV GaSb cells is then a great avenue for providing clean renewable electrical power. GaSb cells absorb infrared radiation and convert it into electrical energy. There are many systems where these cells can be applied as heat can be supplied from a multitude of sources. 2. GaSb Cells 2.1 P on N Junction Cells GaSb cells are fabricated using n type tellurium doped single crystal GaSb wafers as a substrate. The wafers go through a zinc diffusion process creating a p type layer and a p on n junction. An anti-reflective layer of SiN is applied. The SiN layer is then pattern etched exposing sections of the GaSb creating openings for grid lines. The wafer then receives a metal deposition on both the front and back. The front metal is Ti/Pd/Ag and is the positive side of the cell. The back metal is Sn/Pd/Ag and is the negative side of the cell, figure 3a shows the structure of the cell. Excess metal is removed on the front of the wafer leaving only metal on the grid lines and a bus bar for soldering on contacts. This process is simple, and it resembles the Si solar cell process and can be low cost when scaled up in production. Figure 3b shows current I vs voltage V flash test result for a P on N GaSb cell in a TPV application. Fig. 3a: P on N junction GaSb cell structure Fig 3b: Current I (Amps) vs voltage V (Volts) flash test result for a P on N GaSb cell in a TPV application. Power is in Watts. There are several factors that affect the efficiency of the GaSb cells that come from both the cell and the infrared source. The factors that come from the cell are the IR quantum efficiency IQE, the temperature of the cell, and the cell band gap. The cell absorbs IR radiations with wavelengths shorter than 1.8 microns. To get the best efficiency the cell must be kept at a temperature around 30o C and the IQE is typically 85% and higher [1]. The variables of the infrared source are the power density and the spectrum that it emits. 2.2 N on P Junction Cells Inverting the junction of GaSb cells to n on p could offer improved efficiency to the cells and higher power output. The p on n junction cells IQE typically does not surpass 85% with wavelengths greater than 1000 nm while an n on p junction cell can theoretically achieve an IQE of 95% [3]. A large part of the improvement is because p-GaSb material has a longer electron diffusion length for photon generated minority carriers as is shown in the figure 4. Fig. 4 Electron diffusion length n vs. p type GaSb cell The n on p junction GaSb cell was prepared by MOCVD for the 4-junction cell reported in Figure 2. However, MOCVD may not be the most optimal way of making an n on p GaSb cell. A heterojunction cell consisting of a p-GaSb substrate with an N+ transparent conducting oxide layer could prove to be much lower cost which figure 5 shows a basic design of the cell structure. Infra Red Top Grid Contact N+ TCO P GaSb Back Side Contact Fig. 5 Heterojunction N on P cell structure with N+ transparent Conductive Oxide Coating (TCO) 3. Applications The challenges for GaSb cells now are to find the first niche application and to reduce costs by scaling up production. Fig 6 shows possible applications. Fig 6: With IR core tech, launch one application. 3.1 Combined heat and Power for the home - Midnight Sun Stove The Midnight Sun Stove is a completed TPV unit that is designed to generate both heat and power. It is designed to be used off the grid in small cabins. The stove is powered by a burner that used natural gas. It has two circuits inside of it with cells that are mounted in a shingle style. Each circuit produces 150 W of power for a total of 300 W shown by the IV curve of one of the circuits in figure 7. The internal temperature of the IR emitter in the stove is 1200o C. Each circuit consist of 72 GaSb cells and is 5 cm x 26 cm. The electric power produced by the GaSb cells is 150 W/130 cm2 = 1.15 W/cm2. Fig 7: The JX Crystals Inc Midnight Sun Stove for combined heat and power uses two 72 GaSb cell 150 W shingle circuits. The problem with this stove product is that in low volume production (kWs), it is too expensive for customers to buy. Volume production is required. This leads potentially to the steel industry where one customer can potentially buy a MW of product. 