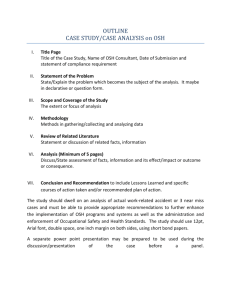

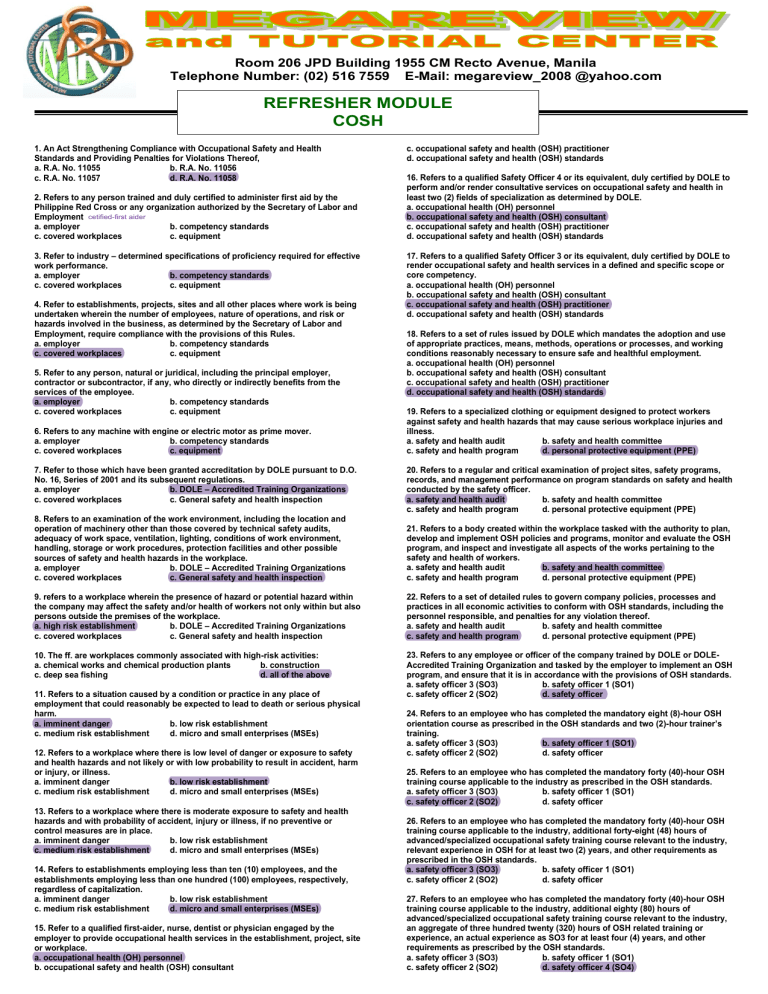

Room 206 JPD Building 1955 CM Recto Avenue, Manila Telephone Number: (02) 516 7559 E-Mail: megareview_2008 @yahoo.com REFRESHER MODULE COSH 1. An Act Strengthening Compliance with Occupational Safety and Health Standards and Providing Penalties for Violations Thereof, a. R.A. No. 11055 b. R.A. No. 11056 c. R.A. No. 11057 d. R.A. No. 11058 2. Refers to any person trained and duly certified to administer first aid by the Philippine Red Cross or any organization authorized by the Secretary of Labor and Employment cetified-first aider a. employer b. competency standards c. covered workplaces c. equipment 3. Refer to industry – determined specifications of proficiency required for effective work performance. a. employer b. competency standards c. covered workplaces c. equipment 4. Refer to establishments, projects, sites and all other places where work is being undertaken wherein the number of employees, nature of operations, and risk or hazards involved in the business, as determined by the Secretary of Labor and Employment, require compliance with the provisions of this Rules. a. employer b. competency standards c. covered workplaces c. equipment 5. Refer to any person, natural or juridical, including the principal employer, contractor or subcontractor, if any, who directly or indirectly benefits from the services of the employee. a. employer b. competency standards c. covered workplaces c. equipment 6. Refers to any machine with engine or electric motor as prime mover. a. employer b. competency standards c. covered workplaces c. equipment 7. Refer to those which have been granted accreditation by DOLE pursuant to D.O. No. 16, Series of 2001 and its subsequent regulations. a. employer b. DOLE – Accredited Training Organizations c. covered workplaces c. General safety and health inspection c. occupational safety and health (OSH) practitioner d. occupational safety and health (OSH) standards 16. Refers to a qualified Safety Officer 4 or its equivalent, duly certified by DOLE to perform and/or render consultative services on occupational safety and health in least two (2) fields of specialization as determined by DOLE. a. occupational health (OH) personnel b. occupational safety and health (OSH) consultant c. occupational safety and health (OSH) practitioner d. occupational safety and health (OSH) standards 17. Refers to a qualified Safety Officer 3 or its equivalent, duly certified by DOLE to render occupational safety and health services in a defined and specific scope or core competency. a. occupational health (OH) personnel b. occupational safety and health (OSH) consultant c. occupational safety and health (OSH) practitioner d. occupational safety and health (OSH) standards 18. Refers to a set of rules issued by DOLE which mandates the adoption and use of appropriate practices, means, methods, operations or processes, and working conditions reasonably necessary to ensure safe and healthful employment. a. occupational health (OH) personnel b. occupational safety and health (OSH) consultant c. occupational safety and health (OSH) practitioner d. occupational safety and health (OSH) standards 19. Refers to a specialized clothing or equipment designed to protect workers against safety and health hazards that may cause serious workplace injuries and illness. a. safety and health audit b. safety and health committee c. safety and health program d. personal protective equipment (PPE) 20. Refers to a regular and critical examination of project sites, safety programs, records, and management performance on program standards on safety and health conducted by the safety officer. a. safety and health audit b. safety and health committee c. safety and health program d. personal protective equipment (PPE) 8. Refers to an examination of the work environment, including the location and operation of machinery other than those covered by technical safety audits, adequacy of work space, ventilation, lighting, conditions of work environment, handling, storage or work procedures, protection facilities and other possible sources of safety and health hazards in the workplace. a. employer b. DOLE – Accredited Training Organizations c. covered workplaces c. General safety and health inspection 