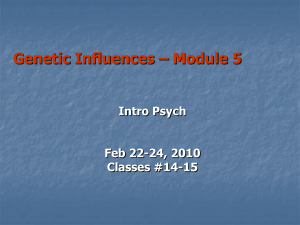

CM2 – Technical Challenges Haritha Jayasinghe EPSRC Centre for Doctoral Training in Future Infrastructure & Built Environment: Resilience in a Changing World MRes Coursework Cover Sheet Name: Haritha Jayasinghe College: Churchill College Module Number: CM2 Module Title: Technical challenges Coursework Number: 1 Coursework Name: Individual report I confirm that this piece of work is my own unaided effort and conforms with the Department of Engineering guidelines on plagiarism I declare the word count for this piece is: 2086 Date handed in for marking:25/03/2022 Marker's Name: ….. Student's Signature: Date Marked: ……. This piece of work has been completed to a standard which is (Please mark as appropriate): Letter Grade Percentage Scale Range Letter Grade Percentage Scale Range Outstanding 85-100 B 65-69 A+ 80-84 C 60-64 A 75-79 D 55-59 B+ 70-74 Unsatisfactory Less than 55 MRes Pass mark is 60% Marker's Comments: See attached sheet ----------------------------------------------------------------------------------------------------------------------------- -------------------------------------------------------------------------------------------------------------------------------- ---------------------------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------ ------------------------------------------------------------------------------------------------------------------------------------------------------ ---------------------------------------------------------------------------------------------------- ---------------------------------- Marker's Signature: ……. CM2 – Technical Challenges Haritha Jayasinghe This essay covers applications of digitisation, interoperability and digital twins in infrastructure and the built environment. P art I: D igital Tw inning for the B uilt Environm ent Based on lecture by. Prof. Ioannis Brilakis Introduction There are very few industries which have not been completely revolutionised by digitisation in the past few decades. Yet most existing infrastructure systems are currently operated with outdated technology and information. Of late, there has been renewed interest in digitisation within the infrastructure domain, particularly catalysed by the covid pandemic. Fortunately, infrastructure systems contain many opportunities for digitisation, ranging from virtual simulations to pre-fabrication and collaboration. Most, if not all of these technologies are brought together by the concept of digital twins. A digital twin is a virtual instance of a physical system (twin) that is continually updated with the latter’s performance, maintenance, and health status data throughout the physical system’s life cycle.[1] There must be a bi-directional relationship between the digital and physical twins. As the value of the digital twin is dependent upon the reliability of the data it contains, it is crucial to ensure that a digital twin is kept up-to-date. The Singapore city digital twin serves as an example of an outdated, hence unused digital twin. Furthermore, digital twins are used throughout the lifecycle of the infrastructure system, specifically through design, construction, operation and deconstruction. Throughout these stages, digital twins offer a variety of use cases. During design, digital twins are utilized to convey design intent and allow collaboration between stakeholders. In the construction phase, they are useful for construction monitoring and efficiency enhancement, pre-fabrication and construction automation, identification of faults etc.[2] As the infrastructure moves into the operational phase, they will be utilized to facilitate inspections, predictive maintenance and prevent unplanned shutdowns, handle emergency scenarios, increase automation and monitor infrastructure and employee performance, speed up decision making, improve interconnections between infrastructure systems and many other use cases.[3, 2, 4, 5, 6] Finally, once the system reaches end of life, digital twins can facilitate retrofitting, more efficient deconstructions and provide material passports for re-use or recycling.[7] C hallenges of technological uncertainty Despite the variety of use cases offered by infrastructure digital twins, the concept is still in its infancy. One of the key challenges to the adoption of digital twins is the lack of standardisation across various digital twin platforms. The effects of this are twofold. Firstly, the lack of standards leads to a variety of definitions on digital twins[2] with no clear criteria as to what constitutes a digital twin. This in turn allows vendors to easily label their products as digital twins, which causes infrastructure owners to lose confidence in digital twins, and harm their understanding of the benefits of digital twins. This in turn hinders the adoption of digital twins. CM2 – Technical Challenges Haritha Jayasinghe Secondly, the lack of standards prevent the interoperability of digital twins.[8] One of the key advantages of digital twins is the facilitation of exchange of information between infrastructure systems. For instance, this could be between an offshore wind plant and a thermal power plant communicating to balance the power grid output based on changing wind patterns, or a railway and coach system communicating to handle excess passengers due to a breakdown in one of the systems. The current lack of standardised formats leads to uncertainty and the existence of multiple incompatible standards, preventing such interoperability between systems. Another key challenge to the adoption of digital twins is the long life-span of infrastructure systems, in contrast to the shorter life-span of various technologies. This inevitably leads to technology built into infrastructure becoming outdated early in their life cycle. For instance, many existing infrastructure facilities pre-date Computer Aided Design (CAD) and Building Information Modelling (BIM) adoption, thus they lack the data to facilitate the creation of digital twins. In fact, new infrastructure only accounts of around 0.5% of value added to national infrastructure per year. The current process for creating digital twins for existing infrastructure systems is extremely labour intensive and time-consuming, often negating the perceived benefits of digital twins.