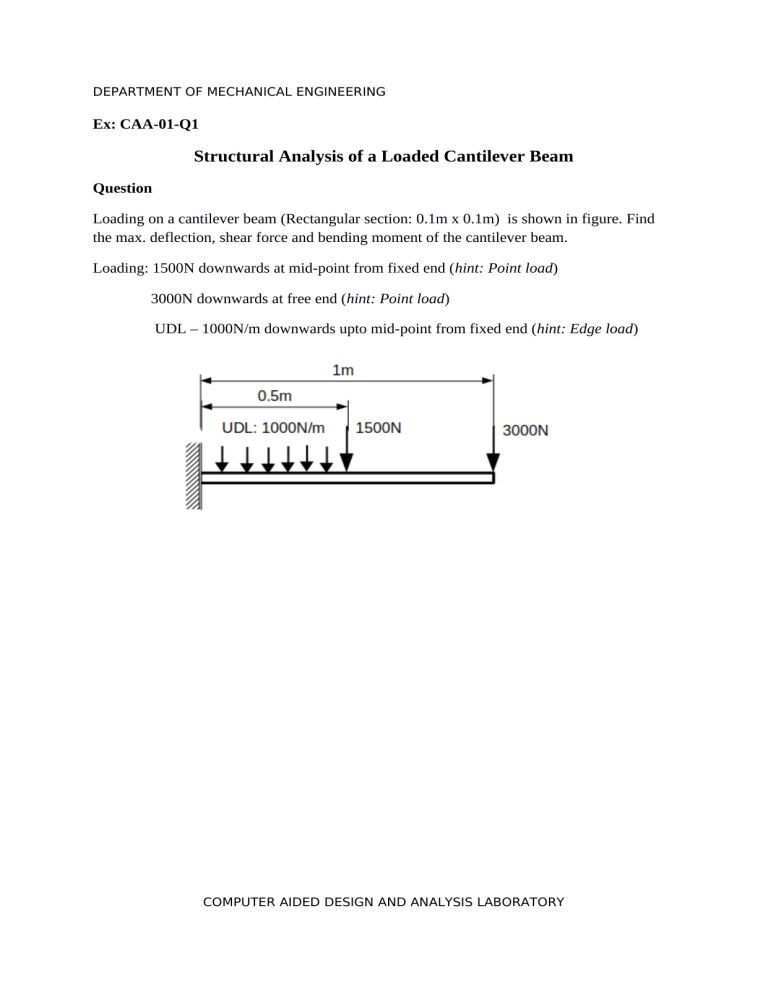

DEPARTMENT OF MECHANICAL ENGINEERING Ex: CAA-01-Q1 Structural Analysis of a Loaded Cantilever Beam Question Loading on a cantilever beam (Rectangular section: 0.1m x 0.1m) is shown in figure. Find the max. deflection, shear force and bending moment of the cantilever beam. Loading: 1500N downwards at mid-point from fixed end (hint: Point load) 3000N downwards at free end (hint: Point load) UDL – 1000N/m downwards upto mid-point from fixed end (hint: Edge load) COMPUTER AIDED DESIGN AND ANALYSIS LABORATORY DEPARTMENT OF MECHANICAL ENGINEERING Ex: CAA-01 Structural Analysis of a Loaded Cantilever Beam Aim To find maximum deflection, shear force and bending moment of a loaded (Point loads and Uniformly Distributed Load) cantilever beam. Tools used Grid, Geometry-Keypoints, Geometry-Curve, Mesh, Load/BC-Displacement BC, Load/BCPoint Load, Load/BC-Edge Loads, Property-Material, Property-Physical, Analysis, Run Solver, Post tools etc. Steps involved Step-1: Setting Grid The FEASTSMT Analysis software was opened and set ‘Grid’ from ‘Settings’ (last tab on Control panel) > Grid as per requirement. Step-2: Creating geometric model In 'Main' (first tab on Control panel), Commands > Geometry > Key point > Create > By X/Y/Z Parameters for the command (shown below the Control Panel) Required coordinate data was entered to create three points P1(0,0,0) and P2 (1,0,0). Geometry > Curve > Create > Line. Also ‘Snap to point’ (Below the Control panel) was selected. Parameters for the command A line (i,e, a beam of 1m length) was drawn by selecting previously created points (P1 and P2). Step-3: Meshing the geometric model Mesh > FE Mesh > Bar Parameters for the command Previously drawn line was selected with suitable ‘Subdivisions’ (Say, 10). COMPUTER AIDED DESIGN AND ANALYSIS LABORATORY DEPARTMENT OF MECHANICAL ENGINEERING Step-4: Applying boundary constraints Load/BC > Displacement BC > Add Parameters for the command Point P1 was selected as ‘Node IDs’, which is the fixed end of the cantilever beam and all degrees of freedom (DOF) was set to zero (‘BC values’ set as Translation: Ux=Uy=Uz=0 and Rotation: Rx=Ry=Rz=0). Step-5: Applying Load Load/BC > Point Load > Add Parameters for the command The node (‘Node IDs’) on the midpoint of the line (beam) was selected, applied suitable load value (‘Data’) and direction (‘Component’). Node IDs: The node at mid-point of the beam Data: -1500 (Numerical value in Newton) Component: Fy Repeated the same procedure for the node corresponding to the free end of