21. Refers to a body created within the workplace tasked with the authority to plan, develop and implement OSH policies and programs, monitor and evaluate the OSH program, and inspect and investigate all aspects of the works pertaining to the safety and health of workers. a. safety and health audit b. safety and health committee c. safety and health program d. personal protective equipment (PPE) 9. refers to a workplace wherein the presence of hazard or potential hazard within the company may affect the safety and/or health of workers not only within but also persons outside the premises of the workplace. a. high risk establishment b. DOLE – Accredited Training Organizations c. covered workplaces c. General safety and health inspection 22. Refers to a set of detailed rules to govern company policies, processes and practices in all economic activities to conform with OSH standards, including the personnel responsible, and penalties for any violation thereof. a. safety and health audit b. safety and health committee c. safety and health program d. personal protective equipment (PPE) 10. The ff. are workplaces commonly associated with high-risk activities: a. chemical works and chemical production plants b. construction c. deep sea fishing d. all of the above 23. Refers to any employee or officer of the company trained by DOLE or DOLEAccredited Training Organization and tasked by the employer to implement an OSH program, and ensure that it is in accordance with the provisions of OSH standards. a. safety officer 3 (SO3) b. safety officer 1 (SO1) c. safety officer 2 (SO2) d. safety officer 11. Refers to a situation caused by a condition or practice in any place of employment that could reasonably be expected to lead to death or serious physical harm. a. imminent danger b. low risk establishment c. medium risk establishment d. micro and small enterprises (MSEs) 12. Refers to a workplace where there is low level of danger or exposure to safety and health hazards and not likely or with low probability to result in accident, harm or injury, or illness. a. imminent danger b. low risk establishment c. medium risk establishment d. micro and small enterprises (MSEs) 13. Refers to a workplace where there is moderate exposure to safety and health hazards and with probability of accident, injury or illness, if no preventive or control measures are in place. a. imminent danger b. low risk establishment c. medium risk establishment d. micro and small enterprises (MSEs) 14. Refers to establishments employing less than ten (10) employees, and the establishments employing less than one hundred (100) employees, respectively, regardless of capitalization. a. imminent danger b. low risk establishment c. medium risk establishment d. micro and small enterprises (MSEs) 15. Refer to a qualified first-aider, nurse, dentist or physician engaged by the employer to provide occupational health services in the establishment, project, site or workplace. a. occupational health (OH) personnel b. occupational safety and health (OSH) consultant 24. Refers to an employee who has completed the mandatory eight (8)-hour OSH orientation course as prescribed in the OSH standards and two (2)-hour trainer’s training. a. safety officer 3 (SO3) b. safety officer 1 (SO1) c. safety officer 2 (SO2) d. safety officer 25. Refers to an employee who has completed the mandatory forty (40)-hour OSH training course applicable to the industry as prescribed in the OSH standards. a. safety officer 3 (SO3) b. safety officer 1 (SO1) c. safety officer 2 (SO2) d. safety officer 26. Refers to an employee who has completed the mandatory forty (40)-hour OSH training course applicable to the industry, additional forty-eight (48) hours of advanced/specialized occupational safety training course relevant to the industry, relevant experience in OSH for at least two (2) years, and other requirements as prescribed in the OSH standards. a. safety officer 3 (SO3) b. safety officer 1 (SO1) c. safety officer 2 (SO2) d. safety officer 27. Refers to an employee who has completed the mandatory forty (40)-hour OSH training course applicable to the industry, additional eighty (80) hours of advanced/specialized occupational safety training course relevant to the industry, an aggregate of three hundred twenty (320) hours of OSH related