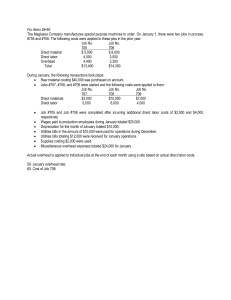

Job Order Cost Systems and Overhead Allocations Chapter 17 McGraw-Hill/Irwin Copyright © 2010 by The McGraw-Hill Companies, Inc. All rights reserved. Job Order Cost Systems and Overhead Allocations To explain the purposes of cost accounting systems. To identify the processes for creating goods and services that are suited to job order costing To explain the purpose and computation of overhead application rates for job order costing. 17-2 Job Order Cost Systems and Overhead Allocations To describe the purpose and the content of a job cost sheet. To account for the flow of costs when using job order costing. To define overhead-related activity cost pools and provide several examples. Demonstrate how activity bases are used to assign activity cost pools to units produced. 17-3 Learning Objective To explain the purposes of cost accounting systems. LO1 7-4 Cost Accounting Systems Determining unit manufacturing costs Planning and control functions Cost accounting systems provide information supporting decisions making the business successful Assessing the efficiency and effectiveness of operations Providing products or services to customers 17-5 Cost Accounting Systems Evaluate and reward employee performance Disclose inventories and cost of goods sold Cost accounting systems are the procedures and techniques used by management Manage activities that consume resources Track resources consumed by products and services 17-6 Learning Objective To identify the processes for creating goods and services that are suited to job order costing. LO2 7-7 Job Order Costing Used for production of large, unique, high-cost items. l Built to order rather than mass produced. l Many costs can be directly traced to each job. l Typical job order cost applications: w Special-order printing w Building construction l Also used in service industry w Hospitals w Law firms l 17-8 Job Order Cost Systems and the Creation of Goods and Services Receive orders from customers Schedule jobs Begin production Order materials 17-9 Job Order Cost Systems and the Creation of Goods and Services Manufacturing overhead (OH) Direct Tra ced materials dire to e ctly ach job Applied to each job using a predetermined rate (POHR) THE JOB Direct labor tly c e ir d ed b c o a j r T ch a e to 17-10 Job Order Cost Systems and the Creation of Goods and Services Direct Materials Charge direct material and direct labor costs to each job as work is performed. Job No. 1 Direct Labor Manufacturing Overhead Job No. 2 Job No. 3 Apply overhead to each job using a predetermined rate. 17-11 Learning Objective To explain the purpose and computation of overhead application rates for job order costing. LO3 7-12 Overhead Application Rates The predetermined overhead rate (POHR) used to apply overhead to jobs is determined before the period begins. POHR = Estimated total manufacturing overhead cost for the coming period Estimated total units in the activity base for the coming period Ideally, the activity base is a cost driver that causes overhead. 17-13 Overhead Application Rates Using a predetermined rate makes it possible to estimate total job costs. sooner. $ Actual overhead for the period is not known until the end of the period. 17-14 Overhead Application Rates Based on estimates, and determined before the period begins. Overhead applied = POHR × Actual activity Actual amount of the cost driver such as units produced, direct labor hours, or machine hours incurred during the period. 