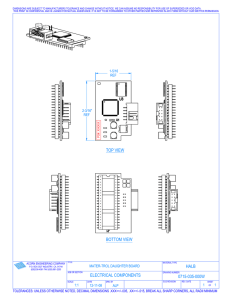

Inspection Test Record CITR501-C COATING Reference SBM Purchase Order: 001.17056.00000057 Date: 29-Dec-2021 Package description: Slop Water Treatment Package Project: Almirante Tamandaré FPSO Supplier: Frames Separation Technologies B.V. Parent tag: 113-PKHP-5300 Supplier Group: - Main Component tag: 113-CPHY-5301 & 113-VECA-5302 Item Y Description 1. Specification (Note 1) Verify approval of documents 1.1 Ref: 1.2 ES45000-PECEMCPF006007-A1-Ch 6.1.4 Notes: CONTRACTOR’s personnel shall be qualified in accordance to the provisions specified in Section 6.1 of this Specification. Ref: ES45000-PECEMCPF006007-A1-Ch 6.1 Notes: If not qualified to tradesman level, operator’s skills and his/her ability for undertaking surface preparation or coating application shall be evaluated upon qualification test. 1.3 The test shall be directed by a qualified supervisor and inspected by a qualified Coating Inspector. Qualification shall witnessed by a COMPANY representative. Ref: 1.4 3 ES45000-PECEMCPF006007-A1-Ch 6.1.4 Notes: Ensure requirements for the application of Pre-Fabrication Primers are followed up by the Supplier. Ref: 1.6 Notes: Verify working procedure(s) is / are approved by SBM before starting coating activities Ref: 1.5 ES45000-PECEMCPF006007-A1-Ch 6.1 ES45000-PECEMCPF006007-A1-Ch 6.2.8 Notes: All inspection equipment shall have valid and up to date calibration certificates, details of which shall be issued for review along with the CONTRACTOR’s coating records Dry Film Thickness gauges shall be zeroed and calibrated in accordance with the manufactures instructions at the start of each shift and thereafter every three hours. SBM Offshore Page 1 of 12 P/L N/A Inspection Test Record CITR501-C COATING Ref: ES45000-PECEMCPF006007-A1-Ch 6.4.4 & 6.4.5.4 Notes: 2. Preparation 2.1 As far as possible the direct contact of different metals shall be avoided. In cases where this is unavoidable due to specific design requirements, suitable isolation shall be installed between the differing metals to mitigate bi-metallic corrosion, such as Pikotek, Teflon or similar approved isolation systems. Ref: 2.2 SO17033- PESDMCPF006001-A2-Ch. 4.6 Notes: All coating materials shall be supplied to the work site in their original unopened and clearly identified containers, bearing readable labels. Storage requirements according to specification Ch. 6.1.3.1 Ref: ES45000-PECEMCPF006006-A1-Ch. 6.1.3.1 Notes: Ensure test panels are available, cleaned and painted during coating activities 2.3 Ref: 2.4 ES45000-PECEMCPF006007-A1-Ch 6.1.4 Notes: Where possible, fixed scaffolding or staging shall be used for surface preparation and coating and will be subject to COMPANY approval. Ref: ES45000-PECEMCPF006007-A1-Ch 7.5 Notes: Make sure that adequate ventilation is installed during blasting and coating activities. 2.5 Ref: ES45000-PECEMCPF006007-A1-Ch 7.6 Notes: In order to prevent condensation, the steel temperature should always be at least 3°C above the dew point. All surfaces shall be visibly dry and clean at time of application and this condition shall be maintained until the coating is cured. 