training or experience, an actual experience as SO3 for at least four (4) years, and other requirements as prescribed by the OSH standards. a. safety officer 3 (SO3) b. safety officer 1 (SO1) c. safety officer 2 (SO2) d. safety officer 4 (SO4) Room 206 JPD Building 1955 CM Recto Avenue, Manila Telephone Number: (02) 516 7559 E-Mail: megareview_2008 @yahoo.com REFRESHER MODULE COSH 28. Refers to any emergency, warning or danger signpost or safety instruction using the standard colors and sizes, including the standard symbols for safety instructions and warnings in the workplace, prescribed by DOLE in accordance with the OSH standards. a. safety signage b. workplace c. worker d. workers’ OSH Seminar 29. Refers to any site or location where workers need to be present or to go to by reason of their work, and which are under the direct or indirect control of the employer, including, but not limited to, work areas, employee lounges and restrooms, conference and classroom spaces, employee cafeterias, hallways and emergency access. a. safety signage b. workplace c. worker d. workers’ OSH Seminar 30. Refers to any member of the labor force, regardless of employment status. a. safety signage b. workplace c. worker d. workers’ OSH Seminar 31. Refers to the mandatory eight (8)-hour module conducted by the safety officer of the workplace as prescribed by the OSH standards. a. safety signage b. workplace c. worker d. workers’ OSH Seminar SITUATION: Given: DURATION (DAYS) 1 2 3 4 5 6 No. of Workers 3 6 5 7 6 4 32. Compute the total number of man-hours worked. a. 240 b. 244 c. 248 d. 256 33. Compute the Frequency Rate per 1 million employee-hours of exposure. a. 12500 b. 12296 c. 12097 d. 11719 34. Compute the Severity Rate per 1 million employee-hours of exposure. a. 8334 b. 8197 c. 8065 d. 7813 35. Compute the Incidence Rate per 1000 workers. a. 400 b. 450 c. 500 d. 550 36. What are the misconceptions about safety? 1. accidents cannot be prevented 2. companies do not have may accidents 3. safety is expensive 4. companies are insured anyway b. 1, 2 & 4 c. 2 & 4 d. 1, 2, 3, & 4 37. What are the common types of accidents? 1. fall from height and fall from the same level 2. struck against rigid structure, sharp or rough objects 3. struck by falling objects 4. caught in, on or in between objects 5. electrocution 6. fire a. 1, 2, & 3 c. 2, 3 & 4 b. 2, 3 & 6 d. all of the above 38. Freedom from accidents; absence of hazardous conditions and acts. a. safety b. health c. hazard d. risk 39. Freedom from illness; state of wellness, not just absence of disease. a. safety b. health c. hazard d. risk 40. The potential of an act or condition that can lead to an accident. a. safety b. health c. hazard d. risk 41. The chance of physical or personal loss. a. safety b. health c. hazard d. risk 43. A disruption in the normal process which does not results to injury or equipment damage. a. near miss b. accidents c. unsafe/unhealthy act d. unsafe/unhealthy condition 44. Any human action that violates a commonly accepted safe work procedure or standard operating procedure. a. near miss b. accidents c. unsafe/unhealthy act d. unsafe/unhealthy condition 45. defines as the physical or chemical property of a material, machine or the environment which could possibly cause injury to people, damage to property, disrupt operations in a plant or office or other forms of losses. Can be guarded or prevented. a. near miss b. accidents c. unsafe/unhealthy act d. unsafe/unhealthy condition 46. The process where you identify hazards, analyze or evaluate the risk associated with that hazards, and determine appropriate ways to eliminate or control the hazard. a. risk assessment b. hazard assessment c. unsafe/unhealthy act d. unsafe/unhealthy condition 47. Which of the following are considered as construction hazards? 1. open excavation 4. Dust and dirt 2. falling objects 5. Temporary wirings 3. welding operations 6. Temporary overhead electrical lines If the number of lost time injury reported is 3, number of man-days lost is 2 mandays. a. 1 & 2 42. An unexpected, unforeseen, unplanned and unwanted occurrence or event that causes damage or loss of materials or properties, injury or death. a. near miss b. accidents c. hazard d. risk a. 1, 2, 3 c. 5 & 6 b. 4, 5, 6 d. all of the above 48. Which of the following are correct about standard color of signs for safety? 