Protective Relay Setting & Coordination Study - Timor-1 CFSPP

advertisement

PROTECTIVE RELAY SETTING & COORDINATION STUDY

Timor-1

Coal Fired Steam Power Plant 2 X 50 MW

(Timor-1 CFSPP Project)

Consortium of

PT IKPT - PT PP (Persero) Tbk. - ITOCHU Corporation Sumitomo Heavy Industries, Ltd. - PT Medco Power Indonesia

Date:

B

MECHANICAL

ELECTRICAL

REVIEW

☐

☐

A

CIVIL

Comm No:

APPROVED

NOTED

APPROVED AS

C

☐

NOT APPROVED

I

☐

INFORMATION

T1-PP-000-ELE-STU-00003

PLN UPP TIMOR

Date:

Log

out

SUPPORT

PLN UIP NUSRA (HO)

REVIEWED DOES NOT RELIEVE

CONTRACTOR FROM RESPONSIBILITY

FOR ERROR OR DEVIATIONS FROM

CONTRACT REQUIREMENTS

By:

PLN DOC. NO.:

I&C

CONTRACTOR DOC. NO. :

Date:

DISTRIBUTION

Log

in

PLN PUSENLIS (JKT)

✓

CONTRACT NO. :

0389.PJ/DAN.02.01/010000/2019

JAYA CM (SITE)

CONTRACTOR (JKT)

✓

CONTRACTOR (SITE)

Comm No:

Note:

0

2022-09-05

REV

DATE

Issued for Approval

PURPOSE OF ISSUE

PREPARED

CHECKED

APPROVED

AUTHORIZED

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REVISION HISTORY

REV. NO.

DATE

0

2022-09-05

DESCRIPTION

Issued for Approval

REV. 1

Page 2 of 17

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

1.

2.

3.

4.

5.

6.

7.

8.

9.

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

TABLE OF CONTENT

GENERAL .................................................................................................................................................... 4

CODE AND STANDARD ............................................................................................................................. 4

REFFERENCE DOCUMENT ....................................................................................................................... 4

LANGUAGE AND SYSTEM OF UNITS ...................................................................................................... 4

PRINCIPLES OF PROTECTIVE RELAY APPLICATION ........................................................................... 4

DESIGN BASIS ............................................................................................................................................ 4

COORDINATION RELAY ............................................................................................................................ 5

METHODOLOGY AND CALCULATION CRITERIA................................................................................... 7

8.1 Study Case .......................................................................................................................................... 10

CONCLUSION ............................................................................................................................................. 17

ATTACHMENT

ATTACHMENT 1.

: SINGLE LINE DIAGRAM

ATTACHMENT 2.

: TABLE SETTING FOR PROTECTION RELAY

ATTACHMENT 3.

: COORDINATION CURVE

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

1.

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

GENERAL

This document covers the calculation of protection relay coordination study and shall constitute the

setting of each breaker and relays for TIMOR-1 CFSPP (2 x 50 MW) at Kupang, Nusa Tenggara

Timur Province, Indonesia. The result of the calculation is used to determine the setting rating relay.

2.

CODE AND STANDARD

All calculation shall be in accordance with:

International Standards

IEEE Std. 141-1993

IEEE Std. 399-1997

: Recommended Practice for Electric Power Distribution for Industrial Plants

: Recommended Practice for Industrial and Commercial Power System

Analysis

IEEE Std. 242-1986 : Recommended Practice for Protection and Coordination of Industrial and

Commercial Power Systems

IEEE C37.101-1993 : Guide for AC Generator Ground Protection

IEEE C37.102-1987 : Guide for AC Generator Protection

IEC 60909

: Short Circuit Current Calculation in Three-phase A.C. Systems

IEC 60255

: Measuring Relays and Protection Equipment

3.

REFFERENCE DOCUMENT

The electrical system configuration and load data are

a. Electrical Load Data Calculation

b. Overal Single Line Diagram

c. SLD For MV 6.3 kV Medium Voltage System

d. SLD For LV 400/230 V AC Low Voltage System

4.

based on the list below:

(T1-PP-000-ELE-CAL-00002)

(T1-PP-000-ELE-SLD-00002)

(T1-PP-000-ELE-SLD-00003)

(T1-PP-000-ELE-SLD-00004)

LANGUAGE AND SYSTEM OF UNITS

All units of measurement shall be in the metric system. All documents to be submitted shall be written

in English.

5.

PRINCIPLES OF PROTECTIVE RELAY APPLICATION

This power load flow study is performed using computer software analysis program ETAP. The

calculations using load flow analysis which is based on Newton-Raphson method. Load Flow Analysis

calculates the bus voltages, branch power factors, currents, and power flows throughout the electrical

system.

6.

DESIGN BASIS

Protection is arranged to cover the electrical power system completely, leaving no parts unprotected.

When fault occurs, the protection is required to selectivity to trip only the nearest circuit breakers.

This concept of protection is so called discrimination or selectivity.

For time graded protection as presented in this report, the tripping time is inversely proportional to the

fault current level for any given protective gears and the actual characteristic is a function of both the

time and current settings.

The protective gears in the successive zones are set to operate in time, which is graded through the

sequence of equipment, such that upon the occurrence of a fault, only the protective gear nearest of

the fault will complete the tripping function although more than one protective gear will response.

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

7.

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

COORDINATION RELAY

The overall protective element used in the system is summarized below:

a. Incoming 150 kV to GT (HV)

Differential Protection Relay

Circuit Breaker (CB) 50 kA, 150 kV, 300 A.

Protective elements:

•

•

•

•

•

•

•

•

Differential Transformer Protection (87 GT)

Restricted Earth Fault (64 REF)

Over Current (50/51)

Earth Fault (50N/51N)

Transformer Over Winding Temperature (49 WT)

Transformer Over Oil Temperature (49 OT)

Transformer Gas Protection/Buchholz For Main Tank and OLTC (63)

Transformer Over Flux Protection (24)

b. Incoming 150 kV to GT (LV)

Differential Protection Relay

Circuit Breaker (CB) 50 kA, 15 kV, 4000 A.

Protective elements:

•

•

•

c.

Restricted Earth Fault (64 REF)

Over Current (50/51)

Earth Fault (50N/51N)

Outgoing 15 kV to UAT (HV)

Differential Protection Relay

Vacuum Circuit Breaker (VCB) 50 kA, 15 kV, 630 A.

Protective elements:

•

•

•

•

•

•

•

•

d.

Differential Transformer Protection (87 UAT)

Restricted Earth Fault (64 REF)

Over Current (50/51)

Earth Fault (50N/51N)

Transformer Over Winding Temperature (49 WT)

Transformer Over Oil Temperature (49 OT)

Transformer Gas Protection/Buchholz for Main Tank and OLTC (63)

Standby Earth Fault for NGR (SBEF)

Outgoing 15 kV to UAT (LV)

Differential Protection Relay

Vacuum Circuit Breaker (VCB) 25 kA, 6,3 kV, 1600 A.

Protective elements:

•

•

Restricted Earth Fault (64 REF)

Over Current (50/51)

Page 2 of 17

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

•

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

Earth Fault (50N/51N)

e. Incoming 15 kV from Generator

Generator Protection relay

Vacuum Circuit Breaker (VCB) 50 kA, 15 kV, 4000 A.

Protective elements:

f.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Generator 100% Stator Earth Fault Protection (59G)

Generator Differential Protection (87G)

Overall Differential Protection (87O)

Generator Negative Phase Sequence Protection {46)

Generator Loss of Excitation Protection (40)

Generator Over-Excitation (V/Hz) Protection (24)

Generator Reverse Power Protection (32)

Generator Overvoltage Protection (59)

Generator Under voltage Protection (27)

Generator Voltage Controlled Over current relay (51V)

Generator Rotor Earth Fault (64F)

Impedance Protection (21)

Voltage Balance Protection ("60)

Frequency Protection (81)

•

•

Generator Out of Step Protection (78)

Generator Stator Thermal Protection ( 49) Over current and Earth Fault Protection (50/51:

50N/51 N)

Incoming 6.3 kV from UAT

Vacuum Circuit Breaker (VCB) 25 kA, 6.3 kV, 1600 A.

Protective elements:

•

•

•

•

•

•

•

•

g.

Medium Voltage System Protection

-

h.