2.6 Verify that de-humidification is installed where required. Ref: ES45000-PECEMCPF006007-A1-Ch 6.3.2 & 7.7 Notes: Ensure proper lighting is installed 2.7 Ref: ES45000-PECEMCPF006007-A1-Ch 7.8 Notes: Ensure that safety precautions are implemented 2.8 Ref: 2.9 ES45000-PECEMCPF006007-A1-Ch 5.2 Notes: Prior to blasting, all sharp edges shall be rounded with a minimum radius of 2 mm in accordance with ISO 8501-3 P3 (Table 1, item 2). SBM Offshore Page 2 of 12 Inspection Test Record CITR501-C COATING Ref: ES45000-PECEMCPF006007-A1-Ch 6.2.2 Notes: Surface preparation before blasting: 2.10 Removal of steel / weld imperfections, pre-cleaning and degreasing. Ref: ES45000-PECEMCPF006007-A1-Ch 6.2 Notes: 3. Abrasive blast cleaning Ensure that equipment for abrasive blast cleaning complies with the specification 3.1 Ref: ES45000-PECEMCPF006007-A1-Ch 6.2.4 Abrasive materials used for blast cleaning must be in compliance with specification. 3.2 Ref: 3.3 ES45000-PECEMCPF006007-A1-Ch 6.2.4.2 Notes: Blast cleaning shall not be conducted when the surfaces are less than 3°C above dew point or when the relative humidity of the air is above 85% (or as per Manufacturer recommendations). Ref: ES45000-PECEMCPF006007-A1-Ch 6.2.4.3 Notes: Check Compressed air is free of oil and contamination (2 times per shift) 3.4 Ref: 3.5 Notes: Abrasive blast cleaning shall be performed according to the SSPC standard reported in the applicable paint system sheet in the Project Coating Specification. However, NACE and ISO blasting standards will be accepted based on the conversion table. Ref: 3.6 ES45000-PECEMCPF006007-A1-Ch 6.2.4.4 ES45000-PECEMCPF006007-A1-Ch 6.2.4.1 Table 6.2.4.1 Notes: 4 Surface profile/roughness shall be measured according to ISO 8503 Parts 1-5 or NACE SP0287. However, measurements shall not be determined by using comparators only. Ref: ES45000-PECEMCPF006007-A1-Ch 6.4.5.3 Notes: 2 Verify dust test are performed. 3.7 Ref: ES45000-PECEMCPF006007-A1- (Table 6.4.5-2) Notes: 4. Power tool cleaning 4.1 N/A Ensure power tool cleaning is executed according specification SBM Offshore Page 3 of 12 Inspection Test Record CITR501-C COATING Ref: ES45000-PECEMCPF006007-A1-Ch 6.2.5 Notes: 5. Paint application Before painting application all Coating materials, thinners, curing agents shall be checked for their suitability and shall include, at least: 5.1 · Mixing and thinning · Induction period · Pot life · Storage conditions · Batch numbers, expiry dates. Ref: ES45000-PECEMCPF006007-A1-Ch 6.3.3 Notes: Ensure environmental conditions are according to specification 5.2 Ref: ES45000-PECEMCPF006007-A1-Ch 6.3.2 Notes: Ensure that requirements for application are followed: Chapter 6.3 for spray application Chapter 6.4 for brush application 5.3 Chapter 6.5 for roller application Chapter 6.6 stripe coating Ref: ES45000-PECEMCPF006007-A1-Ch 6.3.4, 6.3.5, 6.3.6 & 6.3.7 Notes: Check Compressed air is free of oil and contamination (2 times per shift) 5.4 Ref: ES45000-PECEMCPF006007-A1- (Table 6.4.5-2) Notes: Perform wet and dry film thickness checks and visual inspections 5.5 Ref: ES45000-PECEMCPF006007-A1- (Table 6.4.5-2) Notes: Ensure requirements for repair of defects and touch up are followed 5.6 Ref: ES45000-PECEMCPF006007-A1- (Table 6.4.5-2) SBM Offshore Notes: Page 4 of 12 