17-15 Overhead Application Rates Compuline, Inc., applies overhead based on direct labor hours. Total estimated overhead for the year is $360,000. Total estimated labor hours are 30,000. What is Compuline’s predetermined overhead rate per hour? 17-16 Overhead Application Rates Estimated total manufacturing POHR = overhead cost for the coming period Estimated total units in the allocation base for the coming period POHR = $360,000 30,000 direct labor hours (DLH) POHR = $12.00 per DLH For each direct labor hour worked on a job, $12.00 of manufacturing overhead will be applied to the job. 17-17 Learning Objective To describe the purpose and the content of a job cost sheet. LO4 7-18 Job Order Costing The primary document for tracking the costs associated with a given job is the job cost sheet. Let’s investigate 17-19 The Job Cost Sheet Oak and Glass Furniture Co. Job Cost Sheet 831 Product: French Court Dining Tables Date started Number of units: Date Completed 1/21/09 100 Manufacturing Direct Direct Labor Department Materials Hours Cost Milling $ 10,000 700 $ 14,000 Finishing 15,000 300 6,000 1/03/09 Manufacturing Overhead Rate Cost Applied 150% $ 21,000 150% 9,000 Cost Summary Direct materials used Direct Labor Manufacturing overhead applied Cost of finished goods manufactured (100 tables) Total Cost Unit Cost $ 25,000 $ 250 20,000 200 30,000 300 $ 75,000 $ 750 17-20 The Job Cost Sheet Oak and Glass Furniture Co. Job Cost Sheet Product: French Court Dining Tables Number of units: 100 Manufacturing Direct Department Materials Milling $ 10,000 Finishing 15,000 831 Date started 1/03/09 Date Completed 1/21/09 A materials requisition Direct Labor Manufacturing Overhead form is used to Hours Cost Rate Cost Applied 70 $authorize 14,000 150%the use$ of 21,000 300 6,000 150% materials on a job. 9,000 Cost Summary Direct materials used Direct Labor Manufacturing overhead applied Cost of finished goods manufactured (100 tables) Total Cost Unit Cost $ 25,000 $ 250 20,000 200 30,000 300 $ 75,000 $ 750 17-21 The Job Cost Sheet Oak and Glass Furniture Co. Job Cost Sheet Product: French Court Dining Tables Number of units: 100 Manufacturing Direct Direct Labor Department Materials Hours Cost Milling $ 10,000 70 $ 14,000 Finishing 15,000 300 6,000 831 Accumulate direct1/03/09 labor Date started costs by Date Completed 1/21/09 means of a Manufacturing Overhead Rate work Costrecord, Applied such as a$ time 150% 21,000 150% 9,000 ticket, for each employee. Cost Summary Direct materials used Direct Labor Manufacturing overhead applied Cost of finished goods manufactured (100 tables) Total Cost Unit Cost $ 25,000 $ 250 20,000 200 30,000 300 $ 75,000 $ 750 17-22 The Job Cost Sheet Oak and Glass Furniture Co. manufacturing Joboverhead Cost Sheet to Apply jobs using 831 a predetermined overhead rate (POHR) based on Product: French Court Dining Tables Date started 1/03/09 direct labor cost. Number of units: 100 Manufacturing Direct Direct Labor Department Materials Hours Cost Milling $ 10,000 700 $ 14,000 Finishing 15,000 300 6,000 Date Completed 1/21/09 Manufacturing Overhead Rate Cost Applied 150% $ 21,000 150% 9,000 Cost Summary Direct materials used Direct Labor Manufacturing overhead applied Cost of finished goods manufactured (100 tables) Total Cost Unit Cost $ 25,000 $ 250 20,000 200 30,000 300 $ 75,000 $ 750 17-23 Learning Objective To account for the flow of costs when using job order costing. LO5 7-24 Flow of Costs in Job Costing A materials requisition indicates the cost of direct material to charge to jobs and the cost of indirect material to charge to overhead. Direct Material Job Cost Job Cost Job Cost Sheets Job Cost Sheets Sheets Sheets Materials Material Requisitioin Materials Requisitioin Materials Requisitioni Requisition Indirect Material Manufacturing Overhead Account 17-25 Flow of Costs in Job Costing Employee time tickets indicate the cost of direct labor to charge to jobs and the cost of indirect labor to charge to overhead. Direct Labor Job Cost Job Cost Job Cost Sheets Job Cost Sheets Sheets Sheets Employee Time Employee Time Ticket Employee Time Ticket Employee Time Ticket Ticket Indirect Labor Manufacturing Overhead Account 17-26 Flow of Costs in