the beam with Data: -3000 and Component: Fy. Load/BC > Edge Loads > Add All nodes from fixed end upto mid-point of the beam were selected (‘Element edges’), applied suitable load value (‘Edge load data’) and direction (‘Direction’). Parameters for the command Two nodes (‘Node IDs’) were selected, applied suitable load value (‘Data’) and direction (‘Component’). Element edges: 1T5(D1) Data: -1000 (Value in Newton) Direction: Normal to edge. COMPUTER AIDED DESIGN AND ANALYSIS LABORATORY DEPARTMENT OF MECHANICAL ENGINEERING Step-6: Adding material to the model Property > Materials > Structural > Isotropic > Add Parameters for the command All elements (line) was selected and required material data was entered. Element IDs: All [Click ‘All’ (Tool bar below the Control panel)] Material-Data: 2E+11/0.3/0/0/0 (For Steel, Modulus of elasticity: 200GPa and Poisson’s ratio: 0.3) Note: Material data can be retrieved from the Materials library of the software, if available, otherwise enter user specified values of relevant properties. Step-7: Setting physical properties Property > Physical > Beam properties > Standard section > Add Parameters for the command Parameters of the beam cross section (Rectangular) were added. Element IDs: All Cross-section shape: RECT/0.1/0.1 [Click the button ‘dialog box’ next to ‘Cross-section shape’, ‘Beam sections’ dialog box was opened, set ‘Shape’ as ‘RECT’ and dimensions, both ‘b’ and ‘h’ values as 0.1 (i.e, 0.1 m)] Step-8: Setting analysis type Analysis > Analysis Type Parameters for the command Set analysis type as ‘Static’. Step-9: Analysing/Solving the problem Analysis > Run Solver Or click on ‘!’ (‘Run solver’ button placed on the tool bar). COMPUTER AIDED DESIGN AND ANALYSIS LABORATORY DEPARTMENT OF MECHANICAL ENGINEERING Step-10: Post processing of analysis/solution Post > Beam Plots > Force diagram Parameters for the command For shear force diagram Component: SHEAR1 Plane: Plane-1 For bending moment diagram Component: BM2 Plane: Plane-1 Watched the animation of the deflected beam. Post > Deformed shape Maximum deflection of the beam was obtained. Options available are ‘Superimpose’ (shows original position of the beam), ‘Highlight maximum’ (maximum deflection of the beam) and ‘Animate Deflection’. Result Hence the analysis (shear force and bending moment) of the loaded cantilever beam was done. Maximum deflection at free end = 0.00071092 m (or 0.71 mm) Maximum shear force = 4.95 kN at fixed end Maximum bending moment = 3.875 kNm at fixed end COMPUTER AIDED DESIGN AND ANALYSIS LABORATORY