[4] Solutions Tackling the above challenges requires the creation of industry wide standards for digital twins, with clear definitions and criteria for interoperability, as well as the adoption of open source formats.[8] Collaboration between various vendors who have traditionally utilized proprietary formats is required. There is an emergence of Platform as a service (PaaS) vendors such as Azure digital twins and Nvidia Omniverse which utilize open source formats, but further work is needed to improve interoperability, and the models must be able to scale with their demands. A key requirement in preventing the obsolescence of infrastructure facilities is designing flexible infrastructure and developing methods of retrofitting existing infrastructure with newer technologies. Recently, the advent of computer vision and deep learning has allowed the automation of digital twin generation from point cloud scans of existing infrastructure. This technology, while in its early stages, offers a cost-effective method for digital twinning of existing facilities. The process consists of; capturing 3D scans, element identification, model generation and enrichment. In particular, element identification can be automated by using various 3D segmentation methods to identify the various elements within the infrastructure, for instance the columns of a bridge. Next, each element can be modelled, either by representing them with an idealized model picked through a model repository, or by generating a custom mesh model to depict the segmented element. The latter method can capture the nuances of the element at a high level of detail. Finally, the model can be enriched by various additional information such as material properties, defects such as cracks etc. The identification of such information can also be automated through computer vision, for instance through automated crack detection using images. Furthermore, a digital twin must be intrinsically linked to the physical twin, and constantly updated. This can be achieved through integration with the various sensors within the physical asset, as well as by periodic updates of data, for instance through regular scanning. CM2 – Technical Challenges Haritha Jayasinghe Figure 1. Instance segmentation of bridge elements [13] The above methodology has been utilized for the automated digital twinning of various types of infrastructure ranging from bridges, roads, and railways to buildings and industrial facilities. It is still in its early stages and only supports limited elements, and requires significant human correction. Yet it provides a promising method to facilitate the digitisation of aging infrastructure. In conclusion, standardisation and automation have become the key to ensuring that infrastructure facilities can remain up-to-date and reap the benefits of digitisation in the face of technological uncertainty. P art II: Infrastructure, System of System s, B IM & D igital Tw ins Based on lecture by Dr Jenifer Schooling Introduction Infrastructure plays a key role in the development of a society and the wellbeing of its people. Many of the sustainable Development Goals such as Industry, Innovation and Infrastructure, Clean Water and Sanitation, Affordable and Clean Energy, and Sustainable Cities and Communities are intrinsically linked with infrastructure. However, infrastructure development and operation have become increasingly challenging, due to the rapidly rising threat of global warming, as well as economic constraints. As infrastructure faces increasing environmental, economic, demographic and technological threats, better decision-making and efficient operation have become crucial. Data is perhaps the most integral requirement to achieve this. D ata for a w hole life perspective As elaborated in part I, data is crucial in all stages of infrastructure from design to deconstruction. Throughout the life cycle of an infrastructure project, various decisions must be taken, which have both economic and environmental consequences. Data is vital to ensure that informed decisions that minimizes the above concerns are taken. Such data may be generated from a variety of sources ranging from embedded systems within infrastructure to observed material flows and other process data, data captured through remote sensing and other means or even social media. This creates a vast volume of data, which often overwhelms facility operators, resulting in data being unnecessarily collected without deriving useful inferences. Thus, proper curation of data, and designing pipelines that automate processes or the generation of insights is crucial. Current advancements in machine learning are a key tool for processing such large datasets. CM2 – Technical Challenges Haritha Jayasinghe While such information has a vast variety of use cases, life-cycle analysis is particularly noteworthy. Partially as a consequence of lack of data availability and the resultant uncertainty, infrastructure operators often tend to ignore the entire life cycle of infrastructure projects, and focus primarily on up front cost, both with regards to economic costs and carbon costs, leading to sub-optimal performance during later years. This can also occur on a national level, as a life cycle of an infrastructure project is far greater than that of a government term, leading to optimisation of short-term goals. Now, with the availability of data, as well as statistical and machine learning tools that can collate large amounts of data and draw predictions, infrastructure owners can identify options that maximize utility over the entire life cycle of a project, for instance sacrificing embedded carbon during construction for a more energy efficient operation, through various design decisions. In addition, data can also be used to predict impacts of one on various other interconnected infrastructure systems. Interoperability and ‘System of System s’ The infrastructure system of a country is an amalgamation of traditional economic infrastructure such as transport energy, etc., social infrastructure as well as the natural environment. All of these are strongly linked with each other, forming a system of systems, often with complicated links. For instance, whilst the relationship between a breakdown in a section of railway overhead line equipment and a surge in vehicular traffic in the same area may be somewhat obvious, the link between a power outage in an area, and increased traffic near the local hospital due to electrically powered home medical equipment failure may be harder to predict. Ideally, infrastructure control systems should be linked with automated information flows, to ensure that the infrastructure can adapt rapidly to changing requirements. An analogy can be drawn with a natural ecosystem, which returns to equilibrium after an external threat through various complex material and energy flows.