Job Costing Employee Time Ticket Other Actual OH Charges Materials Requisition Indirect Labor Manufacturing Overhead Account Overhead Applied with POHR Job Cost Sheets Indirect Material 17-27 Flow of Costs in Job Costing Materials Inventory •Material •Direct Purchases Material •Indirect Material Work in Process (Job Cost Sheet) •Direct Material Mfg. Overhead •Indirect Material 17-28 Flow of Costs in Job Costing Labor •Direct Labor •Indirect Labor Mfg. Overhead •Indirect •Overhead Material Applied to Work in •Indirect Process Labor Work in Process (Job Cost Sheet) •Direct Material •Direct Labor •Overhead Applied When Actual Applied factory = factory overhead overhead the difference is closed to cost of goods sold. / 17-29 Flow of Costs in Job Costing Work in Process (Job Cost Sheet) •Direct •Cost of Material Goods •Direct Mfd. Labor •Overhead Applied Finished Goods •Cost of Goods Mfd. •Cost of Goods Sold Cost of Goods Sold •Cost of Goods Sold 17-30 Over- or Underapplied Overhead If Manufacturing Overhead is . . . Effect of Closing to Cost of Goods Sold UNDERAPPLIED (Applied OH is less than actual OH) INCREASE Cost of Goods Sold OVERAPPLIED (Applied OH is greater than actual OH) DECREASE Cost of Goods Sold 17-31 Learning Objective To define overhead-related activity cost pools and provide several examples. LO6 7-32 Activity-Based Costing (ABC) One of the most difficult tasks in computing accurate unit costs lies in determining the proper amount of overhead cost to assign to each job. Assigning overhead is difficult. I agree! 17-33 Activity-Based Costing (ABC) Activity-Based Costing Departmental Overhead Rates Plantwide Overhead Rate A B C v e L o l e e l p m o C f ty i x Overhead Allocation In the ABC method, we recognize that many activities within a department drive overhead costs. 17-34 The Benefits of ABC More detailed measures of costs. Better understanding of activities. More accurate product costs for . . . u Pricing decisions. u Product elimination decisions. u Managing activities that cause costs. Benefits should always be compared to costs of implementation. A B C 17-35 Identifying Cost Drivers Most cost drivers are related to either volume or complexity of production. l Examples: machine time, machine setups, purchase orders, production orders. Three factors are considered in choosing a cost driver: l Causal relationship. l Benefits received. l Reasonableness. 17-36 Activity-Based Costing Procedures Identify activities that consume resources. Assign costs to a cost pool for each activity. Identify cost drivers associated with each activity. Compute overhead rate for each cost pool: Rate = Estimated overhead costs in activity cost pool Estimated number of activity units Assign costs to products: Overhead × Actual Rate Activity 17-37 Learning Objective Demonstrate how activity bases are used to assign activity cost pools to units produced LO7 7-38 ABC Versus a Single Application Rate: A Comparison Pear Company manufactures a product in regular and deluxe models. Overhead is assigned on the basis of direct labor hours. Budgeted overhead for the current year is $2,000,000. Other information: Direct Material Direct Labor Cost Direct Labor Time Expected Volume (units) Deluxe Model $ 150 16 1.6 hours 5,000 Regular Model $ 112 8 0.8 hours 40,000 First, determine the unit cost of each model using a single application rate. 17-39 Single Application Rate Deluxe Model Regular Model 5,000 units @ 1.6 hours 40,000 units @ 0.8 hours Direct Labor Hours 8,000 32,000 Total Direct Labor Hours (DLH) 40,000 Overhead = Estimated overhead costs Rate Estimated activity Overhead = $2,000,000 = $50 per DLH Rate 40,000 DLH 17-40 Single Application Rate ABC will have different overhead cost per unit. Direct Material Direct Labor Manufacturing Overhead $50 per hour × 1.6 hours $50 per hour × 0.8 hours Total Unit Cost Deluxe