Inspection Test Record CITR501-C COATING Inspection and testing on completion of coating 5.7 Ref: ES45000-PECEMCPF006007-A1- (Table 6.4.6-3) SBM Offshore Notes: Page 5 of 12 Inspection Test Record CITR501-C COATING Component Tag number 113-CPHY-5301 113-VECA-5302 SBM Offshore Page 6 of 12 5.7 5.6 5.4 5.3 5.2 5.1 4.1 3.7 3.6 3.5 3.4 3.3 3.2 3.1 2.10 2.9 2.8 2.7 2.6 2.5 2.4 2.3 2.2 2.1 1.5 1.4 1.3 1.2 1.1 Punch List item Inspection Test Record CITR501-C COATING Tag number Photo reference 2.1 2.2 113- CPHY 5301 & 113-VECA5302 2.3 2.4 & 2.5 SBM Offshore Page 7 of 12 Inspection Test Record CITR501-C COATING 2.6 2.7 & 2.8 113- CPHY 5301 2.9 & & 113-VECA5302 2.10 3.1 3.2 SBM Offshore Page 8 of 12 Inspection Test Record CITR501-C COATING 3.3 3.4 113- CPHY 5301 & 3.5 113-VECA5302 3.6 3.7 SBM Offshore Page 9 of 12 Inspection Test Record CITR501-C COATING 5.1 5.2 113- CPHY 5301 & 113-VECA5302 5.3 5.4 SBM Offshore Page 10 of 12 Inspection Test Record CITR501-C COATING 5.5 113- CPHY 5301 & 5.6 113-VECA5302 5.7 Item Documents Attached 1 N/A Company Completed By (Supplier) Completed By (Sub-Supplier) Frames Alpha-ECC Signature Print name Date SBM Offshore Page 11 of 12 Inspection Test Record CITR501-C COATING Notes Notes Description [1] Applicable Specifications: ES45000-PECEMCPF006007-A1- Material & Corrosion Protection Surface Preparation and Application of Coatings Supporting Specification ES45000-PECEMCPF006006-A2 - Material & Corrosion Protection Coatings Specification Inspections on water jetting, hot dip galvanizing, passive fire protection not listed. [2] Referenced codes: [17] ISO 8502 Parts 1-10 Preparation of steel substrates before application of paints and related products - Test for the assessment of surface cleanliness [18] ISO 8503 Parts 1-5 Preparation of steel substrates before application of paints and products – Surface roughness characteristics of blast cleaned steel substrates related [3] The test shall be carried out on a carbon steel test panel (minimum 1m x 1m) containing at least 1 pipe end, 2 pipes, 1 angle and 1 flat bar. Alternatively, a location providing similar geometrical complexity to the component to be coated can be used. Test Panel shall be blasted to SSPC-SP 10 (Ref. [24]) and coated with following Paint System: • 1st Coat – 2-component Zinc Rich Epoxy Primer to 75μm DFT • 2nd Coat – 2-component High Build Epoxy to 200μm DFT • 3rd Coat – 2-component Polyurethane Topcoat to 50μm DFT. The acceptance criteria shall be the requirements of the paint system given above and the requirements of this Specification. Operators failing to meet these standards shall not be allowed to carry out coating procedures required by this Specification. [4] Surface preparation cleanliness grades comparison Surface Cleanliness Grade SSPC ISO 8501-1 NACE (Ref. [6]) White Metal Blast Cleaning SSPC-SP 5 – Ref.[21] Sa 3 NACE 1 Near White Metal Blast Cleaning SSPC-SP 10 – Ref. [24] Sa 2.5 NACE 2 Commercial Blast Cleaning SSPC-SP 6 – Ref. [22] Sa 2 NACE 3 Brush-Off Blast Cleaning Brush-Off Blast Cleaning of Coated and Uncoated Galvanized Steel, Stainless Steels, and Non-Ferrous Metals SSPC-SP 7 – Ref. [23] Sa 1 NACE 4 SSPC-SP 16 – Ref. [27] N/A N/A SBM Offshore Page 12 of 12