[9] Unfortunately, most infrastructure systems currently operate within silos, with little data sharing between infrastructure operators, which leads to inefficiencies in operations.[9] To change this, a mindset shift is required, where operators proactively promote knowledge sharing and interoperability between infrastructure systems. Furthermore, standardisation is required to ensure that systems are compatible with each other. The Milton Keynes Smart Consortium is an example of the creation of a data hub for sharing information from city wide infrastructure systems.[9, 10] Ideally, all infrastructure systems within the nation should be coalesced into a national digital twin, which includes both economic and social infrastructure systems, as well as the natural environment. In addition to the many use cases of individual digital twins presented in part I, such an interconnected system of systems would be much more resilient to threats due to the ability to better predict threats and identify courses of action using the available data. It could also promote synergies between systems, both at an industry level (ex. load distribution between transport systems) and across industries (ex. energy grid adapting to increased ‘work from home’ due to a scheduled transportation system maintenance). While the concept of a ‘national digital twin’ is far from reality, the Gemini Principles provide a strong foundation for its creation.[11] Specifically, the Gemini Principles emphasize the importance of the design of digital twins being driven by clear purpose / use cases, the need to balance open data sharing with security CM2 – Technical Challenges Haritha Jayasinghe and privacy of citizens, as well as the need to evolve, interoperate, and be governed with clear standards. Ultimately, such digital twins must be created with the core focus of creating public value. In addition to operational efficiencies, a national digital twin would facilitate various simulations of impacts of decisions across the entire infrastructure system, resulting in more informed long-term policy decisions. A vision of such a system was presented by the Climate Resilience Demonstrator.[12] Figure 2. Gemini principles by the Centre for Digital Built Britain [11] In conclusion, data plays a key role in supporting a nation’s infrastructure, to the point where data infrastructure has become a part of the national infrastructure system. As infrastructure faces increasing challenges, data has become an essential tool to maintain infrastructure resilience. Yet, adoption of a data-centric view to infrastructure management is severely lacking across the UK. To achieve resilience, and maximize value to the public, infrastructure decisions must be driven by a data backed life cycle analysis within individual systems, while interoperability must be achieved among all systems within the nation. R eferences [1] A. Madni, C. Madni, S. Lucero Leveraging digital twin technology in model-based systems engineering Systems, 7 (2019), p. 7, 10.3390/systems7010007 [2] E. Agapaki, G. Miatt, and I. Brilakis, ‘Prioritizing object types for modelling existing industrial facilities’, Automation in Construction, vol. 96. Elsevier BV, Dec. 2018. doi: 10.1016/j.autcon.2018.09.011. [3] V. Dilda, L. Mori, O. Noterdaeme, and J. V. Niel. Using advanced analytics to boost productivity and profitability in chemical manufacturing, 2018. CM2 – Technical Challenges Haritha Jayasinghe Available: https://www.mckinsey.com/industries/chemicals/our-insights/usingadvanced-analytics-to-boost- productivity-and-profitability-in-chemical-manufacturing [4] E. Agapaki, ‘Automated Object Segmentation in Existing Industrial Facilities’, Apol– o - University of Cambridge Repository, May 2020, doi: 10.17863/CAM.52102. [5] Arayici Y. Towards building information modelling for existing structures. Struct surv [Internet]. 2008;26(3):210–22. Doi: 10.1108/02630800810887108 [6] Cho YK, Alaskar S, Bode TA. BIM-integrated sustainable material and renewable energy simulation. In: Construction Research Congress 2010. Reston, VA: American Society of Civil Engineers; 2010. [7] Volk R, Stengel J, Schultmann F. Building Information Modeling (BIM) for existing buildings — Literature review and future needs. Autom Constr [Internet]. 2014;38:109–27. doi: /10.1016/j.autcon.2013.10.023 [8] V. Piroumian, "Digital Twins: Universal Interoperability for the Digital Age," in Computer, vol. 54, no. 1, pp. 61-69, Jan. 2021, doi: 10.1109/MC.2020.3032148. [9] Grafius DR, Varga L, Jude S. Infrastructure Interdependencies: Opportunities from Complexity [Internet]. Vol. 26, Journal of Infrastructure Systems. American Society of Civil Engineers (ASCE); 2020. p. 04020036. Available from: http://dx.doi.org/10.1061/(asce)is.1943-555x.0000575 [10] MK:Smart Consortium, 2017. Available: https://www.mksmart.org/about/ [11] The Gemini Principles, 2018. Center for Digitally Built Britain, available: https://www.cdbb.cam.ac.uk/system/files/documents/TheGeminiPrinciples.pdf [12] The National Digital Twin programme produces a film and interactive app for COP26 showcasing the role of connected digital twins in tackling the climate emergency, 2021. Center for Digitally Built Britain, available: https://www.cdbb.cam.ac.uk/news/nationaldigital-twin-programme-produces-film-and-interactive-app-cop26-showcasing-role [13] Riveiro B, DeJong MJ, Conde B. Automated processing of large point clouds for structural health monitoring of masonry arch bridges [Internet]. Vol. 72, Automation in Construction. Elsevier BV; 2016. p. 258–68. Available from: http://dx.doi.org/10.1016/j.autcon.2016.02.009