Model $ 150 16 Regular Model $ 112 8 80 $ 246 $ 40 160 17-41 Activity-Based Costing Pear Company plans to adopt activity-based costing. Using the following activity center data, determine the unit cost of the two products using activity-based costing. Activity Cost Pool Purchasing Scrap Rework Testing Machine Related Total Overhead Cost Driver Orders Orders Tests Hours Overhead Cost for Activity $ 84,000 216,000 450,000 1,250,000 $ 2,000,000 Units of Activity Deluxe Regular 400 800 300 600 4,000 11,000 20,000 30,000 17-42 Activity-Based Costing Activity Cost Pool Purchasing Scrap Rework Testing Machine Related Total Overhead Cost Driver Orders Orders Tests Hours Overhead Cost for Activity $ 84,000 216,000 450,000 1,250,000 $ 2,000,000 Units of Activity 1,200 900 15,000 50,000 Rate 400 deluxe + 800 regular = 1,200 total 17-43 Activity-Based Costing Activity Cost Pool Purchasing Scrap Rework Testing Machine Related Total Overhead Cost Driver Orders Orders Tests Hours Overhead Cost for Activity $ 84,000 216,000 450,000 1,250,000 $ 2,000,000 Units of Activity 1,200 900 15,000 50,000 Rate $ 70 per order $240 per order $ 30 per test $ 25 per hour Rate = Overhead Cost for Activity ÷ Units of Activity 17-44 Activity-Based Costing Activity Cost Pool Purchasing Scrap Rework Testing Machine Related Total Overhead Rate $ 70/order $240/order $ 30/test $ 25/hour Deluxe Actual Units of Activity 400 300 4,000 20,000 Model Cost Allocated to Product $ 28,000 ? ? ? ? Regular Model Actual Cost Units of Allocated Activity to Product 800 $ 56,000 600 ? 11,000 ? 30,000 ? ? Cost Allocated to Product = Actual Units of Activity × Rate $70 × 400 = $28,000 Let’s complete the table. 17-45 Activity-Based Costing Activity Cost Pool Purchasing Scrap Rework Testing Machine Related Total Overhead Rate $ 70/order $240/order $ 30/test $ 25/hour Deluxe Actual Units of Activity 400 300 4,000 20,000 Model Cost Allocated to Product $ 28,000 72,000 120,000 500,000 $ 720,000 Regular Model Actual Cost Units of Allocated Activity to Product 800 $ 56,000 600 144,000 11,000 330,000 30,000 750,000 $ 1,280,000 Cost Allocated to Product = Actual Units of Activity × Rate Total overhead = $720,000 + $1,280,000 = $2,000,000 Recall that $2,000,000 was the original amount of overhead assigned to the products using traditional overhead costing. 17-46 Activity-Based Costing Overhead Costs Assigned to Products: Deluxe Model $720,000 ÷ 5,000 units = $144 per unit Regular Model $1,280,000 ÷ 40,000 units = $32 per unit Direct Materials Direct Labor Manufacturing Overhead Total Unit Cost Deluxe Model $ 150 16 144 $ 310 Regular Model $ 112 8 32 $ 152 17-47 ABC Versus a Single Application Rate: A Comparison Single Deluxe Model Direct materials $ 150 Direct labor 16 Overhead 80 Total cost $ 246 Rate Regular Model $ 112 8 40 $ 160 ABC Deluxe Regular Model Model $ 150 $ 112 16 8 144 32 $ 310 $ 152 This result is not uncommon when activity-based costing is used. Many companies have found that low-volume, specialized products have greater overhead costs than previously realized. 17-48 Costs and Cost Drivers in Activity-Based Costing Cost Materials purchasing Materials handling Personnel processing Equipment depreciation Quality inspection Indirect labor for equipment setups Engineering costs for product modifications Cost Driver Number of purchase orders Number of materials requisitions Number of employees hired or laid off Number of products produced or hours of use Number of units inspected Number of setups required Number of modifications 17-49 Ethics, Fraud, and Corporate Governance In addition to allocating manufacturing overhead costs to products, many companies allocate corporate overhead charges to their segments or divisions. Failure to allocate corporate overhead properly can result in misleading financial statement information. 17-50 End of Chapter 17 17-51