Differential Transformer Protection (87 UAT)

Restricted Earth Fault (64 REF)

Over Current (50/51)

Earth Fault (50N/51N)

Transformer Over Winding Temperature (49 WT)

Transformer Over Oil Temperature (49 OT)

Transformer Gas Protection/Buchholz for Main Tank and OLTC (63)

Standby Earth Fault for NGR (SBEF)

Outgoing 6.3 kV to Electric Motor

Air Circuit Breaker (ACB) 63 kA, 400 V, 2000 A

Protective elements :

• Excessive starting time and locked rotor (48-51LR)

• Over Current (50/51)

• Over Load (49)

• Phase imbalance (46)

• Under Voltage (27)

• Ground Fault (50N/51N)

Low Voltage System Protection

-

Incoming 400 V from Power Distribution Transformer

Feeder Protection Relay

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

Air Circuit Breaker (ACB) 63 kA, 400 V, 2000 A

Protective elements :

• Instantaneous / time delay current relay (ANSI 50/51)

• Earth Fault Relay (ANSI 50N/51N)

• Over voltage (ANSI 59)

-

Outgoing 400 V to Power Feeders

Molded Case Circuit Breaker (MCCB)

Protective elements:

• Instantaneous Over Current Protection (ANSI 50)

-

Outgoing 400 V to Electric Motor

Molded Case Circuit Breaker (MCCB)

Protective elements:

• Instantaneous Over Current Protection (ANSI 50)

REV. 1

Page 2 of 17

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

8.

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

METHODOLOGY AND CALCULATION CRITERIA

8.1 Study Case

The study is based on the data and parameter as performed by ETAP Power System Analysis

Software ver. 12.5.0C which has provided some characteristic curved used as parameter in this

project as follow:

•

•

•

•

•

•

Transformer thermal damage and inrush current curve

Cable thermal damage curve

Protection Device (Circuit Breaker, MCCB) curve

Motor Starting Curve (if any)

Thermal Overload relay Curve (if any)

Protective Relay Curve

For initial setting, the protection devices used are listed as below:

•

•

•

•

Circuit Breaker

ACB Relay

VCB Relay

Electronic Motor Protection Relay

Time grading between protective devices is determined with the following consideration:

•

•

•

Circuit Breaker Operating Time

Retardation Time

Safety Margin

: 80 ms

: 20 ms

: 100 ms

Therefore, minimum time grading is considered at 0.2 s to achieve acceptable breaker operating

time. In case time grading is not applied, current grading shall be concerned. In this study, time

grading for upstream and downstream of feeder and transformer are only applied for low set

overcurrent only, high set overcurrent setting is not considered within this stage.

Protection relays setting which are considered in this study is listed below,

•

•

49 – Thermal Overload Relay

50/51 – Instantaneous/Overcurrent Relay

Others required setting to be developed during detail design after relay/switchgear vendor

selected. The following list of protection setting and grading are basis consideration only. Detailed

relay coordination by considering equipment characteristic shall refer to the Relay Coordination

Curve attached in Appendix-xx and shall be updated after receiving Vendor data.

8.2 Protection for Line Differential

This setting is to protect overhead line cable. This setting should be defined as the minimum

pickup differential current to operate the element under the normal load conditions and steady

state CT error during no load condition. There are, however, conditions, which may result a

differential current even when there would be no fault. Therefore, it is important to take care of

these conditions while calculating this setting. Following conditions shall be considered:

Errors due to the CT Inaccuracy:

Ierror = 0.1 * 1 = 0.1 pu [10]

Cable Charging Currents :.

X1line_capacitive = DC resistance * length

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

= 1/(2*3.14*50*0.143) *0.35 km

= 11.13 Ω

Since the capacitance is too small, the setting is not applicable.

Icharging

=(Vline-ground)/(X1line_capacitive)

= (86 KV)/11.13Ω

= 7.72 A (0.003 pu)

And since charging current is too small, it can be negligible.

Therefore, the pickup setting equation could be:

Pickupdifferential=Ierror+Itap_changer+SafetyMargin

In this case, Itap changer is 10% and assuming safety margin is 5%

Pickupdifferential=0,1+0,1+0,05 = 0,25pu

8.3 Protection for Overall Differential

Overall differential protection is required to protect big generator-transformer units. For this

particular application this maximum power corresponds to the following base currents on three

different voltage levels connected to the relay :

- At 150 kV :

Ifl = 281 A. This corresponds to 0,937 A on the secondary side 300/1 CT.

- At 15 kV :

Ifl = 2853 A. This corresponds to 0,71325 on the secondary side 4000/1 CT.

- At 15 kV :

Ifl = 1066 A. This corresponds to 1,6931 on the secondary side of 630/1 CT.

Above currents will be the base current for each side. Overall differential protection can be set

to minimum pickup 20%. All other settings for the operating characteristic can be left to default

values.

8.4 Protection for LV Feeder

Molded Case Circuit Breaker (MCCB) is used to protect outgoing 400 V Power Feeder. Feeder

protection to be provided by manufacturer to provide the following protection elements:

- 50/51 – Instantaneous/Time Delay Overcurrent (MCCB)

➢

➢

Overcurrent Setting: 110% x FLA

Instantaneous Setting: 1000% x FLA

8.5 Protection for LV Motor

Multifunction motor protection relay and Molded Case Circuit Breaker (MCCB) is used to protect

outgoing 400 V Motor. Minimum protection relay to be provided by manufacturer is specified as

follow:

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

- 49 – Thermal Overload

➢

➢

➢

This function is used to protect motor against overload based on measurement of current

consumed. The protection gives a trip when the temperature reaches setting limit.

Thermal class selected is Class 10, by considering Lock Rotor Current is 6xFLA (to be

revisited after receiving vendor motor data

Current Setting: 110% x FLA

- 50/51 – Instantaneous/Time Delay Overcurrent (MCCB)

➢

➢

➢

➢

➢

This protection will be covered by MMC, to protect cable and motor from short circuit

current

Current setting of instantaneous overcurrent is mainly determined by the maximum short

circuit current and starting current of motor

Current Setting (with DOL Starter): 800%-1000% x FLA

Current Setting (with Soft Starter): 800%-1000% x FLA

Time Setting: 0.05 s (instant)

8.6 Protection for 6.3/0.4 kV Power Distribution Transformer

Multifunction feeder protection relay is used to protect transformer. Minimum protection relay to

be provided by manufacturer is specified as follow:

•

•

•

50 – Instantaneous Overcurrent Relay

51 – Time Inverse Overcurrent Relay

87T – Transformer Differential Relay

In this study, the basis coordination setting for this function is as follow:

Secondary Side (0.4 kV)

-

50 – Instantaneous Overcurrent

➢

➢

-

Current Setting: 300% x FLA (LV Side)

Time Delay: time graded 0.2 second from downstream protection.

51 – Time Inverse Overcurrent

➢

Current Setting: 110% x FLA (LV Side)

Primary Side (6.3 kV)

-

50 – Instantaneous Overcurrent

➢

➢

-

51 – Time Inverse Overcurrent

➢

-

Current Setting: 300%* x 110% x FLA (HV Side)

Time Delay: no time grading with downstream incomer required.

Current Setting: 110% x 110% x FLA (HV Side)

87T – Differential Transformer

➢

Pickup Setting: 20%

Note:

1.

* → Shall be above transformer inrush current value, to be updated during detailed

design

8.7 Protection for 15/6.3 kV Unit Auxiliary Transformer

Multifunction feeder protection relay is used to protect transformer. Minimum protection relay to

be provided by manufacturer is specified as follow:

•

•

50 – Instantaneous Overcurrent Relay

51 – Time Inverse Overcurrent Relay

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

In this study, the basis coordination setting for this function is as follow:

Secondary Side (6.3 kV)

-

50 – Instantaneous Overcurrent

➢

➢

-

Current Setting: 300% x FLA (LV Side)

Time Delay: time graded 0.2 second from downstream protection.

51 – Time Inverse Overcurrent

➢

Current Setting: 110% x FLA (LV Side)

8.8 Protection for 150/15 kV Generator Transformer

Multifunction feeder protection relay is used to protect transformer. Minimum protection relay to

be provided by manufacturer is specified as follow:

•

•

•

50 – Instantaneous Overcurrent Relay

51 – Time Inverse Overcurrent Relay

87T – Differential Transformer Relay

In this study, the basis coordination setting for this function is as follow:

Primary Side (150 kV)

-

50 – Instantaneous Overcurrent

➢

➢

-

51 – Time Inverse Overcurrent

➢

-

Current Setting: 300%* x FLA (HV Side)

Time Delay: time grading with downstream incomer required.