3.2 Waist Heat Recovery - TPV for Electric power from Hot steel One industry that shows potential for using GaSb TPV cells to generate power is the steel industry. As steel is heated it reaches temperatures over 1100 o C and is left to cool. All this heat energy is lost to the air and is not being used. The thermal energy can instead be converted into electrical power by placing a module containing GaSb cells around the hot steel billets to absorb this energy shown in figure 8. This would provide electricity 24/7 as steel is manufactured 24/7. The modules would provide a high-power density of 1 W/cm2. It is projected that a single steel mill could output 20 MW of power and worldwide 10 GW of power could be produced. The steel mill would be able to produce power for itself as well as the surrounding area. This application would be a clean and renewable energy source. The payback could be a short time of 1.5 years at $1 per watt. Fig. 8 The left image shows a steel billet with 3 GaSb modules surrounding it. The right image is what the modules could look like and their dimensions. The module could use 9 stove shingle circuits The problem for this application is that funding for an initial demonstration is required. This leads next to the potential for a lightweight quiet battery replacement for military applications because the military can afford the development costs. 3.3 Light Weight Fuel-Fired TPV DC Cylindrical Generator A small portable fuel fired TPV cylindrical power generator has been built under an Army Research Lab contract. The inside of the cylinder contains a Power Converter Array (PCA) (Fig. 9) of GaSb cells that encompass a Burner Emitter Recuperator (BER). The BER system consists of a burner which heats an emitter to 1200o C. The emitter is made of NiO/MgO that has an emissions band that peaks at 1.6 microns which is near ideal for the GaSb cells. The PCA has fins on the back side. The fins and cells are cooled with a fan. Fig. 9: Light Weight Battery Replacement - 20 W or 50 W TPV Cylindrical Generator TPV circuits for this application are described in a companion paper. The power converter array (PCA) consists of 2 Power Converter Modules (PCM). Each PCM consist of 54 cells. The design consists of cells on 9 facets with fold lines so that a cylindrical PCA can be made by combining two PCM’s that each make a half circle. Each facet has 6 cells in two groups of triplet cells. The cells in each triplet are wired in parallel and the top 9 triplets are wired in series as are the bottom 9 triplets creating 2 strings of 9 triplets per PCM. The PCM wiring configuration is designed to accommodate the cylindrical emitter which is assumed to be hottest in the middle and falling off in temperature toward either end. Each PCM can output 50 watts of power. With 2 PCMs making up a PCA that is inside of the cylindrical generator, 100 watts of power output can be achieved with an emitter temperature of 1300o C. Multiple cylinders can be combined to increase the power output of the generator. 3.3 Solar Satellite Power Beaming an IR Laser to TPV Cells A very exciting use of these IR GaSb cells could be for solar power satellites [4][5]. A solar power satellite in geosynchronous orbit could laser beam power 24 hours a day to 40% efficient GaSb cells on the ground. The satellite would be equipped with 40% efficient multijunction InGaP/GaInAs/GaSb concentrator cells that have been demonstrated in figure 2 [2]. These cells would be in large wing arrays attached to the satellite. The satellite would have an eye safe infrared laser attached to it that would emit a beam with a wavelength of 1.6 microns [4]. The laser would be powered by the solar concentrator cell arrays. The beam would have an intensity of 1 kW per square meter. The beam would be received by a station on the ground. The ground station would have an array of concentrator GaSb cells shown in figure 10. Calculations show GaSb concentrator cells have an efficiency of 45% when receiving 1.6 micron (0.8 eV) IR radiation [5]. (from fig 3b Vmax = 0.37 V and 0.37/0.8 = 46%) Fig. 10 GaSb cells in mini dome concentrator array This key concept was first described in “A Solar Power Satellite Sending an Infrared Beam from GEO to 40% efficient Concentrating Solar Power Modules on the Ground 24 Hours per Day”. Harvesting solar energy in space from a GEO orbit and RF beaming it down to earth has been a dream since the oil crisis in the 1970’s. However, the colossal and expensive first step required to achieve this goal has stifled its initiation. The problem derives