1. red – for fire protection 2. green – for design safety, first aid 3. white – for designation of traffic 4. black, white, combination of black & white – for traffic designation & housekeeping marking. 5. yellow – for caution 6. orange – for warning 7. blue – for notice 8. purple – for radiation a. 1,3,4 & 6 c. 2,3,4 & 8 b. 3,4,7 & 8 d. all of the above 49. Which of the following are basic safety rules that can prevent all hazards involved in the use of power tools? 1. keep all tools in good condition with regular maintenance. 2. use the right tool for the job. 3. examine each tool for damage before use. 4. operate according to the manufacturer’s instructions. 5. provide and use the proper protective equipment. a. 1,3 & 5 c. 1,4, & 5 b. 2,3 & 4 d. all of the above 50. What are the safety measures in Excavation in Confined Spaces? 1. check the atmosphere condition before entry. 2. do not work alone in confined space. 3. provide ventilation or blower before entering the confined spaces. 4. emergency rescue equipment such as breathing apparatus, safety harnesses and line and basket stretcher shall be readily available where adverse atmospheric conditions are suspected or may develop in excavations. a. 1 & 3 c. 1 & 2 b. 1,2 & 4 d. all of the above 51. What are the hazards associated with demolition? 1. falls 6. manual demolition 2. lift shafts 7. Hazardous substance 3. being hit/trapped/crushed by objects 8. Dangerous goods 4. use of equipment (crane lifting loads) 9. Noise & vibrations 5. manual handling 10. Electric shocks ALL OF THE ABOVE Room 206 JPD Building 1955 CM Recto Avenue, Manila Telephone Number: (02) 516 7559 E-Mail: megareview_2008 @yahoo.com REFRESHER MODULE COSH 52. What are the fall protection system categories. 1. surface protection (non-slip flooring) 2. fixed barriers (handrails, guardrails) 3. surface opening protection (removable covers, guardrails) 4. travel restraint systems (safety line and belt) 5. fall arrest systems (safety line and harness) 6. fall containment systems (safety nets) a. 2,4 & 6 c. 1,3 & 4 b. 1,2,3 & 5 d. all of the above 53. What are the hazards present in heavy equipment operation 1. moving parts of the equipment 2. uneven terrain 3. energized electrical lines 4. fall 5. dust 6. overloaded equipment 7. noise 8. vibration 9. unsecured loads 10. improvised attachments 11. blind spots a. 1,2,3,4,5,6,7 & 10 c. 1,2,3,4,5,6,7 & 9 b. 1,2,3,4,5,6,7 & 11 d. all of the above 54. Which of the following are hazard prevention and controls in heavy equipment operation. 1. perimeter fencing, enclosures, signs. 2. spotters provided for in-the-blind, backing machines and/or equipment 3. poor planning forces workers to commit unsafe acts! (office trailers, change trailers, haul roads, parking areas) 4. be alert; stay clear; hear warnings 5. temporary barricades around hazards a. 1,3 & 5 c. 1 & 2 b. 1,3,4 & 5 d. all of the above 55. What are the hazards in the use of scaffolding? 1. fall of person from height 2. fall of materials and objects from height 3. collapse of scaffold 4. overloading of the scaffold 5. safe access not provided 6. electrocution a. 1,2,3,4 & 5 c. 1,2,3 & 6 b. 1,2,3 & 4 d. all of the above 56. The three (3) general environmental control measures that are useful in the workplace are: 1. Elimination 2. Substitution 3. Engineering Controls 4. Administrative Controls 5. PPE a. 1,2 & 5 c. 3,4 & 5 b. 3 & 4 d. all of the above 57. What are the main types of health hazards? a. Physical, Chemical, Biological, Ergonomic, Psychological b. Noise, Vibration, Heat Stress, Cold Stress, Illumination, Pressure c. Bacteria, Viruses, Fungi, Parasites, Insects, Plants d. all of the above 58. This is a short meeting usually held to discuss safety and health conditions in the workplace. a. BOSH meeting b. COSH meeting c. Tool Box meeting d. Management meeting 59. A real safety & health inspection. It is deliberate, thorough, and systematic by design. a. Unplanned inspection b. continuous inspection c. on-going inspection d. planned inspection 60. It is a collective effort that focuses both on the different jobs in a company, and a group of people tasked to identify them. a. accident investigation b. job hazard analysis c. safety and health program d. none of the above