Current Setting: 110% x FLA (HV Side)

87T – Differential Transformer

➢

Pickup Setting: 20%

Note:

1.

* → Shall be above transformer inrush current value, to be updated during detailed

design

8.9 Protection for Generator

Multifunction protection relay is used to protect generator. Minimum protection relay to be

provided by manufacturer is specified as follow:

•

•

•

50 – Instantaneous Overcurrent Relay

51 – Time Inverse Overcurrent Relay

87G – Generator Differential Relay

Within this study, only relay 50/51 are coordinated with the following setting:

-

50 – Instantaneous Overcurrent

➢

➢

-

51 – Time Inverse Overcurrent

➢

-

Current Setting: before generator steady state short circuit curve

Time Delay: time grading 0.2 second from GT & AUT protection.

Current Setting: 110% x FLA

87T – Differential Transformer

➢

Pickup Setting: 20%

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

8.10

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

Protection for Emergency Diesel Generator (EGD)

Multifunction protection relay is used to protect generator. Minimum protection relay to be

provided by manufacturer is specified as follow:

•

50 – Instantaneous Overcurrent Relay

•

51 – Time Inverse Overcurrent Relay

Within this study, only relay 50/51 are coordinated with the following setting:

-

50 – Instantaneous Overcurrent

➢

➢

-

Current Setting: before generator steady state short circuit curve

Time Delay: time grading 0.2 second from downstream protection.

51 – Time Inverse Overcurrent

➢

Current Setting: 110% x FLA

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

8.11

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

Study Case

1. Case 1 – Motor Type Load Relay Coordination on 0.4 kV Essential MCC Bus

Picture.1 – Coordination Relay Case – 1

•

•

•

•

For example, coordination relay for Jacking Oil Pump 1A motor with CB Incoming 0.4 kV

Essential MCC Bus

Coordination motor relay (Over Load Relay /Thermal Overload) with Incoming protection

relay (Over current Relay).

Fault from downstream.

Trip Sequence

Motor Protection

1

MCCB for Motor

2

Relay Protection for Incoming CB

3

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

2. Case 2 – Feeder Type Load Relay Coordination on 0.4 kV Essential MCC Bus

Picture.2 – Coordination Relay Case – 2

•

•

•

•

For example, relay for feeder Generator Anti-Cond Heater with CB Incoming 0.4 kV

Essential MCC Bus

Coordination feeder protection relay (Include with CB) with Incoming protection relay

(Over current Relay).

Fault from downstream.

Trip Sequence

MCCB for Feeder

1

Relay Protection for Incoming CB

2

3. Case 3 – Motor Type Load Relay Coordination on 0.4 kV MCC Bus

Picture.3 – Coordination Relay Case – 3

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

•

•

•

•

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

For example, coordination relay for motor Bottom Ash Shieving Equipment with CB

Incoming 0.4 kV MCC Bus

Coordination feeder motor relay (Over Load Relay /Thermal Overload) with Incoming

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Motor Protection

1

MCCB for Motor

2

Relay Protection for Incoming CB

3

4. Case 4 – Feeder Type Load Relay Coordination on 0.4 kV MCC Bus

Picture.4 – Coordination Relay Case – 4

•

•

•

•

For example, coordination relay for feeder Fuel Feeding Line with CB Incoming 0.4 kV

MCC Bus

Coordination feeder protection relay (Include with CB) with Incoming protection relay

(Over current Relay).

Fault from downstream.

Trip Sequence

MCCB for Feeder

1

Relay Protection for Incoming CB

2

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

5. Case 5 – Motor Type Load Relay Coordination on 0.4 kV SWGR Bus

Picture.5 – Coordination Relay Case – 5

•

•

•

•

For example, coordination relay for motor Vacuum Pump 1A with CB Incoming 0.4 kV

SWGR Bus

Coordination feeder motor relay (Over Load Relay /Thermal Overload) with Incoming

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Motor Protection

1

MCCB for Motor

2

Relay Protection for Incoming CB

3

6. Case 6 – Feeder Type Load Relay Coordination on 0.4 kV SWGR Bus

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

Picture.6 – Coordination Relay Case – 6

•

•

•

•

For example, coordination relay for feeder ESP Package – 1 with CB Incoming 0.4 kV

MCC SWGR

Coordination feeder protection relay (Include with CB) with Incoming protection relay

(Over current Relay).

Fault from downstream.

Trip Sequence

MCCB for Feeder

1

Relay Protection for Incoming CB

2

7. Case 7 – Motor Type Load Relay Coordination on MV Switchgear Bus

Picture.7 – Coordination Relay Case – 7

•

•

•

•

For example, coordination relay for Primary Air Fan 1A motor with CB Incoming 6.3 kV

MV Switchgear

Coordination feeder motor relay (Over Load Relay /Thermal Overload) with Incoming

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Motor Protection

1

MCCB for Motor

2

Relay Protection for Incoming CB

3

8. Case 8 – Power Distribution Transformer Protection Coordination

Picture.8 – Coordination Relay Case – 8

•

For example, coordination relay for CB Outgoing 6.3 kV MVSG-1A with CB Incoming 0.4

kV LVSG-1A.

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

•

•

•

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

Coordination Outgoing protection relay (Over Current Relay) with Incoming feeder

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Relay Protection for Incoming CB

1

Relay Protection for Outgoing CB

2

9. Case 9 – MV Switchgear Protection Coordination

Picture.9 – Coordination Relay Case – 9

•

•

•

•

For example, coordination relay for CB Outgoing 6.3 kV MVSG-1A with CB Incoming 6.3

kV MVSG-1A.

Coordination Outgoing protection relay (Over Current Relay) with Incoming feeder

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Relay Protection for Incoming CB

1

Relay Protection for Outgoing CB

2

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

10. Case 10 – Interconnecting Cable (MVSG & MVSG Common) Protection Coordination

Picture.10 – Coordination Relay Case – 10

•

•

•

•

For example, coordination relay for CB Incoming 6.3 kV MVSG – 12A Common with CB

Incoming 6.3 kV MVSG-1A.

Coordination Incoming protection relay (Over Current Relay) with Incoming feeder

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Relay Protection for Incoming CB (MVSG-12A Common)

1

Relay Protection for Incoming CB (MVSG-1A)

2

11. Case 11 – Feeder Type Load Relay Coordination on MV Switchgear Common Bus

Picture.11 – Coordination Relay Case – 11

•

•

•

•

For example, coordination relay for CSU Trans. T001 Feeder with CB Incoming 6.3 kV

MVSG-12A Common Bus.

Coordination Incoming protection relay (Over Current Relay) with Incoming feeder

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Relay Protection for outgoing Feeder CSU Trans. T1001

1

Relay Protection for incoming CB (MVSG-12A Common)

2

12. Case 12 – Generator and UAT Protection Coordination

Picture.12 – Coordination Relay Case – 12

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2022-08-30

•

•

•

•

Project Document No: T1-PP-000-ELE-STU-00003

REV. 1

Page 2 of 17

Coordination relay for CB Incoming 15 kV Bus (Generator – 1) with CB Incoming 6.3 kV

MVSG-1A.

Coordination Incoming protection relay (Over Current Relay) with Incoming feeder

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Relay Protection for Incoming CB (UAT)

1

Relay Protection for Incoming CB (Generator)

2

13. Case 13 – Generator and GT Protection Coordination

Picture.13 – Coordination Relay Case – 13

•

•

•

•

9.

Coordination relay for CB Incoming 15 kV Bus (Generator – 1) with CB Outgoing 150 kV

Bus (HV Side GT(Generator Transformer)).

Coordination Incoming protection relay (Over Current Relay) with Outgoing feeder

protection relay (Over current Relay).

Fault from downstream.

Trip Sequence

Relay Protection for Incoming CB (Generator)

1

Relay Protection for Outgoing CB (GT)

2

CONCLUSION

Based on these above calculations, the relays setting should be followed as attachment.

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2020-11-12

Project Document No: T1-PP-000-ELE-STU-00003

ATTACHMENT 1

SINGLE LINE DIAGRAM

REV.