from the dispersion of the beam associated with the long RF wavelength leading to a multi km size receiver station and a km size satellite and a costly multibillion dollar development project for a GW sized satellite. Using a shorter wavelength infrared beam reduces the dispersion and ground station size and consequently the satellite size from GWs to MWs or less. If a satellite with a diode pumped Er:YAG laser generating an IR beam is used, then a 40 m diameter ground station can receive eye safe IR radiation. Modular concentrating IR arrays with GaSb IR photovoltaic cells can then generate electricity 24 hours per day with an efficiency of 40%. In Ref 5, the economics for this concept were described and seem promising for national security niche power markets. The ground stations would need to be 40 m in diameter. The station would be capable of producing 400 kW of power 24 hours per day. Fig 11: Left image is a basic concept design for a power beaming satellite. Right image is of a broadcast satellite that is in orbit today as an example that remarkably similar satellites are in use today. The designed satellite is similar in size to a direct broadcast communication satellite as show in figure 11. It uses a 40 kW solar array to provide power to a 20 kW IR laser. Because the dispersion of the eye safe 1.6 micron IR laser beam is much less than the dispersion for a microwave beam the spot size on earth from GEO is only tens of meters in diameter rather than several km. Even though the laser intensity on the ground will be low, nevertheless, modules with concentrating lenses at the ground can boost the intensity on IR GaSb PV cells and could still deliver 8 KW of solar power 24 hours per day for a first space to ground solar power satellite demonstration. In the context of recent extreme heat days here on earth, is the 40% conversion number the relevant efficiency number? The answer is yes. Even though there are three energy conversion steps, i.e. the 40% solar to electric on the satellite and the 50% electric to laser beam on the satellite and the 40% beam energy conversion to electricity on the ground, the two waste heat steps on the satellite are dissipated in space and do not contribute to global warming. So, in conclusion, the idea of solar 24 hours per day with 40% conversion efficiency is remarkable and rivals natural gas conversion numbers without the burden of CO2 global warming. 4. Conclusion GaSb cells are a promising technology for providing electricity in a variety of ways. The cells IQE of 85% with wavelengths over 1000 nm can be increased to 95% with the development of n on p junction cells. The cells can be designed into a variety of modules to fit different applications. They can be mounted on a circuit that encompasses a burner to create generator. This has been demonstrated with the Midnight Sun and the lightweight Fuel-Fired TPV DC Cylindrical Generator. GaSb cells can be used in industrial plants such as steel mills to convert wasted heat into useable electrical power. GaSb cells can also be used to generate solar power 24 hours a day with an efficiency of 40%. This would be achieved with an array of GaSb cells on the ground receiving an infrared laser that is beamed from a solar power satellite in geosynchronous. There are many satellites in orbit today, for example a broadcast satellite, that have similar solar cell wing arrays attached to them. With that in mind GaSb cells offer the ability to create the first demo system of efficient power beaming from space. The technology offers clean energy solutions that would pay for itself in a matter of years. References [1] L. Fraas, J. Avery, P. Gruenbaum, V. Sundaram, Fundamental Characterization Studies of GaSb Solar Cells [2] F. Predan, A. Franke, O. Hoehn, D. Lackner, H. Helmers, G. Siefer, A. Bett, F. Dimroth, Wafer-bonded GaInP/GaInAs/GaSb four-junction solar cells with 43.8% efficiency under concentration [3] L. Tank, L. Fraas, Z. Liu, Y. Zhang, H. Duan, C. Xu, N-type vapor diffusion for fabrication of GaSb thermophotovoltaic cells to increase the quantum efficiency in the long wave range [4] L. Fraas, M. O’Neil, Terrestrial Electric Power 24 Hours per Day Using 40% Efficient GaSb Concentrator Photovoltaic (CPV) Cells [5] L. Fraas, M. O,Neil, A Solar Power Satellite Sending an Infrared Beam from GEO to 40% Efficient Concentrating Solar Power Modules on the Ground 24 Hours per Day