0

One-Line Diagram - OLV1 (Edit Mode)

150 kV EXISTING SWITCHYARD

GT-1

GT-2

CBGRID5

CBGRID6

CBGRID3

CBGRID4

SWITCHYARD

150 kV

SWITCHYARD

SWITCHYARD

CBHV1

CBGRID1

CBGRID2

CBHV2

GT-1

73 MVA

GT-2

73 MVA

BUS-100

15 kV

BUS-200

15 kV

BusDuct3

BusDuct2

BusDuct7

BusDuct6

GCB-1

GCB-2

UAT-1A

16 MVA

UAT-2A

16 MVA

BusDuct1

BusDuct5

BusDuct15

Gen1

63 MW

CB1100

MVSG-1A

6.3 kV

CB10-1

CB10-11

CB1104

CB1105

CB1106

CB1110

CB1111

CB1112

CB1113

CB1114

CB1115

CB1116

CB1002

CB1003

CB1004

CB1006

CB1007

CB1008

CB1009

Cable0MV2

Cable0MV3

Cable0MV4

Cable0MV6

Cable0MV7

Cable0MV8

Cable0MV9

Bus0MV2

Bus0MV3

Bus2MV1

CB1212

CB1213

CB0LV5

CB0LV10

CB0LV11

CB0LV12

CB0LV13

CB0LV20

CB0LV21

Interface Busbar 2B

CB2LV2

Open

LVSG-2A

0.4 kV

LVSG-2B

0.4 kV

CB0LV22

CB0LV23

CB0LV24

CB0LV18

CB0LV19

CB2LV3

CB0LV6

CB2LV4

CB2LV5

CB2LV6

Cable2LV2

Cable2LV3

CB2LV11

CB2LV13

CB2LV7

CB2LV12

CBCHLV2

Cable1LV1

Cable1LV2

Bus1LV1

Bus1LV2

Cable1LV3

Cable0LV2

Cable0LV4

Bus0LV2

Bus0LV9

Cable0LV6

Bus0LV10

Cable0LV7

Bus0LV4

Cable0LV14

0.4 kV

LV SWI MCC

Cable0LV15

Cable0LV16

Bus0LV12

Cable0LV18

Bus0LV14

Cable0LV12

Bus0LV15

Bus0LV6

0.4 kV

LV ESP 2 MCC

NET_LV-2 ESS MCC

Open

CB34

CB39

Open

Cable17

CB36

CB45

Open

Cable28

CB41

Open

Cable30

CB47

CB2LV10

Open

HP AIR FAN 3 - 2

149 kW

CB2LV9

Bus2LV4

HP AIR FAN 2 - 2

149 kW

CB2LV8

Open

Bus2LV2

Cable2LV4

HP AIR FAN 1 - 2

149 kW

CB0LV9

Bus2LV1

ESP PACKAGE 2

282.4 kVA

CB33

LVSG EDG

0.4 kV

LV-2 ESS MCC

LV-12 ESS COMMON MCC

LV-1 ESS MCC

Project File: Timor1-CFSPP-2x50MW

0.4 kV

LV WTP-WWTP MCBCus0LV3

NET_LV-2AB MCC

EDG

1600 kW

Aug 28, 2022

Cable2LV1

Cable30

NET_LV-12AB COMMON MCC

EDG

10:15:33

Cable0LV3

NET_LV CH MCC

Cable28

NET_LV-1AB MCC

Cable0LV13

WTP & WWTP

276.5 kVA

RF at TH

110 kVA

TRANS + SERV AIR 3

171.6 kVA

TRANS + SERV AIR 2

171.6 kVA

TRANS + SERV AIR 1

171.6 kVA

NET_LV-12 ESS COMMON MCC

Cable17

Cable0LV17

Bus0LV13

DB LP

411.8 kVA

SWI & CHLOR

77.07 kVA

HVAC at STG

110 kVA

AIR COMP 3

117.6 kVA

AIR COMP 2

117.6 kVA

AIR COMP 1

CB0LV8

CB0LV7

Cable0LV5

Bus0LV8

117.6 kVA

CB1LV10 Open

HP AIR FAN 3

149 kW

HP AIR FAN 2

149 kW

NET_LV-1 ESS MCC

page 1

Bus0LV1

Bus1LV4

HP AIR FAN 1

149 kW

ESP PACKAGE 1

CB1LV9

Cable0LV1

Cable1LV4

0.4 kV

LV ESP 1 MCC

282.4 kVA

CB1LV8

Bus1

0.4 kV

CB1216

CW Pump 2B

580 kW

CB0LV4

CB1215

CW Pump 2A

580 kW

CB1LV12

CB1214

CE Pump 2B

160 kW

LV-CH MCC

0.4 kV

CB0LV3

CB1LV7

CE Pump 2A

160 kW

BFW Pump 2C

950 kW

Interface Busbar 2A

CB2LV1

LVSG-12B COMMON

0.4 kV

CB1211

BFW Pump 2B

950 kW

BFW Pump 2A

950 kW

ID FAN 2B

680 kW

CB1LV13

ID FAN 2A

CB1LV11

CB1210

PDC-CH2

Open

LVSG-12A COMMON

0.4 kV

CB1LV3

CB1LV6

CB1206

CBCHLV4

Open

CB0LV2

CB1205

680 kW

PDC-CH1

CB1204

CB1218

Bus2MV2

LV-CH MCC

CBCHLV1

CB1203

SECONDARY AIR FAN 2B

250 kW

Interface Busbar CH-2

CB1202

SECONDARY AIR FAN 2A

250 kW

PDC-2A

1.6 MVA

PDC-CH2

0.8 MVA

CB1201

PRIMARY AIR FAN 2B

650 kW

CB0LV1

Open

Gen2

63 MW

CB1200

PRIMARY AIR FAN 2A

650 kW

TRANS/RECT B

235.3 kVA

LV-CH MCC

SHIP UNLOADER B

563.8 kVA

PDC-CH1

0.8 MVA

Open

CB1217

Bus0MV10

PDC-12B

2 MVA

Interface Busbar CH-1

CB1011

Cable0MV11

Bus0MV8

Bus0MV6

Interface Busbar 12B

Interface Busbar 12A

CB1LV2

LVSG-1B

0.4 kV

CB1LV5

Bus0MV7

STACKER RECLAIMER

574.7 kVA

PDC-1B

1.6 MVA

TRANS/RECT A

235.3 kVA

PDC-12A

2 MVA

CB10-2

MVSG-2A

6.3 kV

Interface Busbar 1B

CB1LV1

LVSG-1A

0.4 kV

CB1LV4

Bus0MV4

Bus0MV5

SHIP UNLOADER A

563.8 kVA

CW Pump 1B

580 kW

Interface Busbar 1A

CW Pump 1A

580 kW

CE Pump 1B

160 kW

CE Pump 1A

160 kW

BFW Pump 1C

950 kW

BFW Pump 1B

950 kW

BFW Pump 1A

950 kW

ID FAN 1B

680 kW

ID FAN 1A

680 kW

SECONDARY AIR FAN 1B

250 kW

SECONDARY AIR FAN 1A

250 kW

PRIMARY AIR FAN 1B

650 kW

PRIMARY AIR FAN 1A

650 kW

PDC-1A

1.6 MVA

CB1001

Cable0MV1

Bus0MV1

Bus1MV2

Open

Cable33

CB1103

CB10-12

MVSG-12B COMMON

6.3 kV

Cable2MV17

CB1102

CableMV18

CableMV17

6

.3sk1V

Bu

MV1

CB1118

CB1101

Bus2

6.3 kV

BusDuct8

CB10-10

MVSG-12A COMMON

6.3 kV

Open

CB1117

BusDuct16

BusDuct9

BusDuct4

PDC-2B

1.6 MVA

PROTECTIVE RELAY SETTING & COORDINATION

STUDY

Timor-1 CFSPP Project

Issued

2020-06-26

Project Document No: T1-PP-000-ELE-STU-00003

ATTACHMENT 2

TABEL SETTING FOR PROTECTION RELAY

REV.

0

Table A

VT Ratio (V)

Circuit Breaker Tag

Incoming 150 kV to GT (HV)

Panel Location

CB 40 kA, 150 kV, 300A

Voltage

150kV

Device

7UT86

150 kV

Overall Incoming, GT, UAT

-

15 kV

REX640

15 kV

Incoming 150 kV to GT (LV)

Outgoing 15 kV to UAT (HV)

GCB 50 kA, 15 kV, 4000 A

VCB 40 kA, 15 kV, 630 A

15 kV

15kV

RET615

7UT82

Prim.

150000

CT Ratio (A)

Sec

100

Prim.

300

150000

100

300

15000

100

4000

15000

100

630

15000

15000

100

100

630

630

Existing Setting

Protection

Sec

Incoming 15 kV from Generator

VCB 25 kA, 15 kV, 1600 A

VCB 50 kA, 15 kV, 4000A

6,3kV

15kV

7UT82

REX640

6300

15000

100

100

Set Point

(A, V, Hz)

Time Dial

(s)

Remarks

87L

Definite Time

25%xIpckup

0s

Differential Transformer Protection

87T

Definite Time

20%xIpckp

0s

Restricted Earth Fault

64 REF

Definite Time

0.05 A

1s

Time Delay Overcurrent

50

IEC - SIT

Table

Instataneous Overcurrent

51

Definite Time

Table

50N

Definite Time

Table

Instataneous Ground Overcurrent

51N

Definite Time

Transformer Over Winding Temperature

49 WT

Definite Time

90%xTn

1s

Transformer Over Oil Temperature

49 OT

Definite Time

90%xTn

1s

Transformer Gas Protection/Buchholz

63

OFF

OFF

OFF

Transformer Over Flux Protection

24

Definite Time

115% V/f

1s

Definite Time

20%xIpckup

0.2 s

0.05 A

800 ms

1 Time Delay Ground Overcurrent

1

1 Overall Differential Protection

Table

opt. via CO

87O

1

Restricted Earth Fault

64 REF

Definite Time

Time Delay Overcurrent

50

IEC - SIT

Table

1 Instataneous Overcurrent

51

Definite Time

Table

Time Delay Ground Overcurrent

50N

Definite Time

Table

Instataneous Ground Overcurrent

51N

Definite Time

Differential Transformer Protection

87 UAT

Definite Time

20%xIpckp

0s

Restricted Earth Fault

64 REF

Definite Time

0.05 A

1s

Time Delay Overcurrent

50

IEC - SIT

Table

Instataneous Overcurrent

51

Definite Time

Table

50N

Definite Time

Table

Instataneous Ground Overcurrent

51N

Definite Time

Transformer Over Winding Temperature

49 WT

Definite Time

90%xTn

1s

Transformer Over Oil Temperature

49 OT

Definite Time

90%xTn

1s

Transformer Gas Protection/Buchholz

63

OFF

OFF

OFF

SBEF

Definite Time

0.02 A

0s

64 REF

Definite Time

0.05 A

1s

50/51

-

-

-

Table

Earth Fault

50N/51N

-

-

-

Table

Generator 100% Stator Earth Fault

Protection

59G

Generator Differential Protection

87G

Definite Time

10%xIpckp

0s

Generator Negative Phase Sequence

Protection

46

IEC - SIT

0,05 A

2s

Generator Loss of Excitation Protection

40

IEC - SIT

0,66 ohm

50 ms

Generator Over-Excitation (V/Hz) Protection

24

Definite Time

120% V/Hz

6s

Generator Reverse Power Protection

32

Definite Time

8Vph

30 s

Generator Overvoltage Protection

59

Definite Time

110Vph

1s

Generator Under voltage Protection

27

Definite Time

80Vph

50 ms

Generator Voltage Controlled Over current

relay

51V

Generator Rotor Earth Fault

64F

Impedance Protection

21

Voltage Balance Protection

60

Definite Time

80%Unp

Overfrequency

81H

Definite Time

51,5 Hz

2s

Underfrequency

81L

Definite Time

48,5 Hz

2s

Generator Out of Step Protection

78

Generator Stator Thermal Protection

49

IEC - LIT

1,05 A

1s

Time Delay Overcurrent

50

1 Time Delay Ground Overcurrent

1600

2 Standby Earth Fault for NGR

1600

1 Over Current

4000

Curve

Line Differential Protection

Restricted Earth Fault

Outgoing 15kV to UAT (LV)

ANSI Code

1

Table

Table

opt. via CO

OFF

OFF

OFF

OFF

Incoming 6.3 kV from UAT

VCB 25 kA, 6.3 kV, 1600 A

6.3 kV

7UT82

6300

100

1600

1600

Outgoing 6.3 kV to Electric Motor

Incoming 400 V from Power Distribution

Transformer

ACB 6.3 kA, 400 V, 1600 A

Air Circuit Breaker (ACB) 65 kA, 400 V, 2500 A

6.3 kV

400 V

7SJ80

7SJ80

400

400

100

100

2500

2500

Instataneous Overcurrent

51

Time Delay Ground Overcurrent

50N

Instataneous Ground Overcurrent

51N

Differential Transformer Protection

87 UAT

Restricted Earth Fault

64 REF

Over Current

50/51

-

-

-

Table

50N/51N

-

-

-

Table

Transformer Over Winding Temperature

49 WT

Definite Time

90%xTn

1s

Transformer Over Oil Temperature

49 OT

Definite Time

90%xTn

1s

Transformer Gas Protection/Buchholz

63

OFF

OFF

OFF

opt. via CO

SBEF

Definite Time

0,02 A

1 Earth Fault

2 Standby Earth Fault for NGR

1

Definite Time

OFF

Excessive starting time and locked rotor

48-51LR

Over Current

50/51

-

-

-

Table

Over Load

49

IEC - LIT

1,05 A

500 ms

Table

Phase imbalance

46

Define Time

0,2 A

2s

Under Voltage

27

Definite Time

80 Vph

2s

Ground Fault

50N/51N

-

-

-

Time Delay Phase Overcurrent

51

Table

Instantaneous Phase Overcurrent

50

Table

51N

Table

1 Time Delay Ground Overcurrent

Instantaneous Ground Overcurrent

50N

Over voltage

59

Table

Table

Definite Time

110 Vph

1s

Outgoing 400 V to Power Feeders

Molded Case Circuit Breaker (MCCB)

400 V

MCCB

400

100

2500

1 Instantaneous Over Current Protection

50

Table

Outgoing 400 V to Electric Motor

Molded Case Circuit Breaker (MCCB)

400 V

MCCB

400

100

2500

1 Instantaneous Over Current Protection

50

Table

FLA

Isc

MF

Full Load Ampere

Short Circuit Current or Breaking Capacity of Breaker

Margin Factor

150 kV

No

Tag No.

Description

Protection-Type

CT Ratio

FLA (A)

Isc max

1

2

11BAT01GT001

12BAT01GT001

GT - 1

GT - 2

SIEMENS 7SJ80

SIEMENS 7SJ80

300/1

300/1

281

281

40

40

No

Tag No

Protection-Type

CT Ratio

Ifl

ISC Max

Low Set O/C

MF x FLA

(A)

309,1000

309,1000

High Set O/C

Pick-Up

Type

Range

TMS

Inst

Type

Range

Td (s)

1,0

1,0

IEC - Inverse

IEC - Inverse

0.1-4 x CT Sec

0.3-5 x CT Sec

0,10

0,10

2

2

Definite

Definite

0.5-35 x CT Sec

0.5-35 x CT Sec

0,20

0,20

Note

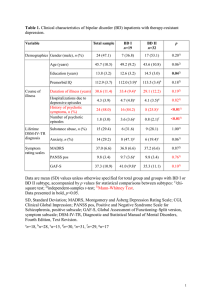

15 kV IINCOMING MV SWITCHGEAR

Description

Low Set O/C

High Set O/C

Ifl x MF

Pick-Up

Type

Range

TMS

Inst

Type

Range

Note

Td (s)

1

11BAY01BR001

Gen-1

SIEMENS 7SJ80

4000/1

2853

40

3138,3

0,8

IEC - LI

0.3-5 x CT Sec

0,20

5,3

Definite

0.5-35 x CT Sec

0,40

2

12BAY01BR001

Gen-2

SIEMENS 7SJ80

4000/1

2853

40

3138,3

0,8

IEC - LI

0.3-5 x CT Sec

0,20

5,3

Definite

0.5-35 x CT Sec

0,40

Tag No.

Description

Protection-Type

CT Rated /

MCCB Capacity

FLA (A)

0.4 kV OUTGOING LV SWITCHGEAR

No

ISC Max

(kA)

Low Set O/C Relay or Thermal Trip MCCB

High Set O/C Relay or Magnetic

Trip MCCB

MF x FLA

(A)

Pick-Up

Type

TMS

Pick-up

Type

TD (s)

MVSG-1A

1

11BBA01BR001

UAT-1

Siemens 7UT82

1600/1

1612,9

25

1774,21

1,1

IEC - LI

0,70

3,0

Definite

0,40

12BBA01BR001

UAT-2

Siemens 7UT82

1600/1

1612,9

25

1774,21

1,1

IEC - LI

0,70

3,0

Definite

0,40

MVSG-2A

2

Note

0.4 kV OUTGOING LV SWITCHGEAR

No

Tag No.

Discription

Protection-Type

CT Rated / MCCB

Capacity

FLA (A)

ISC Max

(kA)

Low Set O/C Relay or Thermal Trip MCCB

High Set O/C Relay or Magnetic

Trip MCCB

MF x FLA

(A)

Pick-Up

Type

TMS

Pick-up

Type

TD (s)

MVSG-1A

1

11BFT01GT001

PDC-1A

Siemens 7UT82

400/1

108,8

25

131,62

0,3

IEC - LI

0,70

0,9

Definite

0,40

2

11HLB11AN101-M01

Primary Air Fan 1A

Siemens 7SJ80

200/1

72,9

25

80,20

0,4

IEC - LI

0,70

2,9

Definite

0,20

3

11HLB12AN101-M01

Primary Air Fan 1B

Siemens 7SJ80

200/1

72,9

25

80,20

0,4

IEC - LI

0,70

2,9

Definite

0,20

4

11HLB21AN101-M01

Secondary Air Fan 1A

Siemens 7SJ80

100/1

28,5

25

31,37

0,3

IEC - LI

0,70

1,1

Definite

0,20

5

11HLB22AN101-M01

Secondary Air Fan 1B

Siemens 7SJ80

100/1

28,5

25

31,37

0,3

IEC - LI

0,70

1,1

Definite

0,20

6

11HNC10AN201-M01

Induced Draft Fan 1A

Siemens 7SJ80

200/1

77,7

25

85,45

0,4

IEC - LI

0,70

3,1

Definite

0,20

7

11HNC20AN201-M01

Induced Draft Fan 1B

Siemens 7SJ80

200/1

77,7

25

85,45

0,4

IEC - LI

0,70

3,1

Definite

0,20

8

11LAC11AP001-M01

Boiler Feed Water Pump 1A

Siemens 7SJ80

200/1

100,3

25

110,31

0,6

IEC - LI

0,70

4,0

Definite

0,20

9

11LAC12AP001-M01

Boiler Feed Water Pump 1B

Siemens 7SJ80

200/1

100,3

25

110,31

0,6

IEC - LI

0,70

4,0

Definite

0,20

10

11LAC13AP001-M01

Boiler Feed Water Pump 1C

Siemens 7SJ80

200/1

100,3

25

110,31

0,6

IEC - LI

0,70

4,0

Definite

0,20

11

11LCB11AP001-M01

Condensated Extraction Pump 1A

Siemens 7SJ80

100/1

18,3

25

20,14

0,2

IEC - LI

0,70

0,7

Definite

0,20

12

11LCB12AP001-M01

Condensated Extraction Pump 1B

Siemens 7SJ80

100/1

18,3

25

20,14

0,2

IEC - LI

0,70

0,7

Definite

0,20

13

11PAC11AP101-M01

Cooling Water Pump (CWP) A

Siemens 7SJ80

200/1

69,6

25

76,53

0,4

IEC - LI

0,70

2,8

Definite

0,20

14

11PAC12AP101-M01

Cooling Water Pump (CWP) B

Siemens 7SJ80

200/1

69,6

25

76,53

0,4

IEC - LI

0,70

2,8

Definite

0,20

15

11BFT02GT001

PDC-1B

Siemens 7UT82

400/1

108,8

25

131,62

0,3

IEC - LI

0,70

0,9

Definite

0,40

MVSG-2A

16

12BFT01GT001

PDC-2A

Siemens 7UT82

400/1

108,8

25

131,62

0,3

IEC - LI

0,70

0,9

Definite

0,40

17

12HLB11AN101-M01

Primary Air Fan 1A

Siemens 7SJ80

200/1

72,9

25

80,20

0,4

IEC - LI

0,70

2,9

Definite

0,20

18

12HLB12AN101-M01

Primary Air Fan 1B

Siemens 7SJ80

200/1

72,9

25

80,20

0,4

IEC - LI

0,70

2,9

Definite

0,20

19

12HLB21AN101-M01

Secondary Air Fan 1A

Siemens 7SJ80

100/1

28,5

25

31,37

0,3

IEC - LI

0,70

1,1

Definite

0,20

20

12HLB22AN101-M01

Secondary Air Fan 1B

Siemens 7SJ80

100/1

28,5

25

31,37

0,3

IEC - LI

0,70

1,1

Definite

0,20

21

12HNC10AN201-M01

Induced Draft Fan 1A

Siemens 7SJ80

200/1

77,7

25

85,45

0,4

IEC - LI

0,70

3,1

Definite

0,20

22

12HNC20AN201-M01

Induced Draft Fan 1B

Siemens 7SJ80

200/1

77,7

25

85,45

0,4

IEC - LI

0,70

3,1

Definite

0,20

23

12LAC11AP001-M01

Boiler Feed Water Pump 1A

Siemens 7SJ80

200/1

100,3

25

110,31

0,6

IEC - LI

0,70

4,0

Definite

0,20

24

12LAC12AP001-M01

Boiler Feed Water Pump 1B

Siemens 7SJ80

200/1

100,3

25

110,31

0,6

IEC - LI

0,70

4,0

Definite

0,20

25

12LAC13AP001-M01

Boiler Feed Water Pump 1C

Siemens 7SJ80

200/1

100,3

25

110,31

0,6

IEC - LI

0,70

4,0

Definite

0,20

26

12LCB11AP001-M01

Condensated Extraction Pump 1A

Siemens 7SJ80

100/1

18,3

25

20,14

0,2

IEC - LI

0,70

0,7

Definite

0,20

27

12LCB12AP001-M01

Condensated Extraction Pump 1B

Siemens 7SJ80

100/1

18,3

25

20,14

0,2

IEC - LI

0,70

0,7

Definite

0,20

28

12PAC11AP101-M01

Cooling Water Pump (CWP) A

Siemens 7SJ80

200/1

69,6

25

76,53

0,4

IEC - LI

0,70

2,8

Definite

0,20

29

12PAC12AP101-M01

Cooling Water Pump (CWP) B

Siemens 7SJ80

200/1

69,6

25

76,53

0,4

IEC - LI

0,70

2,8

Definite

0,20

30

12BFT02GT001

PDC-2B

Siemens 7UT82

400/1

108,8

25

131,62

0,3

IEC - LI

0,70

0,9

Definite

0,40

PDC-12A

Siemens 7UT82

400/1

141,6

25

171,33

0,4

IEC - LI

0,70

1,2

Definite

0,40

MVSG-12A COMMON

31

10BBB01GS001

32

10EAA1112AF001

CSU Transformer T001

Siemens 7SJ80

400/1

56,6

25

62,30

0,2

IEC - LI

0,70

0,4

Definite

0,20

33

10BFT02GT001

PDC-CH1

Siemens 7SJ80

400/1

68,3

25

82,63

0,2

IEC - LI

0,70

0,6

Definite

0,40

34

11GH302A

Stepdown transformer for rectifier transformer of electrolyser A

Siemens 7SJ80

400/1

24,0

25

26,35

0,1

IEC - LI

0,70

0,2

Definite

0,20

MVSG-12B COMMON

35

10BFT01GT002

PDC-12B

Siemens 7SJ80

400/1

141,6

25

171,33

0,4

IEC - LI

0,70

1,2

Definite

0,20

36

10BFT02GT002

PDC-CH2

Siemens 7SJ80

400/1

68,3

25

82,63

0,2

IEC - LI

0,70

0,6

Definite

0,20

37

10EAA1112AF001

CSU Transformer T201

Siemens 7SJ80

400/1

56,6

25

62,30

0,2

IEC - LI

0,70

0,4

Definite

0,20

38

11GH302B

Stepdown transformer for rectifier transformer of electrolyser B

Siemens 7SJ80

400/1

25,5

25

28,00

0,1

IEC - LI

0,70

0,2

Definite

0,20

39

10EAF10AF001

Stacker Reclaimer

Siemens 7SJ80

400/1

48,5

25

53,34

0,1

IEC - LI

0,70

0,4

Definite

0,20

Note

0.4 kV OUTGOING LV SWITCHGEAR

No

Tag No.

Discription

Protection-Type

CT Rated / MCCB

Capacity

FLA (A)

ISC Max

(kA)

Overload Relay Setting

(49)

Low Set O/C Relay or Thermal Trip MCCB

MF x FLA (A)

Class

MF x FLA

(A)

Pick-Up

Type

TMS

High Set O/C Relay or Magnetic

Trip MCCB

Pick-up

Type

TD (s)

1

IN-LVSG-1A from PDC-1A

Siemens 7UT82

2500/1

1713,2

40

-

-

1884,51

0,8

IEC - LI

0,70

2,1

Definite

0,40

2

IN-LVSG-1B from PDC-1B

Siemens 7UT82

2500/1

1713,2

63

-

-

1884,51

0,8

IEC - LI

0,70

2,1

Definite

0,40

3

IN-LVSG-2A from PDC-2A

Siemens 7UT82

2500/1

1713,2

63

-

-

1884,51

0,8

IEC - LI

0,70

2,1

Definite

0,40

4

IN-LVSG-2B from PDC-2B

Siemens 7UT82

2500/1

1713,2

63

-

-

1884,51

0,8

IEC - LI

0,70

2,1

Definite

0,40

5

IN-LVSG-12A from PDC-12A

Siemens 7UT82

3000/1

2230,1

63

-

-

2453,14

0,8

IEC - LI

0,70

2,2

Definite

0,40

6

IN-LVSG-12B from PDC-12B

Siemens 7UT82

3000/1

2230,1

63

-

-

2453,14

0,8

IEC - LI

0,70

2,2

Definite

0,40

7

IN-LV-CH MCC from PDC-CH1

Siemens 7UT82

1250/1

1075,5

40

-

-

1183,05

0,9

IEC - LI

0,70

2,6

Definite

0,40

8

IN-LV-CH MCC from PDC-CH2

Siemens 7UT82

1250/1

1075,5

40

-

-

1183,05

0,9

IEC - LI

0,70

2,6

Definite

0,40

Note

0.4 kV OUTGOING LV SWITCHGEAR

No

Tag No.

Discription

Protection-Type

CT Rated / MCCB

Capacity

FLA (A)

ISC Max

(kA)

Overload Relay Setting

(49)

Low Set O/C Relay or Thermal Trip MCCB

High Set O/C Relay or Magnetic

Trip MCCB

MF x FLA (A)

Class

MF x FLA

(A)

Pick-Up

Type

TMS

Pick-up

Type

TD (s)

LVSG-1A

1

11HHM01AN601-M01

HP Air Fan 1

Siemens 7SJ80

400/5

270,2

63

297,21

10

297,21

3,7

IEC - LI

0,02

23,6

Definite

0,20

2

11BJA01GS001

ESP Package Unit-1

Siemens 7SJ80

800/5

654,4

63

-

-

719,85

4,5

IEC - LI

0,70

28,6

Definite

0,20

3

11BMA01GS001

0.4kV ESS Unit-1 MCC

Siemens 7SJ80

630/5

388,6

63

-

-

427,43

3,4

IEC - LI

0,70

21,6

Definite

0,20

4

11BFA02GS001

0.4kV Unit-1 MCC

Siemens 7SJ80

630/5

461,9

63

-

-

508,13

4,0

IEC - LI

0,70

25,7

Definite

0,20

10

297,21

3,7

IEC - LI

0,02

23,6

Definite

0,20

5

11HHM02AN601-M01

HP Air Fan 2

Siemens 7SJ80

400/5

270,2

63

297,21

LVSG-1B

6

11BFA02GS001

0.4kV Unit-1 MCC

Siemens 7SJ80

630/5

461,9

63

-

-

508,13

4,0

IEC - LI

0,70

25,7

Definite

0,20

7

11HHM03AN601-M01

HP Air Fan 3

Siemens 7SJ80

400/5

270,2

63

297,21

10

297,21

3,7

IEC - LI

0,02

23,6

Definite

0,20

LVSG-2A

8

12HHM01AN601-M01

HP Air Fan 1

Siemens 7SJ80

400/5

270,2

63

297,21

10

297,21

3,7

IEC - LI

0,02

23,6

Definite

0,20

9

12BJA01GS001

ESP Package Unit-2

Siemens 7SJ80

800/5

654,4

63

-

-

719,85

4,5

IEC - LI

0,70

28,6

Definite

0,20

10

12BMA01GS001

0.4kV ESS Unit-2 MCC

Siemens 7SJ80

630/5

388,6

63

-

-

427,43

3,4

IEC - LI

0,70

21,6

Definite

0,20

11

12BFA02GS001

0.4kV Unit-2 MCC

Siemens 7SJ80

630/5

461,9

63

-

-

508,13

4,0

IEC - LI

0,70

25,7

Definite

0,20

12

12HHM02AN601-M01

HP Air Fan 2

Siemens 7SJ80

400/5

270,2

63

297,21

10

297,21

3,7

IEC - LI

0,02

23,6

Definite

0,20

0,20

LVSG-2B

13

12BFA02GS001

0.4kV Unit-2 MCC

Siemens 7SJ80

630/5

461,9

63

-

-

508,13

4,0

IEC - LI

0,70

25,7

Definite

14

12HHM03AN601-M01

HP Air Fan 3

Siemens 7SJ80

400/5

270,2

63

297,21

10

297,21

3,7

IEC - LI

0,02

23,6

Definite

0,20

MCCB

250

190,9

63

-

-

210,01

1,0

FIXED

FIXED

5,0

FIXED

FIXED

LVSG-12A

15

10QEA60AN701

Air Compressor #3

16

10QEA70AN701

Air Compressor #2

17

10QEA80AN701

Air Compressor #1

18

19

10BFA01GS001

250

190,9

63

-

-

210,01

1,0

FIXED

FIXED

FIXED

FIXED

MCCB

250

190,9

63

-

-

210,01

1,0

FIXED

FIXED

5,0

FIXED

FIXED

0.4kV ESS COM-12AB MCC

Siemens 7SJ80

MCCB

630/5

408,6

63

-

-

449,41

3,6

IEC - LI

0,70

22,7

5,0

Definite

0,20

0.4kV COM-12AB MCC

Siemens 7SJ80

630/5

457,3

63

-

-

503,07

4,0

IEC - LI

0,70

25,4

Definite

0,20

MCCB

300

253,0

63

278,30

10

278,30

1,0

FIXED

FIXED

8,0

FIXED

FIXED

20

Electrical Pump

21

HVAC Switchgear Room

MCCB

250

198,5

63

-

-

218,31

1,0

FIXED

FIXED

5,0

FIXED

FIXED

22

SWI & Chlorination Package

Siemens 7SJ80

250/5

247,3

63

-

-

272,00

5,4

IEC - LI

0,70

34,6

Definite

0,20

0.4kV COM-12AB MCC

LVSG-12B

23

Siemens 7SJ80

630/5

457,3

63

-

-

503,07

4,0

IEC - LI

0,70

25,4

Definite

0,20

24

Air Compressor #1

MCCB

250

190,9

63

-

-

210,01

1,0

FIXED

FIXED

5,0

FIXED

FIXED

25

10BFA02GS001

Air Compressor #2

MCCB

250

190,9

63

-

-

210,01

1,0

FIXED

FIXED

5,0

FIXED

FIXED

26

Air Compressor #3

MCCB

250

190,9

63

-

-

210,01

1,0

FIXED

FIXED

5,0

FIXED

FIXED

27

WTP & WWTP Package

Siemens 7SJ80

630/5

480,7

63

-

-

528,74

4,2

IEC - LI

0,70

26,7

Definite

0,20

Note

INCOMMING-0.4kV MCC

Thermal Trip MCCB

High Set O/C Relay or Magnetic Trip MCCB

Protection-Type

CT Rated /

MCCB Capacity

FLA (A)

ISC Max

(kA)

MF x FLA (A)

Pick-Up

Type

TMS

MF x FLA (A)

Pick-Up

Type

TD (s)

0.4kV UNIT-1A SWITCHGEAR

Siemens 7SJ80

630/1

461,9

63

508,13

0,8

IEC - LI

0,1

3233,5

5,13

Definite

0,20

11BFA01GS002

0.4kV UNIT-1B SWITCHGEAR

Siemens 7SJ80

630/1

461,9

63

508,13

0,8

IEC - LI

0,1

3233,5

5,13

Definite

0,20

12BFA01GS001

0.4kV UNIT-2A SWITCHGEAR

Siemens 7SJ80

630/1

461,9

63

508,13

0,8

IEC - LI

0,1

3233,5

5,13

Definite

0,20

12BFA01GS002

0.4kV UNIT-2B SWITCHGEAR

Siemens 7SJ80

630/1

461,9

63

508,13

0,8

IEC - LI

0,1

3233,5

5,13

Definite

0,20

5

10BFA01GS001

0.4kV COMMON-12A SWITCHGEAR

Siemens 7SJ80

630/1

457,3

63

503,07

0,8

IEC - LI

0,1

3201,4

5,08

Definite

0,20

6

10BFA02GS001

0.4kV COMMON-12B SWITCHGEAR

Siemens 7SJ80

630/1

457,3

63

503,07

0,8

IEC - LI

0,1

3201,4

5,08

Definite

0,20

7

10BFA03GS001

0.4kV COAL HANDLING MCC

Siemens 7SJ80

1250/1

1075,5

40

1183,05

0,9

IEC - LI

0,1

7528,5

11,95

Definite

0,20

7

10BFA03GS001

0.4kV COAL HANDLING MCC

Siemens 7SJ80

1250/1

1075,5

40

1183,05

0,9

IEC - LI

0,1

7528,5

11,95

Definite

0,20

No

Tag No.

1

11BFA01GS001

2

3

4

Discription

Note

OUTGOING-0.4kV MCC-1

No

Tag No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

11PAH20GH001

11PAH10AT010-M01

11LCM21AP110-M01

11LCM22AP110-M01

11MAJ51AP110-M01

11MAJ52AP110-M01

11MAM65AN110-M01

11MAM65AN120-M01

11MAX10AH110

11MAX21AP110-M01

11MAX22AP110-M01

11MAX51AN110-M01

11MAX51AP110-M01

11MAX52AN110-M01

11MAX52AP110-M01

11PUE10AP110-M01

11BUC10

11CHA10

11CJJ10

11CJN10

11MKA10GA050

11PAC21AP101-M01

11PAC22AP101-M01

11PAC21AT001

11QCC11AP001-M01

11QCC12AP001-M01

11QCA11AP001-M01

11QCA12AP001-M01

11QCD11AP001-M01

11QCD12AP001-M01

11HAC70AA152-M01

11HAH01AA152-M01

11HAH40AA102-M01

11HAH40AA152-M01

11HAH41AA102-M01

11HAH41AA104-M01

11HAH41AA152-M01

11HAH42AA102-M01

11HAH42AA104-M01

11HAH42AA152-M01

11HAH81AA152-M01

11HAH81AA102-M01

11HAH82AA152-M01

11HAH82AA102-M01

11HCB01AA101-M01

11HCB10AA101-M01

11HCB10GH001

11HCB10GH002

11HCB10GH003

11HCB10GH004

11HCB10GH005

11HCB10GH006

11HCB10BN101-M01

11HCB10BN102-M01

11HCB10BN103-M01

11HCB10BN104-M01

11HCB10BN106-M01

11HCB10BN105-M01

11HCB20AA101-M01

11HCB20GH001

11HCB20GH002

11HCB20GH003

11HCB20GH004

11HCB20GH005

11HCB20GH006

11HCB20GH007

11HCB20GH008

11HCB20GH009

11HCB20GH010

11HCB20GH011

11HCB20GH012

11HCB20GH013

11HCB20GH014

11HDA12AF301-M01

11HDA11AF301-M01

11HDA51AF201-M01

11HDA52AF201-M01

11HHE10GH001-E11

11HHE10GH010-E11

11HHE11AF101-M01

11HHE21AF101-M01

11HHE31AF101-M01

11HHE41AF101-M01

11HHE20GH001-E11

11HHE30GH001-E11

11HHE40GH001-E11

11HHH10AN601-M01

11HHM01AN401-M01

11HHM01AN601-E11

11HHM02AN401-M01

11HHM02AN601-E11

11HHM03AN401-M01

11HHM03AN601-E11

Discription

Condenser Cleaning System

Actuator Screen

Drains Condensate Pump 1 Motor

Drains Condensate Pump 2 Motor

Vacuum Pump 1 Motor

Vacuum Pump 2 Motor

Waste Steam Condenser Suction Fan 1 Motor

Waste Steam Condenser Suction Fan 2 Motor

Control Oil Tank Heating

Control Oil Pump 1 Motor

Control Oil Pump 2 Motor

Control Oil Cooler Fan 1 Motor

Control Oil Cooler Pump 1 Motor

Control Oil Cooler Fan 2 Motor

Control Oil Cooler Pump 2 Motor

Vacuum Pump Water Box Condenser Motor

Turbine Subdistrib. 220V DC, Socket Outlet, Lighting

Generator Protection, Socket Outlet, Lighting

Central I&C Cabinet, Socket Outlet, Lighting

Automatic Voltage Regulation, Socket Outlet, Lighting

IRIS FLUX TRAC II-R and exciter hood lighting

ACW Booster Pump A

ACW Booster Pump B

Debris Filter to Condenser and ACW

Phosphate Injection Pump Unit 1

Phosphate Injection Pump Unit 1

Hidrazine Injection Pump Unit 1

Hidrazine Injection Pump Unit 1

Ammonia Injection Pump Unit 1

Ammonia Injection Pump Unit 1

MOV Distribution Panel Unit 1

LV Cubicle & Resistor

CMK Motor

Water Cooled Hanger Tubes

Saturated steam

Steam Cooled Convection Cage

Steam Cooled Convection Cage

Convective Superheater I

Convective Superheater I

Convective Superheater I

Convective Superheater II

Convective Superheater II

Convective Superheater II

Intrex Superheater

Intrex Superheater

Intrex Superheater

Intrex Superheater

Sootblowing steam hp

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Sootblowing steam, 1 back pass

Bottom ash from Furnace, line 1

Bottom ash from Furnace, line 2

Bottom ash from Furnace

Bottom ash from Furnace

Fuel line 1 (Coal Feeder LCP)

Fuel line 1 (Heat Tracing LCP)

Fuel feeding line 1

Fuel feeding line 2

Fuel feeding line 3

Fuel feeding line 4

Fuel line 2 (Coal Feeder LCP)

Fuel line 3 (Coal Feeder LCP)

Fuel line 4 (Coal Feeder LCP)

Bed material silo

HP air fan 1

HP air fan 1

HP air fan 2

HP air fan 2

HP air fan 3

HP air fan 3

Overload Relay Setting (49)

Type

Starting

Type

Protection-Type

CT Rated /

MCCB Capacity

FLA (A)

F

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

F

F

F

F

F

M

M

F

M

M

M

M

M

M

F

F

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

F

F

F

F

F

F

M

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

M

M

M

M

F

F

M

M

M

M

F

F

F

M

M

F

M

F

M

F

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

DOL

VFD

VFD

VFD

VFD

FR

FR

FR

FR

DOL

DOL

DOL

DOL

-

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

MCCB

16

6

6

6

100

100

6

6

25

25

25

6

6

6

6

16

16

16

16

16

6

32

32

16

6

6

6

6

6

6

120

25

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

50

32

32

32

32

6

6

6

6

6

6

6

6

6

6

12,00

1,60

4,41

4,41

81,55

81,55

2,26

2,26

10,83

14,26

14,26

0,99

3,17

0,99

3,17

5,65

10,23

10,23

10,23

10,23

0,15

26,10

26,10

7,56

4,89

4,89

1,06

1,06

1,06

1,06

132,53

23,85

0,74

0,24

0,24

0,50

0,24

0,50

0,24

0,24

0,50

0,50

0,24

0,24

0,48

0,24

0,48

2,87

0,50

1,51

1,51

1,51

1,51

1,51

1,51

0,50

1,51

1,51

1,51

1,51

1,51

1,51

1,78

1,78

1,78

1,78

1,78

1,78

1,78

1,78

1,78

1,78

1,78

1,78

1,78

1,78

3,42

3,42

3,42

3,42

2,96

32,26

21,45

21,45

21,45

21,45

2,96

2,96

2,96

5,65

1,65

1,81

1,65

1,81

1,65

1,81

Thermal Trip MCCB

High Set O/C Relay or Magnetic Trip MCCB

Note

MF x FLA (A)

Class

Thermal Set

Pick-Up (A)

Type

TMS

1,76

4,85

4,85

89,71

89,71

2,48

2,48

11,91

15,68